DOI:10.32604/iasc.2022.026748

| Intelligent Automation & Soft Computing DOI:10.32604/iasc.2022.026748 |  |

| Article |

CI-Block: A Blockchain System for Information Management of Collaborative Innovation

1School of Economics and Management, Harbin Engineering University, Harbin, 150001, China

2School of Astronautics, Harbin Institute of Technology, Harbin, 150001, China

3The Insight Centre for Data Analytics, School of Computer Science, University College Dublin, Dublin, Ireland

*Corresponding Author: Ruhao Ma. Email: mrh9506@163.com

Received: 04 January 2022; Accepted: 15 February 2022

Abstract: Blockchain technology ensures the security of cross-organizational data sharing in the process of collaborative innovation. It drives the development of collaborative innovation in discrete manufacturing to intelligent innovation. However, collaborative innovation is a multi-role, networked, and open resource-sharing process. Therefore, it is easy to form information barriers and increase the risk of cooperation between organizations. In this paper, we firstly analyze the blockchain-based information management models in the traditional discrete manufacturing collaborative innovation process. Then, we found that in the process of industry-university-research (IUR) collaborative innovation, consensus servers maintain too many connections due to the high latency between them, which leads to lower consensus performance and efficiency. To solve this problem, we proposed the dependency analysis (DA) model, which separates and assembles transactional data and non-transactional data into different blocks by analyzing read_set and write_set of transactions. Besides, we propose the out-of-order Raft (OORaft) model to allow non-transactional blocks to be copied in parallel, which can also prioritize transactional blocks. Finally, we implement the blockchain model in the discrete manufacturing scenario based on Hyperledger Fabric. The experimental results show that our model improves the transactions per second (TPS) performance of 1.9X-3.7X and reduces transactional data committing latency by more than 40% in the target scenario.

Keywords: Consensus model; blockchain; collaborative innovation; discrete manufacturing

With the development of intelligent manufacturing, discrete manufacturing has joined the upsurge of digitization and intelligence [1]. Emerging technologies have driven changes in the industry, affecting the reconstruction of the entire economic system, which accelerated the world into the era of the digital economy. The intelligent innovation of discrete manufacturing includes many theoretical and technical issues. Among them, the multi-role, networked, and open collaborative innovation model can quickly adapt to its needs of development [2]. Therefore, collaborative innovation is a necessary direction for the development of intelligent discrete manufacturing.

The Internet enables users’ information and behaviors to be stored in the cloud. The combination of big data and the make-to-order (MTO) model makes it easier for discrete manufacturing to meet multi-level and personalized consumer needs [3]. Nonetheless, the amount of information resources that need to be stored and processed is increasing exponentially, and the information interaction among organizations in the collaborative innovation process is becoming more and more complicated [4]. Besides, the trust relationship among organizations of collaborative innovation affects the progress of information exchange. To reduce the risk of cooperation among members, most traditional collaborative innovation mechanism introduces third-party supervision and management organization [5]. However, it cannot guarantee the impartiality of the third-party organization. Thus, information barriers between members still exist, which creates additional risk costs. From the discussions above, we conclude key problems that have to be solved in the information management of collaborative innovation: 1) How to ensure that the data stored in the third party is not tampered with and can be called by users with corresponding permissions? 2) How to make the database trustworthy, which can ensure that participants bear a lower risk of cooperation without the supervision of a third-party organization?

Blockchain has the characteristics of decentralization, data transparency, smart contracts, and information traceability. In the collaborative innovation field, it can realize the co-construction, co-governance, and sharing of information among organizations. Thus, it can effectively solve the information mismatch, low data transfer efficiency, and other issues in the IUR cooperation model [6]. However, in the discrete manufacturing collaborative innovation scenario, the transfer of innovation data is frequent, the relationship between the participants of the blockchain system is flexible, the network environment is unstable, and the amount of data generated by smart sensors is huge. Therefore, how to establish a reasonable blockchain architecture while ensuring its processing efficiency under large-scale data is a key factor in determining whether it can meet the needs of this scenario.

In this paper, we propose a blockchain architecture for collaborative innovation in discrete manufacturing. Firstly, we analyze the process of collaborative innovation and information management in discrete manufacturing scenarios and establish a blockchain 3.0 architecture. Secondly, we analyze its data dependence and network environment in this scenario and establish the DA and OORaft model to construct blocks based on transaction characteristics. Finally, we implemented a blockchain system based on Hyperledger Fabric and verified the effect of our model. The paper is arranged as follows: In Section 2, we summarize the related research; In Section 3, we build the collaborative innovation blockchain system and analyze the performance problems; We detailed the DA and OORaft model in Section 4; In Section 5, we show our experiments; Section 6 summarizes our work.

2.1 Collaborative Innovation and Information Management Mechanism

From the perspective of knowledge innovation, collaborative innovation refers to the process that enterprises, universities, research institutes, governments, etc. as the subject of innovation [7], through knowledge acquisition, transmission, application, and feedback activities to promote value creation. The goal of knowledge transfer between innovation subjects is to create the increment of value to information resources. In the big data era, information resources are no longer limited to the knowledge stored in the human brain. Data flows such as technology, services, information, and funds run through all the links in the industrial chain, becoming the main source of collaborative innovation big data [8].

Collaborative innovation mechanism is the entire process of collaboration between various collaborative entities. It involves the operating principles of each link, related regime, and the mode of action. Besides, it is the sum of the power, rules, and procedures for the interconnection of various entities in the entire collaborative innovation process. Most researchers believe that the formation of innovation networks is an effective way for individual innovation organizations to avoid innovation competition risks and enhance innovation competitiveness [9]. In addition, it conducts centralized information management in collaborative innovation by establishing an information management platform. The operating path of the information management platform should rely on networking and use information technology to integrate big data resources of various technologies and human resources. At the same time, high-level cooperation platforms such as research and development institutions, technology alliances, and economic entities integrating production, education, and research should be built together [10]. However, the method of centralizing information management authority also has drawbacks. Even in the case of consistent goals, due to human bounded rationality and knowledge complexity, coordination problems will arise in knowledge sharing in collaborative innovation [11]. This leads to more transaction costs and generates dilemmas such as high cost, low efficiency, and untrustworthiness.

2.2 Development of Blockchain Technology

Blockchain technology solves the problem of trust between system participants. Through the consensus agreement, every sensitive operation in the system needs to be approved by the participants of the blockchain network [12]. Currently, based on different application scenarios, blockchain technology is divided into two categories: public chains and private chains. In the public chain, participants are anonymous with equal status and can join the network at any time. Therefore, ensuring that data cannot be tampered with is the goal of the public chain. To achieve it, the public chain needs to restrict the consensus process and encourage the honest nodes on the network to participate in the consensus process. which can prevent the system from being attacked. Otherwise, malicious nodes can tamper with blocks easily.

However, the public chain system based on proof-of-work (PoW) and proof-of-stake (PoS) is designed to ensure the security of the blockchain system in an anonymous and open environment. Its complex security mechanism results in poor transaction processing performance [13]. Different from the public chain, any node needs to undergo strict identity verification to participate in the private blockchain network [14]. Therefore, malicious behavior in the private chain will be easily discovered and tracked. It allows the private chain system to weaken the security design that works in anonymous environments and adopt consensus models that support better TPS performance and scalability. Therefore, the existing widely used private chain architecture uses Crash Fault Tolerate (CFT) protocols (such as Raft [15], Paxos [16]) instead of Byzantine Fault Tolerate (BFT) protocols (such as Practical Byzantine Fault Tolerate (PBFT) and PoW), thereby improving the scalability and consistency of the cluster.

However, the CFT protocol is designed for a low-latency environment, which is different from the cyber-physical system (CPS) environment where discrete manufacturing works in. In the case of high network latency, most geo-distributed CFT protocols use leader-based state-machine replication (SMR) to achieve data consistency, which can avoid the performance loss caused by replication conflicts in the BFT-based SMR process (for example, livelock in Paxos [17]). Nevertheless, when the consistency model runs under high concurrency, the leader's overhead can cause severe performance degradation. Although it is a good idea to dynamically select a better-performed node as the leader to control the replication process, it requires a stable network environment between each node to obtain the real-time node status. Otherwise, the consistency model will run at the speed of the slowest node [18].

2.3 Application of Blockchain Technology in Information Management

Discrete manufacturing leads to a distributed, highly automated, and dynamic production network. This requires an interconnected CPS to achieve. Among them, the data generated by smart devices is a key factor driving the production process, supply chain, and other links. Its information management efficiency, confidentiality, and security are the core issues that the participants in the production process pay attention to [19]. Blockchain provides a decentralized, trustless, and transparent platform for the massive amount of Industrial Internet of Things (IIoT) devices to communicate and share information during the different stages of a manufacturing process without a single authority entity. Therefore, with the development of blockchain technology, the IioT combined blockchain has become a popular solution in this field.

However, the efficiency of information management in blockchain systems is a key concern to researchers [20]. Before the introduction of blockchain 3.0, researchers used Ethereum to implement smart contracts and blockchain systems [21]. However, the flexibility of its network management model is insufficient which leads to scalability issues and limits the promotion and application of such blockchain systems. The blockchain 3.0 architectures represented by Hyperledger Fabric solve the problems well. Since then, blockchain application architecture has become stable and has been widely used in discrete manufacturing, such as sensor data management, supply chain, manufacturing cloud and edge computing [22], etc. Therefore, related research has shifted from architecture issues to transaction processing efficiency issues. In the industrial information system represented by discrete manufacturing, machine tools, robots, sensors, and programmable logic controllers typically exchange small-sized data packets with very short intervals [23]. Therefore, the performance optimization models that are based on the characteristics of the data have become the mainstream approaches [24]. Among them, the transaction characteristics of data are a popular optimization point for researchers. The reason is that the existing blockchain systems all adopt a pessimistic way of committing transactions, i.e., it is believed that most transactions are interrelated. However, in the discrete manufacturing scenario, data generated by smart devices is non-transactional, and it accounts for 80% of all data. This makes the blockchain system's transaction-dependent design and application scenarios deviate, causing performance bottlenecks.

3.1 Traditional Collaborative Innovation Information Management Mechanism

Discrete manufacturing changes and assemble the physical shape of raw materials to make them into products and generate extra value. It mainly adopts an MTO production policy and conducts product design, testing, production, and service. The production method of discrete manufacturing leads to 4 problems: 1) the number of potential candidate combinations of each production factor higher; 2) each production unit is more independent; 3) the coupling of technological requirements is low 4) the tightness of the organizations of various production factor is reduced. These factors make the production process is “disorderly and inefficient”. Due to the many production links and the scattered distribution of workshops, the mutual information transmission relies on a multi-level information management system. Therefore, many uncertain factors are prone to occur in the production process. Besides, the large amount and the high complexity of information greatly increase the difficulty of information management and control.

The essence of collaborative innovation is the exchange and the increment of value of resources. Information resources are one of the important basic resources for collaborative innovation, and they are also the link that maintains the relationship between innovative organizations. Information collaboration is an important guarantee for collaborative innovation. Collaborative innovation members such as discrete enterprises, innovative participants, and collaborators realize the exchange and the increment of value of innovative knowledge through the interaction of information resources.

According to the different sources of information, information resources can be divided into two categories: internal information and external information. Among them, discrete manufacturing enterprises use intelligent information management systems to achieve information acquisition, screening, processing, transmission, etc. Then they set up information management subsystems for production equipment and management departments according to the characteristics of modular processing and business. Finally, a multi-level management information collaboration network is formed. Discrete manufacturing companies output internal company information through this information network, including inventory information, product information, production workshop information, and equipment monitoring information. The external information of the enterprise includes the original knowledge information output by innovation participants such as universities and scientific research institutes, the policy, and system information output by the government and cooperative enterprises and other partners, and the demand information output by the external environment such as consumers and suppliers, user feedback information, and customers information, etc.

The main characteristics of information resource transmission in discrete manufacturing collaborative innovation are as follows: (1) The number of innovation organizations is large, and the composition is complex, which generates more types of information resources that need to be transmitted. (2) Due to the repeated process of innovation, innovative organizations need to frequently initiate interaction requests and access cloud platform information multiple times. (3) All data relies on the information network cloud platform, and all members can only apply for the use of information resources through the cloud platform. Through the establishment of a collaborative innovation information network cloud platform, each collaborative innovation member collects and stores information resources in a database. Then the database transmits different information according to the different needs of each organization. The architecture is shown in Fig. 1.

Figure 1: The message flow in discrete manufacturing

Therefore, the traditional information management model is inevitable that there will be administrator characteristics. Centralization is conducive to the centralized management of data, but it cannot provide a strong guarantee for data security. For collaborative innovation organizations, the information network cloud platform is a “center”. If there is a problem in the collaborative process, the member will seek help. The cloud platform has functions such as information storage, control, transmission, etc., and performs supervisory duties. So, the cloud server requires very powerful operation and storage capabilities. Once there is a problem with the “center”, the link of information transmission will be severely affected, and the cooperative relationship between innovative participants will also collapse. In contrast, the blockchain allows all organizations who set up servers to participate, and these organizations who set up servers will also become a node in the blockchain, and they are all equal and synchronized. In this case, the consistency of the data can be guaranteed to the utmost extent. From this point of view, decentralization has the characteristics of openness, immutability, autonomy. Because the blockchain has the characteristics of data traceability, the blockchain is a core tool for verifying the provenance and accuracy of data. It can be used for data upgrade tracking and help different data fields to establish truly authoritative data. Blockchain can solve the problem of data ownership and eliminate the island effect of big data.

3.2 Blockchain-based Collaborative Innovation Information Management Mechanism

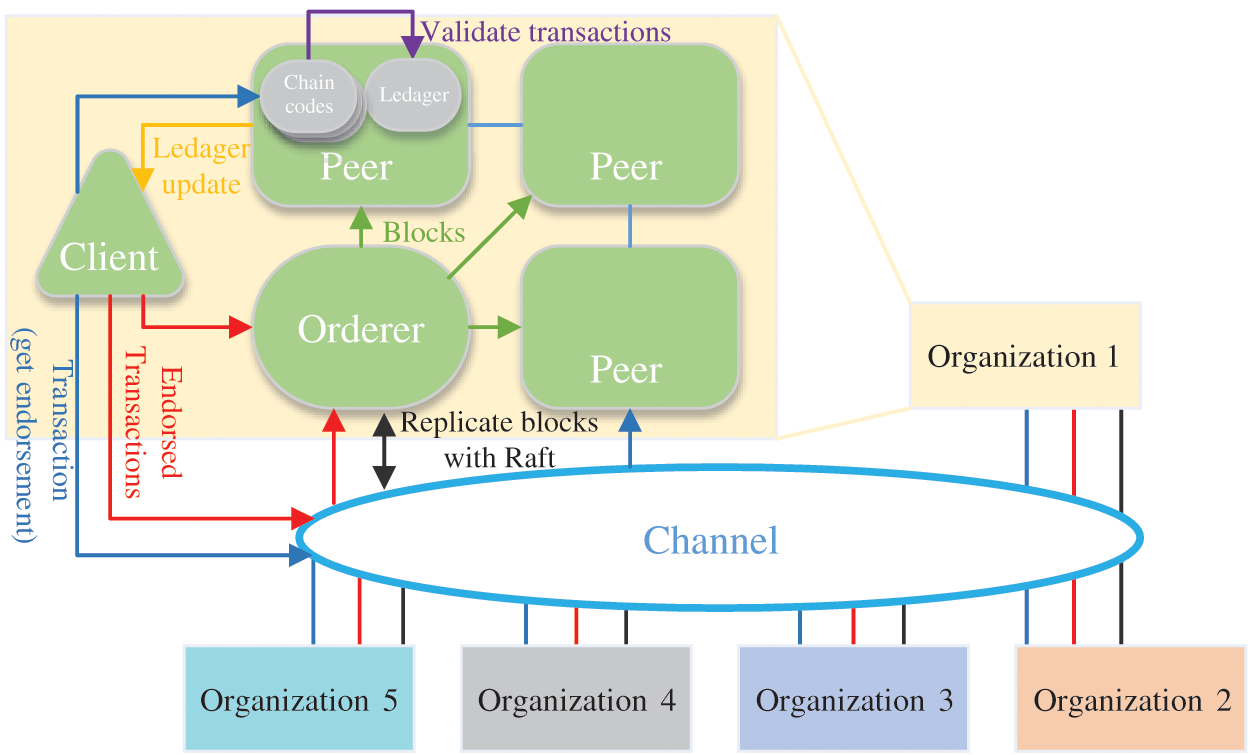

In the process of collaborative innovation information management with the application of blockchain, each innovative organization no longer depends on the information cloud platform as the “center” but adopts a “distributed” network interaction model for information transactions. When there is information transaction demand between discrete manufacturing companies, innovation participants, stakeholders, and the market environment, transaction requests are sent through smart contracts to match and filter the demand information of the information demander. When the requirements of the “commitment” in the contract are met, the transaction can be executed automatically. In the blockchain, the behavior of innovative members is completely transparent. The blockchain records and stores all information related to innovation. The calculation and storage requirements of a large amount of transaction information are distributed to the various servers of the information network to avoid the failure of a single node in the network. The consensus mechanism can verify the validity of each record, thereby preventing any node from tampering with the data at will. If any transactions in blocks tamper, each node in the blockchain will perceive this change. Therefore, all active consensus nodes jointly maintain transactions and databases, which makes the transactions trustworthy and have strong security, as shown in Fig. 2.

Figure 2: The blockchain architecture in discrete manufacturing

For blockchain systems, decentralization, security, and scalability are a trilemma. Although the blockchain 3.0 systems such as Hyperledger Fabric can be better integrated with the IIoT, we found that it still has the following problems:

1) In the discrete manufacturing scenario, the data generated by massive smart devices is non-transactional, and the frequency of such data generation is too high. It makes the transaction processing capacity requirements exceed the capabilities of the blockchain system.

2) In CPS scenarios where discrete manufacturing works, participants are geo-distributed, and the network latency between consensus nodes is large. It leads to longer synchronization delays between them and generates many concurrent connections.

3) The dependency between non-transactional data and transactional data is not properly processed, which leads to increased transaction completion delays and a greater probability of transaction conflicts.

Therefore, a blockchain optimization solution in a collaborative innovation scenario in discrete manufacturing is needed. It can start from the dependence between data and consider the characteristics of the network environment. In this paper, we want to achieve that by allowing non-transactional data to use an independent block submission method, thereby ensuring that transactional data can be processed preferentially and improving the transaction processing efficiency of the blockchain system.

4 Transaction Dependency Oriented TPS Optimization Method in Blockchain Systems

This paper achieves the effect of improving TPS performance by changing block transaction packaging strategy and optimizing Raft's consensus protocol. The block transaction packaging strategy can achieve the effect of reducing inter-block transaction dependency. Besides, the block out-of-order submission strategy can reduce block replication latency, thereby achieving the effect of improving TPS.

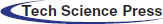

4.1 Block Transaction Packaging Strategy

For the read_set rsi and write_set wsi of transaction ti in the transaction buffer TB, the version of the key is in rsi is vri(key), and wsi = vwi(key). If the orderer packs the transactions into blocks according to the order of the arrival of the transactions, the relationship between transaction ti and another transaction tj (i < j) in the TB have the following two patterns in the process of verifying:

a) There is a key in rsj, and key not in any wsi

b) There is a key in rsj, and key shown in wsi and vri(key) > vwi(key)

As we explained in Section 1, in the discrete manufacturing scenario, a large amount of production data is non-transactional, i.e., the key written into it has not appeared before. In this case, the transactions conform to pattern a). For transactions that form to pattern a), the probability of failure in the verification process is lower. As we know, if the verification fails, it will cause transaction rollbacks and resubmissions, making users perceive greater latency. Besides, the latency makes it easier for other transactions to read staled data, which causes more transaction conflicts. Therefore, we propose hypothesis 1: Deferred processing non-transactional data will generate fewer conflicts and reduce the committing delay of transactional data, but it will not cause other conflictions.

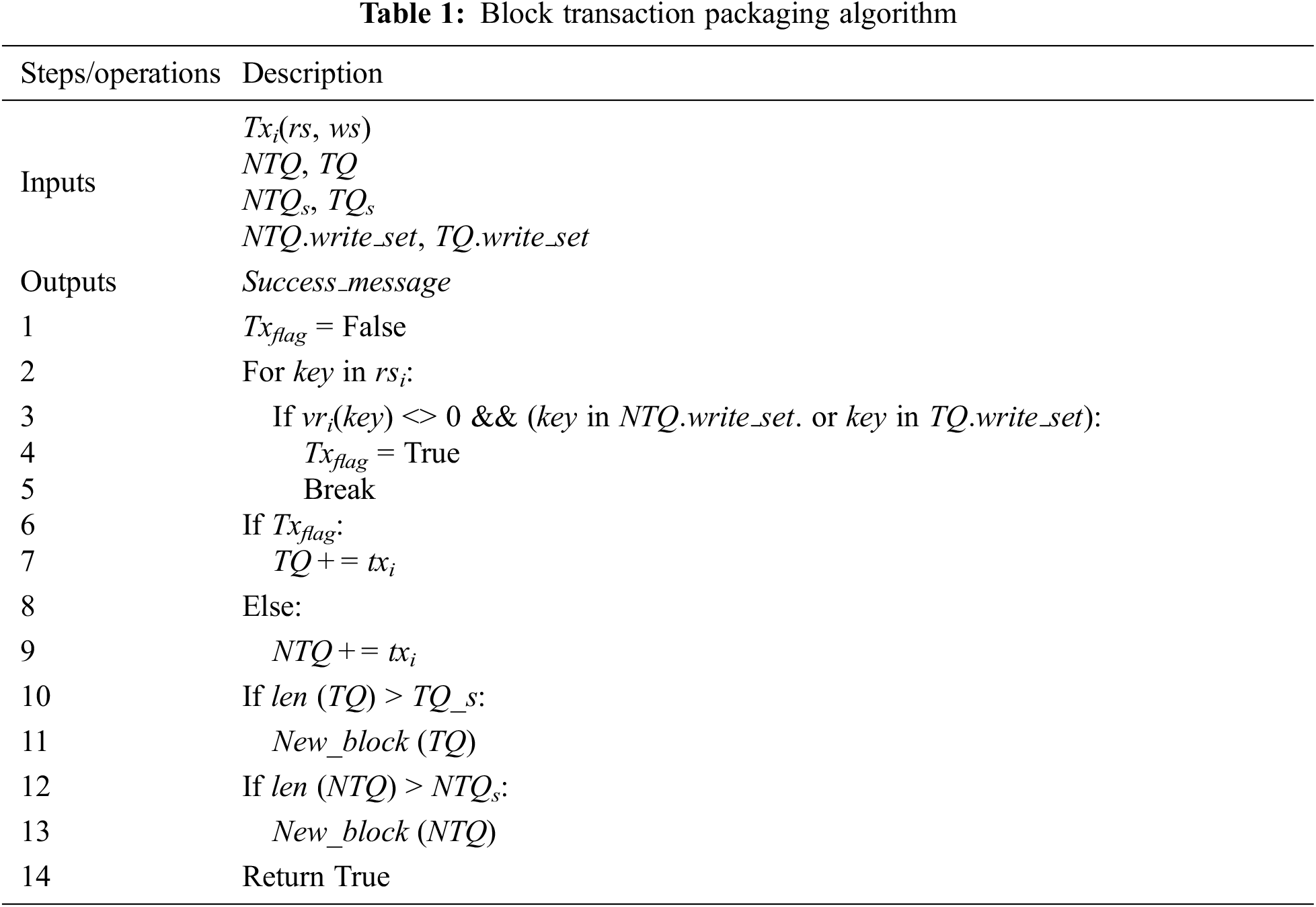

Therefore, to better handle the dependencies between transactions, we set a longer transaction buffer parameter c to enable the orderer to gain a larger view. Subsequently, we extract non-transaction records from TB, save them to the non-transaction queue NTQ, and save other transaction records to transaction queue TQ. When NTQ or TQ is fulfilled, orderer packs them into new blocks non-transactional block NTB and transactional block TB. To better show our model, we will describe it in Fig. 3 and Tab. 1.

Figure 3: Workflow of dependency analyze model in orderer

4.2 Block Out-of-Order Committing Model

As we mentioned in Section 3.2, in the Hyperledger Fabric system, the geo-distribution of orderer makes the Raft protocol a performance bottleneck. Therefore, in this section, we propose the block out-of-sequence committing model OORaft. Here, we propose hypothesis 2: Using different block packaging strategies for non-transactional data and transactional data can relieve the relationship dependence between some blocks, to ensure that transactional data can reach consensus faster and achieve the effect of increasing transaction concurrency. The model process is shown in Fig. 4, and the model operation at steps is explained in Tab. 2.

Figure 4: Out-of-order replication process of OORaft

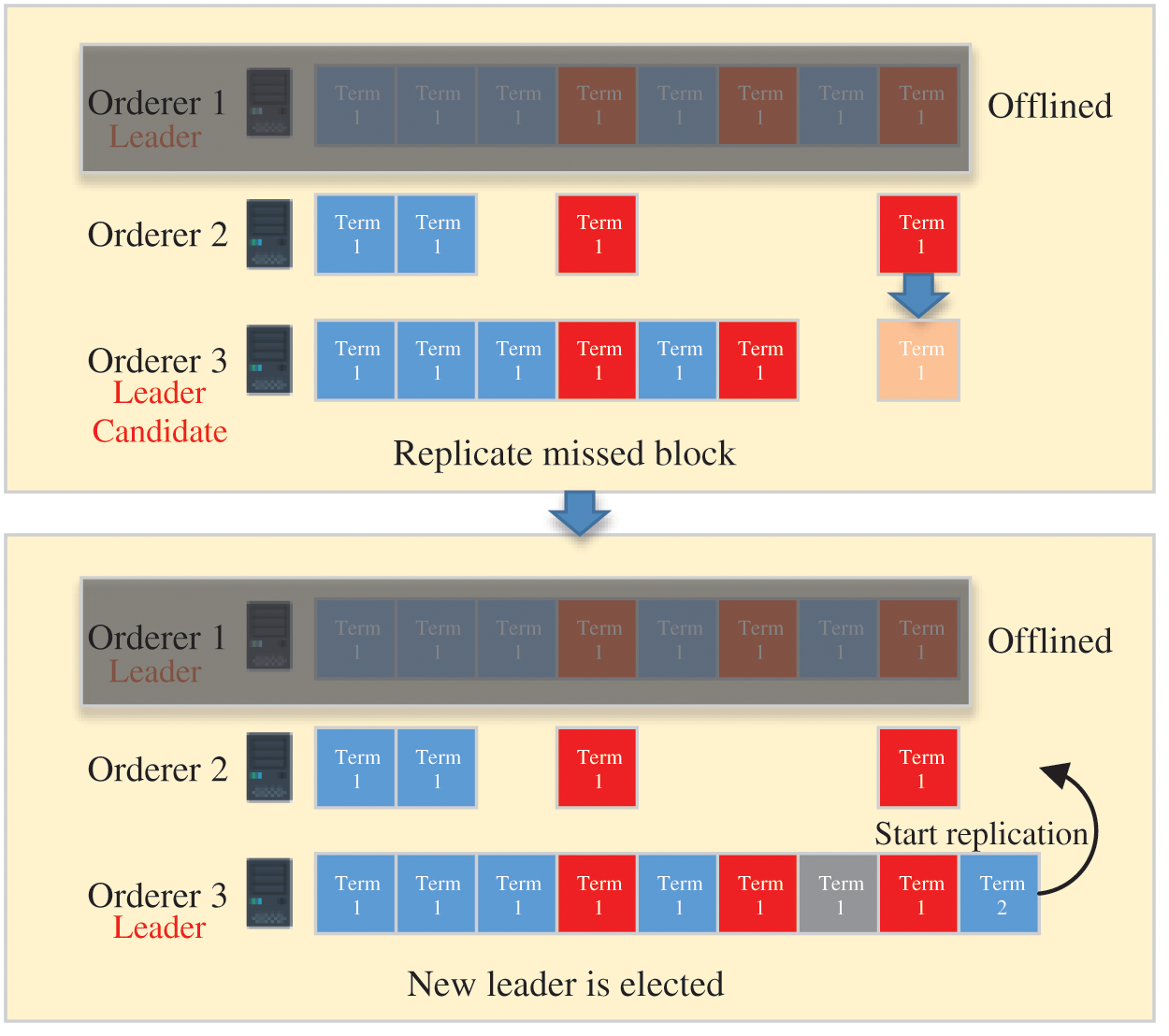

However, it brings another problem. When the leader is replaced before the out-of-order blocks are replicated to every node, it cannot be guaranteed that the new leader contains all the non-transactional blocks that have been committed. Therefore, when the term is changed, we make the new leader node coordinate all NTB during the voting process. We modified the voting principle. In the pre-voting and voting process, the leader candidate must include the NTB. that saved in all other nodes. The process is shown in Fig. 5.

Figure 5: The re-replication process when the leader is replaced

We re-replicate the missing data from other orderers to leader candidate and fill the missing blocks with empty blocks to ensure continuity. Although the empty block loses the data, this block has not yet reached a consensus in Raft, so the transactions in it have not completed its life cycle. They are only be noted as failed transactions. At the same time, because the correctness of the Raft protocol ensures that when the leader node is replaced, the committed data will not be lost, so we use the hash value of the previous and subsequent blocks to complement the connected part of the block. If there is no corresponding block at the block id – 1, then use − 1. as a special id.

To verify our hypothesis, we implemented the model in Hyperledger Fabric. In this section, we first introduced our experimental configuration. Second, we verified the performance of the model in a simulated discrete manufacturing business scenario. Finally, we evaluate the effects of the model.

5.1 Experimental Environment and Configuration

Among them, we modified the consensus sorting part of the orderer and the implementation of the consensus protocol that is based on etcd-raft. We deployed Hyperledger Fabric on a virtualization platform composed of 3 servers of the same performance and used Docker to achieve the distributed deployment. The detailed environment is shown in Tab. 3

In terms of network configuration, we use the tc command to impose virtual network latency and fluctuations on the network card. Its latency fluctuation range obeys a 25% uniform distribution to simulate the geo-distribution environment of organizations. Our non-transactional data consists of three parts, the key-value data is 64 bit uuid:

1) MES: production data information with a size of 120 Bytes. It was collected from a processing company MES in Shandong Province.

2) WQ: 80 Bytes of water quality monitoring data collected from pollution data on a water quality monitoring platform in Tianjin.

3) SG: 140 Bytes of desensitized electricity consumption data, collected from the remote meter reading sensor of the State Grid of Shandong Province.

The transactions are generated by the client at a rate of 700 TPS. In the experiment, we initialize all key values and set them to millisecond timestamps. Assuming that the current timestamp is t, a transaction randomly reads the key = t − k, and writes a random value to key = t, where k satisfies the Poisson distribution of λ = 1000. This makes the probability of transaction conflicts positively correlated with TPS. The configuration of block package is set to TQs = NTQs = 100.

We established 5 organizations and 3 channels to simulate a discrete manufacturing business scenario and used different ratios of non-transactional data to evaluate the TPS and latency performance of our model. Its structure is shown in Fig. 6.

Figure 6: The blockchain deployment model in the experiments

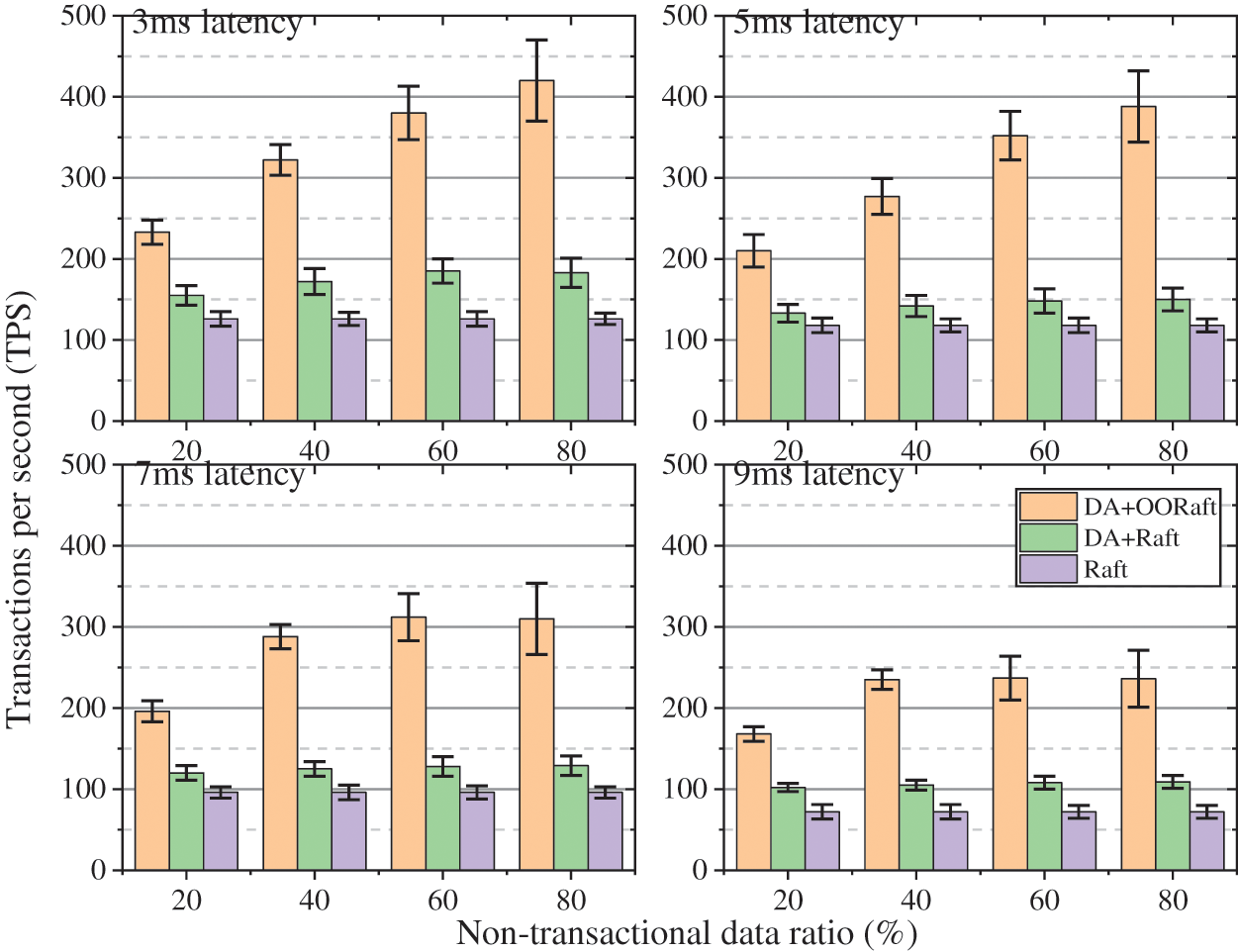

We let the client generate endorsement requests according to different non-transactional ratios θ, and control the latency between organizations to simulate geo-distributed scenarios. We choose 3, 5, 7, and 9 ms as the round trip time (RTT) fointer-organizational network latency. At the same time, we compared only the DA model and DA + OORaft model to show the effect of the model. The results of our experiment are shown in Fig. 7.

Figure 7: The results of TPS performance in different non-transactional data ratio and network latency

It can be seen from Fig. 7 that our model performs better in different network latency environments than Hyperledger Fabric's endorsement strategy. Among them, the DA + OORaft model can improve the TPS performance of 1.9X-3.7X. Even the DA + Raft model can achieve 1.3X-1.5X TPS performance.

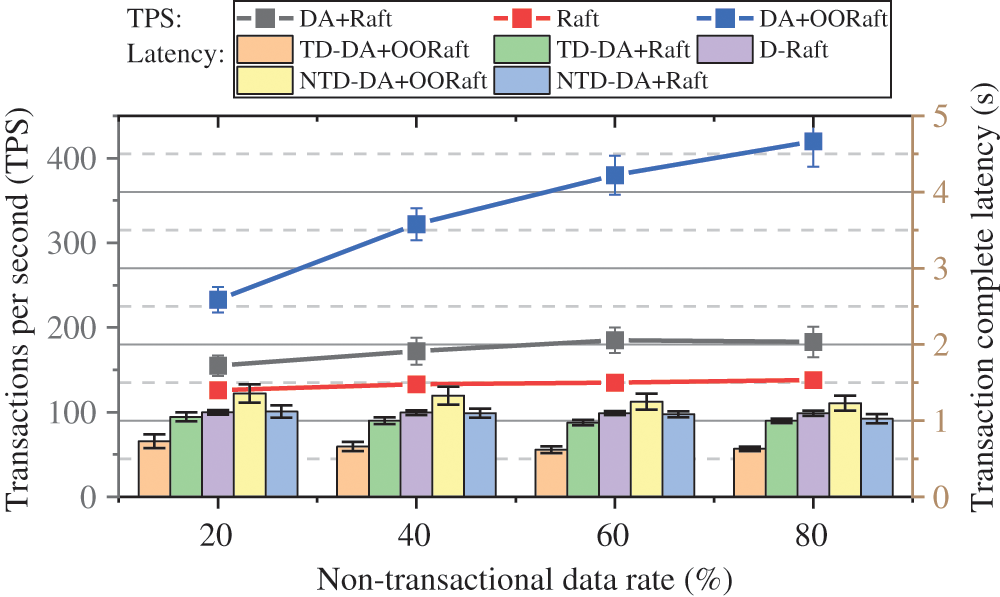

We verify another hypothesis in this section, that is, non-transactional data being processed later will produce fewer conflicts, reduce the complete latency of transactional data, but will not cause TPS performance degradation. We conduct experiments in a scenario where the network latency between organizations is 5 ms, and the experimental results are shown in Fig. 8.

Figure 8: The results of the TPS and transaction complete latency performance

As we can see, in the DA + OORaft model, compared to Raft, the transactional data complete latency is reduced by about 40%-50%, while the complete latency of non-transactional data is reduced by 15%-20%. The reason is that the priority of non-transactional data that forms non-transactional block is lower than transactional block, so they are postponed. This is in line with our hypothetical expectations. This proves that our model has a significant performance optimization effect on the blockchain system in a discrete manufacturing scenario dominated by non-transactional data.

According to the experimental results in Sections 5.2 and 5.3, we believe that the effect of the DA model is that the priority packaged transactional data can be updated to the Peer's ledger faster. It makes the client have a smaller probability of reading staled data, thus reducing the probability of transaction conflictions. This makes it has a good optimization effect in terms of transaction complete latency, and it also has a small contribution to the improvement of TPS performance. For the OORaft model, it can enable non-transactional blocks to quickly reach consensus between orderers. Its parallel replication mechanism makes it possible to greatly improve the replication performance of the state machine when the proportion of non-transactional data is high. Therefore, it can achieve the effect of greatly improving the TPS performance.

In this paper, we analyze the collaborative innovation and information management process in the discrete manufacturing scenario, establish a blockchain-based data management architecture, and establish DA and OORaft models to optimize the system performance in this scenario. We verified the effect of the model based on Hyperledger Fabric. The experimental results show that under the latency in geo-distributed environments, the DA + OORaft model can improve the TPS performance of 1.9X-3.7X in the target scenario and reduce the transaction complete latency of transactional data by more than 40%. This proves that our model is suitable for collaborative innovation business in discrete manufacturing scenarios.

Acknowledgement: This work is supported by the CSC scholarship (2021061202101).

Funding Statement: This work is funded by Natural Science Foundation of Heilongjiang Province (LH2020G004).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. G. Chen, P. Wang, B. Feng, Y. Li and D. Liu, “The framework design of smart factory in discrete manufacturing industry based on cyber-physical system,” International Journal of Computer Integrated Manufacturing, vol. 33, no. 1, pp. 79–101, 2020. [Google Scholar]

2. H. Wang, L. Liu, Y. Fei and T. Liu, “A collaborative manufacturing execution system oriented to discrete manufacturing enterprises,” Concurrent Engineering, vol. 24, no. 4, pp. 330–343, 2016. [Google Scholar]

3. D. Gupta and S. Benjaafar, “Make-to-order, make-to-stock, or delay product differentiation? A common framework for modeling and analysis,” IIE Transactions, vol. 36, no. 6, pp. 529–546, 2004. [Google Scholar]

4. V. Serrano and T. Fischer, “Collaborative innovation in ubiquitous systems,” Journal of Intelligent Manufacturing, vol. 18, no. 5, pp. 599–615, 2007. [Google Scholar]

5. F. Wei and W. Chan, “The cooperative stability evolutionary game analysis of the military-civilian collaborative innovation for China's satellite industry,” Mathematical Problems in Engineering, vol. 2019, pp. 1–17, 2019. [Google Scholar]

6. P. Sahu, S. K. Singh and A. Kumar Singh, “Blockchain based secure solution for cloud storage: A model for synchronizing industry 4.0 and IIoT,” Journal of Cyber Security, vol. 3, no. 2, pp. 107–115, 2021. [Google Scholar]

7. Y. Song, J. Zhang, Y. Song, X. Fan, Y. Zhu et al., “Can industry-university-research collaborative innovation efficiency reduce carbon emissions?,” Technological Forecasting and Social Change, vol. 157, pp. 120094–120094, 2020. [Google Scholar]

8. M. Adil, J. Ali, M. S. Khan, J. Kim, R. Alturki et al., “An intelligent hybrid mutual authentication scheme for industrial internet of thing networks,” Computers, Materials & Continua, vol. 68, no. 1, pp. 447–470, 2021. [Google Scholar]

9. S. Gretzinger, H. Hinz and W. Matiaske, “Cooperation in innovation networks: The case of danish and German SMEs,” Management Revue, vol. 21, no. 2, pp. 193–216, 2010. [Google Scholar]

10. I. Roaldsen and O. J. Borch, “Entrepreneurial Strategies of SMEs in Mature Industries: The Role of R & D Alliances and Value Chain Configuration,” in Entrepreneurship and Technological Change, Cheltenham, UK: Edward Elgar Publishing, pp. 10–15, 2011. [Google Scholar]

11. M. Bogers, “The open innovation paradox: Knowledge sharing and protection in R&D collaborations,” European Journal of Innovation Management, vol. 14, no. 1, pp. 93–117, 2011. [Google Scholar]

12. M. Alwabel and Y. Kwon, “Blockchain consistency check protocol for improved reliability,” Computer Systems Science and Engineering, vol. 36, no. 2, pp. 281–292, 2021. [Google Scholar]

13. L. M. Bach, B. Mihaljevic and M. Zagar, “Comparative analysis of blockchain consensus algorithms,” in 2018 41st International Convention on Information and Communication Technology, Electronics and Microelectronics (MIPRO), Opatija, Croatia, pp. 1545–1550, 2018. [Google Scholar]

14. Y. Chen, J. Gu, S. Chen, S. Huang and X. S. Wang, “A Full-spectrum blockchain-as-a-service for business collaboration,” in 2019 IEEE Int. Conf. on Web Services (ICWS), Milan, Italy, pp. 219–223, 2019. [Google Scholar]

15. D. Ongaro and J. Ousterhout, “In search of an understandable consensus algorithm,” in 2014 USENIX Annual Technical Conf. (USENIX ATC 14), Philadelphia, USA, pp. 305–319, 2014. [Google Scholar]

16. L. Lamport, “Paxos made simple,” ACM Sigact News, vol. 32, no. 4, pp. 18–25, 2001. [Google Scholar]

17. D. Huang, X. Ma and S. Zhang, “Performance analysis of the raft consensus algorithm for private blockchains,” IEEE Transactions on Systems, Man, and Cybernetics: Systems, vol. 50, no. 1, pp. 172–181, 2019. [Google Scholar]

18. I. Moraru, D. G. Andersen and M. Kaminsky, “There is more consensus in egalitarian parliaments,” in Proc. of the Twenty-Fourth ACM Symposium on Operating Systems Principles, Pennsylvania, USA, pp. 358–372, 2013. [Google Scholar]

19. T. Feng, H. Pei, R. Ma, Y. Tian and X. Feng, “Blockchain data privacy access control based on searchable attribute encryption,” Computers, Materials & Continua, vol. 66, no. 1, pp. 871–890, 2021. [Google Scholar]

20. I. Devi and G. Karpagam, “Energy-aware scheduling for tasks with target-time in blockchain based data centres,” Computer Systems Science and Engineering, vol. 40, no. 2, pp. 405–419, 2022. [Google Scholar]

21. C. Pop, T. Cioara, M. Antal, I. Anghel, I. Salomie et al., “Blockchain based decentralized management of demand response programs in smart energy grids,” Sensors, vol. 18, no. 1, pp. 162–183, 2018. [Google Scholar]

22. R. V. Barenji, “A blockchain technology based trust system for cloud manufacturing,” Journal of Intelligent Manufacturing, pp. 1–15, 2021. [Google Scholar]

23. J. Backman, Y. Seppo, V. Kristiina and M. Olli, “Blockchain network slice broker in 5G: Slice leasing in factory of the future use case,” in 2017 Internet of Things Business Models, Users, and Network, Copenhagen, Denmark, pp. 1–8, 2017. [Google Scholar]

24. H. Du, D. Zhu, Y. Sun and Z. Tian, “Leader confirmation replication for millisecond consensus in private chains,” IEEE Internet of Things Journal, pp. 1–14, 2021. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |