DOI:10.32604/cmc.2022.019695

| Computers, Materials & Continua DOI:10.32604/cmc.2022.019695 |  |

| Article |

Bayesian Group Chain Sampling Plan for Poisson Distribution with Gamma Prior

1School of Quantitative Sciences, Universiti Utara Malaysia, UUM Sintok, 06010, Kedah, Malaysia

2Institute of Strategic Industrial Decision Modelling (ISIDM), Universiti Utara Malaysia, UUM Sintok, 06010, Kedah, Malaysia

*Corresponding Author: Nazrina Aziz. Email: nazrina@uum.edu.my

Received: 22 April 2021; Accepted: 07 June 2021

Abstract: Acceptance sampling is a statistical quality control technique that consists of procedures for sentencing one or more incoming lots of finished products. Acceptance or rejection is based on the inspection of sampled products drawn randomly from the lot. The theory of previous acceptance sampling was built upon the assumption that the process from which the lots are produced is stable and the process fraction nonconforming is a constant. Process variability is inevitable due to random fluctuations, which may inadvertently lead to quality variation. As an alternative to traditional sampling plans, Bayesian approach can be used by considering prior information of the process. Using different combinations of design parameters, this study introduces a Bayesian group chain sampling plan (BGChSP). For the first time in group chain sampling plan, the probability of lot acceptance is derived by using Poisson distribution to estimate an average number of defectives. Gamma distribution is used as a prior distribution with Poisson distribution. Taking into account both consumer’s and producer’s risks, this research considers two quality regions namely, probabilistic quality region (PQR) and indifference quality region (IQR). By minimizing consumer’s and producer’s risks, BGChSP can be used to minimize the average number of defective products in industry.

Keywords: Bayesian; acceptance sampling; gamma; produce risk; consumer risk

There is tough competition in the industry by rapidly increasing the needs of statistical and analytical techniques towards the improvement of product quality [1–3]. This study is related to Bayesian group chain sampling plan (BGChSP) by using a novel approach called quality region. Instead of considering a point estimate of the quality of a process, this plan is based on a range of quality levels. The producer’s risk and consumer’s risk are associated with every sampling plan [4]. A good plan delivers decision rules of acceptance for both producer and consumer to meet the present quality condition of the product [5]. Improvement in technology is rapidly increasing with the passage of time and supplier needs high-quality products with low defective fraction [6]. Unfortunately, in some situations, traditional methods cannot detect the defective product with such quality level. Thus, quality regions were introduced to overcome such problems [7,8]. By involving probabilistic quality region (PQR) and indifference quality region (IQR), this study designs the parameters for the plan indexed with quality region.

Bayesian approach is based on the combination of current and prior information for the selection of distribution. In acceptance sampling plan, Bayesian approach is required to specify a distribution of defectives from lot to lot [7]. Prior distribution is the expected distribution of the lot quality, that is under inspection. Prior distribution is formulated before taking the sample and empirical knowledge is based on the sample under study called the distribution of sample or data. The combination of prior and empirical information leads to a decision about the current lot either it will be accepted or rejected.

Epstein [9] was the first who introduced the idea of single sampling plan (SSP), to distinguish between good and bad lot for zero and one acceptance number. Dodge [10] introduced the chain sampling plan to overcome the deficiency of SSP, with more than one acceptance number and for the general family of chain sampling inspection plan [11]. Under an assumption that cost is linear in

Aslam et al. [18] developed a group sampling plan (GSP), by considering multiple testers at the same time. In GSP the sample size is divided into

Mughal et al. [23] developed a GChSP plan for the lifetime of a product following Pareto distribution of 2nd kind. Satisfying pre-assumed design parameters at several quality levels, probability of lot acceptance was obtained. Based on their sampling plan, Mughal [24] extended and proposed a generalized GChSP. By considering several values of the proportion of defectives, the minimum sample size and probability of lot acceptance were found to satisfy pre-specified consumer's risk. Recently, Hafeez et al. [25] also worked on this plan and estimated AQL and LQL for the average proportion of defective products in their study.

Based on Mughal et al. [23] plan, this study concerns with the development of a Bayesian group chain sampling plan (BGChSP). In group chain sampling plan, the probability of lot acceptance is derived by using Poisson distribution and gamma is used as a prior distribution. For PQR and IQR, this study designs the plan indexed parameters which are: AQL, LQL, producer’s risk

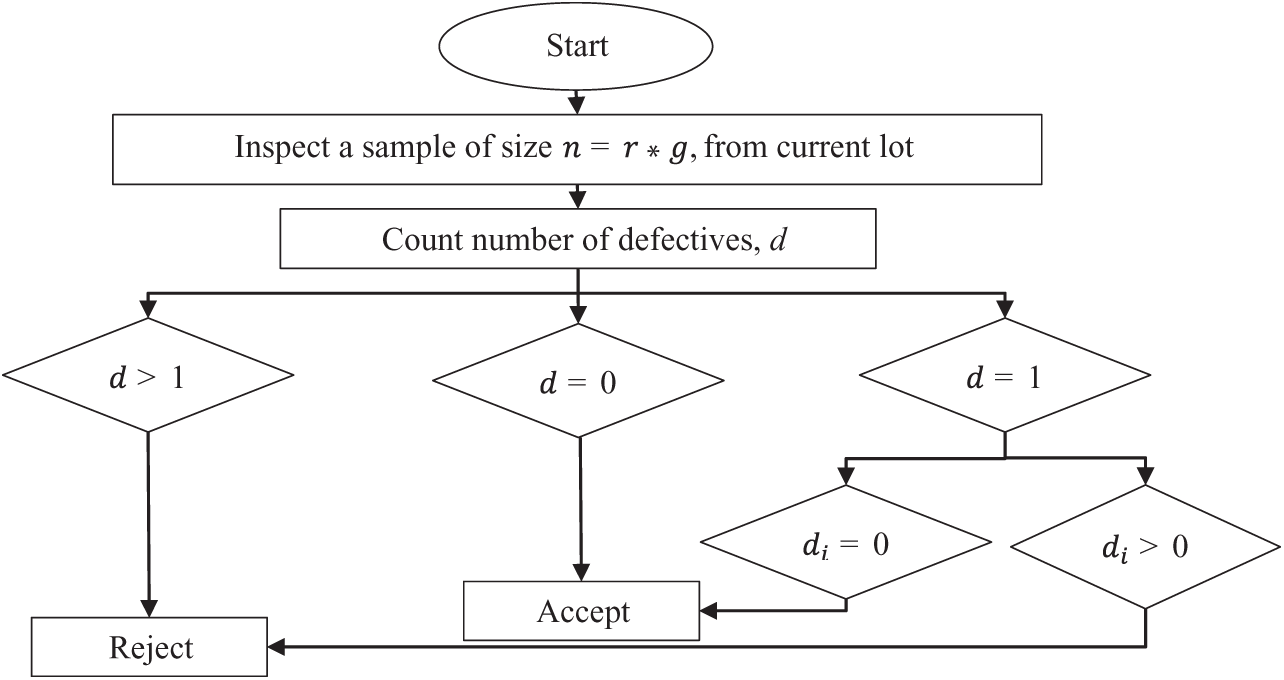

The operating procedure for the proposed plan is based on the following steps:

1. Select an ideal number of

2. Count the number of defectives

3. If

4. If

5. If

All the above steps can be summarized in a flow chart presented in Fig. 1.

Figure 1: Operating procedure of the proposed sampling plan

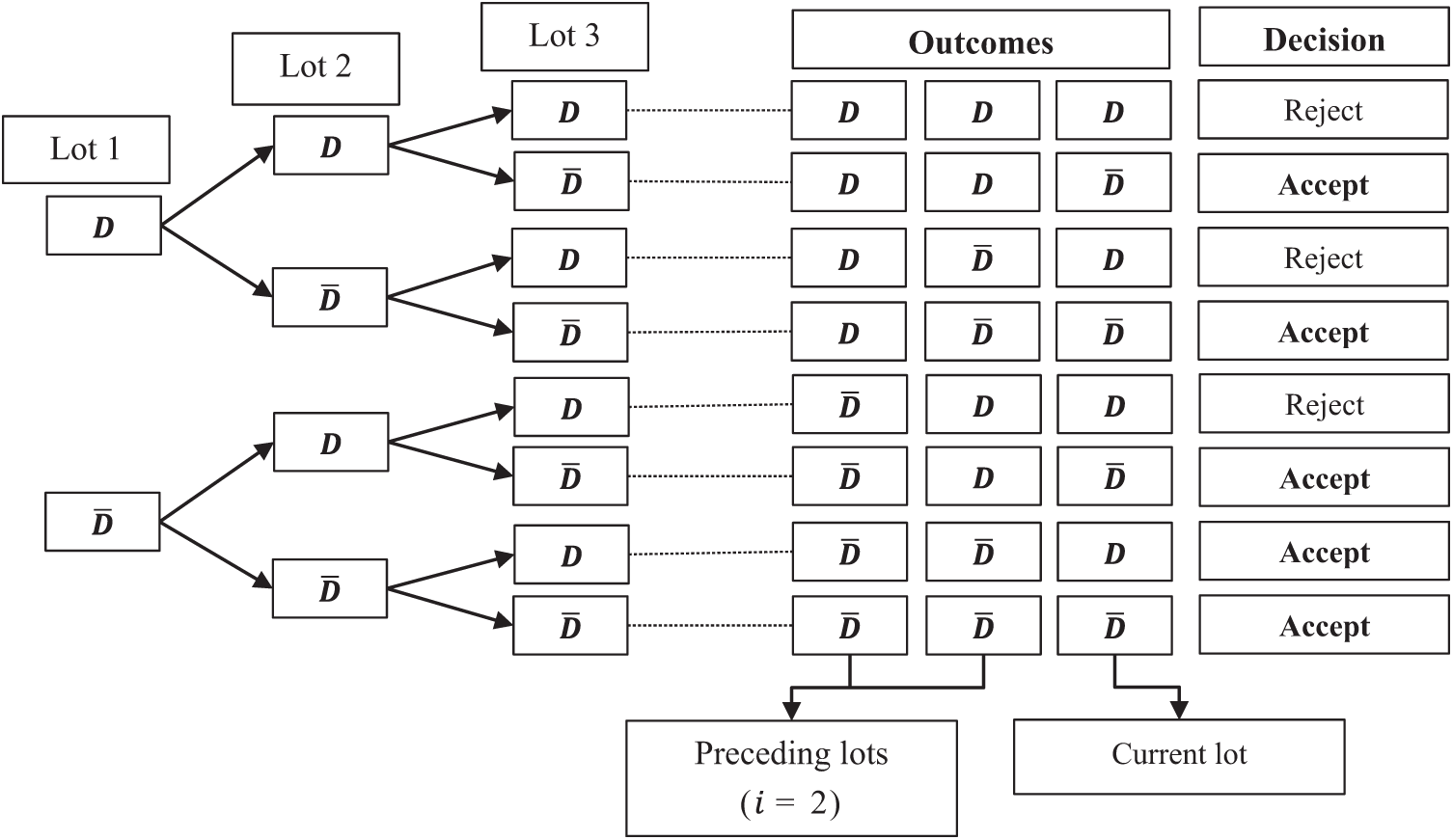

Figure 2: Tree diagram for the proposed sampling plan

In attribute acceptance sampling, lot inspection is based on the number of defectives (discrete variable). The procedure of GChSP for

The general expression for

For the average number of defectives, consider Poisson distribution with mean

After replacing Eqs. (4) and (5) in Eq. (3), we get:

Let us consider gamma distribution as a suitable prior for the Poisson distribution [26,27], with pdf:

where shape parameter,

After replacing Eqs. (6) and (7) in Eq. (8) and then from simplification we get:

Upon substituting mean

Further simplification of Eq. (11), for

It is to be noted that Newton’s approximation is employed in Eqs. (12)–(14) to find the quality regions of BGChSP, where

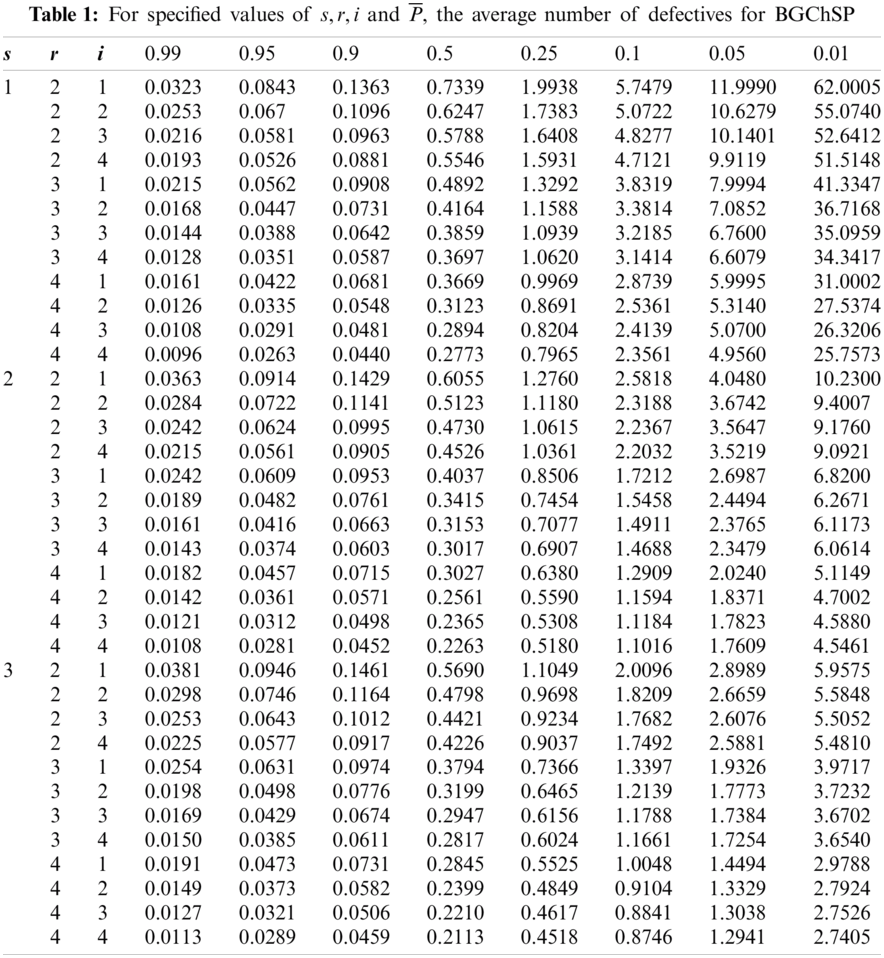

Example 1: In Tab. 1, for

3.1 Designing Sampling Plans for Given AQL and LQL

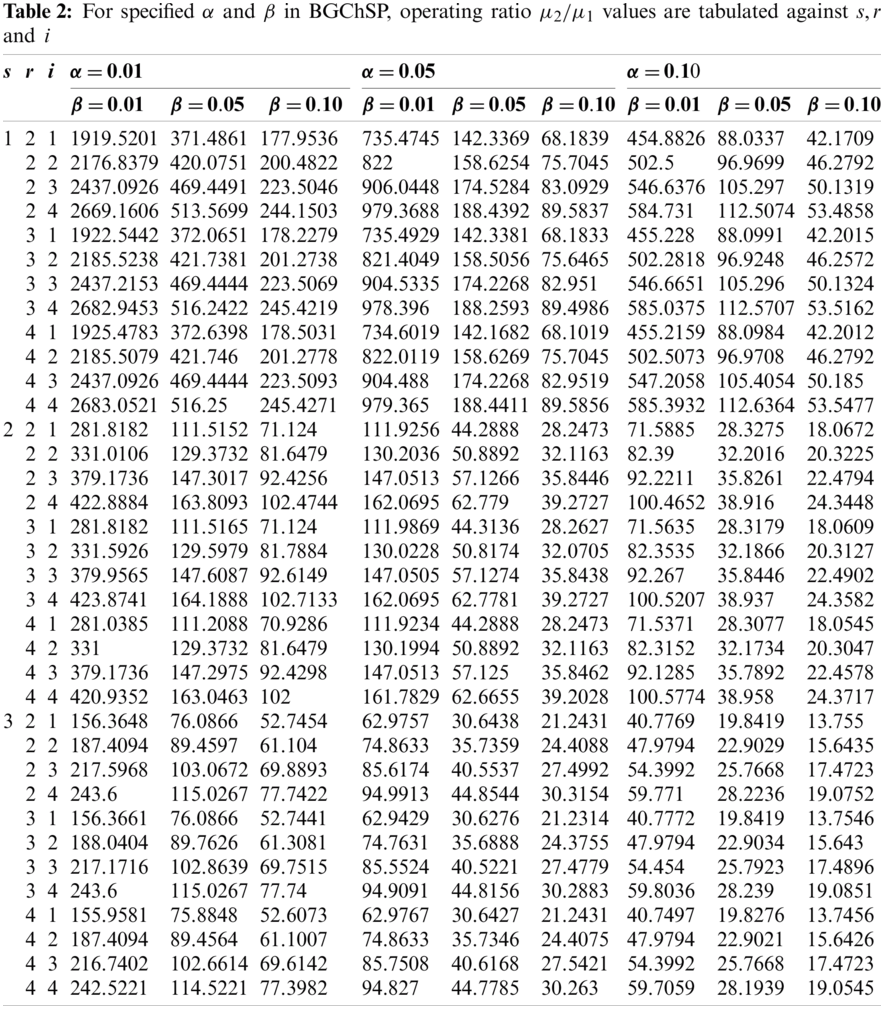

For the selection of BGChSP, Tabs. 1–2 are used for specified AQL, LQL,

3.2 Construction of Quality Regions

3.2.1 Probabilistic Quality Region (PQR)

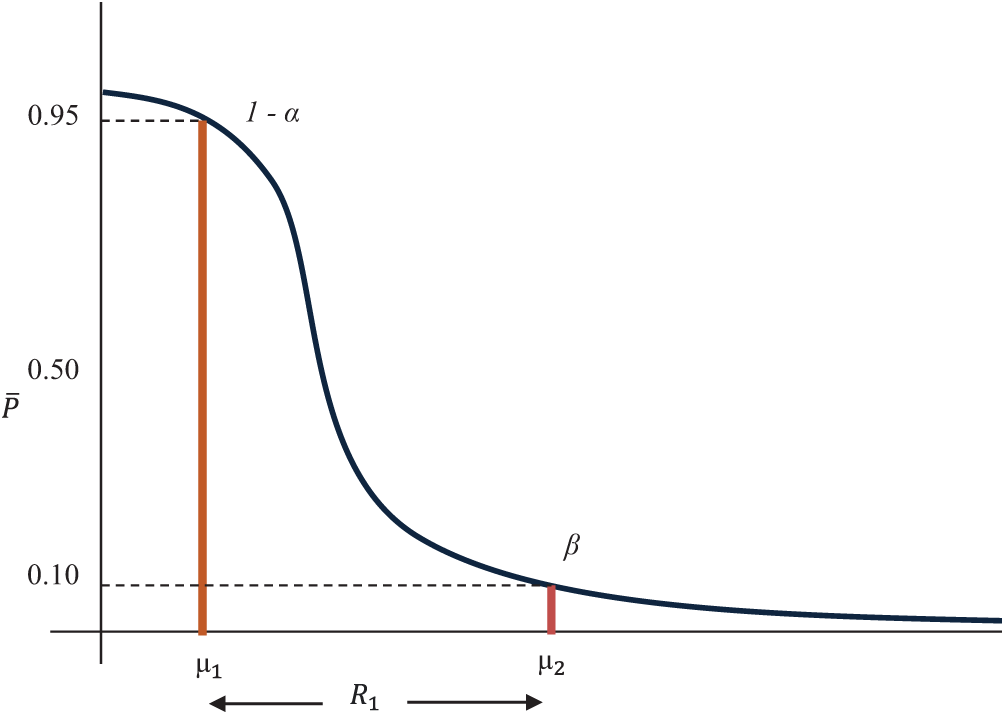

In this quality region, the product is accepted with the maximum probability of 0.95 and minimum probability of 0.10, where 0.95 corresponds to (AQL,

The range of probability is

3.2.2 Indifference Quality Region (IQR)

In IQR, the product is accepted with maximum and minimum probabilities 0.95 and 0.50, that correspond to (AQL,

Figure 3: OC curve with pair of coordinates for PQR

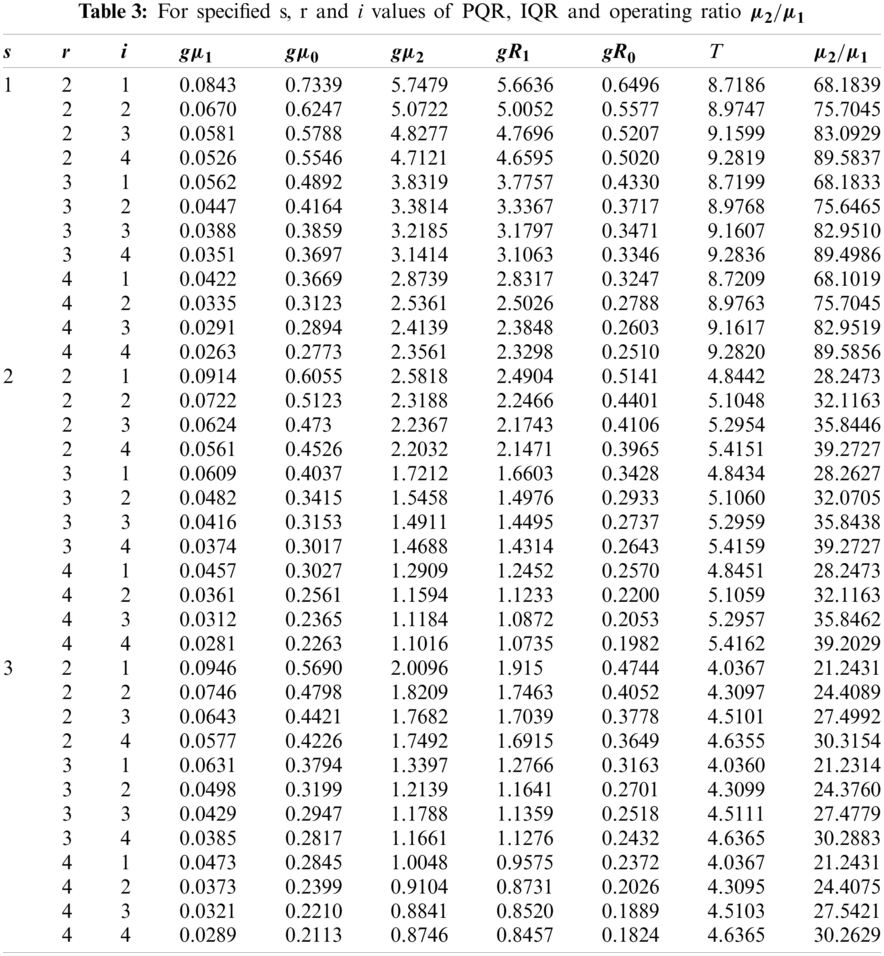

Example 2: Let

3.3 Selection of Sampling Plans

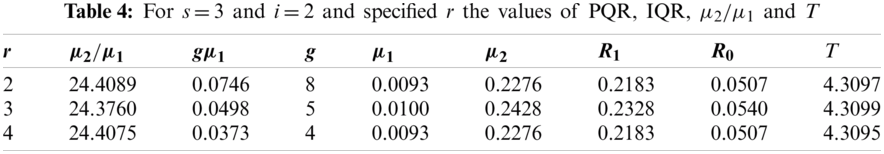

For different values of

Example 3: At

Hence from Tab. 4, through quality region the required plan has parameters

In this acceptance sampling plan, both risks are used to balance the expected losses for the consumers and producers. The presented work is limited to BGChSP and estimate PQR and IQR for the specified producer’s and consumer’s risks. This research gives the idea to estimate an interval of average number of defectives for prespecified design parameters. Quality interval sampling plans have wider potential applications in the industry to ensure that the product or process complies with a higher quality standard. Thus, quality interval sampling could be useful for outlining product quality, planning, and quality control arrangements that are ready for electronic industrial applications. Many electronic components such as transport electronics systems, wireless systems, global positioning systems, and computer-supported and integrated manufacturing systems can be evaluated by using the proposed plan. Many other distributions and other quality and reliability characteristics can be explored in the future.

Funding Statement: This research was supported by the Ministry of Education (MOE) through Fundamental Research Grant Scheme (FRGS/1/2020/STG06/UUM/02/2), S/O Code 14884.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. M. Aslam, “A variable acceptance sampling plan under neuromorphic statistical interval method,” Symmetry, vol. 11, no. 1, pp. 114, 2019. [Google Scholar]

2. P. C. Ramyamol and M. Kumar, “Optimal reliability acceptance sampling plan based on accelerated life test data,” International Journal of Productivity and Quality Management, vol. 30, no. 3, pp. 354– 370, 2020. [Google Scholar]

3. V. Gorgin, B. S. Gildeh, M. Sarmad and M. Amini, “On bivariate control charts for the mean of autocorrelated process,” International Journal of Productivity and Quality Management, vol. 32, no. 1, pp. 72–91, 2021. [Google Scholar]

4. S. A. Dobbah, M. Aslam and K. Khan, “Design of a new synthetic acceptance sampling plan,” Symmetry, vol. 10, no. 11, pp. 653, 2018. [Google Scholar]

5. M. Aslam and A. H. Al-Marshadi, “Design of sampling plan using regression estimator under indeterminacy,” Symmetry, vol. 10, no. 12, pp. 754, 2018. [Google Scholar]

6. K. P. Veerakumari and S. Suganya, “Characteristic evaluation of SkSP-T with special type double sampling plan as reference plan,” International Journal of Productivity and Quality Management, vol. 28, no. 3, pp. 360–371, 2019. [Google Scholar]

7. W. T. Huang and Y. P. Lin, “An improved Bayesian sampling plan for exponential population with type I censoring,” Communications in Statistics-Theory and Methods, vol. 31, no. 11, pp. 2003–2025, 2002. [Google Scholar]

8. M. S. F. Nezhad and S. Seifi, “Designing optimal double-sampling plan based on process capability index,” Communications in Statistics-Theory and Methods, vol. 46, no. 13, pp. 6624–6634, 2017. [Google Scholar]

9. B. Epstein, “Truncated life tests in the exponential case,” The Annals of Mathematical Statistics, vol. 25, no. 3, pp. 555–564, 1954. [Google Scholar]

10. H. F. Dodge, “Chain sampling plan,” Industrial Quality Control, vol. 11, pp. 10–13, 1955. [Google Scholar]

11. H. F. Dodge and K. S. Stephens, A general family of chain sampling inspection plans. NJ: Rutgers-The State University New Brunswick, 1964. [Google Scholar]

12. A. Hald, “Bayesian single sampling plans for discrete prior distribution,” Mat. Fys. Skr. Dan. Vid. Selsk., vol. 3, no. 2, pp. 88, 1965. [Google Scholar]

13. K. Subbiah and M. Latha, “Selection of Bayesian single sampling plan with weighted Poisson distribution based on (AQL, LQL),” International Journal of Engineering Technology, vol. 5, no. 6, pp. 122– 134, 2017. [Google Scholar]

14. C. Raju and K. K. Vidya, “Chain sampling plan (ChSP-1) for desired acceptable. Quality level (AQL) and limiting quality level (LQL),” in AIP Conf. Proc., AIP Publishing LLC, vol. 1905, pp. 50036, 2017. [Google Scholar]

15. M. Latha and K. K. Suresh, “Construction and evaluation of performance measures for Bayesian chain sampling plan (BChSP-1),” For East Journal of Theoretical Statistics, vol. 6, no. 2, pp. 129–139, 2002. [Google Scholar]

16. M. Latha and R. Arivazhagan, “Selection of Bayesian double sampling plan based on beta prior distribution index through quality region,” International Journal of Recent Scientific Research, vol. 6, no. 5, pp. 4328–4333, 2015. [Google Scholar]

17. M. C. Mathew and R. Murugesan, “Two sided complete Bayesian chain sampling plan with gamma Poisson as prior distribution,” International Journal of Pure and Applied Mathematics, vol. 18, no. 5, pp. 207–213, 2018. [Google Scholar]

18. M. Aslam and C. H. Jun, “A group acceptance sampling plan for truncated life test having Weibull distribution,” Journal of Applied Statistics, vol. 36, no. 9, pp. 1021–1027, 2009. [Google Scholar]

19. M. Aslam, A. R. Mughal, M. Ahmad and Z. Yab, “Group acceptance sampling plans for Pareto distribution of the second kind,” Journal of Testing and Evaluation, vol. 38, no. 2, pp. 143–150, 2010. [Google Scholar]

20. A. R. Mughal and M. Aslam, “Efficient group acceptance sampling plans for family Pareto distribution,” Continental Journal of Applied Sciences, vol. 6, no. 3, pp. 40–52, 2011. [Google Scholar]

21. A. R. Mughal and M. Ismail, “An economic reliability efficient group acceptance sampling plans for family Pareto distributions,” Res. J. Appl. Sci., Eng. and Tech., vol. 6, no. 24, pp. 4646–4652, 2013. [Google Scholar]

22. A. R. Mughal, Z. Zain and N. Aziz, “Economic reliability GASP for pareto distribution of the 2nd kind using poisson and weighted poisson distribution,” Research Journal of Applied Sciences, vol. 10, no. 8, pp. 306–310, 2015. [Google Scholar]

23. A. R. Mughal, Z. Zain and N. Aziz, “Time truncated group chain sampling strategy for pareto distribution of the 2(nd) Kind,” Research Journal of Applied Sciences Engineering and Technology, vol. 10, no. 4, pp. 471–474, 2015. [Google Scholar]

24. A. R. Mughal, “A family of group chain acceptance sampling plans based on truncated life test,” Ph.D. dissertation. Universiti Utara Malaysia, Malaysia, 2018. [Google Scholar]

25. W. Hafeez and N. Aziz, “Bayesian group chain sampling plan based on beta binomial distribution through quality region,” International Journal of Supply Chain Management, vol. 8, no. 6, pp. 1175– 1180, 2019. [Google Scholar]

26. K. K. Suresh and V. Sangeetha, “Construction and selection of Bayesian chain sampling plan (BChSP-1) using quality regions,” Modern Applied Science, vol. 5, no. 2, pp. 226–234, 2011. [Google Scholar]

27. K. M. Hamdia, M. A. Msekh, M. Silani, T. Q. Thai, P. R. Budarapu et al., “Assessment of computational fracture models using Bayesian method,” Engineering Fracture Mechanics, vol. 205, no. 5, pp. 387–398, 2019. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |