DOI:10.32604/cmc.2022.021517

| Computers, Materials & Continua DOI:10.32604/cmc.2022.021517 |  |

| Article |

Performance of Gradient-Based Optimizer for Optimum Wind Cube Design

1Faculty of Computer Studies (FCS), Arab Open University (AOU), Muscat, 130, Sultanate of Oman

2Faculty of Science, Minia University, Minia, Egypt

3Faculty of Computers and Information, Minia University, Minia, Egypt

4Electronics Research Institute, Giza, Egypt

5Electrical Engineering Department, Faculty of Engineering, Fayoum University, Fayoum, Egypt

*Corresponding Author: Mokhtar Said. Email: msi01@fayoum.edu.eg

Received: 05 July 2021; Accepted: 15 August 2021

Abstract: Renewable energy is a safe and limitless energy source that can be utilized for heating, cooling, and other purposes. Wind energy is one of the most important renewable energy sources. Power fluctuation of wind turbines occurs due to variation of wind velocity. A wind cube is used to decrease power fluctuation and increase the wind turbine’s power. The optimum design for a wind cube is the main contribution of this work. The decisive design parameters used to optimize the wind cube are its inner and outer radius, the roughness factor, and the height of the wind turbine hub. A Gradient-Based Optimizer (GBO) is used as a new metaheuristic algorithm in this problem. The objective function of this research includes two parts: the first part is to minimize the probability of generated energy loss, and the second is to minimize the cost of the wind turbine and wind cube. The Gradient-Based Optimizer (GBO) is applied to optimize the variables of two wind turbine types and the design of the wind cube. The metrological data of the Red Sea governorate of Egypt is used as a case study for this analysis. Based on the results, the optimum design of a wind cube is achieved, and an improvement in energy produced from the wind turbine with a wind cube will be compared with energy generated without a wind cube. The energy generated from a wind turbine with the optimized cube is more than 20 times that of a wind turbine without a wind cube for all cases studied.

Keywords: Wind turbine; wind cube; gradient-based optimizer; metaheuristics; energy source

Quality of life improvements are necessary as an economy and society develop. One corresponding challenge is to decrease environmental pollution. Replacing fossil fuels with clean energy is one of the main components to decrease environmental pollution. Renewable energy utilized at a large scale can help to meet daily energy demands [1–5]. Industries and academic institutions alike are interested in developing electricity from renewable and clean energy sources, and with the advancement of existing technology, these factors justify the importance of wind energy in recent years [6,7]. A wind cube is a modern wind turbine built to absorb and amplify more kilowatt-hours (kWh) of wind. When wind hits the wind cube, it concentrates and generates the speed, in turn producing more power. The modern wind cube system has been designed to solve low wind speed problems and collect wind power under these circumstances [8]. Wind cubes are used to improve the efficiency of wind turbines and result in great productivity [8]. Because of the wind's nonlinear nature, optimization techniques are essential. Optimizing the layout is achieved through soft computing technology [7]. The meta-heuristic optimization algorithms are used to extract the optimum solution for several problems. One of these problems is the estimation of parameters in photovoltaic models such as the Harris Hawks optimization [9], the Marine Predators Algorithm [10], the multi-strategy success-history-based adaptive differential evolution [11], the bacterial foraging algorithm [12], the differential evolution algorithms [13], Enhanced leader particle swarm optimization (ELPSO) [14], Time varying acceleration coefficients particle swarm optimization (TVACPSO) [15], and the shuffled frog leaping algorithm [16]. Meta-heuristic optimization applied to a wind farm layout is one of the main tools used to determine optimum wind farm position and maximize the generated power. The optimization algorithms used for these are modified genetic algorithms based on a Boolean code [17], the Monte Carlo method [18], a genetic algorithm-based local search [19], a new pseudo-random number generation method [20], and a multi-level extended pattern search algorithm [21].

The following items summarize the contributions of this paper:

• Increasing the power generated from the wind turbine over a year using the wind cube.

• The inner and outer radius of the wind cube, roughness factor and the height of the wind turbine hub are the decision variables extracted using a new optimization algorithm (Gradient-Based Optimizer).

• Comparison between the proposed GBO algorithm with Tunicate swarm algorithm (TSA) and Chimp optimization algorithm (ChOA) is performed for the same wind turbine.

• Minimizing the probability generated energy loss.

• Minimizing the wind turbine and wind cube cost using the meter cubic function.

• Comparison between the power generated from the wind turbine with and without a wind cube.

The paper organization is as follows, Section two explains the problem formulation and metrological data. The objective function is illustrated also in Section 2. Section 3 dissects the Gradient-Based Optimizer algorithm. The study cases are illustrated in Section 4. The conclusion and future work is in Section 5.

2 Problem Formulation and Metrological Data

The variation of wind speed is the main factor affecting the power generated from the wind turbine. The characteristics of wind turbine output power are dependent on the boundaries of the wind speed (cut-in speed

where

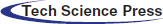

where Vh.2 is the velocity at the new hub height h2 and Vh.1 is the reference velocity at the reference hub of height for the wind turbine h1. For the neutral stability condition, α is the roughness ingredient factor which ranges from 0.14 to 0.25 [25]. The improvement of the power generated from the wind turbine is processed using the wind cube. The principle theory for wind cube design is the Bernoulli theory. The wind cube size is changed to achieve the optimal design. The configuration of the wind cube is explained in Fig. 1.

Figure 1: Wind cube configuration

Based on Bernoulli’s theory and continuity equation, the main equation for the wind cube is shown as follows:

where

where

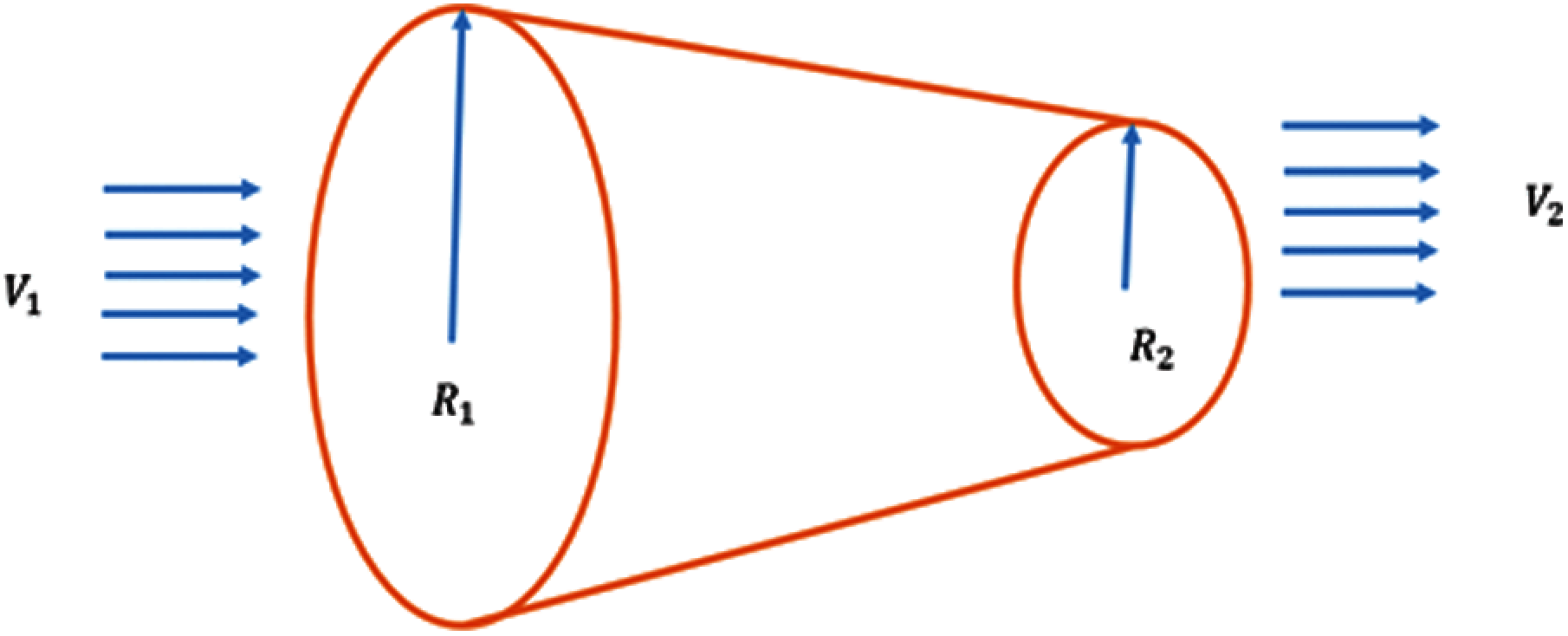

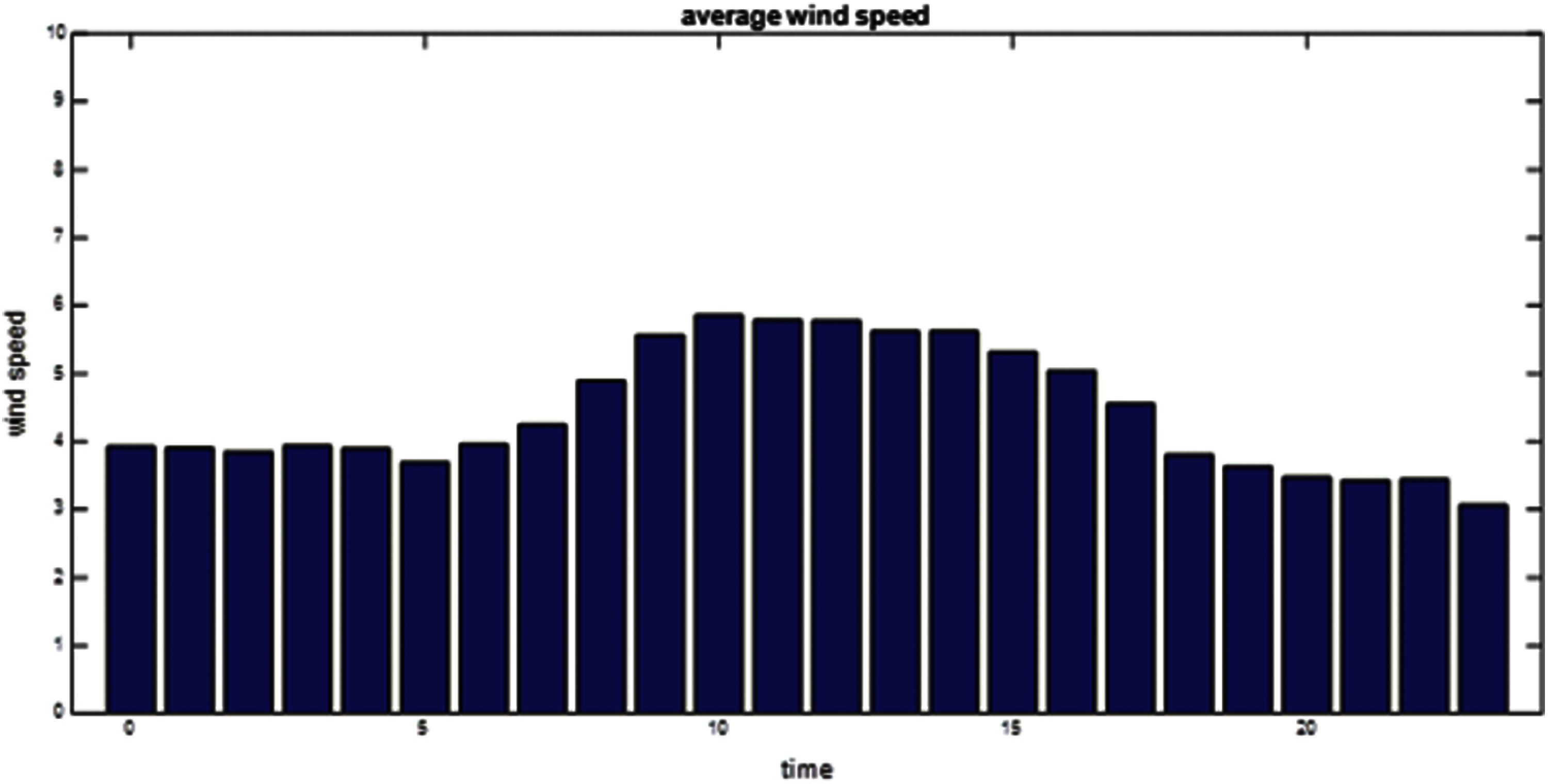

Hurghada City in the Red Sea governate of Egypt is the site used in this work to simulate the power output improvement. The latitude is

2.3 Analysis of Objective Function

The improvement to the power generated from the wind turbine corresponds with decreasing the loss of energy generated probability (LEGP) with the maximum speed out from the outer radius of the wind cube not increasing 80% of the cut-off speed for the turbine. The decision variables required for optimal sizing are the two radiuses of the wind cube, the wind turbine hub’s height, and the roughness factor. The mathematical equation for the LEGP is as follows:

where

Figure 2: The average wind speed for each month

Figure 3: The wind speed average over the year

3 Gradient-Based Optimizer (GBO)

Recently, Ahmadianfar et al. [26–28] have proposed a new metaheuristic algorithm called the Gradient-Based Optimizer (GBO), which mimics the gradient and population-based methods together. In the GBO, in order to explore the search domain utilizing a set of vectors and two main operators (like local escaping operators and the gradient search rule), Newton’s method is utilized to specify the search direction. The main process of the GBO are as follows:

3.1 The Initialization Process

In the GBO, the control parameters α and the probability rate are used to balance and switch from exploration to exploitation. Furthermore, the population size and iteration numbers are due to the problem’s complexity. In the GBO, N vectors in a D-dimensional search space can be defined as:

Usually, the initial vectors of the GBO are randomly generated in the D-dimensional search domain, which can be defined as:

where

3.2 Gradient Search Rule (GSR) Process

In the GBO algorithm, to guarantee a balance between exploration of significant search space regions and exploitation to reach near optimum and global points, a significant factor

where

The concept of GSR is to provide the GBO algorithm with a random behavior through iterations, therefore strengthening exploration behavior and escape from local optima. In Eq. (12), it is defined by the factor

where

Moreover, Direction Movement (DM) is employed to converge around the solution area xn. To provide a convenient local search tendency with a significant effect on the GBO convergence, the term DM uses the best vector and moves the current vector xn in the direction of xbest − xn and is computed as follows:

where, rand is a uniform distributed number within the range [0, 1], and

Finally, depending on these terms GSR and DM, Eqs. (18) and (19) are used to update the position of the current vector

where,

where

while xn represents the current solution vector, randn is a random solution vector of dimension n, xworst and xbest represent the worst and best solutions, and ∆x is given by Eq. (13). Based on the previous formula, when replacing the best solution vector xbest with the current solution vector

Specifically, the GBO algorithm aims to enhance the exploration and exploitation phases using Eq. (19) to improve the global search for the exploration phase, while Eq. (21) is used to improve the local search capability for the exploitation phase. Finally, the new solution for the next iteration is as follows:

where

3.3 The Local Escaping Operator (LEO) Process

The LEO is introduced to strengthen the performance of the optimization algorithm to solve complex problems. The LEO can effectively update the position of the solution, to assist an algorithm to exit local optima points and speed the convergence of the optimization algorithm. The LEO targets generate a new solution with a superior performance

where pr is a probability value, pr = 0.5, the values f1 and f2 are uniform distribution random numbers

where rand represents a random number

where L1 is a binary parameter take value 0 or 1, such as if parameter

where xrand is a random generated solution according to the following formula:

and

4 Analysis of Results and Discussion

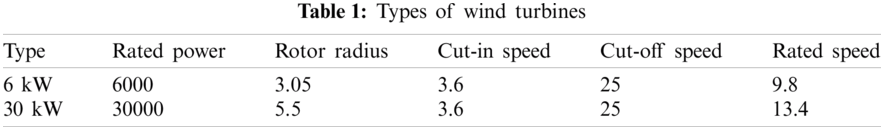

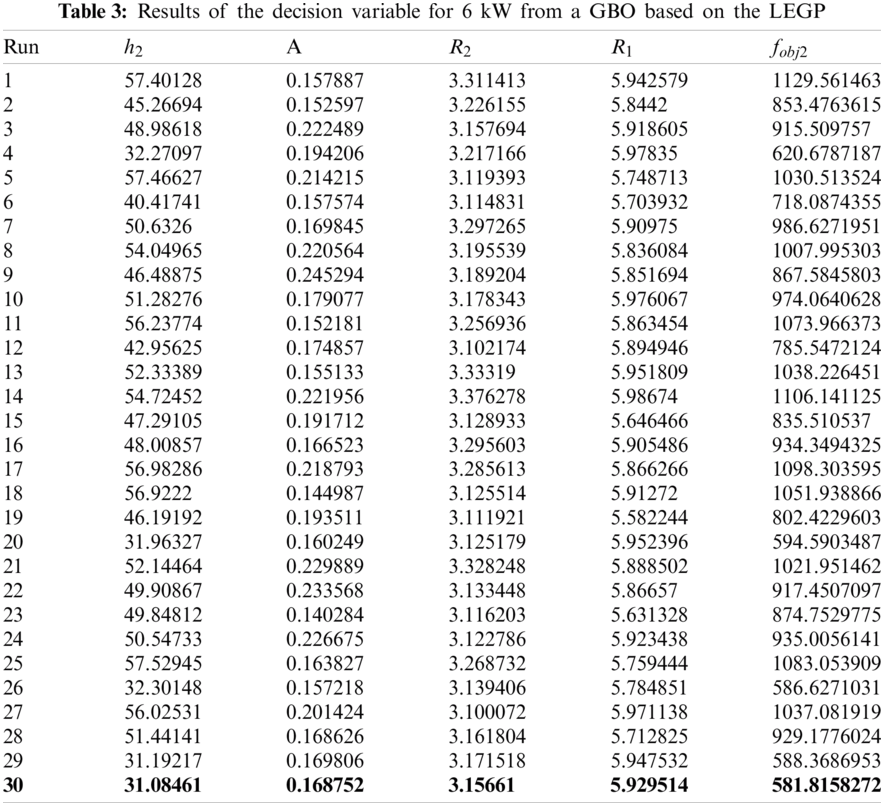

For fair benchmark comparison, the simulation settings are the same for all algorithms. furthermore, the algorithm parameter is set to their default values. This section presents the analysis of the proposed algorithm's results for the wind turbine explained in Tab. 1. The boundary limits for the decision variable of each turbine are explained in Tab. 2. The selection of boundaries for each turbine is dependent on the rotor blades radius and the height of the turbine hub. The wind cube radius from the turbine side is not almost less than the rotor blades radius. The wind cube radius from the airside is more than the rotor blade radius and smaller than the hub height with a specific distance according to each turbine to ensure that the cube does not touch the ground.2,3

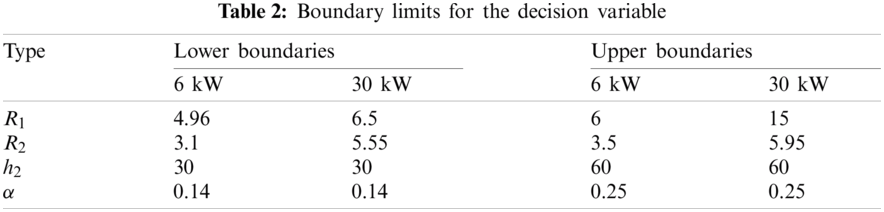

Based on analysis described in Section 2 and data reported in Tabs. 1 and 2, the proposed GBO algorithm is applied to the 6-kW wind turbine. Tab. 3 explains the proposed GBO algorithm’s results for a 6-kW wind turbine based on minimizing the loss of the probability of a generated energy loss. The optimum solution for these results is determined according to the second objective function that satisfies the minimum meter cubic function.

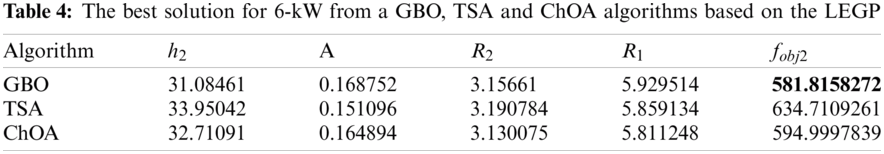

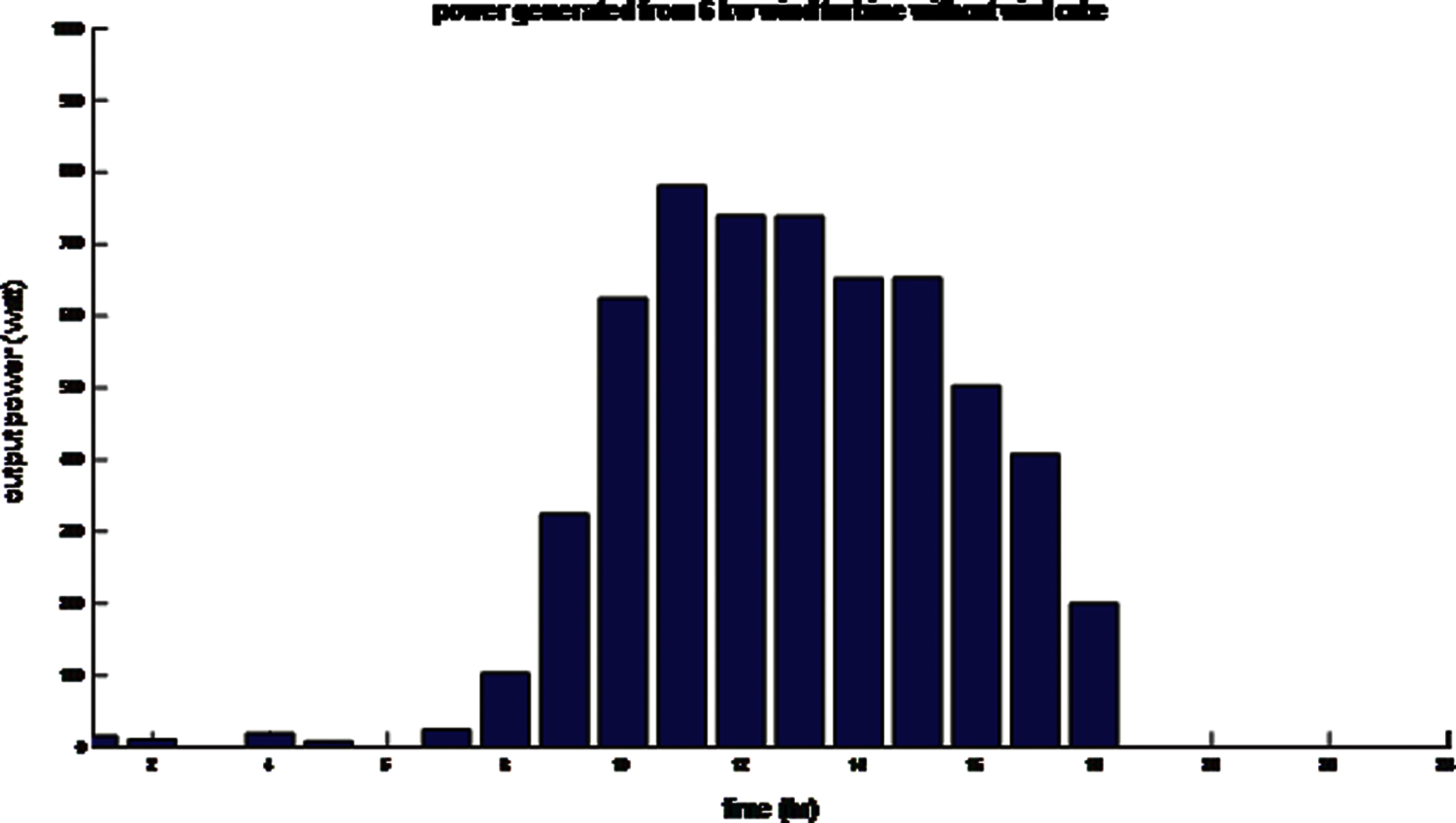

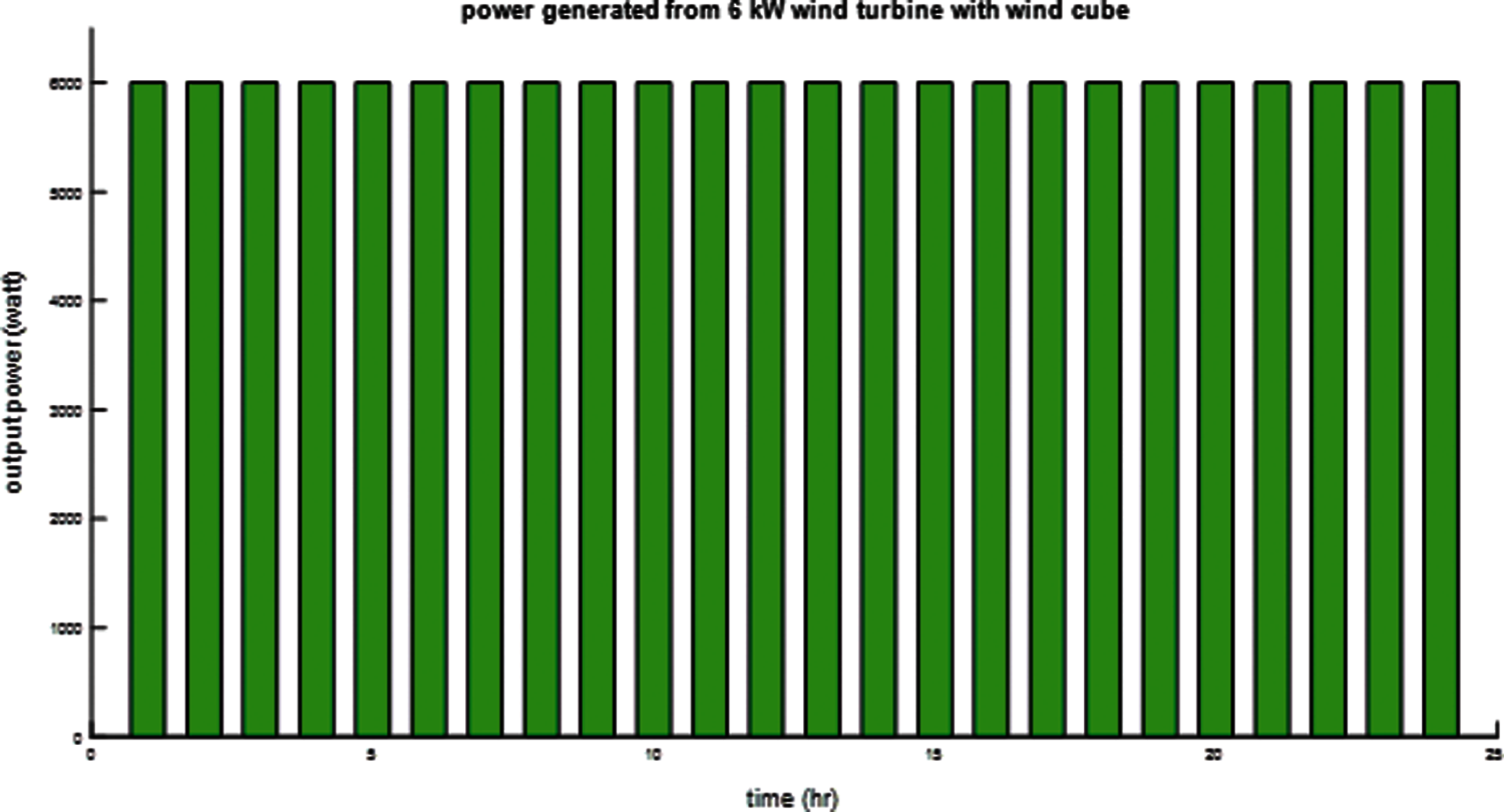

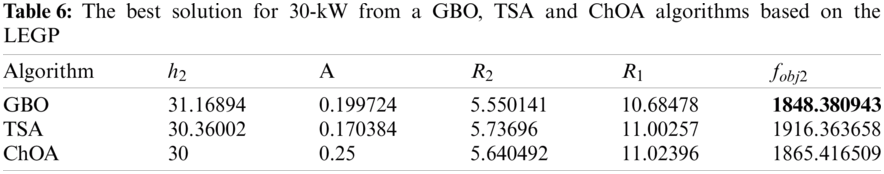

Tab. 3 shows that all runs achieve zero probability of generated energy loss; the result in run 30 is the optimum solution due to this solution achieving the minimum objective function of minimizing the meter cubic function. Tab. 4 show the best solution from the proposed GBO algorithm in compared with Tunicate swarm algorithm (TSA) [29] and Chimp optimization algorithm (ChOA) [30] for 6-kW wind turbine. Based on this results the proposed GBO achieve the best meter cubic function compared with the other competitor algorithms. Fig. 4 shows the power demand output from the wind turbine without a wind cube at the same height as the wind turbine hub and the optimum solution's roughness coefficient. Fig. 5 shows the power demand output from the wind turbine with wind cube at the optimum solution for run 30 of the proposed GBO algorithm.

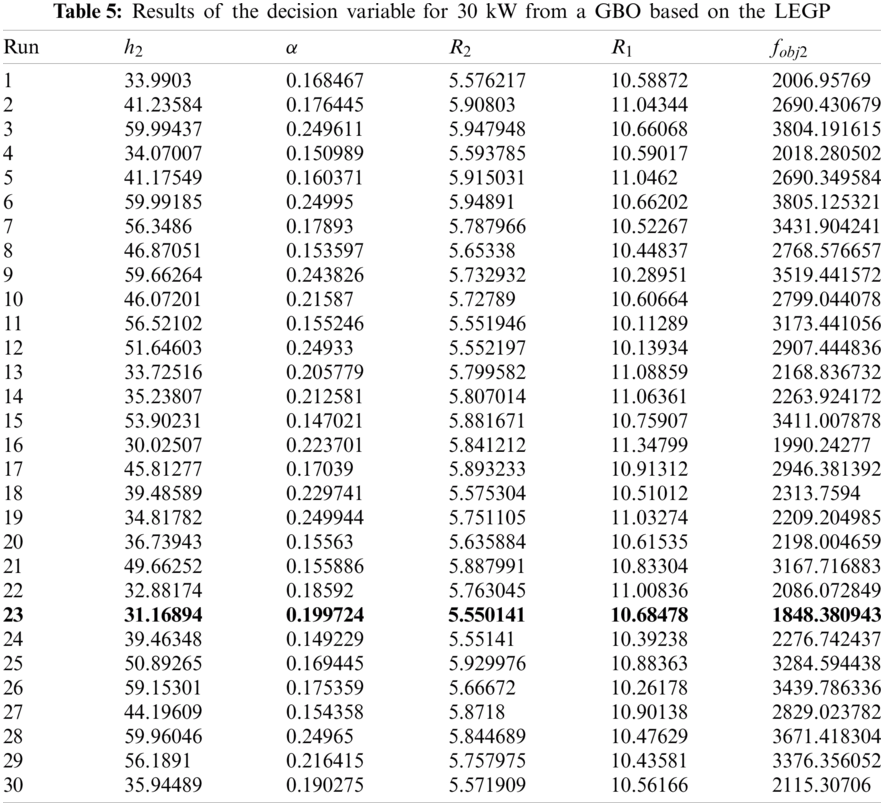

Based on analysis described in Section 2 and data reported in Tabs. 1 and 2, the proposed GBO algorithm is applied to the 30-kW wind turbine. Tab. 5 explains the proposed GBO algorithm’s results for a 30-kW wind turbine based on minimizing the loss of the probability of a generated energy loss. The optimum solution for these results is determined according to the second objective function that satisfies the minimum meter cubic function.

Figure 4: Power generated from a 6-kW wind turbine without a wind cube

Figure 5: Output power of a 6-kW wind turbine with an optimized wind cube

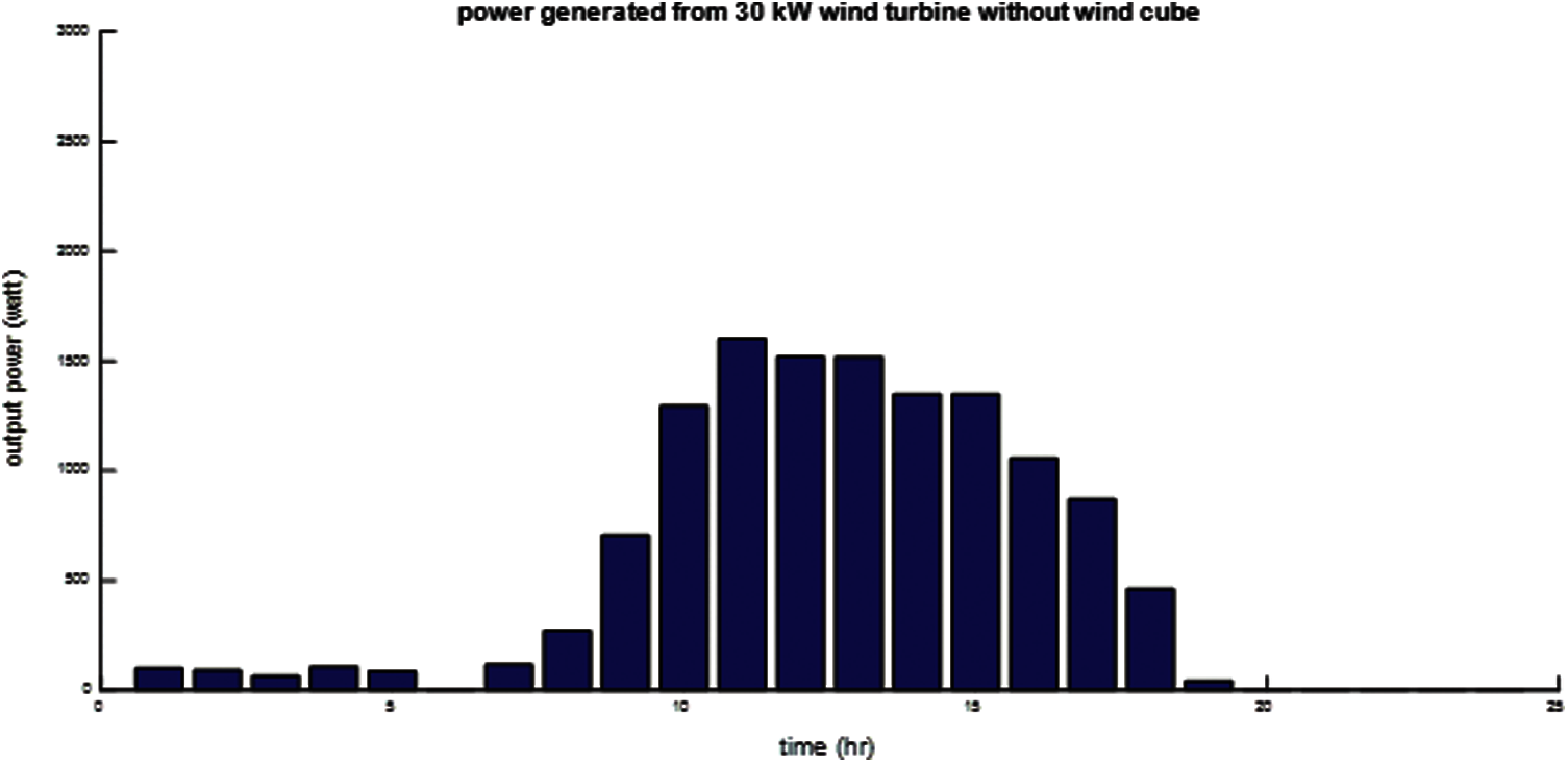

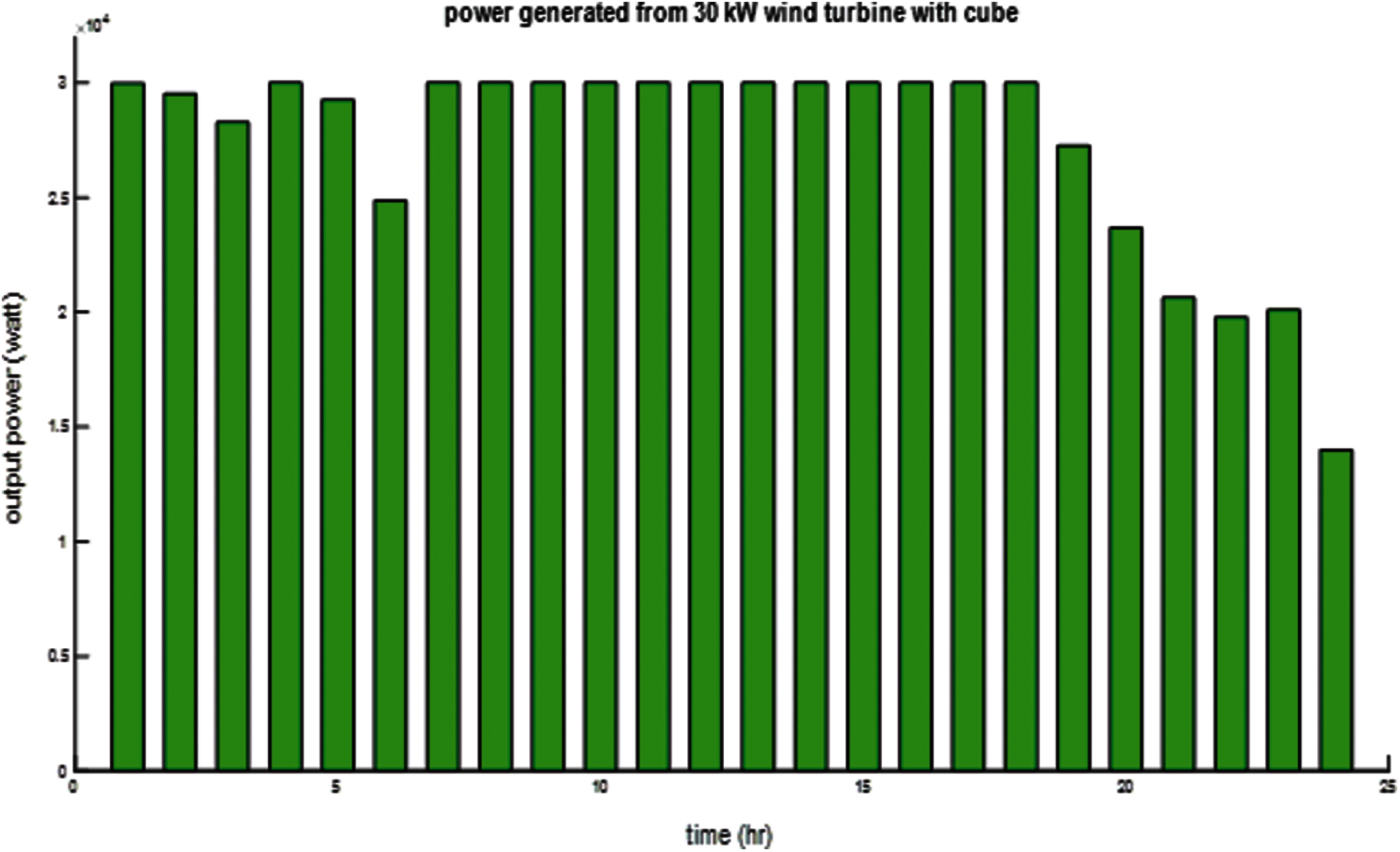

Tab. 5 shows that all runs achieve 0.079240007 probability of a generated energy loss; the result in run 23 is the optimum solution because this solution achieves the minimum objective function of minimizing the meter cubic function. Tab. 6 show the best solution from the proposed GBO algorithm in compared with Tunicate swarm algorithm (TSA) and Chimp optimization algorithm (ChOA) for 30-kW wind turbine. Based on this results the proposed GBO achieve the best meter cubic function compared with the other competitor algorithms. Fig. 6 shows the power demand output from the wind turbine without a wind cube at the same height as the wind turbine hub and the optimum solution's roughness coefficient. Fig. 7 shows the power demand output from the wind turbine with a wind cube at the optimum solution for run 30 of the proposed GBO algorithm.

Figure 6: Power generated from 30-kW wind turbine without a wind cube

Figure 7: Output power of a 30-kW wind turbine with the optimized wind cube

Increasing the generated energy from the wind turbine is important work. Wind cubes improve wind turbine output using an effective optimization technique. A GBO is used to estimate the roughness factor’s decision variable, the inner radius of the wind cube, the wind turbine hub's height, and the outer radius of the wind cube. The extraction of these parameters is dependent on minimizing the probability of a loss of generated energy and decreasing the decision variable to make these variables more cost-efficient. There is a tolerance of a 20% air speed increase for the site as compared with the speed recorded in this work. A comparison between wind turbine output power with and without the optimized wind cube was performed. Based on this comparison, the energy generated from a 30-kW wind turbine with the optimized wind cube as 55.7317 times the energy generated without the wind cube. The energy generated from a 6-kW wind turbine with the optimized wind cube is 23.8123 times the energy generated without the wind cube. The future work will concentrate on apply GBO for several problems such as power flow in power system, wind farm layout problem.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

2https://en.wind-turbine-models.com/turbines/493-aeolian-aeo-20

3https://en.wind-turbine-models.com/turbines/1380-aerolite-a-11

1. X. Xu, W. Hu, D. Cao, Q. Huang, C. Chen et al., “Optimized sizing of a standalone pv-wind-hydropower station with pumped-storage installation hybrid energy system,” Renewable Energy, vol. 147, no. 4, pp. 1418–1431, 2020. [Google Scholar]

2. A. Makhsoos, H. Mousazadeh, S. S. Mohtasebi, M. Abdollahzadeh and H. Jafarbiglu, “Design, simulation and experimental evaluation of energy system for an unmanned surface vehicle,” Energy, vol. 148, no. 5, pp. 362–372, 2018. [Google Scholar]

3. H. Hou, T. Xu, X. Wu, H. Wang and A. Tang, “Optimal capacity configuration of the wind-photovoltaic-storage hybrid power system based on gravity energy storage system,” Applied Energy, vol. 271, no. 2, pp. 115052, 2020. [Google Scholar]

4. D. Zhang, J. Wang, Y. Lin, Y. Si, C. Huang et al., “Present situation and future prospect of renewable energy in china,” Renewable and Sustainable Energy Reviews, vol. 76, pp. 865–871, 2017. [Google Scholar]

5. B. Sun, Y. Yu and C. Qin, “Should china focus on the distributed development of wind and solar photovoltaic power generation? A comparative study,” Applied Energy, vol. 185, no. 2, pp. 421–439, 2017. [Google Scholar]

6. K. Balasubramanian, S. B. Thanikanti, U. Subramaniam, N. Sudhakar and S. Sichilalu, “A novel review on optimization techniques used in wind farm modelling,” Renewable Energy Focus, vol. 35, no. 4, pp. 84–96, 2020. [Google Scholar]

7. W. Sabry, A. Eliwa, U. AbouZayed and R. Youssef, “Design and implementation of the 10 kw wind cube,” in Proc. 21st Int. Conf. on Electricity Distribution, Frankfurt, Germany, pp. 1–4, 2011. [Google Scholar]

8. A. F. Abdelgawad, W. Sabry, U. R. Abouzayed, R. Y. Abdellateef and M. E. Fathy, “The 30 kva permanent magnet synchronous generator wind-cube design, implementation, control; and performance measurements and analysis,” in Proc. 20th Int. Middle East Power Systems Conf. (MEPCONCairo, Egypt, IEEE, pp. 260–265, 2018. [Google Scholar]

9. M. H. Qais, H. M. Hasanien and S. Alghuwainem, “Parameters extraction of three-diode photovoltaic model using computation and harris hawks optimization,” Energy, vol. 195, no. 12, pp. 117040, 2020. [Google Scholar]

10. M. A. Soliman, H. M. Hasanien and A. Alkuhayli, “Marine predators algorithm for parameters identification of triple-diode photovoltaic models,” IEEE Access, vol. 8, pp. 155832–155842, 2020. [Google Scholar]

11. Q. Hao, Z. Zhou, Z. Wei and G. Chen, “Parameters identification of photovoltaic models using a multi-strategy success-history-based adaptive differential evolution,” IEEE Access, vol. 8, pp. 35979–35994, 2020. [Google Scholar]

12. B. Subudhi and R. Pradhan, “Bacterial foraging optimization approach to parameter extraction of a photovoltaic module,” IEEE Transactions on Sustainable Energy, vol. 9, no. 1, pp. 381–389, 2017. [Google Scholar]

13. V. J. Chin, Z. Salam and K. Ishaque, “An accurate modelling of the two-diode model of pv module using a hybrid solution based on differential evolution,” Energy Conversion and Management, vol. 124, no. 8, pp. 42–50, 2016. [Google Scholar]

14. A. Rezaee Jordehi, “Enhanced leader particle swarm optimisation (ELPSOAn efficient algorithm for parameter estimation of photovoltaic (PV) cells and modules,” Solar Energy, vol. 159, pp. 78–87, 2018. [Google Scholar]

15. A. R. Jordehi, “Time varying acceleration coefficients particle swarm optimisation (TVACPSOA new optimisation algorithm for estimating parameters of PV cells and modules,” Energy Conversion and Management, vol. 129, no. 4, pp. 262–274, 2016. [Google Scholar]

16. H. M. Hasanien, “Shuffled frog leaping algorithm for photovoltaic model identification,” IEEE Transactions on Sustainable Energy, vol. 6, no. 2, pp. 509–515, 2015. [Google Scholar]

17. Q. Yang, J. Hu and S. -S. Law, “Optimization of wind farm layout with modified genetic algorithm based on boolean code,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 181, no. 1, pp. 61–68, 2018. [Google Scholar]

18. L. Wang, J. Yuan, M. E. Cholette, Y. Fu, Y. Zhou et al., “Comparative study of discretization method and monte carlo method for wind farm layout optimization under weibull distribution,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 180, no. 1, pp. 148–155, 2018. [Google Scholar]

19. A. M. Abdelsalam and M. El-Shorbagy, “Optimization of wind turbines siting in a wind farm using genetic algorithm based local search,” Renewable Energy, vol. 123, no. 1, pp. 748–755, 2018. [Google Scholar]

20. S. Zergane, A. Smaili and C. Masson, “Optimization of wind turbine placement in a wind farm using a new pseudo-random number generation method,” Renewable Energy, vol. 125, no. 51, pp. 166–171, 2018. [Google Scholar]

21. B. DuPont, J. Cagan and P. Moriarty, “An advanced modeling system for optimization of wind farm layout and wind turbine sizing using a multi-level extended pattern search algorithm,” Energy, vol. 106, no. 1, pp. 802–814, 2016. [Google Scholar]

22. G. E. -B. M. S. El-Negamy and A. Galal, “Controller energy management for hybrid renewable energy system,” International Journal of Engineering and Applied Sciences IJEAS, vol. 3, no. 9, pp. 72–77, 2016. [Google Scholar]

23. M. Said and A. Yassin, “Operation study of a combined system of diesel engine generators and wind turbine with battery storage system,” in Proc. 5th Int. Conf. on New Paradigms in Electronics & information Technology (PEITEgypt, IEEE, Hurgada, pp. 1–5, 2019. [Google Scholar]

24. A. A. Masud, “An optimal sizing algorithm for a hybrid renewable energy system,” International Journal of Renewable Energy Research, vol. 7, pp. 1595–1602, 2017. [Google Scholar]

25. S. Moghaddam, M. Bigdeli, M. Moradlou and P. Siano, “Designing of stand-alone hybrid pv/wind/battery system using improved crow search algorithm considering reliability index,” International Journal of Energy and Environmental Engineering, vol. 10, no. 4, pp. 429–449, 2019. [Google Scholar]

26. I. Ahmadianfar, O. Bozorg-Haddad and X. Chu, “Gradient-based optimizer: A new metaheuristic optimization algorithm,” Information Sciences, vol. 540, pp. 131–159, 2020. [Google Scholar]

27. A. A. K. Ismaeel, E. H. Houssein, D. Oliva and M. Said, “Gradient-based optimizer for parameter extraction in photovoltaic models,” IEEE Access, vol. 9, pp. 13403–13416, 2021. [Google Scholar]

28. S. Deb, D. S. Abdelminaam, M. Said and E. H. Houssein, “Recent methodology-based gradient-based optimizer for economic load dispatch problem,” IEEE Access, vol. 9, pp. 44322–44338, 2021. [Google Scholar]

29. S. Kaur, L. K. Awasthi, A. L. Sangal and G. Dhiman, “Tunicate swarm algorithm: A new bio-inspired based metaheuristic paradigm for global optimization,” Engineering Applications of Artificial Intelligence, vol. 90, no. 2, pp. 103541, 2020. [Google Scholar]

30. M. Khishe and M. R. Mosavi, “Chimp optimization algorithm,” Expert Systems with Applications, vol. 149, pp. 1–26, 2020. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |