| Energy Engineering |  |

DOI: 10.32604/ee.2022.019028

REVIEW

A Literature Review on Sustainability of Bio-Based and Biodegradable Plastics: Challenges and Opportunities

Faculty of Industrial Management, Universiti Malaysia Pahang, Malaysia

*Corresponding Author: Fatimah Mahmud. Email: fatimahm@ump.edu.my

Received: 20 August 2021; Accepted: 07 December 2021

Abstract: This study examines the literature on bio-based and biodegradable plastics published between 2000 and 2021 and provides insights and research suggestions for the future. The study gathers data from the Scopus and ISI Web of Science databases, then picks 1042 publications objectively and analyses their metadata. Furthermore, 144 papers from the Web of Science are analysed to present insights and classifications of the literature based on content analyses, including assessment/evaluation of the sustainability of bio-based and biodegradable Plastics, sustainability of biodegradable Plastics, and factors driving the uptake of biodegradable plastics. The study finds that most research on bio-based and biodegradable plastic film evaluations considered only one dimension of sustainability, few considered two dimensions, and very few considered three dimensions. Though, in recent years, academic and industrial interest has grown dramatically in biodegradable plastics towards sustainability. The triple bottom line method in this report (economic benefit, social responsibility, and environmental protection) was employed to assess the biodegradable plastics towards sustainability. Top journals, Influential authors, top contributing institutions, top contributing nations, and contributions by fields are all identified in this study. This research gives a detailed but straightforward theoretical design of bio-based and biodegradable polymers. The study’s results and future research initiatives provide a new path for further investigation and contribution to the field.

Keywords: Biodegradable plastic; bioplastic; influential factors; life cycle assessment; biopolymers; triple bottom line (TBL)

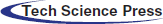

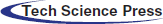

The World Wide Fund for Nature (WWF) has claimed, as reported by Taylor [1], that Malaysia is the leading user of plastic packaging in Asia and that countries such as China, Indonesia, Malaysia, the Philippines, Thailand, and Vietnam contribute to the world’s ocean pollutants, with 60% of the estimated 8 million tons of plastics going to the ocean each year. This plastic waste phenomenon was then simplified to three major factors: less environmental concern, lower environmental awareness, and less perceived value towards the environment [1]. Summarizing the specifics of these points mentioned in the above sections, it is estimated that 8.3 billion tons of plastic have been produced since large-scale plastic manufacturing began in the 1950s [2,3], and it is projected to rise twenty-fold again by 2030 [4]. Almost all of this plastic is now available in one way or another since, on a global scale, there are no adequate structures to handle the waste efficiently [4]. Almost 40 percent of the total plastic produced worldwide is for packaging purposes, in terms of what plastic is widely used (see Figs. 1 and 2) (Malaysian Plastics Manufacturers Association) [5,6].

• Packaging (40% in 2008 and 47% in 2018)–includes plastic bags (shopping, packaging, and garbage), containers, sheets, plates, strip bottles, boxes, and foils. Packaging is the largest market for the plastics industry;

• Electrical and electronics (23% in 2008 and 27% in 2018)–comprises electrical mechanisms/home appliances and parts such as radio, coverings for television sets, telephone and accessories, air-conditioning;

• Household (15% in 2008 and 4% in 2018)–comprises kitchen wares, toiletries products, and plastic tableware;

• Automotive (9% in 2008 and 8% in 2018)–Bioplastics are used for a variety of vehicle products and parts like the dashboard, steering wheels, and hood;

• Construction (7% in 2008 and 8% in 2018)–bioplastics are used for manufacturing pipes, cable shields, and valves;

• Agriculture (3% in 2008 and 3% in 2018)–includes products such as raffia string, planting bags, nursery trays, rain shields, and flower pots;

• Others (3% in 2008 and 3% in 2018)–other sub-sectors comprise bioplastic furniture, medical devices, toys, stationeries, and gifts.

Figure 1: Market share of plastic in Malaysia

In referring to Figs. 1 and 2, plastic wrapping or packaging was discovered by marine species as rubbish floating in the ocean, discarded in landfills, or ingested by marine animals. Malaysia’s condition is comparable as the market share of plastics in the packaging sector was highest in 2008 at 40 percent, with a rise of 8 percentage points between 2008 and 2018 to 48 percent a decade later, as seen in Fig. 1 [7].

Although plastic materials, with their numerous make-ups and manufacturing costs, are of high quality, it is of great concern if this plastic material can be appropriately managed in our society [8]. While plastics have become highly valued for their long-lasting functional use, many perspectives on plastics-related environmental hazards and energy crises have recently been raised. Plastics are popular because they provide human beings with a smaller amount of monetary charge for things they want [9]. Consumers are, however, now more aware of the harmful environmental effects of plastics. Therefore, because of how it can be sustained and handled in the global environment, bio-based and biodegradable polymeric materials are one of the most appropriate means to realise this [10].

Figure 2: Global plastics used, 2019

Also, different policymakers have established programs to ensure the promotion of research and improvement of bio-based polymers [11]. In this regard, efforts have been advanced by both the political and regulatory bodies in North America and Europe. The governments of Malaysia and Germany have shown considerable interest in biodegradable plastics research [12]. Therefore, this situation indicates the possibility of advancements in biodegradable plastics [13]. Governments, companies, and universities are making great efforts to find a feasible solution to plastics in the increasing social, economic, and environmental crisis.

Biodegradable plastic can be seen as one of the alternatives to accomplish this sustainable growth of the plastic industry and offer a solid alternative to petrochemical plastics in the near future [14]. By redirecting part of large volume plastics to other waste management methods and littering single-use plastics that are otherwise difficult to recycle and simultaneously contributing to the recycling of non-renewable materials and environmental protection of biodegradable plastics from renewable resources, biodegradable plastics could serve as a possible solution for overwhelmed landfills [15]. With adequate humidity, oxygen, and a suitable quantity of microorganisms, where this condition can be found enough in natural landfills or manure, biodegradable plastic can be decayed into carbon dioxide (CO2) and water (H2O) only within 20 to 45 days [16] compared to conventional plastics that their life expectancy is about hundred to thousand years [17,18].

The factors that drive biodegradable plastics’ accomplishment rates and position are their sustainability credentials and customers, regulations, technology, and resources [19]. The adoption and sustainability of biodegradable plastics focused on two technology areas–materials production and waste management. On the waste handling line, first. The improved composting infrastructure, including compost sorting, would make it easier to treat biodegradable plastics in the composting plant [20,21]. Improved, financially feasible sorting technology would also mitigate recycling issues. Fluorescent markers are a viable technology in this field [3]. Fluorescent markers include an entail labelling of the resin that generates a light that can be sensed and used to sort products when irradiated. In terms of material properties, one crucial point is that biodegradable plastics with the same characteristics as traditional plastics can be developed in order to ensure competition in the market. Policy and intervention will dramatically alter the rate at which bio-based polymers are used [19,22].

In contrast with biofuel development supporters, biodegradable plastics suffer from a lack of favourable government policies [23]. Deposit bans (zero waste to deposit or waste mitigation to deposit) have an excellent connection to lower plastic deposit rates. However, it is cautious to ensure that all measures are related to particular recycling priorities and then tracked so that the amount of plastic waste incinerated does not only rise [3]. In finding and disposing of biodegradable plastics, customers’ awareness must be encouraged. The project Open-Bio aims to solve this problem by using standards, labels, and harmonized product information lists for organic products and developing a biologic product database and their characteristics [3]. In order to promote the switch to biodegradable materials, fiscal policy initiatives would be required. This includes funding for low greenhouse gases practices and strong landfill prices (which will boost pathologic waste management’s competitive position); and market control of farm feedstock (to ensure they cope with natural gas, thereby pushing migration towards biological materials) [3]. Therefore, to navigate the global sustainability of biodegradable plastics uncertainty, a company needs to achieve a strategic edge. Although it is still essential for companies to manage their risks, sustainability has added another dimension to the sustainability of biodegradable plastics uncertainty [24].

However, previous research has summarised the articles using a subjective technique for evaluation and insights that may lead to bias. Therefore, data needs to be collected via the objective strategy. Literature on bio-based and biodegradable plastics is advancing rapidly, which justifies the necessity to give fresh insights and guidelines for research based on current developments in the existing knowledge. The research questions addressed by the study are as follows: who are the dominant authors? What are the most critical journals? What is the publishing trend? What are the top nations, institutes and subjects that contribute? In addition, how can a simple framework be developed to grasp the notion of sustainability for biodegradable plastics and the existing literature on bio-based and biodegradable plastics? Therefore, this research aims to evaluate the available literature review on bio-based and biodegradable plastics and provide insight into the current phenomena and future study paths. From 2000 to June 2021, data have been taken from the Scopus and Web of Science bases.

The study examines 1042 publications collected objectively from the Scopus database to offer metadata analysis. The bio-based and biodegradable plastics literature includes descriptive statistics on prominent authors, influential journals, institutions, topic areas, significant articles, and the list of nations contributing publications. In the process, the study offers several insights that could be useful for future research. This study makes several contributions. The article begins with a comprehensive discussion of bio-based and biodegradable polymers. Second, the study uncovers certain conclusions that vary from previous research. Third, there are just a few categories in the classification of literature that assist readers in comprehending and seeing the literature from various perspectives. Finally, the study offers a novel, straightforward, and easy-to-understand framework for assessing the long-term sustainability of biodegradable polymers. Academics and researchers will benefit from this paper’s insights and future study directions in grasping the notion of bio-based and biodegradable polymers and further inquiry in this field. Section 2 of the article introduces bio-based and biodegradable plastic, followed by Section 3 detailed methodology. Section 4 addresses the findings, insights into the sustainability of bio-based and biodegradable plastics, and Section 5 addresses the conclusion, limits, and future research directions.

2 Overview of the Bio-Based and Biodegradable Plastics

Bio-based and biodegradable plastics are increasingly being utilised in (food) packaging, (food service) ware, (retail) bags, fibres/nonwovens, and agricultural applications [25]. Bio-based drop-in plastics, such as bio-PE and bio-PET, can be utilised in the same applications as fossil-based polymers. PLA, starch-based plastics, and cellophane are three of the most common bio-based polymers, each with its own set of characteristics [26]. As with fossil-based plastics, carefully selecting a bio-based and biodegradable packaging material is critical to ensure that a packed product has the required shelf life. Some plastic qualities can be an impediment in one use and an advantage in another, for example, the low water vapour barrier of bio-based plastics [11]. PLA is a drawback for a water bottle but a plus for (breathable) vegetable and fruit packaging. Bio-based and biodegradable polymers must also follow the same food safety regulations as fossil-based polymers. Many bio-based plastics have certificates proving their suitability for food-contact applications [27].

Presently, the level of awareness in society regarding the effect of plastic waste on the environment has made it necessary to reduce its impact on natural resources and decrease the emission of CO2 [17]. Plastics, which take a long time to decompose and are immune to natural processes, account for a large portion of household and industrial waste (10%–30%) [28]. They contain chemicals that can pose a risk to the atmosphere, and they need more resources to manufacture [29]. The accumulation of plastic waste obstructs water and oxygen flow, causing harm to the atmosphere and all living things. The traditional way of disposing of plastic waste was to dump it in landfills. Because of environmental issues and insufficient garbage capacity, the emphasis is now on how waste materials can be recycled [30]. Even if it is possible to reuse plastic materials environmentally friendly, further tests should be done to ensure that the content achieves the appropriate consistency. Recycling also has several issues, including difficulties in recycling due to a complicated polymer composition, lack of specific beneficial properties, and the need for advanced technologies or more resources [31,32]. Dust and toxic gases (CO2, NOx, and SOx) are released into the atmosphere as traditional plastic composites are recycled [17,33]. Companies involved in packaging need to search for other environment-friendly resources to reduce how plastic waste fills the environment drastically to overcome these problems. Adopting biodegradable plastics is a novel way out of the increasing demand for plastic packaging [30].

Biodegradable plastics are easily disintegrated by living organisms’ activities, commonly known as microbes in the water [34]. This type of plastic can be substituted for plastics that are non-degradable to minimise the stress from the dwindling availability of landfill sites and plastic pollution. Also, the application of biodegradable plastics can decrease greenhouse gas emissions in the course of usage [30].

After being disposed of, biodegradable plastics are naturally reduced into nontoxic constituents in a manufacturing composting location [35]. The rate at which plastic materials are being adopted in packaging has led to the emergence of biodegradable plastics. The use of polymers materials in packaging products meant to be used within a short time is deemed unnecessary [36]. Thus, biodegradable packaging was adopted because it disintegrates very fast in a manufacturing composting location. It can be created through synthetic or natural resin [37]. Petroleum-based products are used to produce synthetic biodegradable plastics, a non-renewable resource.

In contrast, natural biodegradable plastics can be primarily produced from renewable resources or synthesised from renewable substances [38]. Because renewable-based biodegradable plastics are being made from plants, they have received more attention because of the great benefit industries will derive from them. Besides, bio-based polymers can reduce the total dependence on petroleum supply, which will curtail carbon emissions into the atmosphere [30].

Different types of biodegradable biopolymers are used for numerous packaging purposes. According to their source, there are three groups of natural biodegradable polymers:

• Biomass products such as starches and lignocellulosic products,

• Polymers obtained by extraction of microorganisms such as poly (hidroxyalkanoate) (PHA),

• Polymers synthesised from renewable materials such as polylactides (PLA).

The most considered bio-based and eco-friendly plastic resources examined currently are PLA and polyhydroxyalkanoates (PHAs) [39]. The starting material for PLA and PHA production is extracted from annually renewable plant materials. This ensures that all aliphatic polyesters will, in theory, be processed sustainably. These bio-based plastics may be restored to CO2 and then be photosynthesized by plants because they are biodegradable [40]. The development of PLA and PHA can thus be considered carbon-neutral and null pollution processes. In the long run and internationally, the net amount of carbon is constant in the atmosphere [41]. Bio-based and biodegradable plastics, including PLA and PHA, are commonly called eco-friendly and renewable to decrease fossil fuels. There is also a prediction for the expanded use of these products and the production for regulatory purposes of new levels of international biodegradability [42]. The modification of the molecule features (which are the weight of the molecule, sequence of the monomer distribution, and crystallinity) can regulate the rate at which PLA and PHA disintegrate. The biomedical and pharmaceutical fields have succeeded in using the PLA and its copolymers to produce recyclable sutures and matrices intended to coordinate the drug’s delivery [43].

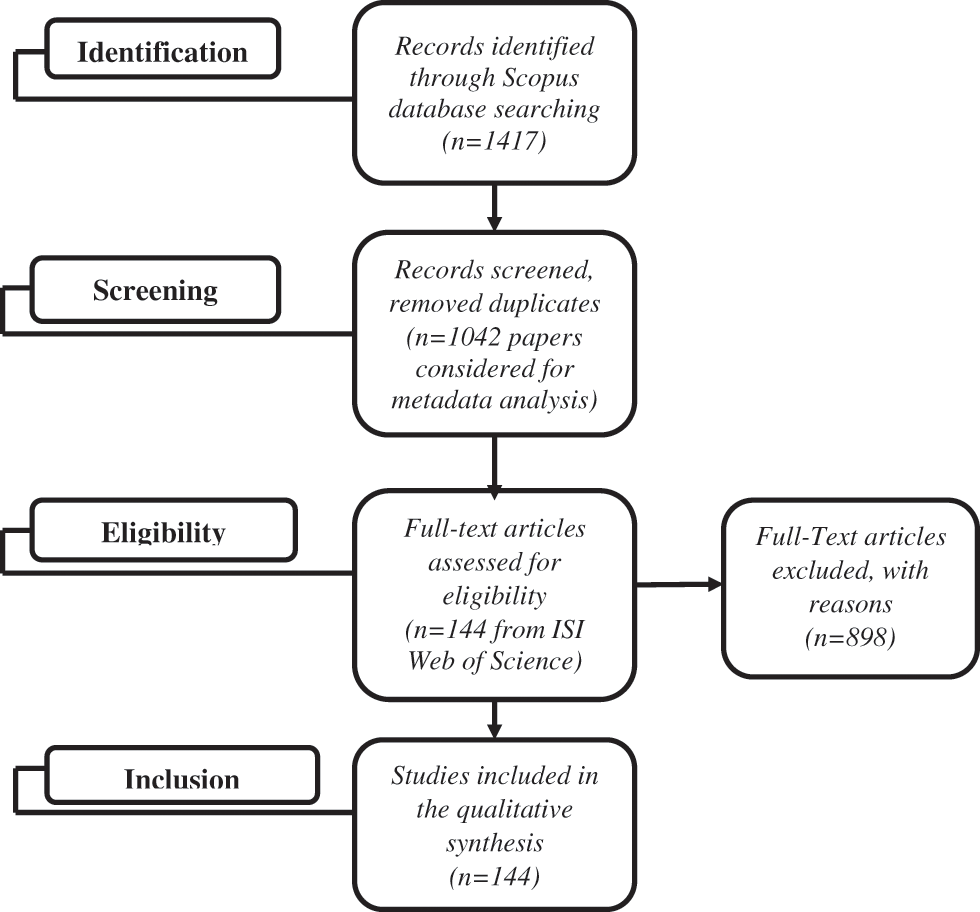

The data for this study was gathered in a systematic way from credible sources. According to Saunders et al. [44], a systematic literature review starts with relevant keywords to search and obtain material from databases and present the literature analysis. According to Tranfield et al. [45], a literature review aims to discover gaps in the existing literature and knowledge constraints. Furthermore, a literature review analyses and categorises current studies based on essential topics and makes recommendations for future research [46,47]. These guidelines should be followed, and the current research uses a systematic approach to extract data and classify literature based on content analysis and future research directions [48]. In short, the study used a four-step technique (see Fig. 3) that included identifying the data, screening preliminary data, evaluating eligibility, and ultimately including the data. The purpose of gathering this information is to propose new ideas and suggestions for future study. The researchers used the Scopus (metadata analysis) and Web of Science (classifications and insights) databases to compile their findings. Many researchers regard the Scopus database to be trustworthy [49–51]. Furthermore, academicians have praised the Web of Science database for high-quality indexing information. Many previous research has relied on it as a credible and high-quality data source [48,52].

Figure 3: Overview of paper identification, selection, and inclusion process

3.1 Identification of the Data

Scopus integrated databases were used to compile the data, including all major publishers such as Emerald, Taylor & Francis, Springer, and Wiley. The articles published between 2000 and June 2021 are included in the search. The study begins with terms like ‘bio-based,’ ‘biodegradable,’ and ‘plastics.’ The original search terms were restricted to the paper’s title and keywords. Initially, 1417 documents were generated from three keyword combinations.

The first search result included conference papers, books, book chapters, and articles. However, all except the articles were eventually removed. In order to eliminate books, conference proceedings, and magazines from the pile, the search was confined to ‘article titles’ and ‘keywords.’ Consequently, following the first refining, 1417 papers survived as articles. After deleting duplicates, a total of 1042 publications were selected for the metadata analysis.

The study objectively chose 144 articles from the Web of Science by just running a keyword search on the title to present the findings. The search was limited to the article title, abstract and utilised the keyword “bio-based plastics, biodegradable plastics.” The research covered publications published between 2000 and June 2021. It is worth noting that the 1042 articles produced from Scopus databases contain all of the articles that appear on the Web of Science. Many previous research by Coronado et al. [53], Fetscherin et al. [54], Apriliyanti et al. [52], Tseng et al. [48] utilised the Web of Science to present findings.

The researchers used 1042 Scopus articles for metadata assessment and 144 Web of Science articles to give insights and future prospects. As a result, the study reveals that the information is taken from trustworthy sources. Furthermore, because it indexes journals from other important databases such as Science Direct, Wiley, Elsevier, Emerald, MDPI, Taylor & Francis, IGI Global, Springer, and others, these databases are appropriate for generalizability purposes. On the other hand, the data should originate from a much more reputable source to convey insights and prospects for the future. Many previous research used subjective judgement to choose data to analyse the collected data [49,50].

On the other hand, the current study chose 144 articles from prestigious journals and authors based on objective criteria. As a result, data were rigorously acquired from the Web of Science using keywords search to verify that the data originated from a rich source of data and kept an impartial conception of the study. Papers that appear in the Web of Science web browser are also included in Scopus [48].

4 Observations and Recommendations

The metadata analysis and insights are presented in the next section. The insights were offered based on content analysis of 144 articles, while the metadata analysis was based on 1042 publications.

The descriptive statistics in this section are dependent on the metadata of 1042 articles. The metadata study included publication dates, journals, authors, nations, citations, topic areas, and institutions for 1042 articles. If a manuscript has numerous authors, it is counted many times while undertaking metadata analysis. Lambert and Wagner, for example, each receive one publication credit if they co-authored an article. In the same way, both their nations and institutes receive one publication credit. Some of the statistics in this study are presented in a summary style rather than a full list to improve reading.

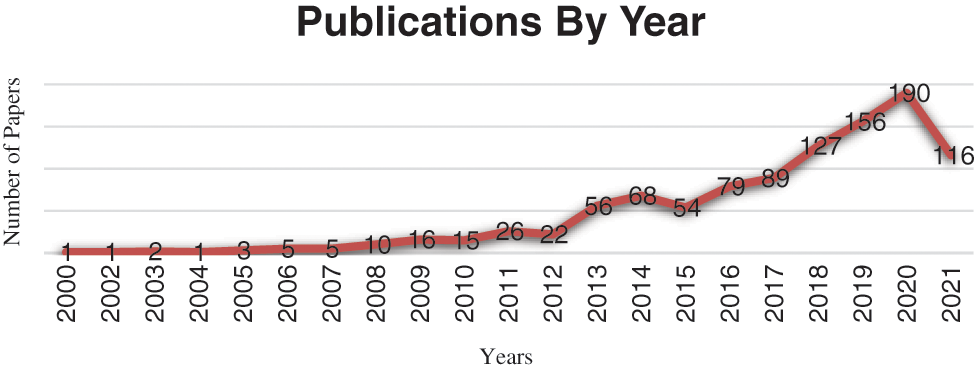

The appearance of papers on bio-based plastics and biodegradable plastics began in 2000 and continued to develop steadily until 2016. Fig. 4 shows that there has been an exponential increase since 2016 and continues until now. Furthermore, the trend line shows an upward tendency, implying that the literature on bio-based and biodegradable polymers is continually expanding. In the year 2020, 190 articles have been published, which is a substantial increase over prior years. As a result, there are growing concerns and attention to bio-based plastics and biodegradable plastics, which coincides with developing issues such as environmental stability, industrial and household pollution, and business and government concerns about social responsibility.

Figure 4: Publications on bio-based and biodegradable plastics by year

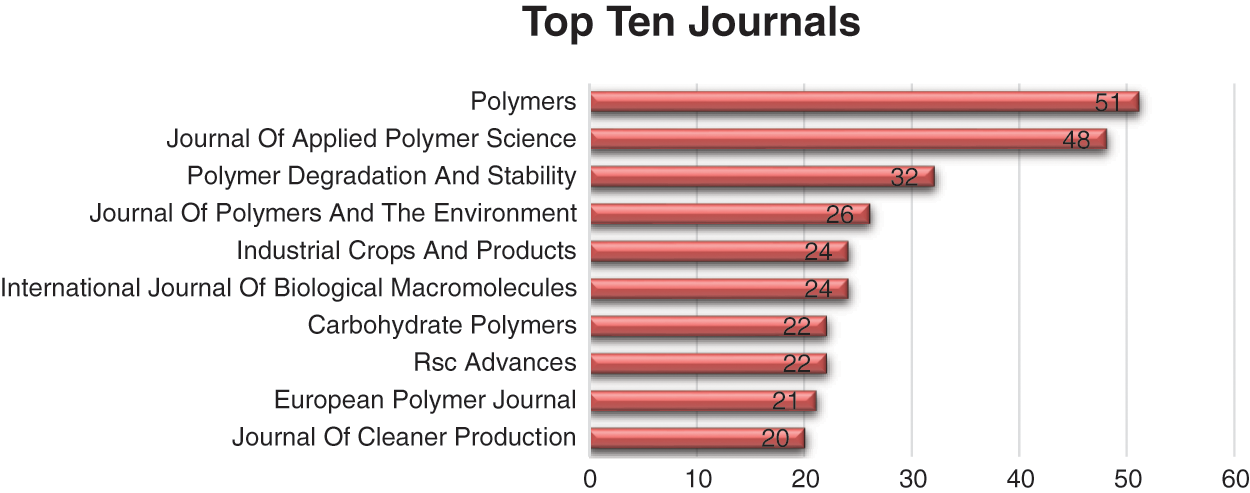

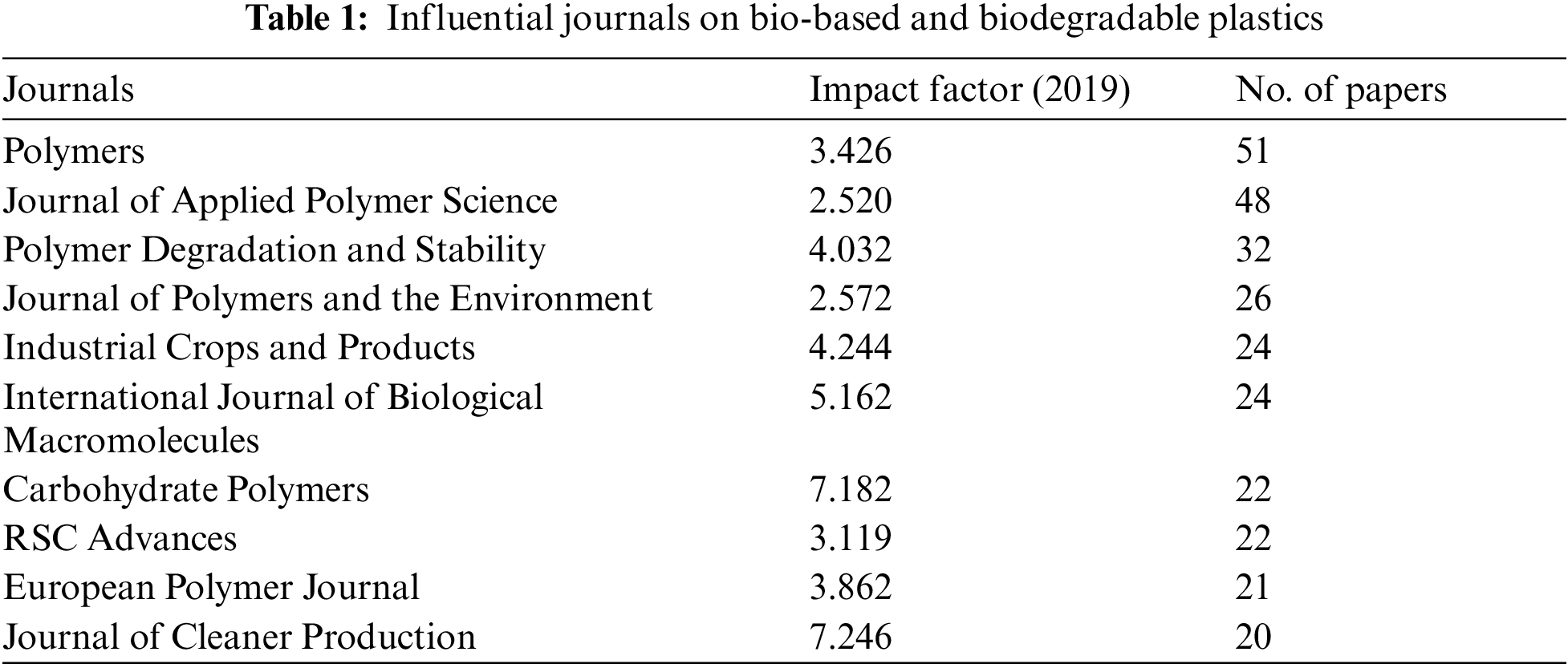

4.1.2 Publications by Journals

Polymers published the most publications (51), out of a total of 1042, as seen in Fig. 5. Table 1 also shows the influential journals and their impact factors. This is also the same journal that has a high impact factor (3.426). As a result of its effect and popularity in the field of bio-based and biodegradable plastics, Polymers might be recognised as the number one journal. The Journal of Applied Polymer Science is the second most popular journal, with 48 papers on bio-based and biodegradable plastics published out of 1042 and an impact factor of 2.52. Polymer Degradation and Stability published 32 articles and has an impact factor of (4.032). Despite the fact that the Journal of Cleaner Production published just 20 of the total publications, it has the most significant impact factor of 7.246, putting it among the best in this field.

Figure 5: Publications by journals

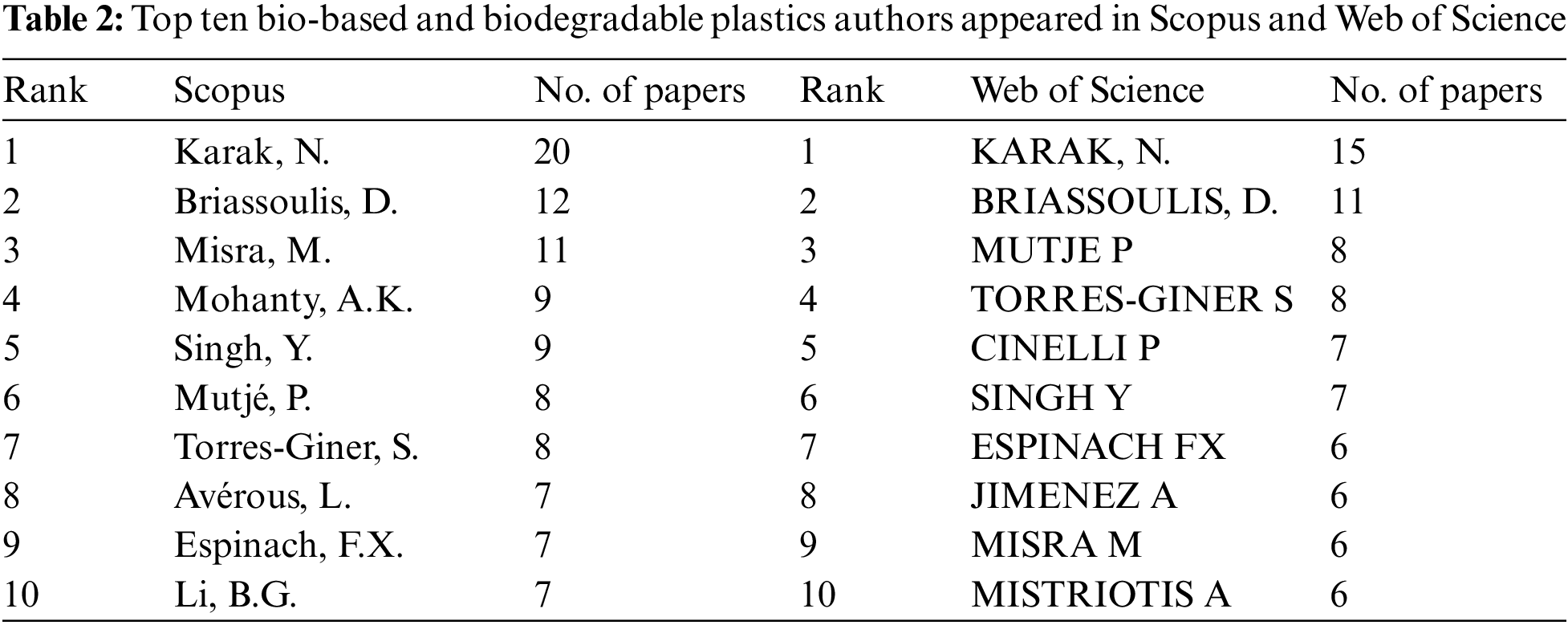

According to Table 2, Karak published the most articles on bio-based and biodegradable polymers (20 out of 1042). Briassoulis, and Misra, respectively, are the second and third authors with the most articles published. The present analysis compares the number of articles published by authors in the Scopus and ISI Web of Science databases to better understand who the top 10 authors are. Table 2 shows the ranking of the top ten authors in Scopus and Web of Science. The names of the authors and the number of articles published are somewhat different in each listing. The authors are ranked in the same order in both databases until they reach number three. Mutjé is ranked third in Web of Science, while his name is ranked sixth in Scopus’ top ten list. Torres-Giner was placed number 4 on the Web of Science list but number 7 in Scopus. Mohanty is ranked fourth in Scopus but does not appear in the top ten in Web of Science. This means the author uses the total number of articles published by each author from both Scopus and ISI Web of Science to determine the author’s ranking.

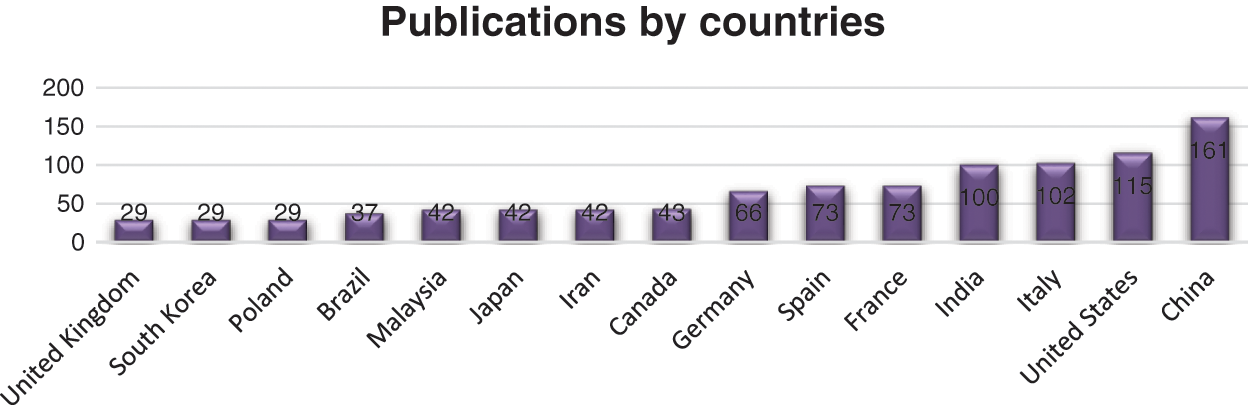

4.1.4 Publications by Countries

According to Fig. 6, the bio-based and biodegradable plastics literature, China published the most articles (161), followed by the United States (115). Italy and India are next, with 102 and 100 articles published, respectively. Malaysia is ranked 11th, accounting for 42 articles published. The literature on bio-based and biodegradable plastics has clearly shown that Asia, America, and Europe dominate. It is also worth noting that China and the United States published 26.6 percent of all articles published together. This might be attributed to a rise in the knowledge of sustainable environmental practices in these nations, as they are responsible for much of the world’s pollution and have consumed a large proportion of synthetic plastics in recent decades.

Figure 6: Top fifteen countries that contributed to bio-based and biodegradable plastics literature

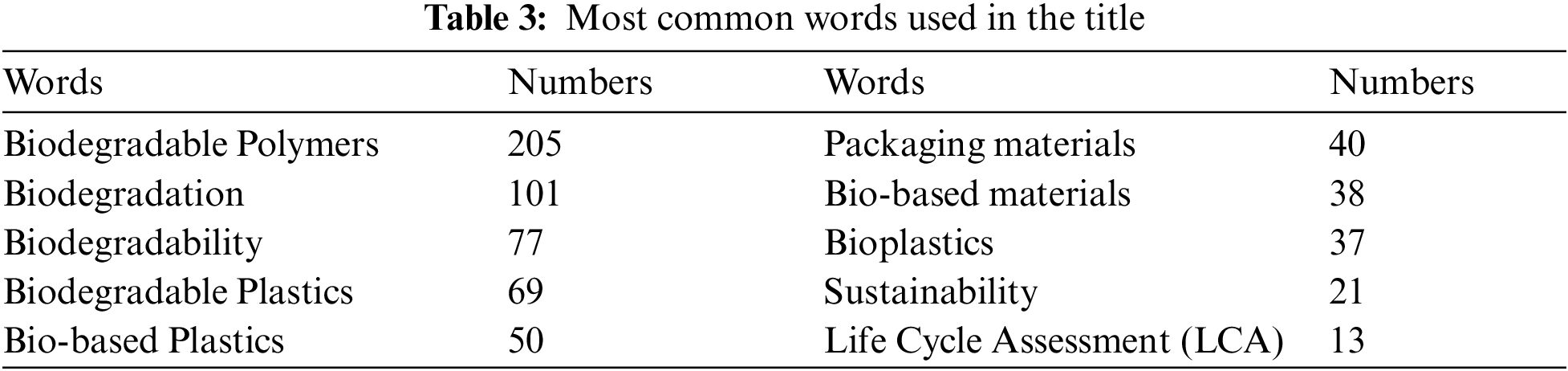

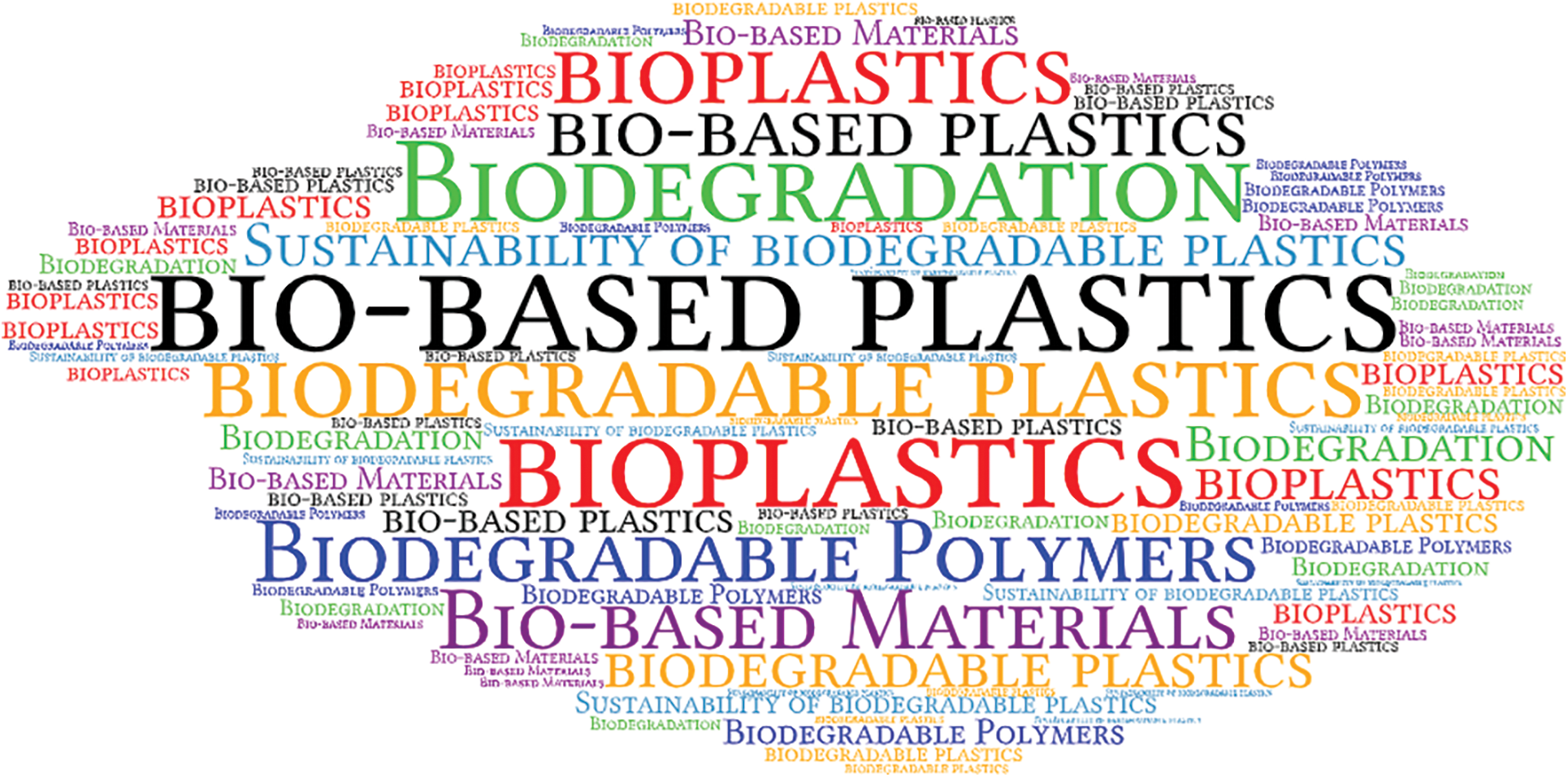

4.1.5 Most Typical Words Used in the Title

The most prevalent word used in bio-based and biodegradable plastics articles was identified using wordart.com (a free, open-source web software for text search and word cloud). Table 3 shows that the most frequently used terms in the title are ‘biodegradable polymers’ and ‘biodegradation’, which appear 306 times, followed by ‘biodegradability’, ‘biodegradable plastics’, ‘bio-based plastics’, and so on. The word cloud generated by the software is depicted in Fig. 7, with the most common terms highlighted in larger and bold letters and the less common terms in smaller fonts. This word cloud [55] is a simple way to find frequent terms in a complicated environment, and it may be used to find the most prevalent subject and keywords in publications.

Figure 7: Word cloud for most common words in bio-based and biodegradable plastics publications

4.1.6 Publications by Institutions

Fig. 8 and Table 4 show authors’ affiliations who have published on bio-based and biodegradable polymers. As seen in the figure, China’s Ministry of Education published the most articles in the bio-based and biodegradable plastics literature. Only one institution publishes 27 of the total number of articles published. CNRS Centre National de la Recherche Scientifique comes in second with the most articles published, followed by Tezpur University. Since educational institutions are recognised based on the work of their authors, a specific institute may rise to the top if its workers produce more articles.

Figure 8: Top fifteen institutions by publications

4.1.7 Contribution by Subject Area

The relevance and acceptability of bio-based and biodegradable plastics in the academic arena is demonstrated by using several disciplines in the literature. Fig. 9 shows that materials science, chemistry, and chemical engineering disciplines produced the most articles. With 192 papers, environmental science came in fourth, followed by physics and astronomy with 145 papers. Although materials science dominates the literature on bio-based and biodegradable plastics, other disciplines are becoming more interested in the subject. This might be due to the issue of environmental deterioration, which is very important in today’s economic world [56]. Firms are under carefully and critically pressure from the government and pressure from environmentally concerned consumers and suppliers due to environmental degradation [48]. Because bio-based and biodegradable plastics increase environmental sustainability, numerous disciplines have contributed to the literature on bio-based and biodegradable plastics, resulting in a wide range of topics of interest.

Figure 9: Contributions of bio-based and biodegradable plastics papers by subject area

4.2 Insights on Bio-Based and Biodegradable Plastics

This section provides information based on an impartial review of 144 papers in the Web of Science database. The following sections summarise the classifications of papers in the bio-based and biodegradable plastics literature into three basic groups before constructing a conceptual framework based on the present literature. The literature has been divided into three categories: (i) Assessment/evaluation of the sustainability of bio-based and biodegradable Plastics, (ii) Sustainability of biodegradable Plastics, (iii) Factors driving the uptake of biodegradable plastics.

4.2.1 Assessment/Evaluation of the Sustainability of Bio-Based and Biodegradable Plastics

The articles from Web of Science were evaluated to provide insights and future perspectives for studying environmental, economic, and social aspects of bio-based and biodegradable plastics, focusing on bio-based or biodegradable plastics’ sustainability, respectively. The research looked at the triple bottom line (TBL), life cycle assessment (LCA), social life cycle assessment (S-LCA), and life cycle costing (LCC) of bio-based or biodegradable polymers. Social and economic aspects receive far less attention in the literature than environmental LCA studies [57]. As a result, the study was broadened to include social, environmental, and economic research on bulk bio-based or biodegradable plastics because the upstream processes of these product systems are identical to biodegradable plastics, as shown in Table 5.

Referring to Table 5, the scope, analysed product systems, measurement techniques, and indicators assessed in the studies under review vary; as a result, this report focuses on identifying significant issues related to bio-based and biodegradable plastics’ sustainability, such as social, environmental, and economic hotspots, as well as the indicators used [59]. This will necessitate a thorough examination of both procedures and scopes, which is beyond the context of this investigation. Additionally, the following search words have been used for the broadened search for social, environmental and economic aspects in the area of biodegradable and bio-based products: bio-based products social, social elements of biodegradable and bio-based products, sustainability indicators of biodegradable plastics, economic aspects of biodegradable and bio-based plastics, economic indicators of biodegradable plastics, environmental aspects of biodegradable and bio-based plastics, environmental indicators of biodegradable plastics, respectively [38].

It was also noticed from the literature review that most bio-based and biodegradable plastic film evaluations considered only one dimension of sustainability [79,82,83]; few considered two dimensions [80], and very few considered three dimensions [78]. Academic and industrial interest has grown dramatically in biodegradable plastics towards sustainability in recent years. The triple bottom line method in this report (economic benefit, social responsibility, and environmental protection) was employed to assess the biodegradable plastics towards sustainability. In general, biodegradable plastic film analyses have concentrated on the product itself and have scarcely contemplated evaluating biodegradable plastics’ sustainability from a TBL and determinants viewpoint. As the biodegradable plastic film grows, more and more organizations gradually focus on sustainable assessment.

Therefore, both developed and developing countries have a vast volume of literature on factors affecting the organization [11]. To the best of our understanding, a little study has incorporated the triple bottom line approach for biodegradable plastic film sustainability, and few assessments have been made on the sustainability of biodegradable plastic film. This study will identify the sustainability of biodegradable plastics, for which the research mentioned above can offer a useful reference. It is evident that such sustainability dimensions, assessment methods, and performance measurement indicators are a significant and integral part of sustainable plastic film. Moreover, previous literature has given less attention to critical factors influencing the sustainability of the biodegradable plastics market. This research would identify factors driving the uptake of biodegradable plastics to assist operation managers, government agencies and organizations from the business viewpoints.

4.2.2 Sustainability of Biodegradable Plastics

One of the major criteria for current management concentration on sustainable development is identifying sustainability principles for biodegradable plastics [83]. For biodegradable plastics sustainability evaluations, the triple bottom line (TBL) theory generally distinguishes three dimensions: economic performance, social responsibility, and environmental protection. The idea of sustainability is based on the assumption that society will accept an actual and realisable scale that future generations will be able to embrace as well [83]. Therefore, the development that will be successfully sustained needs the adoption of rigorous efforts concerning different aspects of society and the activities of a human being to achieve this objective [84,85]. Sustainable, biodegradable plastics development is essentially about regulating the relationship between human and environmental demands so that non-renewable materials with severe environmental constraints are not used up unnecessarily. Simultaneously, existing ethics of societal justice and essential civil liberties are unaffected. It might also imply avoiding environmental and societal failure to preserve the current society’s and future generations’ existence [86].

➢ Social sustainability

Biodegradable plastic materials, either biodegradable or as manure alternatives, have been developed to reduce litter generated by wasted plastics [87]. Biodegradable plastics are commonly used in the packaging of disposable items, and they are also used in agriculture, where biodegradability is encouraged. The recently better developed bio-based non-biodegradable plastics (bio-PE and bio-PET) can be utilized in food packaging [88]. Currently, there is a growing awareness about the societal influence of packaging products made from “Biodegradable Plastics.” Many people in society are willing to change to an alternative packaging material with a lesser carbon impression or produced from renewable resources. This situation has been the major motivation to improve biodegradable plastics to decrease plastic waste management in our society [89].

Corporate social responsibility (CSR) reflects the social components of biodegradable plastics sustainability, and the terms “social sustainability” and “CSR” are frequently used interchangeably. Trendafilova et al. [90] described CSR as the company’s continuous contribution to ethical actions and contributes to economic growth while increasing its quality of life and the local and social communities at large [91]. Equity issues are the core goals of minimizing poverty and increasing the health of developed nations. So the idea of social sustainability addresses the cultural, economic, social, and emotional needs of a human being [92]. Societal capital tackles cultural or communities topics, such as poverty, inequality, human rights, corruption, community development, welfare, family concerns, lack of schooling, public health, youth activity problems, and democracy [93]. Developing corporate capital encourages trust in the company and its stakeholders, thus enhancing a company’s credibility with its stakeholders [94].

⮚ Social sustainability in planning practice

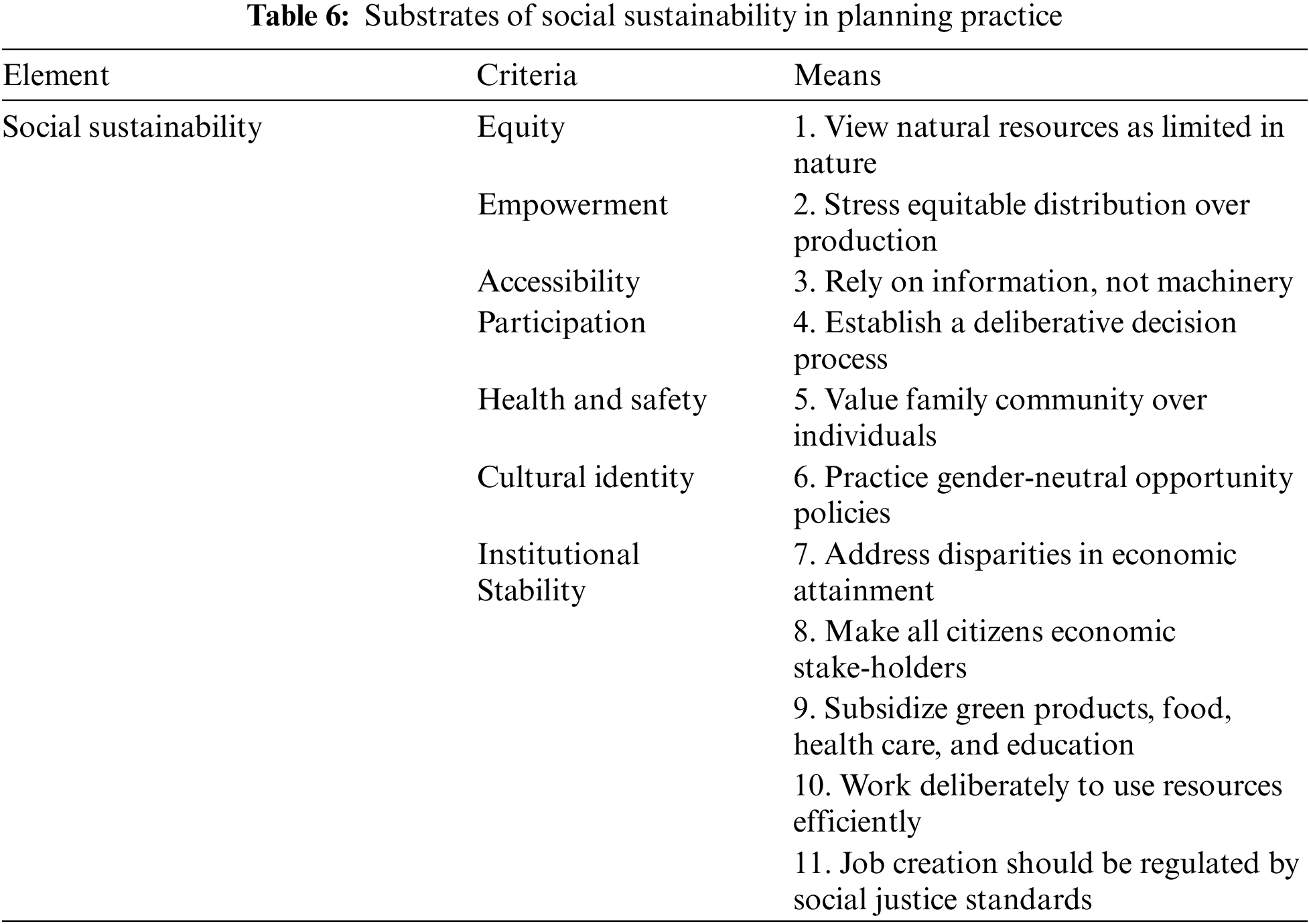

According to the principle of social sustainability, job creation should be regulated by social justice standards, according to the principle of “social sustainability.” In order to connect these, an enabling environment must be built to maximise resource use, prioritise resource allocation, and promote fair resource distribution [95]. Table 6 shows the substrates of social sustainability.

➢ Economics sustainability

In order to assure the economic consequences of long-term biodegradable plastics, techniques that can conserve cost-effectiveness, the environment, human, and social capital for a long time should be explored [96,97]. The capital strategy will provide the theoretical strategy for measuring all shared resources in various units, which will afford stable, hypothetically comprehensive, and policy-relevant assessments among countries [98].

The establishment of jobs and enterprises for the general public is a good indicator of the economic impact of using biodegradable plastics. It is relatively straightforward to add taxable bases and physical goods when establishing employment [34]. Furthermore, the use of sustainable materials has the potential to reduce energy consumption, waste disposal, and manufacturing costs throughout operations [3]. In order to reduce the vast and dangerous trash on disposal sites, there is a need to recycle metallic objects, glass, wood, plastics, paper, waste oil and inks, and manufacturing liquid. This besides will reduce the cost involved in disposing of waste [99]. Furthermore, while plastics’ production prices can be reduced when biodegradable plastics are utilized, there will be a reduction in the cost of energy in the process of producing plastics if lesser energy pumps, vehicles, and illumination fittings are used [100,101].

⮚ Economic sustainability in planning practice

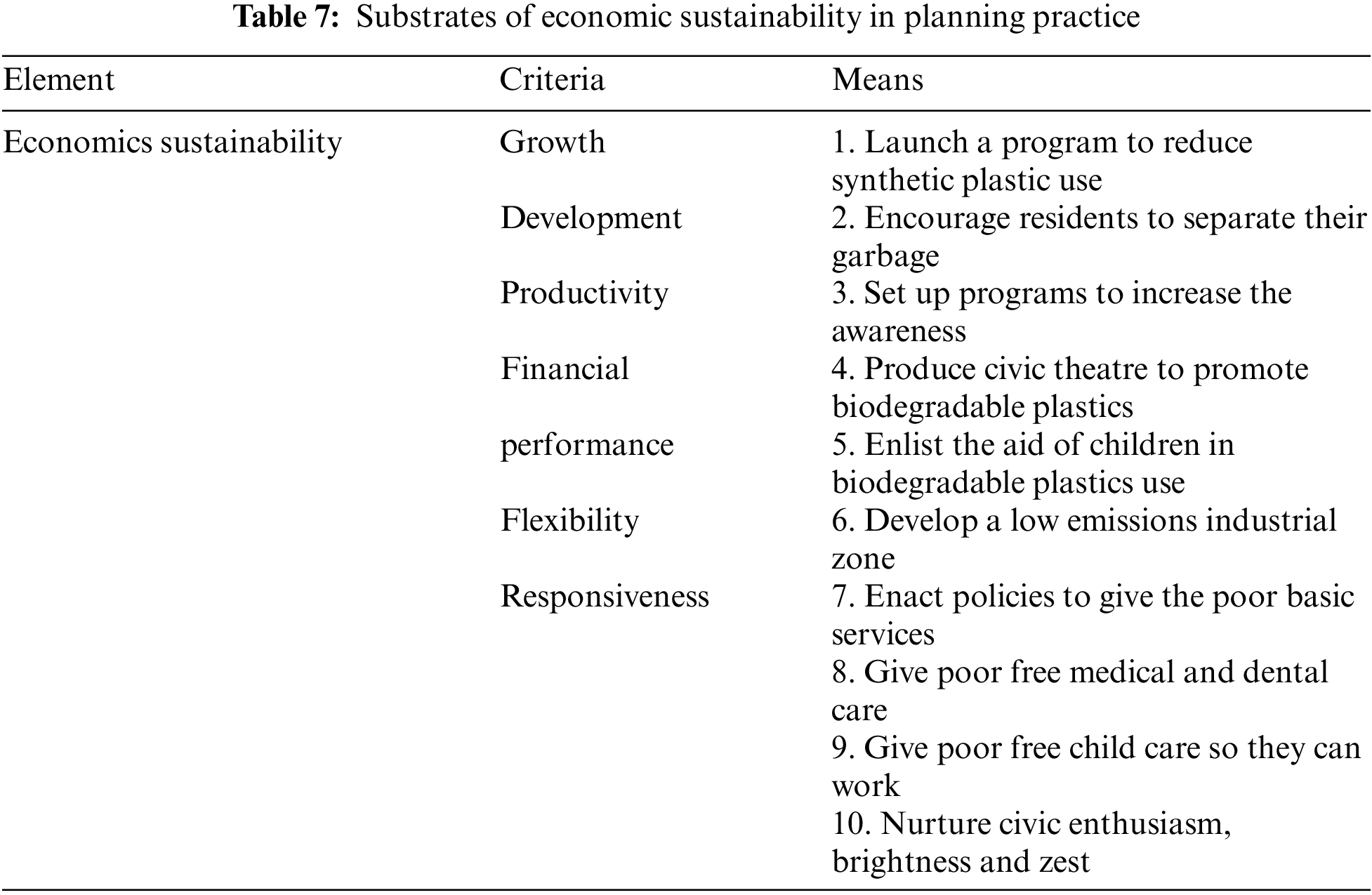

A technique of urban design that serves the social service demands of the general public, especially the urban poor, while increasing the genuineness of the urban environment is one approach to putting the notion of “economic sustainability” into practice [102]. Table 7 shows the substrates of economic sustainability.

➢ Environmental sustainability

Monitoring exhausted resources and technical pollution during the creation of products or services may assess biodegradable plastics’ environmental sustainability [89]. While the depletion of resources comprises usage of the land, usage of energy, usage of water, the use of fossil fuel, etc., the emission of the effluence consists of a change of climate, GHGs, contamination of water, contamination of the air, release of a lethal substance, poisoning human, the release of cancer-causing agents, summer smog creation, acidification, eutrophication, etc. Assessing the environment through strategic means is very important to creating sustainable products and services [103]. This strategy will ensure the development of policies, procedures, and packages that are sensitive and favourable to the environment [95,104].

The emphasis is on the control of harmful environmental effects of company activities in terms of ecological sustainability. According to Kopnina [105], in recent research on environmental sustainability, unrestrained economic development is one of the most significant risks to the natural world and ecological processes. Kasayanond [106] described environmental sustainability as protecting and renewing the present and the potential generations’ biosphere. Recent environmental dangers such as climatic change, global warming, pollution, erosion, and biodiversity depletion are global issues. Consumers are rapidly pressuring businesses to implement environmentally sustainable policies to boost their efficiency [63].

⮚ Environmental sustainability in planning practice

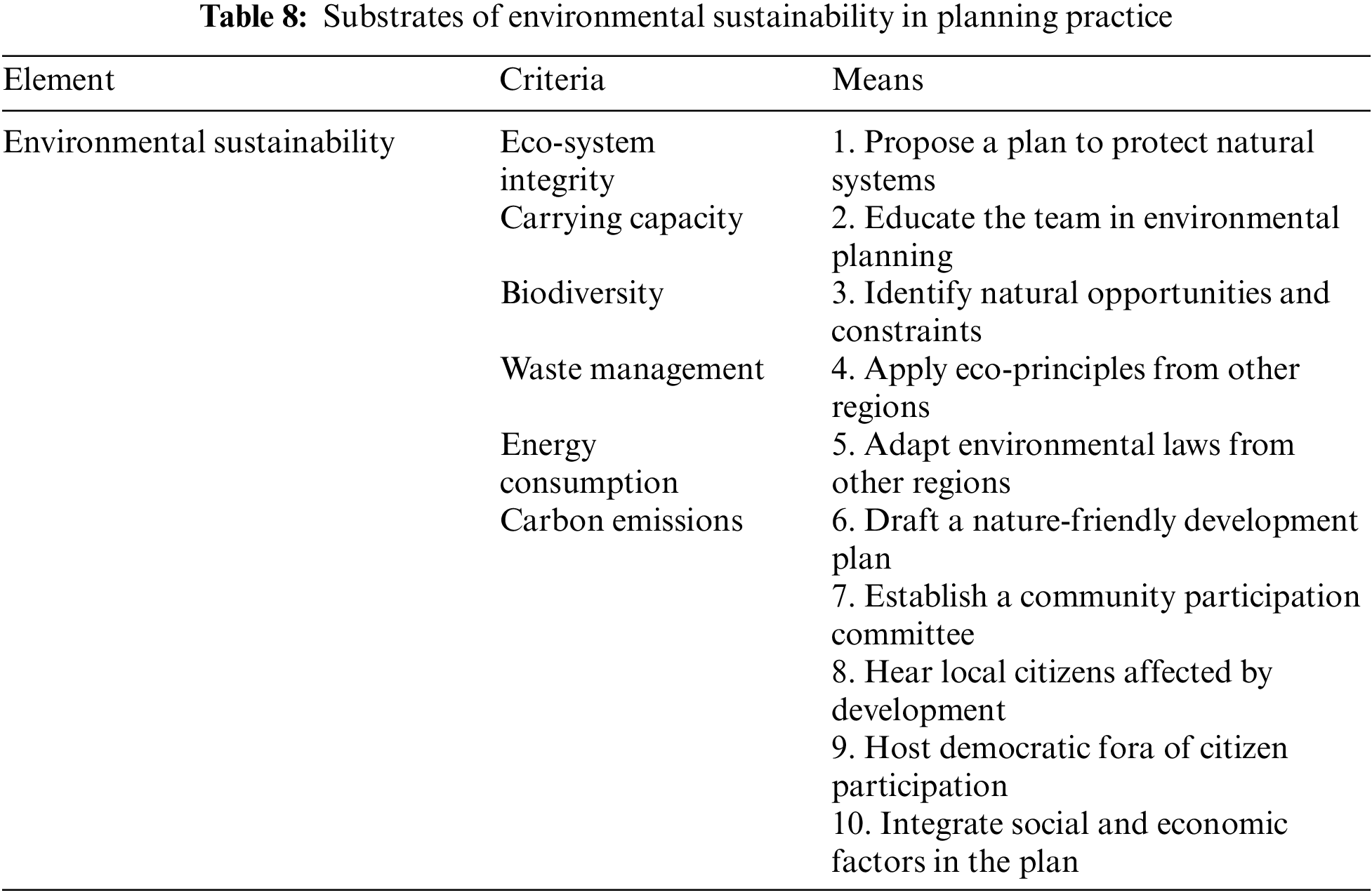

In practice, environmental sustainability theory offers a planning approach that permits human civilization to survive within the biophysical environment’s constraints [107]. Table 8 shows the substrates of environmental sustainability.

5 Challenges and Opportunities

It is possible to analyse opportunities (achievable advantages) and challenges (unknown factors that must be addressed and handled) from a variety of various points of view and approaches. The simultaneous evaluation of several aspects may prove to be quite beneficial in gaining a basic comprehension of the subject matter.

Bioplastics are frequently utilised in the food packaging, pharmaceutical, and medical equipment industries. PLA, PHA, and nanocomposites might be used to make bioplastics. However, starch is the most often utilised substance in the production of bioplastics [108]. Corn or potato starch is used to make it. Starch was chosen because it has a biodegradable natural properties and can be manufactured in large quantities at a reasonable cost. It is said to be one of the most promising options for bio-plastics manufacturing. PLA, PHA, and nanocomposites are the most popular types of bioplastics utilised in packaging applications.

PLA is used in various packaging materials, including cups, bottles, films, and containers [108]. It also works in the textiles business, producing shirts, furniture fabrics, and diapers. Due to the stereo complex, Mazda and Teijin developed heat-resistance PLA for automotive materials. Spun fibres and biaxially stretched film are two possible characteristics of PLA. Another kind of PLA that Synbra, Sulzer, and PURAC created is foamed PLA, which is utilised for expanded polystyrene (EPS) foam as a bio-based alternative. PLA is also used to strengthen the casing of mobile phones with kenaf fibre [42]. PHA has a wide range of applications in the industry. Medical implant materials, medication delivery carriers, agricultural applications, medical applications, aerospace and automotive, consumer electronics, cosmetics and even granule surface proteins were all covered. PHA has been synthesised into various structures to fulfil these goals, including PHB, PHBV, P4HB, and P3HO. Sutures, repair devices, repair patches, tendon repair devices, artificial oesophagus, and wound dressings are researched. PHA oligomers have also been discovered to have nutritional and medicinal properties [108].

Furthermore, because of its biodegradability, biocompatibility, and breakdown through surface erosion, PHA is also employed as a drug carrier. Moreover, PHA monomers have been produced as RHA, which has significant uses as initiators in synthesising acceptable compounds such as antibiotics, vitamins, aromatics, and pheromones. R3HB, a different PHA monomer, has also been utilised to make carbapenem antibiotics and macrolides [108].

A number of research have looked into the possibility of using biobased materials for food packaging, particularly in comparison to traditional packaging materials, and their findings have been published. At the moment, it appears that biobased packaging is mostly used for fresh (respiring) produce such as fruits and vegetables, fresh meat, and fresh juices, but it is possible that biobased packaging might be used for other items such as fat-rich foods and dairy products. Comparing biobased packaging to traditional packaging for these items has been shown to have a favourable influence on the food product. On the whole, it can be stated that biobased packaging is currently being developed for applications with short shelf lives and dry items that do not require high oxygen or water vapour barrier to function properly.

5.2 End-of-Life Management for Bioplastics

End-of-life management scenarios were created for this research to see if upgrading the EOL management system might reduce the environmental effect. Approximately 75% of plastic trash is now disposed of in sanitary landfills, with the other 25% being recycled [109]. In landfills, bioplastics can decompose anaerobically, producing methane, a powerful greenhouse gas. Bioplastics may be turned to compost with suitable composting facilities. Bioplastics, on the other hand, are theoretically recyclable [110]. When biobased and biodegradable plastics are used more often, disposal must be considered. There are no issues with using drop-in biobased polymers like bioPE because they are chemically similar to their petroleum-derived equivalents and can be recycled in the same stream [111].

On the other hand, Biodegradable plastics are a new class of materials that are chemically different from existing plastics. Most individuals (62%) said they would recycle biodegradable plastic in their usual recycling container if they could identify it [112]. Recycling, organic recovery, and energy recovery are the most advantageous end-of-life options for fibre and bio-based packaging materials since they avoid landfilling [113]. The recovery chain must include the following stages to adhere to this hierarchy in a long-term manner: (a) collection–creating appropriate collection methods based on the source of packaging waste; and (b) sorting–adequate categorization for each end-of-life solution following the quality standards [114]. The main objective for bioplastic goods at the end of their intended usage is to close the loop, cycling the product back to be reutilized at the end of its life [109]. Reduce, reuse, recycle, and compost are the preferred methods of disposal at the end of a product’s life cycle.

The end-of-life options for bioplastics include:

• Recycling

• Renewable energy recovery (incineration)

• Compost/biodegradation

• Anaerobic digestion and

• Feedstock recovery

Bioplastics may be recycled; however, they must be separated into distinct streams [115]. Suppose biodegradable material is introduced into the conventional plastics stream and fully degrades throughout the recycling process. In that case, the features and specifications of the traditional material with which it is mixed may be altered. Furthermore, if it does not entirely decay, it may do so in the completed recycled product, causing premature failure [116]. Though the technology for separating bioplastics from ordinary plastics exists, it is still in its infancy. It will be practical soon as commercial quantities rise enough to pay the necessary investments. Because of the large quantity of heat created by plastics, energy recovery is worldwide [117]. PLA and other biodegradable polymers created from renewable resources typically include carbon, oxygen, and hydrogen atoms, with no chlorine atoms. They do not develop dioxins during combustion or incineration since they do not contain chlorine atoms. Bioplastics have always lacked heavy-metal additions [118]. As a result, they may generally be properly burned without producing dioxins or heavy metals [113]. End-of-life alternatives such as recycling, composting, and anaerobic digestion should be prioritised above energy recovery because of the great potential for other choices such as those mentioned above [119]. Even though biodegradability is the primary goal of bioplastics, they should be the least desired end-of-life choice because there is a great possibility for alternative end-of-life alternatives such as recycling, composting, and anaerobic digestion [120].

The bioplastic may not only be melted and turned into granules for new use during recycling, but it can also be broken down into its chemical building block in some circumstances [121]. Lactic acid, for example, may be extracted from PLA and utilized to create PLA resin once more. Chemical recycling is another term for it [122]. The product that has been certified biodegradable or compostable and the difference between the two must be well understood [123]. Biodegradable products are always compostable, whereas compostable products are not necessarily biodegradable. In order to be biodegradable, a product must satisfy specific standards (time, environmental conditions, quality of compost produced). Composability is a feature of several bioplastic materials [124]. However, this composability will only occur under the strict supervision of industrial composting facilities [125]. At the moment, the approach of utilizing waste from biodegradable plastics in bio-gasifiers to turn it into usable methane is also being used on a small scale. When coupled with composability, anaerobic digestion of bioplastics offers a lot of potential for more effective waste management [126].

5.3 Factors Driving the Uptake of Biodegradable Plastics

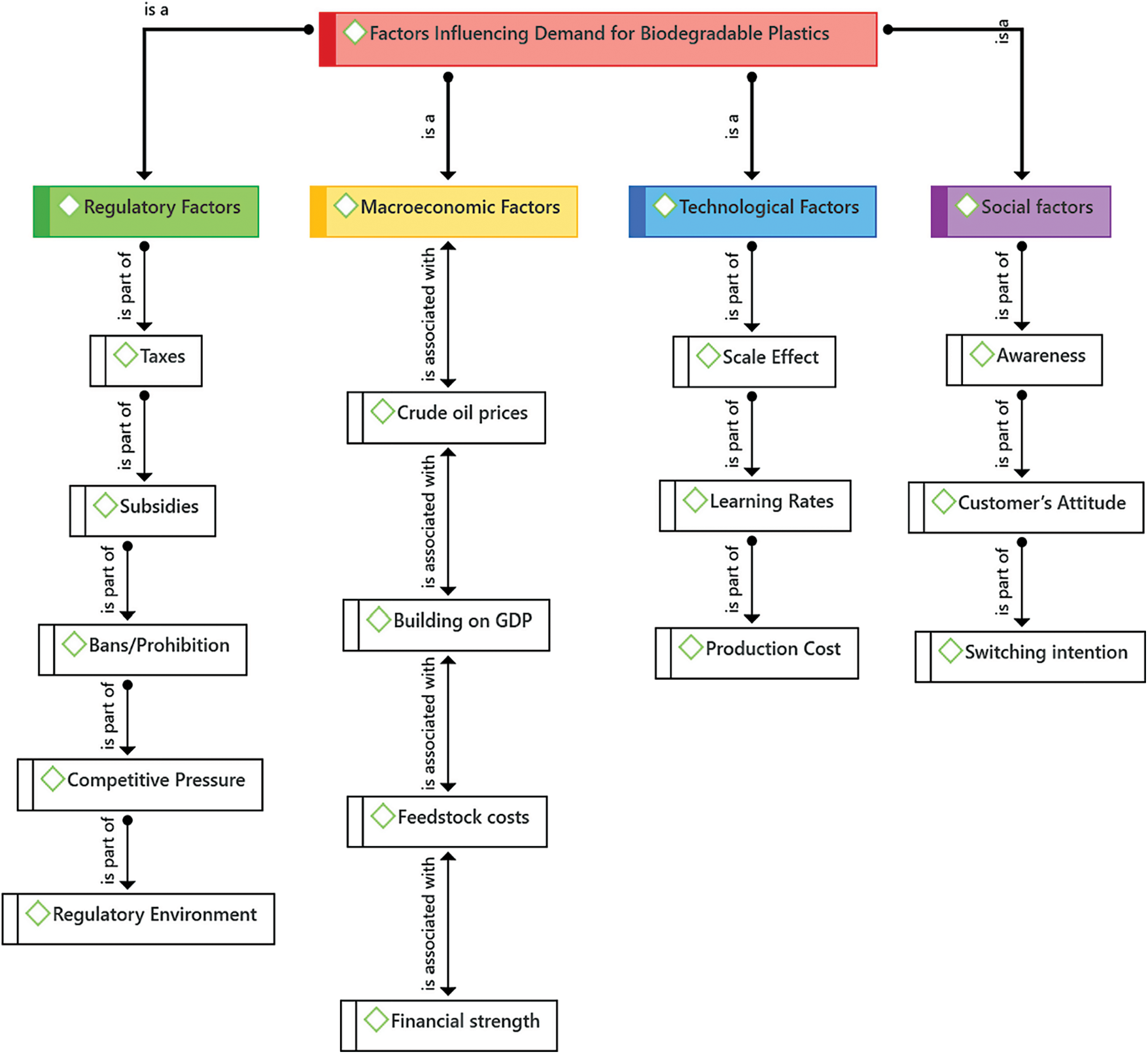

Biodegradable plastics’ achievement rates and position are influenced by their sustainability credentials and clients and rules, technology, and resources. There are a few brief instances:

⮚ Technology/material properties

Biodegradable plastics’ acceptance and long-term viability were determined by two technological areas: materials manufacturing and waste management. First is the waste handling line. With upgraded composting infrastructure, including compost sorting, it would be easier to process biodegradable plastics in the composting facility in the composting facility [20,21]. Improved, financially feasible sorting technology would also mitigate recycling issues. Fluorescent markers are a viable technology in this field [3]. Fluorescent markers include an entail labelling of the resin that generates a light that can be sensed and used to sort products when irradiated. Other firms are developing the performance and durability of plastic sorting machines (e.g., Tomra) [20,21]. One crucial point regarding material properties is that biodegradable plastics with the same characteristics as traditional plastics can be developed to ensure competition in the market.

⮚ Economies of scale

By increasing production volume for biodegradable plastics, businesses may benefit from cost and generate more income at somewhat lower (unit) costs. Manufacturing quantities of biodegradable polymers are currently modest, and production costs are considerable [22].

⮚ Competitive pressure

In the literature, competitive pressure is described as the pressure that arises from the possibility of losing a competitive advantage. It applies to the competitive pressure on companies to embrace new technologies. The market in which an organisation works influences the probability of innovation acceptance [127]. The higher the level of competition, the higher the rate of technological acceptance. Competitive pressure has been described as a critical factor in the introduction of new technologies. Firms may easily imitate their rivals and adapt to pressure, regardless of the anticipated gains, when their performance is all that matters [128]. Increased rivalry makes businesses feel compelled to innovate to gain a competitive edge over their competitors.

⮚ Regulatory environment

Policy and intervention will dramatically alter the rate at which bio-based polymers are used [129]. In contrast with biofuel development supporters, bioplastics suffer from a lack of favourable government policies [34]. Deposit bans (zero waste to deposit or waste mitigation to deposit) have an excellent connection to lower plastic deposit rates. However, it is cautious to ensure that all measures are related to particular recycling priorities and then tracked so that the amount of plastic waste incinerated does not only rise [3].

⮚ Taxes

Traditional plastics may see a price increase as a result of taxes on fossil-fuel-based items. In contrast, this would cut the cost of biodegradable polymers and expand the biodegradable plastics market [22].

⮚ Subsidies

Biodegradable plastics producers may be able to sell their products at a cheaper cost due to government incentives, hence increasing demand [22].

⮚ Bans/Prohibition

State prohibitions on fossil plastics will bolster the market for biodegradable plastic goods. However, if the limitations extend to any kind of plastic, biodegradable plastic products may still be prohibited, and standards may deteriorate [22].

⮚ Awareness

As consumers become more aware of natural resources and environmental conservation, their willingness to pay for organic items develops [22]. For customers to get familiar with green companies, marketers must provide information on biodegradable plastics, eco-labelling, and the use of green message content. To encourage the use of biodegradable plastics, they must be affordable, energy-efficient, and of high quality [130]. The sale of biodegradable plastics will increase if the government and non-government organizations work together to develop environmental awareness among buyers [95].

⮚ Attitudes of consumer

In finding and disposing of biodegradable plastics, customers must be encouraged [131]. The project Open-Bio aims to solve this problem by using standards, labels, and harmonized product information lists for organic products and developing a biologic product database and their characteristics [132]. It was proposed to create an identity code for composting containers and bags to help separate them from recyclable items to encourage proper disposal [3].

⮚ Crude oil prices

Crude oil prices influence the rise of demand for biodegradable plastics. Because conventional plastics are primarily manufactured from crude oil, the price is determined by oil price [133]. With the rising expense of fossil polymers and the high oil price, biodegradable polymers have become more tempting as a solution. Increased demand for biodegradable plastics would arise from an increase in the price of oil [22,134].

⮚ Building on the gross domestic product (GDP)

Biodegradable plastics manufacturing and growth will increase as GDP rises, and biodegradable plastics consumption will rise as well [22]. If higher-income market participants spend more on environmental solutions, demand for biodegradable plastics will grow even more [11].

⮚ Feedstock costs

Feedstock price increases greatly influence the cost of producing biodegradable polymers. Currently, maize starch or sugar cane are the principal sources of biodegradable polymers [135]. If the price of maize or sugar rises, so will the cost of production and, as a result, the cost of biodegradable plastics [22]. On the other hand, higher prices result in a decrease in the manufacturing of biodegradable plastics. Maize and sugar markets are particularly volatile worldwide [136].

⮚ Financial strength

Financial strength includes interest rate fluctuations, credit ratings, capital supply, cash flows, and pension coverage. In order to promote the switch to biodegradable materials, fiscal policy initiatives would be required [137]. This includes funding for low GHG practices and strong landfill prices (which will boost pathologic waste management’s competitive position); and market control of farm feedstock (to ensure they cope with natural gas, thereby pushing migration towards biological materials) [138]. The innovative techniques in economics are shown by the example of two of the best recycling/incineration countries [139]: The Netherlands (where waste is expensive due to being near to the sea) and Japan, where waste excavation includes burial into hard volcanic rock [3]. Fig. 10 shows the factors influencing demand for biodegradable plastics.

Figure 10: Factors influencing demand for biodegradable plastics

Therefore, as previously stated, the many influencing factors are challenging to quantify to employ in a system for forecasting bioplastic demand [22]. The information on bioplastic needs is derived from a time series of linked data on crude oil prices, feedstock costs, and GDP. Several technical prospects are being produced across the literature and throughout this study [140] since there is a high degree of misunderstanding in the prospective application of these aspects. It’s also challenging to estimate policy measures that can be implemented in the future because there are various policy interventions with varying outcomes [137]. Furthermore, the implementation of national and international policies will be problem-sensitive, resulting in different outcomes. The perceptual impact will be significantly more difficult to implement [22,141].

The study starts with a discussion of bio-based and biodegradable polymers and then moves on to assess the existing research. This research systematically assesses the literature on bio-based and biodegradable plastics, including descriptive analysis based on metadata analysis and content analysis findings. The information was gathered from reputable databases. Influential authors, prominent journals, publications by year, top contributing nations, institutions, and fields are revealed through metadata analysis. Based on the number of publications and citations, Karak and Briassoulis are the most prominent authors in the bio-based and biodegradable plastics field.

Furthermore, Polymers was shown to be the most influential journal in this field regarding the impact and the number of articles published. At the same time, the Journal of Cleaner Production was discovered to be among the top 10 journals in the field. The survey also finds that China and the United States dominate this field in terms of influence and quantity of publications. Furthermore, the analysis discovers that the fields of materials science, chemistry, and chemical engineering account for a significant portion of the literature on bio-based and biodegradable plastics.

Following that, the study presents findings based on Web of Science shortlisted publications. Based on content analysis, the findings were provided. All of the shortlisted articles were grouped into three categories as part of the content analysis. The categories consist of assessment/evaluation on the sustainability of bio-based and biodegradable Plastics, sustainability of biodegradable Plastics, and factors driving the uptake of biodegradable plastics. The content analysis reveals that most bio-based and biodegradable plastic film evaluations considered only one dimension of sustainability [79,81,83]; few considered two dimensions [80], and very few considered three dimensions [78]. Academic and industrial interest has grown dramatically in biodegradable plastics towards sustainability in recent years. The triple bottom line method in this report (economic benefit, social responsibility, and environmental protection) was employed to assess the biodegradable plastics towards sustainability. In general, biodegradable plastic film analyses have concentrated on the product itself and have scarcely contemplated evaluating biodegradable plastics’ sustainability from a TBL and determinants viewpoint. As biodegradable plastic film grows, more and more organizations are gradually focused on sustainable assessment. Furthermore, this research has valuable insights into the state of applying influential factors towards the sustainability of the biodegradable plastics industry in organization context and highlight its related problems. Having addressed the general history of the relevant firms, this research has provided an appropriate interpretation of the sustainability of biodegradable plastics, shaping influential factors to optimize awareness and combining with the environment’s complexities. This study’s proposed findings would also help biodegradable plastics businesses achieve various benefits, including improved awareness of sustainability and enhanced sustainability understanding through the application of TBL and its related techniques.

From the sustainability standpoint, this study evaluated existing strengths and challenges in terms of regulatory, market, and technology for biodegradable plastics. Although bioplastics appear biodegradable and beneficial to our environment, progress toward sustainability is still sluggish due to biodegradable plastics production technology constraints and biodegradability application in natural environments. The potential of reduced food availability due to rising basic grain prices resulting from rivalry with bioenergy industries for feedstock must also be addressed for future generations. It also opens up new commercial and employment prospects for agriculture and chemical industries. Biodegradable plastics are still poorly recognised, and consumers lack a thorough understanding of what they are and how to dispose of them. Because the usage of biodegradable plastic items in the plastic market is low, there is not much push for proper disposal. However, introducing biodegradable polymers without a sustainable product design over the whole life cycle would be pointless. Our research has found that biodegradable plastics have the potential to become more sustainable in the future if sustainability strategies are implemented, such as improving technology to extend the lifespan of biodegradable plastics products and developing new additives to make biodegradable plastics completely compostable. These TBL and system thinking tactics will also teach organisations the best sustainable measures to guarantee long-lasting product development and satisfy market demands. After examining the current state of biodegradable plastics production and creating a vision for future biodegradable plastics in a sustainable society, several leverage points for increasing the biodegradable plastics industry’s sustainability were identified, primarily in environmental policies, feedstock production, and manufacturing stages.

There are certain limitations to the research. In order to begin with, the study’s data was gathered from the Scopus and Web of Science databases, which do not contain all of the publications. As a result, numerous articles have been omitted, potentially raising concerns about generalizability. Second, the data for the study was gathered objectively using keyword searches rather than through a subjective screening and shortlisting process. Although subjective judgement can be valuable in some cases, this technique has the potential to provide biased outcomes. Finally, the study limits itself to metadata and content analysis to make readers understand. In order to undertake more research, future research may use various citations and network analytic software.

In terms of future research, few studies have attempted to undertake an inter-sectoral comparison analysis. For example, Rahman et al. [142] conducted a study on an overview of biomass to bioplastics production. The findings indicate that additional research in this area is needed in the future in other nations. Furthermore, there are few transcontinental or comparative studies between regions in the literature. Despite the fact that few research collects data from multiple countries, the comparison results were poorly presented [143]. Future research might look into the interaction between bio-based, biodegradable polymers and feedstock production in other nations and positively contribute. In addition, future research should also provide network analysis among authors, countries, and keywords.

Funding Statement: We would like to acknowledge the Ministry of Higher Education of Malaysia for providing financial support for this research through the Transdisciplinary Research Grant Scheme (TRGS) No. TRGS/1/2018/UMP/01/1 (University Reference: RDU191801-5).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Taylor, M. (2020). Malaysia top plastic consumer in Asia, says WWF. Star Media Gr. https//Www.Thestar.Com.My/News/Nation/2020/02/17/Malaysia-Top-Plastic-Oceanpolluter-in-Asia-Says-Wwf. [Google Scholar]

2. Geyer, R., Jambeck, J. R., Law, K. L. (2017). Production, use, and the fate of all plastics ever made. Science Advances, 3(7), e1700782. DOI 10.1126/sciadv.1700782. [Google Scholar] [CrossRef]

3. Dilkes-Hoffman, L. S. (2020). Exploring the role of biodegradable plastics (Ph.D. Thesis). The University of Queensland. [Google Scholar]

4. Wadstein, V. (2019). Circular economy in plastic production: The recycling challenges and solutions in plastic production. http://urn.kb.se/resolve?urn=urn%3Anbn%3Ase%3Akth%3Adiva-264551. [Google Scholar]

5. Napper, I. E., Thompson, R. C. (2019). Environmental deterioration of biodegradable, oxo-biodegradable, compostable, and conventional plastic carrier bags in the sea, soil, and open-air over 3 years. Environmental Science & Technology, 53(9), 4775–4783. DOI 10.1021/acs.est.8b06984. [Google Scholar] [CrossRef]

6. Ritchie, H., Roser, M. (2019). Outdoor air pollution. https://ourworldindata.org/outdoor-air-pollution. [Google Scholar]

7. Khazanah Research Institute (2019). The times they are A-changin’: Technology, employment, and the Malaysian. http://www.krinstitute.org/assets/contentMS/img/template/editor/20170504_KRI. [Google Scholar]

8. Weinstein, J. E., Dekle, J. L., Leads, R. R., Hunter, R. A. (2020). Degradation of bio-based and biodegradable plastics in a salt marsh habitat: Another potential source of microplastics in coastal waters. Marine Pollution Bulletin, 160, 111518. DOI 10.1016/j.marpolbul.2020.111518. [Google Scholar] [CrossRef]

9. Saygin, H., Baysal, A. (2020). Similarities and discrepancies between bio-based and conventional submicron-sized plastics: In relation to clinically important bacteria. Bulletin of Environmental Contamination and Toxicology, 105(1), 26–35. DOI 10.1007/s00128-020-02908-8. [Google Scholar] [CrossRef]

10. Chek, M. F., Kim, S. Y., Mori, T., Tan, H. T., Sudesh, K.et al. (2020). Asymmetric open-closed dimer mechanism of polyhydroxyalkanoate synthase PhaC. iScience, 23(5), 101084. DOI 10.1016/j.isci.2020.101084. [Google Scholar] [CrossRef]

11. Mazhandu, Z. S., Muzenda, E., Mamvura, T. A., Belaid, M., Nhubu, T. (2020). Integrated and consolidated review of plastic waste management and bio-based biodegradable plastics: Challenges and opportunities. Sustainability, 12(20), 8360. DOI 10.3390/su12208360. [Google Scholar] [CrossRef]

12. Bhuyar, P., Muniyasamy, S., Govindan, N. (2018). Green revolution to protect the environment–identification of potential microalgae for the biodegradation of plastic waste in Malaysia. World Congress on Biopolymers and Bioplastics & Recycling Expert Opin Environ Biol, 7. DOI 10.4172/2325-9655-C5-033. [Google Scholar] [CrossRef]

13. Dussud, C., Hudec, C., George, M., Fabre, P., Higgs, P. et al. (2018). Colonization of non-biodegradable and biodegradable plastics by marine microorganisms. Frontiers in Microbiology, 9, 1571. DOI 10.3389/fmicb.2018.01571. [Google Scholar] [CrossRef]

14. Steven, S., Octiano, I., Mardiyati, Y. (2020). Cladophora algae cellulose and starch-based bio-composite as an alternative for environmentally friendly packaging material. AIP Conference Proceedings, 2262(1), 040006. [Google Scholar]

15. Sintim, H. Y., Bandopadhyay, S., English, M. E., Bary, A. I., DeBruyn J. M. et al. (2019). Impacts of biodegradable plastic mulches on soil health. Agriculture, Ecosystems & Environment, 273, 36–49. DOI 10.1016/j.agee.2018.12.002. [Google Scholar] [CrossRef]

16. Ecosystem, G. (2011). A study on plastic management in peninsular Malaysia. National Solid Waste Management Department Ministry of Housing and Local Government Malaysia, pp. 1–282. [Google Scholar]

17. Wang, J., Tan, Z., Peng, J., Qiu, Q., Li, M. (2016). The behaviours of microplastics in the marine environment. Marine Environmental Research, 113, 7–17. DOI 10.1016/j.marenvres.2015.10.014. [Google Scholar] [CrossRef]

18. Ghimire, S., Flury, M., Scheenstra, E. J., Miles, C. A. (2020). Sampling and degradation of biodegradable plastic and paper mulches in the field after tillage incorporation. Science of the Total Environment, 703, 135577. DOI 10.1016/j.scitotenv.2019.135577. [Google Scholar] [CrossRef]

19. Shen, L., Haufe, J., Patel, M. K. (2009). Product overview and market projection of emerging bio-based plastics PRO-BIP 2009-Final report. Report for European Polysaccharide Network of Excellence (EPNOE) and European Bioplastics, 243, 1–245. [Google Scholar]

20. Gross, R. A., Kalra, B. (2002). Biodegradable polymers for the environment. Science, 297(5582), 803–807. DOI 10.1126/science.297.5582.803. [Google Scholar] [CrossRef]

21. Körner, I., Redemann, K., Stegmann, R. (2005). The behaviour of biodegradable plastics in composting facilities. Waste Management, 25(4), 409–415. DOI 10.1016/j.wasman.2005.02.017. [Google Scholar] [CrossRef]

22. Moshood, T. D., Nawanir, G., Mahmud, F., Mohamad, F., Ahmad, M. H. (2021). Expanding policy for biodegradable plastic products and market dynamics of bio-based plastics: Challenges and opportunities. Sustainability, 13(11), 6170. DOI 10.3390/su13116170. [Google Scholar] [CrossRef]

23. Philp, J. C., Ritchie, R. J., Guy, K. (2013). Biobased plastics in a bioeconomy. Trends in Biotechnology, 31(2), 65–67. DOI 10.1016/j.tibtech.2012.11.009. [Google Scholar] [CrossRef]

24. Ravindran, A. R., Ravindran, A. R. (2016). Multiple criteria decision making: An overview. Multiple Criteria Decision Making in Supply Chain Management, 15, 1–13. DOI 10.1201/CRCOPERRESE. [Google Scholar] [CrossRef]

25. Matsuura, E., He, X. (2008). Sustainability opportunities and challenges of bioplastics, pp. 16–32. Sweden: School of Engineering Blekinge Institute of Technology Karlskrona. [Google Scholar]

26. Iordanskii, A. (2020). Bio-based and biodegradable plastics: From passive barrier to active packaging behaviour. Polymers, 12(7), 1537. DOI 10.3390/polym12071537. [Google Scholar] [CrossRef]

27. Razza, F., Briani, C., Breton, T., Marazza, D. (2020). Metrics for quantifying the circularity of bioplastics: The case of bio-based and biodegradable mulch films. Resources, Conservation and Recycling, 159, 104753. DOI 10.1016/j.resconrec.2020.104753. [Google Scholar] [CrossRef]

28. Kolybaba, M., Tabil, L. G., Panigrahi, S., Crerar, W. J., Powell, T. et al. (2006). Biodegradable polymers: Past, present, and future. ASABE/CSBE North Central Intersectional Meeting, pp. 1–15. American Society of Agricultural and Biological Engineers, USA. [Google Scholar]

29. Marsh, G. (2003). Next step is for automotive materials. Materials Today, 4(6), 36–43. DOI 10.1016/S1369-7021(03)00429-2. [Google Scholar] [CrossRef]

30. Widiastuti, I. (2014). Mechanical performance of a PLA-based biodegradable plastic for liquid packaging application. https://researchbank.swinburne.edu.au/file/4048d2e4-4a06-43a2-82e4-4865e168095c/1/Indah%20Widiastuti%20Thesis.pdf. [Google Scholar]

31. Zoungranan, Y., Lynda, E., Dobi-Brice, K. K., Tchirioua, E., Bakary, C. (2020). Influence of natural factors on the biodegradation of simple and composite bioplastics based on cassava starch and corn starch. Journal of Environmental Chemical Engineering, 8(5), 104396. DOI 10.1016/j.jece.2020.104396. [Google Scholar] [CrossRef]

32. Shovitri, M., Nafi’ah, R., Antika, T. R., Alami, N. H., Kuswytasari, N. D. et al. (2017). Soil burial method for plastic degradation performed by Pseudomonas PL-01, Bacillus PL-01, and indigenous bacteria. AIP Conference Proceedings, 1854(1), 020035. AIP Publishing LLC. [Google Scholar]

33. Wang, Y., Yin, J., Chen, G. Q. (2014). Polyhydroxyalkanoates, challenges and opportunities. Current Opinion in Biotechnology, 30, 59–65. DOI 10.1016/j.copbio.2014.06.001. [Google Scholar] [CrossRef]

34. Briassoulis, D., Pikasi, A., Hiskakis, M. (2021). Recirculation potential of post-consumer/industrial bio-based plastics through mechanical recycling-techno-economic sustainability criteria and indicators. Polymer Degradation and Stability, 183, 109217. DOI 10.1016/j.polymdegradstab.2020.109217. [Google Scholar] [CrossRef]

35. Holden, G. (2011). Thermoplastic elastomers. Applied Plastics Engineering Handbook, pp. 77–91. USA: William Andrew Publishing. [Google Scholar]

36. Siracusa, V., Blanco, I. (2020). Bio-polyethylene (Bio-PEBio-polypropylene (Bio-PP) and Bio-poly (ethylene terephthalate) (Bio-PETRecent developments in bio-based polymers analogous to petroleum-derived ones for packaging and engineering applications. Polymers, 12(8), 1641. DOI 10.3390/polym12081641. [Google Scholar] [CrossRef]

37. Kolybaba, M., Tabil, L. G., Panigrahi, S., Crerar, W. J., Powell, T. (2006). Biodegradable polymers: Past, present, and future. ASABE/CSBE North Central Intersectional Meeting, pp. 1. USA, American Society of Agricultural and Biological Engineers. [Google Scholar]

38. Walker, S., Rothman, R. (2020). Life cycle assessment of bio-based and fossil-based plastic: A review. Journal of Cleaner Production, 261, 121158. DOI 10.1016/j.jclepro.2020.121158. [Google Scholar] [CrossRef]

39. Ipsos (2019). The last straw: Discouraging single-use plastic. Ipsos Sdn Bhd. [Google Scholar]

40. Sudesh, K., Iwata, T. (2008). Sustainability of biobased and biodegradable plastics. CLEAN–Soil, Air, Water, 36(5--6), 433–442. DOI 10.1002/clen.200700183. [Google Scholar] [CrossRef]

41. Din, M. I., Ghaffar, T., Najeeb, J., Hussain, Z., Khalid, R. et al. (2020). Potential perspectives of biodegradable plastics for food packaging application-review of properties and recent developments. Food Additives & Contaminants: Part A, 37(4), 665–680. DOI 10.1080/19440049.2020.1718219. [Google Scholar] [CrossRef]

42. RameshKumar, S., Shaiju, P., O’Connor, K. E. (2020). Bio-based and biodegradable polymers-state-of-the-art, challenges and emerging trends. Current Opinion in Green and Sustainable Chemistry, 21, 75–81. DOI 10.1016/j.cogsc.2019.12.005. [Google Scholar] [CrossRef]

43. Lam, H. C. (2013). Biodegradable plastics: Feasible in Hong Kong? HKU Online (HKUTO). [Google Scholar]

44. Saunders, M., Lewis, P. H. I. L. I. P., Thornhill, A. D. R. I. A. N. (2007). Research methods. Business Students 4th edition Pearson Education Limited, England. [Google Scholar]

45. Tranfield, D., Denyer, D., Smart, P. (2003). Towards a methodology for developing evidence-informed management knowledge by means of a systematic review. British Journal of Management, 14(3), 207–222. DOI 10.1111/1467-8551.00375. [Google Scholar] [CrossRef]

46. Seuring, S., Müller, M., Westhaus, M., Morana, R. (2005). Conducting a literature review—The example of sustainability in supply chains. Research Methodologies in Supply Chain Management, 15(1), 91–106. DOI 10.1007/3-7908-1636-1. [Google Scholar] [CrossRef]

47. Moshood, T. D., Nawanir, G., Sorooshian, S., Okfalisa, O. (2021). Digital twins driven supply chain visibility within logistics: A new paradigm for future logistics. Applied System Innovation, 4(2), 29. DOI 10.3390/asi4020029. [Google Scholar] [CrossRef]

48. Tseng, M. L., Islam, M. S., Karia, N., Fauzi, F. A., Afrin, S. (2019). A literature review on green supply chain management: Trends and future challenges. Resources, Conservation and Recycling, 141, 145–162. DOI 10.1016/j.resconrec.2018.10.009. [Google Scholar] [CrossRef]

49. Fahimnia, B., Sarkis, J., Davarzani, H. (2015). Green supply chain management: A review and bibliometric analysis. International Journal of Production Economics, 162, 101–114. DOI 10.1016/j.ijpe.2015.01.003. [Google Scholar] [CrossRef]

50. Malviya, R. K., Kant, R. (2015). Green supply chain management (GSCMA structured literature review and research implications. Benchmarking: An International Journal, 22(7), 1360–1394. DOI 10.1108/BIJ-01-2014-0001. [Google Scholar] [CrossRef]

51. Seuring, S., Müller, M. (2008). From a literature review to a conceptual framework for the sustainable supply chain management. Journal of Cleaner Production, 16(15), 1699–1710. DOI 10.1016/j.jclepro.2008.04.020. [Google Scholar] [CrossRef]

52. Apriliyanti, I. D., Alon, I. (2017). Bibliometric analysis of absorptive capacity. International Business Review, 26(5), 896–907. DOI 10.1016/j.ibusrev.2017.02.007. [Google Scholar] [CrossRef]

53. Coronado, R. A., Riddle, D. L., Wurtzel, W. A., George, S. Z. (2011). Bibliometric analysis of articles published from 1980 to 2009 in physical therapy, journal of the American physical therapy association. Physical Therapy, 91(5), 642–655. DOI 10.2522/ptj.20100267. [Google Scholar] [CrossRef]

54. Fetscherin, M., Heinrich, D. (2015). Consumer brand relationships research: A bibliometric citation meta-analysis. Journal of Business Research, 68(2), 380–390. DOI 10.1016/j.jbusres.2014.06.010. [Google Scholar] [CrossRef]

55. Birko, S., Dove, E. S., Özdemir, V. (2015). A delphi technology foresight study: Mapping social construction of scientific evidence on metagenomics tests for water safety. PLoS One, 10(6), e0129706. DOI 10.1371/journal.pone.0129706. [Google Scholar] [CrossRef]

56. Tseng, M. L., Chiu, A. S. (2013). Evaluating firm’s green supply chain management in linguistic preferences. Journal of Cleaner Production, 40, 22–31. DOI 10.1016/j.jclepro.2010.08.007. [Google Scholar] [CrossRef]

57. Kamau-Devers, K., Miller, S. A. (2020). The environmental attributes of wood fibre composites with bio-based or petroleum-based plastics. The International Journal of Life Cycle Assessment, 25(6), 1145–1159. DOI 10.1007/s11367-020-01744-6. [Google Scholar] [CrossRef]

58. Mendes, A. C., Pedersen, G. A. (2021). Perspectives on sustainable food packaging:–is bio-based plastics a solution? Trends in Food Science & Technology, 112, 839–846. DOI 10.1016/j.tifs.2021.03.049. [Google Scholar] [CrossRef]