| Fluid Dynamics & Materials Processing |  |

DOI: 10.32604/fdmp.2022.021975

ARTICLE

Numerical Simulation of a Granular Flow on a Smooth Inclined Plane

1Laboratory of Materials and Energy, Faculty of Sciences, Ibn Tofail University, Kenitra, Morocco

2LERMAB/IUT Longwy, Institut Carnot, Nancy, France

3ASELab Advanced Systems Engineering Laboratory, National School of Applied Sciences, Ibn Tofail University, Kenitra, Morocco

*Corresponding Author: Aouatif Saad. Email: saad.aouatif@uit.ac.ma

Received: 15 February 2022; Accepted: 21 March 2022

Abstract: Unlike most fluids, granular materials include coexisting solid, liquid or gaseous regions, which produce a rich variety of complex flows. Dense flows of grains driven by gravity down inclines occur in nature and in industrialprocesses. To describe the granular flow on an inclined surface, several studies were carried out. We can cite in particular the description of Saint-Venant which considers a dry granular flow, without cohesion and it only takes into account the substance-substrate friction, this model proposes a simplified form of the granular flow, which depends on the one side on the angle of inclination of the substrate with respect to the horizontal plane and on the other side on the thickness of the substance H. The numerical simulation we have developed is first based on the Saint-Venant model, it allowed us to visualize the variation of the speed according to the thickness of the substance (from 0 to H) and to deduce the average speed of the substance on an inclined plane. However, this restrictive model does not take into account the effect of particle friction on the flow and considers that the thickness H is constant. To make our simulation more realistic, we opted for the Savage-Hatter model. We took into account the variation of the thickness on the particles speed, in addition we have studied the effect of the variation of many parameters on the granular flow, namely the temperature and the roughness of the substrate, the density and the compactness of the substance, we found that the speed of the particles increases and the treatment time decreases with an increase in temperature.

Keywords: Granular flow; friction; cohesion; angle ofinclination; temperature

Granular materials have a multiphase behavior as they can behave like solids, fluids or gases. They appear in many industrial applications such as food processing or pharmaceutics and also in geotechnical and physical phenomena like avalanches.

Despite a large amount of dedicated research [1–9], modeling and predicting granular flows remains a challenging goal. Granular flows are characterized by a very large diversity of behaviors. For example, the simple controlled experiment of a granular layer flowing on an inclined plane reveals more intriguing features than one would expect. Many researches [10–12] were based on the Saint-Venant equations to model the granular flow, this restrictive model consider a dry granular flow taking into consideration only the interaction between substances-substrat and neglecting the cohesion between grains themselves.

In our numerical study and in order to enlarge the specter of parameters and factors that intervenes in the flow, we have opted for the Savage-Hatter model [13]. Many macroscopic models have been proposed to describe granular flows, including this model for simulating the motion of granular flows on a gentle slope [13]. The main assumptions in the Savage–Hutter model are: (1) the density of the granular flow is constant; (2) the effects of side wall and erosion are ignored; (3) the granular material remains shallow during flow. In our numerical study, we furthermore, studied the effect of thickness variation, compactness, density, roughness and temperature on the flow velocity. We have found that these parameters often neglected by previous researches [14,15] mainly influence the granular flow behavior.

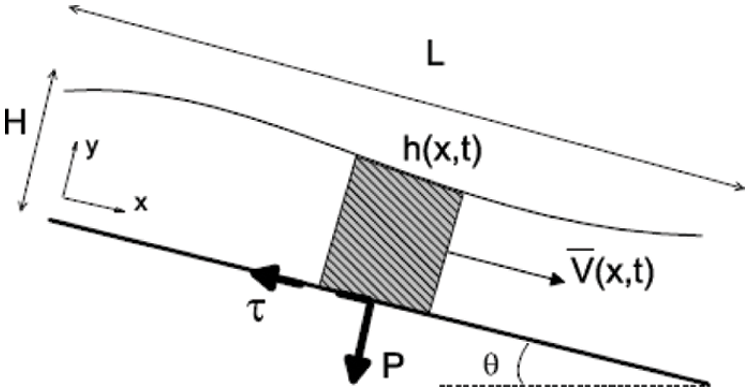

We consider the flow of a granular mass (we denote “m” and “d” for the average mass and the diameter of the grains) along a slope of inclination θ, under the effect of gravity g.

For simplicity, we describe the two-dimensional situation, where the position along the slope is marked by the direction ‘x’. We denote ‘y’ the direction perpendicular to the slope (y = 0 corresponds to substance-substrate contact surface), and u(y) the velocity profile (Fig. 1). We denote H the thickness of the flowing layer and

Figure 1: Principle of the saint-venant formalism to simulate a flow along a slope

At the base of the flow, there is a pressure P and a shear stress τ in the material. We call

The effective description of the flow, known as of Saint-Venant model, is obtained by integrating the mass conservation equations (Eq. (1)) and the momentum equation (Eq. (2)) along the thickness of the material, we thus obtain two derivative partial equations for the two quantities H and

The K parameter determined by the ratio of the normal stresses within the flow. We can see in the second equation the crucial importance of the effective coefficient of friction

The granular flow is similar to the dense flow regime; thus, we have the following friction law [16]:

With:

I: Inertial Nombrer

ρg: Surface mass,

P: Pressure,

b: Parameter of grain type.

Hypothesis:

For a uniform stationary flow, the inclination θ is equal to the effective coefficient of friction

We then used the friction law just identified in homogeneous shear to discuss the shear rate profile in dense stationary flow on a rough inclined plane. The shear rate allowed to determine the variation of the speed ux(y) which will be integrated along the thickness (H) of the layer to have the average speed

To determine the shear rate, we consider the density

The latter (shear rate) is used to determine the speed profile:

We thus find the law of flow:

The combined measurement of the thickness H of the flowing layer, the inclination θ and the average speed

where ∅︀ appears as the threshold flow angle (stop angle).

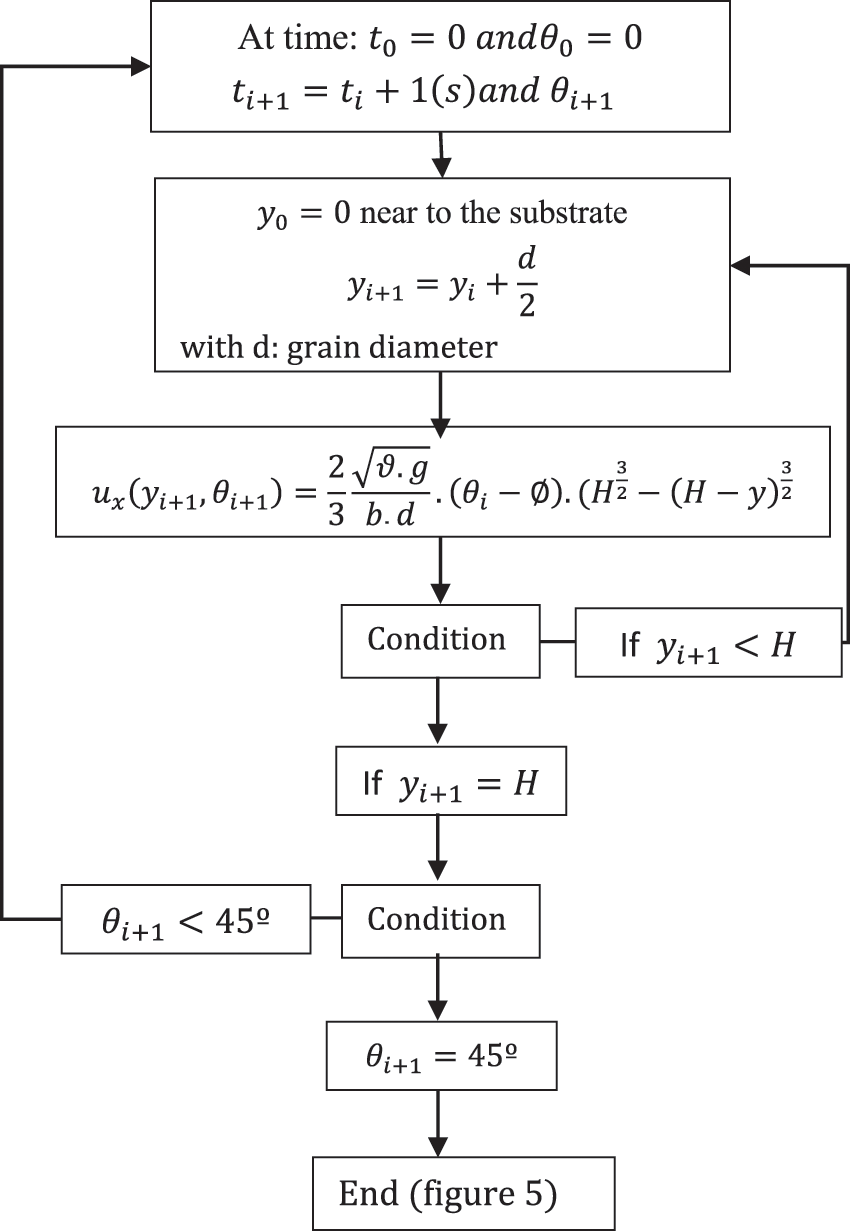

We have developed a computational program that aims to visualize the velocity profile and the effect of substrate roughness on flow blockage.

A study is carried out on an elementary volume of a rectangular substance 10 m long and 6 m thick placed on a rough substrate. The substance is characterized by a density of

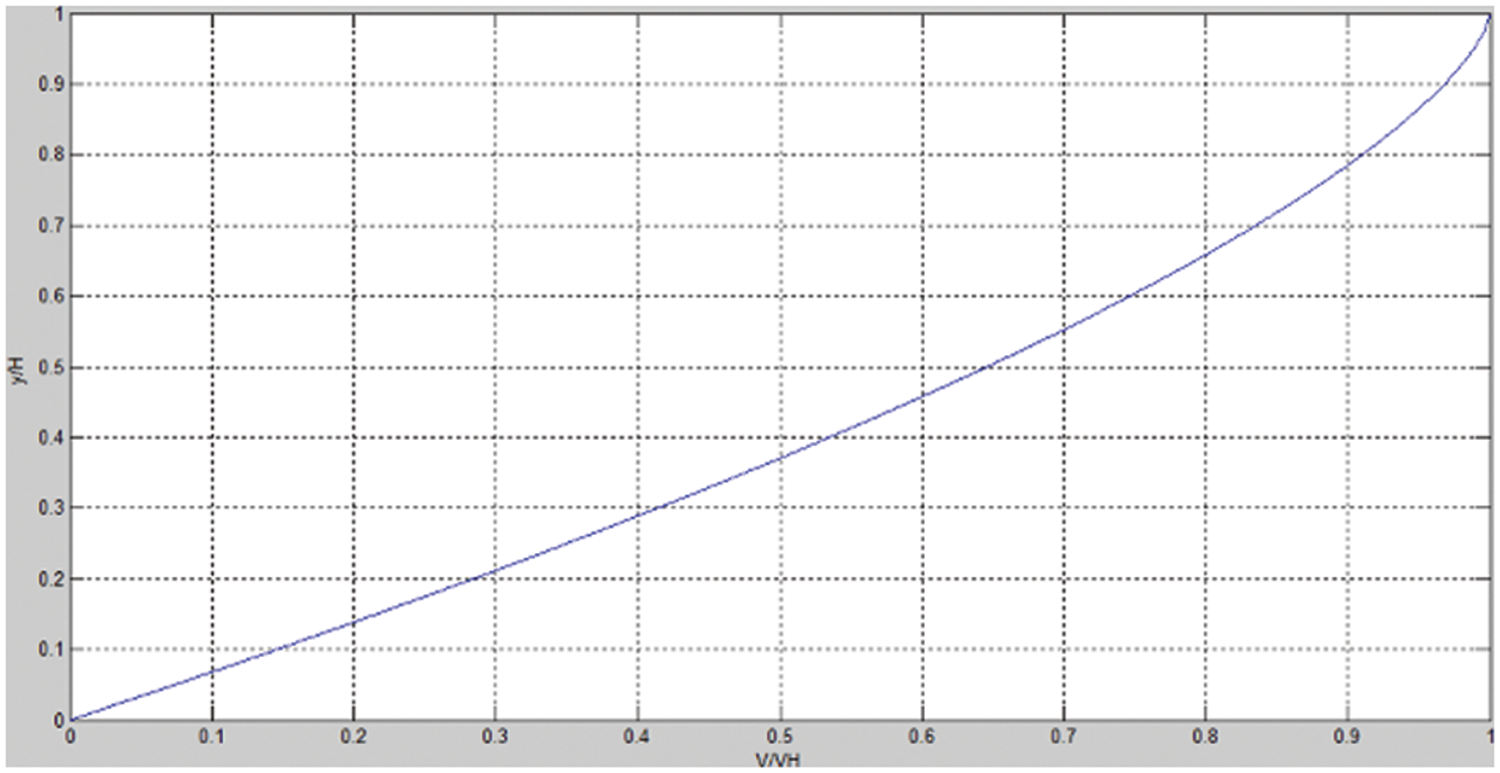

Our first simulation consists in visualizing the profile of the speed along the thickness

Figure 2: The variation of speed as a function of substance thickness

In our second simulation, we have used the effective description of Saint-Venant flow, Eq. (2) will be simplified since H = cst→

Several simulations were performed to visualize the effect of height, density, compactness and temperature of the substance on the flow velocity. From Fig. 2, we see that for a fixed angle of inclination the speed profile

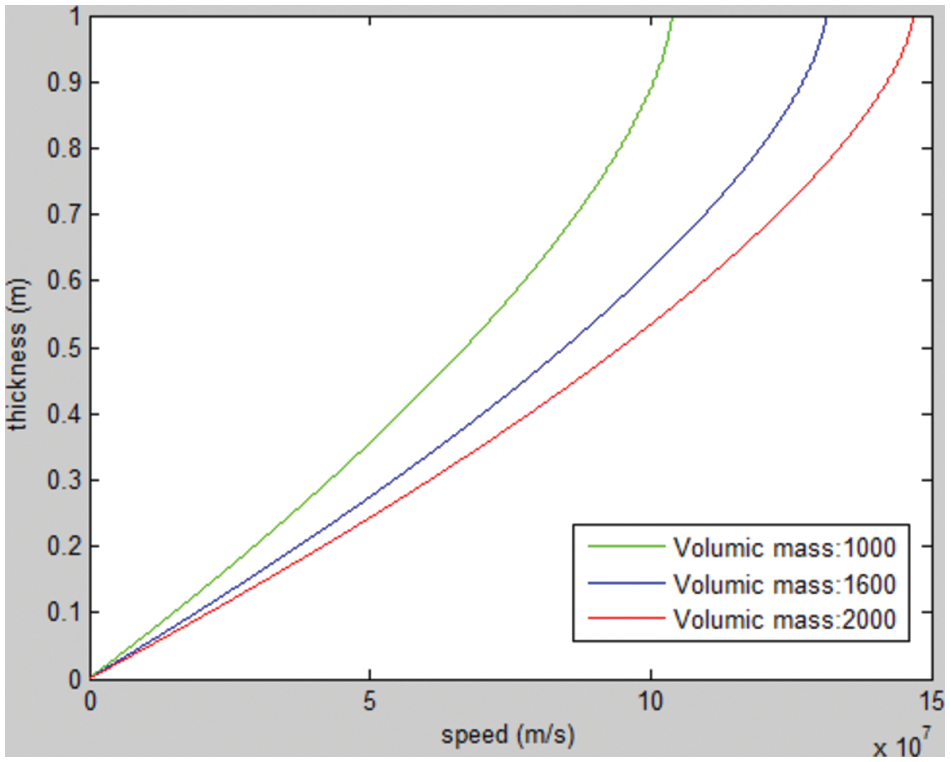

Density and compactness are crucial parameters that affect the speed of the flow. In order to visualize the effect of density, we have considered three different values as (ρ1 = 1000, ρ2 = 1600, ρ3 = 2000 kg/m3). It can be seen from Fig. 3 that the more the density increases, the more the flow speed increases. The compactness follows the same analogy as the density, we have chosen 3 different compactness values for each simulation (c1 = 0.78, c2 = 0.88 and c3 = 0.98) (see Fig. 4).

Figure 3: Effect of density on speed, with compactness = 0.78, H = 4 and the angle of inclination = 45°

Figure 4: Effect of compactness on speed, with density ρ = 1600, H = 4 and the angle of inclination = 45°

Furthermore, to study the variation of the flow velocity as a function of the substance temperature, it was necessary to add to the momentum (Eq. (2)), a viscosity term. This results to the following equation after solving with the finite-difference method:

η: viscosity (η = cste T)

In our simulation, we have chosen the water viscosity for three different temperatures η1 = 1, 787e − 3 at T = 0°-C, η2 = 1, 002e − 3 at T = 20°-C and η3 = 0.2818e − 3 at T = 100°-C).

The results presented in Fig. 5 show that the temperature increases, the more the flow speed decreases.

Figure 5: The variation of the speed as a function of time for 3 different substance temperatures

In this second part, we have studied the effect of roughness on the blocking of the flow. We mean by blocking the flow when the grains are trapped in the roughness and can only start rolling from an inclination θstart.

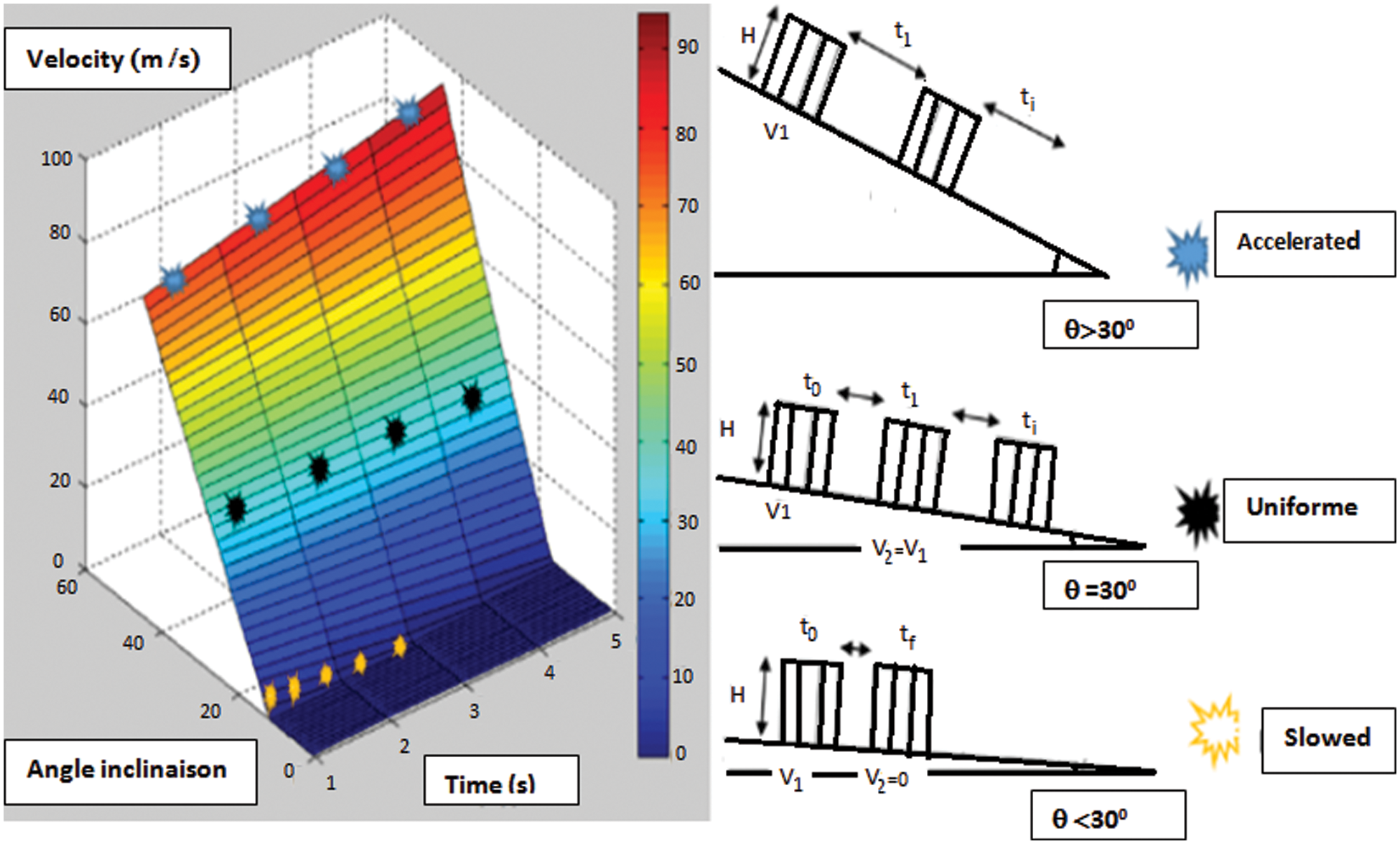

Accelerated by gravity and slowed down by dissipative shocks on the substrate, the grains reach a stationary speed

For a coefficient of friction

– The average layer speed will be slowed down to blockage for all θi < 30°-.

– The mean velocity of the layer will be uniform for θi = 30°-.

– The average speed of the layer will be accelerated for all θi > 30°-.

Figure 6: The variation of speed as a function of time with coefficient of friction 0.54774

This simulation proves that in order that our substance does not block, it is necessary that (

In this work we have opted for the Savage-Hatter model to study a granular flow in an inclined plane. We have provided new numerical results that highlight the effect of substrate temperature, the roughness, the compactness, the density of the substance on the flow behavior, which was neglected in previous models. We demonstrated that, the more the density and the compactness are important and the temperature of the substance is low, the more we will have a significant flow velocity. Furthermore, the inclination angle plays an important role in the speed of the granular flow, to have a flow; the angle of inclination must be greater than the start angle. Despite, the advantages of the Savage-Hatter model, but this latter, do not take into account the effects of forces that appear between particles during the flow. For this purpose, we aimed in the future work to highlight the effect of these forces (Forces of Hertz, Visco-elastic force…) on the flow velocity of particles on a plane with variable angles of inclination.

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Brown, R. L., et Richards, J. C. (1970). Principles of Powder Mechanics. The Boulevard, Langford Lane, Kidlington, OX51GB, Oxford, UK: Pergamon Press. [Google Scholar]

2. Duran Sables, J. (1997). Poudres et grains. Paris : Eyrolles Sciences. [Google Scholar]

3. Savage, S. B. (1989). Flow of granular materials in theoretical and applied mechanics, pp. 241–266. North Holland, Amsterdam. [Google Scholar]

4. Hutter, K., Rajagopal, K. R. (1994). On flows of granular materials. Continuum Mechanics andThermodynamics, 6, 81–139. DOI 10.1007/BF01140894. [Google Scholar] [CrossRef]

5. Desrues, J., Chambon, R., Mokni, F., Mazeroll, M. (1996). Void ratio evolution inside shear bands intriaxial sand specimens studied by computed tomography. Géotechnique, 46, (3), 529–546. DOI 10.1680/geot.1996.46.3.529. [Google Scholar] [CrossRef]

6. Michaél, P. (2002). Ecoulements denses de grains secs (Ph.D. Thesis). Ecole desPonts ET CHAUSSÉESParisTech. [Google Scholar]

7. Nicolas, T. (2005). Ecoulements gravitaires de materiaux granulaires (Ph.D. Thesisvol. 1. Université Rennes. [Google Scholar]

8. Pierre, R. (2006). Rhéologie des matériaux granulaires cohésifs. Application aux avalanches de neige dense (Ph.D. Thesis). Ecole des Ponts ParisTech. [Google Scholar]

9. Christelle, L. (2013). Modélisation numérique des écoulements gravitaires viscoplastiques avec transition fluide/solide (Ph.D. Thesis). Ecole Nationale des Ponts et Chaussées. [Google Scholar]

10. Bell, J. B., Colella, P., Glaz, H. M. (1989). A Second-order projection method for the incompressible navier–Stokes equations. Journal of Computational Physics, 85, 257–283. DOI 10.1016/0021-9991(89)90151-4. [Google Scholar] [CrossRef]

11. Saingier, G., Deboeuf, S., Lagrée, P. Y. (2015). On the front shape of an inertial granular flow down a rough incline. Physics of Fluids, 28(5). DOI 10.1063/1.4948401. [Google Scholar] [CrossRef]

12. Mangeney-Castelnau, A., Bouchut, F., Vilotte, J. P., Lajeunesse, E., Aubertin, A. et al. (2005). On the use of saint venant equations to simulate the spreading of a granular mass. Journal of Geophysical Research, 110, B09103, DOI 10.1029/2004JB003161. [Google Scholar] [CrossRef]

13. Minglong, F., Qicheng, S., Deyu, Z., Gordon G. D. Z. (2012). Simulations of granular flow along an inclined plane using the savage–Hutter model. Particuology, 10(2), 236–241. DOI 10.1016/j.partic.2011.11.007. [Google Scholar] [CrossRef]

14. Pudasaini, S. P., Hutter, K. (2007). Avalanche dynamics—Dynamics of rapid flows of dense granular avalanches. Berlin: Springer. [Google Scholar]

15. Savage, S. B., Hutter, K. (1989). The motion of a finite mass of granular material down a rough incline. Journal of Fluid Mechanics, 199, 177–215. DOI 10.1017/S0022112089000340. [Google Scholar] [CrossRef]

16. Pierre, R., Jean-Noël, R., Mohamed, N., François, C. (2007). Bidisperse granular flows on an inclined plane: Friction law and two-layer model. Bulletin de Liaison des Laboratoires des Ponts et Chaussees. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |