| Energy Engineering |  |

DOI: 10.32604/EE.2021.013888

ARTICLE

Optimum Calculation of Coal Pillars in Inclined Weathered Oxidation Zone

1College of Water Resources and Architectural Engineering, Northwest A&F University, Yangling, 712100, China

2Key Laboratory of Agricultural Soil and Water Engineering in Arid and Semiarid Areas, Ministry of Education, Northwest A&F University, Yangling, 712100, China

*Corresponding Author: Shi Chen. Email: chensun2006@nwafu.edu.cn

Received: 25 August 2020; Accepted: 23 November 2020

Abstract: In the mining process of coal mine, waterproof coal pillars should be set between the weathered oxidation zone and the first mining face. In order to determine the reasonable upper limit of the first mining face of Hongyi Coal Mine, the waterproof coal pillar needs to be wide enough to resist the lateral hydrostatic pressure of the oxidation zone, and to ensure that the top plate aquifer does not run through the water guide crack zone, while also liberating as much stagnant coal as possible. In this paper, the first coal mine face’s waterproof coal pillar was calculated using conventional and optimized calculation methods, taking into account the dip angle of the coal seam, the height of the water-guide crack zone, and the rock shift influence zone, and finally the upper limit of the first face of Hongyi Coal Mine was determined.

Keywords: efflorescent oxygenized belts; upper limit; water flowing fractured zone; waterproof pillar

Hongyi Coal Mine in Hongdunzi Mine (hereinafter referred to as Hongyi Mine) is a newly-built mine of China Power Investment Corporation Ningxia Qingtongxia Energy Aluminum Group Co., Ltd., China. It is located in Hongdunzi Mine, Xingqing District, Yinchuan City. The first coal mining face is 1150401 working face of No. 4 Coal Group. The average thickness of the coal seam is about 2.2 m. The elevation of the coal seam is decreasing from west to east, and the inclination angle is 15–25°. In the early exploration, it was found that there is a coal seam wind oxidation zone on the west side of the first mining face. The wind oxidation zone is replenished by the Paleogene aquifer, and it is very rich in water, which will threaten the recovery safety of the first mining face. On the other hand, the water conduction fracture zone may extend to the Paleogene aquifer in the roof after the first mining face. Therefore, it is necessary to keep a certain distance between the coal seam aeration zone and the first coal mining face.

The determination of the upper limit coal pillar for coal mining is closely related to the thickness, distance, water richness, and height of water-conducting fracture zone of the overlying aquifer [1]. In addition, the mechanical properties of the rock layer, the mining method of the coal seam, the strength of the coal seam itself, and the mechanical parameters of the roof and floor also affect the determination of the upper limit of mining [2–4].

The first mining face of Hongyi Coal Mine is close to the aeolian oxidation zone and the roof is close to the water-rich Paleogene aquifer. The determination of the upper mining limit of the first mining face needs to consider both the height of the impermeable coal rock pillar and the water conduction crack zone. In this paper, while using the calculation of conventional drainage coal pillars, a new method to optimize the retention of waterproof coal pillars is adopted [5–8]. On the premise of ensuring safe mining, the new calculation method can increase the height of upper mining limit, reduce the waste of coal resources, increase the production rate of mining area, and extend the service life of the mine [9–12].

The Hongyi well field is located in the arid region of the northwest, with sparse precipitation. The surface water system in the well field is not developed, and the perennial rivers are small. The larger gully in the area is the northern gully, because the flow is very small, it has little effect on coal mining. Therefore, the main threat to the mine comes from the groundwater aquifer. Due to the high water pressure in the groundwater, coupled with the mining pressure relief of the mine and the secondary mining cracks caused by the damage to the floor, the high pressure Groundwater may be bulged in the relatively weak section of the floor.

The direct water-filled aquifer in the mine includes the Shanxi Formation fissure aquifer group, the Taiyuan Formation sandstone fissure aquifer group. Whether the mine water-filled water source can enter the mine depends on structural conditions, coal burial conditions, stability and water-resistance of the aquifer, and faults and mining fractures.

Hongyi Coal Mine, as the first mining well in Hongdunzi Mine, is still in a natural state due to the presence of groundwater.

The coal stratum in the mine field belongs to the Carboniferous Permian system. The upper 4 coals and 5 coals were mined in the initial stage of the mine, and the 1150401 working face of the 4 coal group was designated as the first mining face.

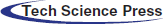

As shown in Fig. 1, the main aquifer affecting the recovery of No. 4 coal and No. 5 coal in Hongyi Mine is the pore fissure aquifer in the Paleogene bedrock weathering zone. The aquifer is composed of various grades of sand in the Paleogene and semi-cemented sandstone conglomerates at the bottom and sandstones of different grades in the weathering zone of the bedrock.

Figure 1: Schematic diagram of the positional relationship between coal seam and water-bearing layer

According to the statistics of drilling data during exploration, the distance between No. 4 coal roof and the Paleogene aquifer is 98–440 m. By calculating the height of the head of the aquifer, the conversion shows that when the aquifer is connected to No. 4 coal through the water guide channel, the head pressure of No. 4 coal roof will be between 5.3 and 7.3 Mpa. The average thickness of the No. 4 coal seam is about 1.7 m, the inclination angle is 15–25°, the mining height is considered as 2.2 m, and the working face length and width is 210 m × 2066 m. For the calculation of upper limit of the first mining face, the waterproof coal (rock) pillar must be calculated first.

3 Routine Calculation of Anti-Waterproof Coal (Rock) Pillar

3.1 Calculation of Vertical Height of Water Conducting Crack Zone and Water-Proof Coal (Rock) Pillar

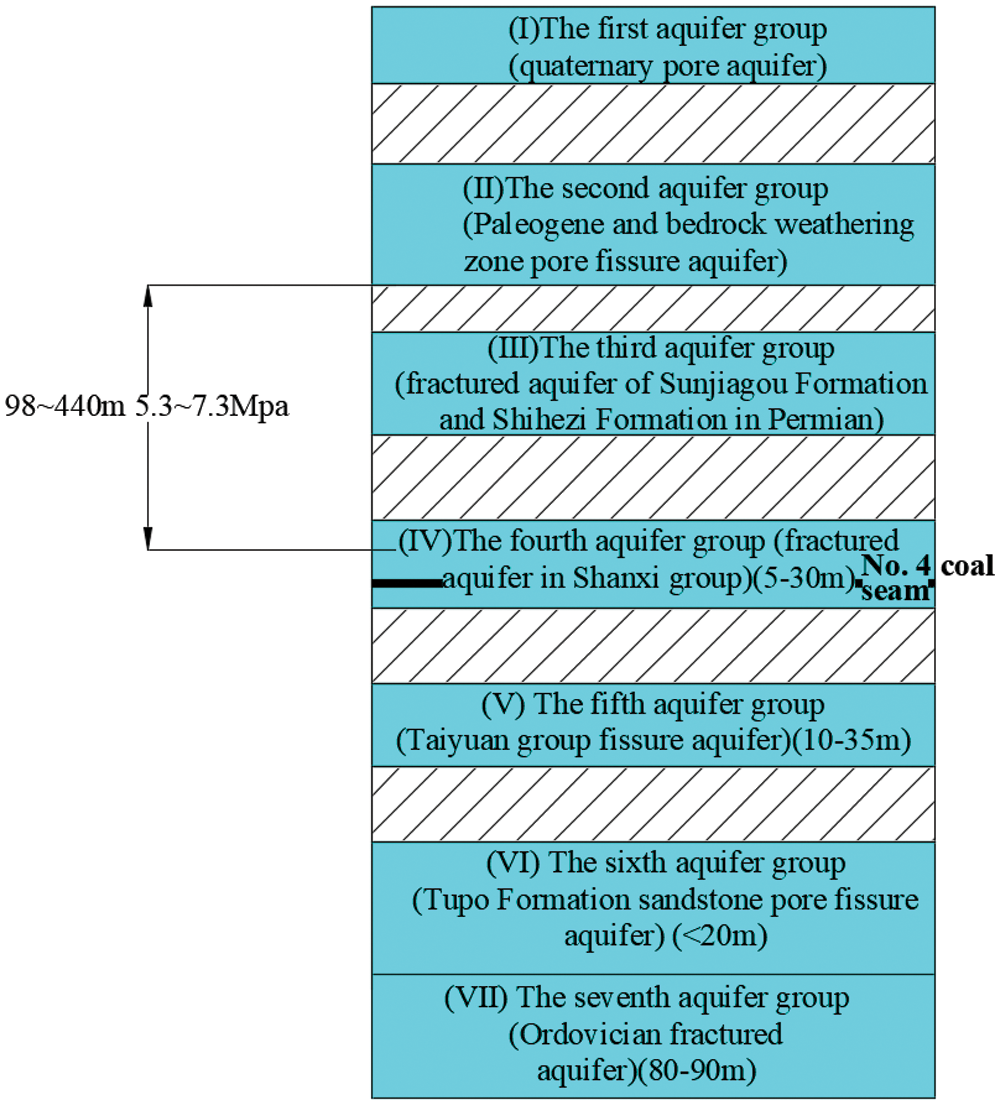

As shown in Fig. 2, when a coal seam outcrop is covered by a loose water-rich aquifer, the water-proof coal (rock) pillar can be calculated as follows:

In the formula:

Figure 2: Retaining figure of water-proof coal (rock) pillars when coal seam outcrop is covered by loose water-rich strong aquifer

1–Water conduction crack zone affected area. 2–The area affected by the cavitation zone. 3–The goaf.

According to the classification standards in The Regulations on Coal Mine Water Prevention and Control, the lithology of the roof should be calculated according to the medium and hard when calculating the height of the water-conducting fracture zone of the coal direct roof.

Therefore, the height of the water conduction crack zone should be calculated as follows:

In the formula:

According to the “Code for the Preservation and Pressing of Coal Pillars in Buildings, Water Bodies, Railways and Main Wells and Roadways,” the vertical height of water-proof coal (rock) pillars is calculated as follows:

In the formula:

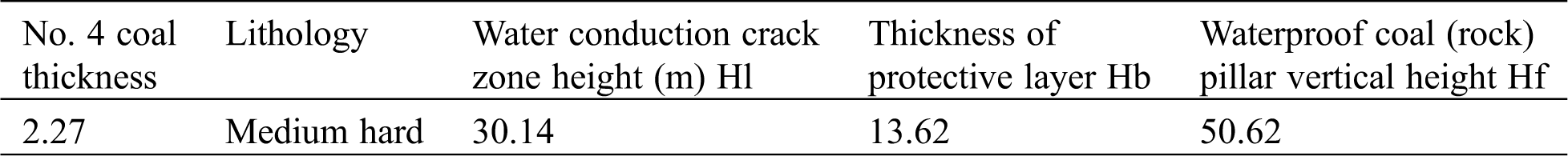

Table 1: Calculation table of vertical height of Waterproof Coal (Rock) pillar

According to the conventional calculation method, and the vertical height of the anti-waterproof coal (rock) pillar is 50.62 m.

3.2 Calculation of Slant Length of Anti-Waterproof Coal (Rock) Pillar

According to the “Preliminary Design Specification for Hongyi Coal Mine of Hongdunzi Coal Mining District of Ningxia Qingtongxia Energy Aluminum Group Co., Ltd., of China Power Investment Corporation”, the inclination angle of No. 4 and No. 5 coal seams is 15–25°, which is a gently inclined seam. Therefore, the inclination angle of coal seam is 15°.

The oblique length of coal pillar:

The width of coal pillar in the horizontal direction:

4 Optimal Calculation of Water-Proof Coal (Rock) Pillars

4.1 Principle of Optimization of Water-Proof Coal (Rock) Pillar

In order to design more scientifically and rationally waterproof coal pillars, the following principles must be followed in the optimization calculation:

(1) The retention design of waterproof coal pillars must consider various factors, such as geological structure, hydrogeological conditions, coal seam occurrence conditions, coal physical, mechanical properties, and roof management methods, which affect the stability of the coal pillars.

(2) In general, it is considered as a homogeneous in the design of coal pillars. Sometimes, the strength parameters are reduced according to the crushing of the coal bodies by structural action, but there are vertical water channels or unknown in the coal bodies. The situation of other water-bearing bodies should be solved through the exploration of specific water-filling conditions. This part of the content has exceeded the scope of coal pillar design. But this is an important aspect that must be fully considered in production.

The design of the waterproof coal (rock) pillar between the first mining face of Hongyi Mine and the boundary of the aerobic zone should consider the destruction of coal mining. For the coal pillar near the stope, due to the action of abutment pressure, the coal seam will produce a crack, forming a yield zone, and then become a strong permeability zone. This part of coal body has lost a large part of the water insulation ability, and becomes the coal pillar residual reserve zone which can hardly be water insulation, and it is the middle part of coal pillar that really plays the role of water insulation.

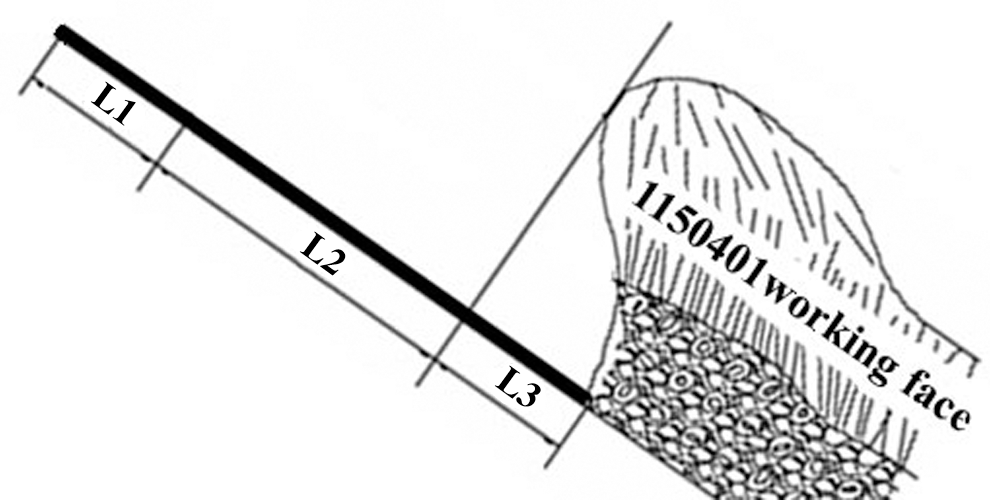

Therefore, the coal pillars between coal mines are composed of three parts (as shown in Fig. 3), L1–The influence zone width of the wind oxidation zone, L2–The width of the middle belt of the coal pillars, and L3–The influences zone width of rock movement on the first mining face.

Figure 3: Coal pillar rock movement influence zone and its intermediate zone

4.2 Optimal Calculation Method of Anti-Waterproof Coal (Rock) Pillar

The influence zone width (L1) of the wind oxidation zone has been delineated by the exploration report.

1. Determination of calculation formula

There are two ways to calculate the width of the middle belt of the coal pillars.

(1) Formula derived from theory

This formula can be used to calculate the width of coal pillar subjected to hydrostatic pressure laterally, which derived from the principle of simply supported beam of material mechanics.

In the formula:

(2) The empirical formula for verification

In the formula:

2. Parameter determination

Considering that the hydrogeology and structure exploration work in this area is relatively weak, so the safety factor (K) is 5;

The tensile strength of coal seam (Kp) is 0.2 MPa;

During the hydrogeological supplementary exploration, the sandstone aquifer on the roof of the working face was observed;

The water burst coefficient (Ts) is 0.06.

Boreholes H101, H102, 2401, H201, H202, HK501, HK502 around the No. 1150401 working face of No. 4 coal seam can be used as the reference for calculating the parameter value. The static water level elevation of H202 is +12030.720 m, No. 4 coal seam seam roof Depth of H202 is +572.37 m, drilling elevation of H202 is +1209.285 m. Therefore, the maximum water head pressure on the coal pillar, that is, the water pressure on the coal pillar in the mining area is 5.67 MPa;

3. The calculation results

According to the above parameters, the calculation is carried out by using Formulas 6 and 7, and the larger value of the two results is taken, so the width of the middle belt of the coal pillars(L2) is 104.5 m.

1. Determination of calculation formula

The influence zone width (L3) of rock movement on the first mining face can be determined by calculating the distance of overburden movement and the height of roof water-conducting fracture zone.

The influence zone width (L3) of rock movement on the first mining face:

In the formula:

2. Parameter determination

The height of the water conduction fracture zone is calculated according to Tab. 1, and the Hf is 50.62 m. According to the test, the collapse angle of the first coal mining face is smaller, the δ is 37°.

3. The calculation results

The influence zone width (L3) of rock movement on the first mining face:

4.2.4 Calculation of Waterproof Coal (Rock) Pillar

1. Determination of the width of waterproof coal pillars

2. Determination of the upper limit of mining

The lower limit elevation of the aeolian oxidation zone adjacent to the first mining face is about +780 m. According to the above calculation results, it is determined that the width of the coal pillar in the horizontal direction of the first mining face should be greater than 165.83 m, and the upper limit elevation of the mining face is +735.57 m.

In this paper, the waterproof coal pillar of the first working face of Hongyi mine is designed by using the conventional calculation method. Then, the influence of mining on coal pillar is considered comprehensively, and the coal pillar is calculated piecewise. In this method, the width of the affected zone is not considered as the width of the yield zone in a general way, which reduces the width of the required coal pillar, increase the upper limit of mining, and recover a large amount of stagnant reserves from the originally designed waterproof coal pillars for Hongyi Coal Mine. It was finally determined that the width of the coal pillars in the horizontal direction of the first mining face should be greater than 165.83 m, and the upper limit of the mining height is +735.57 m. The calculation results and methods in this paper provide a general reference value for the upper limit design of stoping on other working surfaces near the wind oxidation zone.

Funding Statement: This work is supported by the Open Fund of State Key Laboratory of Water Resource Protection and Utilization in Coal Mining (Grant No. GJNY-18-73.15), the National Natural Science Foundation of China (NSFC) under grant No. 41602254, the National Natural Science Foundation of China (NSFC) under grant No. 41807221, the Science and Technology Innovation Project of Northwest A&F University, the Double-Class Discipline Group Dry Area Hydrology and Water Resources Regulation Research funding project (Z102022011), and the Special Funding Project for Basic Scientific Research Business Fees of Central Universities (2452016179).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Booth C. J. (1986). Strata-movement concepts and the hydrogeological impact of underground coal mining. Ground Water, 24(4), 507–515. DOI 10.1111/j.1745-6584.1986.tb01030.x. [Google Scholar] [CrossRef]

2. Zhang, R., Liang, X., Jin, M., Wan, L., Yu, Q. (2011). Fundamentals of hydrogeology. Beijing: Geological Publishing House. [Google Scholar]

3. Lobe, I., Sandhage-Hofmann, A., Brodowski, S., Du Preez, C. C., Amelung, W. (2011). Aggregate dynamics and associated soil organic matter contents as influenced by prolonged arable cropping in the South African Highveld. Geoderma, 162(3–4), 251–259. DOI 10.1016/j.geoderma.2011.02.001. [Google Scholar] [CrossRef]

4. Jichun, W., Yu-qun, X. (2009). Groundwater dynamics. Beijing: Geological Publishing House. [Google Scholar]

5. Yan, Z. G., Du, P. J., Guo, D. Z. (2007). SVM models for analyzing the headstreams of mine water inrush. Journal of China Coal Society, 32, 842–847. [Google Scholar]

6. Casasent, D., Wang, Y. C. (2005). A hierarchical classifier using new support vector machines for automatic target recognition. Neural Networks, 18(5–6), 541–548. DOI 10.1016/j.neunet.2005.06.033. [Google Scholar] [CrossRef]

7. Yang, Y. G., Huang, F. C. (2007). Water source determination of mine inflow based on non-linear method. Journal of China University of Mining & Technology, 36(3), 283–286. [Google Scholar]

8. Guo, G., Wang, S., Sun, X., Zhao, X. H. (2009). Ultrasonic double exponential model and its parameter determination. Acta Electronic Sinica, 37(7), 1501–1504. [Google Scholar]

9. Sun, L., Gui, H. (2015). Source quantification of major ions in groundwater and hydrological implications: Liuqiao case study. Electronic Journal of Geotechnical Engineering, 20(5), 1791–1800. [Google Scholar]

10. Subramanya, K. (2013). Engineering hydrology,vol. 4e.New Delhi: Tata McGraw-Hill Education. [Google Scholar]

11. Wei, G., Zhou, Z., Guo, Y., Dong, Y., Dang, H. et al. (2014). Long-term effects of tillage on soil aggregates and the distribution of soil organic carbon, total nitrogen, and other nutrients in aggregates on the semi-arid loess plateau. China Arid Land Research and Management, 28(3), 291–310. DOI 10.1080/15324982.2013.845803. [Google Scholar] [CrossRef]

12. Wu, Q., Guo, X., Shen, J., Xu, S., Liu, S. et al. (2017). Risk assessment of water inrush from aquifers underlying the Gushuyuan coal mine. China Mine Water and the Environment, 36(1), 96–103. DOI 10.1007/s10230-016-0410-8. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |