| Energy Engineering |  |

DOI: 10.32604/ee.2022.019450

ARTICLE

Suitability Evaluation of Hydrogen Production and Hydrogenation Station Based on AHP-Fuzzy Comprehensive Evaluation Method

School of Management, China University of Mining and Technology (Beijing), Beijing, 100083, China

*Corresponding Author: Jing Xue. Email: xuejing05@126.com

Received: 25 September 2021; Accepted: 21 December 2021

Abstract: Since there are multiple influencing factors and lack of evaluation standards for the construction of hydrogen production and hydrogenation station in China, this paper establishes the suitability evaluation index system of hydrogen production and hydrogenation station from four aspects of technology, economy, environment and safety. Combined with actual conditions, this paper uses Analytic Hierarch Process (AHP) and Fuzzy Comprehensive evaluation to evaluate water electrolysis hydrogen and hydrogenation production station and natural gas reformation hydrogen production and hydrogenation station. The results show that hydrogen producing by water electrolysis is more efficient than natural gas reformation in hydrogen production and hydrogenation station, and it should be choose firstly. Furthermore, natural gas reformation hydrogen producing is inferior in technology, environment and safety, but it is superior to water electrolysis hydrogen producing in economy. In the future, we can strengthen development of the hydrogen production from renewable energy sources, so as to enhance the economic benefit of that by water electrolysis. In addition, we can also adopt two ways of hydrogen production in hydrogen production and hydrogenation station to achieve favorable integrative benefits.

Keywords: Hydrogen production and hydrogenation station; suitability evaluation; AHP; fuzzy comprehensive evaluation

Hydrogen energy, as a clean and efficient secondary energy source, is also the main direction of future clean energy development, and will certainly drive a major change in the field of energy technology in China [1]. China has a vast energy consumption market, while has a sound hydrogen production foundation. Since 2013, the scale of hydrogen production in China has been increasing year by year. In 2019, China hydrogen output surpassed 22 million tons, becoming the world’s largest hydrogen producer [2]. It is predicted that demand of hydrogen in China will reach 5% of final energy structure by 2030, and to 10% in 2050. Meanwhile, the forecasting production value will achieve 12 trillion yuan in the industrial chain [3].

In the development of the hydrogen energy industry, the construction of hydrogen energy infrastructure, represented by the construction of hydrogenation stations, is at the downstream of the industrial chain. With which both upstream hydrogen production and midstream hydrogen transportation are closely related to it. As an important construction method of hydrogenation station, on-site hydrogen production and hydrogenation station can produce hydrogen, and the hydrogen can be directly used for vehicle filling after purification, compression and storage. The process can effectively reduce the energy consumption and cost of hydrogen in the midstream of the storage and transportation process, improve the safety of hydrogen filling, reduce the time cost, and connect the entire hydrogen industry chain closely. Since 2020, 118 hydrogen fueling stations have been constructed excluding the demolished, and 167 new stations are being and will be installed in China [4]. Nowadays, the stations which have entered service are mostly used in off-site hydrogen supply. In 2018, Datong officially launched the construction of China’s first hydrogen production and hydrogenation station [5]. At present, on-site hydrogen production stations mainly include Beijing Yongfeng Hydrogen Station, Dalian Tongji-Xinyuan Hydrogen Station and Nanzhuang Hydrogen Production and Hydrogenation etc. [6]. A complete network system of hydrogen production and hydrogenation station has not been formed in China. There are still deficiencies, such as low localization rate of key materials and core components, high construction cost, high production cost, and imperfect technical standards and testing systems [7]. The awareness of the technology, economy, environment protection and safety of hydrogen production and hydrogenation stations should be strengthened urgently. Therefore, the construction of hydrogen production and hydrogenation station systems has important practical significance.

In recent years, there are many research about the evaluation system of hydrogen production or hydrogenation stations. In 2007, Niu [8] designed an evaluation index system for hydrogen production technology system. Through the analytic hierarchy process, fuzzy comprehensive evaluation method (FCE) and Delphi direct weight construction method, Niu Jiao evaluated the hydrogen production system from natural gas reforming, coal gasification and water electrolysis from the four dimensions of technology, economy, society and environment. In 2009, Pilavachi et al. [9] used AHP to evaluate seven common hydrogen production processes from five aspects. In 2012, Gim et al. [10] analyzed the scale economy of water electrolysis hydrogen production and methane steam reforming hydrogen production, to determine the optimum energy structure and total construction cost of hydrogen refueling stations in South Korea. In 2014, Thengane et al. [11] used AHP and Fuzzy Analytical Hierarchy Process to analyze the cost-benefit of eight different hydrogen production technologies. In 2016, Wang [12] put forward a risk assessment model suitable for the environment security of hydrogen refueling stations, based on characteristic of the stations. In 2018, Lucrezia Ravasio took the small-scale on-site hydrogen production station in Narvik, northern Norway, as an example to introduce the techniques of hydrogen production by steam reforming and water electrolysis. Then they calculated the overall thermal efficiency of the hydrogen station [13]. In 2019, Xu [14] established an evaluation system model suitable for hydrogen production technology from the three aspects of society, economy and safety. AHP and FCE were used to evaluate the hydrogen production station of natural gas reforming, electrolytic water and coke oven gas, respectively. Yang et al. [15] constructed a method for calculating the income of hydrogen production by used two indicators, net present value and internal return rate, to represent the economics of hydrogen use.

Therefore, it can be seen that the evaluation of hydrogen production or hydrogen refueling stations at home and abroad is often limited to a single process, and there is a lack of comprehensive evaluation of the integrated operation mode of hydrogen production and hydrogenation stations. This paper proposes 15 indicators to establish the evaluation system for hydrogen production and hydrogenation stations from four aspects of technology, economy, environment and safety. In addition, based on the current development situation in China, evaluation of on-site hydrogen production by water electrolysis and by natural gas reforming is carried out by AHP-FCE, in order to develop some understandings about the construction of China’s hydrogen filling stations. This is crucial for finding a suitable way to develop hydrogen production and hydrogenation station in China.

This article consists of four parts. The first part is the introduction, which mainly introduces the development of China’s hydrogen production and hydrogenation stations, and current situation about the relevant research in China and abroad. The second part offers the method on establishment of suitability index system and the evaluation model of on-site hydrogen refueling stations. The third part is about the findings and discussion, including the calculation of determining index weight by AHP, and then analyzing the results based on FCE. In the last part it is a summary of this paper.

2.1 Establishment of Evaluation Index System

In the process of establishing the suitability evaluation system of hydrogen production and hydrogenation station, the most important thing is to select the appropriate evaluation indicators. First of all, the selection of evaluation indicators should be targeted, that is, the indicators should be listed according to the characteristics and actual situation of the station to ensure its practicability. Secondly, the selection of evaluation indicators should follow the principle of comprehensiveness. There are many factors affecting the hydrogen production and hydrogenation station, but the more indicators are not the better. If the correlation between indicators is too high, it will reduce the degree of differentiation and affect the judgment. At the same time, the selection of evaluation indicators should follow the principle of operability. In the actual calculation, some indicator data are difficult to obtain, or qualitative indicators are difficult to quantify, so we should try to select the indicators which are easy to obtain data [16]. Finally, the selection of evaluation indicators should also be comparable, so as to facilitate comparative analysis between different hydrogen production modes in different stations [17]. To sum up, the selection of suitability evaluation system of hydrogen production and hydrogenation station should be in accordance with the above-mentioned regulations. At the same time, in the process of establishing the adaptability evaluation system, various factors are comprehensively considered and constantly adjusted to determine the suitability evaluation system of hydrogen production and hydrogenation station.

2.1.2 Selection of Evaluation Index

For the evaluation criteria of the suitability of hydrogen production and hydrogenation station, this paper selects the evaluation indicators from four aspects of technology, economy, environment and safety, and constructs the suitability evaluation index system of hydrogen production and hydrogenation station in the station, as shown in Table 1.

2.2 Construction of Evaluation Model

AHP-fuzzy comprehensive evaluation method is an evaluation method which combines AHP and fuzzy comprehensive evaluation [19].

The analytic hierarchy process (AHP) is an evaluation method, was proposed by Satie in the 1970 s. It can quantify the decision-makers subjective judgment by integrating qualitative analysis and quantitative analysis, and reflect the relationship between target and different indicators of hydrogen production and hydrogen refueling station [20]. The principle of this method is to decompose the problem into several levels, such as goal level, criterion level and scheme level, to form a multi-level structure model. By comparing and analyzing the influence degree of the bottom factors on the upper factors, the importance judgment is made by comparing the factors and consulting experts, and the weight is obtained by constructing the matrix to help decision makers make decisions.

Using fuzzy mathematical tools, the fuzzy comprehensive evaluation method compares factors with given evaluation criteria, uses the affiliation function or fuzzy mapping to determine the affiliation degree of each indicator to the evaluation set, combines the indicator weights determined by the hierarchical analysis method, weights the scores and finally obtains the fuzzy comprehensive evaluation results. It transforms qualitative evaluation into quantitative evaluation by applying the membership theory in fuzzy mathematics, which is suitable for solving various non-deterministic problems.

2.2.1 Determine the Weight of the Index System Based on AHP

(1) Hierarchy building

According to the interrelationship between various indicators, a hierarchical evaluation indicator system is established. Generally, there is only one element in the highest level of the hierarchical hierarchy, namely the goal level A. The middle level is generally the criterion level and the sub-criteria level. The criterion level is governed by the decision-making goal, and the sub-criteria level is governed by the upper level. The relationship between indicators at all levels is shown in Appendix A.

(2) Construct judgment matrix and calculate weight

After the indicator system is established, the importance of each factor in each single layer is compared in pairs to construct a judgment matrix:

(3) Hierarchical order and consistency check

The “harmony method” is used to normalize the column vector and row vector of the judgment matrix, and obtain the weight vector W of each factor in each single layer,

When performing the consistency test, it is necessary to calculate the consistency index CI, the relative consistency index CR, and find the random one-time index RI corresponding to the n value according to Table 3.

It is generally believed that when

(4) Total level ranking and consistency check

Assuming that there are h layers

Multiply the weight vectors of each layer, calculate the comprehensive weight W of the bottom layer to the goal layer, and check its consistency.

2.2.2 Construction of Evaluation Model Based on Fuzzy Comprehensive Evaluation Method

(1) Determine the set of factors

U is a collection of evaluation indicators, which is used to analyze the different hydrogen production methods of the hydrogen production and hydrogenation stations. Among them, technical indicators, economic indicators, environment indicators and safety indicators constitute the evaluation index system set, that is, the factor set, denoted as

For all the evaluation indicators, the higher the value of an indicator, the better the suitability of the hydrogenation station is. For example, the higher the value of “energy efficiency” index, the better the environmental benefits are, so it is classified as “the-larger-the-better index”. Nevertheless, the smaller the value, the better the suitability is. For instance, the smaller the value of “greenhouse gas emissions from hydrogen production”, the better the environmental benefits of the station are, so it can be attributed to “the-smaller-the-better index”. The-larger-the-better index membership function is shown in Table 4. The-smaller-the-better index membership function is shown in Table 5.

(2) Determine the comment set

The set of possible evaluation results for the evaluation object U is called the comment set, which is represented by V [22]. Since the evaluation value of each indicator is different, the comment level will form different levels, such as excellent, good, fair, and poor. The set of comments composed of various decisions is called the set of comments, which is recorded as

(3) Determine the fuzzy comprehensive judgment matrix

For the index

among them,

(4) Single factor fuzzy comprehensive evaluation

We commonly use membership functions such as the triangular distribution, the trapezoidal distribution and the normal distribution and so on. Although the selection of membership function is subjective, it reflects the objectivity of the fuzzy state of things. This paper selects trapezoidal distribution for calculation. Then the evaluation of a single factor i is

(5) Multi-factor fuzzy comprehensive evaluation.

Multiply the weight set and the fuzzy comprehensive judgment matrix to obtain the first-level fuzzy comprehensive evaluation set, which is then calculated from the lowest level to the criterion level. Finally, the comprehensive judgment matrix D can be obtained:

The data in this paper were obtained from China Hydrogen Energy Industry Infrastructure Development Blue Book (2018) [18], Technical requirements for hydrogen supply system of proton exchange membrane fuel cell: GB/T 34872-2017 [23], Acoustic environmental quality standard: GB 3096-2008 [24], Technical requirements for water electrolysis hydrogen production system: GB/T 19774-2005 [25] and other materials. For quantitative indicators, the collected data are shown in Table 7.

3.2 The Weighing Values for Assessment Index

Considering the importance of the pairwise comparison between the suitability evaluation indexes of hydrogen production and hydrogenation station, the paper used the expert scoring method to obtain the score. In order to evaluate the system, multiple questionnaires were delivered to 15 experts and scholars in the field of hydrogen energy from State Power Investment Corporation and Beijing Sinohytec Co., Ltd., China. Then the quantifiable results using the 1–9 scale method were processed and calculated by Yaahp software. Finally, the judgment matrices were constructed [30].

Taking the determination of the level weight of the first-level indicators as an example, the first-level indicators include four aspects: technical indicators, economic indicators, environment indicators, and safety indicators. The constructed judgment matrix is shown in Table 8.

By ranking the importance of the first-level indicators, we can see that: technical indicators > safety indicators > economic indicators > environment indicators. Among them, the highest proportion is the technical indicator, accounting for 46.0%, which includes four aspects: ambient temperature of hydrogen production, working pressure of hydrogen production, hydrogen purity and availability of hydrogen production energy. For any hydrogen production and hydrogenation station, its construction and operation will be meaningless without technology requirements. The second is the safety indicators, accounting for 27.2%, because once safety problems occur in the process of hydrogen production and hydrogenation, it will cause much losses to people’s life and properties. Besides, the development of technology can effectively reduce the risk of safety accidents. The third-ranking is economic indicators, accounting for 18.0%, which is the essential criteria to make profits from hydrogen production and hydrogenation stations, and it consists of three elements: construction cost of hydrogen production station, operation cost of hydrogen production station and unit hydrogen production cost. The reason for its ranking is that the government will provide subsidies for the construction and operation of hydrogen filling stations. The last is the environment indicators, accounting for 8.8%. With the growing progress of technology and the increasing demand of the safety, the negative impact on environment will decline.

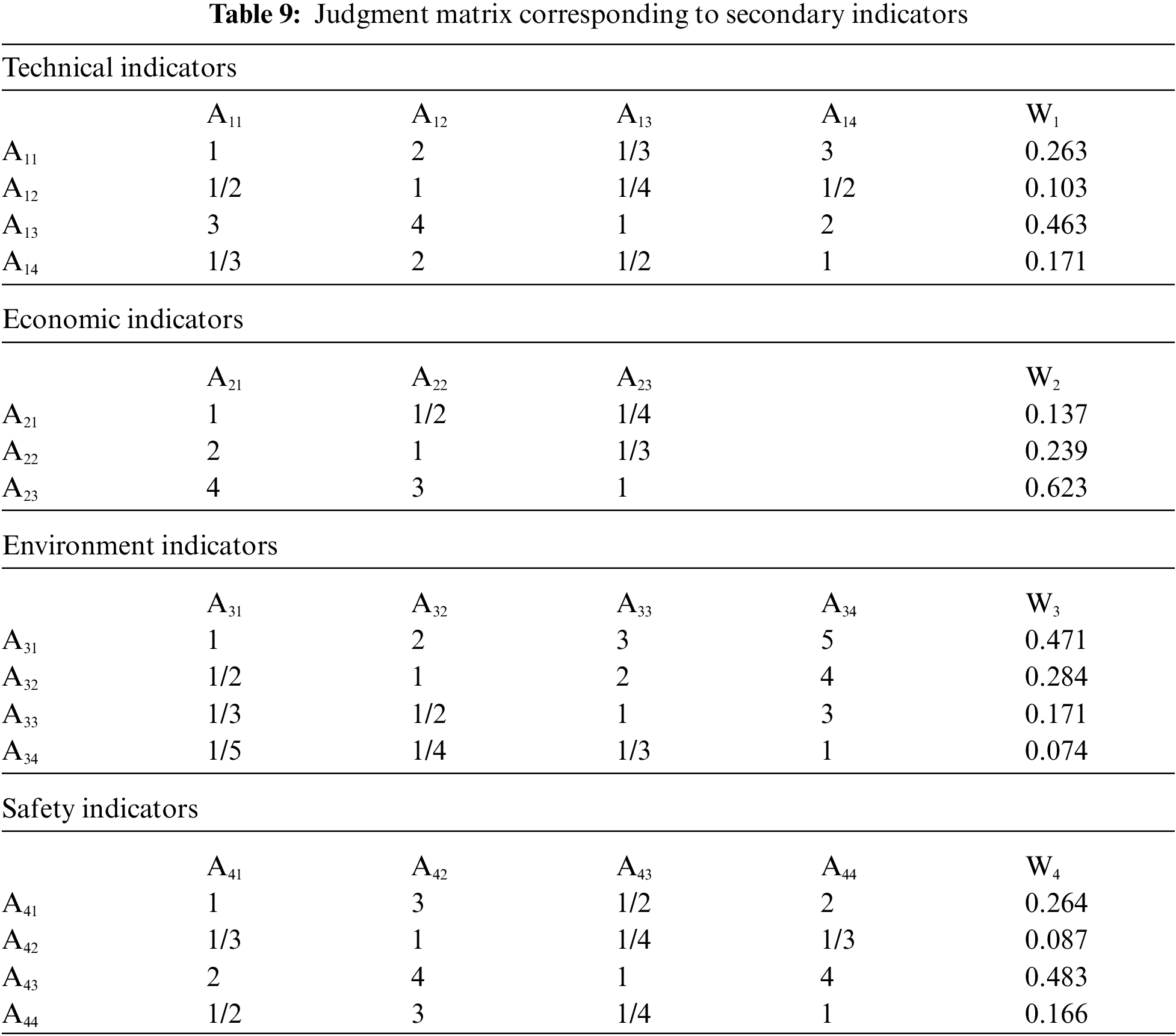

The importance of secondary indicators is logically assumed, and the constructed judgment matrix is shown in Table 9. Taking technical indicators as an example, the order of importance is hydrogen purity (46.3%) > ambient temperature of hydrogen production (26.3%) > hydrogen production accessibility (17.1%) > working pressure of hydrogen production (10.3%). Then testing consistency of the indicators, the results are shown in Appendix B. It suggests that all the results meet

Subsequently, 15 secondary indicators are adopted to compare water electrolysis hydrogen production and hydrogenation stations (represented by EL) and natural gas reforming hydrogen production and hydrogenation stations (represented by NA), respectively, and 15 judgment matrices are constructed. The judgment matrices of the secondary indexes of different hydrogen production and hydrogenation stations is shown in Table 10. Finally, summarizing the calculation results, the scores of hydrogen production and hydrogenation stations is shown in Table 11, and the final scores is shown in Table 12.

From Table 12, we can see the final score of hydrogen production and hydrogenation station with electrolyzed water (0.518) is higher than that of hydrogen production and hydrogenation station with natural gas reforming (0.482). It shows that the comprehensive benefit of water electrolysis hydrogen production and hydrogenation station is better. Among the technical indicators, the final score of hydrogen production by water electrolysis (0.532) is slightly higher than that by natural gas reforming (0.468), mainly because the former main raw material for water is obviously better than the latter. In the economic indicators, the score (0.704) of hydrogen production by natural gas reformation is higher than that of hydrogen production by water electrolysis (0.295), owing to the lower unit cost of hydrogen production. In terms of environment indicators, the final score of hydrogen production by water electrolysis (0.517) is slightly higher than that of natural gas reformation (0.483). Due to its renewable performance, hydrogen production by water electrolysis can reduce its negative impact on environment. In the safety index, the final score of hydrogen production by water electrolysis (0.643) is higher than that by natural gas reforming (0.357). Because hydrogen production by natural gas reforming is unfavorable in combustibility and explosibility of the materials.

3.3 Fuzzy Comprehensive Evaluation Results

Based on the collected data, the standard value of the evaluation index for the suitability of the hydrogen production and hydrogenation stations is determined. The results are shown in Table 13.

For qualitative indicators, the membership degree of each indicator is determined by calculating according to the trapezoid diagram, and for quantitative indicators, it is determined based on the questionnaire. The number of returned questionnaires is 100. The membership degree of each evaluation indicator relative to each level is obtained by comparing the number of people selected for each indicator with the total number of people participating in the questionnaire survey [31]. The results are shown in Table 14.

3.3.1 First-Level Fuzzy Comprehensive Evaluation

Data from Table 14 is fed into the calculation formulas (6) and (7) to obtain the first-level fuzzy judgment matrix elements, and the specific results are shown in Table 15.

As can be seen from Table 15, in terms of technical indicators, the value of hydrogen production by water electrolysis in the “Excellent” grade is 0.721, and that by natural gas reformation is 0.613. The result shows that the technical condition of water electrolysis hydrogen production is superior to natural gas reformation. Economically, the maximum value of hydrogen production by water electrolysis and by natural gas reformation are respectively 0.468 as “Fair” and 0.868 as “Good”. It proves that, in the present stage, hydrogen production by natural gas reformation can generate better economic benefits. This is consistent with the main method of hydrogen production in China. Overall, concerning the environment, the value of “excellent” for water electrolysis hydrogen production and hydrogenation stations (0.375) is superior to natural gas reformation hydrogen production and hydrogenation stations (0.313). In terms of safety, the “Excellent” values of water electrolysis hydrogen production and hydrogenation stations and natural gas reformation hydrogen production and hydrogenation stations are 0.863 and 0.439 respectively. The safety of hydrogen production technology by water electrolysis is obviously better than that by natural gas reformation.

3.3.2 Second-Level Fuzzy Comprehensive Evaluation

Take the first-level evaluation results as rows to form a single-factor evaluation matrix for the second-level evaluation.

As known weight set

In the same way, the evaluation result of natural gas reformation is obtained as

According to the calculation results of FCE, the maximum value of hydrogen production and hydrogenation stations by water electrolysis and by natural gas reformation are 0.604 and 0.451, respectively, and the two results correspond to “Excellent”. The explanation is that both methods of on-site hydrogen production have better technical, economic, environment and safety benefits. What’ s more, the water electrolysis hydrogen production is more valuable, indicating that the method of hydrogen production and hydrogenation stations should choose the water electrolysis method firstly. Generally speaking, the water electrolysis hydrogen production methods is limited by electricity and higher cost in the process of water electrolysis. Comparing to the natural gas reformation method, the unit cost of water electrolysis method is high. But it is superior in technology, environment and safety. The conclusion suggests that it is necessary to consider a variety of factors to reflect the evaluated object more scientifically [8].

The AHP-fuzzy integrated evaluation model is very useful for researchers to make a reasonable choice when selecting hydrogen production methods for hydrogen production and hydrogenation stations. This paper constructs the suitability evaluation index system for the hydrogen production and hydrogenation stations from four aspects of technology, economy, environment and safety. The evaluation system has cited a total of 15 indicators, which are representative and involved in every area of construction and operation of hydrogen production and hydrogenation station, to analyze thoroughly and comprehensively. Whereafter, AHP and FCE methods are used for comprehensive evaluation. The computational results show that the comprehensive evaluation result of water electrolysis hydrogen production is better than that of gas reformation hydrogen production, so it should be choose firstly.

In the future, environment protection is mandatory to ensure cleaner production and more harmonious development [32]. It is important that we actively research power generation with renewable electricity, and use it as a source of electrical energy for on-site hydrogen production by water electrolysis, thus reducing the cost of electricity utilization and promoting economic efficiency. In addition, on-site hydrogen production can use two ways to produce hydrogen, combining the advantages of both ways to improve the overall efficiency of hydrogen production and hydrogenation stations. It is worth noting that the differences in weights, pairwise comparison matrices and AHP-based methods can determine the evaluation results. Therefore, it is recommended to make the final decision under the guidance of experts in this field, rather than directly selecting the results of AHP.

Funding Statement: This work is supported by the Major National Key R&D Program of China 2018YFF0214804 and Chinese Academy of Engineering Consulting Project “Research on China’s Hydrogen Energy and Fuel Cell Development Strategy” (2019-ZD-3).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Ling, W., Liu, W., Li, Y. L., Wan, Y. M. (2019). Development strategy of hydrogen infrastructure industry in China. Strategic Study of CAE, 21(3), 76–83. DOI 10.15302/J-SSCAE-2019.03.003. [Google Scholar] [CrossRef]

2. Zhang, J. X., Meng, J. L., Lv, K. J., Wang, X. Y. (2021). Current situation and trend outlook of hydrogen application development in China. New Materials Industry, (1), 36–39. DOI 10.19599/j.issn.1008-892x.2021.01.010. [Google Scholar] [CrossRef]

3. Lu, C. Y., Sun, H. T., Tian, Z. P. (2021). Opportunities, challenges and countermeasures suggestions for the development of China’s hydrogen energy industry. New Economic Journal, (3), 26–30. DOI 10.3969/j.issn.1009-959X.2021.03.005. [Google Scholar] [CrossRef]

4. Niu, X. F. (2020). 118 hydrogen refueling stations will be built in China by 2020, distributed in 20 provinces and cities. https://mp.weixin.qq.com/s/Bg717XlHYdJP382kWt59w. [Google Scholar]

5. Da, T. (2019). Constructs the first integrated hydrogen production and hydrogen refueling station in China. Chlor-alkali Industry, 55(1), 47–48. [Google Scholar]

6. Jiang, Y. (2021). Nanzhuang integrated station, “hydrogen” is easy to move. China Petroleum & Petrochemicals, (19), 38–39. DOI 10.3969/j.issn.1671-7708.2021.19.013. [Google Scholar] [CrossRef]

7. Shao, Z. G., Yi, B. L. (2019). Developing trend and present status of hydrogen energy and fuel cell development. Bulletin of Chinese Academy of Sciences, 34(4), 469–477. DOI 10.16418/j.issn.1000-3045.2019.04.012. [Google Scholar] [CrossRef]

8. Niu, J. (2007). Research on systematic assessment of hydrogen production technology. Beijing University of Chemical Technology, China. [Google Scholar]

9. Pilavachi, P. A., Chatzipanagi, A. I., Spyropoulou, A. I. (2009). Evaluation of hydrogen production methods using the analytic hierarchy process. International Journal of Hydrogen Energy, 34(13), 5294–5303. DOI 10.1016/j.ijhydene.2009.04.026. [Google Scholar] [CrossRef]

10. Gim, B., Yoon, W. L. (2012). Analysis of the economy of scale and estimation of the future hydrogen production costs at on-site hydrogen refueling stations in Korea. International Journal of Hydrogen Energy, 37(24), 19138–19145. DOI 10.1016/j.ijhydene.2012.09.163. [Google Scholar] [CrossRef]

11. Thengane, S. K., Hoadley, A., Bhattacharya, S., Mitra, S., Bandyopadhyay, S. (2014). Cost-benefit analysis of different hydrogen production technologies using AHP and fuzzy AHP. International Journal of Hydrogen Energy, 39(28), 15293–15306. DOI 10.1016/j.ijhydene.2014.07.107. [Google Scholar] [CrossRef]

12. Wang, C. L. (2016). Study on management system of environmental and safety risk assessment for hydrogen fueling station. Shanghai Jiao Tong University. DOI 10.27307/d.cnki.gsjtu.2016.001141. [Google Scholar] [CrossRef]

13. Ravasio, L., Ravelli, S., Mustafa, M. (2018). Thermal efficiency of on-site, small-scale hydrogen production technologies using liquid hydrocarbon fuels in comparison to electrolysis: A case study in Norway. Energy Procedia, 148, 1002–1009. DOI 10.1016/j.egypro.2018.08.061. [Google Scholar] [CrossRef]

14. Xu, R. H. (2016). Study on the layout planning and safety evaluation of urban hydrogen refueling station. Shandong Jianzhu University. https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CMFD201902filename=1019066063.nh. [Google Scholar]

15. Yang, C. H., Wan, Z., Liu, Z. Y., Tuo, J. J., Cao, Z. et al. (2019). Economic analysis of comprehensive utilization of hydrogen. Electrical & Energy Management Technology, (21), 83–88. DOI 10.16628/j.cnki.2095-8188.2019.21.016. [Google Scholar] [CrossRef]

16. Yu, Z. X., Ma, D. C., Fan, X. J., Wang, J. H. (2020). Research on the performance evaluation of PPP project of urban water environment treatment based on AHP and fuzzy comprehensive evaluation. Ecological Economy, 36(10), 190–194. [Google Scholar]

17. Shang, B. L., Han, X. M., Chen, Y. F., Lin, G. M., Wang, K. (2020). Assessment of stealth aircraft susceptivity based on analytic hierarchy process-fuzzy comprehensive evaluation. Journal of Ordnance Equipment Engineering, 41(9),105–110. DOI 10.11809/bqzbgcxb2020.09.019. [Google Scholar] [CrossRef]

18. China National Institute of Standardization (2018). National hydrogen energy standardization technical committee. China hydrogen energy industry infrastructure development blue book. Beijing: China, Quality Inspection Press. [Google Scholar]

19. Guo, J. Y., Zhang, Z. B., Sun, Q. Y. (2008). Study and applications of analytic hierarchy process. China Safety Science Journal, (5), 148–153. DOI 10.16265/j.cnki.issn1003-3033.2008.05.018. [Google Scholar] [CrossRef]

20. Deng, X., Li, J. M., Zeng, H. J., Chen, J. Y., Zhao, J. F. (2012). Research on computation methods of AHP wight vector and its applications. Mathematics in Practice and Theory, 42(7), 93–100. DOI 10.3969/j.issn.1000-0984.2012.07.012. [Google Scholar] [CrossRef]

21. Wang, W. J., Li, Z. L., Hu, N. L., Yang, H. (2014). Evaluation of corporate social responsibility for mining enterprises in Tibet. China Mining Magazine, 23(10), 71–76. DOI 10.3969/j.issn.1004-4051.2014.10.017. [Google Scholar] [CrossRef]

22. Ba, Z. N., Han, Y. X., Liang, J. W. (2018). Risk assessment of the gas pipeline corrosion based on the improved AHP and fuzzy comprehensive. Journal of Safety and Environment, 18(6), 2103–2109. DOI 10.13637/j.issn.1009-6094.2018.06.009. [Google Scholar] [CrossRef]

23. GB/T 34872-2017 (2017). Technical requirements for hydrogen supply system of proton exchange membrane fuel cell. SAC, China. [Google Scholar]

24. GB 3096-2008 (2008). Acoustic environmental quality standard. SAC, China. [Google Scholar]

25. GB/T 19774-2005 (2005). Technical requirements for water electrolysis hydrogen production system. SAC, China. [Google Scholar]

26. China Statistical Yearbook (2019). http://www.stats.gov.cn/tjsj/ndsj/2019/indexch.htm. [Google Scholar]

27. Wang, Z. (2016). Discussion on economic comparison of hydrogen production by natural Gas, methanol and water electrolysis. Natural Gas Technology and Economy, 10(6), 47–49 + 83. DOI 10.3969/j.issn.2095-1132.2016.06.013. [Google Scholar] [CrossRef]

28. Zhang, X. C. (2013). Current status and energy efficiency analysis of foreign commercial water electrolysis hydrogen production equipment. Gas Separation, (2), 45–51. [Google Scholar]

29. Li, M., Zhang, X., Li, G. (2016). A comparative assessment of battery and fuel cell electric vehicles using a well-to-wheel analysis. Energy, 94, 693–704. DOI 10.1016/j.energy.2015.11.023. [Google Scholar] [CrossRef]

30. Thengane, S. K. (2019). Assessment of different technologies for managing yard waste using analytic hierarchy process. Process Integration and Optimization for Sustainability, 3(2), 255–272. DOI 10.1007/s41660-018-0070-1. [Google Scholar] [CrossRef]

31. Zhao, L., Xie, H. Q., Li, W. X., Cao, Y., Zhuo, L. (2020). Research on the evaluation of university innovation and entrepreneurship incentive mechanism based on fuzzy comprehensive evaluation method. Experiment Science and Technology, 18(4), 98–103. DOI 10.12179/1672-4550.20190324. [Google Scholar] [CrossRef]

32. Sun, Q., Zhang, J. X., Li, M., Zhou, N. (2020). Experimental evaluation of physical, mechanical, and permeability parameters of key aquiclude strata in a typical mining area of China. Journal of Cleaner Production, 267, 122109. DOI 10.1016/j.jclepro.2020.122109. [Google Scholar] [CrossRef]

Appendix A. Hierarchical structure diagram of suitability evaluation index of hydrogen production and hydrogenation station

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |