| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.019091

ARTICLE

Field Application of Mulberry Straw Arch in Ecological Bank Revetment

1Geotechnical Research Institute, Yancheng Institute of Technology, Yancheng, 224051, China

2Yancheng City Channel Management Office, Yancheng Transportation Bureau, Yancheng, 224051, China

*Corresponding Author: Chao Liu. Email: soaringdeer@163.com

Received: 02 September 2021; Accepted: 12 October 2021

Abstract: With the growing level of awareness and increasing demand for environmental protection, timber pile revetments with significant ecological effects have experienced increasingly wide application in China. The current timber pile revetment system has two problems: continuous dense piles have high construction costs and require large timber consumptions, while the discrete pile-bamboo fence systems have poor retaining effects. Considering these problems, an original revetment structure form is proposed: a discrete pile-mulberry straw arch structure. To investigate the mechanical properties of the mulberry straw, some mechanical tests are conducted on mulberry straw and its arch structure. It is found that the average compressive strength of mulberry straw is 2.30 MPa, the bending strength is 20.08 MPa and the shear strength is 2.99 MPa; considering the structural characteristics of arches, mulberry straw arches have a high bending strength, which affords immense potential for their application in revetment structures. Furthermore, by doing field study of the discrete timber pile-mulberry straw arch structure for bank revetment, it is found that the arch height of the mulberry straw arch changes 1.4–1.6 cm after 489 d observation. The soil settlement before the straw arch is 0.13–0.18 cm and the settlement of the pile is 0.66–0.72 mm. Compared with bamboo fence structure, the cost of using mulberry straw arch structure as revetment material can save up to 27.07%. Therefore, the discrete timber pile-mulberry straw arch has a rational and stable structure that provides effective support for protecting the riverbank and the toe of gentle slopes and effectively prevents the collapse of bank slopes in the rear. The new revetment structure proposed in this paper has significant ecological and economic effects, is easy to construct and feasible for standard production, and consequently has great application potential.

Keywords: Mulberry straw arch; ecological bank revetment; field test

Timber pile revetments have gained prevalence in China due to their ecological effect [1]; typically, a continuous dense structure is used to build these revetments, but the discrete timber pile-bamboo fence structure may also be used [2]. The gaps between the piles cause water and soil loss behind the piles, which compromise the protective effect on the slope toe [3]. In the case of the discrete timber pile-bamboo fence structure, the bamboo fence is easy to deform and poor in durability, which contributes to unsatisfactory supporting effects; severe water and soil loss usually occur behind the piles, and the collapse of the soil body may also occur [2]. Therefore, this study has proposed an original ecological revetment structure: the discrete timber pile-mulberry straw arch structure. This revetment structure makes full use of agricultural waste and straw; therefore, it consumes much less timber than the consecutive dense pile structure and significantly reduces construction cost. Moreover, the new revetment structure solves the following existing problems of the discrete timber pile-bamboo fence structure: (1) Bamboo fences are generally 3 cm thick, easily deform, and are frail in texture, so they have an inadequate retaining effect; the mulberry straw arch proposed herein, however, is thicker than the bamboo fence and dense in texture, contributing to its better rigidity and resistance to deformation. (2) Bamboo fences are arranged in the vertical planes between piles and present the state of a simple supported beam. Under soil pressure, the bamboo fence easily deforms, the geotextile in the rear is susceptible to destruction, and cracks may appear in the joints, causing severe loss of soil. The retaining function drastically decreases and can even be completely lost. The proposed mulberry straw arch constitutes most of the structural properties of arches. Under soil pressure, the mulberry branch will become more compacted, which improves its retaining effect. (3) The bamboo fence is easy to corrode and poor in durability, and the mulberry straw arch is thick and dense with higher resistance to corrosion and enhanced durability.

Straw is a renewable and eco-friendly botanical resource [4]. Therefore, straw has been increasingly widely used in hydraulic and geotechnical engineering. For example, straw fibers are used in the strengthening projects of soft foundations [5–13]. Straw blankets [14], fibers [5], bales [15], wattles [16], sticks [17], bars and rollers [18] are used to control runoff and erosion in slopes and reduce downstream sediment yields in dams. Furthermore, straw checkerboard barriers are used for wind prevention and sand fixation [5,19,20].

There has been ample application of straw in slope engineering in the abovementioned literature, which provides a theoretical foundation. A majority of the literature has focused on rice and wheat straw, which have a high yield but easily perish and are not suitable for toe protection below the low water level. Moreover, mulberry straw is much more resistant to corrosion than rice and wheat straw [21]. Anticorrosive materials such as emulsified asphalt can also be applied to ensure durability, as in the case of piles.

To date, the application of straw in toe protection below the low water level has rarely been reported. The proposed discrete timber pile-mulberry straw arch structure has superior mechanical properties, significant economic and ecological advantages, and consequently great utilization potential and broad prospects for application. To further explore the feasibility and suitability of the proposed structure in the practical application of revetment engineering, a series of laboratory experiments and applied research is conducted at the project site.

2.1 Mulberry Straw and Its Arch Structure

Mulberry straw was taken from the Yancheng Dongtai Mulberry Field (32° 40′ 46″ N, 120° 29′ 23″ E), Dongtai City, Jiangsu Province, China. The area of this field is 160,000 mu. The mulberry branches are trimmed every year before germination in spring and after defoliation in the fall, which produces a large amount of mulberry straw waste. Straw is mostly incinerated, which causes air pollution. Here, this study aims to broaden its application prospects to ameliorate the problem of air pollution due to incineration.

The discarded mulberry straw from the Dongtai Mulberry Field was clipped. To ensure the repeatability of the tests, branches with diameters of 10–12 mm were chosen as experimental subjects. The basic mechanical properties of the mulberry straw and its arch structure were tested as follows:

(1) Compressive strength perpendicular to the grain

Mulberry straw of 18 mm length and 12 mm diameter was selected for the compressive strength test. To avoid contingency, 5 parallel samples were included. Compression tests were conducted in the direction perpendicular to the axial direction of individual mulberry straw to obtain the compressive strength according to the Chinese criterion for compression tests of timber (GB/T1939–2009).

The compressive strength of the samples was measured in a universal testing machine, which is under touch screen control and capable of performing mechanics performance testing and analytical investigation on various materials. Based on the specifications, the maximum load must be reached within 1–2 min. After the preliminary experiments, the press machine operating speed was set to 2 mm/min.

(2) Bending strength

Mulberry straw 150 mm in length and 12 mm in diameter was tested for bending strength. Similarly, 5 parallel samples are tested to avoid contingency. The 3-point bending test is used to obtain the bending strength according to the Chinese criterion (GB/T1936.1–2009). The universal testing machine described above was used. In this research study, the samples were placed on the two bases of the machine and imposed the load at an even rate on the diametric plane of the sample in the middle of the base. The loading rate was set to 5 mm/min.

(3) Shear strength

Mulberry straw 18 mm in length and 12 mm in diameter was tested for shear strength. The methods discussed by Li [20], where the shear strength of maize straw was measured, were used in this test. The loading rate was set to 5 mm/min.

(4) Mulberry straw arch and its mechanical properties

The mulberry straw arch was produced using standardized molds, with different molds for different sizes of arches. The mold to produce the arches in the laboratory tests is similar to those used for the engineering field, except in a smaller size. Details about the mold and production method are elaborated in Section 2.2.3.

The sizes of the mulberry straw arch for the laboratory tests were as follows: the span of the arch was 135 mm; 4 sets of rise span ratios were used: 0.2, 0.3, 0.4, and 0.5; 4 sets of densities were used: 0.353, 0.396, 0.421, and 0.476 g/cm3, which were obtained through preliminary experiments. Beware of and avoid the case where the straw is too sparse in the arch in practical operation.

A universal testing machine was used to perform the 3-point bending test on the mulberry straw arch. To avoid horizontal displacement of the arch springing at the time of load application, the mulberry straw arch was fixed on the prop with superglue. The loading rate was 5 mm/min. When the mulberry straw arch manifested evident yield deformation, loading was stopped, and the experiment completed.

2.2 Discrete Timber Pile-Mulberry Straw Arch Structure in Engineering Applications

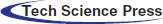

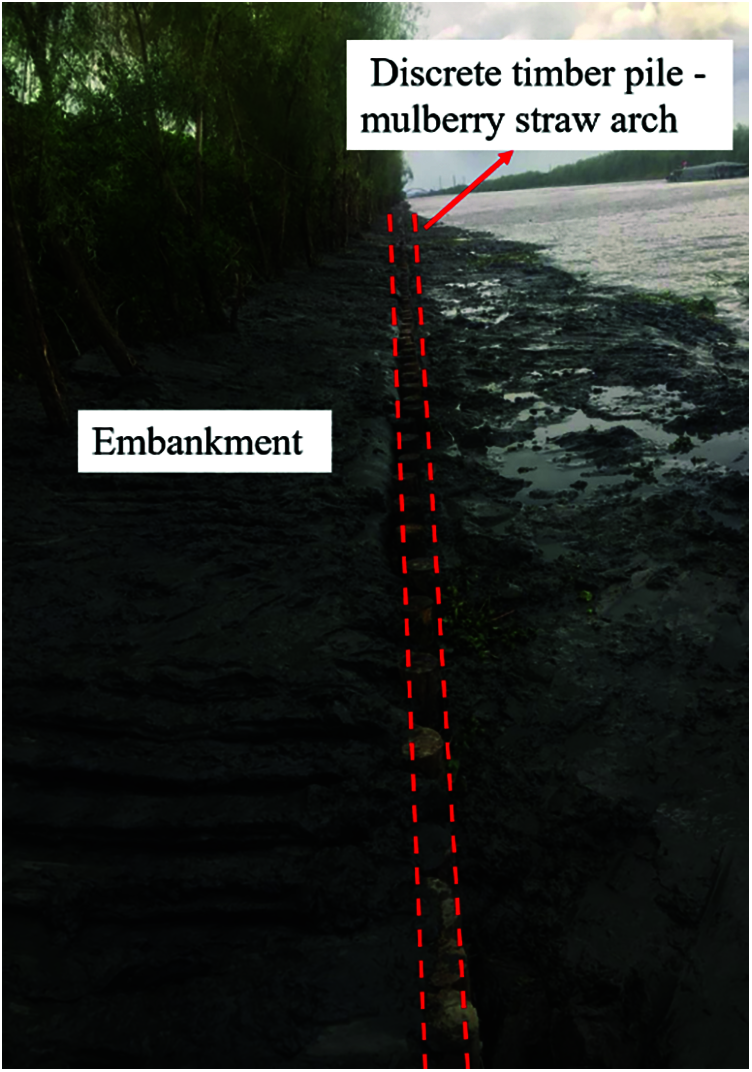

The field application of the discrete timber pile is mulberry straw arch structure in the Lianshen Lane Channel Regulation Project, China. Lianshen Lane is an inland canal along the coastland in northern Jiangsu Province, China, as shown in Fig. 1. It has a full length of 25.73 km and is a key water transport engineering project in Jiangsu Province.

Figure 1: Site overview

Due to the scour of ship waves, the discrete timber pile-bamboo fence structure ecological revetment along the right bank of the 23 K+019–23 K+630 section north of the Gangwan Bridge in Fu’an is severely damaged, which affects the stability of the levees on the rear side, as shown in Fig. 1. To enhance the protection of the waterfront along the lane, repair and reinforcement of the revetment are in dire need. The discrete timber pile-mulberry straw arch structure is applied here as reinforcement.

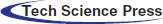

Fig. 2 illustrates the diagram of the joint of the pile and the mulberry straw arch. The length of the engineering application of the discrete timber pile-mulberry straw arch structure was 100 m. Pine piles were used with a 0.5-meter spacing. The top diameter of the pile was 0.16 m, the end diameter was approximately 0.2 m, and the length of the pile was 4–5 m. The length of the mulberry straw arch is 0.8 m. The rise span ratio and density are the optimal values obtained by indoor laboratory tests and are 0.5 and 0.476 g/cm3, respectively. The thickness of the arch refers to the indoor model test results.

Figure 2: Construction scheme and monitoring method

2.2.3 Production of the Mulberry Straw Arch

(1) Material

Mulberry straw with diameters of 10–12 mm was collected from the Dongtai Mulberry Field (32° 40′ 46″ N, 120° 29′ 23″ E), Dongtai City, Jiangsu Province, China. A 1:500 carbendazim solution was used to soak and sterilize the straws by coverage for 5 d, after which the straw was naturally dried and stored in a well-ventilated, sunproofed, and raintight environment.

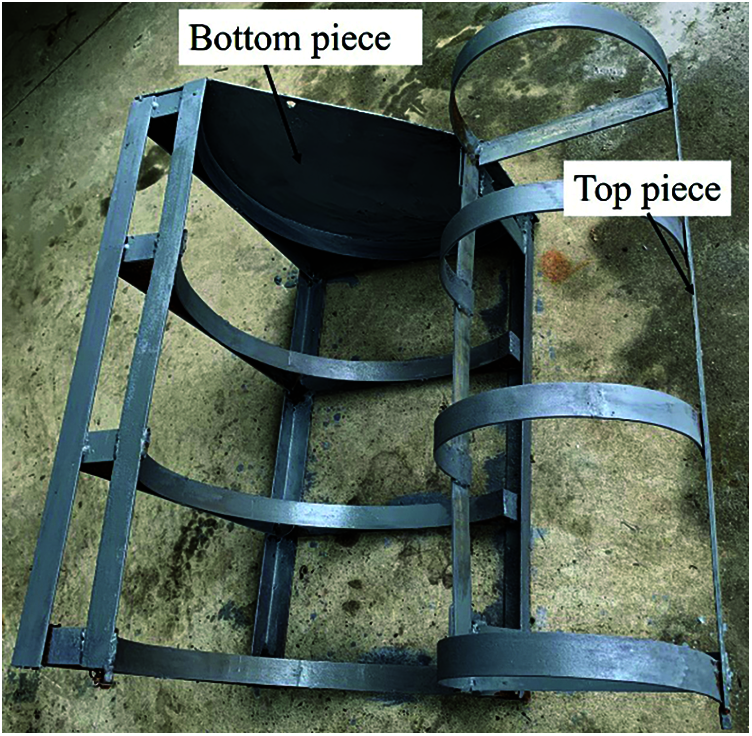

(2) Mold for the arch

Take the mold at the engineering site as an example. The mold was made with bar iron and angle steel, 800 mm in length, and composed of the top and bottom pieces, as shown in Fig. 3. The rise span ratio of the arch was 0.5, the span of the bottom piece was 560 mm, and the arch length was 879 mm. The bottom piece was fixed on the base to place the mulberry straw and control the rise span ratio. The span of the top piece was 500 mm, and the arch length was 785 mm. The top piece is used to compact the straw and control the density. When the two pieces are set up, the rise span ratio and density of the mulberry straw arch can be determined. Four pieces of bar iron were used as the rib strips and placed 263 mm apart on the top piece. These pieces assist in compaction and ensure that the mulberry straw arch is overall the same shape as the mold.

Figure 3: Mold for the arch

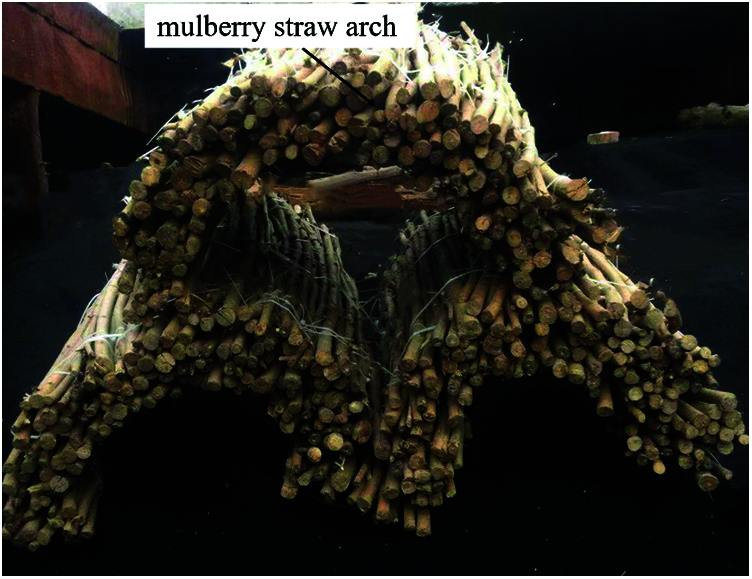

(3) Production of the arch

In this study, the treated mulberry straw was evenly placed on the bottom piece of the mold, the top piece was used to compact the straw and the density was set. The density for the engineering site was set at 0.476 g/cm3 based on laboratory tests. Strapping was used to tie the mulberry straw arch, after which it was removed from the mold, as illustrated in Fig. 4.

Figure 4: Mulberry straw arch

(4) Preservative treatment

The mulberry straw arch and timber pile to be used at the engineering site requires preservative treatment. According to the preservative treatment for timber, the mulberry straw arch and timber pile were soaked in a blend solution (ammoniacal copper quaternary:water = 1:8) for 6 h; then, the mulberry straw arch was placed upright to let dry naturally.

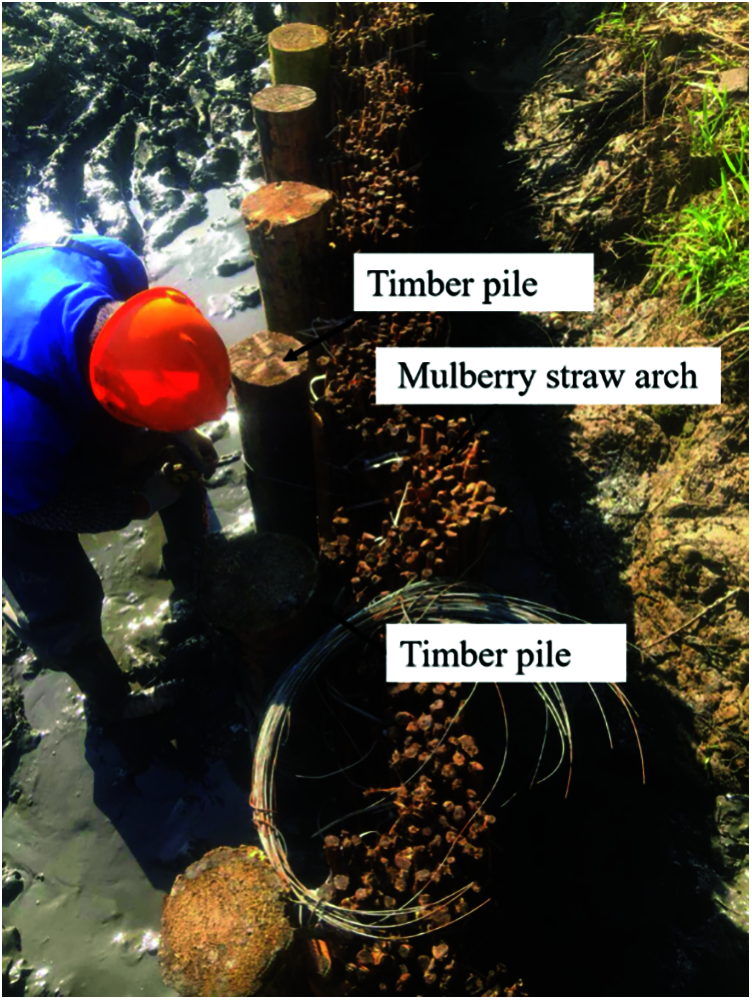

(1) Construction of the timber pile

According to the line type requirements of the design diagram, set the work platform to 0.1 m elevation with a digging machine. Form an earth cofferdam in front of the wall to ensure dry construction. Perform discrete piling, and the top mark of the pile should be at 1.3 m elevation, as shown in Fig. 5.

Figure 5: Construction of the timber pile

(2) Installation of the mulberry straw arch

Fasten 6 × 10 × 80 cm self-locking battens with iron nails on the earth-facing side of the pile to prevent horizontal displacement of the arch, as shown in Fig. 5. Install the mulberry straw arch on the designated location and connect them to the pile through the self-locking battens, as shown in Fig. 6.

Figure 6: Installation of the mulberry straw arch

(3) Layout of the geotextile bag and earthwork backfilling

Place the geotextile bag behind the installed mulberry straw arch. The geotextile bag is composed of 380 g/m2 machine-woven composite cloth. Fill the geotextile bag with earthwork. Fill the top layer of the geotextile bag with 20 cm of topsoil and planting soil. Backfill with earthwork from the side slope and neaten the geotextile bag, as shown in Fig. 7.

Figure 7: The finished layout of the side slope

2.2.5 Monitoring Factors at the Engineering Site

Observe the monitoring factors, including the rise and span of the mulberry straw arch, settlement of the pile and the soil mass settlement behind the arch, as shown in Fig. 2. Construction started in 2020, and detection began immediately after construction. There have been 489 d of observation to date. The monitoring values were observed 5 times in 489 d (63, 128, 275, 435 and 489 d, respectively). Six arch units from the 100-meter application section were selected for observation. The space between arch units was 16.5 m.

3.1 Mechanical Properties of the Mulberry Straw and Its Arch Structure

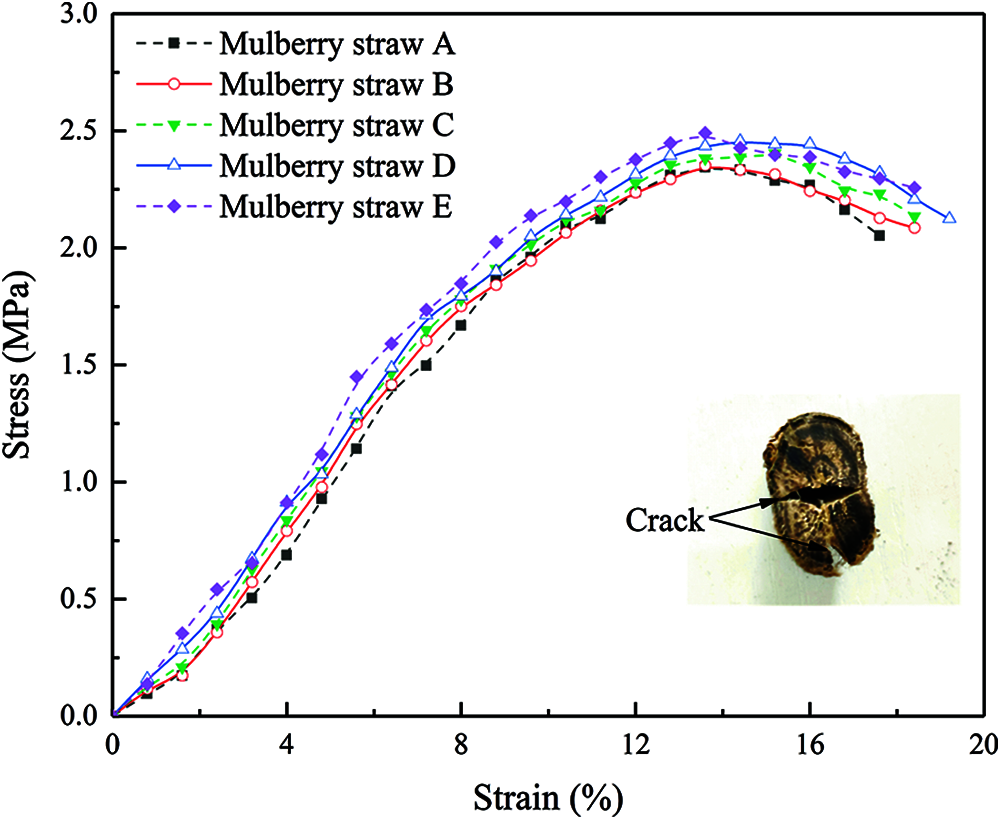

The stress-strain curves of the compression characteristics of the mulberry straw are presented in Fig. 8. As seen, the results of the repeat tests agree well with each other, validating a good repeatability of the compression test of the mulberry straw. It is observed that the stress of mulberry straw the increases nearly linearly with the strain until the peak value is reached. Thereafter, the stress decreases gently with the strain. The stress-strain curves present a softening behavior. The peak stresses of the five the mulberry stalk are approximately 2.22, 2.19, 2.22, 2.40, and 2.45 MPa, respectively, corresponding to axial strains between 0.128% and 0.144%. The average peak stress of mulberry straw is 2.3 MPa. After the test, the obvious cracks appear at the cross section of the mulberry stalk, as shown in Fig. 8.

Figure 8: Stress-strain curves of the compression test

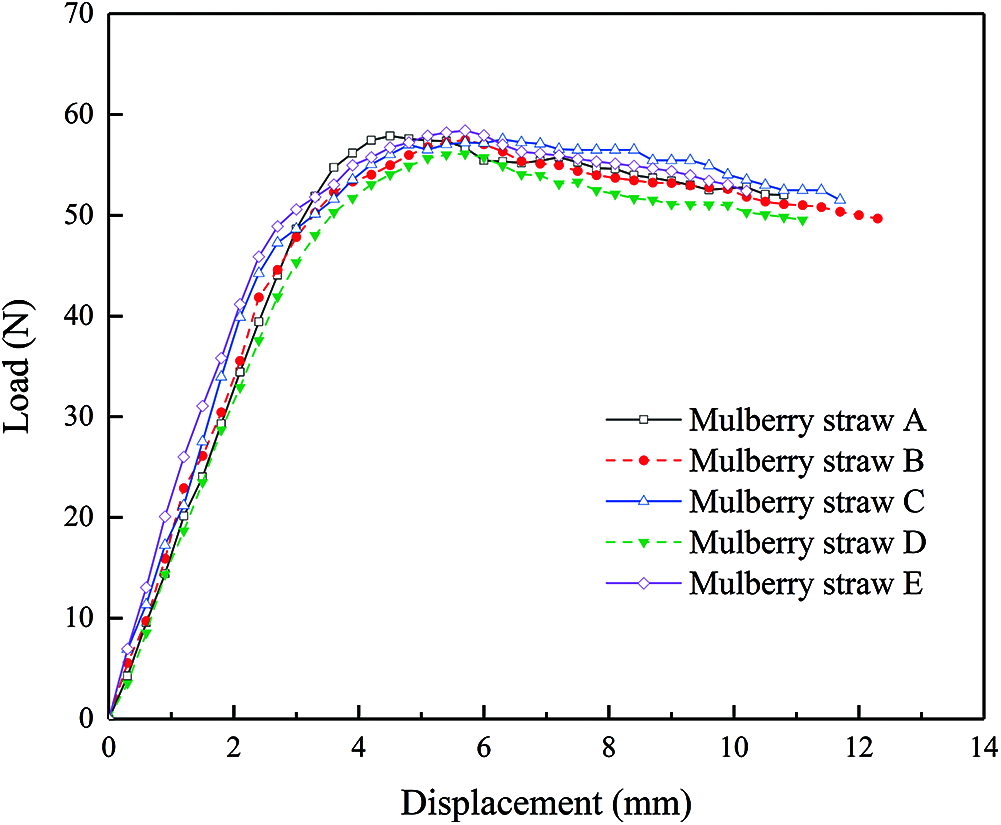

The bending test is repeated five times for self-calibration. The load-displacement curves of the bending characteristics of mulberry straw are shown in Fig. 9. The load of mulberry straw increases with the increase of displacement, and then the load shows a downward trend as the deformation continues to increase. The peak loads of the mulberry straw in the five tests are approximately 57.3, 57.47, 57.54, 57.66 and 58.41 N, respectively, corresponding to peak stresses of approximately 19.94, 20.01, 20.03, 20.07, and 20.33 MPa, respectively. The average bending stress of mulberry straw is 20.08 MPa. A three-point bending test is carried out on the cotton straw, and it is found that the bending strength of cotton stalks was about 5.11 MPa [19,20]. Similarly, the bending strength of corn straw is about 3.41 MPa [19]. Therefore, the bending strength of mulberry straw is better than that of cotton straw and that of corn straw, which indicates the good flexural performance of the mulberry straw.

Figure 9: Load-displacement curves of the bending test

The load-displacement curves of the shear characteristics of mulberry straw are described by Li [20]. The resulting shear strengths of the 5 parallel samples are 3.07, 2.96, 2.94, 2.96, and 3.01 MPa, averaging at 2.99 MPa. To summarize, the compressive strength of the obtained 12-mm-diameter mulberry straw is 2.19–2.45 MPa, the bending strength is 19.94–20.33 MPa, and the shear strength is 2.94–3.07 MPa. These results indicate the fine mechanical properties of mulberry straw and provide a foundation for its application as a retaining material.

Similarly, the load-displacement curves, deformable models, and deformation diagrams of the three-point bending test is reported by Li [20]. The results show that with identical densities, when the rise span ratio increases, the peak load of the mulberry straw arch increases. With identical rise span ratios, when the density increases, the peak load also increases. The peak load of the mulberry straw arch was 417.4 N when the density was 0.476 g/cm3 and the rise span ratio was 0.5, which is far beyond the value of individual straw. This density and rise span ratio are the basis for engineering applications.

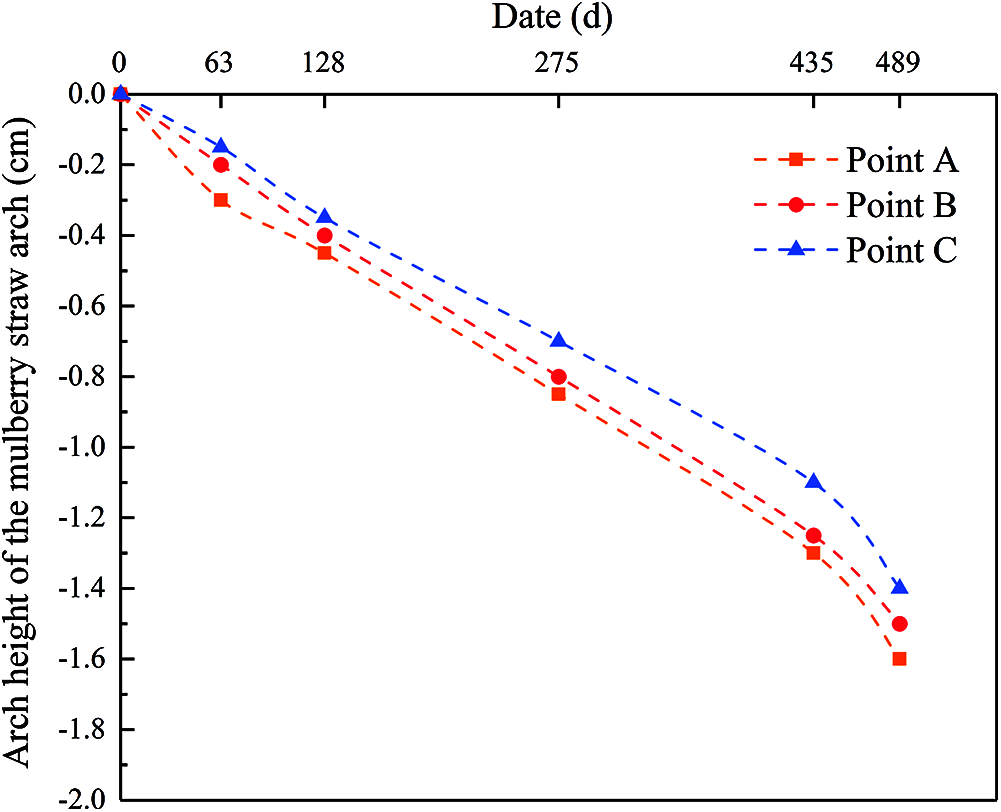

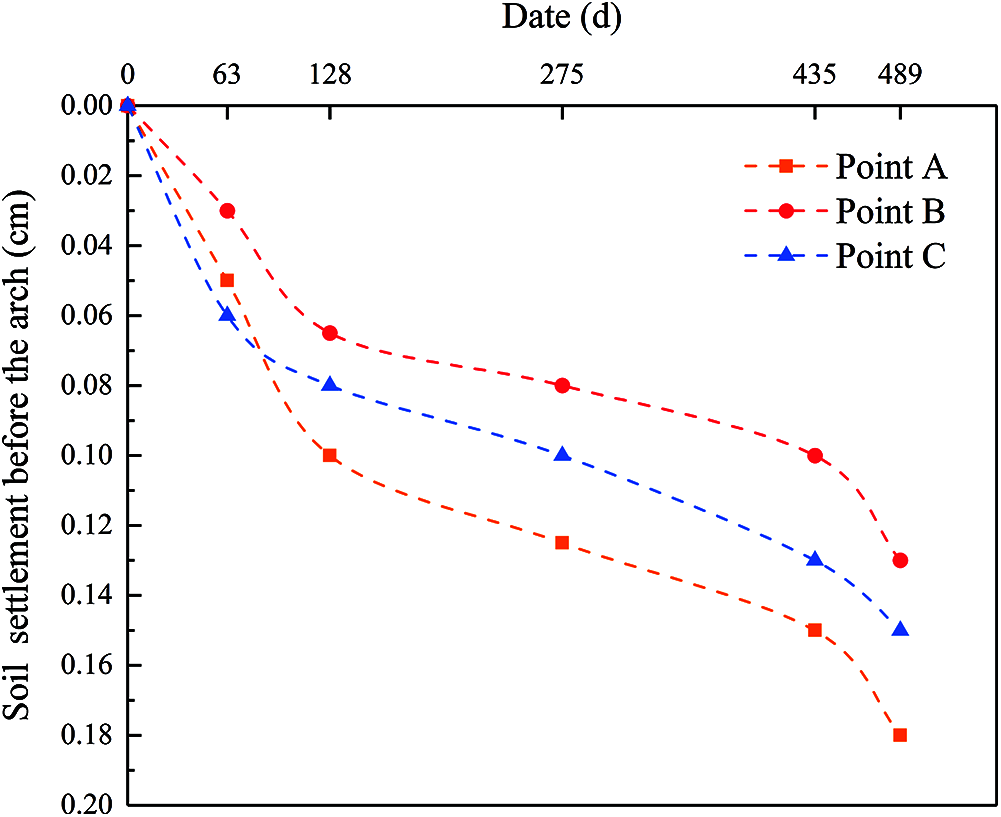

The results of the 489 d field inspection are shown in Figs. 10–13. Fig. 10 shows the change of the arch height of the mulberry straw arch with time. For the Point A, the arch height decreases with time. The variation of the Point A after 63, 128, 275, 435 and 489 d is approximately 0.3, 0.45, 0.85, 1.3 and 1.6 cm, respectively. The maximum variation of the arch height of the mulberry straw arch is 1.6 cm, which is approximately 6.4% of the initial size. For the Point B and Point C, the arch height of mulberry straw arch also decreases with time, but arch height variation is noticeably smaller than that of Point A. The differences between Point A, Point B and Point C may be due to the influence of ship traveling wave [22,23]. The maximum change of the arch height of Point B and Point C is 1.5 and 1.4 cm after 489 d, respectively, which are approximately 6.0% and 5.6% of the initial size, respectively. Therefore, it can be found that the variation of the arch height of the mulberry straw arch is less than 7% over 489 d observation, indicating the proposed structure provides effective support for protecting the river bank.

Figure 10: The arch height of the mulberry straw arch

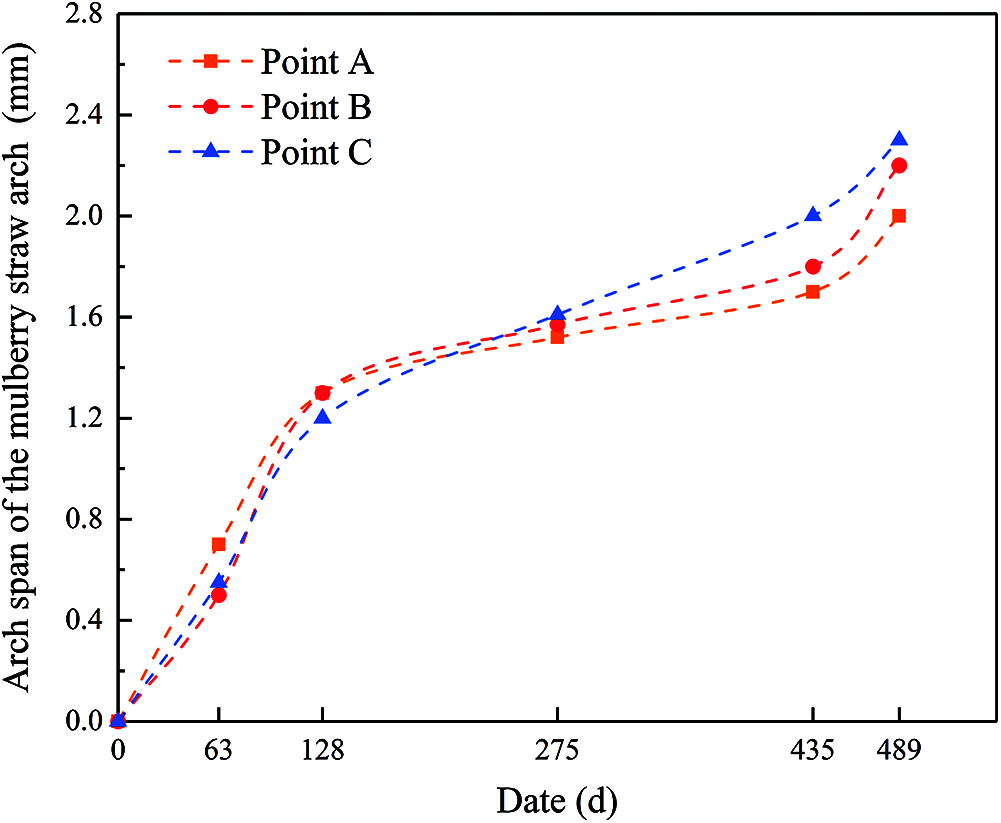

Figure 11: The arch span of the mulberry straw arch

Figure 12: Soil settlement before the arch

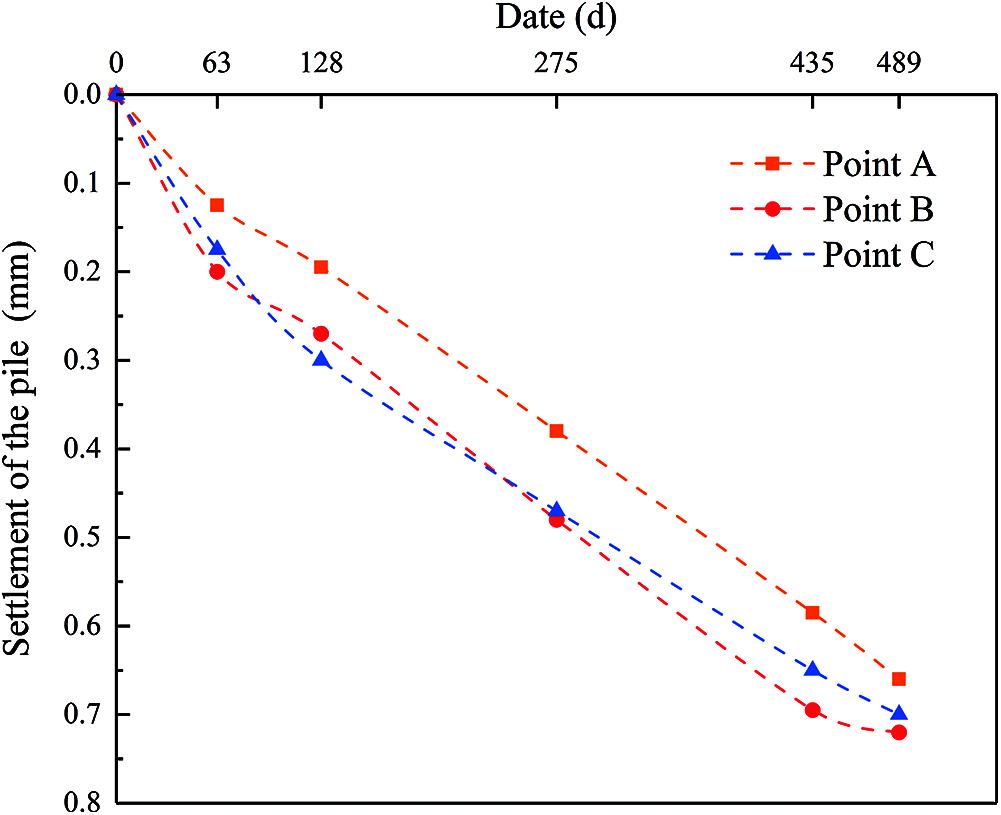

Figure 13: The settlement of the pile

Fig. 11 shows the variation of the arch span of the mulberry straw arch with time. It indicates that as time progresses, the increase in arch span diminishes. The variation in span measurement at the three observation points over 275 d is 1.52–1.61 mm, which is approximately 0.3%–0.32% of the arch span of the mulberry straw arch. The accumulative variation of the span measured at the three observation points over 489 d is 2, 2.2 and 2.3 mm, respectively. The observation Point C witnesses the largest variation, at 2.3 mm. The measurement of the arch span of the mulberry straw arch ranges from 49.97 to 50.20 cm. The rangeability relative to the initial value is 0.46%, which proves the good structure performance of the mulberry straw arch. It is consistent with the variation of the arch height of the mulberry straw arch shown in Fig. 10.

The soil settlement before the mulberry straw arch has significant impact on the deformation of straw arch. Fig. 12 revealing the relationship between the soil settlement before the mulberry straw arch with time. It can be found that the soil settlement of the three observation points increases with time. The cumulative soil settlement of Point A, Point B and Point C is 0.18, 0.13 and 0.15 cm after 489 d, respectively. The observation Point A at the edge of the field test section reaches the maximum settlement, while the observation Point B at the middle of the field test section reaches minimum settlement. Generally speaking, the soil settlement of the three observation points is small over 489 d. It can well limit the deformation of the mulberry straw arch and improve the mechanical load of straw arch. Therefore, from the perspective of the soil settlement before the arch, it proves the discrete timber pile-mulberry straw arch has a good protective effect on the bank slope.

The relationship of the cumulative settlement of the timber pile with time is presented in Fig. 13. As seen, the settlement of the timber pile increases with time in almost linear trend. The pile settlement of Point A, Point B and Point C after 128 d observation is approximately 0.195, 0.27 and 0.3 mm, respectively, which are approximately 0.005%, 0.007% and 0.008% of the 4-m-long timber pile, respectively. After 489 d observation, the cumulative pile settlement of Point A, Point B and Point C is 0.66, 0.72 and 0.7 mm, respectively, which are approximately 0.016%, 0.018% and 0.017% of the 4-m-long timber pile. Therefore, the settlement of the pile is considered negligible relative to the length of the pile. It is precisely because the timber pile is not easy to settle, the mulberry straw arch can be well fixed on the timber pile, so that the straw arch can maintain the original shape. It is consistent with the variation of the arch height and arch span of the mulberry straw arch.

Many scholars propose to use different plant material as revetment structure, such as timber piles, bamboo and Melaleua fences [22–27]. The protection systems with timber piles are often seen on the riverbank revetment, particularly in developing countries such as Thailand [22,24] and Vietnam [23] among many others. Takagi et al. [22,24,25] described in detail the use of timber piles for the bank protection in a coastal city of Vietnam. Hua et al. [2] summarized the specific engineering cases of timber pile revetment in China. Although continuous dense timber pile revetment system appears to be effective, it requires high construction costs due to the large timber consumptions. The gaps between the timber piles cause water and soil loss behind the piles, which compromise the protective effect on the slope toe [2,3]. Furthermore, the use of low-cost bamboo and Melaleua fences has been attempted for bank revetment [26,27]. A successful project case of using the bamboo structure as bank revetment is introduced in Vietnam [23]. However, the bamboo structure is easy to deform and poor in durability, which contributes to unsatisfactory supporting effects in the long run [1–3]. In this paper, an original revetment structure form is proposed: a discrete timber pile-mulberry straw arch structure. Because the dense mulberry straw arch is considerably thick, it has better strength, rigidity, and corrosion resistance than the bamboo fence structure, resulting in a significantly better retaining effect. The discrete pile-mulberry straw arch structure also requires less timber than the continuous dense timber pile structure, making it the more economical choice. A practical application of revetment engineering by using discrete timber pile-mulberry straw arch structure shows that the arch height of the mulberry straw arch changes 1.4–1.6 cm after 489 d observation. The soil settlement before the arch is 0.13–0.18 cm and the settlement of the pile is 0.66–0.72 mm. All the measurement values illustrate the proposed structure can provide effective support for protecting the riverbank.

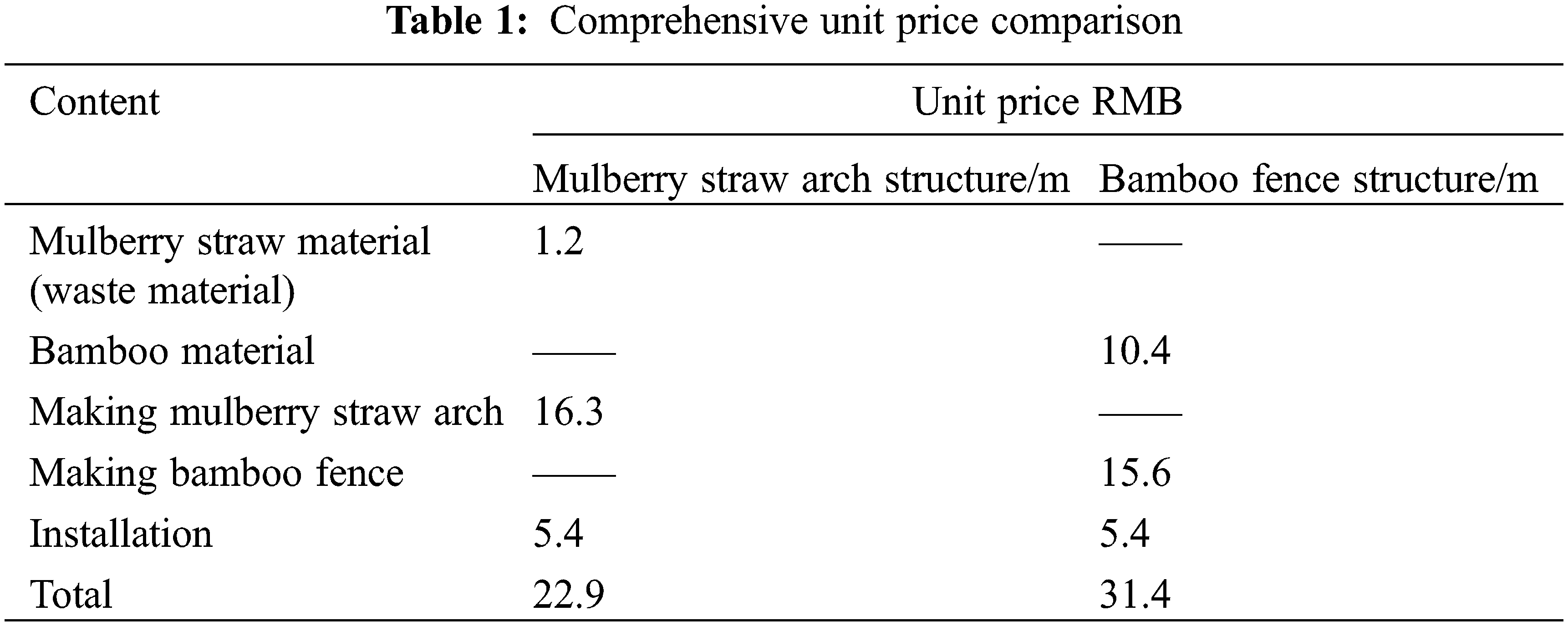

With the purpose to verify the advantage of mulberry straw arch structure from the aspect of the cost saving, the unit price of the mulberry straw arch structure and bamboo fence structure are estimated and presented in Table 1. According to Table 1, the cost of making and installing mulberry straw arch structure is close to the bamboo fence structure. However, the use of mulberry straw arch structure has great advantages over the bamboo fence structure because the mulberry straw is agricultural waste material with low cost. In general, the total cost of using mulberry straw arch structure as revetment material can save up to 27.07% compared with bamboo fence structure.

In order to verify the effective protective effect, the comparison pictures for bank revetment using discrete pile-mulberry straw arch structure and timber pile structure are shown in Fig. 14. It can be found that the integrity of the arch remains in good condition over 489 d, and soil erosion behind the pile was not significant, as shown in Fig. 14a. However, the timber pile has an obvious inclination phenomenon in the timber pile structure, as shown in Fig. 14b. It indicates that the discrete timber pile-mulberry straw arch revetment structure proposed in this study in this study is a rational and stable structure.

Figure 14: Comparison pictures for bank revetment: (a) Discrete pile-mulberry straw arch structure; (b)Timber pile structure

(1) Mulberry straw has good mechanical characteristics. The mulberry straw arch takes full advantage of the superior structural properties of arches to improve the retaining effect. Additionally, the mulberry straw arch is dense, compact and far more durable than bamboo fences, so it provides a good foundation as a bank protection structure.

(2) The spaced timber mulberry-straw arch model is a feasible new revetment structure with good stability. It demonstrates fine support and good adaptability in the protection of the toe in gentle slopes. With water plants such as reeds, the proposed original model can efficiently prevent rear bank slopes from collapsing.

(3) The discrete timer pile-mulberry straw arch structure has significant economic and ecological effects. It is also easy to construct and capable of standardized production. Therefore, the proposed new revetment structure has great potential and broad aspects in engineering applications.

Funding Statement: This study is supported by the National Natural Science Foundation of China (Grant Nos. 51778556, 51978597, 51808481).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Chen, B., Huang, W., Chen, K., Gu, X. (2018). Research progress on the ecological revetment riparian. Environmental Engineering, 36(3), 75–77. DOI 10.13205/j.hjgc.201803015. [Google Scholar] [CrossRef]

2. Hua, Q., Yu, X., Wang, X. (2020). Ecological revetment structure with alternate timber pile and mulberry straw arch. Port & Waterway Engineering, 573(9), 138–141. DOI 10.16233/j.cnki.issn1002–4972.20200820.030. [Google Scholar] [CrossRef]

3. Huang, X., Xie, J. (2017). Types of ecological revetments in river regulation. Port & Waterway Engineering, 536(11), 109–113. DOI 10.16233/j.cnki.issn1002-4972.2017.11.020. [Google Scholar] [CrossRef]

4. Taneli, V., Antti, H., Reijo, L., Laura, T. (2016). Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Management, 54, 62–73. DOI 10.1016/j.wasman.2016.04.037. [Google Scholar] [CrossRef]

5. Tang, Q., Shi, P., Zhang, Y., Liu, W., Chen, L. et al. (2019). Strength and deformation properties of fiber and cement reinforced heavy metal-contaminated synthetic soils. Advances in Materials Science and Engineering, 2019, 5746315. DOI 10.1155/2019/5746315. [Google Scholar] [CrossRef]

6. Aldaood, A., Khalil, A., Bouasker, M., AL-Mukhtar, M. (2021). Experimental study on the mechanical behavior of cemented soil reinforced with straw fiber. Geotechnical and Geological Engineering, 39(4), 2985–3001. DOI 10.1007/S10706-020-01673-Z. [Google Scholar] [CrossRef]

7. Taha, A., Bahnasawey, A., Wu, W. (2010). Compressive strength of fibre reinforced earth plasters for straw bale buildings. Australian Journal of Agricultural Engineering, 1(3), 86–92. DOI 10.3316/informit.633149344967656. [Google Scholar] [CrossRef]

8. Greeshma, P. G., Joseph, M. (2011). Rice straw reinforcement for improvement in Kuttanad clay. Proceedings of the Indian Geotechnical Conference, pp. 15–17. Kochi. [Google Scholar]

9. Abtahi, M., Okhovat, N., Pourhosseini, R. (2010). Improvement of soil strength by natural fibers. From res to des Europ Prac, pp. 2–4. Bratislava, Slovak Republic. [Google Scholar]

10. Fakhari, M. A., Lotfalian, M., Hosseini, S. A., Darvishan, A. K. (2019). Using wood-shred, rice-straw and brush-wood-dams with planting seedlings to runoff and erosion control in a forest road fill slope. Croatian Journal of Forest Engineering, 40(2), 327–339. DOI 10.5552/crojfe.2019.530. [Google Scholar] [CrossRef]

11. Lipscomb, C. M., Johnson, T., Nelson, R., Lancaster, T. (2006). Comparison of erosion control technologies: Blown straw vs. erosion control blankets. Land and Water, 50(4), 48–53. DOI 10.1088/0953-2048/15/9/307. [Google Scholar] [CrossRef]

12. Oslen, M. J., Rikli, A. M., Sillars, D. N. (2012). Investigation of straw wattle influence on surficial slope stability. Proceedings of the Transportation Research Board 91st Annual Meeting, pp. 22–26Washington DC, USA. [Google Scholar]

13. Won, C. H., Shin, M. H., Chor, Y. H., Shin, J. Y., Park, W. J. et al. (2012). Simulations of runoff using rice straw mats and soil amendments. Journal of the Korean Society of Agricultural Engineers, 54(2), 95–102. DOI 10.5389/KSAE.2012.54.2.095. [Google Scholar] [CrossRef]

14. Mitchell, D. J., Barton, A. P., Fullen, M. A., Hocking, T. J., Wu, B. et al. (2003). Field studies of the effects of jute geotextiles on runoff and erosion in Shropshire, UK. Soil Use and Management, 19(2), 182–184. DOI 10.1111/j.1475-2743.2003.tb00301.x. [Google Scholar] [CrossRef]

15. Robichaud, P., Storrar, K., Wagenbrenner, J. (2019). Effectiveness of straw bale check dams at reducing post-fire sediment yields from steep ephemeral channels. Science of the Total Environment, 676, 721–731. DOI 10.1016/j.scitotenv.2019.04.246. [Google Scholar] [CrossRef]

16. Robichaud, P., Pierson, F., Brown, R., Wagenbrenner, J. (2008). Measuring effectiveness of three postfire hillslope erosion barrier treatments, Western Montana, USA. Hydrological Processes, 22(2), 159–170. DOI 10.1002/hyp.6558. [Google Scholar] [CrossRef]

17. Wu, W., Zhang, D., Tian, L., Gao, S., Zhang, M. et al. (2019). Erosion-deposition characteristics and fencing life of straw checkerboard in alpine sandy lands. Environmental Engineering Science, 36(1), 60–69. DOI 10.1089/ees.2018.0155. [Google Scholar] [CrossRef]

18. Heshmati, G. A., Squires, V. R. (2013). Combating desertification in Asia, Africa and the Middle East. Germany: Springer Press. [Google Scholar]

19. Gao, X. (2013). Experimental study of mechanical properties of corn stalks (Master Thesis). Huazhong Agricultural University, Hubei, China. [Google Scholar]

20. Li, Y. B. (2021). River revetment test and engineering application of mulberry straw arch drainage pile (Master Thesis). Anhui University of Science and Technology, Anhui, China. [Google Scholar]

21. Rohela, G. K., Muttanna, P. S., Kumar, R., Chowdhury, S. R. (2020). Mulberry (Morus spp.An ideal plant for sustainable development. Trees, Forests and People, 2, 100011. DOI 10.1016/j.tfp.2020.100011. [Google Scholar] [CrossRef]

22. Takagi, H., Sekiguchi, S., Thao, N. D., Rasmeemasmuang, T. (2020). Do wooden pile breakwaters work for community-based coastal protection? Journal of Coastal Conservation, 24, 1–11. DOI 10.1007/s11852-020-00749-5. [Google Scholar] [CrossRef]

23. Schmitt, K., Albers, T. (2014). Area coastal protection and the use of bamboo breakwaters in the Mekong delta. In: Thao, N. D., Takagi, H., Esteban, M. (Eds.Coastal disasters and climate change in Vietnam: Engineering and planning perspectives, pp. 107–132. Amsterdam: Elsevier. DOI 10.1016/B978-0-12-800007-6.00005-8. [Google Scholar] [CrossRef]

24. Takagi, H., Fujii, D., Esteban, M., Yi, X. (2017). Effectiveness and limitation of coastal dykes in Jakarta: The need for prioritizing actions against land subsidence. Sustainability, 9(4), 619. DOI 10.3390/su9040619. [Google Scholar] [CrossRef]

25. Takagi, H., Tomiyasu, R., Oyake, T., Araki, T., Mori, K. et al. (2020). Tsunami intrusion through port breakwaters enclosed with self-elevating seawalls. Ocean Engineering, 199, 107028. DOI 10.1016/j.oceaneng.2020.107028. [Google Scholar] [CrossRef]

26. Schmitt, K., Albers, T., Pham, T. T., Dinh, S. C. (2013). Site-specific and integrated adaptation to climate change in the coastal mangrove zone of Soc Trang province, Vietnam. Journal of Coastal Conservation, 17(3), 545–558. DOI 10.1007/s11852-013-0253-4. [Google Scholar] [CrossRef]

27. van Cuong, C., Brown, S., To, H. H., Hockings, M. (2015). Using melaleuca fences as soft coastal engineering for mangrove restoration in Kien Giang, Vietnam. Ecological Engineering, 81, 256–265. DOI 10.1016/j.ecoleng.2015.04.031. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |