DOI:10.32604/csse.2023.026502

| Computer Systems Science & Engineering DOI:10.32604/csse.2023.026502 |  |

| Article |

Designing Software to Analyze Sewing Process of Industrial Knitted Products

Hanoi University of Science and Technology, Hanoi, 10000, Vietnam

*Corresponding Author: Phan Thanh Thao. Email: thao.phanthanh@hust.edu.vn

Received: 28 December 2021; Accepted: 02 March 2022

Abstract: In the textile industry, garment manufacturing contains four major processes containing cutting, sewing, finishing, and packaging. Sewing is the most crucial and intricate section, dealing with a large number of varied operations. A successful sewing process needs to be optimized regarding different factors, including time, sewing equipment, and skilled workers. Assembly line flow is combined by a set of operations with a particular sequence. The utmost importance of all garment industry is to arrange the workstations to minimize the number of employees in order to produce at the best productive rate with the most reasonable cost, shortest time, and satisfying quality. In most garment factories, the production lines are balanced using the empirical judgment of the line managers. For the whole process the data of production time at each step, labor productivity, proper choices of equipment were always needed to calculate line efficiency. As far as the issue is concerned, there has not been an academically sewing process analyzing software providing adequate data of sewing motions and sewing time as the credible input for the line balancing tasks. Towards this goal, this paper presents the results of research on optimizing academically self-built software to analyze the sewing process of knitted products applied to industrial production using Java programming language on Google tools. The results achieved by the software are not only to analyze sewing products and the technological sewing process, calculate the sewing time on the machine but also analyze the sewing activities of workers into manipulations, movements, and motions to calculate the preparation time for two typical knitted products, namely, Polo-Shirt and T-Shirt with the case studies at General Textile Garment Joint Stock Company Hanoi and Star Fashion Company Limited.

Keywords: Sewing motion; sewing time; GSD; MTM; polo-shirt; T-shirt; sewing process; sewing operation; analyzing software

The garment industry comprises various manufacturing stages, one of these is sewing with many operations, and a multitude of equipment types to spread, cut, assemble fabric, and attach accessories. The sewing industry requires intensive skilled labor and a complex of machines for varied sewing technology. The most intensive part is sewing different clothing components together, which is laborious and complex, deciding the quality and performance of final products. In this stage, garment pieces and accessories are assembled from one station to another, the objective is to minimize throughput and work time thus improving productivity. To arrange sewing lines demands a lot of input data such as product types, sewing motions, working times for each sewing task, skill levels of the sewing machine operator, and proper selections of machine sets [1,2]. Solving the line balancing problem is to assign the same amount of work to each operator in order to keep equal utilization of all workstations and minimize idle time.

Industry 4.0 significantly has changed the operating processes of traditional businesses. Technology, digital, and artificial intelligence (AI) applications have been put into practice to increase the effectiveness of corporate governance around the world. To be able to firmly integrate into the regional and global economy, garment businesses need to improve their management capacity and optimize both the quantity and quality of products. During the pandemic, the local garment industry has overcome a great deal of difficulties and maintained a solid and stable growth momentum. In 2019, the total export turnover of garments surpassed the threshold of 36.2 billion USD, making Vietnam the world's second-largest garment exporting country and contributing significantly to the overall export turnover of the country. The strategic objective of developing Vietnam's textile and garment industry is to become one of the major export industries; meeting the increasing demand for domestic consumption; creating more job opportunities for the society; improving the competitive ability, firmly integrating the regional and world economy [3]. During the period in which AI technology is being developed strongly, IT infrastructure and big data are being studied intensively to support textile and garment enterprises for effective management, operation, production, and investment [4].

Artificial intelligence is a promising solution to provide optimal results for the line balancing problems in the garment industry with shorter time and more stable production than traditional mathematical methods due to advanced computing technologies. However, currently, the big data for developing AI capabilities are based on data-intensive methods collecting real data from actual production. The research presented in this article is to provide big-data software with user-friendly, easy-to-understand, easy-to-storage, and easy-to-retrieve advantages, the authors focus on building input data library, determining requirements, proposing algorithms and designing functional modules, designing a working interface, storage database system, system security and creating user manual of software analyzing the labor manipulation process of garment workers. In the research, an object-oriented approach was taken as applying, building a model of each object in the system, clearly defining properties and methods, thereby building the relationship among steps as well as processing them. The proposed algorithms have demonstrated in detail the idea of the method, as well as the implementation and testing in the software. The design software has been tested on the actual data set of 10 knitted products production orders at two Vietnamese garment enterprises including General Textile Garment Joint Stock Company Hanoi and Star Fashion Company Limited. These are important initial results in a group of studies promoting digital transformation in the garment industry to build a database systematization, standardize the labor activities of workers with an aim to build AI based software for line balancing, helping Vietnamese garment enterprises develop sustainably in the trend of integration and globalization.

2 Designing Software for Analyzing the Sewing Process of Knitted Products Applied in Industrial Production

2.1 Input Data of Software for Analyzing the Sewing Process of Knitted Products

The input information was entered into the software system, including characteristics of production orders, information on product specifications, materials and equipment used to sew products, a database of analyzing the sewing operation of knitted products from the source data set on sewing preparation operation analysis and the sewing time. Sewing time collection was conducted through self-recording of operator's work time using a stopwatch at General Textile Garment Joint Stock Company Hanoi and Star Fashion Company Limited, other data were reported in our previously published works [5–7].

2.2 The Advantages of Software

The software for analyzing the sewing process of knitted products is built with the aims of providing referred technological sewing processes, sewing operations, and calculating the time to perform the sewing work of knitted products. In order to develop AI technology in the future, the software needs to meet the standards of easy storage and user-friendly characteristics, thus used data were organized in a systematic way. Moreover, the software has a user interface in the Vietnamese language, accessible via a web browser with a network connection, run on multiple platforms (Windows, Linux, and macOS), reasonable searching time, easy to retrieve data, ensuring confidentiality and data safety.

Managing a database of operations analysis and execution time of sewing motions includes security and big data. In order to ensure data security, the system uses Google's tool: Google App Engine. Google App Engine (GAE) is a cloud computing platform as a service for developing and hosting web applications in Google-managed data centers. Compared to other cloud services such as Amazon EC2, or with traditional writing forms services, GAE provides a more favorable environment specifically to write for applications with extended needs for many concurrent users. GAE solves the problems of development and system administration while building a large-scale application, while other models require users to install and configure. GAE needs one admin to administer and enlarge or shrink the service provision [8]. In order to store the massive amount of data, the software also uses Google's tools such as Google Cloud DataStore (GCD). GCD is a suite of cloud computing services that run on the same infrastructure as Google used internally for end-user products, such as Google Search and YouTube. Besides a set of management tools, it offers a range of modular cloud services including computation, data storage, data analytics, and machine learning. GCP stands for Google Cloud Platform, a cloud computing platform that allows organizations and businesses to create, build, and operate their applications on google systems [9]. GCP provides users with solutions for worldwide issues, including mobile, management, networking, computer engine, storage, and big data. There is a data center service system with the highest level of security. Moreover, GCP also meets the strictest standards for a cloud computing platform [10,11].

The designed software was developed to satisfy user functions as follows. Product database management function includes production order information, product specifications, structural analysis of seam types, detailed assemblies, product quality standards. Managing the database of characteristics, standards, sewing equipment, processing methods, and instructions of materials and accessories. Managing the database of product technological sewing process, including block diagram, product assembly line diagram, product technological sewing process analyzing diagram, and technological sewing process table. Managing the database of the moving process, the time to perform the sewing operation, sewing techniques of knitted products from the original data set about the manual operation analysis coding regulation, and sewing time calculation algorithm on machines.

2.2.3 User Convenience Requirements

User account management functions are easy and fast to sign up, sign in. Users can also edit account information. The software offers several key functions such as decentralized management function, adding and editing permissions, user-friendly interface for information editing, intuitive linking functions. The major aim of user management is to control and secure access to database resources. The authentication and authorization of the users are based on security policy from the provided server and virtual organization [12]. The complexity of user management in an environment including a large number of users, resources, and data is challenging regarding administration tasks and time factors. The privileges were granted to users relating to the tasks, which were performed, and connected to user roles. The roles are managed in different hierarchies and independent structures.

2.3 Methods and Techniques Used in Designing Software for Analyzing the Sewing Process of Knitted Products

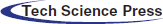

Algorithms used in the process of building the software are straightforward, including the sorting algorithm, Tab. 1. A partial exchange method, which is a very common and effective method, consists of selecting any node in the list called pivot node, determining the valid position of nodes in the list (called pivot position). Next, the remaining nodes were divided in the list so that from position 0 to position pivot-1, all content is less than or equal to the node as the axis, the buttons from position pivot+1 to n-1 all have larger content than the node as the axis. The process continues likewise with two sublists from position 0 to position pivot-1 and from position pivot+1 to position n-1, and so on. Finally, an orderly list would be acquired.

Building algorithm to calculate the time to perform sewing motions is applied according to the following formula.

The parameters were defined as follows.

l: Seam length, taken from a defined constant from the original database.

m: Stitches per centimeter, taken from the information field “densityNumber” entered into the database in the table “ActionInfo”.

n: The maximum speed of a machine, taken from the “speedNumber” information field entered into the database in the “ActionInfo” table.

0.0006: Factor to convert minutes to TMU's.

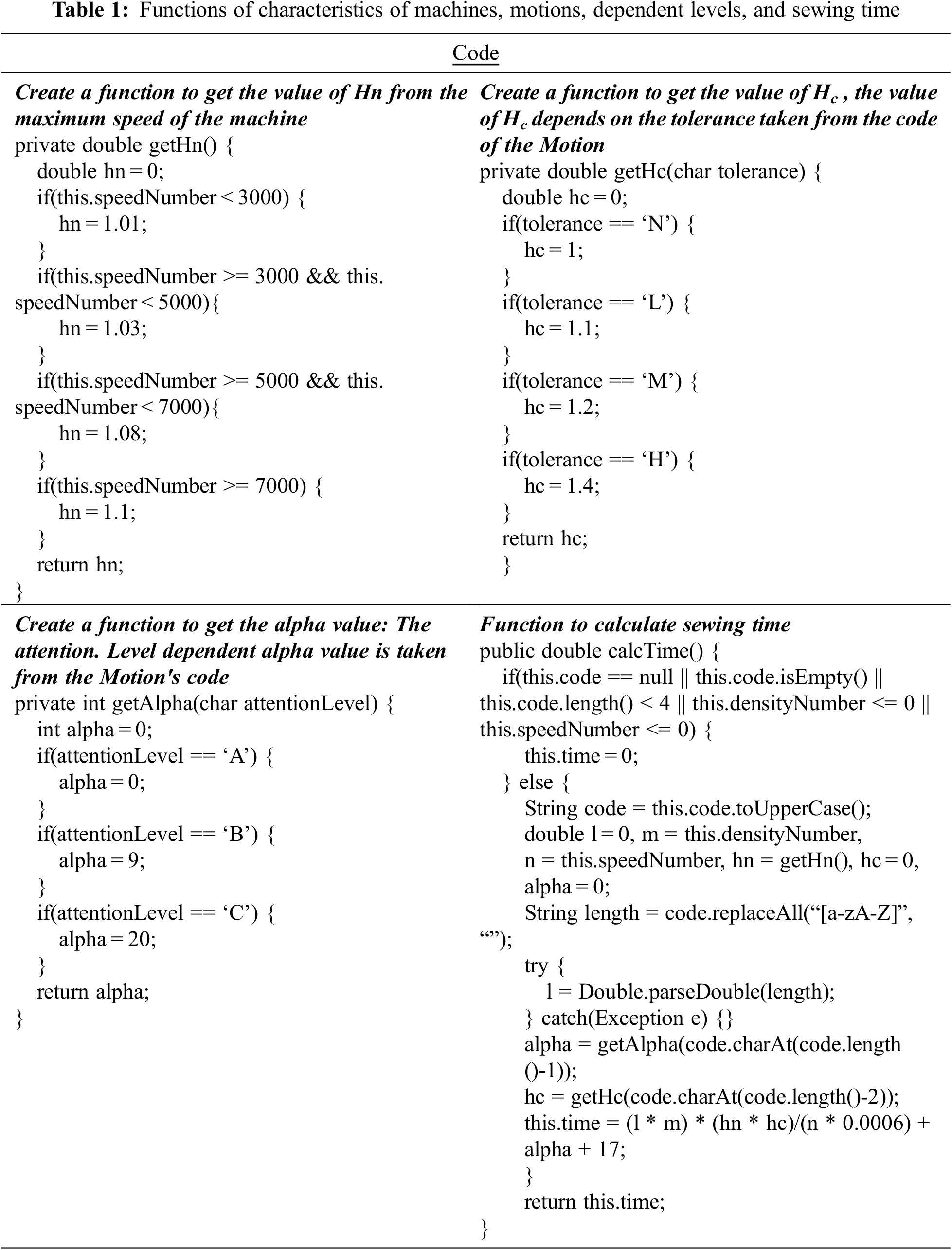

Hc: Factor indicates the degree of Guiding & Tensioning (Tab. 2).

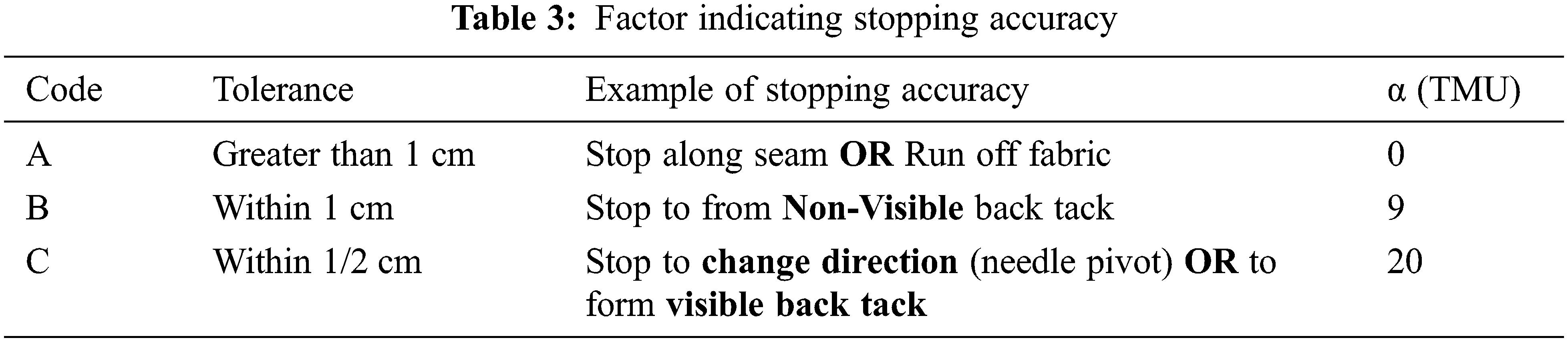

α: Indicate Stopping Accuracy (Tab. 3).

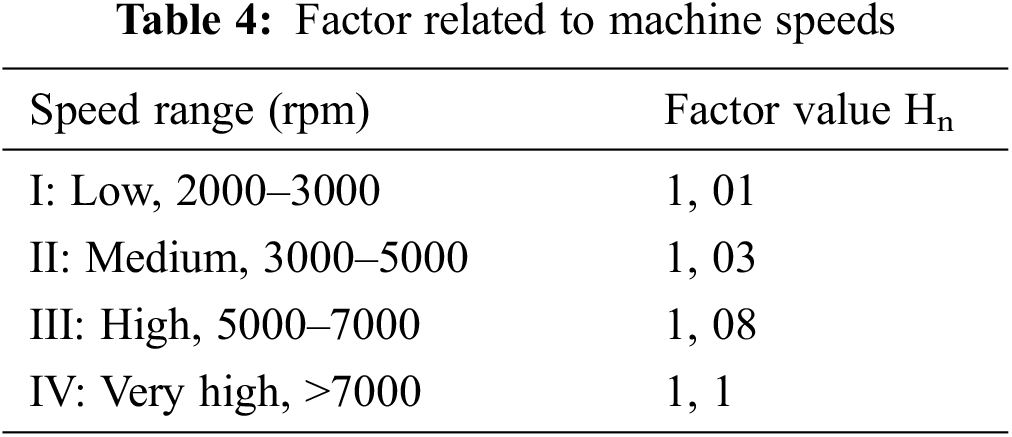

Hn: Factor relates to machine speed, corresponding to 4-speed ranges (Tab. 4).

17: Time for starting and stopping the machine.

2.3.2 Google Web Toolkit (GWT)

GWT is an open-source framework for web development in Java language started and managed by Google. The main difference between GWT and other frameworks is that on GWT, the client-server application is written in Java language instead of JavaScript, using available Java development tools such as Eclipse and Netbeans. Moreover, GWT only uses a single programming language to write web applications for both Client and Server, making the programming process more direct, without switching between multiple languages. Using AJAX through Javascript to provide a client-side technology to call a background command to execute and update information without having to reload the whole page, which is very useful because reloading unnecessary components is time-consuming. GWT is an open-source framework that supports many different graphical user interface packages for platforms like the Web by providing a variety of libraries, especially a library of widgets and panels to handle events like Windows controls and Design layouts with strict rules. When deploying the application, the GWT compiles the Java application into Javascript and HTML. The final result returned to the client is purely Javascript and HTML. Different from traditional web developers, there is no need for GWT developers to configure any individual cases. Moreover, returning HTML and JavaScript do not require configuration of the client-side environment, which is the key point to using GWT to create Web applications [13,14].

2.3.3 Software Development Process

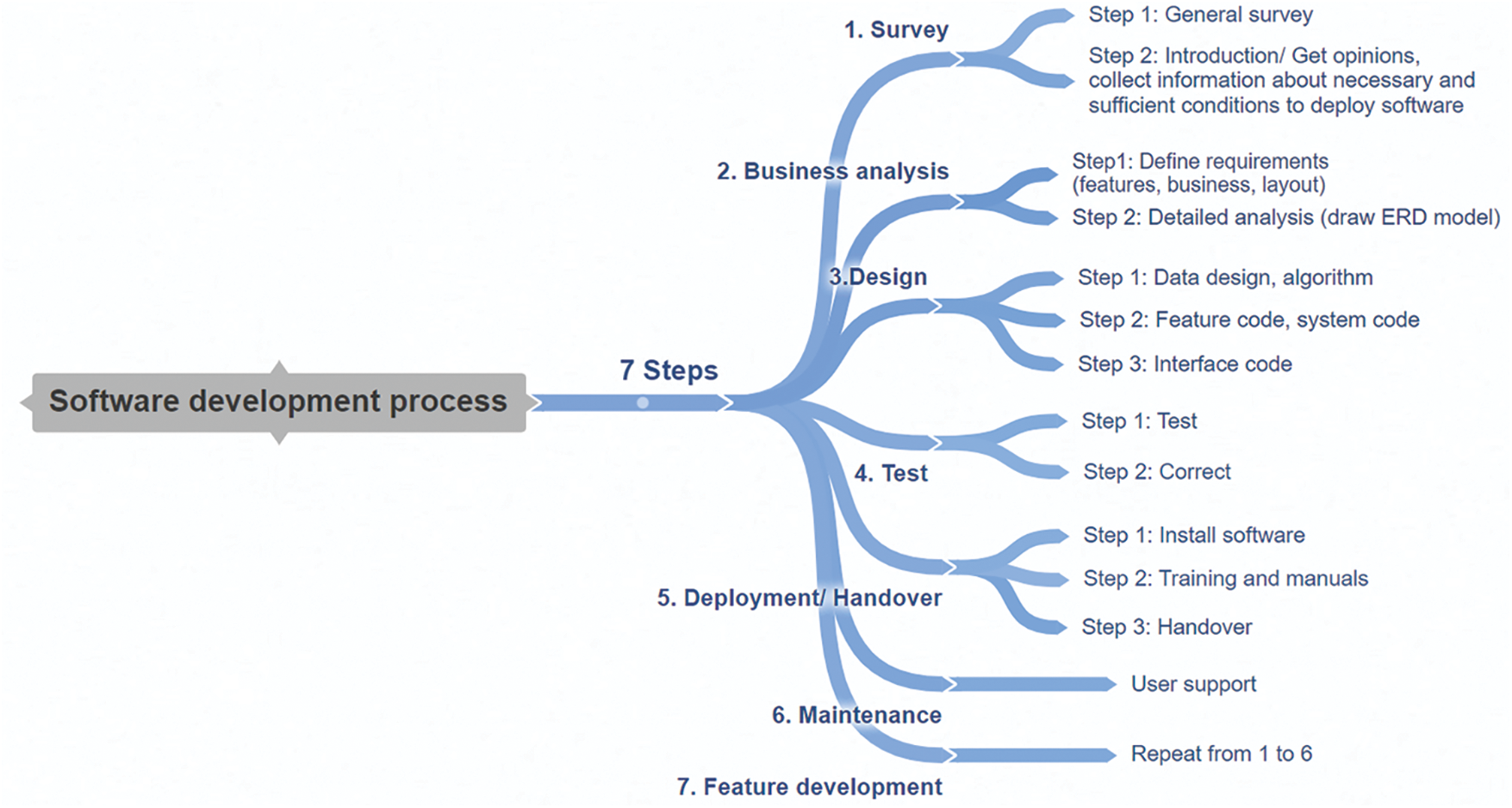

The process of building digital technology software in the garment industry production is illustrated in Fig. 1.

Figure 1: Flowchart of digital software development process

2.3.4 Sewing Motion Time Analysis Technique by MTM (Method Time Measurements) and GSD (General Sewing Data)

Sewing time basically is the time for making seams on the machine. To calculate, we need to analyze factors affecting the sewing time. The sewing time is mainly influenced by the machine speed, stitch length, stitch density, and a number of stops [15]. Seams and difficulty levels can be divided into 4 groups depending on the type of seam made for each sewing operation in Tab. 2.

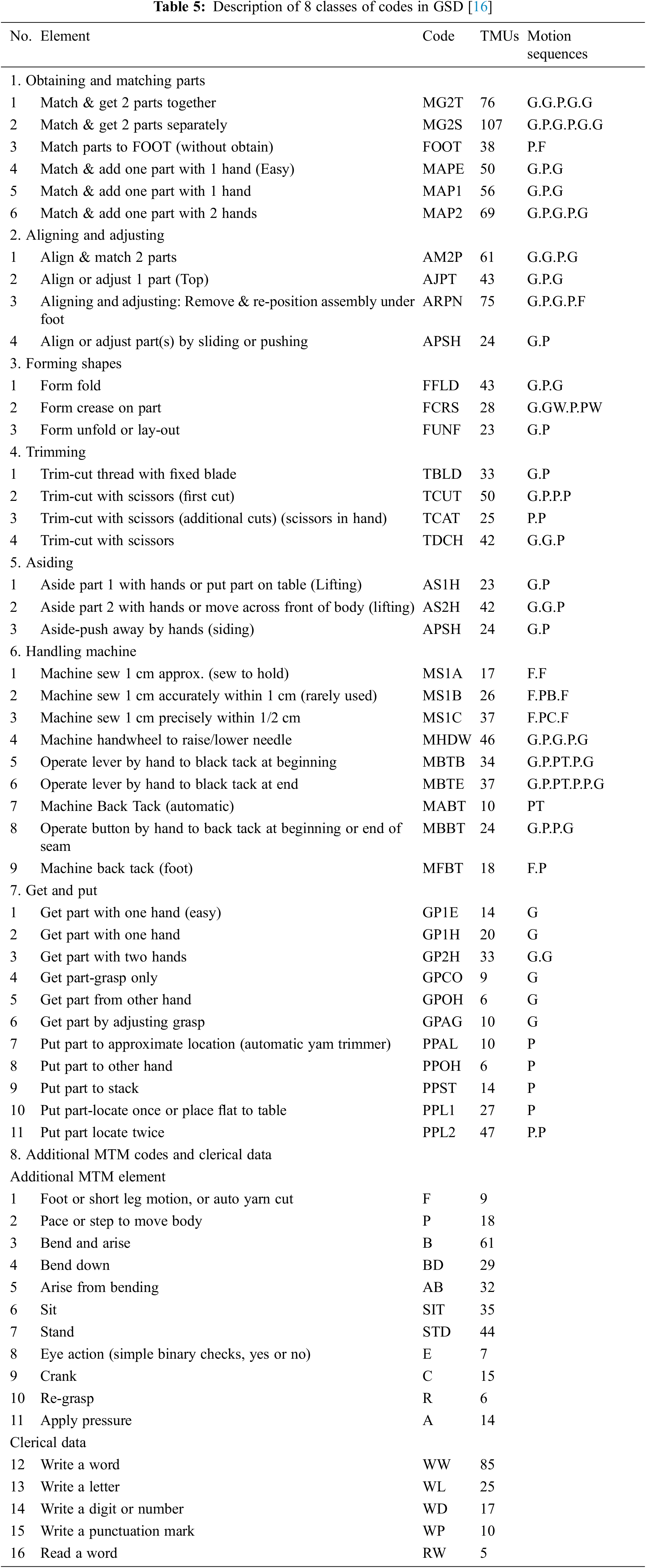

The software uses the code table list, data card with the motion sequence of the MTM method and, the predefined time system GSD to analyze the sewing preparation time shown in Tab. 5.

2.4 Designing Software Modules

Features of production orders include product code, production program, product name, export or domestic market, production unit, receipt date of technical documents and delivery date, the proportion of a number of sizes and colors, initial data provided by the customer. Product specifications include product description drawings, product descriptions, structural features of the product, structural analysis of product lines, structural analysis of product detail clusters, product standards, sewing specifications, and dimensions standards.

Material module characteristics consist of main fabric, interlining, and lining fabric. Accessories can be thread, mex, buttons, labels, and so on. Moreover, instruction sheets for the use of materials and accessories also need to be prepared. Database module on sewing equipment was categorized into the machining method and group of equipment used. Database modules on the technological process of sewing products are a block diagram of product processing, product assembly diagram, schematic analysis of sewing products technological process, product technological sewing process table. Database to manage the operation process and sewing time of the product seams/main detail assemblies.

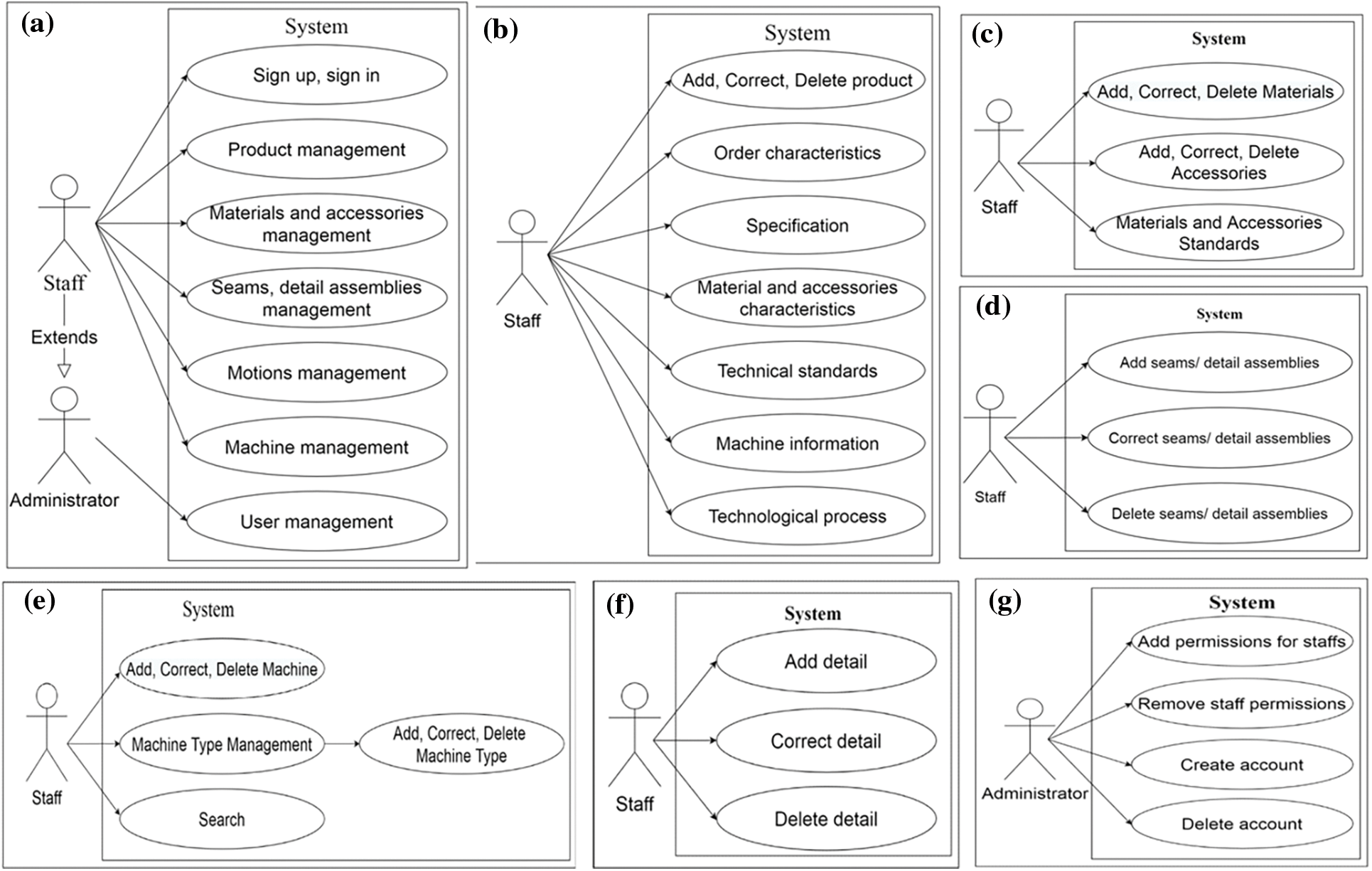

2.5 Designing the Interface and Function of Software

To overview the functions of the software system, a case diagram was constructed, Fig. 2a. Product management function was illustrated in Fig. 2b, which are add product, product deletion, product editing, technological process, device information management, specification management, management of materials and accessories, and order characteristics. The product creating function has 2 styles, quickly add a product and add details to the products. The product deletion function can be assigned to employees who have the right to delete a product. The technological process requires plenty of related data for calculation and it is based on product structure data such as seams, cluster structure, product details, and time to complete every little detail. Device information management manages equipment information used to sew products. Specification management manages information about product specifications. Management of materials and accessories collects information about the characteristics of materials and accessories related to products. Manage order characteristics manage order information about products. Materials and accessories management functions include functions of adding and deleting, Fig. 2c. The machine management function was listed in Fig. 2e. The function of managing technological sewing process of product seams and detail assemblies was illustrated in Fig. 2e, including adding, editing, deleting name information, structure, and symbols of seams and detail assemblies. Product detail management function is about add, edit, delete names, materials, and accessories, Fig. 2f. Decentralized management function includes adding permissions for employees, each employee will be assigned one or more permissions by the administrator to the products that the employee is managed; removing the rights of an employee who is managing a certain product; creating accounts for employees; and deleting an employee's account; Fig. 2g.

Figure 2: Schematic figure of function (a) General use case, (b) Disaggregated use case, (c) Use case for material and accessories management, (d) Use case for seam and detail assemblies, (e) Use case for machine management, (f) Use case for product management, and (g) Use case for decentralized management

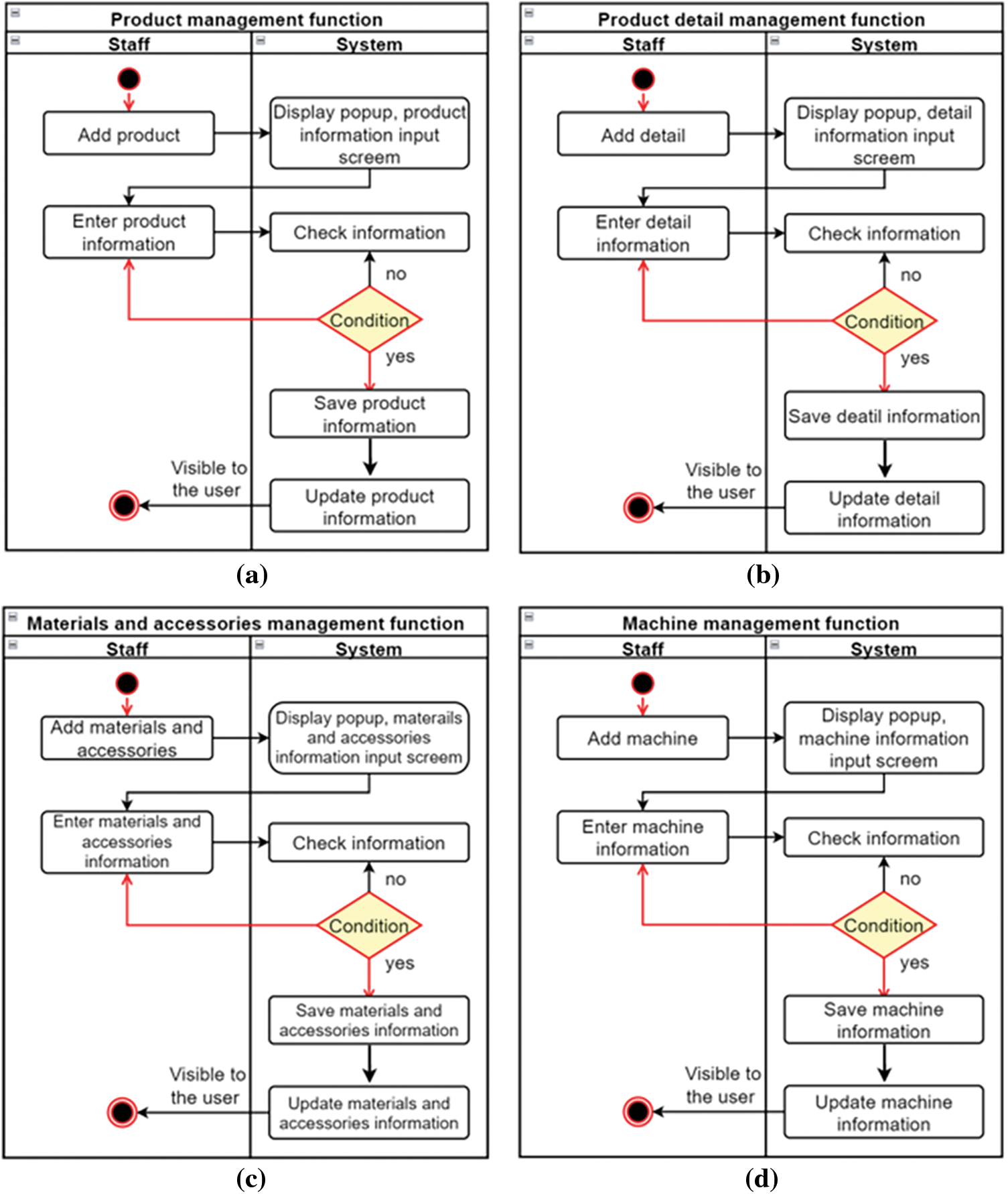

Product, materials and accessories, and machine management functions were specified in Fig. 3.

Figure 3: Schematic figure of operational specifications (a) Product management function, (b) Functional specification of adding product, (c) Materials and accessories management function, and (d) Sewing equipment management function

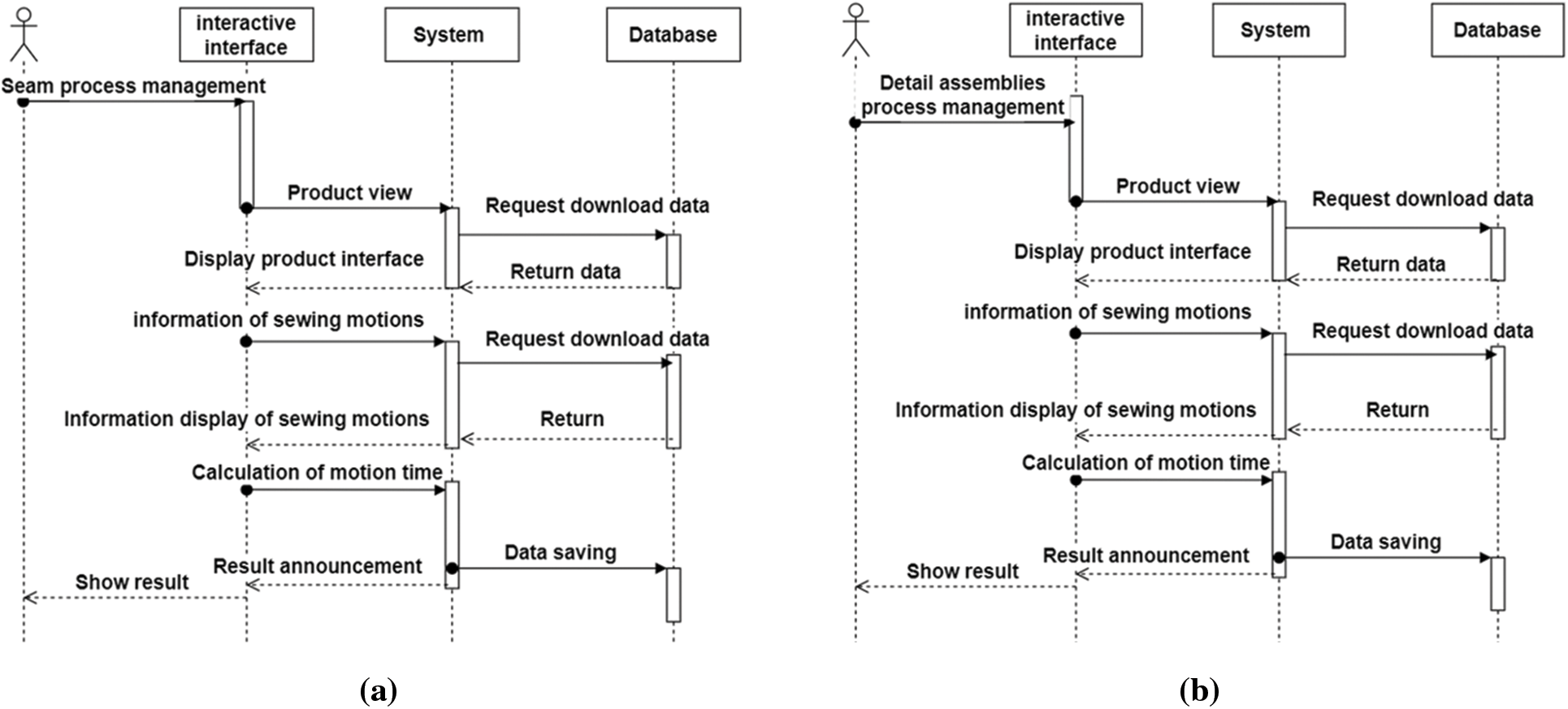

The function of managing the technological process of sewing products was drawn in Fig. 4, which are divided into seam types, detailed assemblies, performing time.

Figure 4: (a) Managing the technological process of seam types, motion process, and sewing time, (b) Managing detailed assemblies, motion processes, and sewing time

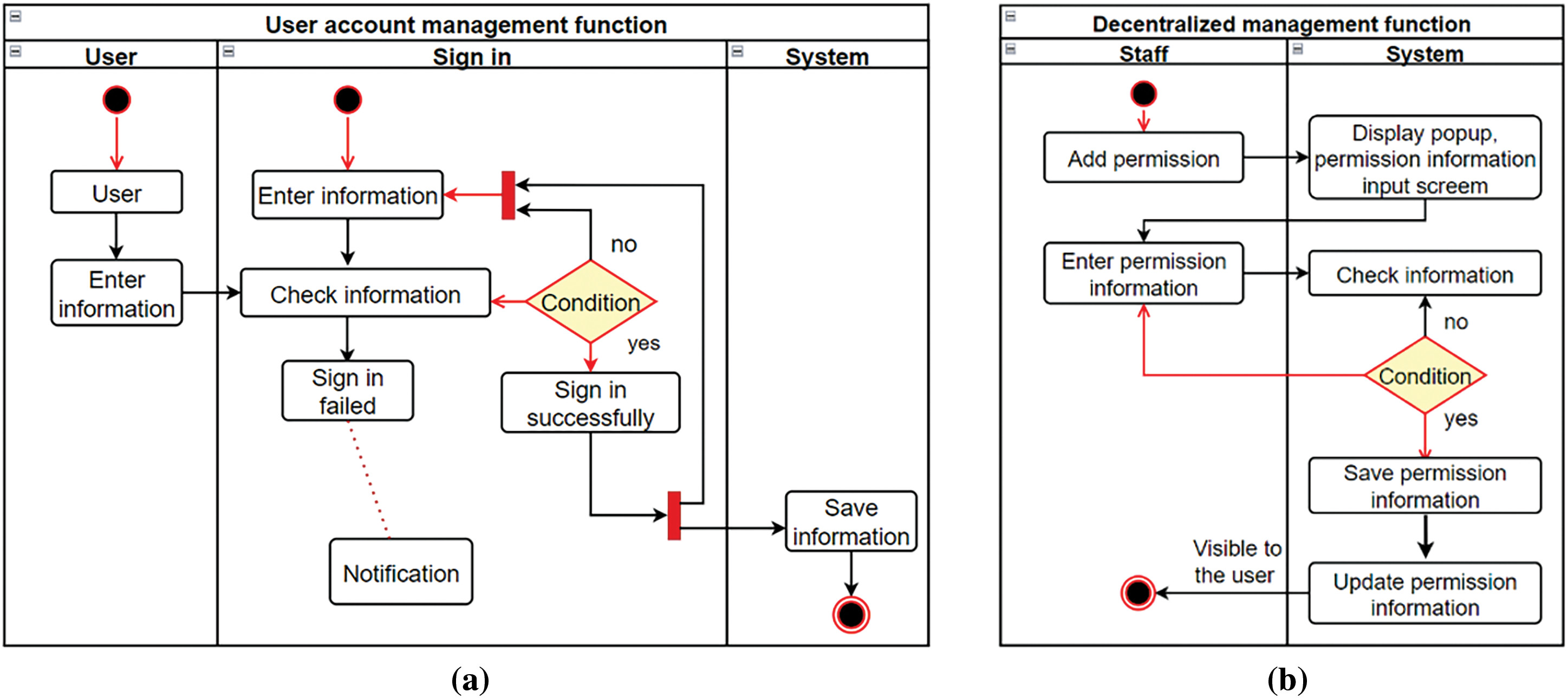

Other management functions were listed in Fig. 5.

Figure 5: Schematic figure of other management functions (a) User account management function and (b) Decentralization management function

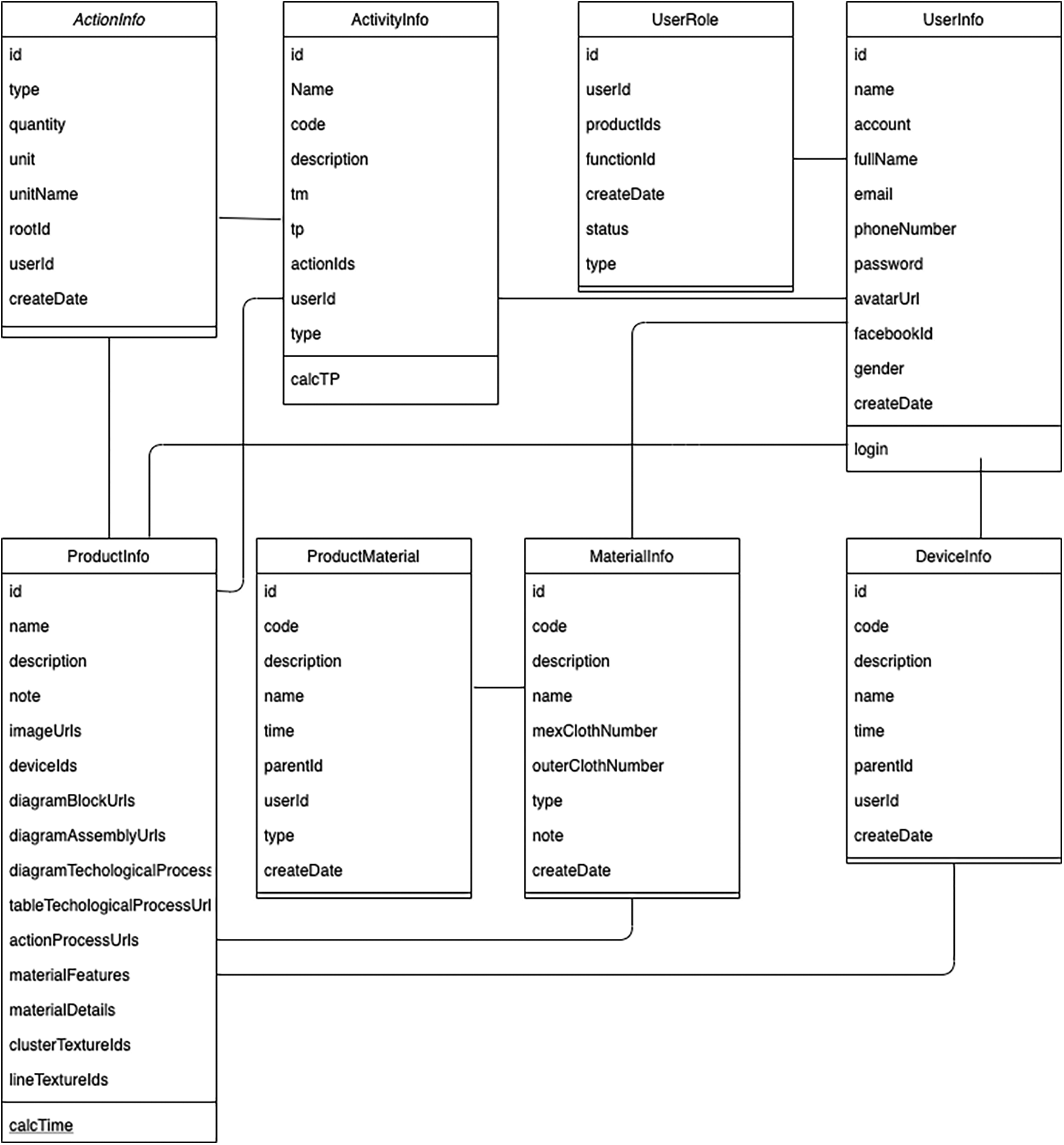

Class diagrams were divided into ActionInfo class, ActivityInfo class, UserRole class, UserInfo class, ProductInfo class, ProductMaterial class, MaterialInfo class, MaterialInfo class, and DeviceInfo class (Fig. 6). ActionInfo class is the total time to perform an action of a product. Information about seams, detailed assemblies, save information of code motions, such as “Holding 2 separate pieces” code is MG2S, coefficient 0.5, the time factor is 107. ActivityInfo class is information about the execution time of the action. Information about machine uptime is used to store a large activity that includes small actions. UserRole class is used to store user rights information. UserInfo class stores information of user accounts, in order to log in to the system. ProductInfo class stores product information. Similarly, ProductMaterial class stores information about materials and accessories. DeviceInfo class stores information about sewing equipment, machine specification performed in the sewing process.

Figure 6: Class diagram of entire relation

The results of the correlation analysis between the analysis data of the sewing process and the actual sewing time of 2 knitted products, Polo-Shirt and T-Shirt, at General Textile Garment Joint Stock Company Hanoi and Star Fashion Company Limited show that experimental data from the software presents very high correlation coefficients R, more than 0.9. The initial research results show that the Software for Analyzing the Sewing Process of Knitted Products established by the research team is capable of providing solutions for investigating the sewing process, calculating the sewing operation time in fast responses with high reliability and accuracy, and meets the requirements of users. Besides, the design software program has an intuitive, simple, friendly and convenient interface for users, supporting displaying and storing analysis and calculation results on the computer. In the future, the research team will continue to test the software for actual production orders with a larger number of random samples and a more diverse product range in order to perfect the features of the software towards technology transfer for industrial production.

In this study, the software to analyze the sewing operations of the production line was built with significant control over multiple aspects including materials and accessories, seams, motions, and machines. The data collected from previous studies were established into the big data of the software for further development into AI technology for line balancing problems. For the current form, line managing engineers can select appropriate methods and techniques in this designed software for analyzing the sewing process of knitted products applied in industrial production. With a friendly interface, and the design of complete and detailed modules, the design software makes it convenient and effective to manage the database of sewing products. The new setup software applies and covers the development of a sewing database for 2 types of knitted products, Polo-Shirt and T-Shirt, which were tested at 2 Vietnamese garment enterprises are General Textile Garment Joint Stock Company Hanoi and Star Fashion Company Limited. In the near future, the research team will develop AI technology and enlarge the big data system for more diverse forms of production from business organizations. It can be affirmed that these are significant initial research results, which have achieved certain success, contributed to promoting digital transformation in the garment industry to build a systematized database, standardize workers’ labor activities helping Vietnamese garment companies to develop sustainably in the trend of integration and globalization.

Acknowledgement: We would like to thank the Hanoi Department of Science and Technology, Hanoi University of Science and Technology for supporting us in completing this study

Funding Statement: This study was carried out within the framework of the topic Science and Technology 01C–02/04–2019–3.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. F. B. Alam and M. M. Hasan, “Analysis on SMV to increase productivity in sewing section: A case study on T-shirt manufacturing in Bangladesh,” International Journal of Research in Engineering and Science, vol. 6, pp. 18–24, 2018. [Google Scholar]

2. H. Rahman, P. K. Roy, R. Karim and P. K. Biswas, “Effective way to estimate the standard minute value (SMV) of a t-shirt by work study,” European Scientific Journal, vol. 10, no. 30, pp. 196–203, 2014. [Google Scholar]

3. W. K. Jung, H. Kim, Y. C. Park, J. W. Lee and S. H. Ahn, “Smart sewing work measurement system using IoT-based power monitoring device and approximation algorithm,” International Journal of Production Research, vol. 58, no. 20, pp. 6202–6216, 2020. [Google Scholar]

4. G. Elnaggar, “Effect of operator skill level on assembly line balancing in apparel manufacturing: A multi-objective simulation optimization approach,” in Proc. of the Int. Conf. on Industrial Engineering and Operations Management, Saudi Arabia, pp. 308–315, 2019. [Google Scholar]

5. V. T. Nhu and T. P. Thao, “Research on solutions to improve labor productivity by improving motions and working speeds of the sewing workers,” Vietnam Mechanical Enginering Magazine, vol. 3, no. 3, pp. 160–168, 2014. [Google Scholar]

6. T. P. Thao and T. L. Trang, “Building standard operating procedures for sewing the main sub-assemblies of knitted products,” in The 1st National Scientific Conf. on Textile, Apparel and Leather Engineering, Agricultural Academy Publisher, Hanoi, Vietnam, pp. 183–194, 2018. [Google Scholar]

7. M. D. Huong and T. P. Thao, “Study on the influence of some factors on sewing conditions to the time of sub-processing of knitting garment workers by MTM method and general sewing data,” in Proc. of the 5th National Conf. on Mechanical Science & Technology, Hanoi Scientific and Technical Publisher, Hanoi, Vietnam, pp. 1492–1499, 2018. [Google Scholar]

8. R. Prodan, M. Sperk and S. Ostermann, “Evaluating high-performance computing on google app engine,” IEEE Software, vol. 29, no. 2, pp. 52–58, 2011. [Google Scholar]

9. E. Bisong, “An Overview of Google Cloud Platform Services. Building Machine Learning and Deep Learning Models on Google Cloud Platform,” Berkeley, CA, Apress, pp. 7–10, 2019. [Google Scholar]

10. C. J. Moin, F. Sarwar and A. S. Doulah, “Investigation of a hybrid production system for mass-customization apparel manufacturing,” Journal of Textile and Apparel, Technology and Management, vol. 8, no. 3, pp. 1–10, 2013. [Google Scholar]

11. S. P. T. Krishnan and J. L. U. Gonzalez, “Building Your Next big Thing with Google Cloud Platform: A Guide for Developers and Enterprise Architects,” Berkeley, CA, Apress, 2015. [Google Scholar]

12. J. Denemark, L. Matyska, M. Ruda, M. Jankowski, N. Meyer et al., “User management for virtual organizations,” Integrated Research in GRID Computing, Springer US, ISBN 978-0-387-47656-8, pp. 135–146, 2007. [Google Scholar]

13. J. Wang, J. Zhou, R. Gu, M. Chen and P. Li, “Manage system for internet of things of greenhouse based on GWT,” Information Processing in Agriculture, vol. 5, no. 2, pp. 269–278, 2018. [Google Scholar]

14. A. Grosch, M. Waldmann, J. H. Göbbert and A. Lintermann, “A Web-based service portal to steer numerical simulations on high-performance computers,” in European Medical and Biological Engineering Conf., Springer, Cham, pp. 57–65, 2020. [Google Scholar]

15. S. Lee, S. Rho, D. Lim and W. Jeong, “A basic study on establishing the automatic sewing process according to textile properties,” Processes, vol. 9, no. 7, pp. 1206–1224, 2021. [Google Scholar]

16. M. Battarra, F. Fraboni, O. Thomasson, G. Erdoğan, G. Laporte et al., “Algorithms for the calzedonia workload allocation problem,” Journal of the Operational Research Society, vol. 72, no. 9, pp. 2004–2017, 2021. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |