DOI:10.32604/cmc.2021.015710

| Computers, Materials & Continua DOI:10.32604/cmc.2021.015710 |  |

| Article |

Numerical Solutions for Heat Transfer of An Unsteady Cavity with Viscous Heating

1Institute of Mathematical Sciences, Faculty of Science, University of Malaya, 50603 Kuala Lumpur, Malaysia

2Unit of Engineering Design and Product Development, Technology and Engineering Division, Malaysian Rubber Board, 47000 Sungai Buloh, Malaysia

3Department of Applied Mathematics & Statistics, Institute of Space Technology, 44000 Islamabad, Pakistan

*Corresponding Author: N. F. M. Noor. Email: drfadiya@um.edu.my

Received: 03 December 2020; Accepted: 15 January 2021

Abstract: The mechanism of viscous heating of a Newtonian fluid filled inside a cavity under the effect of an external applied force on the top lid is evaluated numerically in this exploration. The investigation is carried out by assuming a two-dimensional laminar in-compressible fluid flow subject to Neumann boundary conditions throughout the numerical iterations in a transient analysis. All the walls of the square cavity are perfectly insulated and the top moving lid produces a constant finite heat flux even though the fluid flow attains the steady-state condition. The objective is to examine the effects of viscous heating in the fully insulated lid-driven cavity under no-slip and free-slip Neumann boundary conditions coupled with variations in Reynolds and Prandtl numbers. The partial differential equations of time-dependent vorticity-stream function and thermal energy are discretized and solved using a self-developed finite difference code in MATLAB

Keywords: Lid-driven; viscous heating; vorticity-stream function; finite difference method; finite element method

Nomenclature

| Aspect ratio | |

| Applied velocity [m/s] | |

| Specified heat [ | |

| Velocity vector in x-direction [m/s] | |

| Steady-state criterion | |

| Velocity vector in y-direction [m/s] | |

| Gravity acceleration [m/s2] | |

| Thermal diffusivity [m2/s] | |

| Gravity acceleration [m/s2] | |

| Step size [m] | |

| Gravity acceleration [m/s2] | |

| Step size [m] | |

| Step size [m] | |

| Step time [s] | |

| Column | |

| Velocity boundary layer thickness [m] | |

| Row | |

| Thermal boundary layer thickness [m] | |

| Thermal conductivity [ | |

| Vorticity [m/s2] | |

| Length [m] | |

| Vorticity at top [m/s2] | |

| Slip length [m] | |

| Vorticity at bottom [m/s2] | |

| Number of nodes, number of iterations | |

| Vorticity at left [m/s2] | |

| Prandtl number | |

| Vorticity at right [m/s2] | |

| Reynold number | |

| Fourier number | |

| Temperature [ | |

| Dynamic viscosity [ | |

| Initial temperature [ | |

| Kinematic viscosity [m2/s] | |

| Density [kg/m3] | |

| Time [s], current time step | |

| Stream function [m2/s] | |

| New time step | |

| Maximum stream function [m2/s] | |

| Last time step |

Viscous heating is generated by a fluid’s viscous friction when the fluid is sheared by an external motion, provided the fluid is not inviscid and sluggish [1]. Viscous heating process is important in creating energy sources while Neumann boundary condition (BC) is important in renewable energy applications such as in energy saving or to increase energy efficiency in buildings. Viscous heating is studied in a slipped flow region using a free-slip boundary condition by Mohamed [2]. His study shows a momentous effect on the heat transfer and fluid flow peculiarity in microchannel studies even though the fluid has tenuous viscous flow and possesses a tiny value of hydraulic diameter. Koo et al. [3] discovered that viscous dissipation is effectively influenced by Reynolds number and geometrical aspect ratio. The viscous dissipation effect on free-slip BC is also discussed by Rij et al. [4,5] in a 3D micro-channel gas flow where it is dependent on the amount of rarefaction and other factors.

Another important study of viscous dissipation merged with Joule heating, carried out by Kumar et al. [6], shows an upward trend of temperature distribution in a non-Newtonian fluid flow. The heat transfer process of a Newtonian fluid which takes into account the viscous dissipation in a fully-developed region was performed using an explicit numerical method [7]. The variation of the heat transfer process presented an unusual degree in the fully-developed region, both hydro-dynamically and thermally, due to the thermal energy balance between the heated walls is combined with adiabatic walls and the viscous heating [8–10]. Other applications of combined Neumann BC and constant wall temperature can be discovered in magnetized nanofluids in a porous cylinder [11], buoyancy effects [12], open trapezoidal cavity [13] and in variation of heat source lengths [14]. The catastrophe such as the source of heat in storm or hurricane is derived from the viscous dissipation near the surface [15] and it can be estimated via the turbulent kinetic energy [16] where the heat viscous dissipation is a cubic function of the wind speed.

In some cases, such as in magneto-hydrodynamic (MHD) and mixed convection studies [17,18], the electrically conducting fluid motion is retarded by the magnetic field [19], hence it produces an insignificant viscous heating as compared with the amount of heat generated by a buoyancy force. Generalized differential quadrature method was utilized to study the MHD non-Newtonian nanofluid flow and the impacts of various physical properties [20]. Other numerical methods such as Gear–Chebyshev–Gauss–Lobatto collocation method [21] and the fourth-fifth-order Runge–Kutta–Fehlberg method [22] were used to solve an MHD nanofluid flow with a thermal radiation and an applied magnetic field respectively. The study of MHD flow was also conducted in a fluid thermal analysis where three modes of convection specifically referred as free, forced and Marangoni convections are considered [23]. Besides, Zhou et al. [24] examined Boussinesq approximation [25] in the thermal energy equation when a Newtonian fluid is subject to a mixed convection process with different heat sources in a lid-driven cavity. Rahman et al. [26] revealed that the velocity and temperature profiles of a lid-driven flow with a semi-circular heated wall are independent of the viscous heating when they are subject to magnetic field and Joule heating. Anderson [27] derived the thermal energy equation for a highly viscous flow which includes the viscous terms used to estimate the meteorite surface temperature. Newtonian homogenous and heterogenous nanofluids [28–31] can also be considered in the future studies as the occupying fluids in the cavity flows with viscous heating and slip effects.

The cited literatures [17–27] obviously show that viscous heating is important in fluid dynamics and thermal analyses where the viscous heating is comparable with other effects. The intention of this work is to utilize the lid-driven cavity model combined with Neumann BCs [32]. To make our analysis easier, the moving top lid is not taken into account in the heat transfer analysis thus it will be presumed as an insulator. In order to facilitate the calculations, all the governing equations employed in our paper are given in terms of the vorticity-stream function [33] and thermal energy equation [25]. Then we use an explicit finite difference method (FDM) to discretize all the governing equations and conduct the fluid flow and heat transfer analyses from an unsteady-state until the steady-state flow is achieved. Those results are then compared with the solutions of finite element method (FEM) using Ansys Fluent

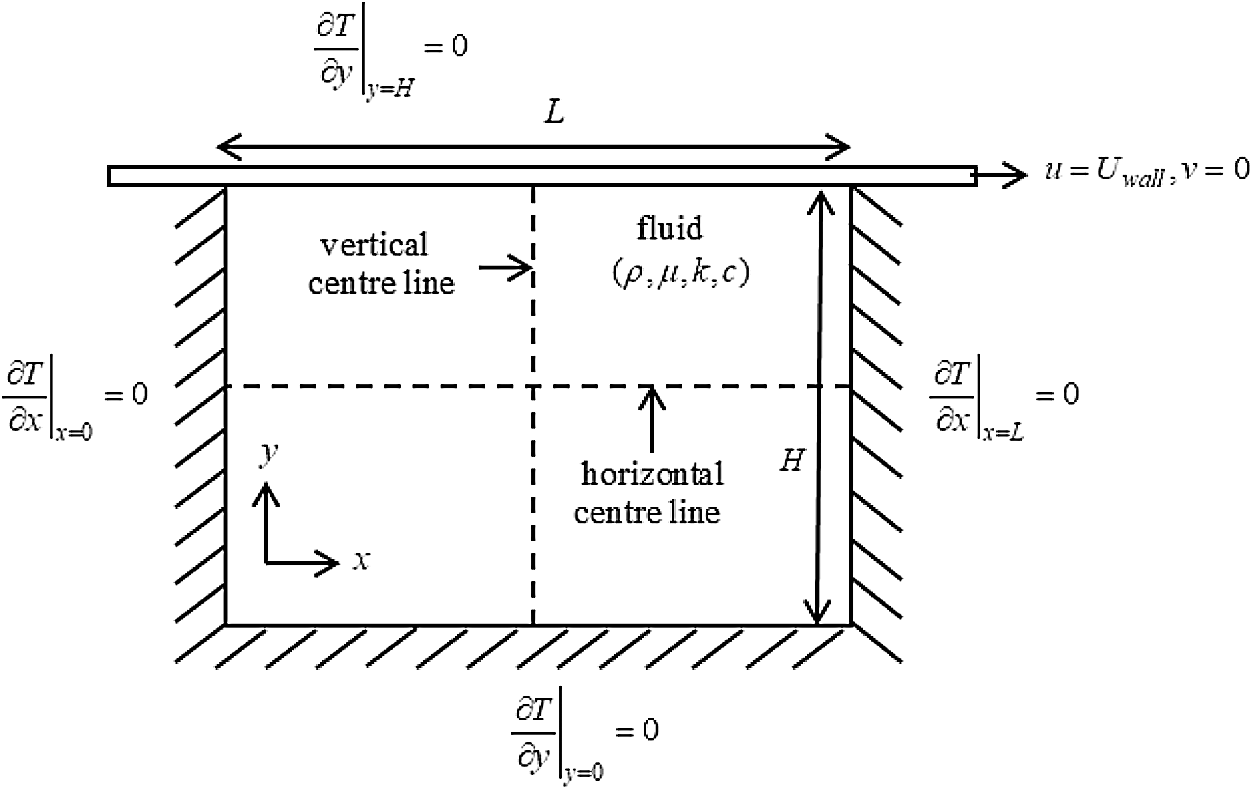

The schematic drawing of a two-dimensional lid-driven cavity model within the Cartesian coordinate system is shown in Fig. 1. In this case, the external velocity, Uwall is imposed on the top lid, u and v are the velocity vectors in x and y directions,

Figure 1: Schematic drawing of a 2D cavity flow with Neumann BC

The continuity and governing equations for the two-dimensional in-compressible viscous unsteady Newtonian fluid flow in x- and y-directions are given by [34]

where t is time and gx = gy = g is gravity acceleration. The curl [35] of Eqs. (2) and (3) is known as vorticity-stream function scheme or vorticity transport equation and it is given by [33] as

where stream function,

The vorticity,

The vorticity,

where

Two-dimensional unsteady thermal energy equation [25] which includes the effect of viscous dissipation is given by

where T is a temperature. Substituting Eqs. (5) and (6) into Eq. (12) will result in

The temperature, T at each of the walls and at each of the corners can be obtained by introducing Neumann BC [32] in the unsteady-state condition where they are given by

where

In this section, some matters related to numerical modelling for solution of the two-dimensional vorticity transport equation and thermal energy equation will be discussed. These issues are applications of the simplest numerical method, stability issue and iteration algorithm. Since Eq. (4) and Eq. (13) are nonlinear second-order partial differential equations, an explicit FDM is the simplest method among the feasible techniques for the numerical solution. However, it is conditionally stable [33]. Eqs. (4) and (13) can be transformed into equivalent finite difference equations (FDE) using forward and central finite-divided-difference formulas.

Rearranging Eq. (22) yields

Similarly, the resultant FDE for the thermal energy equation is given by

Rearranging Eq. (24) yields

From Eq. (23), the criterion is determined by requiring that the coefficient associated with the node of interest at the previous time is greater than or equal to zero [25], such that

and from Eq. (24),

Eqs. (26) and (27) are the conditional stability criteria. However, the maximum allowable time step,

where min ( ) means the smallest element is taken inside the bracket. Eq. (28) is called Poisson equation [32]. Substituting Eqs. (5) and (6) into Eq. (7) yields

Similarly, Eq. (29) can be discretized using the FDE as follows:

where n is the number of iterations. Eq. (29) can later be solved by using Gauss–Seidel method [35]. The time-marching method to solve the forward FDE of the vorticity transport equation and thermal energy equation are carried out in MATLAB

Step I: Initial values of stream function,

Step II: The interior nodes of the stream function,

Step III: The values of vorticity at those four boundaries,

Step IV: The interior nodes of vorticity,

Step V: An initial value of temperature throughout the lid-driven is given. Then Eq. (25) is coupled to the function,

Step VI: The values of temperature at those four walls and four corners namely

Step VII: Steps II–VI are repeated until the steady-state condition of the flow is achieved or at any desired time step.

In this study, the aspect ratio, A = 1 (

where

The Reynolds number, ReL can be reckoned via Eq. (33) [38] as

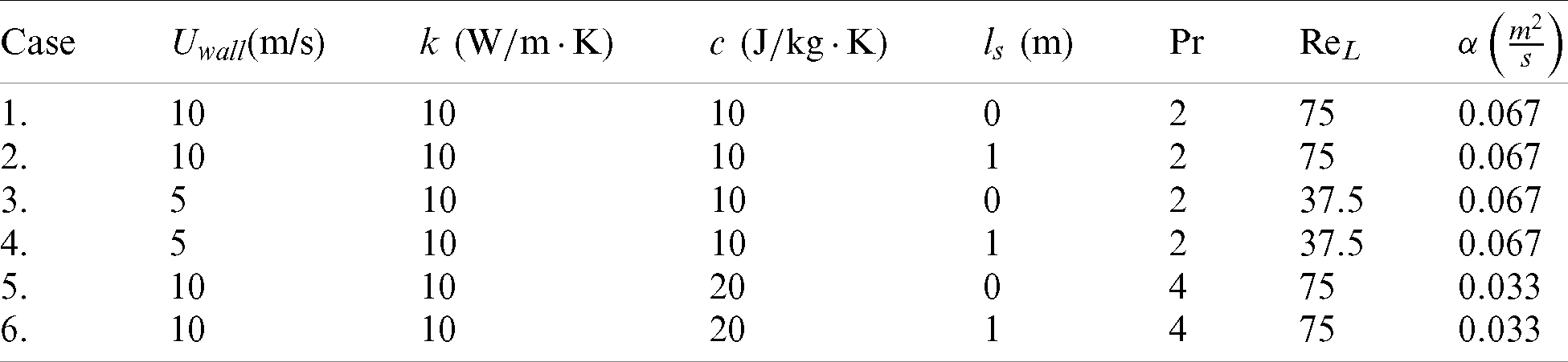

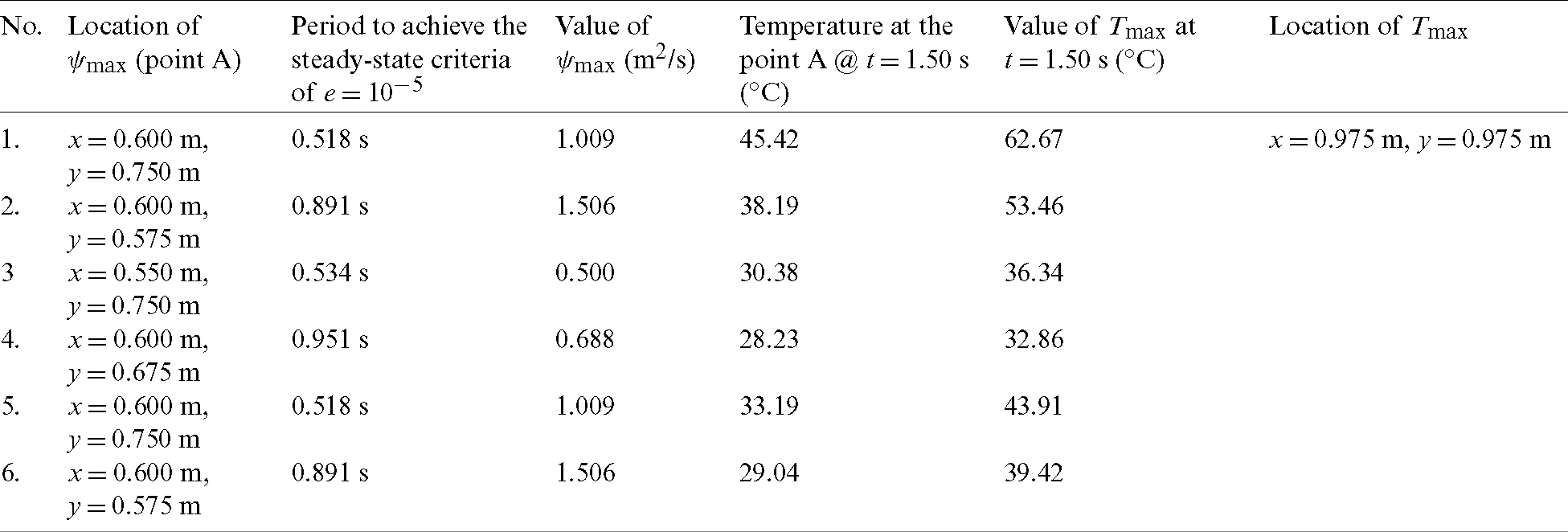

where L is height of the cavity. Then, free-slip BC with slip length value, ls = 1 m is assigned in the second, fourth and sixth test cases while the no-slip BC is assigned with the slip length value, ls = 0 m in other test cases. Tab. 1 shows the values of

Table 1: Flow conditions of six test cases

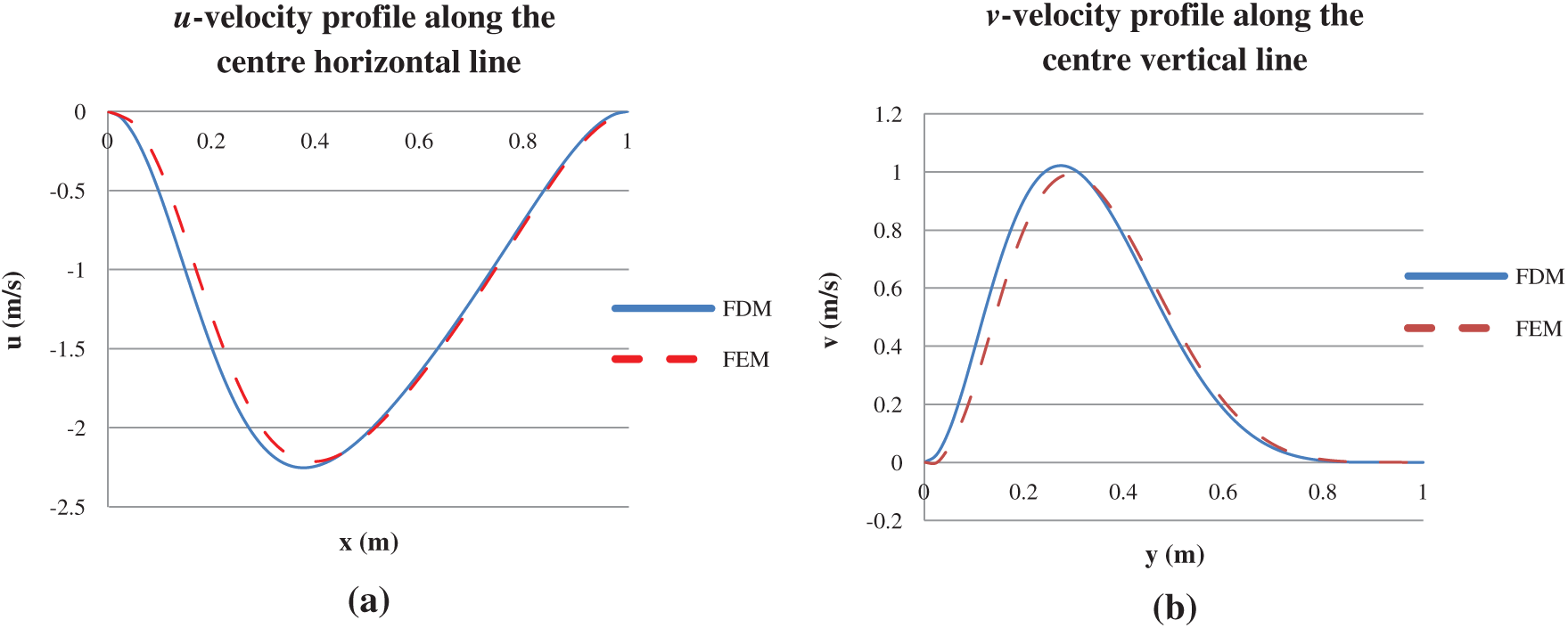

Throughout this paper, the 1st and 2nd test cases will serve as the benchmarks (both cases with identical Reynold number,

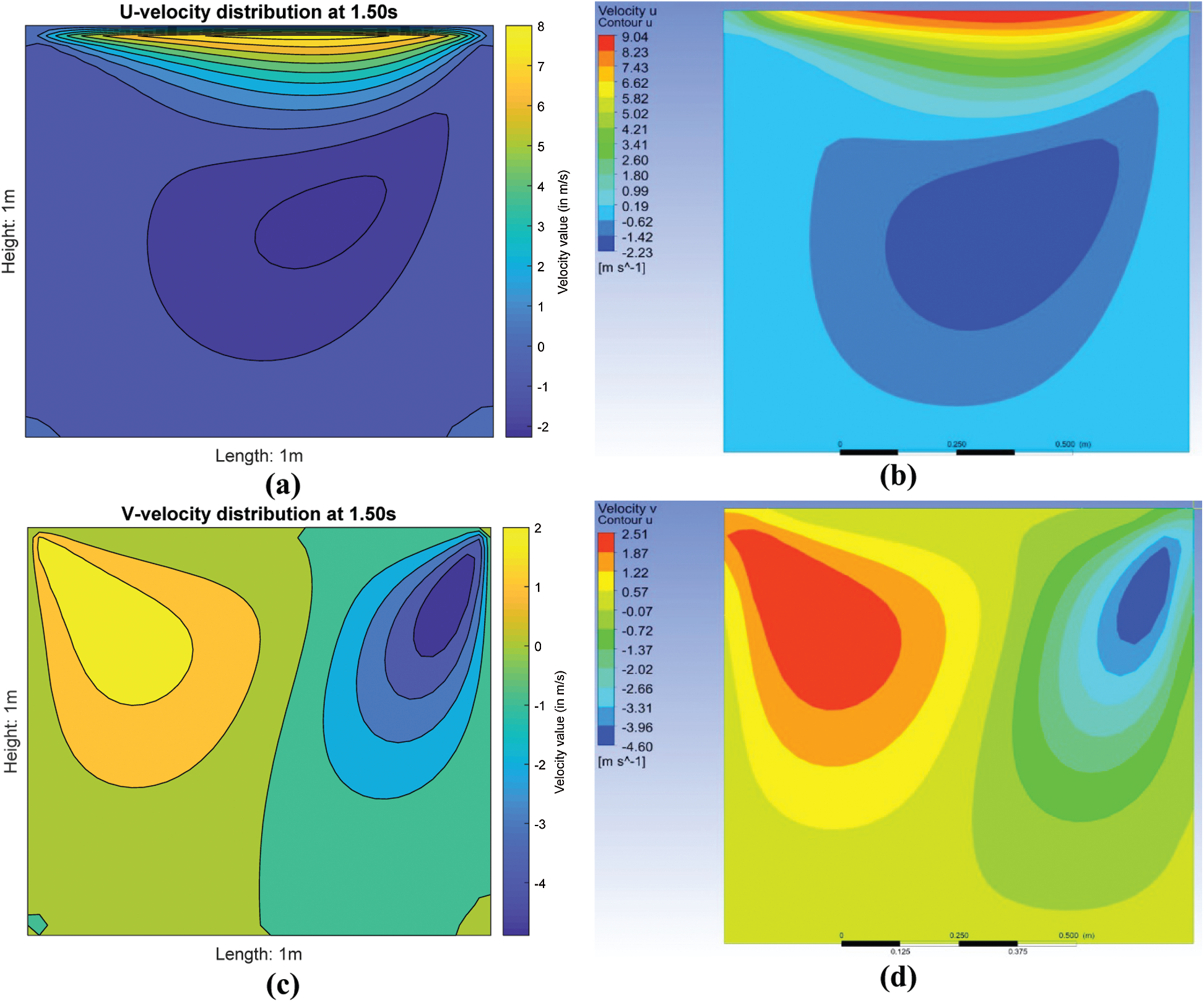

Figure 2: Comparison of contour plots at t = 1.50 s: (a) u-velocity using FDM MATLAB

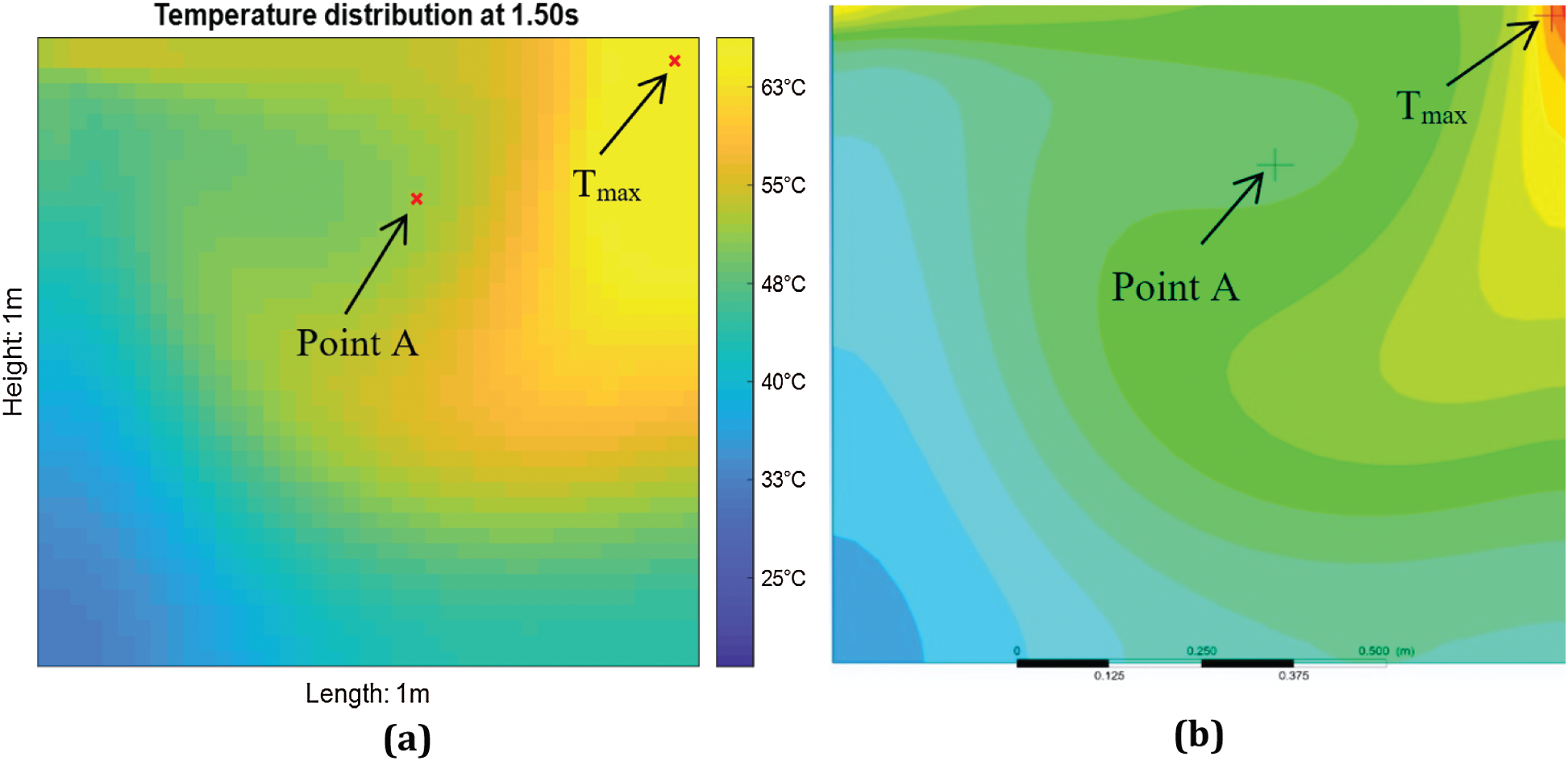

Figure 3: Comparison of image plot at t = 1.50 s (a) using FDM MATLAB

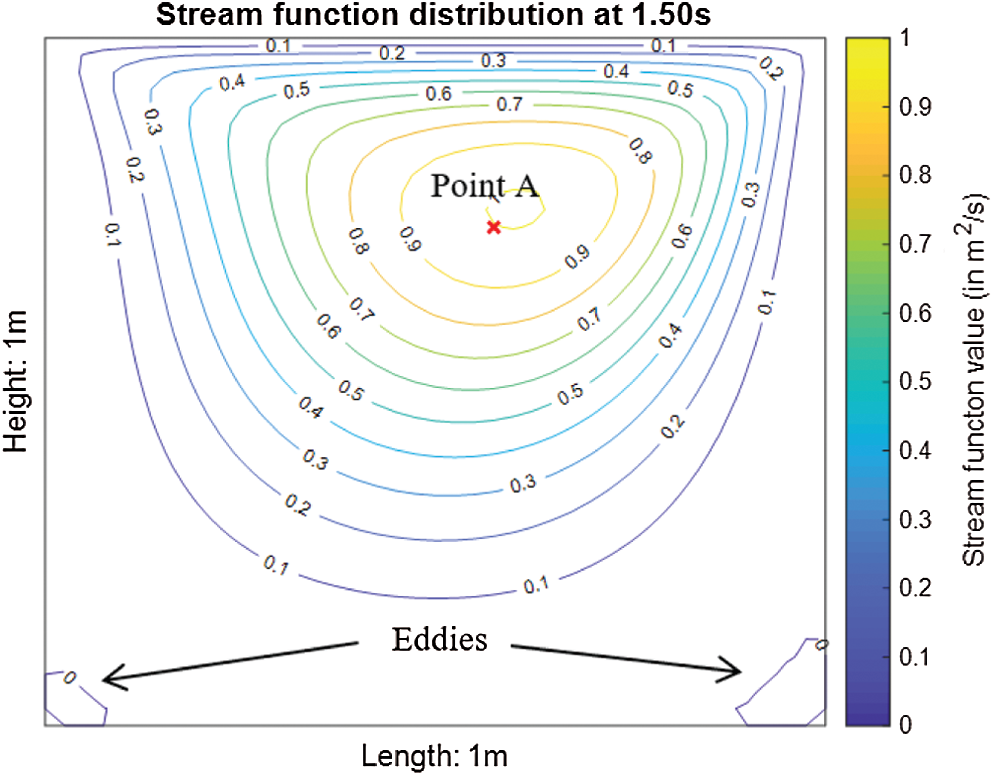

Figure 4: Stream function distribution at t = 1.50 s

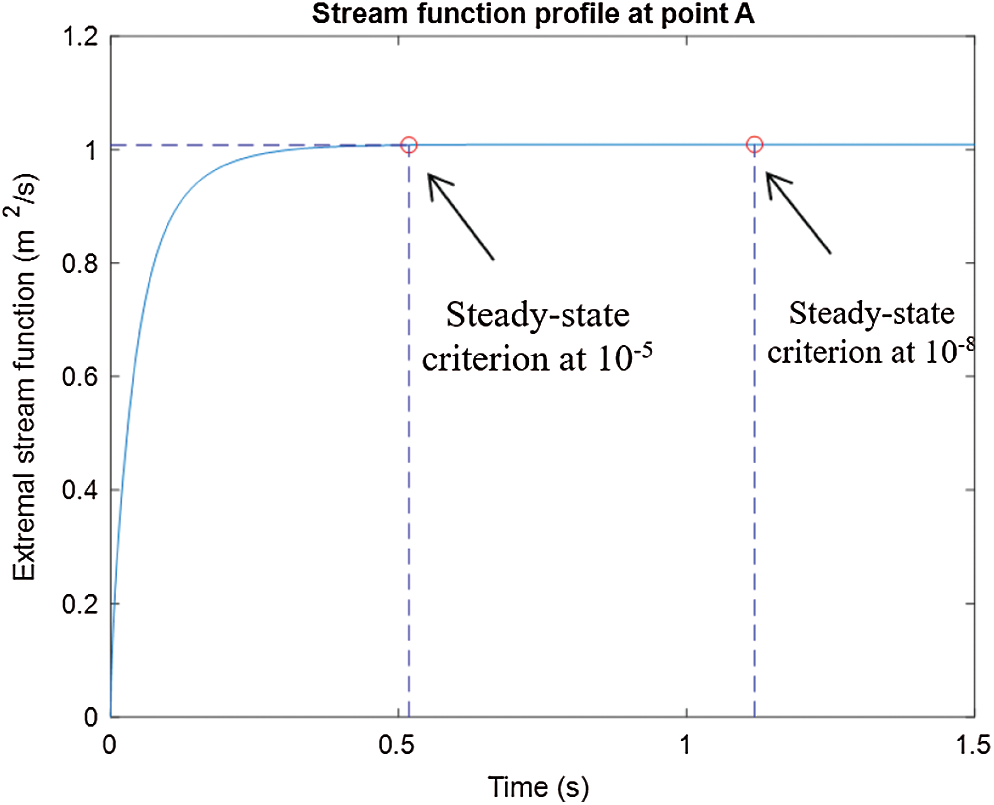

Figure 5: Stream function profile at the point A

Figure 6: Comparison of results for (a) the u-velocity profile and (b) the v-velocity profile

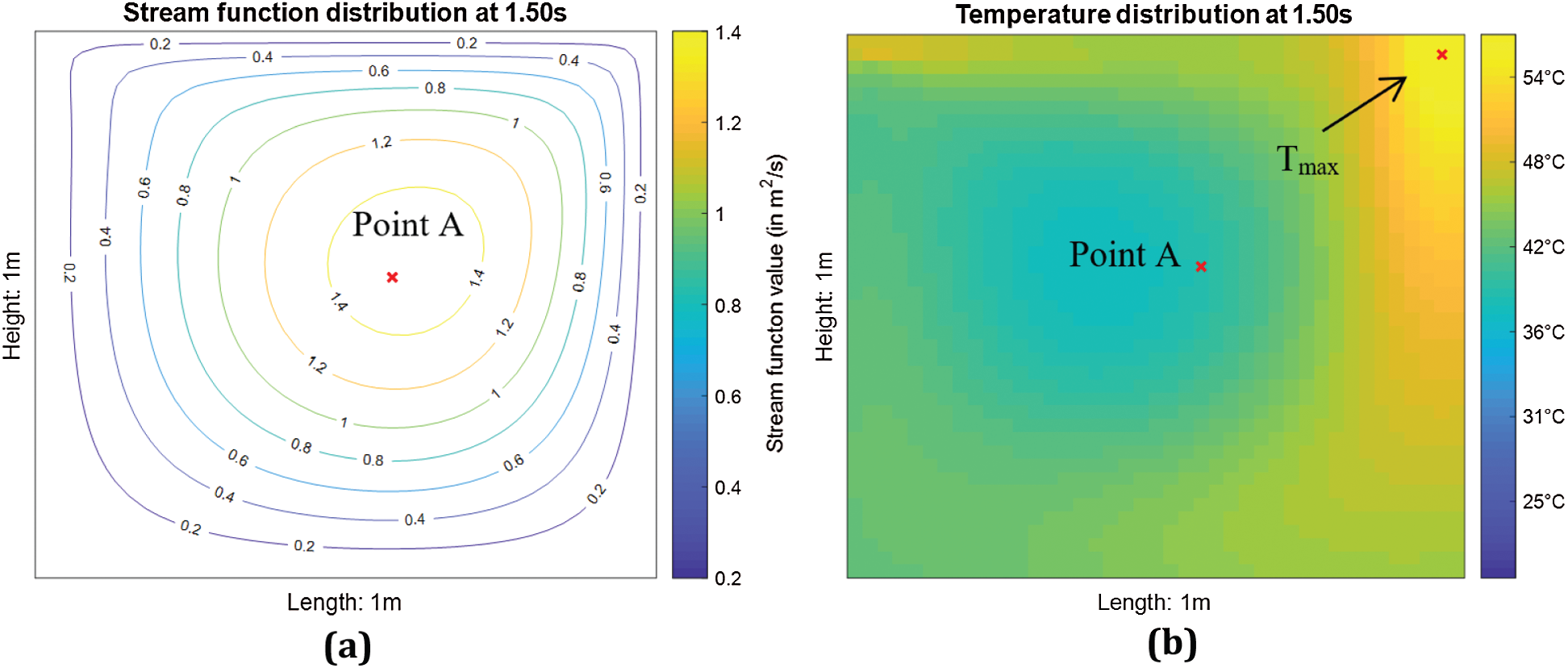

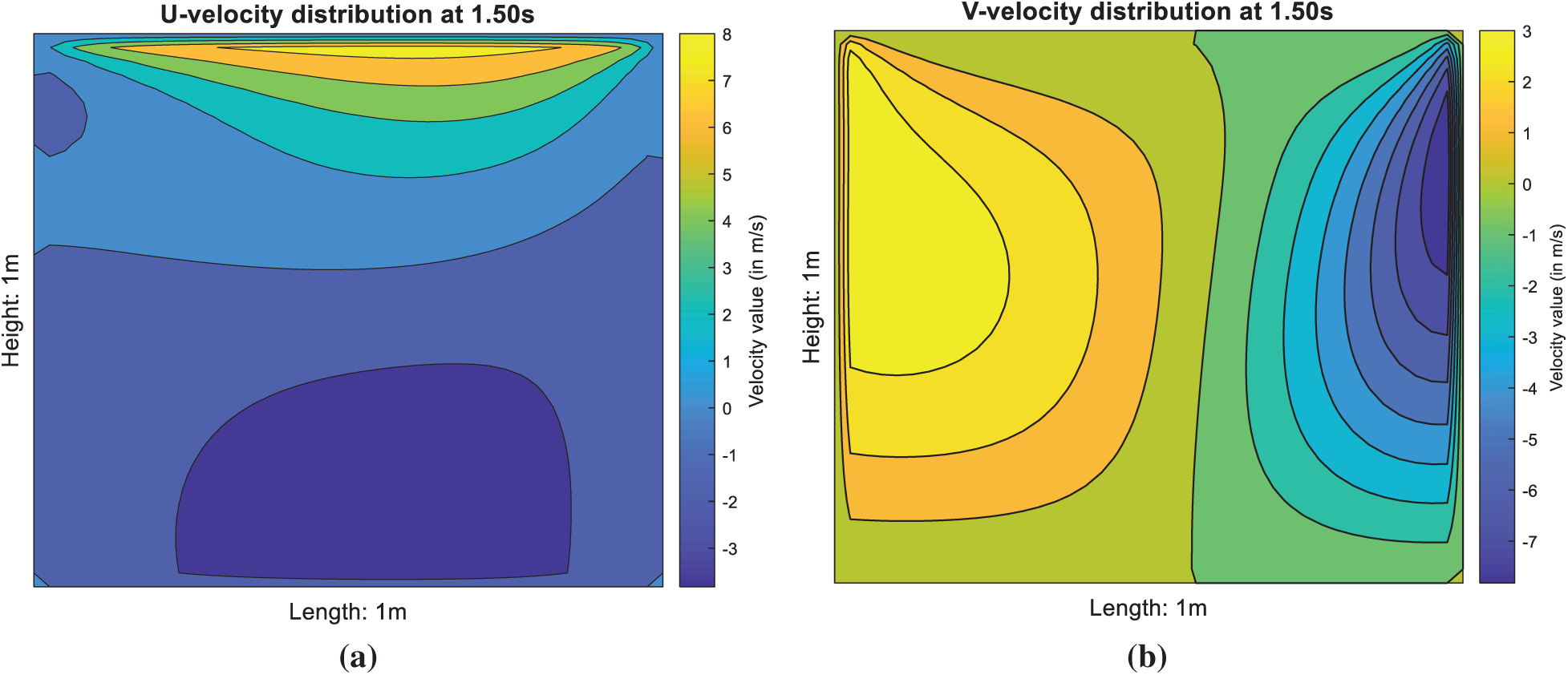

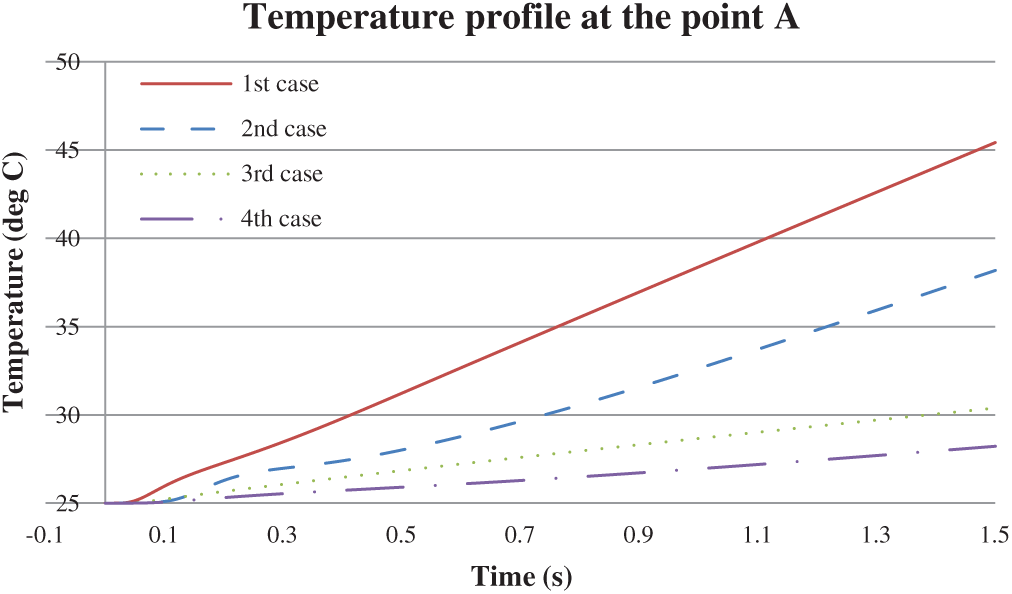

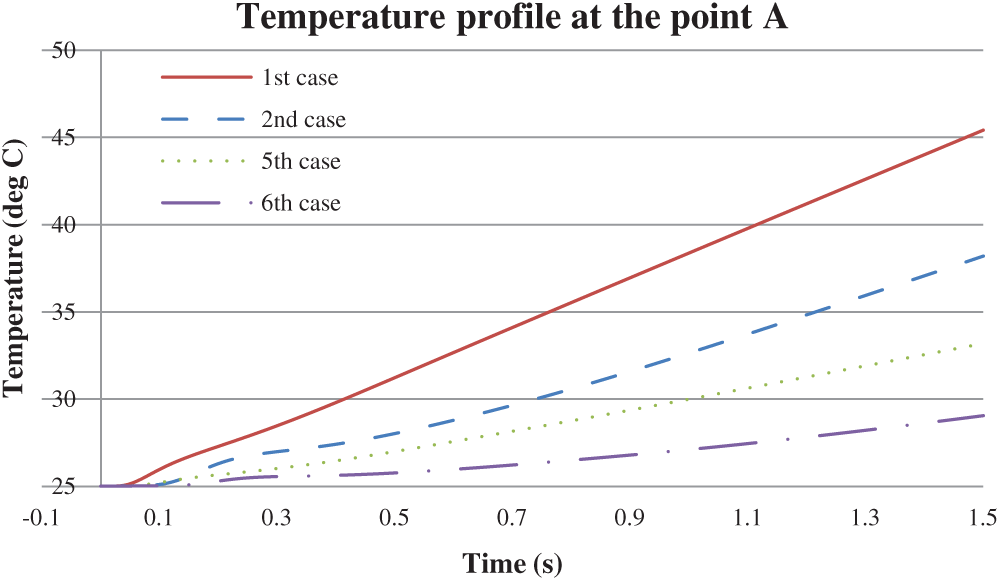

Stream function, temperature distribution and location of the maximum temperature, Tmax for the 2nd test case are shown in Fig. 7. Besides, the associated contour plots of u- and v-velocity distributions of the cavity flow are shown in Fig. 8. Based on Figs. 3a and 7b, the temperature distributions are quite similar in both no-slip (1st test case) and free-slip (2nd test case) BCs. The heat is generated from the moving top lid and concentrated at the top right corner first. Subsequently the heat is slowly propagated to the right bottom corner and to the entire cavity. However, the overall temperature distribution is lower when the lid-driven flow is subject to the free-slip BC in Fig. 7b (2nd test case). Formation of eddies in the free-slip BC is also restricted in contrast with the no-slip BC (1st test case) as depicted in Fig. 7a. Comparison of temperature profiles at the point A for both test cases is shown in Fig. 9.

Figure 7: (a) Stream function and (b) temperature distribution for the 2nd test case (free-slip BC)

Figure 8: (a) U-velocity and (b) V-velocity distributions for the 2nd test case (free-slip BC)

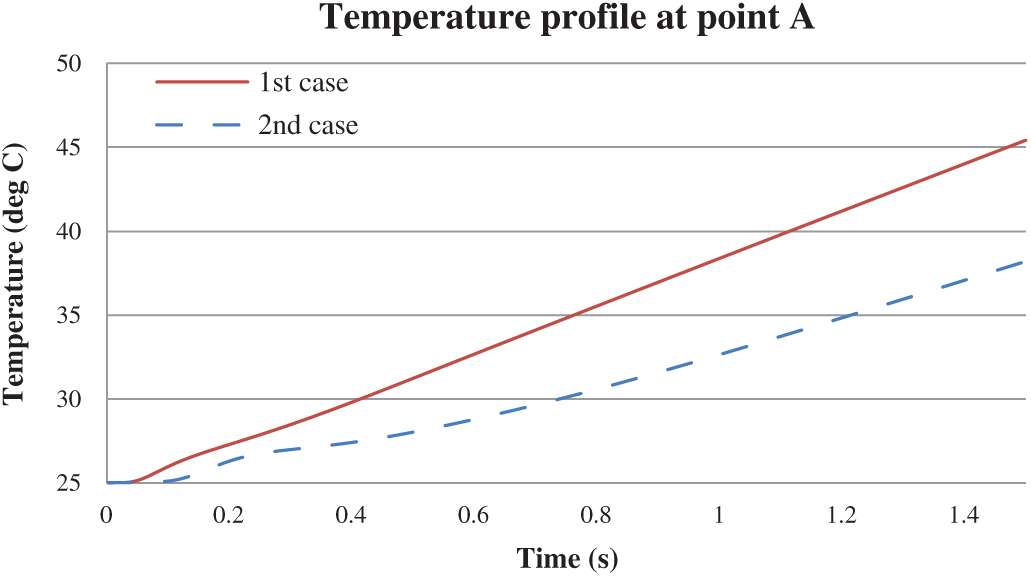

Figure 9: Temperature profile at the point A: (a) 1st test case (no-slip) and (b) 2nd test case (free-slip)

Both slip BCs show similar trend in temperature profile at the point A (location of maximum stream function,

Figure 10: Temperature profile at the point A (

Figure 11: Temperature profile at the point A (

Both the test cases (no-slip and free-slip BCs) show lower temperature profiles at the point A as compared to the benchmarks. Since

where

Table 2: Results of six test cases

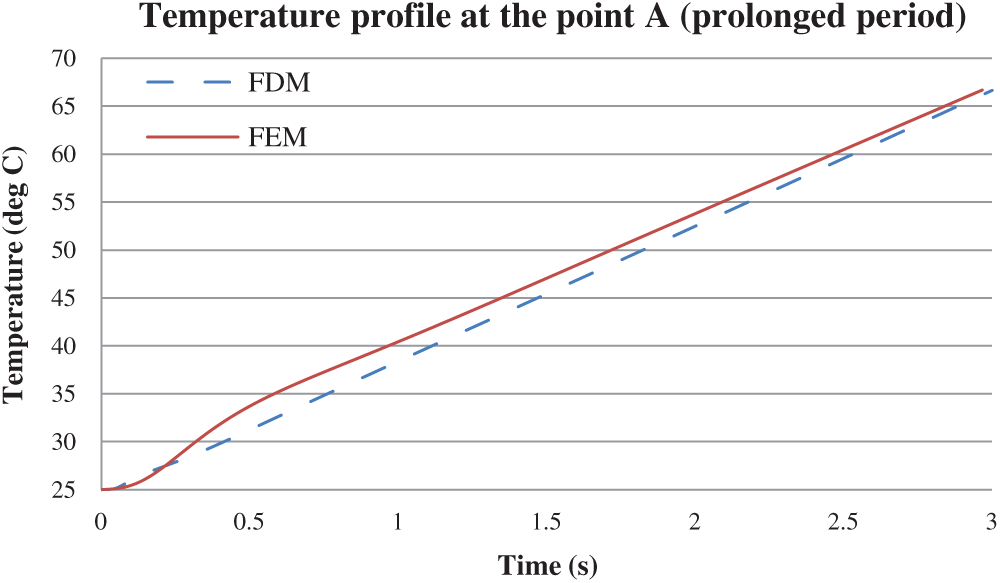

Figure 12: Temperature profile at the point A (1st test case at prolonged period)

In our study, we assume the two-dimensional unsteady lid-driven cavity model is perfectly insulated and no heat loss from the heat flux (viscous heating) is produced by the moving top lid to the environment. The FDM MATLAB solutions are verified earlier with FEM Ansys Fluent

• Temperature profile shows an increasing trend in all test cases as the produced constant heat flux is supplied continuously by the moving top lid. If the iteration period is prolonged to any other period, the temperature profiles of these test cases will keep increasing. This is the reason why the surface temperature of a meteorite during its free-fall keeps increasing although the frictional heating or viscous heating due to the atmospheric air contributes a very small portion of heat.

• Neumann BC is able to trap the heat produced inside the cavity model as the temperature profiles keep increasing quasi-linearly. Trapped heat is important for energy efficiency such as for building insulation during winter season.

• The lower value of Reynolds number,

• Greater value of Prandtl number,

• Free-slip effect will cause the fluid to flow faster but with a lower temperature distribution than that of the no-slip BC as the free-slip effect is assumed to act like a lubricant.

• Although FDM scheme is simple and sufficient to explain the phenomenon of Neumann BC and free-slip effect, this method is limited to simple geometry only.

Funding Statement: The authors acknowledged the funding received from the Ministry of Higher Education, Malaysia and University of Malaya (https://umresearch.um.edu.my/) under the Project No: IIRG006C-19IISS leaded by Z. Siri for this study.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

1. T. Zhang, L. Jia, L. Yang and Y. Jaluria. (2010). “Effect of viscous heating on heat transfer performance in microchannel slip,” International Journal of Heat and Mass Transfer, vol. 53, no. 21, pp. 4927–4934. [Google Scholar]

2. G. Mohamed. (1999). “The fluid mechanics of microdevices,” Journal of Fluids Engineering, vol. 121, no. 1, pp. 5–33. [Google Scholar]

3. J. Koo and C. Kleinstreuer. (2004). “Viscous dissipation effects in microtubes and microchannels,” International Journal of Heat and Mass Transfer, vol. 47, no. 14, pp. 3159–3169. [Google Scholar]

4. J. V. Rij, T. A. Ameel and T. Harman. (2009). “An evaluation of secondary effects on microchannel frictional and convective heat transfer characteristics,” International Journal of Heat and Mass Transfer, vol. 52, no. 11, pp. 2792–2801. [Google Scholar]

5. J. V. Rij, T. A. Ameel and T. Harman. (2009). “The effect of viscous dissipation and rarefaction on rectangular microchannel convective heat transfer,” International Journal of Thermal Sciences, vol. 48, no. 2, pp. 271–281. [Google Scholar]

6. K. G. Kumar, G. K. Ramesh, B. J. Gireesha and R. S. R. Gorla. (2017). “Characteristics of joule heating and viscous dissipation on three-dimensional flow of Oldroyd B nanofluid with thermal radiation,” Alexandria Engineering Journal, vol. 57, no. 3, pp. 1–11. [Google Scholar]

7. P. M. Coelho and F. T. Pinho. (2006). “Fully-developed heat transfer in annuli with viscous dissipation,” International Journal of Heat and Mass Transfer, vol. 49, no. 19, pp. 3349–3359. [Google Scholar]

8. O. Aydın and M. Avcı. (2006). “Heat and fluid flow characteristics of gases in micropipes,” International Journal of Heat and Mass Transfer, vol. 49, no. 9, pp. 1723–1730. [Google Scholar]

9. O. Aydın and M. Avcı. (2007). “Analysis of laminar heat transfer in micro-Poiseuille,” International Journal of Thermal Sciences, vol. 46, no. 1, pp. 30–37. [Google Scholar]

10. F. Mebarek-Oudina. (2017). “Numerical modeling of the hydrodynamic stability in vertical annulus with heat source of different lengths,” Engineering Science and Technology, An International Journal, vol. 20, no. 4, pp. 1324–1333. [Google Scholar]

11. F. Mebarek-Oudina, A. Aissa, B. Mahanthesh and H. F. Öztop. (2020). “Heat transport of magnetized Newtonian nanoliquids in an annular space between porous vertical cylinders with discrete heat source,” International Communication in Heat and Mass Transfer, vol. 117, . https://doi.org/10.1016/j.icheatmasstransfer.2020.104737 [Google Scholar]

12. F. Mebarek-Oudina, N. K. Reddy and M. Sankar. (2021). “Heat source location effects on Buoyant convection of nanofluids in an annulus,” Advances in Fluid Dynamics, pp. 923–937, . https://doi.org/10.1007/978-981-15-4308-1_70. [Google Scholar]

13. M. Sheikholeslami. (2017). “Influence of magnetic field on nanofluid free convection in an open porous cavity by means of Lattice Boltzmann method,” Journal of Molecular Liquids, vol. 234, pp. 364–374. [Google Scholar]

14. H. Laouira, F. Mebarek-Oudina, A. K. Hussein, L. Kolsi, A. Merah et al. (2020). , “Heat transfer inside a horizontal channel with an open trapezoidal enclosure subjected to a heat source of different length,” Heat transfer, vol. 49, no. 1, pp. 406–423. [Google Scholar]

15. M. D. Albright, R. J. Reed and D. W. Ovens. (1995). “Origin and structure of a numerically simulated polar low over Hudson Bay,” Tellus, vol. 47A, no. 5, pp. 834–848. [Google Scholar]

16. E. B. Kraus and J. A. Businger. (1994). Atmosphere-Ocean Interaction. Oxford, England: Oxford University Press. [Google Scholar]

17. F. S. Oğlakkaya and C. Bozkaya. (2018). “Unsteady MHD mixed convection flow in a lid-driven cavity with a heated wavy wall,” International Journal of Mechanical Sciences, vol. 148, no. 1, pp. 231–245. [Google Scholar]

18. M. Manchanda and K. M. Gangawane. (2018). “Mixed convection in a two-sided lid-driven cavity containing heated triangular block for non-Newtonian power-law fluids,” International Journal of Mechanical Sciences, vol. 144, no. 1, pp. 235–248. [Google Scholar]

19. A. Wakif, Z. Boulahia and R. Sehaqui. (2017). “Numerical analysis of the onset of longitudinal convective rolls in a porous medium saturated by an electrically conduction nanofluid in the presence of an external magnetic field,” Results in Physics, vol. 7, pp. 2134–2152. [Google Scholar]

20. M. U. Ashraf, M. Qasim, A. Wakif, M. I. Afridi and I. L. Animasaun. (2020). “A generalized differential quadrature algorithm for simulating magnetohydodynamic peristaltic flow of blood-base nanofluid containing magnetite nanoparticles: A physiological application,” Numerical Methods for Partial Differential Equations, . https://doi.org/10.1002/num.22676. [Google Scholar]

21. A. Wakif, Z. Boulahia, F. Ali, M. R. Eid and R. Sehaqui. (2018). “Numerical analysis of the unsteady natural convection MHD couette nanofluid flow in the presence of thermal radiation using single and two-phase nanofluid models for Cu-water nanofluids,” International Journal of Applied and Computational Mathematics, vol. 4, no. 3, pp. 1–27. [Google Scholar]

22. A. Wakif, Z. Boulahia, S. R. Mishra, M. M. Rashidi and R. Sehaqui. (2018). “Influence of a uniform transerve magnetic field on the thermo-hydrodynamic stability in water-based nanofluids with metallic nanoparticles using the generalized Buongiorno’s mathematical model,” European Physical Journal Plus, vol. 133, no. 181, . https://doi.org/10.1140/epjp/i2018-12037-7. [Google Scholar]

23. N. Biswas and N. K. Manna. (2018). “Magneto-hydrodynamic Marangoni flow in bottom-heated lid-driven cavity,” Journal of Molecular Liquids, vol. 251, no. 1, pp. 249–266. [Google Scholar]

24. W. Zhou, Y. Yan, X. Liu, H. Chen and B. Liu. (2018). “Lattice Boltzmann simulation of mixed convection of nanofluid with different heat sources in a double lid-driven cavity,” International Communications in Heat and Mass Transfer, vol. 97, no. 1, pp. 39–46. [Google Scholar]

25. F. Incropera, D. Dewitt, T. Bergman and A. Lavine. (2006). Fundamentals of Heat and Mass Transfer, 6th ed., New York: John Wiley & Sons. [Google Scholar]

26. M. Rahman, H. F. Öztop, N. Rahim, R. Saidur and K. Al-Salem. (2011). “MHD mixed convection with Joule heating effect in a lid-driven cavity with a heated semi-circular source using the finite element technique,” Numerical Heat Transfer, Part A: Applications, vol. 60, no. 6, pp. 543–600. [Google Scholar]

27. J. D. Anderson. (2003). Modern Compressible Flow: With Historical Perspective, 3rd ed., New York: McGraw-Hill. [Google Scholar]

28. A. Wakif, I. L. Animasaun, P. V. Satya Narayana and G. Sarojamma. (2020). “Meta-analysis on thermo-migration of tiny/nano-sized particles in the motion of various fluids,” Chinese Journal of Physics, vol. 68, no. 6, pp. 293–307. [Google Scholar]

29. A. Wakif, Z. Boulahia and R. Sehaqui. (2018). “A semi-analytical analysis of electro-thermo-hydrodynamic stability in dielectric nanofluids using Buongiorno’s mathematical model together with more realistic boundary conditions,” Results in Physics, vol. 9, no. 1, pp. 1438–1454. [Google Scholar]

30. M. Zaydan, A. Wakif, I. L. Animasaun, U. Khan, D. Baleanu et al. (2020). , “Significances of blowing and suction processes on the occurrence of thermo-magneto-convection phenomenon in a narrow nanofluidic medium: A revised Buongiorno’s nanofluid model,” Case Studies in Thermal Engineering, vol. 22, no. 4, pp. 1–18. [Google Scholar]

31. A. Wakif, A. Chamkha, T. Thumma, I. L. Animasaun and R. Sehaqui. (2020). “Thermal radiation and surface roughness effects on the thermo-magneto-dynamic stability of alumina-copper oxide hybrid nanofluids utilizing the generalized Buongiorno’s nanofluid model,” Journal of Thermal Analysis and Calorimetry, vol. 139, no. 5, pp. 1–20. [Google Scholar]

32. S. C. Chapra and R. P. Canale. (2006). Numerical Methods for Engineers, 5th ed., New York: McGraw Hill. [Google Scholar]

33. N. P. Moshikin and K. Poochinapan. (2010). “Novel finite difference scheme for the numerical solution of two-dimensional incompressible Navier–Stokes equations,” International Journal of Numerical Analysis and Modeling, vol. 7, no. 2, pp. 321–329. [Google Scholar]

34. B. R. Munson, D. F. Young and T. H. Okiishi. (2002). Fundamentals of Fluid Mechanics, 4th ed., New York: John Wiley & Sons. [Google Scholar]

35. H. K. Dass. (1988). Advanced Engineering Mathematics, 1st ed., New Delhi: S. Chand & Company Ltd. [Google Scholar]

36. L. Bostock, S. Chandler and C. Rourke. (1982). Further Pure Mathematics, 1st ed., Cheltenham: Stanley Thornes. [Google Scholar]

37. S. K. Abd-El-Hafiz, G. A. F. Ismail and B. S. Matit. (2004). “Efficient numerical solution of 3D incompressible viscous Navier–Stokes equations,” International Journal of Pure and Applied Mathematics, vol. 13, no. 3, pp. 391–411. [Google Scholar]

38. C. H. Marchi and A. F. C. Silva. (2002). “Unidimensional numerical solution error estimation for convergent apparent order,” Numerical Heat Transfer Part B: Fundamentals, vol. 42, no. 2, pp. 167–188. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |