| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.021968

ARTICLE

Effects of Chemical Treatment on the Physical Properties of Typha

1Efficiency and Energetic Systems Research Group, Alioune Diop University, Bambey, BP 30, Senegal

2Laboratoire Eau, Energie, Environnement et Procédés Industriels (LE3PI), Cheikh Anta Diop University, Dakar-Fann, BP 5085, Senegal

*Corresponding Author: Ibrahima Diaw. Email: ibrahima.diaw@uadb.edu.sn

Received: 15 February 2022; Accepted: 14 March 2022

Abstract: Plant-based concretes are produced from plant aggregates and a binder. Plant fibers are mainly composed of saccharides (sugars) and these sugars can decrease the concentration of Ca2+ ions in the cement pore solution and delay the formation of hydration products. To improve the interfacial bond between fibers and matrix a chemical treatment is widely used. This study investigates the effect of sodium hydroxide treatment on physical and hygroscopic properties of Typha aggregates. In particular, a 5% sodium hydroxide solution is used to treat these aggregates and their bulk and absolute densities, porosity, water content and water absorption are evaluated accordingly. Results indicate that bulk and absolute densities increase after treatment from 56.44 kg/m3 to 122.57 kg/m3 and 541.93 kg/m3 to 555.17 kg/m3, respectively. NaOH treatment reduces porosity of Typha from 89.58 % to 77.92% and decreases water content from 1.4 % to 1%. The treatment with sodium hydroxide reduces substantially the water absorption of the aggregates.

Keywords: Sodium hydroxide treatment; typha aggregates; hygroscopic properties; physical properties

Nomenclature

| ρ | Bulk density |

| ρA | Absolute density |

| PT | Total Porosity |

| H | Moisture content |

| W | Water absorption |

| m0 | Initial mass of the aggregates |

| ms | Dry mass of aggregates |

| mt | Mass of aggregates after water immersion |

The building sector represents 36% of the global final energy consumption and approximately 40% of carbon dioxide (CO2) emissions in 2017 [1]. In Senegal, 67% of the total electricity production is consumed by the building sector [2]. The construction sector is one of the most energy intensive and greenhouse gas-emitting sectors [3]. The manufacture of a building material has an impact on the environment from the extraction of the raw materials to the end of its life cycle. Concrete is one of the most widely used materials in the construction industry. According to Marinković et al. [4], the current world production of concrete is about 6 billion tons per year or one ton per person per year. Due to the high energy consumption of the building sector and its impact on the environment, special attention has been paid to plant-based concretes in recent years. Plant-based concretes are produced from plant aggregates and a binder. Plant fibers are increasingly replacing traditional aggregates. Vegetable fibers have several advantages. In detail, they are light, less expensive, renewable, biodegradable and present a great flexibility and good thermal and acoustic insulation capacities. However, they have also disadvantages such as the low mechanical properties, high moisture absorption, reduced durability and low fire resistance [5]. The mechanical performance of plant fiber reinforced concrete depends strongly on the interfacial bond between the plant fibers and the matrix. The introduction of plant fibers into an inorganic matrix such as cement has negative effects on cement hydration and delays cement setting [6]. Plant fibers are mainly composed of cellulose and non-cellulosic components such as hemicellulose, pectin and lignin [6,7]. Cellulose and hemicellulose are saccharides (sugars) that are insoluble in water, but can be dissolved in basic solutions [8]. According to Kochova et al. [9] the sugars contained in the plant fibers decrease the concentration of Ca2+ ions in the cement pore solution and delay the formation of hydration products. To improve the interfacial bond between fibers and matrix, two possibilities can be considered: a treatment of the plant particles and/or a modification of the matrix. Fibers can be treated with alkali treatment using sodium hydroxide, potassium permanganate, calcium hydroxide, etc., or with acid treatment using calcium chloride, ethylenediamine-tetraacetic acid (EDTA), etc. In this context, several researchers have studied the impact of fiber surface modification on the mechanical and thermal properties of plant fiber reinforced composites. Senthilkumar et al. [10] studied the effect of chemical treatment on the compressive properties of pineapple fiber/polyester composites. The author used two types of treatment. A treatment with sodium hydroxide and a treatment with potassium hydroxide. For the treatment with sodium hydroxide, the 3 mm long fibers were soaked in an aqueous solution of 1 N NaOH for 1 h and then cleaned several times and allowed to dry at room temperature. The treatment of the fibers with KOH was performed by immersing the untreated fibers in an aqueous solution of 1 N KOH for 1 h. The fibers were cleaned with dilute hydrochloric acid and then dried at room temperature. The results show that for the same fiber content, the NaOH and KOH treated fiber composites had lower compressive strength than the untreated fiber composites. According to the author, the compressive properties of composites are not only dependent on the fiber-matrix interfacial adhesion but are also by the strength and modulus of the fibers. Ali-Boucetta et al. [11] studied the effect of processing meshed date palm fibers on the mechanical properties of fiber-cement composites. Three types of treatment were carried out by the author. A thermal treatment in which the fibers were boiled in a cooker for variable boiling times: 5 min, 1, 2 and 3 h. At the end of boiling, the fibers were drained and rinsed with water. The fibers are then dried at room temperature for two days. An alkali treatment in which fibers were immersed for 2 h in a NaOH solution at different concentrations: 1%, 3%, 6% and 9% by weight. The fibers were then rinsed with 1% concentrated acetic acid and distilled water until the rinsing water was chemically neutral. Finally, the fibers are dried in an oven at 60°C for 24 h. A linseed oil coating in which the fibers were dried at 50 ± 0.1°C for 24 h and mixed with linseed oil in a blender. Several linseed oil/fiber mass ratios were tested: 0.25, 0.50, 1, and 1.50. The treated fibers were placed in a ventilated oven at 50 ± 0.1°C until they were completely dry, after about seven days. Results show that boiling water treatment and alkali treatment improve the compressive strength of mortar van de Weyenberg et al. [12] used sodium hydroxide treatment to improve mechanical properties of flax epoxy composites. The fibers were treated with 1%, 2% and 3% sodium hydroxide solution for 20 min at room temperature and then dried at 80°C for 8 h. Results show that mechanical properties of the composite increase with increasing NaOH concentration. Sedan et al. [6] investigated the effect of hemp fiber treatment on the mechanical behavior of hemp cement composites. The fibers were treated with a 6% sodium hydroxide solution by mass at 20 ± 2°C for 48 h and then dried at 60°C for 48 h. Results show that alkali treatment improves the mechanical performance of the composites. Tran et al. [13] studied the effect of alkali treatment on the interfacial and mechanical properties of biodegradable poly(butylene succinate) composites reinforced with coir fibers. Coir fibers were treated with 5% NaOH solution for different soaking times (24 h, 48 h, 72 h and 96 h) at room temperature. Then, the fibers were washed several times with water and air-dried for more than 2 days. Results show that the alkali treatment improved tensile properties of fibers. Alkali treatment of coir fibers increased the interfacial bond strength and wettability of the fibers by PBS resin leading to the improvement of mechanical properties of the composites. Some researchers have been interested in the effect of chemical treatment on the hygroscopic properties of the fiber (water absorption or moisture content). Sreekala et al. [14] studied the effect of soda treatment on the water absorption of oil palm fibers. The fibers were treated with a 5% sodium hydroxide solution by weight for 48 h. Results show that soda treatment reduces the water absorption of the fibers. Ghabo et al. [15] studied the effect of sodium hydroxide treatment on the water absorption and moisture content of Baobab fibers. The fibers were treated with a 5% caustic soda solution for 6 h at room temperature and then dried at room temperature for 72 h. Results show that the treatment fiber reduces the water absorption and moisture content of baobab fibers. Punyamurthy et al. [16] studied the effect of alkali treatment on the water absorption of abaca cellulosic fibers. The fibers were treated in a sodium hydroxide solution at different concentrations for 72 h at the temperature of 30°C. The fibers were then neutralized with 2% acetic acid solution. They were then dried at room temperature for 48 h. Results show that the treated fibers have a lower water absorption than the untreated fibers. Kanchireddy et al. [17] studied the effect of surface treatment on water absorption of Napier Grass Fibers. Different treatments have been used. An alkali treatment was carried out with a 5% sodium hydroxide solution at room temperature for 30 min. The fibers were then washed with water and dried at 105°C. Silane treatment was also performed with a 1% solution of 3 aminopropyltriethoxy silane, which was maintained at pH 5 for 1 h. The fibers were then removed from the solution and dried in an oven at 60°C for 12 h. Results show that the water absorption of the treated fibers decreases and therefore present a better water resistance. Reddy et al. [18] studied the effect of alkali treatment on the moisture content of century fiber. These fibers were treated with 5% sodium hydroxide solution at 30°C during 1 h. These fibers were washed with water and neutralized with acetic acid and washed again with distilled water. The fibers were exposed at 105°C for 24 h. Results show that moisture content of fiber is reduced after treatment from 5.25% to 4.93%. Other researchers have studied the effect of chemical treatment on the physical, mechanical or thermal properties of plant fibers. Manohar et al. [19] investigated the density of oil palm fiber, sugarcane fiber and coconut fiber and the variation of thermal conductivity with bulk density of these fibers. The results show the average diameter are 686 kg/m3 for sugarcane fiber, 755 kg/m3 for coconut fiber and 797 kg/m3 for oil palm fiber. The Increasing the density of the fibers leads to an increase in the minimum thermal conductivity. The thermal conductivity values of these fibers show that they can be used as thermal insulation material. Ghabo et al. [15] studied the influence of sodium hydroxide treatment on the bulk and absolute density of Baobab fibers. Results show that chemical treatment increase bulk and absolute densities of baobab fibers. Bbrigida et al. [20] investigated the effect of chemical treatment on the density of green coconut fiber. In the first treatment, two grams of coconut fibers were submitted to an oxidation using 40 ml of H2O2 solution in basic medium, at 85°C for 2 h. In the second type of treatment. Five grams of fiber were soaked in 100 mL of 0.4% NaOCl for approximately 2 h at 85°C. A third treatment was performed where 5 grams of fibers were soaked in 100 ml of 4–6% NaOCl for 2 h at 30°C and, then the fibers were washed with water and then soaked in 100 ml of 10% NaOH for 1 h at 30°C. After these different treatments, the treated fibers were rinsed with distilled water and dried under vacuum for 2 h. Results show that the treated fibers have a lower density than the untreated ones except for the fibers treated with NaOCl/NaOH which have a higher density than the untreated ones. From the literature review presented it’s obvious the effect of chemical treatment on the hygroscopic and physical properties of Typha fiber has not been studied. The objective of this paper is to investigate how surface modification fibers using sodium hydroxide treatment affect the physical and hygroscopic properties of Typha aggregates. The next section describes materials and experimental methods used in this study. The third section deals with the results and discussions. The conclusion and prospects for future work will be highlighted in the concluding section.

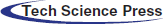

Typha is a plant that grows in aquatic environments or wetlands. Its proliferation has occurred since the construction of the Diama and Manantali dams. Fig. 1 shows a Typha plant. At the microscopic scale, Typha leaf has two main zones. The cortex (peripheral cylinder): rigid zone being used for the manufacture of fiber of Typha. The marrow (central cylinder): spongy zone with cellular structure. The cells are parallelepipedal in shape. The cells are closed (occluded) and separated from each other by a thin membrane. Fig. 2 shows a longitudinal cut of the Typha leaf. We note a periodicity of the cells, which suggests that a modeling by homogenization would allow us to evaluate the mechanical properties of the Typha leaf. The use of a scanning electron microscope should allow us to know the dimensions of the cells.

Figure 1: Typha plant

Figure 2: Longitudinal cut of a Typha leaf

Typha leaves were cut transversely by hand and then sun-dried for one to two weeks. Their length ranges from 2 to 20 mm. Fig. 3 shows Typha aggregates.

Figure 3: Typha aggregates

Typha aggregates were immersed in a 5% sodium hydroxide (NaOH) solution by mass for 24 h at room temperature. After treatment, the aggregates were cleaned with distilled water and then soaked in a 1% sulfuric acid solution for 2 h and cleaned again with distilled water. The aggregates are oven dried at 80°C for 48 h. Fig. 4 illustrates the treated and untreated aggregates.

Figure 4: Typha aggregate (left untreated, right treated)

2.3 Physical Properties Measurement

The bulk density was determined by filling the material without compression into a specimen of known volume. The mass of the aggregates was determined by a hydrostatic balance. The bulk density can be calculated by using Eq. (1). The experiment was repeated three times and then the average was determined.

The absolute density was determined by the pycnometer method. The method consists of weighing the mass m0 of the pycnometer filled with distilled water and previously tared. Weigh a mass m1 of Typha in the pycnometer. Complete the filling of the pycnometer with water and weigh the mass of the whole (water + Typha) m2. The mass of water in the pycnometer with the material present is equal to m3 = (m2 − m1). The absolute density can be calculated by using Eq. (2).

The total porosity of Typha aggregates was determined from the bulk and absolute densities. The total porosity can be calculated by using Eq. (3) [21,22].

2.4 Hygroscopic Properties Measurement

The aggregates were dried inside an oven at a temperature of 100°C for 48 h and the water content can be calculated using Eq. (4).

A sample of material was immersed in water at room temperature at different time intervals (3, 5, 10 mn…). After each immersion time, the aggregates were removed and wiped with absorbent paper to remove intergranular water and water adsorbed on the surface [23]. The water absorption can be calculated using Eq. (5).

3.1 Physical Properties Results

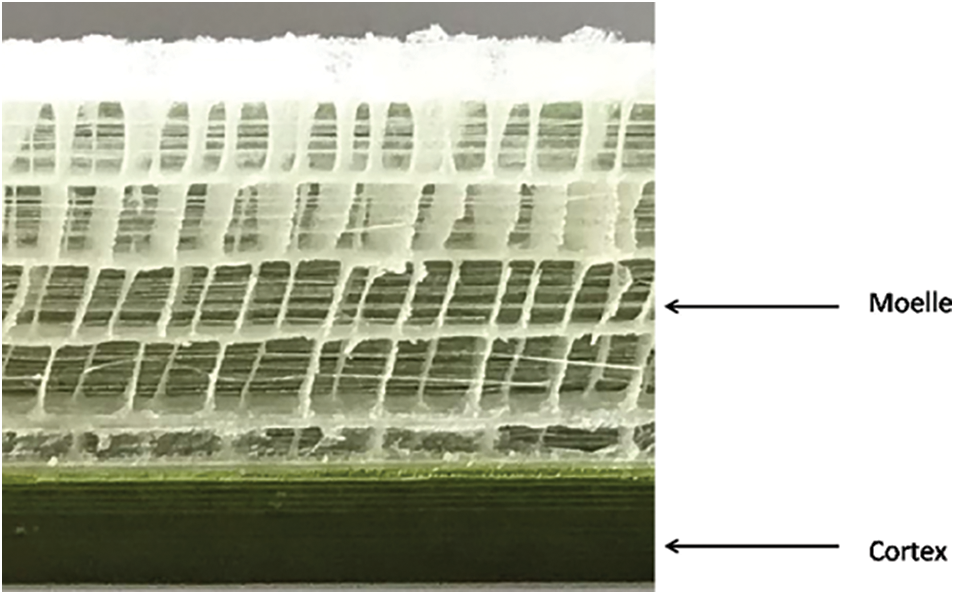

The results of bulk and absolute densities of Typha aggregates are presented in Table 1.

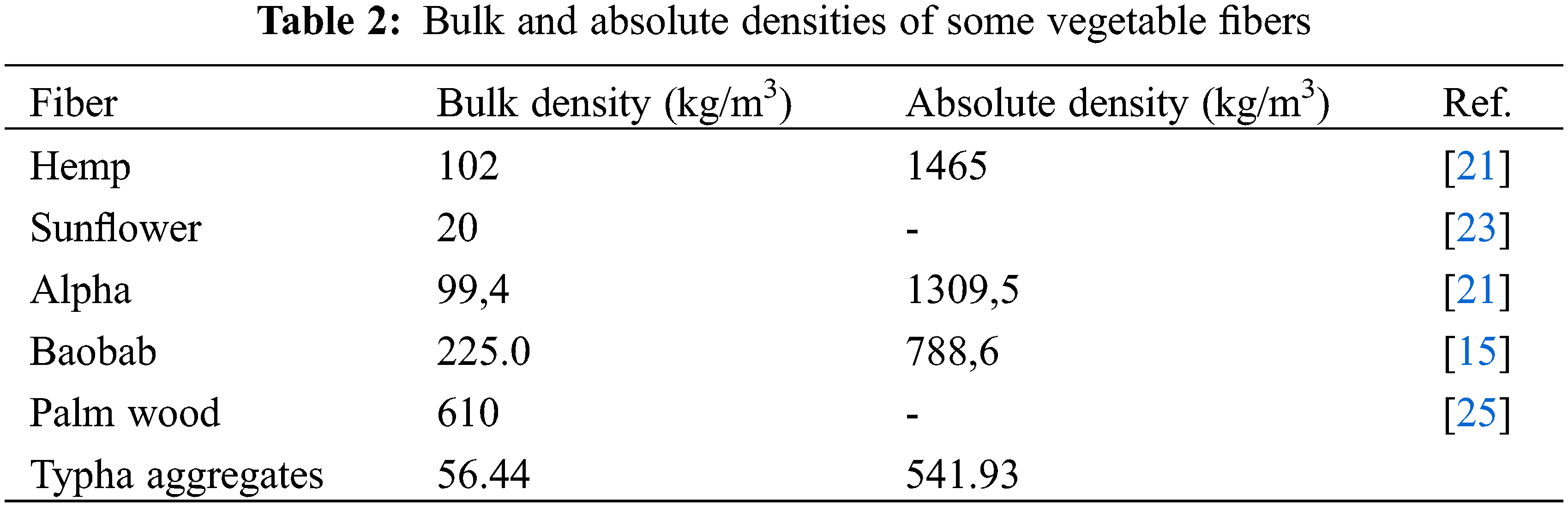

The results show that the absolute density is higher than the bulk density. The bulk density includes aggregate volume, pore volume and inter-granular volumes. The consideration of pore volume and inter-granular volume causes an overestimation of the aggregate volume and consequently a lower density [15]. The increasing density was also observed by Ghabo et al. [15] after the alkali treatment of Baobab fibers and by Dallel [24] after the treatment of Alfa fibers. According to the author [24], cellulose is thus the denser substance. The alkali treatment removes non-cellulose substances due to their low density and favor’s a massive presence of cellulose in the aggregates, hence the increasing density. We observe a thinning of the aggregates when they are treated. The apparent densities of untreated and treated aggregates are 56.44 kg/m3 and 122.57 kg/m3, respectively. Results show that sodium hydroxide treatment increases the density of aggregates. Indeed the treatment contributes to remove the non-cellulosic components. Table 2 presents bulk and absolute densities of some plant fibers studied in the literature [21–23,25,26].

A comparison of the density of Typha aggregates with those found in the literature shows that Typha has a low density compared to many fibers and can therefore be used in lightweight concretes.

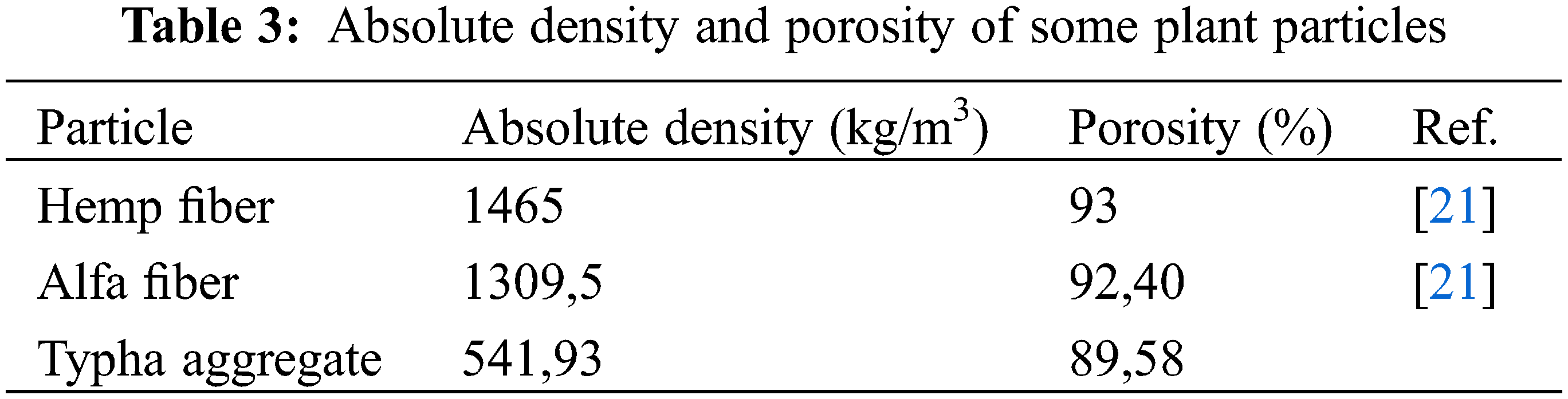

The porosity of untreated and treated Typha are respectively 89.58% and 77.92%. The porosity decreases when the aggregates are treated. This phenomenon is due to the increase absolute density when these aggregates are treated.

Table 3 presents the porosities and absolute densities of some vegetable fibers. The porosity of Typha aggregates is lower than the porosity of hemp and Alpha fibers. However, this difference may be due to the methods used to determine the absolute density of the particles and the nature of the particle (fiber or aggregate).

3.2 Hygroscopic Properties Results

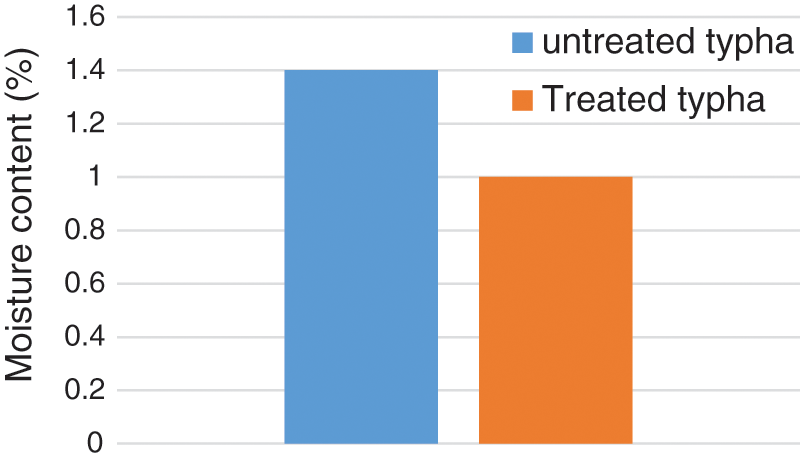

The moisture content of treated and untreated Typha aggregates is shown in Fig. 5. We show that the moisture content decreases when the aggregates are treated. It goes from 1.4% for untreated aggregates to 1% for treated aggregates, a decrease of 0.4%. The porosity of plant particles allows them to fix water vapor contained in the ambient air. The non-cellulosic substances such as lignin, hemicelluloses and pectin are constituted of hydroxyl groups that are able to fix water by the means of interactions Van Der Wall, then by the process of vapor diffusion and capillary condensation, the water moves up into the pores of the particle [15,23]. The treatment of plant particles removes non-cellulosic components and consequently the hydrophilic groups responsible for the presence of water in the fibers, hence the decrease in water content. The study of water content of Typha aggregates reveals that Typha has a lower water content than Diss fiber (6.3%), Alfa fiber (7.28%), Rush fiber (10.22%) of date palm leaflets (8.33%), flax fiber (7.6%) [15].

Figure 5: Moisture content of Typha aggregates

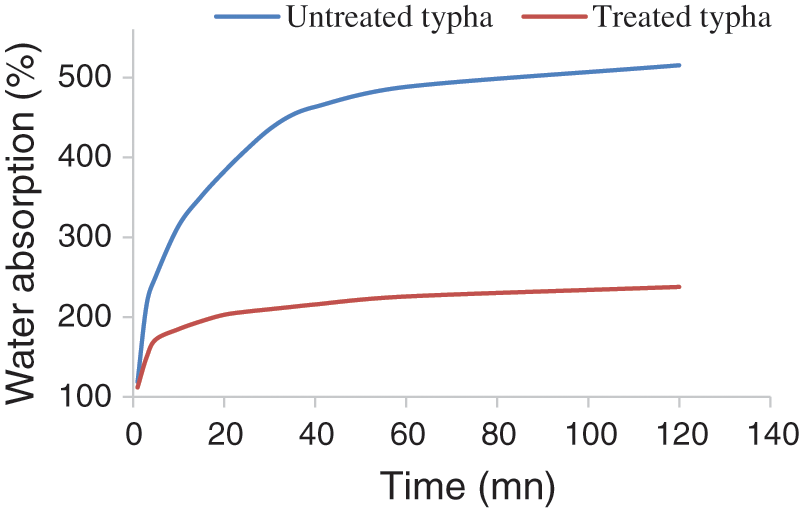

Fig. 6 illustrates the evolution of the water absorption rate of the aggregates as a function of time. Untreated aggregates have the highest water absorption. The hydration kinetics of treated and untreated aggregates follow the same evolution and presents two phases. A first phase where absorption increases very rapidly, this phase shows that the fibers absorb the maximum amount of water in the first few minutes. A second phase where a slowing down of the hydration kinetics is observed. This slowing down is due to the phenomenon of saturation of the pores, which are filled with water and can only absorb a small portion of it. This high absorption capacity is due, on the one hand, to the phenomenon of capillary rise induced by the porosity of the particle structure and, on the other hand, to the presence of hydroxyl groups (OH) and amorphous zones in the cellulosic structure of the fibers [27]. The water absorption of the treated aggregates is lower than that of the untreated aggregates, therefore the treatment has reduced the water absorption rate of the aggregates. This result is already observed in previous work [15,27] where there was a reduction in water absorption of fibers after alkali treatment. Treatment with sodium hydroxide removes impurities, waxy substances, oils and non-cellulosic constituents (hemicellulose, lignin and pectin) from the fiber surface. This makes the internal structure less hydrophilic and creates a rougher topography of the fiber surface. According to Govin [28], chemical treatment makes it possible to substitute hydroxyl groups, responsible for the swelling of plant particles, by hydrophobic groups. Indeed, the hemicelluloses are responsible for the hydrophilic character of the fibers, they participate in the retention of water in the plant fibers. Their elimination results in a decrease in the hydrophilic character and an increasing stability of the fibers with respect to humidity [15,27]. The knowledge of the absorption capacity of the aggregates makes it possible to limit the problems of competition of mixing water between the aggregates and the binder.

Figure 6: Absorption kinetics of aggregates

The objective of this work was to investigate the effect of alkali treatment on the physical and hygroscopic properties of Typha aggregates. The results show that the alkali treatment decreases the water absorption coefficient of Typha aggregates from 488% to 226% after one hour of immersion, a decrease of 262%. The treatment also resulted in increasing bulk and absolute densities and decreasing total porosity and water content of the aggregates. For future research work, it would be interesting to compare the performance of both types of aggregates in a composite for the production of thermal insulation materials. In perspective to this work, we can consider studying the mechanical properties of treated aggregates and composites reinforced with treated aggregates. The use of other types of treatments could also be considered. nutritional and physical properties could be studied.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Global Alliance for Buildings and Construction (2018). Global status report 2018: Towards a zero emission, efficient and resilient buildings and construction sector. [Google Scholar]

2. Ministère de l’Energie et du Développement des Énergies Renouvelables (2014). Rapport du système d’information Énergétique du sénégal (SIE). [Google Scholar]

3. Espuelas Zuazu, S., Echeverría, A. M., Marcelino Sádaba, S., Prieto Cobo, E., Seco Meneses, A. (2018). Technical and environmental characterization of hydraulic and alkaline binders. Journal of Cleaner Production, 196, 1306–1313. DOI 10.1016/j.jclepro.2018.06.090. [Google Scholar] [CrossRef]

4. Marinković, S., Radonjanin, V., Malešev, M., Ignjatović, I. (2010). Comparative environmental assessment of natural and recycled aggregate concrete. Waste Management, 30(11), 2255–2264. DOI 10.1016/j.wasman.2010.04.012. [Google Scholar] [CrossRef]

5. Lee, C. H., Khalina, A., Lee, S. H. (2021). Importance of interfacial adhesion condition on characterization of plant-fiber-reinforced polymer composites: A review. Polymers, 13(3), 438. DOI 10.3390/polym13030438. [Google Scholar] [CrossRef]

6. Sedan, D., Pagnoux, C., Smith, A., Chotard, T. (2008). Mechanical properties of hemp fibre reinforced cement: Influence of the fibre/matrix interaction. Journal of the European Ceramic Society, 28(1), 183–192. DOI 10.1016/j.jeurceramsoc.2007.05.019. [Google Scholar] [CrossRef]

7. Suardana, N. P. G., Piao, Y., Lim, J. K. (2011). Mechanical properties of hemp fibers and hemp/pp composites: Effects of chemical surface treatment. Materials Physics and Mechanics, 11(1), 1–8. [Google Scholar]

8. Delannoy, G., Marceau, S., Gle, P., Gourlay, E., Guéguen-Minerbe, M. et al. (2020). Impact of hemp shiv extractives on hydration of portland cement. Construction and Building Materials, 244, 118300. DOI 10.1016/j.conbuildmat.2020.118300. [Google Scholar] [CrossRef]

9. Kochova, K., Schollbach, K., Gauvin, F., Brouwers, H. J. H. (2017). Effect of saccharides on the hydration of ordinary portland cement. Construction and Building Materials, 150, 268–275. DOI 10.1016/j.conbuildmat.2017.05.149. [Google Scholar] [CrossRef]

10. Senthilkumar, K., Saba, N., Chandrasekar, M., Jawaid, M., Rajini, N., Siengchin, S., Al-Lohedan, H. A. (2021). Compressive, dynamic and thermo-mechanical properties of cellulosic pineapple leaf fibre/polyester composites: Influence of alkali treatment on adhesion. International Journal of Adhesion and Adhesives, 106, 102823. DOI 10.1016/j.ijadhadh.2021.102823. [Google Scholar] [CrossRef]

11. Ali-Boucetta, T., Ayat, A., Laifa, W., Behim, M. (2021). Treatment of date palm fibres mesh: Influence on the rheological and mechanical properties of fibre-cement composites. Construction and Building Materials, 273, 121056. DOI 10.1016/j.conbuildmat.2020.121056. [Google Scholar] [CrossRef]

12. Van de Weyenberg, I., Truong, T. C., Vangrimde, B., Verpoest, I. (2006). Improving the properties of UD flax fibre reinforced composites by applying an alkaline fibre treatment. Composites Part A: Applied Science and Manufacturing, 37(9), 1368–1376. DOI 10.1016/j.compositesa.2005.08.016. [Google Scholar] [CrossRef]

13. Tran, H. N., Shinji, O. T., Nguyen, H. T., Satoshi, K. A. (2011). Effects of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly (butylene succinate) biodegradable composites. Composites, 42(6), 1648–1656. DOI 10.1016/j.compositesb.2011.04.001. [Google Scholar] [CrossRef]

14. Sreekala, M. S., Thomas, S. (2003). Effect of fibre surface modification on water-sorption characteristics of oil palm fibres. Composites Science and Technology, 63(6), 861–869. DOI 10.1016/S0266-3538(02)00270-1. [Google Scholar] [CrossRef]

15. Ghabo, A., Dièye, Y., Touré, P. M., Sambou, V., Sarr, J. (2020). Physical and hygroscopic characterization of fibers extracted from the baobab trunk for their use as reinforcement in a building material. International Journal of Engineering and Technical Research, 10(8), 2454–4698. [Google Scholar]

16. Punyamurthy, R., Sampathkumar, D., Srinivasa, C. V., Bennehalli, B. (2012). Effect of alkali treatment on water absorption of single cellulosic abaca fiber. BioResources, 7(3), 3515–3524. [Google Scholar]

17. Kanchireddy, O. R., Muzenda, E. (2014). Effect of fiber surface treatments on the tensile properties of polycarbonate-coated napier grass fibers. 2nd International Conference on Research in Science, Engineering and Technology, pp. 194–197. Dubai (UAE). [Google Scholar]

18. Reddy, K. O., Reddy, K. R. N., Zhang, J., Zhang, J., Varada Rajulu, A. (2013). Effect of alkali treatment on the properties of century fiber. Journal of Natural Fibers, 10(3), 282–296. DOI 10.1080/15440478.2013.800812. [Google Scholar] [CrossRef]

19. Manohar, K. (2012). Experimental investigation of building thermal insulation from agricultural by-products. British Journal of Applied Science & Technology, 2(3), 227. DOI 10.9734/BJAST. [Google Scholar] [CrossRef]

20. Bbrigida, A. I. S., Calado, V. M. A., Goncalves, L. R. B., Coelho, M. A. Z. (2010). Effect of chemical treatments on properties of green coconut fibre. Carbohydrate Polymers, 79(4), 832–838. DOI 10.1016/j.carbpol.2009.10.005. [Google Scholar] [CrossRef]

21. Harbaoui, M., Bouasker, M., Mounanga, P., Benkahla, N., Hassen, M. B. (2013). Caractérisation thermo-physique des granulats végétaux d’Alfa en vue d’utilisation dans des bétons écologiques. [Google Scholar]

22. Ouedraogo, M., Dao, K., Millogo, Y., Seynou, M., Aubert, J. E., Gomina, M. (2017). Influence des fibres de kenaf (Hibiscus altissima) sur les propriétés physiques et mécaniques des adobes. Journal de la Société Ouest-Africaine de Chimie, 43, 48–63. [Google Scholar]

23. Magniont, C. (2010). Contribution à la formulation et à la caractérisation d’un écomatériau de construction à base d’agroressources (Doctoral Dissertation, toulouse 3). [Google Scholar]

24. Dallel, M. (2012). Evaluation du potentiel textile des fibres d’Alfa (Stipa tenacissima L.Caractérisation physico-chimique de la fibre au fil (Doctoral Dissertation). Université de haute alsace-mulhouse. [Google Scholar]

25. Djoudi, T., Hecini, M., Scida, D., Djebloun, Y., Guerira, B. (2018). Physical and mechanical characterization of wood and fibers from a mature frond of date palm. Materiaux & Techniques, 106(4). DOI 10.1051/mattech/2018056. [Google Scholar] [CrossRef]

26. Tangjuank, S. (2011). Thermal insulation and physical properties of particleboards from pineapple leaves. International Journal of Physical Sciences, 6(19), 4528–4532. DOI 10.5897/IJPS11.1057. [Google Scholar] [CrossRef]

27. Achour, A. (2017). Etude des performances des mortiers renforcés de fibres naturelles: Valorisation des plantes locales (Ph.D. Thesis). Université Aboubakr Belkaïd-Tlemcen, Algérie. [Google Scholar]

28. Govin, A. (2004). Aspects physico-chimiques de l’interaction bois-ciment. modification de l’hydratation du ciment par le bois (Ph.D. Thesis). Ecole Nationale Supérieure des Mines de Saint-Etienne. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |