DOI:10.32604/cmc.2022.018146

| Computers, Materials & Continua DOI:10.32604/cmc.2022.018146 |  |

| Article |

Designing Bayesian New Group Chain Sampling Plan For Quality Regions

1School of Quantitative of Sciences, Universiti Utara Malaysia, Sintok, 06010, Malaysia

2Institute of Strategic Industrial Decision Modelling (ISIDM), Universiti Utara Malaysia, Sintok, 06010, Malaysia

*Corresponding Author: Nazrina Aziz. Email: nazrina@uum.edu.my

Received: 26 February 2021; Accepted: 16 April 2021

Abstract: Acceptance sampling is a well-established statistical technique in quality assurance. Acceptance sampling is used to decide, acceptance or rejection of a lot based on the inspection of its random sample. Experts concur that the Bayesian approach is the best approach to make a correct decision, when historical knowledge is available. This paper suggests a Bayesian new group chain sampling plan (BNGChSP) to estimate average probability of acceptance. Binomial distribution function is used to differentiate between defective and non-defective products. Beta distribution is considered as a suitable prior distribution. Derivation is completed for the estimation of the average proportion of defectives. This study includes four quality regions namely: (i) probabilistic quality region (PQR), (ii) quality decision region (QDR), (iii) limiting quality region (LQR), and (iv) indifference quality region (IQR). The estimated values for the BNGChSP are tabulated and the inflection point values are derived, based on different combinations of design parameters including both consumer’s and producer’s risks. For comparison with the existing plan, the operating characteristic curves expose that BNGChSP is a better substitute for industrial practitioners.

Keywords: Binomial; beta distribution; consumer’s risk; producer’s risk; quality region

Quality assurance is one of the most important factors for industrial production in the world. Since the last century, its applications in the manufacturing and service industries have been increasing. As the people are concerned with their critical importance in the production of manufacturing products [1]. A technique in statistical quality assurance is acceptance sampling, where based on different attributes inspection is performed on a sample of items selected from the lot under inspection. To make a decision about a lot under inspection, one option is to do a hundred percent inspection and the other is acceptance sampling. The cost and the time on inspection can be reduced by using acceptance sampling because they are directly related to sample size [2]. For example, one or few grapes can be tasted to find out whether the bunch of grapes is good or bad. It can be purchased if the selected grapes are good and if selected are bad it means the whole bunch is bad, then purchase is refused. This sampling inspection method can be used to determine whether a product is defective or non-defective. Based on their applications, a variety of acceptance sampling plans are used for inspection of products in industry. For example, in electronics manufacturing, hospital pharmacy, and food control [3–5].

Several acceptance sampling plans have been introduced over the decades. Based on single sample inspection, a single sampling plan (SSP) was proposed by Epstein et al. [6]. SSP is most famous in industrial engineering applications due to its simplicity and user-friendliness [7]. Dodge [8] developed a chain sampling plan (ChSP-1) to improve the probability of lot acceptance. Later, by considering the previous sample in SSP and a general family of chain sampling was suggested [9]. A process for attribute single sampling plan was given by Hald [10], to minimize average inspection cost. A single sampling plan was modified by using the acceptable quality limit (AQL) and limiting quality level (LQL). The Bayesian single sampling plan was considered, with weighted Poisson distribution [11,12] and Poisson distribution [13]. Latha et al. [14] used the gamma prior and proposed Bayesian chain sampling plan for construction and performance measures. Through quality regions, Nirmala et al. [15] designed a plan for Bayesian conditional repetitive group sampling.

Mughal et al. [16] assessed the design parameters for group acceptance sampling plan (GASP). GASP is evaluated in the form of group by using several testers at a time. In GASP sample size,

By considering quality variation, a plan namely Bayesian group chain sampling plan (BGChSP) for binomial distribution with beta distribution as prior was suggested [20]. It is to be noted that BGChSP used five acceptance criteria and can be improved by using more tight acceptance criteria. The main objective of this study is to update the acceptance criteria from five to four. This is more tight criteria against the defective product. Therefore, by tight acceptance criteria for a good plan both producer’s and consumer’s risks need to be minimized. The producer’s risk associated with type I error and the consumer’s risk associated with type II error. To achieve a good decision, both errors should be minimized to increase the correct decision power. With these objectives, this study is proposing a BNGChSP by considering

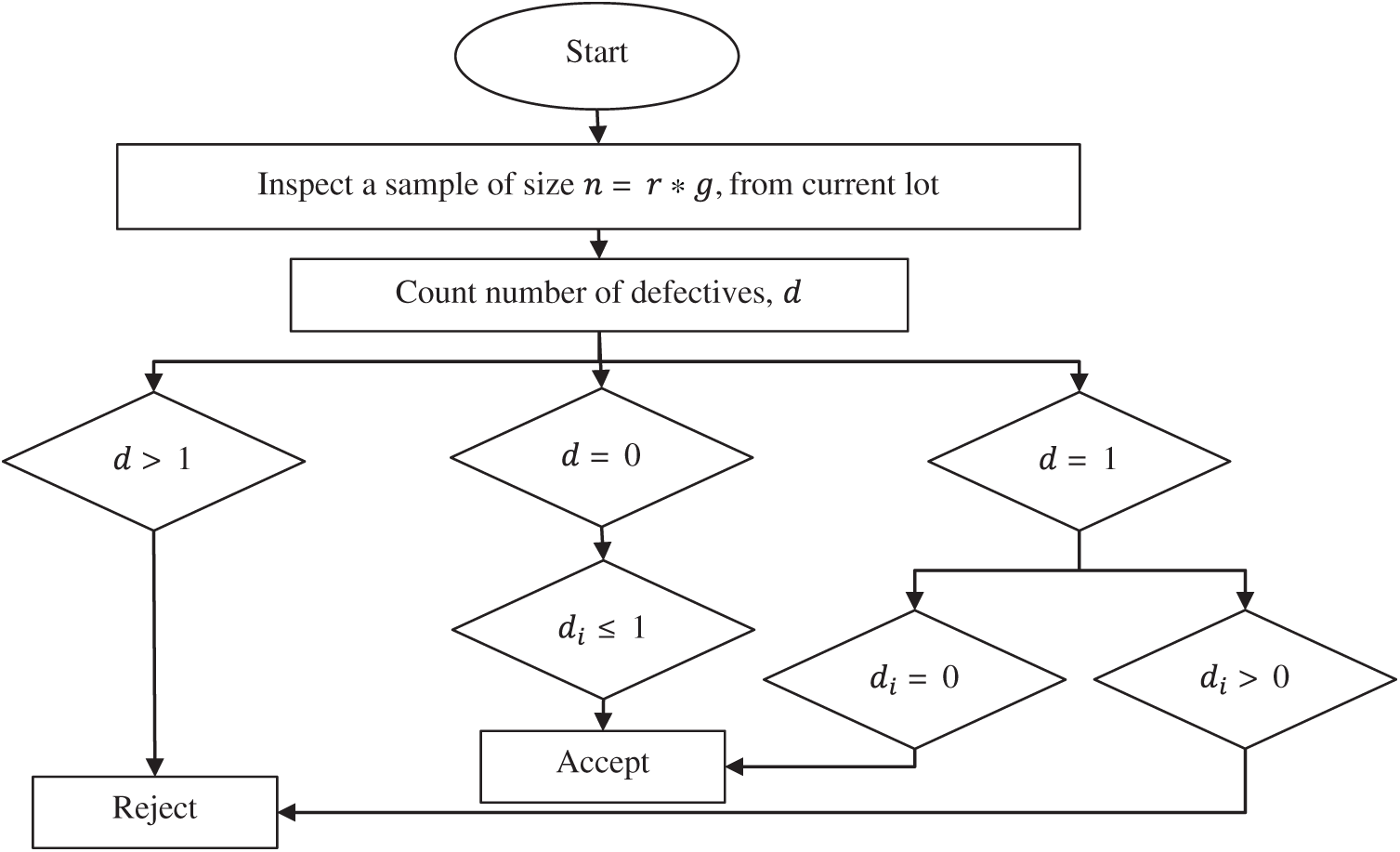

Operating procedure for the proposed plan is based on the following steps:

1. Select an ideal number of

2. Count the number of defectives

3. If

4. If

5. If

All the above steps can be summarized in a flow chart presented in Fig. 1.

Figure 1: Operating procedure of the proposed sampling plan

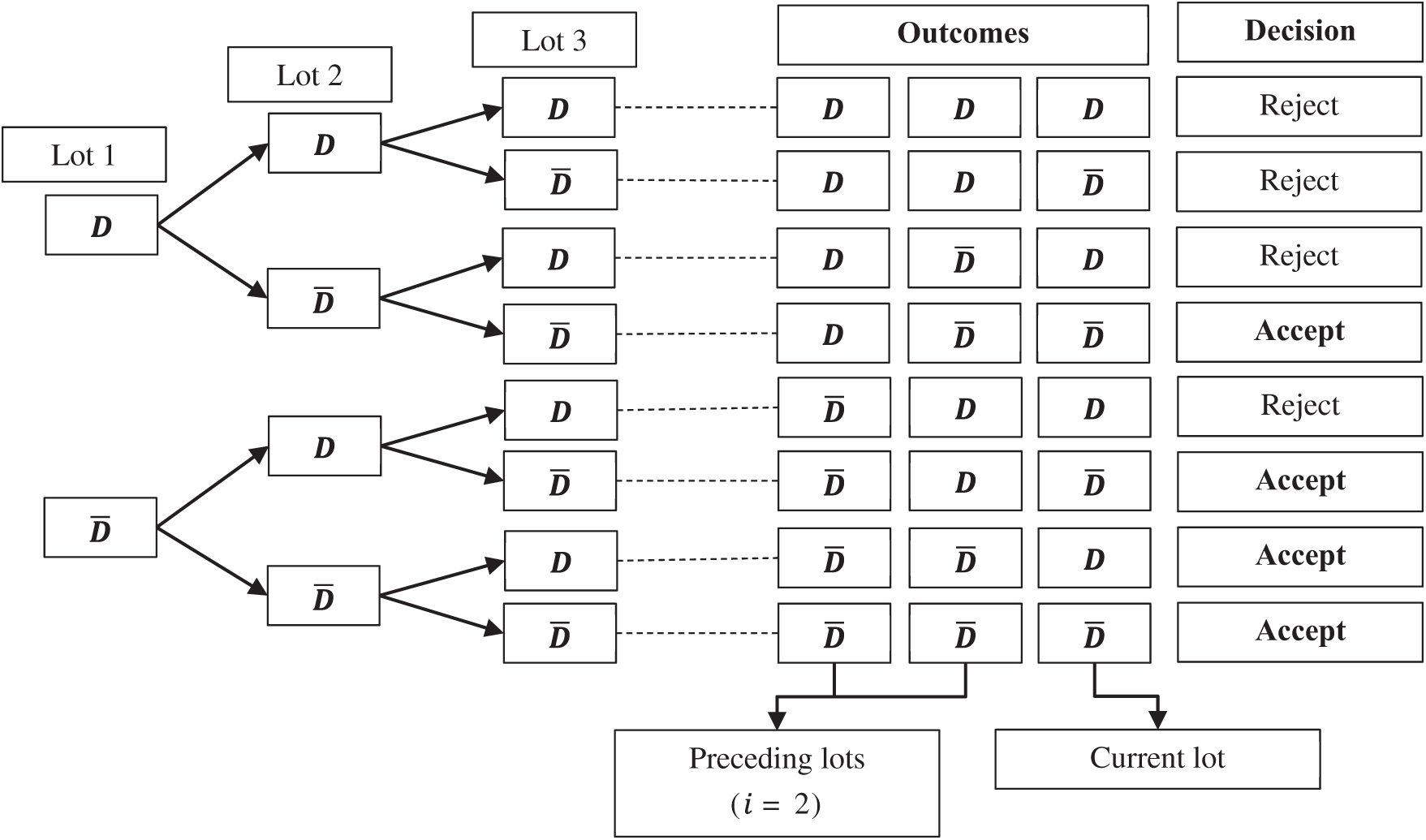

For

With reference to Fig. 2, for

and finally, for

Figure 2: Tree diagram for the proposed sampling plan

Based on the properties of a binomial experiment, binomial distribution can be used to obtain the probability of zero and one defective product. It is valid because lot consists of independent and identical trials. The output from the inspection is based on two mutually exclusive outcomes either defective or non-defective. For large population with sample fraction less than 0.10, binomial distribution can be applied [21]. Hence the probability of acceptance for zero and one defective can be estimated by the binomial likelihood function.

where parameter

After replacing

If the sample has a binomial distribution, then suitable prior distribution is beta distribution [22]. This means that the unknown parameter

where

After replacing Eqs. (8) and (9) in Eq. (10), we obtain:

This is mixed distribution of beta and binomial, after simplify for

Newton’s approximation is used in Eqs. (14)–(16) to find the quality regions for BNGChSP. Where

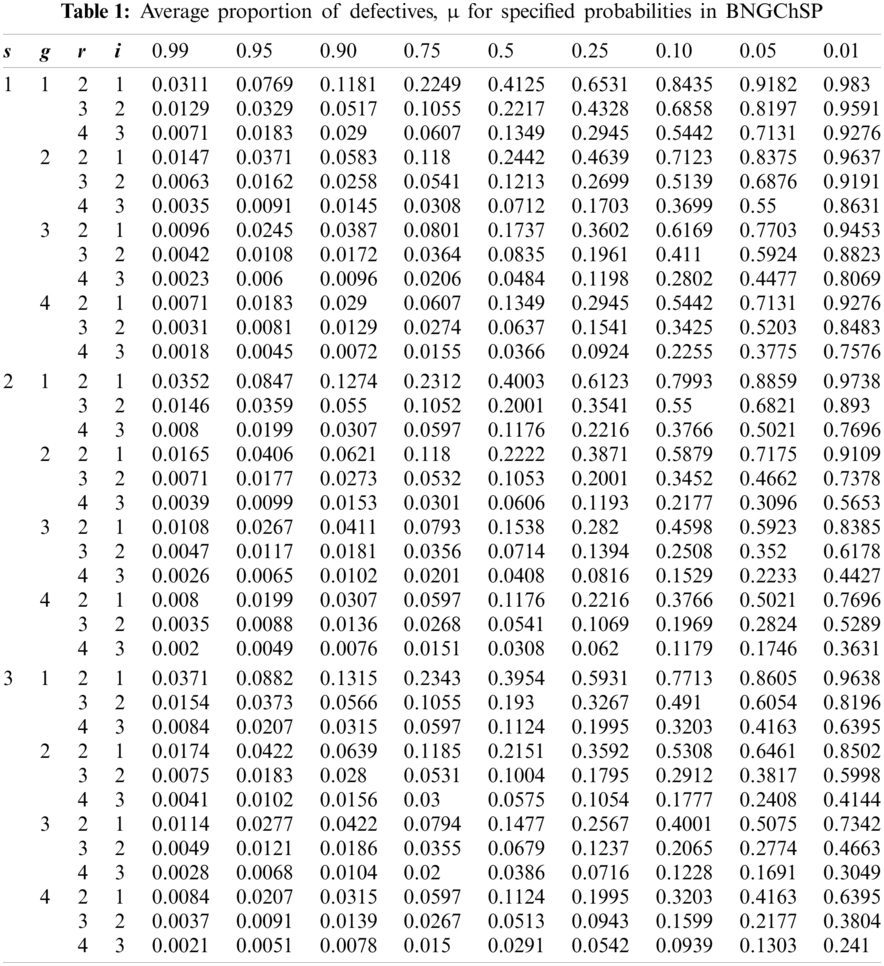

Example 1: In Tab. 1, for

2.1 Designing Sampling Plans for Given AQL and LQL

For the selection of BNGChSP, Tabs. 1 and 2 are used for specified AQL, LQL,

Example 2: Suppose that, the value of AQL

2.2 Designing for Quality Intervals

2.2.1 Probabilistic Quality Region

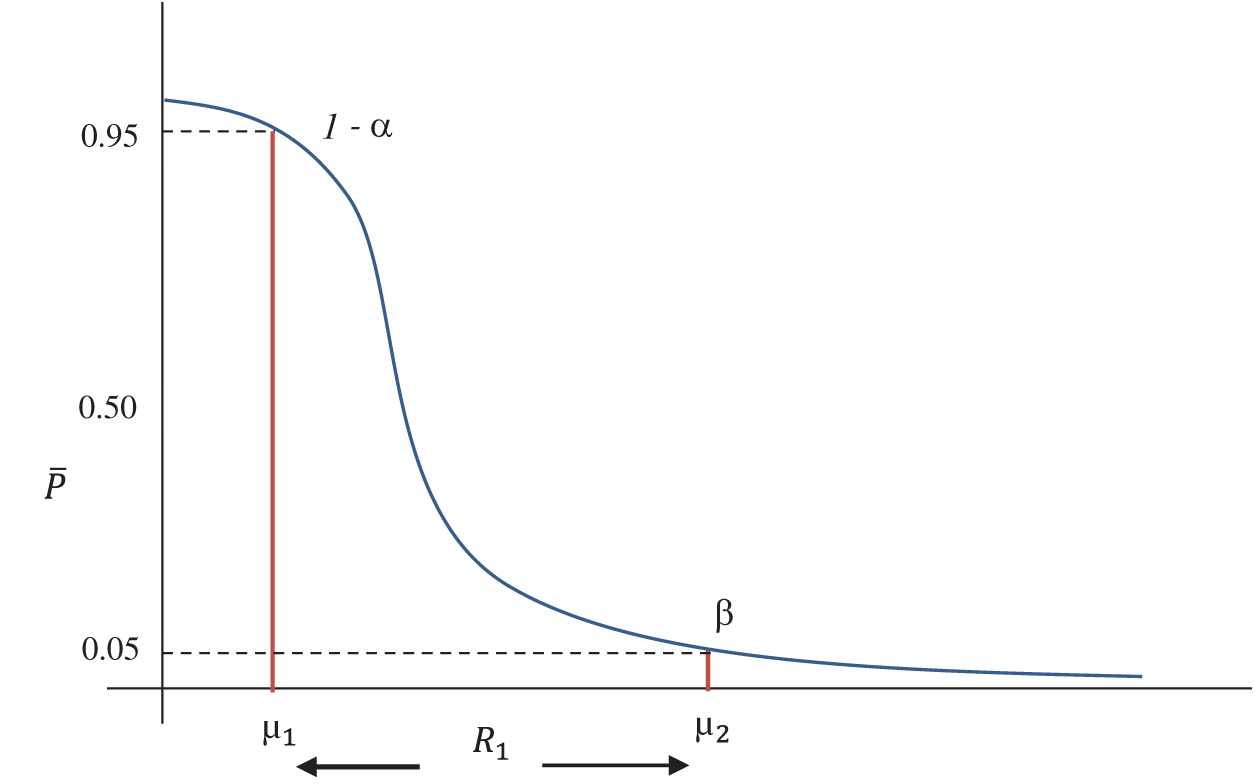

In PQR, the product is accepted with maximum probability 0.95 and minimum probability 0.05, where 0.95 corresponds to AQL

Figure 3: OC curve with pair of coordinates for PQR

This quality region considers the same values for consumer’s and producer’s risk, that is

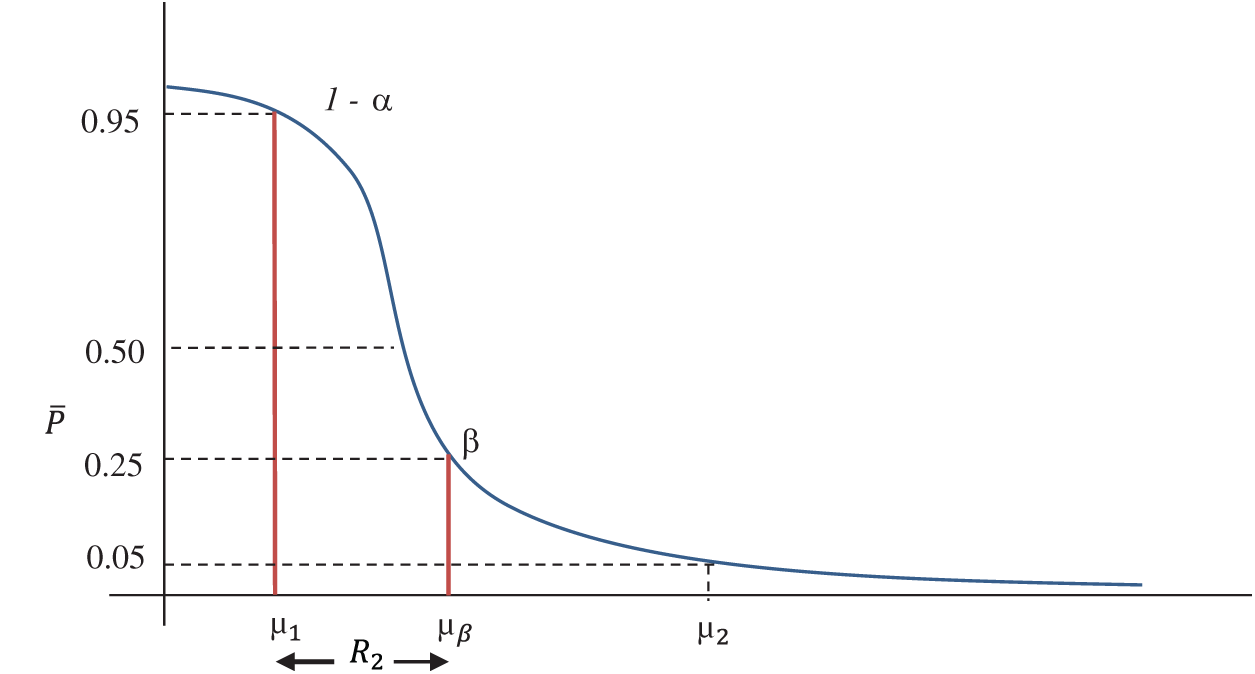

In this quality region, the product is accepted with a maximum probability of 0.95 and the minimum probability of 0.25. Where 0.95 corresponds to AQL

Hence the values considered for consumer’s and producer’s risk are

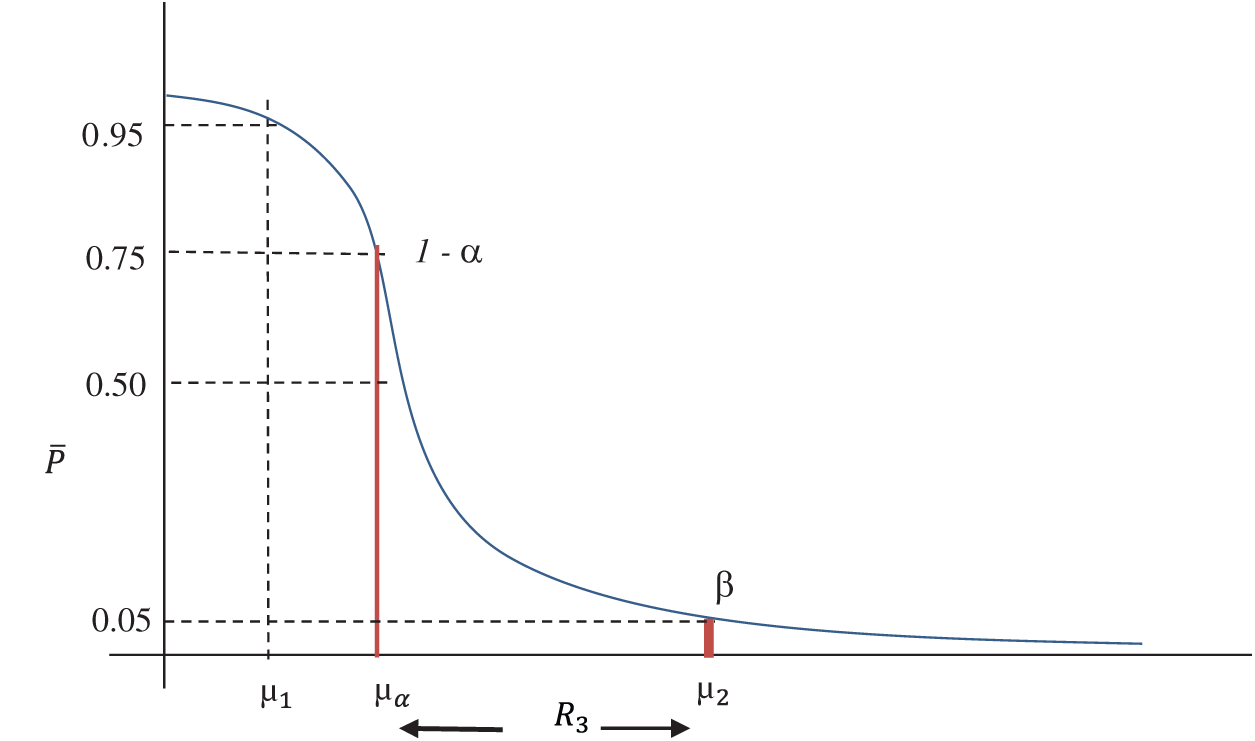

In LQR, the product is accepted with a maximum probability of 0.75 and the minimum probability of 0.05. Where 0.75 corresponds to AQL

Figure 4: OC curve with pair of coordinates for QDR

Figure 5: OC curve with pair of coordinates for LQR

In this region, the values considered for consumer’s and producer’s risk are

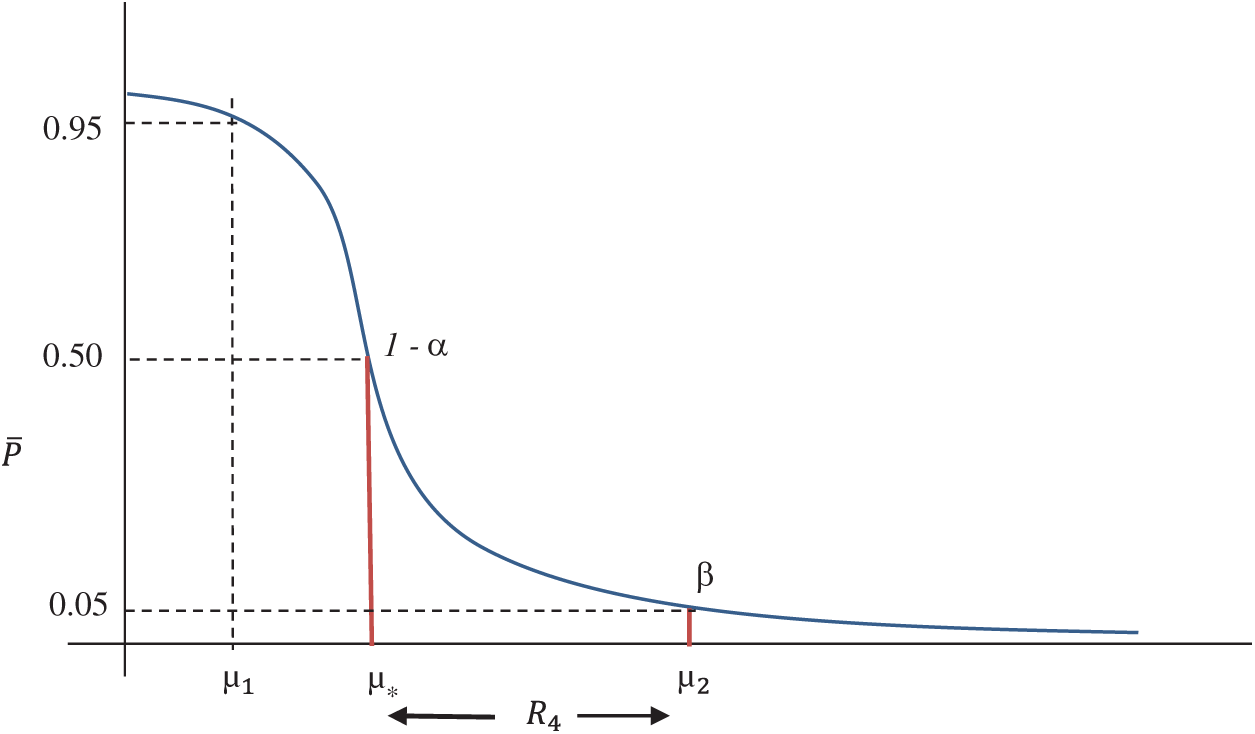

2.2.4 Indifference Quality Region

In this quality region, the product is accepted with a maximum probability of 0.5 and the minimum probability of 0.05, where 0.5 corresponds to AQL

Figure 6: OC curve with pair of coordinates for IQR

In IQR the values considered for consumer’s

2.3 Selection of Sampling Plans

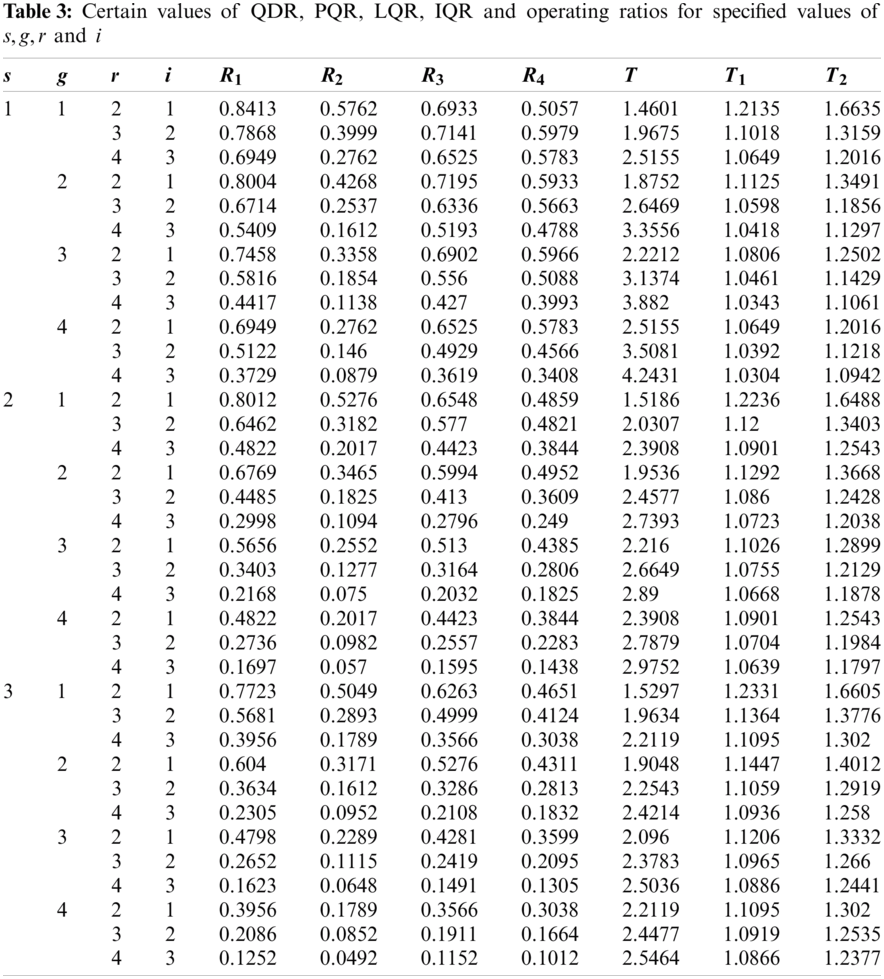

In Tab. 3 the range of quality regions, PQR

Suppose a manufacturer produces defectives within the regions of PQR 0.5% and QDR 0.25%, then

Let in a manufacturer defective product is found in PQR 0.5% and LQR 0.44%. Then

Let a producer found defective in PQR 0.5% and in IQR 0.4%, then

4 Graphical Results and Discussion

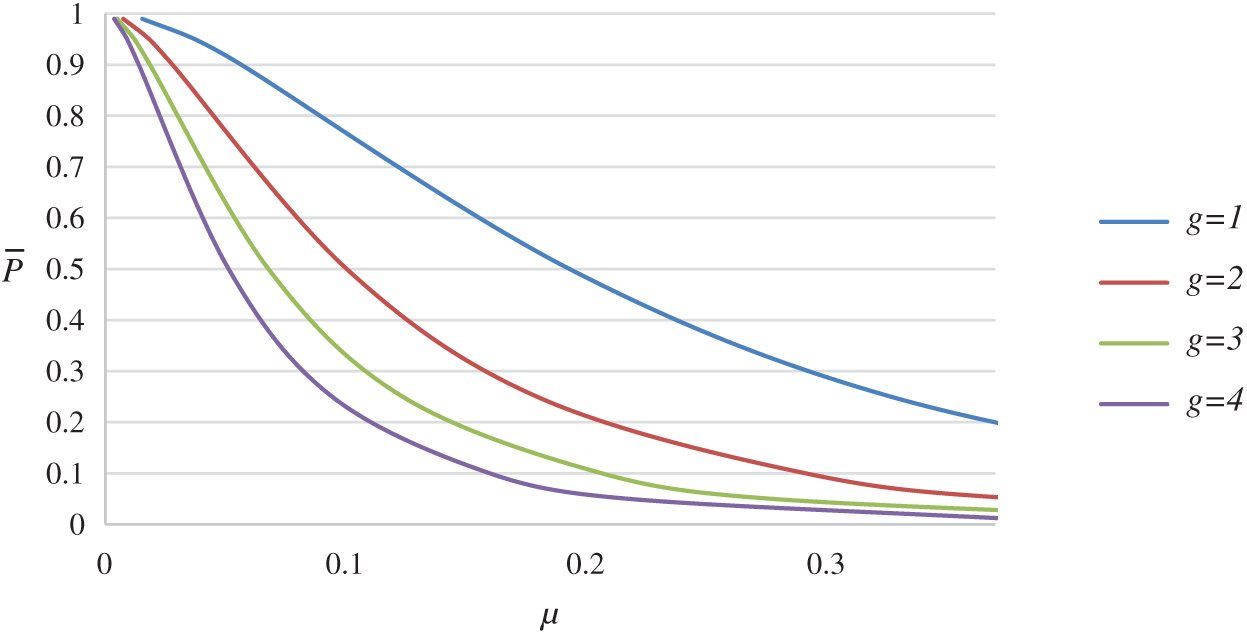

For the specified values of

Figure 7: OC curve for BNGChSP for

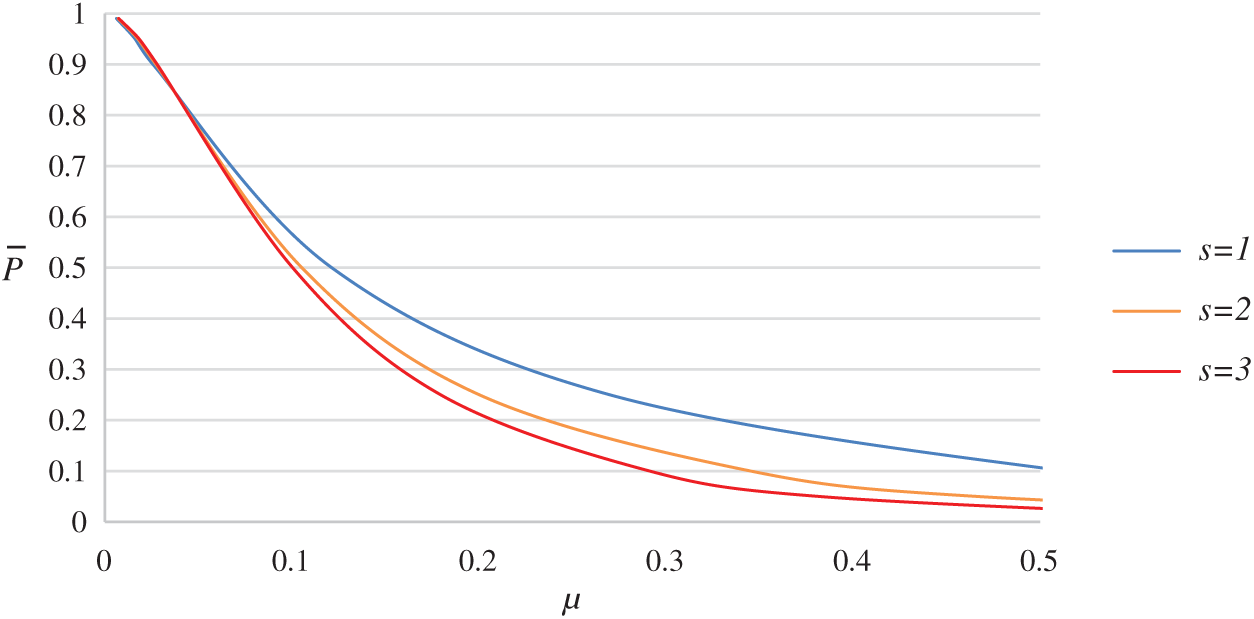

For the specified value of

Figure 8: OC curve for BNGChSP for

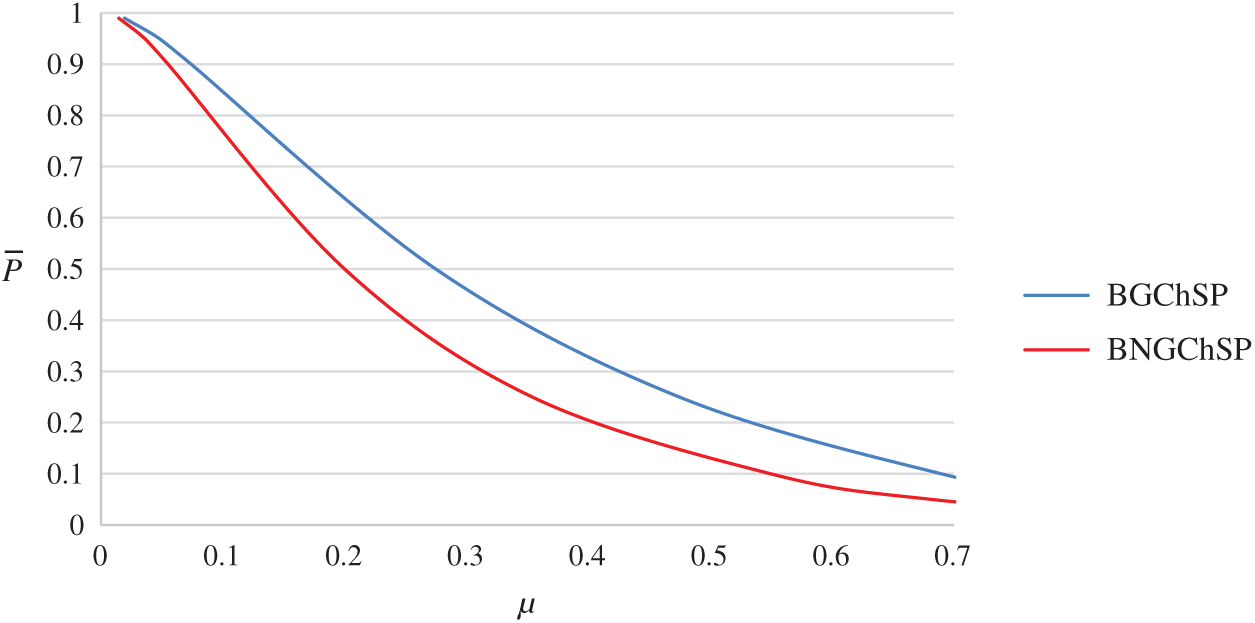

To measure the performance between proposed and existing plan. The OC curve of the proposed BNGChSP is compared with the OC curve of existing BGChSP [20]. Both plans are using binomial distribution with beta prior distribution. For the same values of design parameters

With the average probability of acceptance

Figure 9: OC curves of BNGChSP and BGChSP

Quality interval sampling plans have wider application potential in industry to ensure that the product or process complies with a higher quality standard. Thus, quality interval sampling could be useful for outlining product quality, planning, and quality control arrangements that are ready for electronic industrial applications. For quality control practitioners, BNGChSP will be useful because it is less expensive than other plans in terms of inspection cost and time. To save the time and cost of the experiment, this research suggests the proposed plan to make the same decision as the existing plans. Many electronic components like; transport electronics systems, wireless systems, global positioning systems, and computer-supported and integrated manufacturing systems can be evaluated with proposed plan. In future many other distributions and other quality and reliability characteristics can be explored with proposed plan.

Funding Statement: This research was supported by the Ministry of Education (MOE) through Fundamental Research Grant Scheme (FRGS/1/2020/STG06/UUM/02/2), S/O Code 14884.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. M. Usha and S. Balamurali, “Designing of a mixed-chain sampling plan based on the process capability index with chain sampling as the attributes plan,” Communications in Statistics-Theory and Methods, vol. 46, no. 21, pp. 10456–10475, 2017. [Google Scholar]

2. S. A. Dobbah, M. Aslam and K. Khan, “Design of a new synthetic acceptance sampling plan,” Symmetry, vol. 10, no. 11, pp. 653, 2018. [Google Scholar]

3. C. Gonzalez and G. Palomo, “Bayesian acceptance sampling plans following economic criteria: An application to paper pulp manufacturing,” Journal of Applied Statistics, vol. 30, no. 3, pp. 319–333, 2003. [Google Scholar]

4. I. Borget, I. Laville, A. Paci, S. Michiels, L. Mercier et al., “Application of an acceptance sampling plan for post-production quality control of chemotherapeutic batches in an hospital pharmacy,” European Journal of Pharmaceutics and Biopharmaceutics, vol. 64, no. 1, pp. 92–98, 2006. [Google Scholar]

5. J. D. Legan, M. H. Vandeven, S. Dahms and M. B. Cole, “Determining the concentration of microorganisms controlled by attributes sampling plans,” Food Control, vol. 12, no. 3, pp. 137–147, 2001. [Google Scholar]

6. B. Epstein, “Truncated life tests in the exponential case,” Annals of Mathematical Statistics, vol. 25, no. 3, pp. 555–564, 1954. [Google Scholar]

7. A. Shafqat, Z. Huang and M. Aslam, “Design of X-bar control chart based on inverse Rayleigh distribution under repetitive group sampling,” Ain Shams Engineering Journal, vol. 12, no. 1, pp. 943–953, 2020. [Google Scholar]

8. H. F. Dodge, “Chain sampling plan,” Industrial Quality Control, vol. 11, pp. 10–13, 1955. [Google Scholar]

9. H. F. Dodge and K. S. Stephens, A general family of chain sampling inspection plans. New Jersey: Rutgers-The State University New Brunswick, 1964. [Google Scholar]

10. A. Hald, “Bayesian single sampling plans for discrete prior distribution,” Matematisk-fysiske Skrifter Dan Vid Selsk, vol. 3, no. 2, pp. 88, 1965. [Google Scholar]

11. K. Subramini and V. Haridoss, “Selection of single sampling attribute plan for given AQL and LQL involving minimum risks using weighted Poisson distribution,” International Journal of Quality and Reliability Management, vol. 30, no. 1, pp. 47–58, 2013. [Google Scholar]

12. K. Subbiah and M. Latha, “Selection of Bayesian single sampling plan with weighted Poisson distribution based on (AQL, LQL),” International Journal of Engineering Technology, vol. 5, no. 6, pp. 122–134, 2017. [Google Scholar]

13. C. Raju and K. K. Vidya, “Chain sampling plan (ChSP-1) for desired acceptable quality level (AQL) and limiting quality level (LQL),” in AIP Conf. Proc., 1905. AIP Publishing LLC, Kedah, Malaysia, pp. 50036,2017. [Google Scholar]

14. M. Latha and K. K. Suresh, “Construction and evaluation of performance measures for Bayesian chain sampling plan (BChSP-1),” For East Journal of Theoretical Statistics, vol. 6, no. 2, pp. 129–139, 2002. [Google Scholar]

15. V. Nirmala and K. K. Suresh, “Evaluation of continuous sampling plan indexed through minimum angle and maximum acceptance quality,” Journal of Advancements in Material Engineering, vol. 3, no. 3, pp. 115–123, 2018. [Google Scholar]

16. A. R. Mughal, M. Aslam and A. Rehman, “Economic reliability group acceptance sampling plans for lifetimes following a Marshall-Olkin extended distribution,” Middle Eastern Finance and Economics, vol. 7, pp. 87–93, 2010. [Google Scholar]

17. A. R. Mughal, Z. Zain and N. Aziz, “Economic reliability GASP for pareto distribution of the 2nd kind using Poisson and weighted Poisson distribution,” Research Journal of Applied Sciences, vol. 10, no. 8, pp. 306–310, 2015. [Google Scholar]

18. A. R. Mughal, Z. Zain and N. Aziz, “Time truncated group chain sampling strategy for pareto distribution of the 2(nd) kind,” Research Journal of Applied Sciences Engineering and Technology, vol. 10, no. 4, pp. 471–474, 2015. [Google Scholar]

19. A. R. Mughal, “A family of group chain acceptance sampling plans based on truncated life test,” Ph.D. dissertation. Universiti Utara Malaysia, Malaysia, 2018. [Google Scholar]

20. W. Hafeez and N. Aziz, “Bayesian group chain sampling plan based on beta binomial distribution through quality region,” International Journal of Supply Chain Management, vol. 8, no. 6, pp. 1175–1180, 2019. [Google Scholar]

21. L. Appaia, P. M. Krishnan and S. Kalaiselvi, “Determination of Bayesian reliability sampling plans based on exponential-inverted gamma distribution,” International Journal of Quality and Reliability Management, vol. 31, no. 8, pp. 950–962, 2014. [Google Scholar]

22. M. Latha and R. Arivazhagan, “Selection of Bayesian double sampling plan based on beta prior distribution index through quality region,” International Journal of Recent Scientific Research, vol. 6, no. 5, pp. 4328–4333, 2015. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |