| Energy Engineering |  |

DOI: 10.32604/ee.2022.015982

ARTICLE

Dynamic Simulation and Performance Analysis on Multi-Energy Coupled CCHP System

1State Grid Economic and Technological Research Institute Co., Ltd., Beijing, 102209, China

2Qingdao University of Technology, Qingdao, 266033, China

*Corresponding Author: De-gejirifu. Email: dove@ncepu.edu.cn

Received: 29 January 2021; Accepted: 08 April 2021

Abstract: Although the Combined Cooing, Heating and Power System (hereinafter referred to as “CCHP”) improves the capacity utilization rate and energy utilization efficiency, single use of CCHP system cannot realize dynamic matching between supply and demand loads due to the unbalance features of the user’s cooling and heating loads. On the basis of user convenience and wide applicability of clean air energy, this paper tries to put forward a coupled CCHP system with combustion gas turbine and ASHP ordered power by heat, analyze trends of such parameters as gas consumption and power consumption of heat pump in line with adjustment of heating load proportion of combustion gas turbine, and optimize the system ratio in the method of annual costs and energy environmental benefit assessment. Based on the analysis of the hourly simulation and matching characteristics of the cold and hot load of the 100 thousand square meter building, it is found that the annual cost of the air source heat pump is low, but the energy and environmental benefits are poor. It will lead to 6.35% shortage of cooling load in summer. Combined with the evaluation method of primary energy consumption and zero carbon dioxide emission, the coupling system of CHHP and air source heat pump with 41% gas turbine load ratio is the best configuration. This system structure and optimization method can provide some reference for the development of CCHP coupling system.

Keywords: CCHP (Combined Cooling, Heating and Power System); ASHP (Air Source Heat Pump); annual costs; absorption cooling; transient simulation

CCHP is a multi-energy combined supply system that is built on the basis of energy gradient utilization in compliance with annual diverse load demands of the users [1]. Compared with traditional cooling, heating and power distributed supply equipment, CCHP system is of great significance in high-efficiency, low consumption, energy conservation and emission reduction [2–3], which improves the equipment utilization rate and energy utilization efficiency. The characteristics of its energy system are mainly manifest in energy gradient utilization and contaminant emissions, which reflects the major development direction of future energy technology [4], and has become an important way to solve energy and environmental difficulties that all national governments and energy experts focus on. The US government has listed into its long-term development plan further enhancement of “distributed and combined heating and power system”, and plans to improve the utilization ratio of distributed energy technology of fuel gas in new office buildings or commercial blocks to 50%, installed power-generating capacity newly increases by 95 GW, covering 29% of total electricity consumption in the country [5]; some countries and regions like Japan and EU promote the conducts of CCHP system by means of policy measures such as legislation, tax reduction, etc. [4,6].

Meanwhile, renewable energy technology cannot take the place of traditional technology completely and economically in the near future, so most prime power technologies are still based on fossil fuel combustion. Therefore, CCHP technology provides a reliable and stable energy supply transition system for the world [1]. However, due to the unbalance feature of cooling and heating loads of regional users, single use of CCHP system supply cannot realize dynamic matching of supply and demand loads. At present, the optimum configuration of CCHP system has become one of the research focuses, and Gao et al. [2] took the energy accumulation measure by phase change to adjust peak load, and optimize the system operation strategy enabling the combustion turbine to operate at full load and in combination with controls of start and stop. Smith et al. [7] built a conceptual prototype with unified operation of combined heating and power system and heat pump, validated energy-saving, economical and stable features of system operation by means of exergy analysis, and overcome some drawbacks of household CHP system; M´iguez et al. [8,9] optimized the reciprocating internal combustion engine (RIC) system, coupled it with steam compression heat pump, and recycled the cylinder sleeve for cooling water heat to achieve CCHP; Cardona et al. [10] studied the operating economy and environmental benefits of hot pump (HP) in combination with CCHP system, and introduced SP factor (compare electrovalence and fuel price required to generate unit electricity) to determine the operation mode and system configuration. Huang et al. [11] explored the water-saving, environmental protection and economical features of the operation mode in sewage source heat pump (SSHP) + CCHP system; Wang et al. [12], Zhang [13] further optimized CCHP system configuration, combined it with ground source heat pump (GSHP) and water source heat pump (WSHP), and realized complementary multi-energy supplies. In order to realize deep recycling of waste heat of exhaust gas, Hong et al. [14] proposed a coupled ASHP + CCHP system, and analyzed the influence of recoverable waste heat in the system, coefficient of performance (COP) of heat pump and primary energy ratio; Zhang et al. [15] found that the overall performance of CCHP + GSHP is the optimum after comparative studies, overall annual cost-saving ratio is 0.1582, and CO2 emission reduction ratio is 0.5278; Rong et al. [16] established the optimization model of the coupled CCHP-GSHP system, and adopted the genetic algorithm to optimize the system capacity and operation with variables rated generated capacity of generator set, the GSHP cooling capacity to total cooling load ratio and GSHP heating and total thermal load ratio; Jiang et al. [17] studied the influence of different energy conservation technologies on energy-saving rate (ESRs) of CCHP system, and presented upper and lower limit values of energy utilization efficiency.

All the above studies have built multi-energy coupling cooling, heat and power co-generation systems, and obtained the optimal ratio and operation mode of the coupling system through optimization, which also highlights the limitations of multi-energy co-generation with a single device and proves the superiority of multi-energy coupling co-generation system. However, most of the above studies take fixed working conditions as the research object and do not reflect the dynamic change of load demand. At the same time, it does not take into account that the operating conditions of the equipment are different with the change of meteorological conditions and load rate, so the above research results have certain limitations.

In this paper, a hybrid power supply system based on gas turbine and air source heat pump is proposed. In order to reflect the dynamic change of load and the influence of meteorological parameters on the system, a transient simulation model of the system was built on TRNSYS platform for simulation calculation. Taking the annual cost as the optimization objective function, combined with the evaluation method of primary energy consumption and zero carbon dioxide emission, the optimal system ratio was explored.

2 Operation Plan of Complementary Coupled Multi-Energy Supply System (ASHP and CCHP)

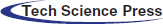

According to the complementary multi-energy theory, the integrated energy system is modelled and optimized in line with load classification and independent supply, with transient cooling, heating and power quantity as known quantity, annual costs and economic benefits of energy as target parameters, in order to adjust preset variables, optimize matching ratio of energy equipment, and realize the optimum target value. Please see the aspect energy optimization logic in Fig. 1.

Figure 1: Optimization logic diagram of integrated energy system

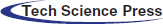

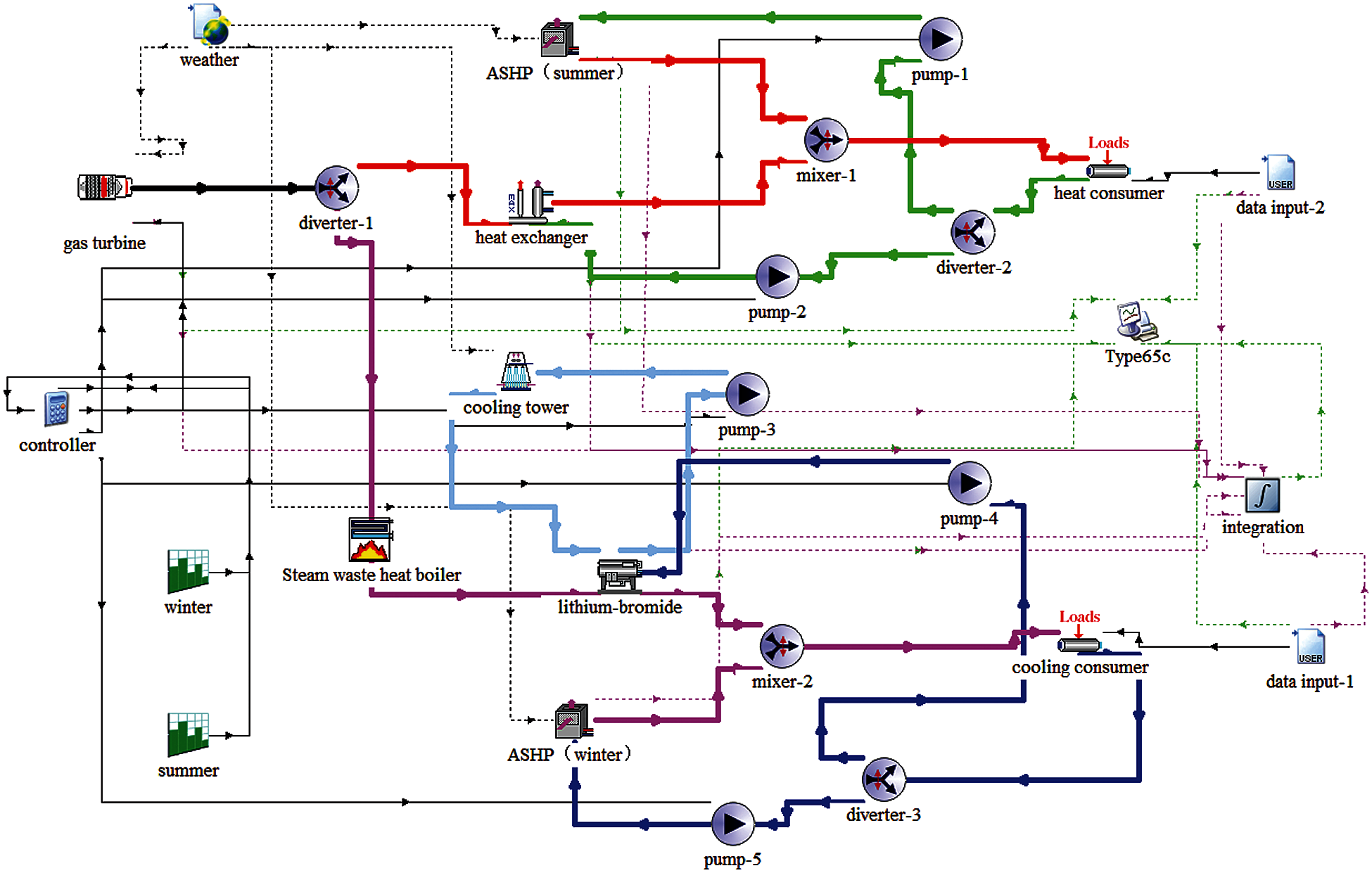

The schematic diagram of CCHP and ASHP system plan is shown as Fig. 2. As for waste heat of exhaust gas after the combustion gas turbine generates, hot and cold water are respectively produced by heat exchanger and gas-hot water lithium bromide unit in winter and summer, and insufficient heat and cooling capacities supplied by the turbine is complemented by ASHP. In order to study the dynamic features of cooling and heating loads, this paper adopts hourly cooling, heating and power loads all around the year and transient calculation model to analyze the economical efficiency of CCHP and ASHP system plan on the basis of TRNSYS software. Please see the TRNSYS system transient model in Fig. 3.

Figure 2: Scheme of CCHP + ASHP system

Figure 3: TRNSYS transient simulation model

3 Key Equipment in the System and Target Optimized Mathematical Model

The relation between the power generation of the gas turbine and the residual heat of flue gas and the heat of the input fuel at any time is as follows:

According to gas turbine data of a typical brand, the relationship between gas turbine power generation, outdoor air temperature and residual heat of flue gas is obtained by fitting as follows:

where,

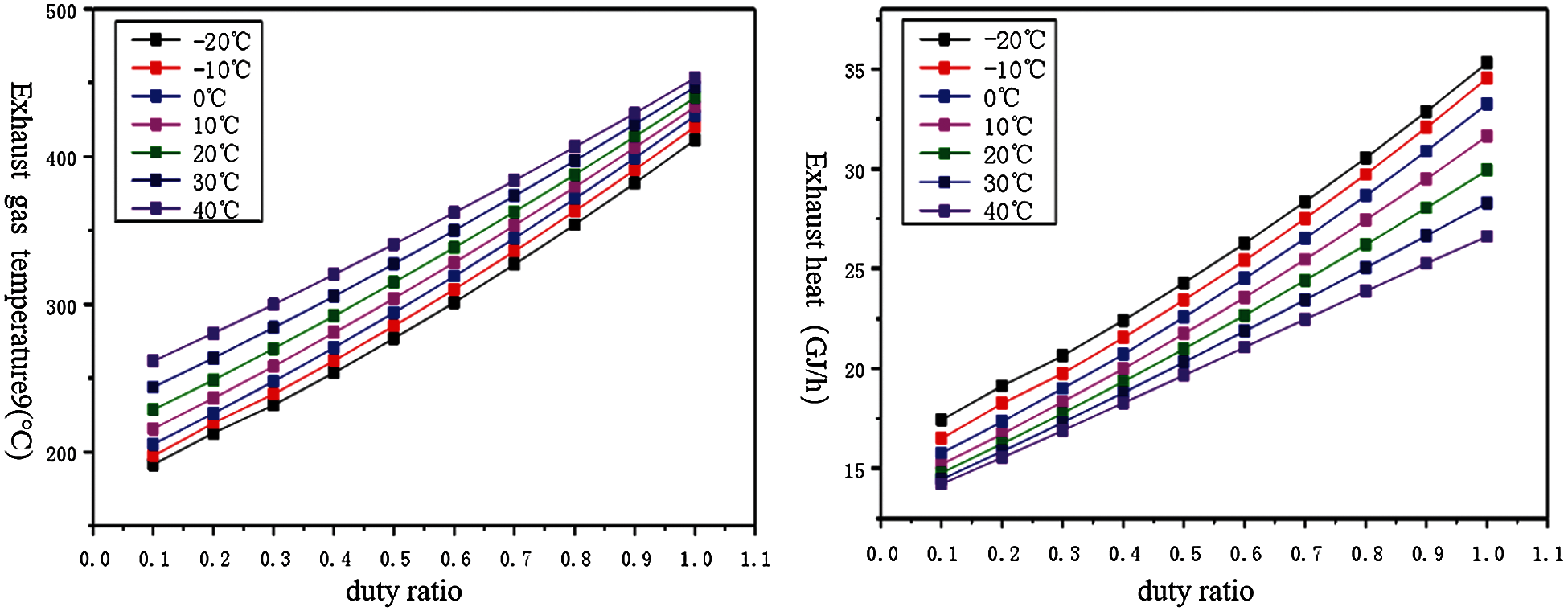

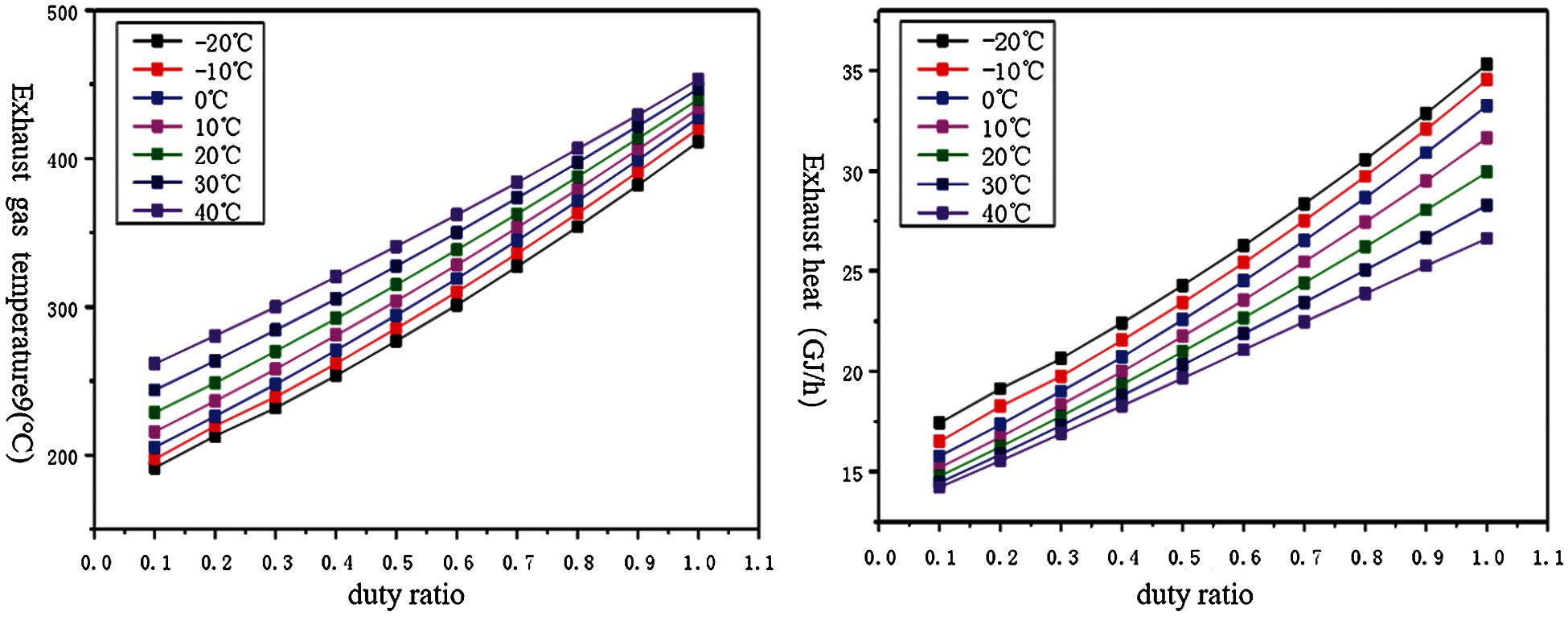

When the gas turbine runs under partial load conditions, by reading the performance parameters of a certain brand of gas turbine under different load rates, the gas turbine performance curve is obtained in Figs. 4 and 5.

Figure 4: Figure of change of exhaust temperature and exhaust heat with load ratio at different outdoor temperatures

Lithium bromide absorption chiller consumes heat energy to provide cold energy. The relationship between the heat energy consumed at any time and the cold energy generated can be shown in the following formula:

where,

Figure 5: Figure of power generation efficiency and gas flow changing with load ratio at different outdoor temperatures

The relation between the electric energy consumed by the air source heat pump unit at any time and the cold quantity/heat generated is expressed by the following formula:

In the formula,

In off-design conditions, the calculation method of each parameter is as follows:

where,

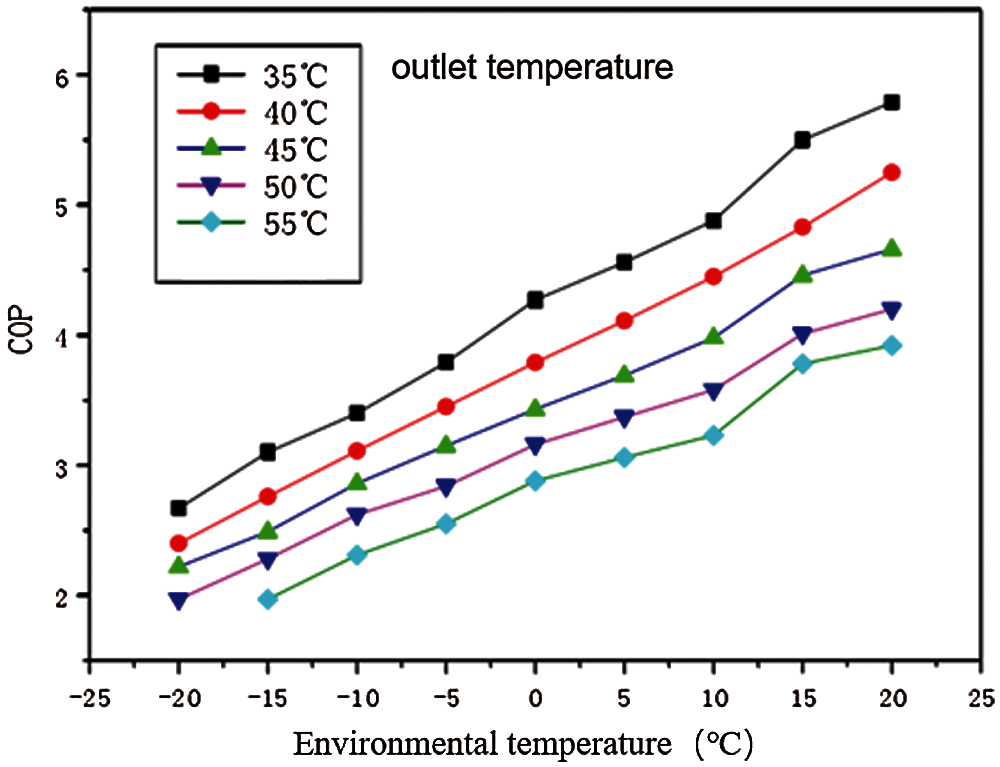

Under different outlet temperature, COP of heat pump varies with outdoor ambient temperature as shown in Fig. 6.

Figure 6:

4.1 Optimized Objective Function

In view of time value of assets, initial system investment is converted into a year as the unit in the annual costs method. The optimal matching under the optimal control mode is selected by comparison annual costs with its corresponding primary energy consumption and CO2 emissions. The calculation formula of annual costs for investments is written as

where

Note:

4.1.2 Primary Energy Consumption

where,

4.1.3 Carbon Dioxide Emissions

The carbon dioxide emissions of the system include the consumption of natural gas, the purchase of electricity from the Internet and the CO2 emissions caused by refrigerant leakage. For every tonne of standard coal consumed, 2620 kg of carbon dioxide is emitted. This part should be subtracted because the power is connected to the grid in the coupled system.

where,

5 Computational Condition Hypothesis of Numerical Simulation

1. When only cooling and heating loads are considered, electrical load of the building is borne by power grid, net on-grid energy in this complementary multi-energy coupled supply system (the difference value between generated energy in the system and power consumption of ASHP) is calculated to be surplus income;

2. Determine the capacity of combustion gas turbine by ordering power by heat;

3. The heating load ratio of combustion gas turbine is the specific value of maximum heating capacity of the turbine to maximum heating load in winter;

4. When heating load in the building is less than maximum heating capacity of combustion gas turbine in winter, the turbine matches with heating load dynamically in the way of partial load operation;

5. The ASHP model is selected according to the condition that hourly cooling and heating loads are converted to rated capacity, and the maximum value shall be taken. Moreover, the ratio of rated heating capacity to rated cooling capacity is taken 1:1;

6. Rated heating conditions of a brand of air source heat pump selected in this paper are as follows: hot water inlet temperature 40°C, outlet temperature 45°C, outdoor dry bulb temperature 7°C, wet bulb temperature 6°C, COP 2.9. Nominal cooling conditions are cold water inlet temperature of 12°C, outlet temperature of 7°C, outdoor dry bulb temperature of 7°C, wet bulb temperature of 6°C, COP is 3.47. The rated working condition of lithium bromide unit is: cold water inlet temperature 12°C, outdoor dry bulb temperature 7°C, outlet temperature 7°C, wet bulb temperature 6°C, COP is 1. The efficiency of the waste heat boiler is 0.8, and the heat exchange efficiency of the flue gas/hot water heat exchanger is 0.95;

7. Gas turbine and gas boiler fuel is natural gas, the main component of alkanes, methane accounts for the vast majority, and a small amount of ethane, propane and butane, in addition to hydrogen sulfide, carbon dioxide, nitrogen and water gas, a small amount of carbon monoxide and trace noble gases, such as helium and argon. The calorific value of natural gas is 35588 kJ/m³;

8. On-grid price is RMB 0.65/kWh, price of fuel gas is RMB 3.25/m3, and electric consumption is RMB 0.55/kWh;

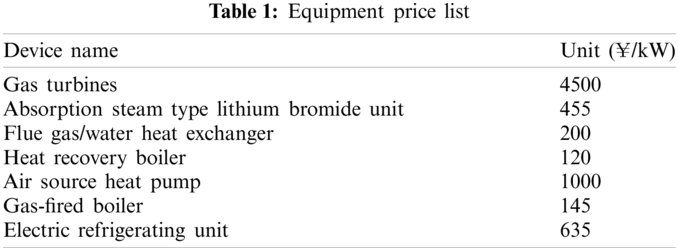

9. Equipment price is an important factor that affects system investment and thus affects the annual cost of the system. For the equipment involved in this paper, the unit heat price of a typical brand of equipment is shown in Table 1, and other projects can be priced according to the actual situation.

6 Example Simulation and Result Analysis

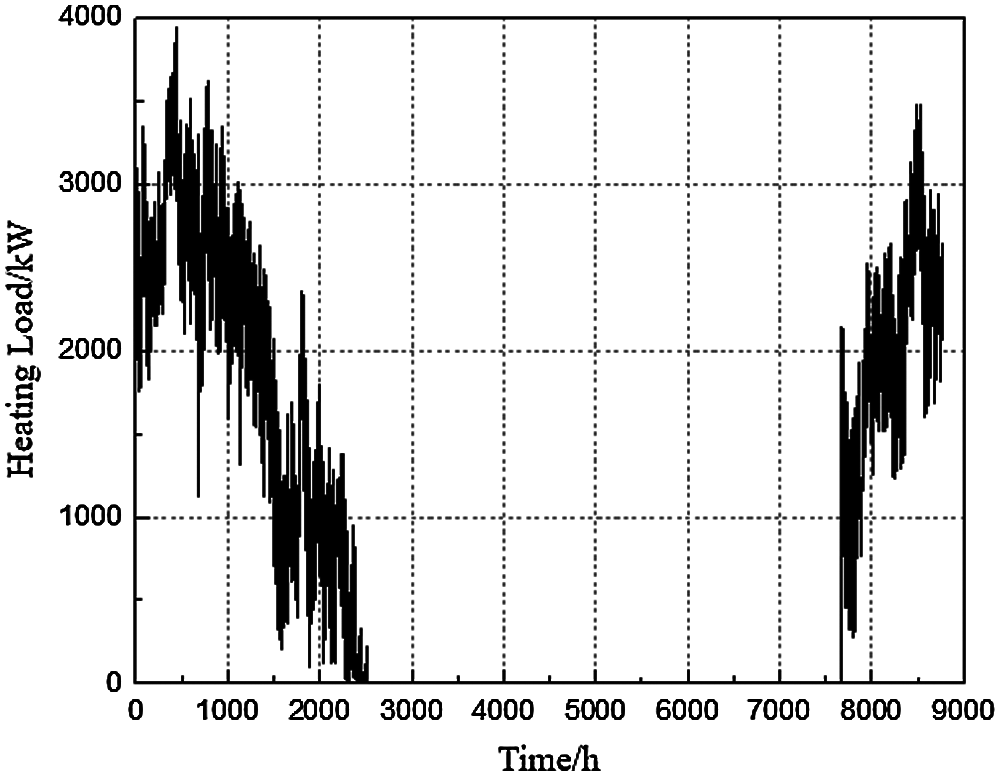

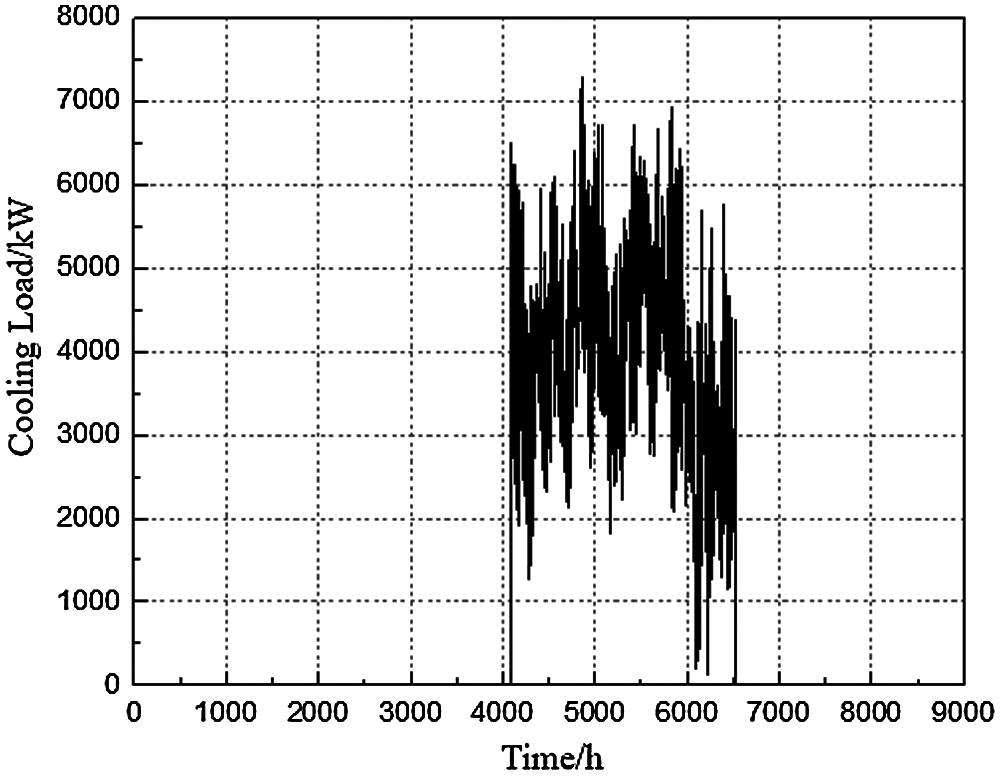

Both hourly cooling and heating loads in 100,000 m2 community in some region are calculated by DEST in accordance with the building envelop structure, and computed results are shown in Figs. 7 and 8.

According to the simulation results, the peak hourly heat load of the hospital is 3940 kW, and the peak hourly cooling load is 7291 kW. According to the statistics, the annual cumulative thermal load of the building is 23946 GJ, and the annual cumulative cooling load is 34948 GJ.

Figure 7: Annual heating load curve

Figure 8: Annual cooling load curve

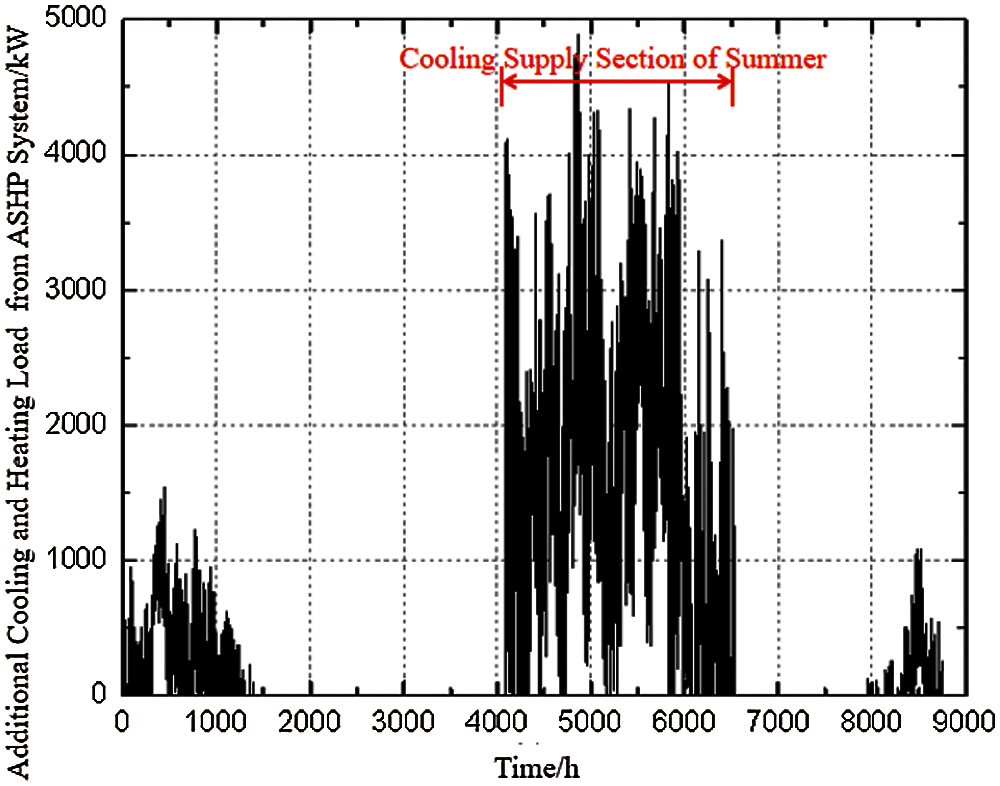

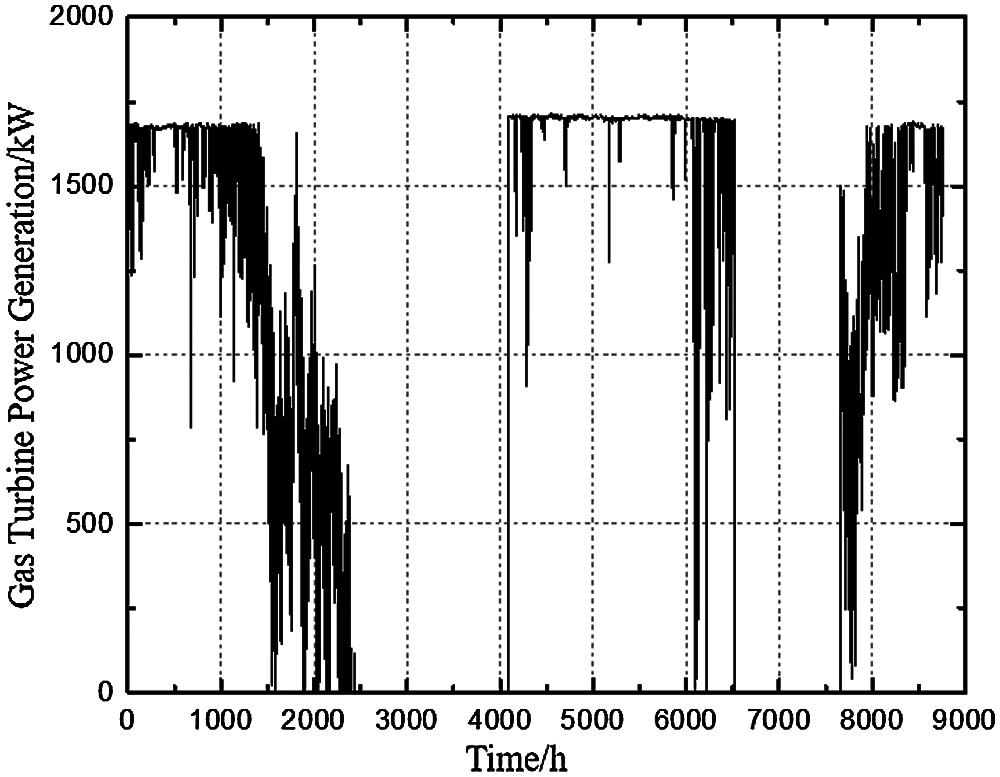

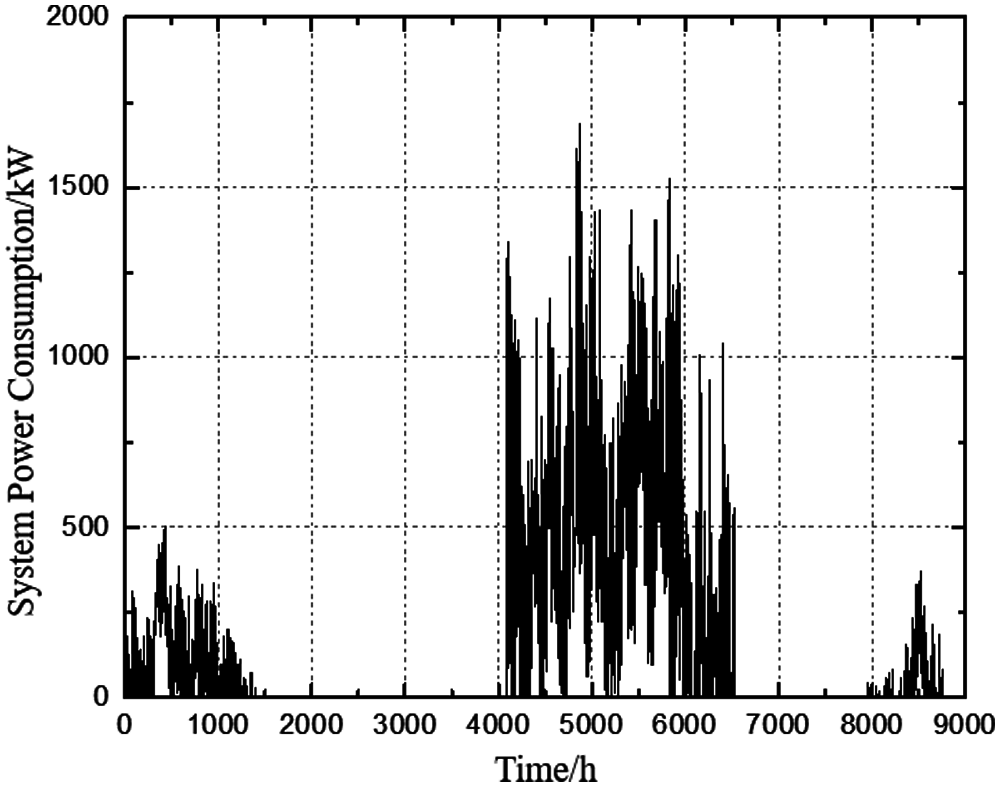

When heating load rate of combustion gas turbine is 60%, namely, its maximum heating capacity covers 60% of maximum heating load in winter, variation trend of ASHP additional cooling and heating capacities is shown in Fig. 9. Cooling load in summer is obviously higher than heating load in winter, and energy efficiency of absorption lithium bromide refrigerator unit is relatively low, which is generally 0.9~1.2 more or less, so cooling capacity in summer is relatively more insufficient, and maximum capacity required by ASHP is 4890 kW, equal to 67.1% of maximum cooling load. Therefore, when combustion gas turbine is guaranteed to operate with full load for most of the time, consumed power of ASHP unit is obviously higher in summer. The hourly generated and consumed power in the system is shown in Figs. 10 and 11.

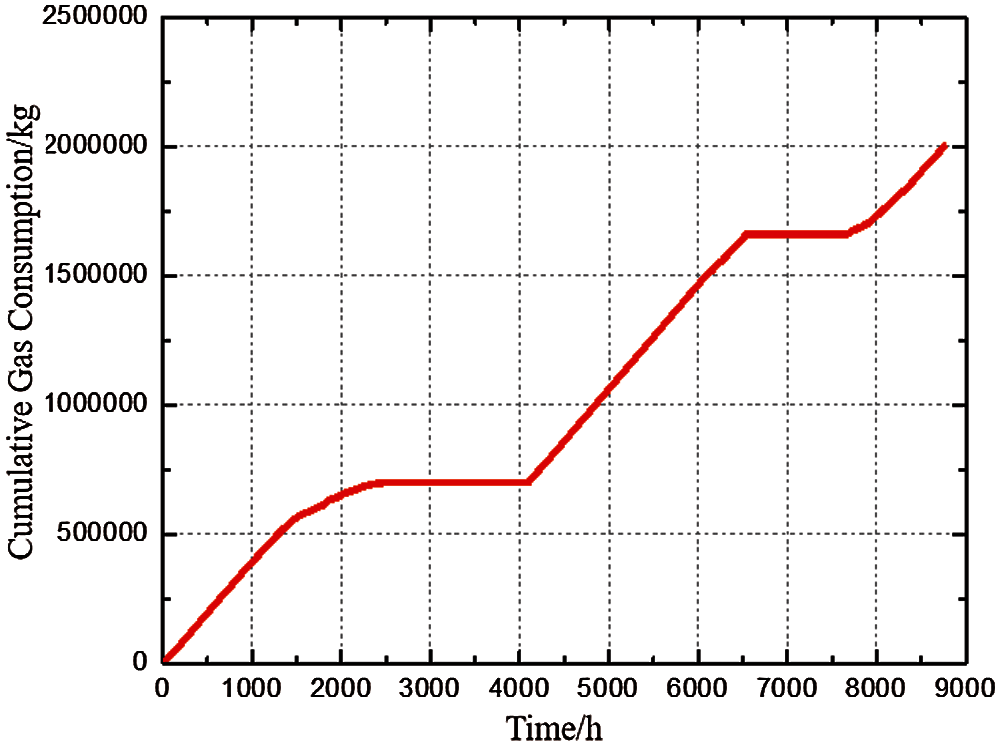

Fig. 12 shows the accumulated gas consumption when heating load rate of combustion gas turbine is 60%. The accumulated gas consumptions in winter and summer are 1.04 × 106 and 9.61 × 105 kg, respectively, which are basically the same. Moreover, it can be seen from the figure that the rise rate of gas consumption quickens compared with that in winter because load rate of combustion gas turbine is large and refrigerating cycle is short. Cooling load is high in summer, combustion gas turbine runs almost under high load, the relevance between operation conditions and environment temperature is low, but the load rate of the turbine evidently varies with temperatures in heating season. Therefore, gas consumption shows the non-linear relationship at the beginning and end of the heating season.

Figure 9: Additional hourly cooling and heating load curve from ASHP system

Figure 10: Hourly power curve of gas turbine

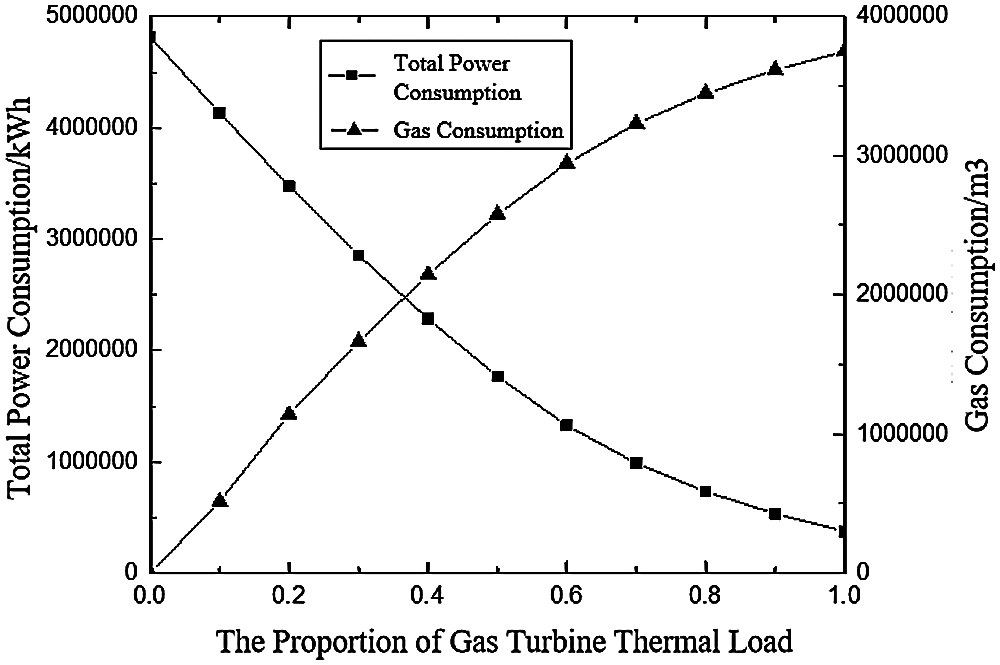

Changes of annual gas consumption and total system power consumption with heating load rate of combustion gas turbine are shown in Fig. 11. It can be seen from this figure that with the heating load rate increase of the turbine, total fuel consumption in the system gradually increases, but total power consumption gradually decreases, because load borne by ASHP reduces from 84.6% to 6.35% due to cooling and heating load increase of the turbine, and the system consumed power declines remarkably.

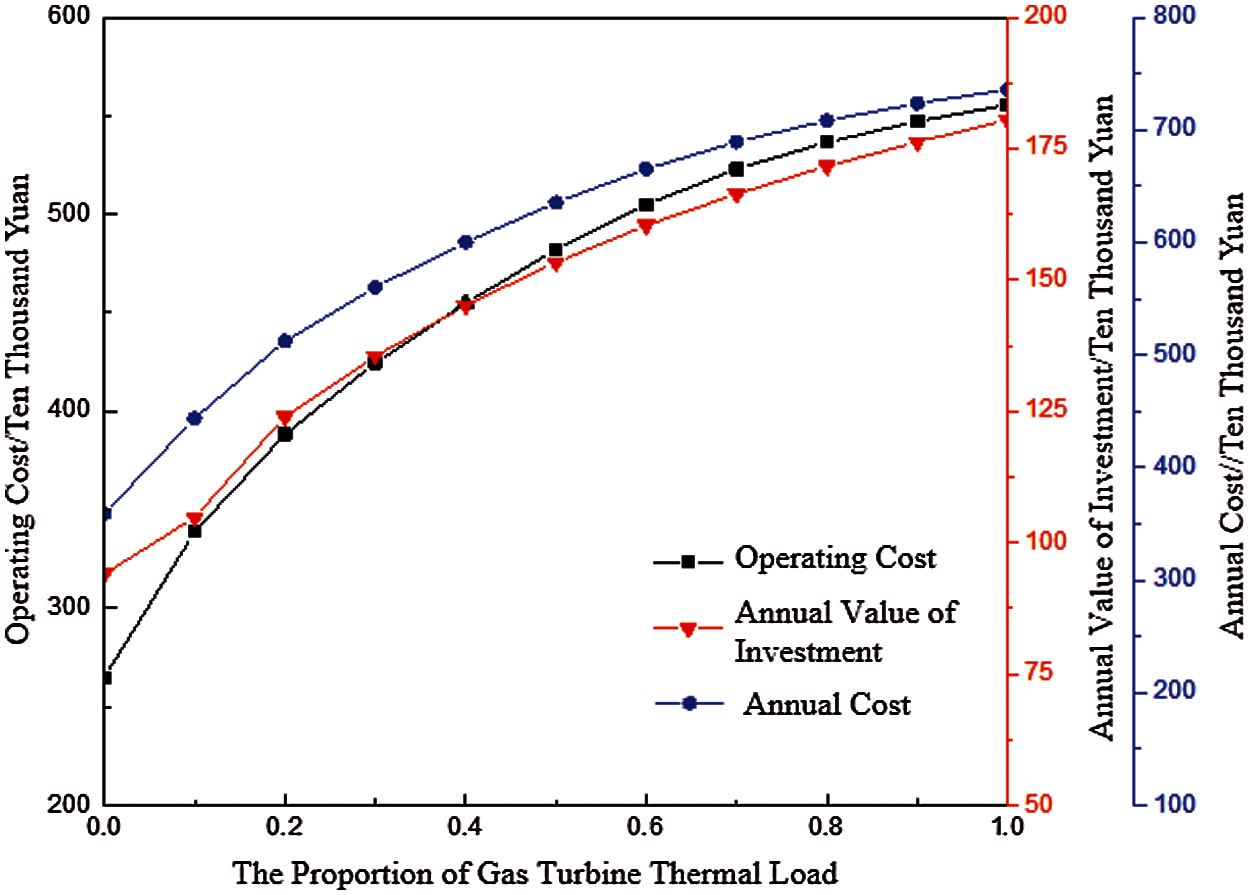

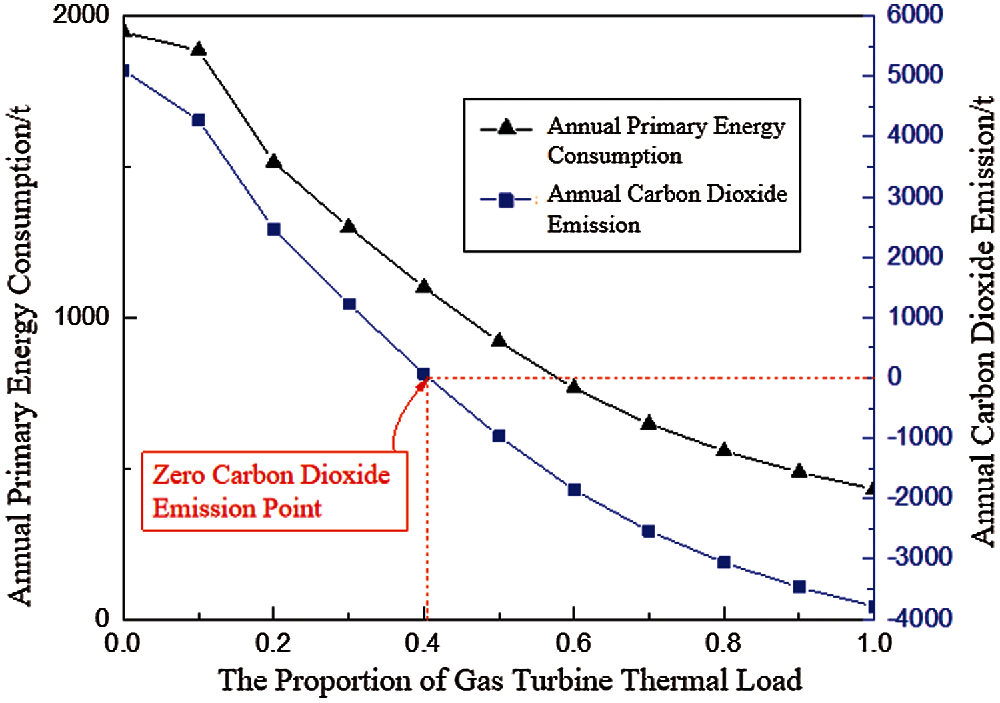

Changes of annual costs, primary energy consumption and CO2 emissions with heating load of combustion gas turbine are shown in Figs. 13 and 14. As for calculation of annual costs, investment period of equipment assets is selected to be 20 years, interest rate is 4.35%, and residual value is 0. After calculation, it is found that installed capacity of heat pump is the maximum, and annual power consumption reaches 4,818,144 kWh in case of heating and cooling supplies with full use of ASHP. However, compared with the coupled gas turbine system, annual investment and operation costs for independent use of ASHP system are relatively low, which are RMB 940,800 and 2,650,000 per year. Since the price of fuel gas is high, with heating load rate increase of gas turbine, increase rate of operation costs is larger than that of annual investment, and it shows a trend that annual costs gradually increase. In this way, it is impossible to determine the optimum system configuration. Therefore, it is practical to add evaluation on primary energy consumption (standard coal) and CO2 emissions (on-grid energy serves as applicable carbon emission index) on the basis of annual costs. Its trend is shown in Fig. 13. The annual change curves of primary energy consumption and cost of the coupled system at different ratios are shown in Figs. 14 and 15.

Figure 11: Hourly system power consumption curve

Figure 12: Annual cumulative gas consumption curve

Figure 13: The change of annual gas consumption and total power consumption with the proportion of gas turbine thermal load

Figure 14: The change of annual cost with the proportion of gas turbine thermal load

Figure 15: The change of annual primary energy consumption and carbon dioxide emission with the proportion of gas turbine thermal load

It can be seen from Fig. 13 that contaminant emissions of CCHP + ASHP system are 0 when heating load rate of gas turbine is approximately 41%. When heating load rate of the turbine increases continuously, its operation costs and fuel gas consumption are relatively high despite of fine environment benefits, which goes against reliability and stability of regional functions. In further considerations of other electrical loads in building, the optimum system proportion will change, i.e., the optimum proportion of gas turbine heating load increases. Therefore, annual costs + zero CO2 emissions can be used as the reference target of system structure optimization.

In order to more clearly highlight the advantages of multi-energy coupled cooling, heating and power system, the coupling system is compared with the traditional distribution system under the same building’s cooling and heating load. Among them, the distribution system chooses the most widely used combination form of gas-fired boiler and electric refrigeration unit. In the calculation process, the efficiency of the gas-fired boiler is 0.95, and the COP of the electric refrigeration unit is 3. According to the cooling and heating load of the building, the annual power consumption of the distribution system is 3,235,925 degrees, the annual natural gas consumption is 708,294 m³, the annual cost is 4.88 million yuan, the primary energy consumption is equivalent to 2094 t of standard coal, and the carbon dioxide emission is 5486 t. It can be seen that when the load proportion borne by gas turbine is less than 0.6, the coupling system is superior to the distribution system economically. From the perspective of energy saving and environmental protection, the performance of the coupling system is superior to the distribution system no matter what the load proportion borne by gas turbine is.

To solve the problem that CCHP equipment cannot realize dynamic matching with cooling and heating loads in buildings, this paper proposes a coupled CCHP system with combustion gas turbine + ASHP by ordering heat by heat, analyze variation trends of such parameters as gas consumption, HP consumed power by means of adjustment of heating load rate of gas turbine, and optimize the system proportion in the evaluation method of annual costs + energy environment benefits. It is found after studies that annual costs are the minimum with single use of ASHP, and with increase of load ratio of gas turbine, increase rate of operation costs is higher than decrease rate of annual investment, which shows an overall trend of gradually increasing annual costs; that in combination with assessment on primary energy consumption and CO2 emissions, the coupled system with CCHP + ASHP (20% load rate of gas turbine) is the optimum configuration, and that this system structure and optimization method may provide some reference for the development of CCHP evaluation system.

Funding Statement: This research was funded by the research on rapid modeling methods for integrated energy systems, Grant No. SGTYHT/17-JS-204.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Wu, D. W., Wang, R. Z. (2006). Combined cooling, heating and power: A review. Progress in Energy & Combustion Science, 32(5--6), 459–495. DOI 10.1016/j.pecs.2006.02.001. [Google Scholar] [CrossRef]

2. Gao, F., Cheng, L., Liu, C. (2015). CCHP operation with phase-change energy storage technology optimization. Electric Power Construction, 36(10), 93–98. DOI j.issn.1000-7229.2015.10.014. [Google Scholar]

3. Li, M. J. (2015). Research on hybrid based CCHP—GSHP system. China: Huazhong University of Science and Technology. [Google Scholar]

4. Kong, X. Q. (2011). Combined cooling heating and power. Beijing: National Defense Industry Press. [Google Scholar]

5. Wang, Y. T. (2013). Study on application of CCHP fueled with natural gas in Beijing City. China: Beijing University of Technology. [Google Scholar]

6. Kang, S. S., Li, H. Q., Cai, B. (2012). Analysis and research of “heating to determine electricity” and “electricity to determine heat” in combined cooling heating and power system. Building Science, pp. 255–259. DOI 10.13614/j.cnki.11-1962/tu.2012.s2.050. [Google Scholar] [CrossRef]

7. Smith, M. A., Few, P. C. (2001). Second law analysis of an experimental domestic scale co-generation plant incorporating a heat pump. Applied Thermal Engineering, 21(1), 93–110. DOI 10.1016/S1359-4311(00)00051-X. [Google Scholar] [CrossRef]

8. Miguez, J. L., Murillo, O. S., Porteiro, J. (2004). Feasibility of a new domestic CHP trigeneration with heat pump: I. Design and development. Applied Thermal Engineering, 24(10), 1409–1419. DOI 10.1016/j.applthermaleng.2004.01.008. [Google Scholar] [CrossRef]

9. Porteiro, J., Miguez, J. L., Murillo, S. (2004). Feasibility of a new domestic CHP trigeneration with heat pump: II. Availability analysis. Applied Thermal Engineering, 24(10), 1421–1429. DOI 10.1016/j.applthermaleng.2004.01.007. [Google Scholar] [CrossRef]

10. Cardona, E., Piacentino, A., Cardona, F. (2006). Matching economical, energetic and environmental benefits: An analysis for hybrid CHCP-heat pump systems. Energy Conversion and Management, 47(20), 3530–3542. DOI 10.1016/j.enconman.2006.02.027. [Google Scholar] [CrossRef]

11. Huang, B. M., Zhu, J. Z. (2010). Discussion of CCHP system in Beijing south railway station. Heating Ventilating & Air Conditioning, 40(5), 15–19. [Google Scholar]

12. Wang, M. Y., Cheng, X. H., Huang, Y. (2012). Application of combined cooling heating and power and groud-source heat pump systems. Heating Ventilating & Air Conditioning, 42(8), 64–67. DOI 10.3969/j.issn.1002-8501.2012.08.013. [Google Scholar] [CrossRef]

13. Zhang, T. X. (2012). Economic analysis of the composite system project of cooling-heating-power supply and river water source heat pump. Construction Economics, 11, 44–46. DOI 10.14181/j.cnki.1002-851x.2012.11.021. [Google Scholar] [CrossRef]

14. Hong, W., Hao, J., Wang, J. (2019). Performance analysis of combined cooling heating and power (CCHP) exhaust waste heat coupled air source heat pump system. Building Simulation, 12(4), 563–571. DOI 571.10.1007/s12273-019-0520-x. [Google Scholar]

15. Zhang, J., Cao, S., Yu, L. (2018). Comparison of combined cooling, heating and power (CCHP) systems with different cooling modes based on energetic, environmental and economic criteria. Energy Conversion and Management, 160, 60–73. DOI 10.1016/j.enconman.2018.01.019. [Google Scholar] [CrossRef]

16. Rong, Z., Li, H., Jiang, R. (2016). A novel multi-objective optimization method for CCHP-GSHP coupling systems. Energy & Buildings, 112, 149–158. DOI 10.1016/j.enbuild.2015.11.072. [Google Scholar] [CrossRef]

17. Jiang, X. Z., Zeng, G., Li, M. (2016). Evaluation of combined cooling, heating and power (CCHP) systems with energy storage units at different locations. Applied Thermal Engineering, 95, 204–210. DOI 10.1016/j.applthermaleng.2015.11.011. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |