| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.017536

REVIEW

A Review of Test Methods for the Determination of the Permeability Coefficient of Gravelly Soils Used for Embankment Dams

1PowerChina Guiyang Engineering Co., Ltd., Guiyang, 550081, China

2State Key Laboratory of Simulation and Regulation of Water Cycle in River Basin, China Institute of Water Resources and Hydropower Research, Beijing, 100038, China

3Key Laboratory of Construction and Safety of Hydraulic Engineering of Ministry of Water Resources, China Institute of Water Resources and Hydropower Research, Beijing, 100038, China

*Corresponding Author: Gang Deng. Email: dgang@iwhr.com

Received: 18 May 2021; Accepted: 12 August 2021

Abstract: The factors influencing the permeability coefficient of gravelly soils used for the development of embankment dams (core wall) are analyzed. Such factors include (but are not limited to) soil size, anisotropy, density and boundary effects. A review of the literature is conducted and new directions of research are proposed. In such a framework, it is shown that gravelly soil with controlled density and vertical stress should be used to optimize the measurement of the vertical and horizontal permeability coefficients, respectively.

Keywords: Wide-grading gravelly soil; core wall materials; permeability coefficient; test method

Embankment dam with earth core wall (core wall dam) originates from the homogeneous earth dam and its derivative earth dam [1] and has gradually become the most common type of embankment dam, especially high embankment dam. Some 300-meter-high embankment dam under planning, design, and construction such as Nurek Dam (300 m), Nuozhadu Dam (261.5 m), Lianghekou Dam (295 m), Shuangjiangkou dam (312 m), and RM Dam (315 m) are all core wall dams [2–9].

Adopting natural materials according to local conditions is the outstanding characteristic of the core wall dam. Since the 1940s and 1950s, the selection range of core wall materials has been relatively broad from the narrow-grading agitated clay, compacted clay, and filling clay in the past to the wide-grading compacted clayey gravel containing coarse grains in recent years (gravelly soil for short, namely the soil with the soil particles mass of particle size larger than 2 mm more than 50%) [10]. The gravelly soil has various forms such as natural moraine soil or natural moraine soil with the super-diameter coarse grains screened out (such as Norway’s Slottmoberget Dam [11]), gravelly soil made by artificially mixing gravel in clay (such as Japan’s Miboro Rockfill Dam [12]), and gravelly soil made by artificially mixing clay in moraine (such as Goschenen [13] in Switzerland). Over the course of last 20 years, natural or artificial gravelly soil has been used for most of the high core wall dams built in the new boom of core dam development [1]. Even for Xiaolangdi embankment dam with earth core wall, an admixture of sand gravel and loam was used for paving impermeable inner coverings.

In addition to the extensive application of compacted wide-grading clayey gravel in the earth core wall, many projects, especially the high dams, which are different from the middle and low dams, used clay to fill the core wall in the past. For example, in the process of filling and initial application, the pore water pressure of the core wall is high, the deformation of the core wall is small or even close to or lower than the dam shell [14], some projects have longitudinal cracks on the dam top, some have sudden leakage in the first storage process [15–17], and a few projects have serious erosion inside the core wall after several years of operation [18–20].

In the analysis of core wall dam, the special phenomenon is that the excess pore water pressure calculated by the classical method is much lower than the actual value. In addition, the time predicted for pore water pressure distribution reaching stability in the initial storage process is less than the actual situation.

Because the pore distribution of the core wall soil is also affected by the stress and deformation of the soil skeleton, and the pore water pressure is closely related to the stress and deformation of the soil skeleton, the actual special phenomenon, as well as the difference between the calculated value and the actual value, is more or less related to the permeability characteristics of the core wall material.

Unlike the clay used in the middle and low core wall dams, the compacted wide-grading gravelly soil used in the high core wall dams contains a certain amount of sand, gravel, and other coarse grains with large particle sizes. Moreover, the high core wall dams bear large compaction work and have large filling density, bear large overburden load, and suffer large stress increment and deformation after filling. In the determination of permeability coefficient, the relevant understanding of clay permeability in middle and low dams is used; however, these complicated factors are not fully considered under real time scenario and may be one of the reasons causing the above special phenomenon for high core wall dams.

The permeability characteristic of core wall determines the safety and performance of the earth core dam; therefore, it is one of the key design indexes in the construction process as well as one of the main control indexes of construction quality. The establishment of a scientific and effective method to determine the permeability coefficient of the earth core wall material can ensure the accuracy and rationality of the design and construction control parameters and improve the accuracy of seepage stability and seepage deformation coupling calculation, which is one of the key technical problems to guarantee the quality and safety of core wall dam. However, at present, the academic and engineering circles have a great controversy in the measurement method for the permeability coefficient of gravel core wall material.

This study analyzes the problems regarding the measurement of permeability coefficient in the current geotechnical test code and the design code of embankment dam, introduces the research progress on permeability coefficient measurement method, and comprehensively summarizes the factors affecting the measured value of permeability coefficient. Based on the analysis and summary of the existing research status, the inability of accurately measuring the permeability coefficient of gravel core wall material and the reason of a dispute between different parties are explained, putting forward the research direction for further improving the measurement technology of permeability coefficient of gravel core wall material.

2 Determination Method of Permeability Coefficient of Gravelly Soil

The test conditions such as consolidation condition, shear rate, and total stress or effective stress are distinguished in the requirements for soil strength, and the maximum dry density and optimal water content of the whole material should be strictly tested. Unlike these requirements, the current design code for embankment dams does not distinguish or require the measurement methods of permeability coefficient of core wall soil, but only puts forward the numerical requirement of permeability coefficient, i.e., no more than 1.0 × 10−5 cm/s [21].

Different from the determination method that is not specified in the above provisions, many methods can be used for the determination of permeability coefficient of gravelly soil, but most of them have not been recognized by the engineering and academic circles in terms of accuracy and credibility.

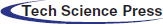

AS shown in Table 1, the determination method of permeability coefficient of gravelly soil can be classified from different perspectives based on (i) the particle size composition of the test material, which can be divided into two categories: original grading test and scale test; (ii) the test object, which can be divided into whole material test and fine material test; (iii) the direction of seepage, which can be divided into vertical permeability test and horizontal permeability test; (iv) the headwater control condition of the test can be divided into constant head test and variable head test; (v) external conditions such as laboratory test and field test; (vi) the degree of nonlinear influence of compaction, which can be divided into the nonlinear permeability coefficient considering the influence of stress or deformation and the fixed (initial) permeability coefficient without the influence of stress or deformation; (vii) the state of soil sample such as saturated permeability coefficient and unsaturated permeability coefficient; (viii) the determination method, and it can be divided into direct measurement and indirect calculation, where the typical calculation method is to carry out feedback calculation of permeability coefficient through the consolidation and drainage test process under the condition of known stress and deformation characteristics [22]. Some of the above methods are discussed in the experimental procedures, while others are limited to academic research and not included in the norms. The typical academic methods are the indirect measurement of permeability coefficient or the calculation method of empirical formula [23–28].

Gravelly soil contains clay particles and thus its permeability coefficient under unsaturated condition is quite different from that under saturated condition. However, if the coarse particles are removed and only the unsaturated permeability coefficient of the remaining fine particles is tested, the results obtained cannot represent the actual permeability coefficient of gravelly soil. In contrast, the gravelly soil has a large particle size; therefore, the unsaturated permeability coefficient test has a stringent requirement for apparatus, which is not available at present. Therefore, at present, the method of determining the permeability coefficient of fine-grained soil is referred in the calculation, and the unsaturated permeability coefficient is considered to be low, which is the saturated permeability coefficient multiplied by the reduction coefficient obtained from the empirical formula. In addition, even for fine-grained soil, calculating the permeability coefficient under unsaturated condition is difficult, and indirect method is more commonly used. However, the indirect determination method such as empirical formula considers that the permeability coefficient is related to one or more factors of particle sizes, porosity, non-uniformity coefficient, and curvature coefficient. For example, the well-known Hazen Formula holds that the permeability coefficient

2.2 Permeability Coefficient Test of Original-Grading Gravelly Soil

Specific technical requirements for gravelly soil in the design code of rolled embankment dams include: the content of particles larger than 5 mm in original-grading impermeable gravelly soil should not exceed 50%, and the content of particles (silt and clay) below 0.075 mm should not be less than 15% [21], and the power industry codes further state that the content of particles less than 0.005 mm (clay) should not be less than 8%. In application, some projects have exceeded the limit of particle size mentioned above, i.e., the lower content of clay particles. In contrast to the above gravelly soil particle size requirements, the soil with lower content of large particles (with size larger than 5 mm) but higher content of clay and silt is classified as clay soil. According to the geotechnical investigation code [10], clayey gravel can be classified as mixed soil or gravelly soil. According to the classification standard of soil [29,30], the gravelly soil with higher content of particles larger than 5 mm can be classified as clayey gravel or silty gravel in engineering, namely, fine-grained gravel, belonging to coarse-grained soil (the soil containing at least 50% of the particle mass of particle size larger than 0.075 mm.

If the original-grading gravelly soil is used for determination of permeability coefficient, the coarse-grained soil method should be adopted in accordance with the code. In the national standard for geotechnical test [31], the part of “permeability coefficient test” does not limit the particle size grading applicable to the test. For coarse-grained soil, a device with an inner cylinder diameter 10 times greater than the maximum particle size of the sample is used to measure the permeability coefficient by the constant water head method. In the “Permeation and Permeation Deformation Test of Coarse-grained Soil”, the inner diameter of the cylinder in the vertical penetration test or the width and thickness of the instrument in the horizontal penetration test shall not be less than 5 times of the maximum particle size, the height or length of the sample shall not be less than the diameter (width), and the penetration slope shall be applied in the test classification, i.e., the constant head method should be used to measure the permeability coefficient. In the above national standards, vertical load can also be applied to the sample for the vertical permeability test of coarse-grained soil. In the power industry standard, the geotechnical test procedure focusing on fine grained soil does not cover the permeability coefficient measurement method of core wall gravelly soil containing large particle [32], and the variable water head permeability test method is only applicable to fine grained soil, not gravelly soil, while the constant water head permeability test method is only applicable to coarse-grained soil with the maximum particle size less than 20 mm. The test procedure for coarse-grained soil [33] includes the field test method for permeability coefficient of coarse-grained soil applicable to gravelly soil with different particle sizes. The constant water head permeability coefficient test applicable to gravelly soil is also incorporated into the “permeability deformation test method of coarse-grained soil”, and the specific test method is consistent with the national standard GB50123 [31].

In engineering, the implementation of the above codes is often combined with the field compaction test of core wall material. The field permeability coefficient test is carried out at the compaction site, and original grading samples after compaction are used to carry out laboratory tests, for instance the typical tests in Wufugou and Nuozhadu projects [34]. The results of field permeability test basically include initial vertical permeability coefficient

Since the permeability coefficient of gravelly soil is mostly less than 10−5 cm/s, when the constant water head method applicable to coarse grained soil is applied to gravelly soil, there is actually a discrepancy with the code itself. In fact, the constant water head method is applicable to the sample with the permeability coefficient in the range 10−2–10−3 cm/s [31].

2.3 Scaled Permeability Coefficient Test of Gravelly Soil

The maximum particle size of the original grading gravelly soil is large and sometimes exceeds the test limit of the equipment. In addition, there is no restriction or prohibition on the use of scaled materials to carry out permeability coefficient tests of gravelly soil in relevant norm. Therefore, permeability coefficient test using reduced scale gravelly soil in very common in practice.

When scaling gravelly soil, the similar gradation method is not suitable because the silt and clay are difficult to be screened and remixed; therefore, the elimination method and the equivalent replacement method are still the most commonly used methods.

For gravelly soil after scaling, the constant head permeability test is carried out according to the test method for coarse-grained soil [31,32]. When the content of coarse particles is low and the maximum particle size is small, the variable head test is carried out according to the basic requirements of fine-grained soil.

Many studies indicate that the permeability of gravelly soil is determined by the nature and content of fine materials, namely, silt and clay particles [35], and it is also largely affected by the content of gravel with particle size greater than 5 mm. For example, in order to ensure the impermeability of earth soil, the design code of compacted embankment dam emphasizes the requirements on gravel content and total content of silt and clay. Therefore, the permeability coefficient of scaled soil material without coarse grain or gravel can be considered as a representative of the permeability characteristics of gravelly soil. In practice, sometimes the variable head method is used to test the fine-grained soil according to the requirements of the test, while, the constant head method is used to carry out the test according to the grading condition and the test requirements of coarse-grained soil. The measured permeability coefficient of scaled earth soil is often used as a representation of permeability coefficient of core wall soil (i.e., gravelly soil). In this study, the permeability coefficient obtained by the above methods is called the initial permeability coefficient without gravel

2.4 The Development Trend of the Measurement Methods of Permeability Coefficient of Gravelly Soil

To sum up, for wide-grading gravelly soil with mixed particle size grading and complex characteristics, a variety of permeability coefficient testing (calculation) methods are used in practice. However, from the technical perspective, the design code for embankment dam [20] only specifies the numerical requirements for the core soil permeability coefficient (no more than 1.0 × 10−5 cm/s) and does not specify the method for determining the permeability coefficient, allowing a relatively open practical operation space. On the other hand, from the perspective of the practical consideration of various methods, the permeability coefficients determined by different methods are quite different, and the magnitude of the relationship between some values is relatively clear, while the differences obtained by various methods have not been recognized unanimously.

According to the existing studies, the definite effect of scaling and scale method on the measurement of permeability coefficient of gravelly soil cannot be determined, as various scale methods have certain limitations [31,33].

Due to the fact that many permeability coefficient test values obtained from geological prospecting are obtained by scaled sample test in the laboratory, some studies [39] believe that using large-diameter equipment to test the permeability of original grading soil materials is not practical. On the other hand, many researchers believe that more accurate measurement of permeability coefficient can be obtained by only using larger equipment, and original grading soil material or soil materials with particle size as large as possible or as close to the original grading soil when conducting tests. For this purpose, a variety of large equipment have been continuously developed to meet the requirements of permeability coefficient tests of original grading geotechnical materials. Based on the literature reports, under the condition of uncontrolled stress or strain, large equipment can not only be initially used for coarse-grained soil such as sand and gravel, but also for vertical permeability [40] and horizontal permeability characteristics of gravelly soil [41]. The maximum width/diameter of the flow section of the test equipment is no less than 1000 mm. Equipment with the width/diameter of the flow section ranging from 100 mm to 300 mm have been extensively used as reported, but is beyond the scope of this study.

Furthermore, considering that the actual density and stress of the gravelly soil in field service are generally greater than that at the beginning of preparation/filling, and sometimes there is a certain shear deformation compared with that at the beginning of preparation/filling, many studies focused on determining the permeability coefficient of the gravelly soil using large-size equipment reflecting the effect of stress and deformation. The maximum diameter of the test equipment for controlling the vertical permeability characteristics of stress is 300 mm [42]. In addition, although horizontal permeability under stress is not mentioned in the code, some existing equipment can still carry out large-scale horizontal permeability test under stress that has not been described in the code. The maximum diameter of test equipment for permeability under controlled stress [43,44] or controlled strain [45] has reached 300–400 mm. In addition, some large equipment can simultaneously conduct permeability tests under the condition of controlling stress and deformation [46,47].

3 Influencing Factors of Permeability Coefficient of Gravelly Soil

3.1 The Effect of the Test Site

According to the existing permeability test results of core wall soil materials of Longhu Reservoir and hydropower stations such as Shuangdugou, Nuozhadu and Miaowei, the field test values of permeability coefficient tests of original grading gravelly soil are generally greater than the laboratory test values in the corresponding direction of seepage, with a difference up to 1 order of magnitude [34].

Due to the use of original grading soil material, excavation and transportation processes are voided and the disturbance is small, some scholars believe that the field measurement of permeability coefficient of original grading soil material is more reliable. In the field tests of permeability coefficient of gravelly soil, the single-ring method and double-ring method considering vertical seepage are mostly adopted, and the permeability deformation test of excavated soil column after compaction considering vertical and horizontal seepage are mostly carried out [48]. From the point of view of mechanism, in the field vertical permeability test, the seepage direction of single ring test is both downward and outward, leading to the comprehensive permeability coefficient of the soil layer [49]. The inner ring of the double-ring method is approximately a unidirectional parallel flow (vertical permeability), but the inner and outer rings both face down and out of the ring. Although the measured permeability coefficient of soil is close to the vertical permeability coefficient, the vertical permeability coefficient is generally larger, because the flow of lateral seepage is accounted in the calculation of permeability coefficient [50]. In the field vertical permeability test and horizontal permeability test of excavated soil column after rolling compaction, the seepage flow perpendicular to the gradient application direction cannot be controlled either, and the lateral seepage flow is still included. Therefore, the test control accuracy is low, and the measured permeability coefficient is generally large.

Considering the measurement and control precision of the test, the authors believe that the lower permeability coefficients measured under rigorous laboratory test conditions are more reliable for the same test soil. The initial value of the real permeability coefficient of gravelly soil can be selected from the original grading test value in the laboratory without considering stress or the original grading test value in the field after the reduction of magnitude treatment.

3.2.1 Influence of the Ratio of Sample Size to Maximum Particle Size of Soil

The code generally restricts the sample size in the flow section to be more than 5 times or 10 times of the maximum particle size of the soil. In fact, the equivalence requirement in the strength characteristic test of coarse granules is accounted, and whether the size requirement is reasonable for the permeability test cannot be evaluated, because the mechanism affecting the scale on the permeability characteristics has not been fully studied.

Some scholars proposed that the sample size affects the test permeability coefficients by affecting the relative area occupied by coarse particles in the water crossing section, and the soil permeability coefficient increases with increasing sample diameter, because the permeability coefficient of the coarse particle itself is very small. When the diameter of the sample is less, a single coarse particle section may occupy a large proportion in the sample section, leading to a low permeability coefficient. With increasing sample diameter, the area proportion of coarse particles in the sample section decreases relatively. With further increase in the sample size, this proportion becomes more and more close to the volume proportion of coarse particles in the soil, and the effect of coarse particles on the measured permeability coefficient becomes increasingly less, and the measured permeability coefficient becomes more and more close to the real value [51].

3.2.2 The Influence of Reduced Scale of Earth Soil

Regarding the determination of permeability coefficient of gravelly soil, one of the effects is scaling, which changes the fine grain content (as well as the gravel content). As mentioned above, the effect of the scale on the permeability characteristics has been investigated, but no unanimous conclusion has been reached yet. However, if the overall fine particle content is not changed, the measured permeability coefficient is not affected significantly. With a significant increase in the content of fine grains, the permeability also changes significantly [52]. In addition, the higher the gravel content of the gravelly soil, the higher the permeability coefficient of the soil material [53,54]. In general, the mechanism of size effect on the measured permeability coefficient is not very clear yet. In order to improve the reliability of the measured values, using the smallest scale ratio or even the original grading soil material to carry out the permeability test is more appropriate, while ensuring that the sample size is much larger than the maximum particle size of the soil.

Due to the directional distribution of particles caused by rolling compaction, gravelly soil often has obvious anisotropic characteristics after rolling compaction, and this may lead to a significant difference in the anisotropic permeability coefficient [49]. Although some scholars considered that the horizontal permeability coefficient is greater than the vertical permeability coefficient [55–57], the horizontal permeability coefficient measured in the same site (on-site or indoor) is usually several times larger than that in the vertical direction according to the actual measurement [34,58–60]. Shen Zhejiang’s inversion analysis of the seepage pressure of the core wall of Lubuge Dam also reveals greater horizontal permeability coefficient in general than the vertical one [61].

The compacted gravel core wall actually comprises several compacted soil layers. In the process of filling and compaction of soil layers, the coarse and fine materials are separated to a certain extent, and since the compaction power is not uniform, uneven distribution and periodic changes in permeability in the vertical direction of soil layers are observed. The vertical permeability coefficient mainly depends on the soil layer with the weakest permeability, while the horizontal permeability coefficient mainly depends on the soil layer with the strongest permeability; therefore, the vertical permeability coefficient may be less than the horizontal permeability coefficient [50]. The measurement of permeability coefficient mainly focuses on the vertical seepage [62,63], and using the same value to represent the horizontal and vertical permeability coefficients will lead to inaccurate prediction and wrong judgment of seepage field distribution.

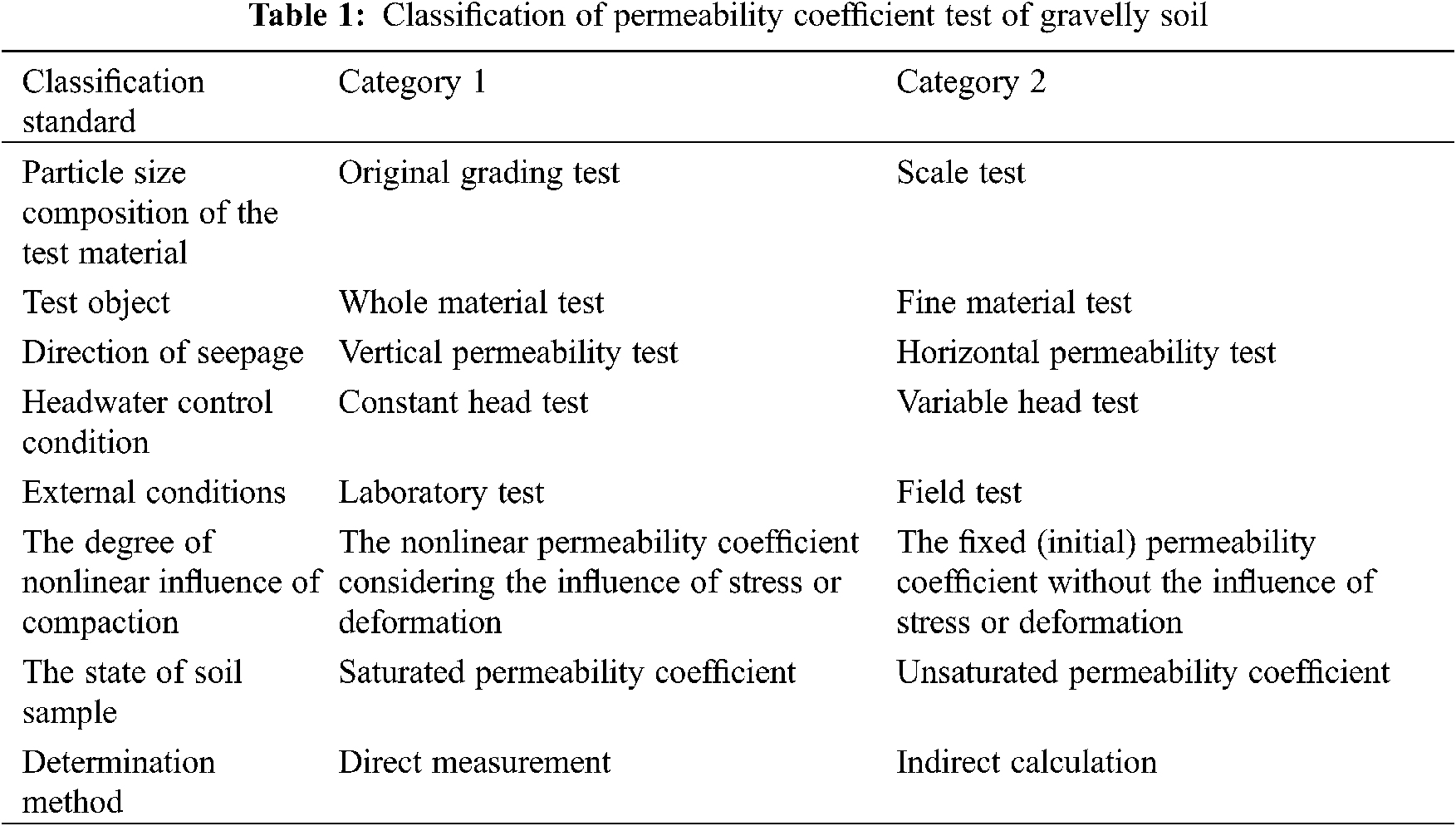

“Anisotropy of permeability coefficient of dam body and foundation” is proposed in the design code of embankment dam [21] and is a mandatory criterion. The actual direction of seepage in the core wall is closer to the horizontal seepage (as shown in Fig. 1). Therefore, the direction of seepage should also be differentiated in the measurement of permeability coefficient, and special attention should be paid to the determination of horizontal permeability coefficient in order to provide a basis for calculation.

Figure 1: Seepage direction in core wall dam (after Chen et al. [44])

In the study of soil permeability, the compactness of soil has a significant effect on its permeability coefficient [64]. Therefore, the empirical formulas for calculating the permeability coefficient are almost expressed as the function of void ratio, porosity, or other similar parameters of the soil. Since the soil density is also affected by the external stress, some empirical formulas also express the nonlinear change of permeability as a function of stress such as the formula used in Shen Zhejiang’s inversion calculation of Lubuge core wall dam [61].

The permeability test of gravelly soil under stress also shows that the permeability coefficient of gravelly soil with nonlinear characteristics is similar to that of other soils. For example, Wu et al. [53] found that the greater the confining pressure of gravelly soil, the smaller the permeability coefficient, showing a negative exponential decline; when the confining pressure increases to a certain value, the soil is difficult to be further compacted, and the permeability coefficient basically remains unchanged. Wang et al. [14] experimentally obtained the porosity-dependent variation law of permeability coefficient of core wall of RM high core wall dam. Zhan et al. [65] carried out the permeability test of the gravelly soil core wall of Changheba Hydropower Station under the stress, and found that even under the same confining pressure, the permeability coefficient of gravelly soil gradually decreased with increasing deviatoric stress and axial stress.

Based on the permeability coefficient measured at the beginning of filling/compaction and considered the influence of stress/density change, the establishment of the nonlinear evolution law of permeability coefficient of the original grading soil can truly provide an accurate basis for the analysis and judgment of the project.

In the seepage test, the boundary effect exists between the soil and the rigid wall because the contact between the rigid boundary and soil particles is different from the contact between soil particles. When the size of the pore between the boundary wall and particles is larger than the pore inside the soil, the seepage velocity at the boundary wall will increase and a dominant seepage channel will be formed; therefore, the test result of permeability coefficient is greater than the true value of the sample [66,67].

On the basis of existing studies, a treatment method for wall protection was established, i.e., applying a flexible boundary material layer of certain thickness to suppress the boundary effect. Some studies have also discussed the optimal thickness of the protective layer [51]. Another way to suppress the boundary effect is to use a flexible boundary wall to fill the large pore between the soil material and the boundary wall through the deformation of the flexible boundary wall of the loading device itself. Many permeability coefficient tests use a flexible wall permeability test device [68–71].

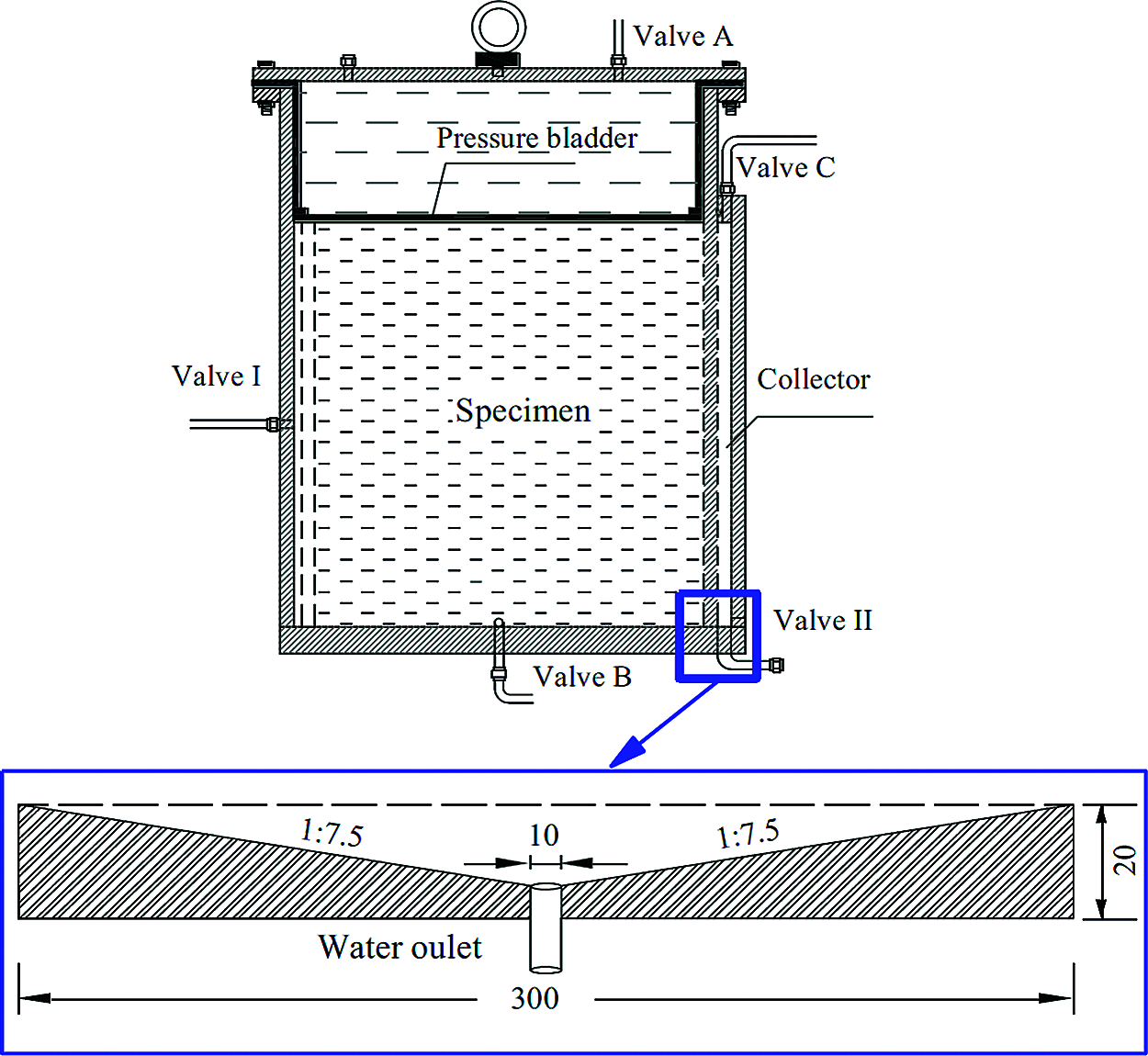

The combination of flexible boundary wall, loading device, and large permeability test device can provide a feasible technical scheme for the large-scale horizontal nonlinear permeability test of gravelly soil under controlled stress (measurement deformation) [43,44], as shown in Fig. 2, indicating that the vertical load is applied to the soil samples by flexible water sac, which automatically prevents the leakage of the top surface of the soil samples due to the settlement deformation after being loaded and suppresses the boundary effect between the top surface of the soil samples and the loading part (water sac), thus solving the coordination problem between the vertical stress and the horizontal hydraulic gradient. This method has been well applied to the permeability coefficient and permeability deformation test of coarse grain and is also a better possible tool for determining the horizontal permeability coefficient of the gravelly soil.

Figure 2: A novel large-scale stress-controlled apparatus for permeability characteristics measurement (after Deng et al. [43] and Chen et al. [44])

Considering that the permeability of gravelly soil mainly depends on the fine grain part and based on the study of clay soil, the measurement of permeability may be affected by many other factors such as the chemical composition of pore water and clay [72–76], the initial water content of sample preparation [77,78], and the method of compaction [79,80]. First, the undisturbed sample was obtained through on-site vibration and rolling compaction, and the compacted soil sample was obtained by indoor dynamic compaction. After that, the soil samples obtained were tested with pure water in order to reduce the inconsistency between different tests to a certain extent and guarantee the reliability of test results.

The permeability coefficient of gravelly soil material of core wall is one of the key designs and quality control indexes of high core wall dam. Only establishing a scientific and reasonable measurement method for determining the permeability coefficient and reflect the real characteristics of material can allow the quality and safety of the project.

The impact of size effect on permeability is not clear yet. Therefore, the undisturbed and original grading gravelly soil from the rolling compaction site should be used as research object and the initial density conditions should be strictly controlled in the test. On this basis, the vertical and the horizontal permeability coefficients as well as their relationship with the stress are measured respectively under controlled vertical stress, which is a more reasonable method to measure the permeability of gravelly soil.

Acknowledgement: The authors sincerely thank the anonymous reviewers for their helpful suggestions.

Funding Statement: The work is supported by National Key Research and Development Program of China (No. 2017YFC0404803); Guizhou High-Level Innovative Talents Project [2018] (No. 5630); Guizhou Science and Support [2019] (No. 2869); State Key Laboratory of Simulation and Regulation of Water Cycle in River Basin (No. SKL2020ZY09); and Science and Technology Project of Huaneng Group Headquarters (HNKJ17-H18).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Deng, G., Ding, Y., Zhang, Y. Y., Zhang, Y. Q., Huang, W. C. (2021). Evolution of earth core embankment dams along with the development of configuration and material. Journal of China Institute of Water Resources and Hydropower Research, 19(2), 1–13. [Google Scholar]

2. Vutsel, V. I., Listrovoy, P. P., Malyshev, M. P. (1973). Measures providing impermeability of the Nurek Dam. Proceeding of 11th International Congress on Large Dams, pp. 551–563. Madrid. [Google Scholar]

3. Savinov, O. A., Ivanov, P. L., Krasnikov, N. D., Mozhevitinov, A. L., Lipovetskaya, T. F. (1986). Concerning the problem of the seismic stability of the Nurek Dam. Hydrotechnical Construction, 20(5), 278–285. DOI 10.1007/BF01436019. [Google Scholar] [CrossRef]

4. Ronzhin, I. S., Kanygin, L. E., Chernenko, V. N., Listrovio, P. P., Kim, F. G. (1986). Grout curtain in the foundation of the Nurek Dam and evaluation of its effectiveness. Hydrotechnical Construction, 20(9), 539–542. DOI 10.1007/BF01434190. [Google Scholar] [CrossRef]

5. Li, J. F., Zhou, Y. X., Ning, Z. J., Zhu, Q. Q. (2011). Rapid detection method of Dr value of large particle size filter materials in earth rock-filling dam of NuoZhadu. Advanced Materials Research, 368–373, 2309–2313 [Google Scholar]

6. Xiao, P., Li, T., Xu, N., Zhou, Z., Liu, X. (2019). Microseismic monitoring and deformation early warning of the underground caverns of Lianghekou Hydropower Station, Southwest China. Arabian Journal of Geosciences, 12(16), 361. DOI 10.1007/s12517-019-4683-7. [Google Scholar] [CrossRef]

7. Lu, X., Zhu, W. S., Ma, Q. S., Zhou, K. (2011). Application of damage model in stability analysis of shuangjiangKou underground caverns. Key Engineering Materials, 462–463, 1391–1396. [Google Scholar]

8. Zhu, W., Lei, Z., Yong, L., Zhang, Q. (2010). A true 3D physical model test study on the stability of an underground cavern group in Shuangjiangkou Hydropower Station. Fourth International Conference on Experimental Mechanics, Boston, USA. [Google Scholar]

9. Ma, H. Q., Chi, F. D. (2016). Major technologies for safe construction of high earth-rockfill dams. Engineering, 2(4), 498–509. DOI 10.1016/J.ENG.2016.04.001. [Google Scholar] [CrossRef]

10. Ministry of Construction and General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Code for Investigation of Geotechnical Engineering GB 50021-2001 (2009e). Beijing: China Architecture and Building Press. [Google Scholar]

11. Kjaernsli, B., Torblaa, I. (1961). Compaction of moraine in three feet layers. Proceeding of the 7th International Congress on Large Dams, vol. 4, pp. 365–377. [Google Scholar]

12. Asao, I. (1964). The Miboro Dam. Proceeding of the 8th International Congress on Large Dams, vol. 3, pp. 803–824. [Google Scholar]

13. Cooke, J. B. (1964). Design methods of construction and performance of high rockfill dams (above or about 80 mProceeding of the 8th International Congress on Large Dams, vol. 4, pp. 521–549. [Google Scholar]

14. Wang, X. G. (2018). Discussion on some problems observed in high earth-rockfill dams. Chinese Journal of Geotechnical Engineering, 40(2), 203–222. [Google Scholar]

15. Deng, G., Huangfu, Z. H., Wu, Y. Li., Zhang, Y. Y., Chen, H. et al. (2020). Development and prospect of deformation compatibility control of earth core embankment dams. Journal of Hydroelectric Engineering, 39(5), 1–16. [Google Scholar]

16. Foster, M., Fell, R., Spannagle, M. (2000). The statistics of embankment dam failures and accidents. Canadian Geotechnical Journal, 37(5), 1000–1024. DOI 10.1139/t00-030. [Google Scholar] [CrossRef]

17. Sherard, J. L. (1987). Lessons from the Teton Dam failure. Engineering Geology, 24(1–4), 239–256. DOI 10.1016/0013-7952(87)90064-0. [Google Scholar] [CrossRef]

18. Luo, Y. L., Xi, J., Li, X., Zhan, M. L., Sheng, J. C. (2013). A new apparatus for evaluation of contact erosion at the soil-structure interface. Geotechnical Testing Journal, 36(2), 20120094. DOI 10.1520/GTJ20120094. [Google Scholar] [CrossRef]

19. Ke, L., Takahashi, A. (2014). Triaxial erosion test for evaluation of mechanical consequences of internal erosion. Geotechnical Testing Journal, 37(2), 20130049. DOI 10.1520/GTJ20130049. [Google Scholar] [CrossRef]

20. Sherard, J. L. (1979). Sinkholes in dams of coarse, broadly graded soils. Proceeding of the 13th International Congress on Large Dams, vol. 2, pp. 25–35. [Google Scholar]

21. Ministry of Water Resources of the People’s Republic of China. Water Resources Industry Standard of the People’s Republic of China: Design Code for Rolled Earth-Rock Fill Dams SL 274-2020 (2020). Beijing: China Water and Power Press. [Google Scholar]

22. Zhang, X. X., Deng, G., Zhang, D., Yu, S. (2017). Influence of boundary and internal defects of specimens on measurement of permeability coefficient of soils. Journal of China Institute of Water Resources and Hydropower Research, 15(4), 278–285. [Google Scholar]

23. Hazen, A. (1892). Some physical properties of sands and gravels, with special reference to their use in filtration. 24th Annual Report, Massachusetts State Board of Health. [Google Scholar]

24. Terzaghi, K., Peck, R. B. (1964). Soil mechanics in engineering practice. New York: Wiley. [Google Scholar]

25. Carman, P. C. (1937). Fluid flow through granular beds. Transactions of the Institution of Chemical Engineers, 15, 150–166. [Google Scholar]

26. Kozeny, J. (1927). Ueber kapillare Leitung des Wassers im Boden. Sitzungsberichte der Wiener Akademie der Wissenschaften, 136(2a), 271–306. [Google Scholar]

27. Taylor, D. W. (1948). Fundamentals of soil mechanics. New York: Wiley. [Google Scholar]

28. Carrier, W. (2003). Goodbye, Hazen; Hello, Kozeny-Carman. Journal of Geotechnical and Geoenvironmental Engineering, 129(11), 1054–1056. DOI 10.1061/(ASCE)1090-0241(2003)129:11(1054). [Google Scholar] [CrossRef]

29. Ministry of Construction of the People’s Republic of China, General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (2008). National Standard of the People’s Republic of China: Standard for Engineering Classification of Soil GB/T 50145-2007. Beijing: China Planning Press. [Google Scholar]

30. ASTM Standard D2487, 2017e1, Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System) (2017). Conshohocken, PA: ASTM International, West. [Google Scholar]

31. Ministry of Housing and Urban-Rural Development, PRC, State Administration for Market Regulation (2019). National standard of the People’s Republic of China: Standard for geotechnical testing method GB/T 50123-2019. Beijing: China Planning Press. [Google Scholar]

32. National Development and Reform Commission, PRC (2006). Code for soil tests for hydropower and water conservancy engineering DL/T 5355-2006. Beijing: China Electric Power Press. [Google Scholar]

33. National Development and Reform Commission, PRC (2006). Code for coarse-grained soil tests for hydropower and water conservancy engineering DL/T 5356-2006. Beijing: China Electric Power Press. [Google Scholar]

34. Lei, Z. H. (1994). Study on engineering properties of impermeable material for core wall of Pubugou hydropower station. Sichuan Hydroelectric Power, 4, 43–50+87. [Google Scholar]

35. Liu, J., Miu, L. J. (1987). Application of weathering material in impermeable body of Lubuge high earth and rockfill dam. Water Resources and Hydropower Engineering, 11, 2–7. [Google Scholar]

36. Wang, G., Wei, X., Zou, T. (2019). A hollow cylinder radial-seepage apparatus for evaluating permeability of sheared compacted clay. Geotechnical Testing Journal, 42(5), 20170215. DOI 10.1520/GTJ20170215. [Google Scholar] [CrossRef]

37. Lei, H. J., Wu, Y. K., Yu, Y. Z. (2016). Influence of shear on permeability of clayey soil. International Journal of Geomechanics, 16(5), 04016010. DOI 10.1061/(ASCE)GM.1943-5622.0000636. [Google Scholar] [CrossRef]

38. Liu, Q. H., Wu, Y. K., Li, Q. M., Yu, Y. Z., Lv, H. (2019). Modified model for hydraulic conductivity of clayey soil under shear. International Journal of Geomechanics, 19(11), 06019015. DOI 10.1061/(ASCE)GM.1943-5622.0001506. [Google Scholar] [CrossRef]

39. Liu, Y. (2020). Study on test method of permeability coefficient of cohesionless coarse grained soil in Hydraulic Engineering. Shaanxi Water Resources, 12, 211–213. [Google Scholar]

40. Chen, S. S., Ling, H., Mi, Z. K., Miao, Z., Mei, S. A. (2019). Experimental study on permeability and its influencing factors for sandy gravel of Dashixia Dam. Chinese Journal of Geotechnical Engineering, 41(1), 26–31. [Google Scholar]

41. Cui, J. Q., Duan, J. B., Ma, L. Y., Zhang, L. (2020). Study on horizontal permeability and filtration erosion test of sand and gravel dam material for Cihaxia Hydropower Station. Northwest Hydropower, 5, 103–107. [Google Scholar]

42. Li, L. P., Liu, S., Li, S. C., Shi, S. S., Liu, C. (2017). Development of testing system for coupled seepage and triaxial stress measurements and its application to permeability characteristic test on filling medium. Rock and Soil Mechanics, 38(10), 3053–3061. [Google Scholar]

43. Deng, G., Chen, R., Liu, J., She, K. X., Yu, S. (2017). The invention discloses a visualized measuring device for horizontal submersible erosion with large deformation and complete airtightness. CN107192811B. [Google Scholar]

44. Chen, R., Liu, L. L., Li, Z. F., Deng, G., Zhang, Y. (2021). A novel vertical stress-controlled apparatus for studying suffusion along horizontal seepage through soils. Acta Geotechnica, 16(3), 1–14. [Google Scholar]

45. Zou, Y. H., Chen, Q., He, C. R. (2013). A new large-scale plane-strain permeameter for gravelly clay soil under stresses. KSCE Journal of Civil Engineering, 17(4), 681–690. DOI 10.1007/s12205-013-0217-0. [Google Scholar] [CrossRef]

46. Deng, G., Zhan, Z. G., Zhang, X. X., Lu, J., Yang, J. X. (2016). The invention discloses a rotary shear type test device for impermeability of contact surface. CN105784568B. [Google Scholar]

47. Deng, G., Zhan, Z. G., Zhang, Y. Q., Lu, J., Yang, J. X. (2020). The invention relates to a test device and a test method for simulating the seepage coupling characteristics of contact surfaces. CN111912760A. [Google Scholar]

48. National Energy Administration (2013). Testing code on material compaction for earth and rock-fill dams NB/T 35016-2013. Beijing: China Electric Power Press. [Google Scholar]

49. Jiang, S. L., Qiu, X. L. (2015). Comparative study on measuring method of permeability coefficient of impervious core material in earth-rock dam. Yangtze River, 46(8), 87–91. [Google Scholar]

50. Bao, H. F., Zhang, Y. Q., Shen, R., Li, S. S. (2008). Experiment and study on gravel weathered material as impervious body for core wall of high dam. Journal of Water Resources and Architectural Engineering, 6(1), 34–37. [Google Scholar]

51. Zhu, G. S., Zhang, J. F., Chen, J. S., H, Z. J. (2012). Study of size and wall effects in seepage test of broadly graded coarse materials. Rock and Soil Mechanics, 33(9), 2569–2574. [Google Scholar]

52. Sheng, X. T., Ding, P. Z., Zhu, G. S. (2016). Experimental study on effects of different scaling methods on maximum dry density and permeability of coarse-grained materials. Yangtze River, 47(24), 80–83. [Google Scholar]

53. Wu, J. H., Yang, S., Lu, T. H. (2015). Permeability tests on middle triaxis of core wall mixed gravel. Advances in Science and Technology of Water Resources, 35(4), 90–94. [Google Scholar]

54. Zhang, G. D., Liao, A. M., Li, M. D., Qiu, C. Y., Xu, Z. H. (2016). Model test studies on permeability of gravel soil. Hydro-Science and Engineering, 5, 91–95. [Google Scholar]

55. Adel, D. H., Bakker, K. J., Breteler, M. K. (1988). Internal stability of minestone. Proceedings of International Symposium of Modelling Soil-Water-Structure Interaction, pp. 225–231. Balkema, Rotterdam. [Google Scholar]

56. Ahlinhan, M. F., Achmus, M. (2010). Experimental Investigation of Critical Hydraulic Gradients for Unstable Soils. Proceedings of Internationnal Conference on Scour and Erosion, pp. 599–608. New York: ASCE. [Google Scholar]

57. Richards, K. S., Reddy, K. R. (2012). Experimental investigation of initiation of backward erosion piping in soils. Géotechnique, 62(10), 933–942. DOI 10.1680/geot.11.P.058. [Google Scholar] [CrossRef]

58. Feng, G. M., Fu, Q. H. (1997). Device and method measuring two-way seepage coefficient. Dam Observation and Geotechnical Tests, 3, 34–36. [Google Scholar]

59. Xu, C. F., Li, C. B., Zhong, K. (2008). Study on the method of measuring the permeability coefficient of red bed filler. Subgrade Engineering, 3, 122–124. [Google Scholar]

60. Munenori, H., Akihiko, U., Taya, Y. J., Takehara, N., Hagisawa, T. et al. (2001). Permeability characteristics of high-quality undisturbed gravelly soils measured in laboratory tests. Soils and Foundations, 41(3), 45–55. DOI 10.3208/sandf.41.3_45. [Google Scholar] [CrossRef]

61. Shen, Z. J. (1994). Back analysis of deformation of lubuge earth core rockfill dam. Chinese Journal of Geotechnical Engineering, 16(3), 1–13. [Google Scholar]

62. Liu, Z. Q., Zhao, K. Y. (2018). Some thoughts on the detection method of the permeability coefficient of dam core wall. Construction Technology, 47(S4), 486–488. [Google Scholar]

63. Chen, Q., Gu, H. H., Zou, Y. H., Duan, B. (2014). Comparative analysis of horizontal and vertical permeability of clayey gravelly soil. Journal of China Three Gorges University (Natural Sciences), 36(5), 1–5. [Google Scholar]

64. Li, M. D., Zhang, G. D., Zhang, Z. H. (2014). The statistical analysis of gravel soil permeability coefficient of the three gorges reservoir area. Advanced Materials Research, 1065–1069, 249–254. [Google Scholar]

65. Zhan, M. L., Xin, Y. X., Tang, J., Huang, Q. F., Sheng, J. C. (2016). Permeability of gravel soil for core wall under complex stress coupling effect. Advances in Science and Technology of Water Resources, 36(4), 36–41. [Google Scholar]

66. Liu, M. S., Luo, Q., Jiang, L. W., Lu, Q. Y., Liang, D. W. (2019). Boundary pore characteristics and optimal treatment thickness in seepage test of coarse grained soil. Rock and Soil Mechanics, 40(5), 1787–1796. [Google Scholar]

67. Zhu, G. S., Zhang, J. F., Zhang, W., Chen, J. S. (2009). Discussion of seepage test method for broadly graded coarse material. Journal of Yangtze River Scientific Reaearch Institute, 26(S1), 10–13. [Google Scholar]

68. Guo, Q. G. (1998). Engineering characteristics and application of coarse grained soil. Zhengzhou, China: The Yellow River Water Conservancy Press. [Google Scholar]

69. Yue, Z. W., Yang, R. S., Sun, Z. H., Dou, B. Y., Han, P. F. (2010). Seepage experimental study of triaxial test of gravel soil in Yili’s first coal mine. China Mining Magazine, 19(12), 98–101. [Google Scholar]

70. Quan, N. D., Chai, J. C. (2015). Permeability of lime- and cement-treated clayey soils. Canadian Geotechnical Journal, 52(9), 1221–1227. DOI 10.1139/cgj-2014-0134. [Google Scholar] [CrossRef]

71. Barden, L., PavlaKis, G. (1971). Air and water permeability of compacted unsaturated cohesive soil. Journal of Soil Science, 22(3), 302–318. DOI 10.1111/j.1365-2389.1971.tb01618.x. [Google Scholar] [CrossRef]

72. Mccallister, L. D., Petry, T. M. (1992). Leach tests on lime-treated clays. Geotechnical Testing Journal, 15(2), 106–114. DOI 10.1520/GTJ10232J. [Google Scholar] [CrossRef]

73. Locat, J., Tremblay, H., Leroueil, S. (1996). Mechanical and hydraulic behaviour of a soft inorganic clay treated with lime. Canadian Geotechnical Journal, 33(4), 654–669. DOI 10.1139/t96-090-311. [Google Scholar] [CrossRef]

74. Chew, S. H., Kamruzzaman, A. H. M., Lee, F. H. (2004). Physicochemical and engineering behavior of cement treated clays. Journal of Geotechnical and Geoenvironmental Engineering, 130(7), 696–706. DOI 10.1061/(ASCE)1090-0241(2004)130:7(696). [Google Scholar] [CrossRef]

75. Al-Mukhtar, M., Khattab, S., Alcover, J. F. (2012). Microstructure and geotechnical properties of lime-treated expansive clayey soil. Engineering Geology, 139–140(4), 17–27. DOI 10.1016/j.enggeo.2012.04.004. [Google Scholar] [CrossRef]

76. Mesri, G., Olsen, R. E. (1971). Mechanisms controlling the permeability of clays. Clays and Clay Minerals, 19(3), 151–158. DOI 10.1346/CCMN.1971.0190303. [Google Scholar] [CrossRef]

77. Stephen, S. B., David, E. D. (1985). Hydraulic conductivity tests on compacted clay. Journal of Geotechnical Engineering, 111(4), 465–478. DOI 10.1061/(ASCE)0733-9410(1985)111:4(465). [Google Scholar] [CrossRef]

78. Sillon, J. F., Richard, G., Cousin, I. (2003). Tillage and traffic effects on soil hydraulic properties and evaporation. Geoderma, 116(1–2), 29–46. DOI 10.1016/S0016-7061(03)00092-2. [Google Scholar] [CrossRef]

79. Mitchell, J. K., Hooper, D. R., Campanella, R. G. (1965). Permeability of compacted clay. Journal of the Soil Mechanics and Foundations Division, 91(4), 41–65. DOI 10.1061/JSFEAQ.0000775. [Google Scholar] [CrossRef]

80. Radford, B. J., Bridge, B. J., Davis, R. J., Mcgarry, D., Yule, D. F. (2000). Changes in the properties of a Vertisol and responses of wheat after compaction with harvester traffic. Soil and Tillage Research, 54(3–4), 155–170. DOI 10.1016/S0167-1987(00)00091-X. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |