| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.021803

ARTICLE

Towards the Development of Mechanical Systems Entirely Based on Natural Materials

Hassan First University of Settat, Settat, 26000, Morocco

*Corresponding Author: Hicham Fihri-Fassi. Email: hichame.fihri-fassi@uhp.ac.ma

Received: 05 February 2022; Accepted: 02 March 2022

Abstract: In order to mitigate the risks stemming from the utilization of mineral and synthetic organic substances, consensus exists in the literature that additional efforts should be devoted to the identification of adequate equivalent natural (ecological) materials. This work presents the outcomes of a preliminary study where the physical, mechanical, chemical and thermal properties of natural fibers have been considered. Initially, areca, and materials such as Moroccan doum and jute are considered. As a case study, a brake pad based on natural fibers is critically assessed.

Keywords: Areca fiber; doum fiber (Dwarf palm); jute fiber; natural materials; natural fibers; palm fiber; fiber’s properties

Nomenclature

| L | Longitudinal |

| T | Transverse |

Many mechanical systems are based on natural materials. They find favor with the public and professionals. Many studies are focused on the point of treating natural materials in terms of their mechanical, physical, thermal, and chemical characteristics. There are three types of natural materials which are minerals, organic of vegetable origin, and organic of animal origin. Indeed, natural materials have been improved and have become more useable than before. Nowadays, many researchers presented knowledge and perspectives on the role of the natural fibers in different mechanical systems, especially brake systems [1]. Recently, several works have been devoted to the utilization of natural materials in mechanical systems, and they have been studied the material properties of natural fibers. A case in point is the works of Essabir et al. [2–4], who covered the mechanical, chemical, and thermal properties of doum fibers (Dwarf palm) reinforced polypropylene composites. Other research study of Kian et al. [5], who carried out the morphological, structural, and thermal properties of date palm fiber. In this context, several studies, such as the study of Baley [6], concentrated on the analysis of the flax fibers tensile behavior and also analysis of the tensile stiffness increase. Another research of Campana [7], aimed to understand and evaluate the durability of natural fiber composites the consequences of aging on the properties of reinforced with this type of fiber. Another recent research of Doan [8], studied jute fibers and their composites which based on polypropylene and epoxy matrices. Other works of Biswas et al. [9], endeavored to shed light on the physical, mechanical, and thermal properties of jute and Bamboo fiber reinforced unidirectional epoxy composites. Another recent research of Elhilali et al. [10], examined different materials used during the manufacturing of the brake system, and compared with natural material jute. Along a similar vein, Murkur et al. [11] focused on the evaluation properties of areca fiber reinforced biodegradable composite material by using NaOH solution. Similarly, A recent work of Dinakaran et al. [12], investigated the development and study of mechanical behavior of a natural fiber-reinforced epoxy composite of areca fiber with different configurations of areca fiber orientation. Another recent study of Christu Paul et al. [13], shed light on empirical research on areca fiber polymer composite for automotive components in modern industry. This present study follows an approach that comprises the environmental side including the use of natural materials. It is a preliminary study stage of natural materials. Mainly local materials. In this context, we highlighted the properties of natural materials include physical, mechanical, chemical, and thermal properties, and studied the strain and stress of natural fibers without forgetting that the fibers need the reinforcing protection called the matrix to be a composite material.

The natural fiber is produced by plants, animals, and geological processes. According to their origin, the natural fibers are divided into three main groups. Firstly, plant fibers include three categories. The first category is bast fibers extracted from plant stems such as flax, hemp, jute, and ramie fiber. The second category is hard fibers extracted from leaves, trunks, and husks of fruits such as sisal, manila hemp, and coconut, respectively. The third category is fibers from seminal hairs of seeds such as kapok cotton. Secondly, mineral fibers such as basalt and asbestos. Finally, animal fibers come from hair, such as animal fleece, and secretions such as silk.

This current study follows the approach of the previously published paper [10] which studied the value of natural fiber jute and made a comparison of jute fiber, and other materials are used in the manufacturing of mechanical systems. In this context, we shed light on the strain, and stress parameter of the brake pad as a case study with some natural fibers such as Areca, Doum, and Jute fiber. On the ANSYS software, we publish a project diagram of three natural fibers used in the analysis.

The dwarf palm or doum palm (Chamaerops humilis L.) which is shown in Figs. 1 and 2, is a small palm, native to the regions bordering the western Mediterranean Sea. It is appreciated as an ornamental plant doum palm (Dwarf palm) is a natural plant which is available in huge spontaneous stands in Morocco.

Figure 1: Chamaerops humilis

Figure 2: Spines of doum palm

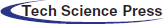

The different physical, mechanical and chemical properties of doum fiber are shown in Table 1.

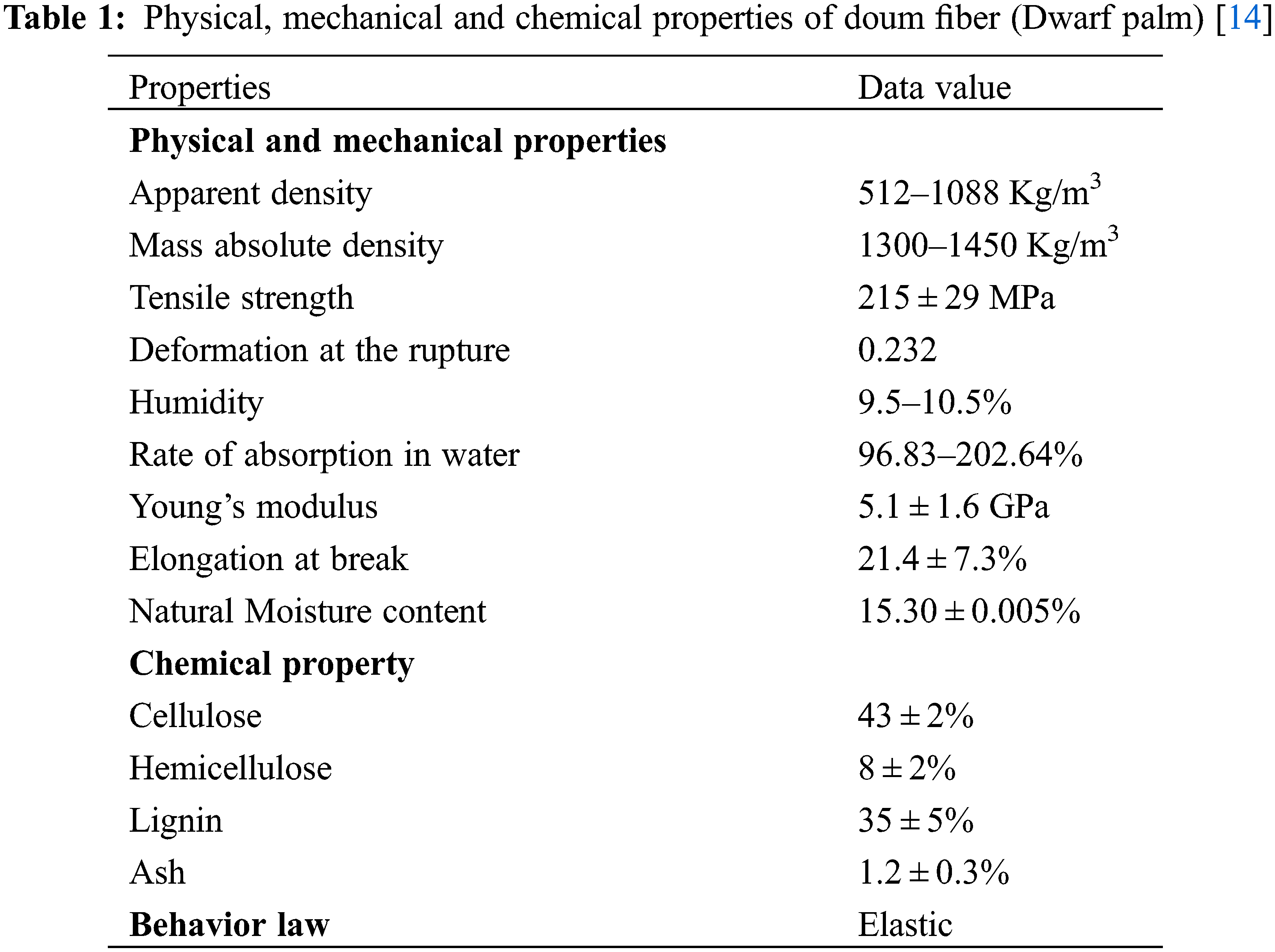

The strain and stresses of brake pad with doum fiber (Dwarf palm) are shown in Fig. 3.

Figure 3: (a) Strain von-mises of brake pad with doum fiber (Dwarf palm); (b) Stress von-mises of brake pad with doum fiber (Dwarf palm)

Jute is a natural plant. Jute fiber which is illustrated in Fig. 4, produced from the stem and ribbon of the jute plant. Jute fiber is obtained from the bark of the jute plant and is mainly produced in India and Bangladesh. It is long, soft, and shiny.

Figure 4: Jute plans & fiber

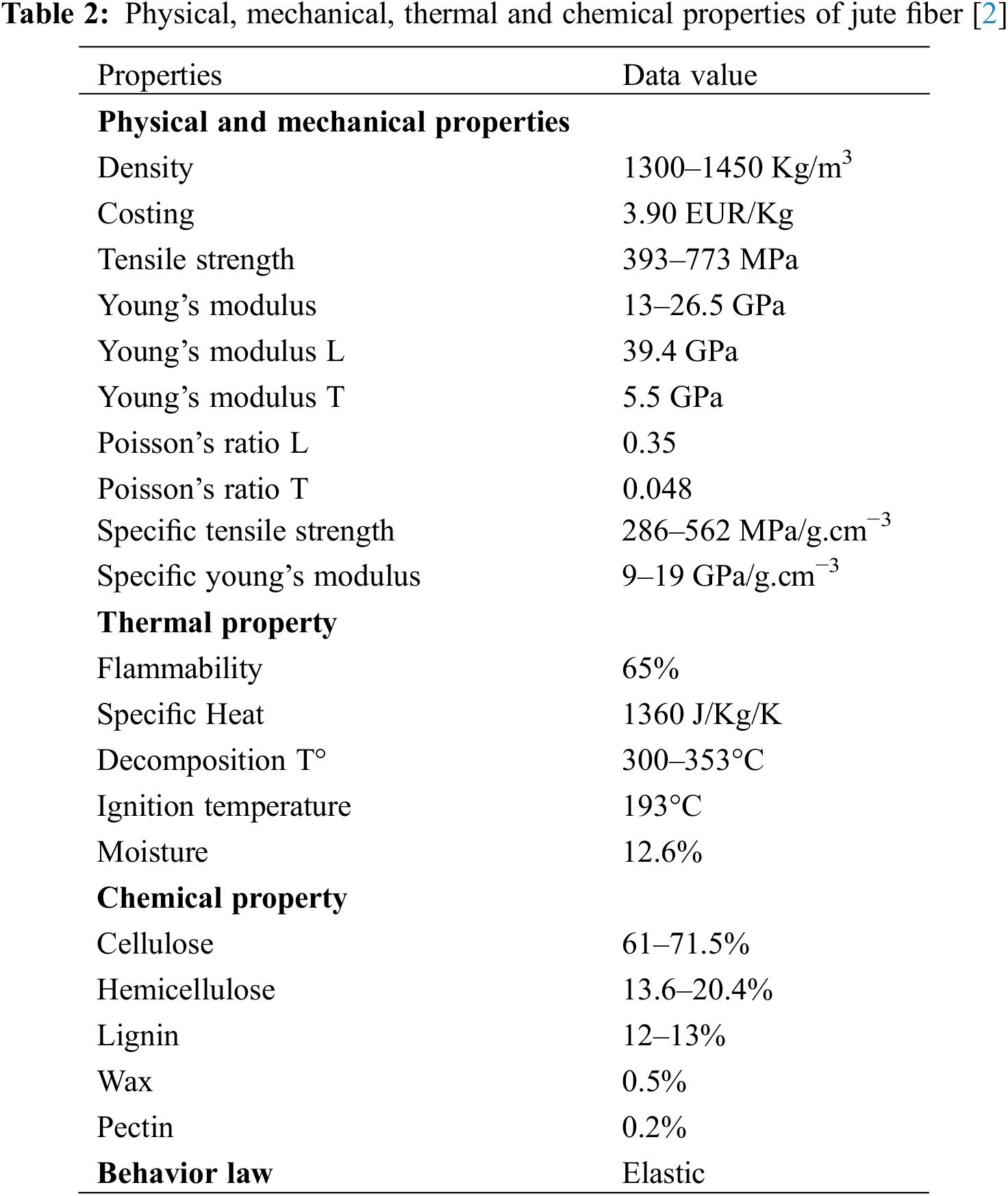

The different physical, mechanical, Thermal, and chemical properties of jute fiber are shown in Table 2.

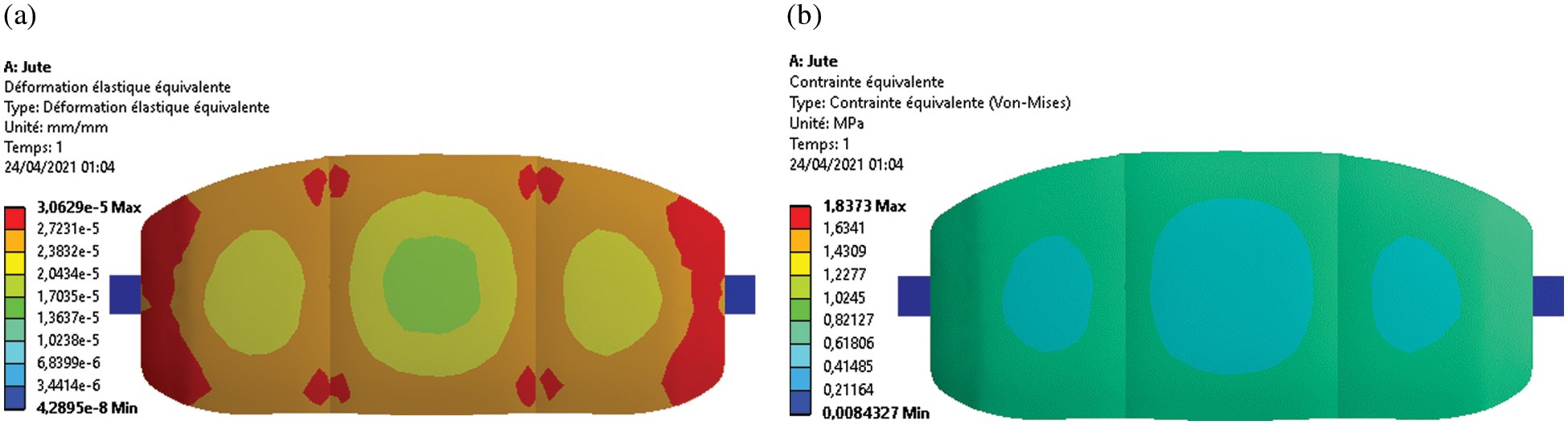

The strain and stresses of brake pad with jute fiber are shown in Fig. 5.

Figure 5: (a) Strain von-mises of brake pad with jute fiber; (b) Stress von-mises of brake pad with jute fiber

Areca is a species of palm which is a natural plant. Areca fiber which is represented in Fig. 6, is a type of about 50 species of palm trees of the Aceraceae family found in the rainforests of China and India, throughout the Malay Archipelago, to the Solomon Islands [15].

Figure 6: Areca fiber

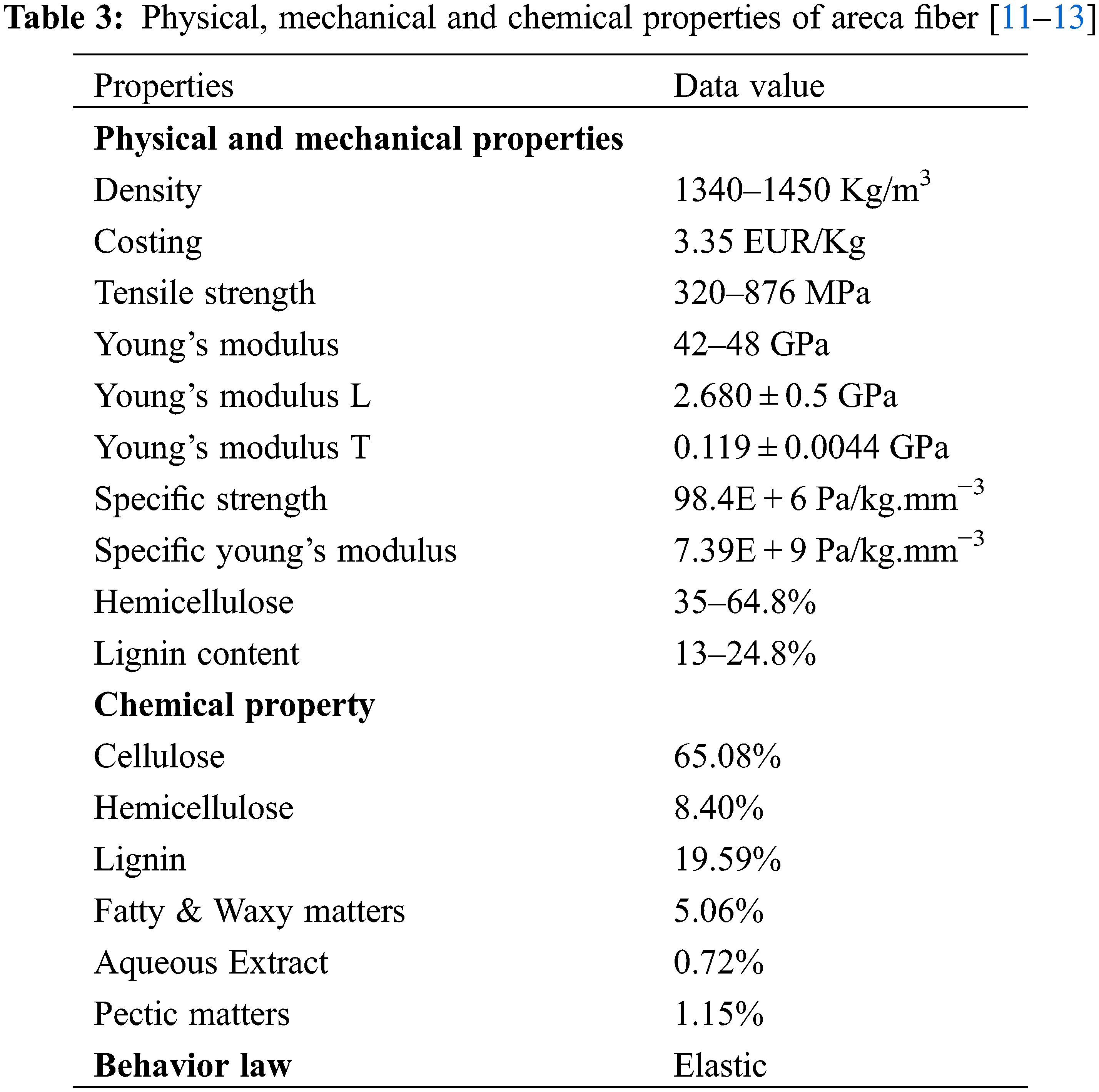

The different physical, mechanical and chemical properties of areca fiber are shown in Table 3.

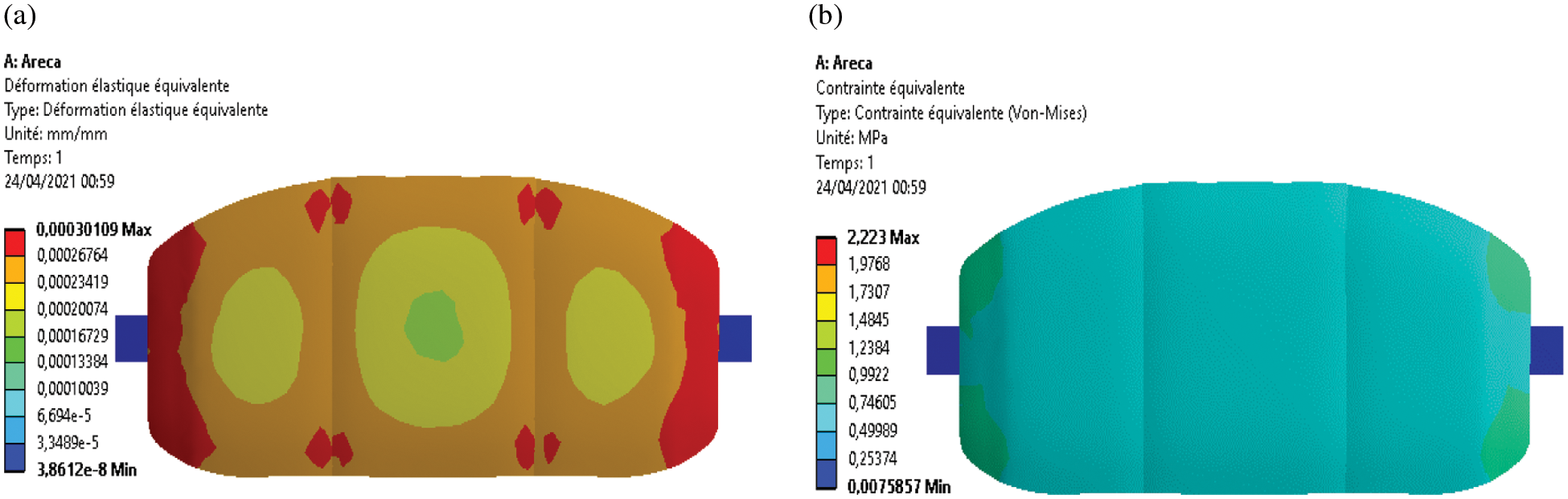

The strain and stresses of brake pad with areca fiber are shown in Fig. 7.

Figure 7: (a) Strain von-mises of brake pad with areca fiber; (b) Stress von-mises of brake pad with areca fiber

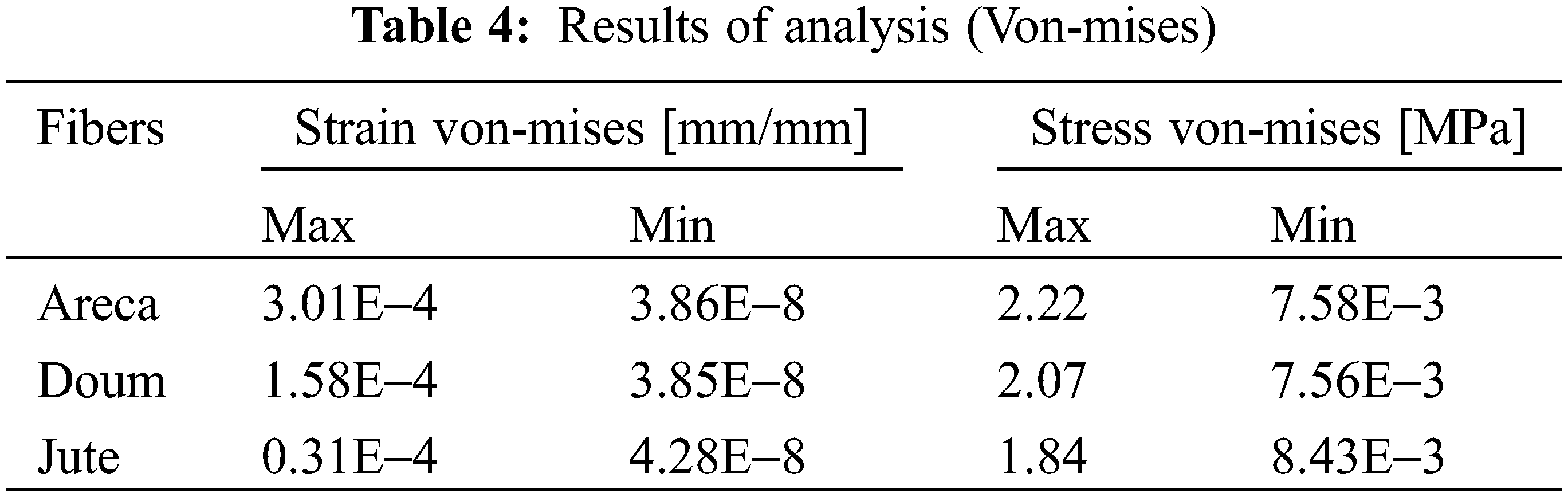

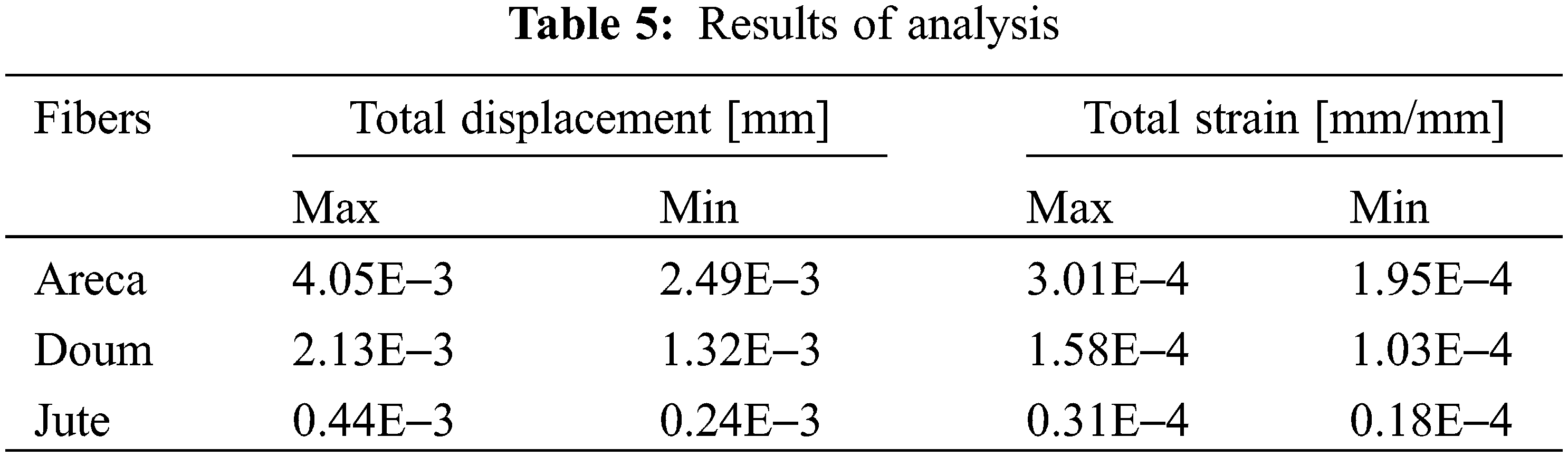

The comparison analysis results of areca, doum (Dwarf palm), and jute fiber are illustrated in the following Tables 4 and 5.

We have extracted from Tables 4 and 5 that natural fibers areca, doum (Dwarf palm), and jute fiber are compliant with the rules for choosing a brake system pad with less strain and important stress.

Indeed, we have illustrated that jute fiber is more resistant than doum (Dwarf palm) and areca fiber.

Starting from the preliminary study stage of natural materials based on the investigation of different properties of natural fibers, specifically local materials, this work has presented natural fiber properties such as physical, mechanical, chemical, and thermal properties. In fact, we have compared the strain, and stress von-mises of the brake pad as a case study with areca, doum, and jute material. The first numerical results are encouraging to continue and deepen this study even more. Currently, work on the optimization and combined use of many natural materials is ongoing and could be presented in a future article.

For this reason, add as a future objective of this study, we are focused to consider natural fibers as a raw material in the manufacture of mechanical systems, and present a finite element analysis of the optimal natural fiber, as well as a study of different behaviors of the mechanical system with natural material such as elasticity, plasticity, stress, temperature, strain, deformation, and damage. With the aim of increasing and improving the efficiency and durability of mechanical systems and respecting the environment.

Funding Statement: The authors certify that this work has no funding statement.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Yashwhanth, S., Mithun Mohan, M., Anandhan, R., Selvaraj, S. K. (2021). Present knowledge and perspective on the role of natural fibers in the brake pad material. Materials Today: Proceedings, 46, 7329–7337. DOI 10.1016/j.matpr.2020.12.995. [Google Scholar] [CrossRef]

2. Essabir, H., Bouhfid, R., Qaiss, A. (2017). 8-Alfa and doum fiber-based composite materials for different applications. In: Jawaid, M., Md Tahir, P., Saba, N. (Eds.Lignocellulosic fibre and biomass-based composite materials, pp. 147–164, Woodhead Publishing Series in Composites Science and Engineering, Elsivier. DOI 10.1016/B978-0-08-100959-8.00008-1. [Google Scholar] [CrossRef]

3. Essabir, H., Elkhaoulani, A., Benmoussa, K., Bouhfid, R., Arrakhiz, F. Z. et al. (2013). Dynamic mechanical thermal behavior analysis of doum fibers reinforced polypropylene composites. Materials & Design, 51, 780–788. DOI 10.1016/j.matdes.2013.04.092. [Google Scholar] [CrossRef]

4. Arrakhiz, F. Z., El Achaby, M., Malha, M., Bensalah, M. O., Fassi-Fehri, O. et al. (2013). Mechanical and thermal properties of natural fibers reinforced polymer composites: Doum/low density polyethylene. Materials & Design, 43, 200–205. DOI 10.1016/j.matdes.2012.06.056. [Google Scholar] [CrossRef]

5. Kian, L. K., Saba, N., Jawaid, M., Alothman, O. Y., Fouad, H. (2020). Properties and characteristics of nanocrystalline cellulose isolated from olive fiber. Carbohydrate Polymers, 241, 116423. DOI 10.1016/j.carbpol.2020.116423. [Google Scholar] [CrossRef]

6. Baley, C. (2002). Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Composites Part A: Applied Science and Manufacturing, 33(7), 939–948. DOI 10.1016/S1359-835X(02)00040-4. [Google Scholar] [CrossRef]

7. Campana, C. (2018). Durabilité de composites à fibres naturelles: Effet du vieillissement couplé sur les performances mécaniques et la réaction au feu (phdthesis). Université Montpellier. https://tel.archives-ouvertes.fr/tel-01844480. [Google Scholar]

8. Doan, T. T. L. (2006). Investigation on jute fibres and their composites based on polypropylene and epoxy matrices (Ph.D. Thesis). Technischen Universität Dresden. [Google Scholar]

9. Biswas, S., Shahinur, S., Hasan, M., Ahsan, Q. (2015). Physical, mechanical and thermal properties of jute and bamboo fiber reinforced unidirectional epoxy composites. Procedia Engineering, 105, 933–939. DOI 10.1016/j.proeng.2015.05.118. [Google Scholar] [CrossRef]

10. Elhilali, F., Fihri-Fassi, H., Ourihi, R. (2021). Towards the development of an optimized numerical model of the brake system pad with natural material. Materials Today: Proceedings, 45, 5419–5425. DOI 10.1016/j.matpr.2021.02.113. [Google Scholar] [CrossRef]

11. Murkur, R., Balaji, K. (2021). Evaluation properties of areca fiber reinforced biodegradable composite material. Materials Today: Proceedings, DOI 10.1016/j.matpr.2021.01.962. [Google Scholar] [CrossRef]

12. Dinakaran, K., Ramesh, H., Joseph, A. D., Murugan, R., Jothi, S. (2019). Development and characterization of areca fiber reinforced polymer composite. Materials Today: Proceedings, 18, 934–940. DOI 10.1016/j.matpr.2019.06.528. [Google Scholar] [CrossRef]

13. Christu Paul, R., Ramachandran, B., Sushma, G., Aditya Harshavardhan, K. H., Rohith, I. (2020). An empirical research on areca fiber polymer composite for automotive components in modern industry. Materials Today: Proceedings, 33, 4493–4497. DOI 10.1016/j.matpr.2020.07.715. [Google Scholar] [CrossRef]

14. Ali-Boucetta, T., Ayat, A., Laifa, W., Behim, M. (2021). Treatment of date palm fibres mesh: Influence on the rheological and mechanical properties of fibre-cement composites. Construction and Building Materials, 273, 121056. DOI 10.1016/j.conbuildmat.2020.121056. [Google Scholar] [CrossRef]

15. Heatubun, C. D., Dransfield, J., Flynn, T., Tjitrosoedirdjo, S. S., Mogea, J. P. et al. (2012). A monograph of the betel nut palms (Areca: Arecaceae) of east malesia. Botanical Journal of the Linnean Society, 168(2), 147–173. DOI 10.1111/j.1095-8339.2011.01199.x. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |