DOI:10.32604/cmc.2021.017857

| Computers, Materials & Continua DOI:10.32604/cmc.2021.017857 |  |

| Article |

Stress Distribution in Composites with Co-Phase Periodically Curved Two Neighboring Hollow Fibers

1Department of Mathematical Engineering, Faculty of Chemistry and Metallurgy, Yildiz Technical University, Davutpasa Campus, Esenler, 34220, Istanbul, Turkey

2Department of Mathematical Engineering, Graduate School of Natural and Applied Sciences, Yildiz Technical University, Davutpasa Campus, Esenler, 34220, Istanbul, Turkey

*Corresponding Author: Resat Kosker. Email: kosker@yildiz.edu.tr

Received: 14 February 2021; Accepted: 04 April 2021

Abstract: In this paper, stress distribution is examined in the case where infinite length co-phase periodically curved two neighboring hollow fibers are contained by an infinite elastic body. The midline of the fibers is assumed to be in the same plane. Using the three-dimensional geometric linear exact equations of the elasticity theory, research is carried out by use of the piecewise homogeneous body model. Moreover, the body is assumed to be loaded at infinity by uniformly distributed normal forces along the hollow fibers. On the inter-medium between the hollow fibers and matrix surfaces, complete cohesion conditions are satisfied. The boundary form perturbation method is used to solve the boundary value problem. In this investigation, numerical results are obtained by considering the zeroth and first approximations to calculate the self-equilibrium shear stresses and normal stress at the contact surfaces between the hollow fibers and matrix. Numerous numerical results have been obtained and interpreted about the effects of the interactions between the hollow fibers on this distribution.

Keywords: Hollow fibers; stress distribution; fibrous composite; periodic curvature

Composite materials have increased in importance as they have superior properties than the materials they are made of. Today, composites have numerous application areas such as energy, sports, military, automotive, marine, aerospace, civil engineering, biomedical and even the music industry [1]. Unidirectional fibrous composites have an important place among composite materials. It is very important to create a mathematical model about the elastic behavior of these materials so that they are used effectively in practice when exposed to various external influences, and to examine them theoretically. These investigations will determine the rheological, mechanical, thermal, electrical and morphological properties of the materials. For example, it has been found that fibrous composites with well-dispersed reinforcing fibers have higher electrical and thermal conductivity [1–3].

As noted in [4–6], one of the main factors that determines the strength of unidirectional fibrous composite is the fibers’ curvature. Curvature can occur as a result of design or as a result of a technological process and is called periodic or local. Practical applications of these composite materials require determination of the stress-strain state considering the curl of the fibers. Self-balanced stresses arise due to the curvature of the fibers, and these stresses can cause the fibers to separate from the matrix under uniaxial tension or stress along the fibers [5,7,8]. This separation leads to the formation of macro cracks, whose accumulation can significantly alter the strength and stiffness properties of the composites [9]. In addition, the initial minor curling of reinforcing fibers is taken as a model for investigating various stability loss or fracture problems of unidirectional composites [10]. Therefore, creating the mechanics of composite materials containing curved structures is important both in terms of fundamental advances in the mechanics of rigid deformable bodies and in modern engineering that uses special composite components. In [11], to achieve this aim, using the three-dimensional exact equations of the elasticity theory together with the piecewise homogenous body model, a method was developed for investigating the stress-strain state produced in unidirectional fibrous composite materials. Fiber curving was considered periodic in that study. Reviews of the numerical results obtained by using this method are given in [5].

The method discussed in [11] is proposed for the case where the concentration of fibers is so small that the interactions between them are negligible. In [12], the method is developed to be used in the problem of two neighboring periodically inclined fibers, and numerical results are given taking into account the interaction between the fibers. In [13], this method is extended to the nonlinear geometric state, and from here, the numerical results obtained for stresses in a composite material containing one and two neighboring periodically inclined fibers are presented. Studies on the loss of stability problems corresponding to these conditions are reviewed in [14]. In [15–18], this approach is developed for a periodically located row of fibers embedded in an infinite matrix and the obtained numerical results are presented. In [19], the stability loss of the related problem is studied. In addition, some similar studies in the local curvature case are presented in publications [20–23].

However, in all the investigations given above, it is assumed that the fibers embedded in the matrix are traditional materials. In [24], the reinforcing element is taken as a double-walled carbon nanotube (DWCNT), and the loss of internal stability in composite materials containing a straight infinitely long DWCNT is examined. In [25], the stress distribution is studied in an infinite body containing an infinite length periodically curved hollow fiber with low concentration. In this study, to calculate the effect of the interactions between the hollow fibers on the stresses, the same situation is developed for the two neighboring hollow fiber cases. The problem is the stress distribution in the infinite body containing infinite length, periodically curved two neighboring hollow fibers. The investigations are made by using the three-dimensional geometric linear exact equations of the elasticity theory with the piecewise homogeneous body model. In addition, it is assumed that uniformly distributed normal forces are acting on the body at infinity along the hollow fibers.

2 Mathematical Formulation of the Problem

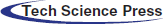

Infinite length, periodically curved two neighboring hollow fibers embedded in an infinite elastic body are taken into account. We assume that the perpendicular sections of the hollow fibers are circles with radius R and thickness H and this does not change throughout the hollow fibers. We also note that the midline of the hollow fibers is in the same plane and has co-phase initial periodic tilting with respect to each other. In the aforementioned model, it is thought that there are normal forces with intensity p that are evenly distributed in the longitudinal direction of the hollow fibers.

Let us select

Assuming that the midlines of the hollow fibers are in the

Here,

In the following, we will show the values belonging to the first and second hollow fibers with the superscript (21) and (22), respectively and the values belonging to the matrix (infinite elastic medium) with the superscript (1).

Figure 1: Geometry and coordinate systems of the considered material structures

Let us write the following governing field equations to be satisfied in each hollow fiber and infinite elastic medium:

Let us denote the inner surface of the hollow fibers with

In the case discussed, the following conditions are also provided:

Tensor notation is used in the formulae given above. We should state that the sum cannot be made according to the underlined indices.

Thus, the formulation of the addressed problem is completed. The problem is reduced to the solution of Eq. (3) within the framework of (4) contact and (5) boundary conditions.

We can write the equations of the surfaces

Here,

The boundary-form perturbation method given in [5] will be used to examine this problem. According to this method, all the expressions are searched in series form in terms of the small parameter defined above.

Expressions (6) and (7) are also written serially according to

The

We will deal with the case where the nonlinear terms in the equations related to the zeroth approximation can be omitted, and since

Thus, the zeroth approach is reduced to the solution of Eq. (11) within the framework of contact conditions (12).

For the first approach, we can write the governing field equations as follows:

For this approach, we obtain the contact conditions as follows:

where

In this section, we will obtain the solutions of the boundary-value problems of the zeroth and first approaches formulated above. For simplicity, we will assume that both fiber materials are the same and that Poisson's ratio of

In this case, we get the following solution for the zeroth approach:

Let us now consider the solution of the problem (13)–(17) belonging to the first approach. Considering the above assumptions and the solution of the zeroth approach (18), the Eq. (13) are obtained as follows:

These equations coincide with the linearized three-dimensional elasticity equations. Similarly, Eq. (14) become:

Considering the solution obtained in the zeroth approach, the contact conditions of the first approach (16) are obtained as follows:

For the solution of Eq. (21), let us use the following representation given in [5], taking into account (19):

The

Thus, the solution of Eq. (23) is obtained by considering the expressions on the right side of Eq. (21) as follows:

In (25) and (26),

In order to write the

Thus, an infinite dimensional system of algebraic equations is obtained from (21) in terms of unknown constants (27) by using (22)–(26). If this system is solved using the convergence criterion and the unknowns are determined, then the desired stress values are determined. Let us show that the convergence criterion is satisfied in order for this system to be replaced by a finite one. Let us introduce the following notations:

The system of infinite algebraic equations in terms of defined notations is written as:

It is obtained from (31) and (33) that

The infinite system of algebraic Eq. (34) must be approximated by the finite one to obtain numerical results. To make this displacement possible, the determinant of the algebraic infinite system of equations must be of normal type [27]. This is achieved if we show that the following series is convergent:

The functions

Since the hollow fibers do not touch each other, the following inequalities are achieved:

From (36)–(37), and analyzing

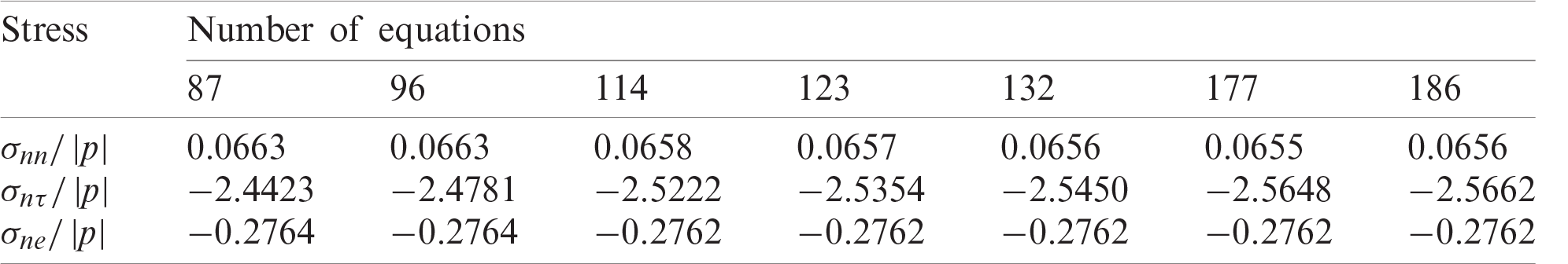

Similar proof is made in [11,12]. Thus, the infinite algebraic system can be replaced by a finite one. The number of equations the finite system will consist of, will be decided by the convergence of the numerical results.

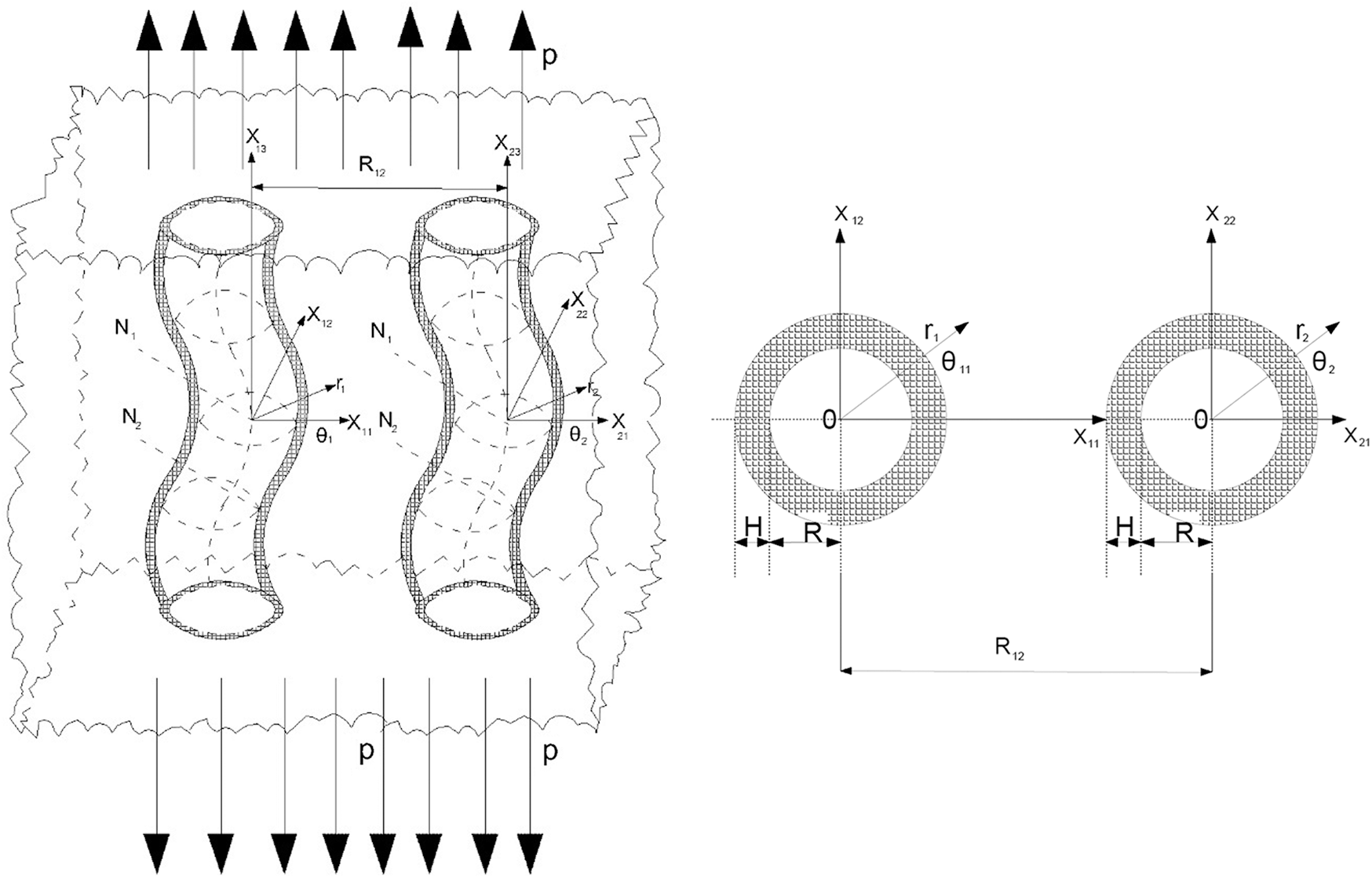

In this study, the numerical results have been obtained using the zeroth and first approximations. Next approaches can only contribute quantitatively to the results. In addition, Poisson ratios are taken as

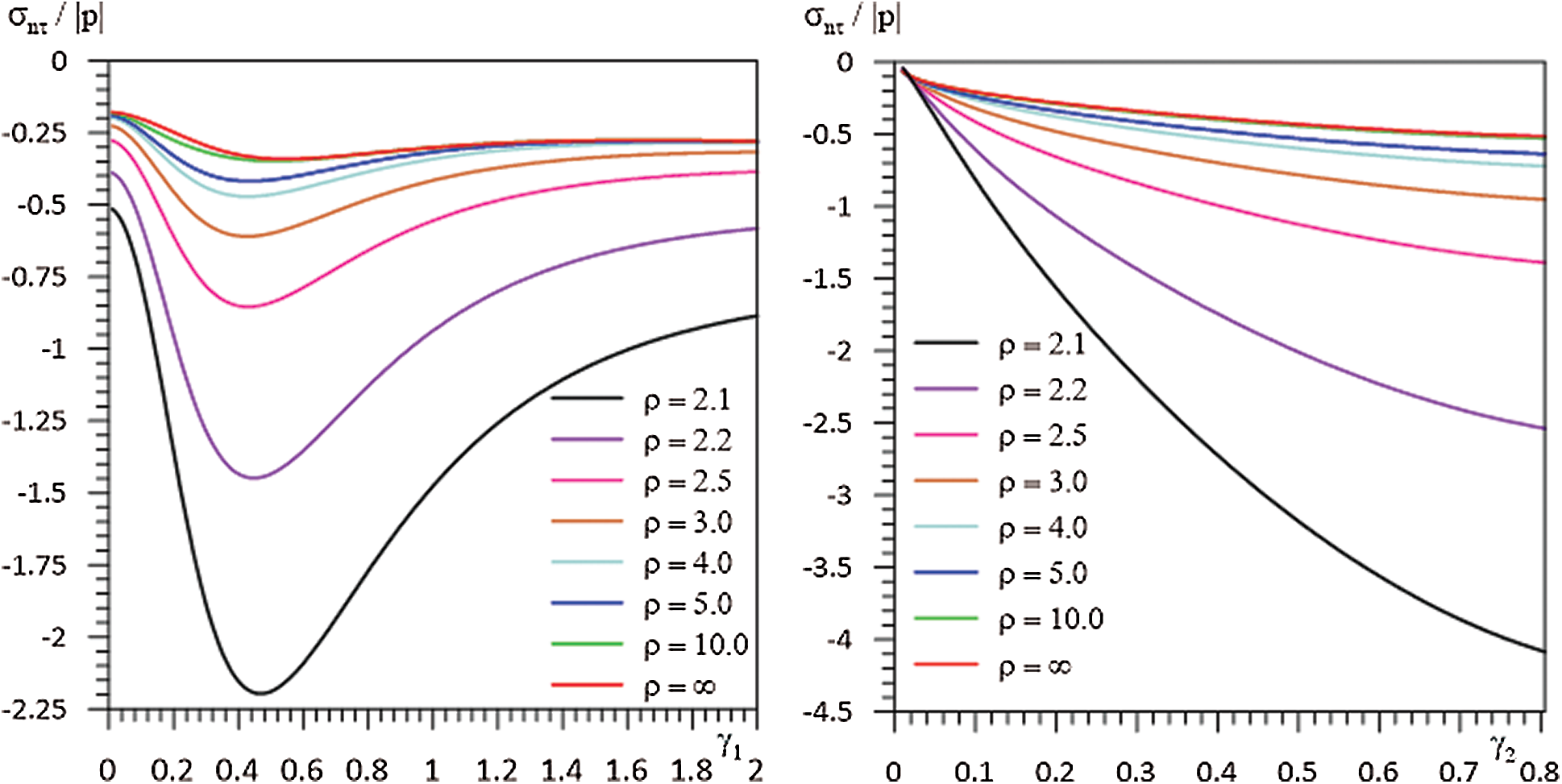

Figure 2: The graph of dependencies between

Figure 3: The graph of dependencies between

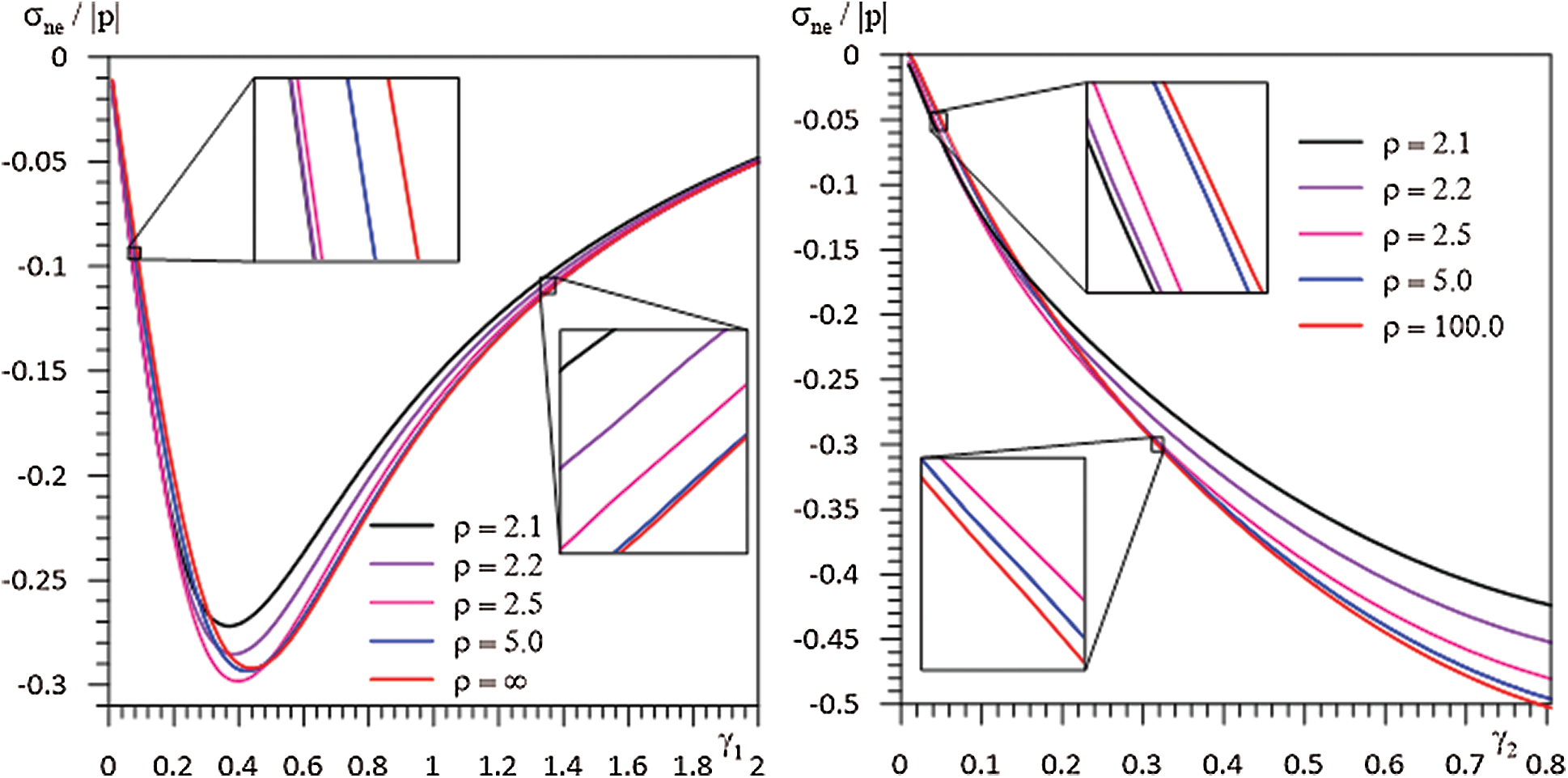

Figure 4: The graph of dependencies between

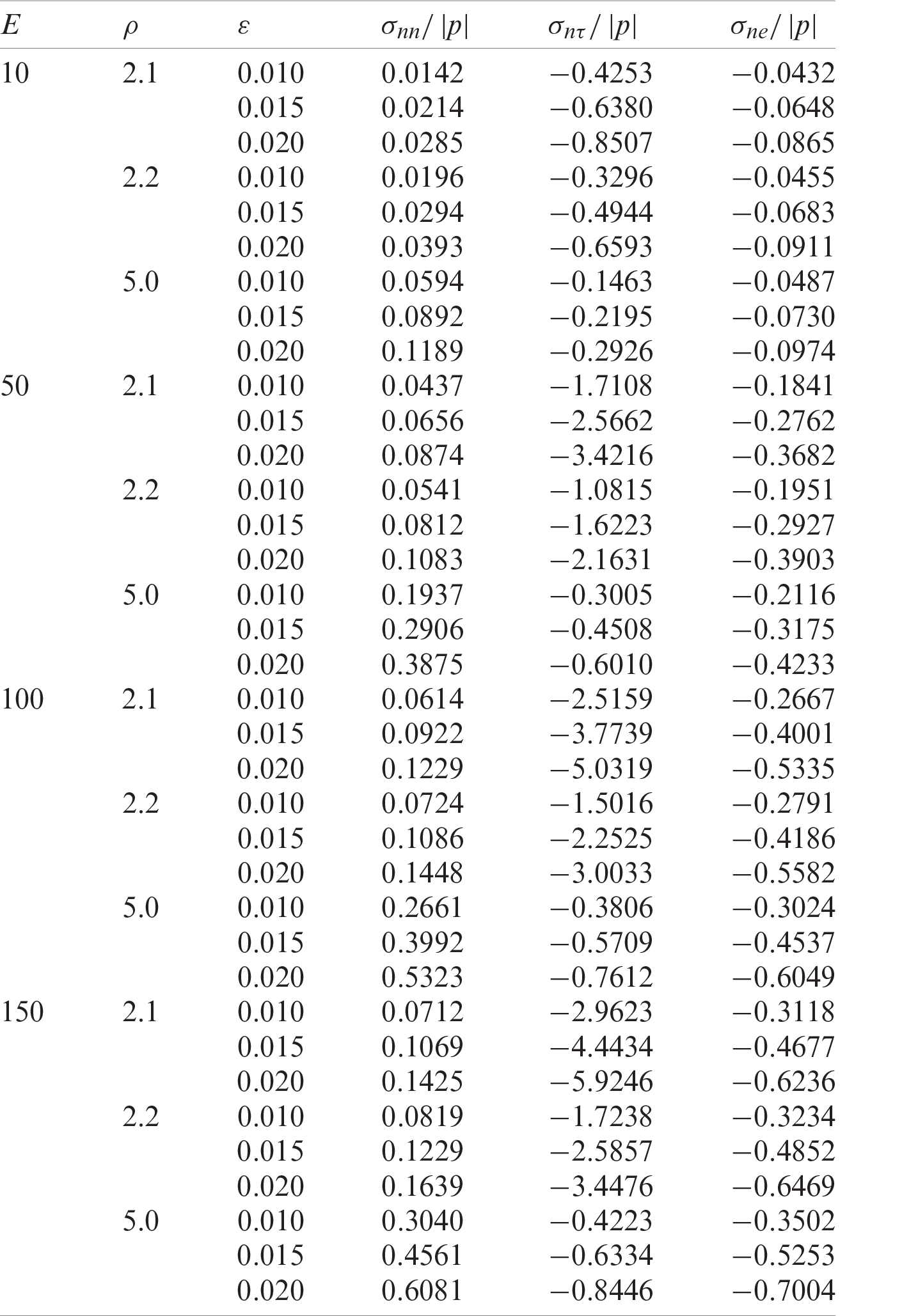

Table 1: The stresses in

In Figs. 2–4, the dependencies between

With the increase of the distance between the hollow fibers, the interaction between the fibers disappears and thus the same values are reached with the stress values obtained in case [25]. This shows the accuracy of both the algorithms used and the programming made by the authors with the FTN77 programming language.

In Tab. 1, the values of

Tab. 2 shows how the values of the stresses converge with the number of equations where

Table 2: Convergence of the values of the stresses with the number of equations where

In this study, the normal and shear stresses at the fiber-matrix interface are studied in the case of two neighboring hollow fibers with infinite length (at least ten times the bending amplitude) with the same phase periodic curvature embedded in an infinite elastic medium. It is thought that the object in question has uniformly distributed normal forces acting along the hollow fibers at infinity, and the midlines which pass through the centers of the fibers have the same plane and phase curvature. The case in which the thicknesses and outer radii of the fibers are the same and where these values do not change along the fibers is discussed. The hollow fibers may be close to each other, but they do not come into contact. The research has been carried out using the piecewise-homogeneous body model and the three-dimensional geometric linear exact equations of elasticity theory. Thus, it is aimed to obtain better quality results than the numerical results obtained using approximate theories.

Within the framework of the above assumptions, the governing field equations provided separately in the hollow fibers and in the matrix are written in accordance with the piecewise-homogeneous body model. Added to these are the conditions provided by the inner surfaces of the fibers and the ideal contact conditions provided at the surfaces where the fibers come into contact with the matrix. Thus, the problem has been formulated as a boundary-value problem which has been solved by using the boundary form perturbation method. According to this method, all expressions related to the surface equations, hollow fibers and matrix are serialized in terms of the small parameter defining the bending degree of the fibers. When these series are used in the governing field equations and boundary conditions, the boundary-value problems provided separately for each approach are obtained. Naturally, the k-th boundary-value problem includes the magnitudes of the previous boundary value problems. Numerical results have been obtained by solving the boundary value problems of the zeroth and first approach. Since the solution of the boundary value problems belonging to the next approaches will affect the numerical results only quantitatively, and not qualitatively, the solutions up to the first approach are considered to be sufficient. With some simple assumptions, the boundary-value problem of the zeroth approach can be solved analytically, while the solution of the boundary-value problem of the first approach is brought to the infinite system of algebraic equations. It has been shown that this infinite system of algebraic equations can be replaced by a finite one by using the convergence criterion. Numerical results are produced by taking a sufficient number of equations according to this criterion.

The obtained numerical results consist of the calculations made at the points where the normal stress of

• The relationship between the

• The relationship between the

• The relationship between the

• The relationship between the stresses under consideration and the thickness of the hollow fibers is monotone.

• The increase in the bending degree and in the ratio of elasticity constants increases the values of the stresses as absolute values.

• The numerical results obtained when the distance between the hollow fibers is increased so that there is no interaction between them, coincides with those obtained in [25]. In addition, the numerical results obtained by taking the inner space of fibers to zero are consistent with the results of [12], in which problem the fibers are filled. This demonstrates the accuracy of the numerical results.

The numerical results obtained should be taken into account in the production of materials which have the properties discussed here, when used as structural elements. In addition, for certain values of the parameters (given in [24]), instead of hollow fibers, carbon nanotubes can be considered, and stress distribution and stability problems can be examined.

Funding Statement: This research has been supported by Yildiz Technical University Scientific Research Projects Coordination Department. Project Number: 2014-07-03-DOP01.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. M. O. Seydibeyoglu, A. K. Mohanty and M. Misra, Fiber Technology for Fiber-Reinforced Composites. Cambridge, United Kingdom: Woodhead Publishing, 2017. [Google Scholar]

2. R. P. Tomic, A. Sedmak, D. M. Catic, M. V. Milos and Z. Stefanovic, “Thermal stress analysis of a fiber-epoxy composite material,” Thermal Science, vol. 15, no. 2, pp. 559–563, 2011. [Google Scholar]

3. A. Ahmed and L. Xu, “Numerical analysis of the electrospinning process for fabrication of composite fibers,” Thermal Science, vol. 24, no. 4, pp. 2377–2383, 2020. [Google Scholar]

4. A. Kelly, “Composite materials: Impediments do wider use and some suggestions to overcome these,” in Proc. Book ECCM-8, Naples-Italy, vol. I, pp. 15–18, 1998. [Google Scholar]

5. S. D. Akbarov and A. N. Guz, Mechanics of Curved Composites. Dortrecht, Boston, London: Kluwer Academic Publishers, 2000. [Google Scholar]

6. A. N. Guz, “On one two-level model in the mesomechanics of compression fracture of Cracked Composites,” International Applied Mechanics, vol. 39, no. 3, pp. 74–285, 2003. [Google Scholar]

7. H. T. Corten, “Fracture of reinforcing plastics,” in Modern Composite Materials, L. J. Broutman, R. H. Krock (Eds.Reading, Massachusetts: Addison-Wesley, pp. 27–100, 1967. [Google Scholar]

8. Yu. M. Tarnopolsky and A. V. Rose, Special Feature of Design of Parts Fabricated from Reinforced Plastics. Riga: Zinatne, 1969. [Google Scholar]

9. M. Yu. Kashtalyan, “On deformation of ceramic cracked matrix cross-ply composites laminates,” International Applied Mechanics, vol. 41, no. 1, pp. 37–47, 2005. [Google Scholar]

10. S. D. Akbarov, Stability Loss and Buckling Delamination: Three-Dimensional Linearized Approach for Elastic and Viscoelastic Composites. Berlin, Heidelberg: Springer-Verlag, 2012. [Google Scholar]

11. S. D. Akbarov and A. N. Guz, “Method of solving problems in the mechanics of fiber composites with curved structures,” Soviet Applied Mech March, vol. 20, no. 9, pp. 777–785, 1985. [Google Scholar]

12. R. Kosker and S. D. Akbarov, “Influence of the interaction between two neighbouring periodically curved fibers on the stress distribution in a composite material,” Mechanics of Composite Materials, vol. 39, no. 2, pp. 165–176, 2003. [Google Scholar]

13. S. D. Akbarov and R. Kosker, “On a stress analysis in the infinite elastic body with two neighbouring curved fibers,” Composites Part B: Engineering, vol. 34, no. 2, pp. 143–150, 2003. [Google Scholar]

14. S. D. Akbarov, “Three-dimensional stability loss problems of the viscoelastic composite materials and structural members,” International Applied Mechanics, vol. 43, no. 10, pp. 3–27, 2007. [Google Scholar]

15. S. D. Akbarov, R. Kosker and Y. Ucan, “Stress distribution in an elastic body with a periodically curved row of fibers,” Mechanics of Composite Materials, vol. 40, no. 3, pp. 191–202, 2004. [Google Scholar]

16. S. D. Akbarov, R. Kosker and Y. Ucan, “Stress distribution in a composite material with the row of anti-phase periodically curved fibers,” International Applied Mechanics, vol. 42, no. 4, pp. 86–493, 2006. [Google Scholar]

17. S. D. Akbarov, R. Kosker and Y. Ucan, “The effect of the geometrical non-linearity on the stress distribution in the infinite elastic body with a periodically curved row of fibers,” Computers, Materials & Continua, vol. 17, no. 2, pp. 77–102, 2010. [Google Scholar]

18. S. D. Akbarov, R. Kosker and Y. Ucan, “Influence of the interaction between fibers periodically located in a composite material on the distribution of stresses in it,” Mechanics of Composite Materials, vol. 52, no. 2, pp. 243–256, 2016. [Google Scholar]

19. R. Kosker, “On internal stability loss of a row unidirected periodically located fibers in the visco-elastic matrix,” Thermal Science, vol. 23, no. S1, pp. 427–438, 2019. [Google Scholar]

20. F. Coban Kayıkci and R. Kosker, “Stability analysis of double-walled and triple-walled carbon nanotubes having local curvature,” Archive of Applied Mechanics, vol. 91, pp. 1669–1681, 2021. [Google Scholar]

21. F. Coban Kayıkci and R. Kosker, “Stress distribution in an elastic body with a locally curved double-walled carbon nanotube,” Journal of the Brazilian Society of Mechanical Sciences and Engineering, vol. 43, no. 52, pp. 1–16, 2021. [Google Scholar]

22. R. Kosker and N. Cinar, “Stress distribution in an infinite body containing two neighboring locally curved nanofibers,” Mechanics of Composite Materials, vol. 45, no. 3, pp. 315–330, 2009. [Google Scholar]

23. N. T. Cinar, R. Kosker, S. D. Akbarov and E. Akat, “Stress distribution caused by two neighboring out-of-plane locally cophasally curved fibers in a composite material,” Mechanics of Composite Materials, vol. 46, no. 5, pp. 555–572, 2010. [Google Scholar]

24. S. D. Akbarov, “Microbuckling of a double-walled carbon nanotube embedded in an elastic matrix,” International Journal of Solids and Structures, vol. 50, no. 16–17, pp. 2584–2596, 2013. [Google Scholar]

25. R. Kosker and I. Gulten, “Stress distribution in elastic media containing hollow fiber with periodic curvature,” European Journal of Science and Technology, vol. 19, pp. 809–820, 2020. [Google Scholar]

26. G. N. Watson, A Treatise on the Theory of Bessel Functions. Cambridge: Cambridge University Press, 1966. [Google Scholar]

27. L. V. Kantarovich and V. I. Krilov, Approximate Methods in Advanced Calculus. Moscow: Fizmatgiz, 1962. (in Russian). [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |