| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.019418

ARTICLE

Characterization of Mechanical Properties of Waste Slurry Modified by Recycled Sand and Cement

School of Civil Engineering, Shaoxing University, Shaoxing, 312000, China

*Corresponding Author: Na Li. Email: lina@usx.edu.cn

Received: 23 September 2021; Accepted: 22 November 2021

Abstract: In order to study the modification effect of recycled sand on cement reinforced waste slurry (CWS), triaxial test, scanning electron microscope test and X-ray diffraction test were carried out. The mechanical test of recycled sand and cement reinforced waste slurry (RCWS) shows that the deviatoric stress–strain curve of RCWS samples changes from hardening type to softening type with the increase of recycled sand content; the peak stress increases with the increase of recycled sand content; recycled sand can enhance the shear strength of CWS by increasing both cohesion and internal friction angle. The microscopic test shows that recycled sand can improve the structural compactness by cementing with hydrated calcium silicate and can reduce the void ratio and orientation index of RCWS samples. Finally, the mathematical model between shear strength parameters and void ratio is established. The research shows that adding an appropriate amount of recycled sand and cement has a good modification effect on waste slurry. This is an effective method to treat two kinds of construction wastes: construction waste slurry and waste concrete.

Keywords: Construction waste slurry; recycled sand; triaxial test; microstructure

With the rapid development of urbanization and civil engineering, the production of construction waste slurry has increased significantly, which poses a serious threat to the urban ecological environment. Therefore, it is an urgent problem to deal with the construction waste slurry scientifically and effectively. Construction waste slurry mainly comes from bored pile and subway tunnel construction, with good fluidity and poor mechanical properties. However, after solidification, construction waste slurry can be used as roadbed filling or directly used as roadbed or building foundation [1,2]. Many scholars [3,4] have conducted researches on the modification of construction waste slurry with different admixtures. Zhang et al. [5] explored the solidification effect of cement and fly ash on the waste slurry in the construction of bored piles. Through unconfined compression test and scanning electron microscope test (SEM), it is clear that the mechanical effect of cement and fly ash solidified slurry at the same time is better than that of cement solidified slurry alone. Further triaxial compression test results show that the cohesion of cement and fly ash solidified slurry increases with the increase of age. Similarly, Shi et al. [6] explored the solidification effect of 425# ordinary Portland cement, CERSM I slurry curing agent, CERSM II slurry curing agent and quicklime on the waste slurry from a slurry shield tunnel in Xiamen City. Comparing the compressive strength, pH value and moisture content of the four slurry curing agents, it can be concluded that the solidification effect of CERSM II slurry curing is the best, and the compressive strength of 28 d curing slurry can reach 1.5 MPa, which can be used as building materials. Cheng et al. [7] deeply explored the improvement effect of lime on waste construction slurry. Through a series of triaxial tests, it is found that the peak strength, residual strength, and failure strain of waste slurry with 8% lime content increase with the increase of confining pressure and age. And the cohesion and internal friction increase with the increase of age.

On the other hand, pollution problems and resource shortages caused by construction and demolition waste are becoming more and more serious [8]. Therefore, the treatment of construction solid waste is also a major project. As a recyclable building material from solid waste, waste concrete aggregate is of great significance for environmental protection and sustainable development in its treatment and application [9]. The use of recycled aggregates in concrete or road subgrades has become a hotspot in engineering research [10–12]. In order to explore the impact of the replacement of natural aggregates by recycled aggregates on the durability of concrete, Xiao et al. [13] thoroughly studied the effects of recycled aggregate replacement rate on concrete chloride ion permeability, freeze-thaw resistance, abrasion resistance, carbonization depth, water absorption shrinkage and drying shrinkage properties. The research results show that as the replacement rate of recycled aggregate increases, the chloride ion permeability and abrasion resistance of concrete decrease linearly, and the freeze-thaw resistance and carbonization resistance also decrease. However, the absorption shrinkage rate and drying shrinkage rate increase linearly with the increase of the replacement rate of recycled aggregate. Ying et al. [14] explored the influence of nano-SiO2 and nano-TiO2 on the pore structure and chloride ion diffusion rate of recycled aggregate concrete. The test results show that the nanoparticles refine the pore structure of recycled concrete and enhance its resistance to chloride ion diffusion. And the degree of refinement and enhancement both increase first and then decrease with the increase of the content of nanoparticles. Nepomuceno et al. [15] and Siempu et al. [16] studied the tensile properties of recycled aggregate concrete. The relevant test results showed that the tensile strength of recycled aggregate concrete decreased with the increase in the replacement rate of recycled aggregate. And its peak tensile strain is higher than that of natural aggregate concrete. Extensive researches have been carried out on the recycled coarse aggregates of construction waste concrete after crushing, but there are few studies on the fine aggregates obtained by sieving, especially the modification of waste slurry [17,18].

For the above-mentioned construction waste slurry and waste concrete recycled sand, the construction waste slurry was modified with recycled sand and cement by changing the recycled sand content in RCWS. Unconsolidated-undrained triaxial (UU) test, scanning electron microscope (SEM) test and X-ray diffraction (XRD) test were carried out to characterize the mechanical properties of recycled aggregate modified construction waste slurry, which provided technical reference for the engineering recycling of two kinds of construction waste.

2 Tests and Materials and Methods

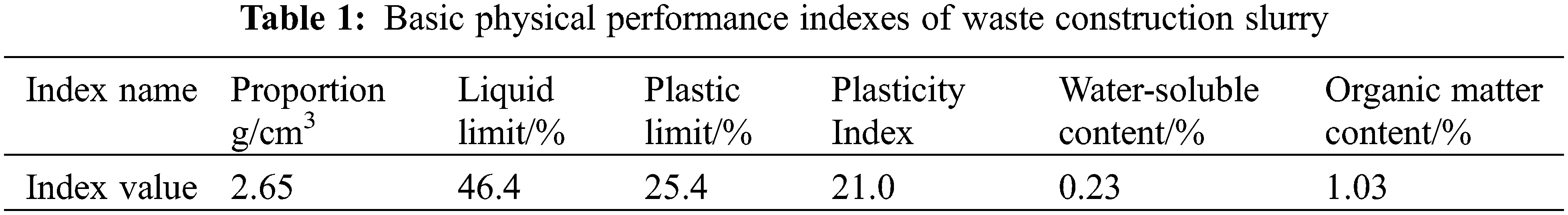

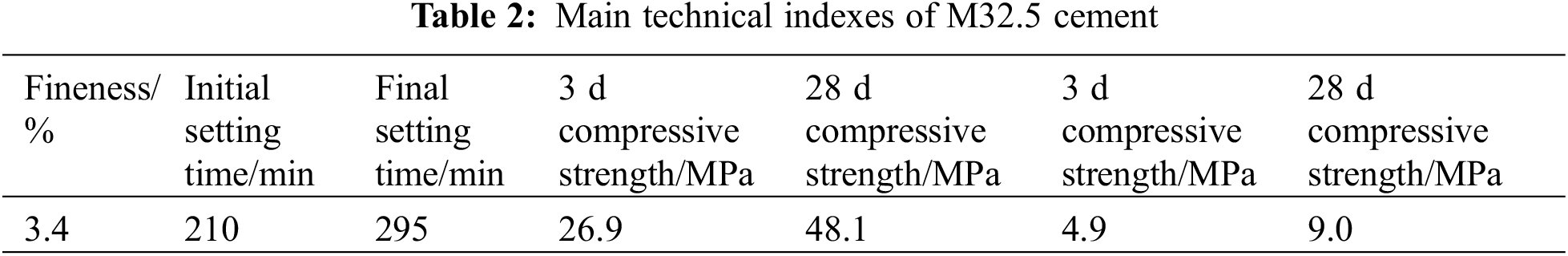

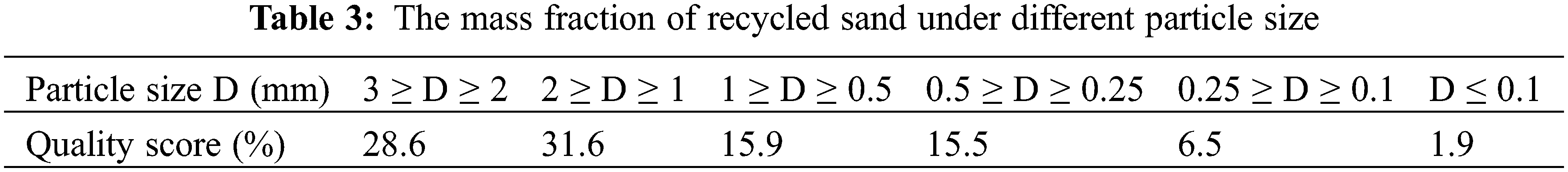

The construction waste slurry sample is collected from a bored pile construction site in Shaoxing City, Zhejiang Province. The specific basic physical performance indicators are shown in Table 1. P.O32.5 Portland cement was selected for the test, and the main technical indicators are shown in Table 2. Recycled sand is produced by Shanghai Youhong Environmental Protection Technology Co., Ltd. (Shanghai, China). It is recycled fine aggregate after crushing waste concrete from the demolition of old houses and is coated with a small amount of cement and other materials. The maximum particle size of reclaimed sand is less than 10 mm, mostly round particles, and the color is blue-gray. Its porosity and water absorption are lower than 47% and 3.0%, respectively, and its apparent density exceeds 2450 kg/m3. The mass fraction of each particle size is shown in Table 3.

In this test, construction waste slurry was mixed with cement curing agent and recycled sand in an appropriate amount. The test was divided into 6 groups with 4 samples in each group. Based on the quality of construction waste slurry, the moisture content of the sample is 80%, the cement content is 20%, and six recycled sand content of 0%, 10%, 20%, 30%, 40%, and 50% are designed. The curing time is 7 d, and a total of four triaxial loading confining pressures of 100 kPa, 200 kPa, 300 kPa, and 400 kPa are designed.

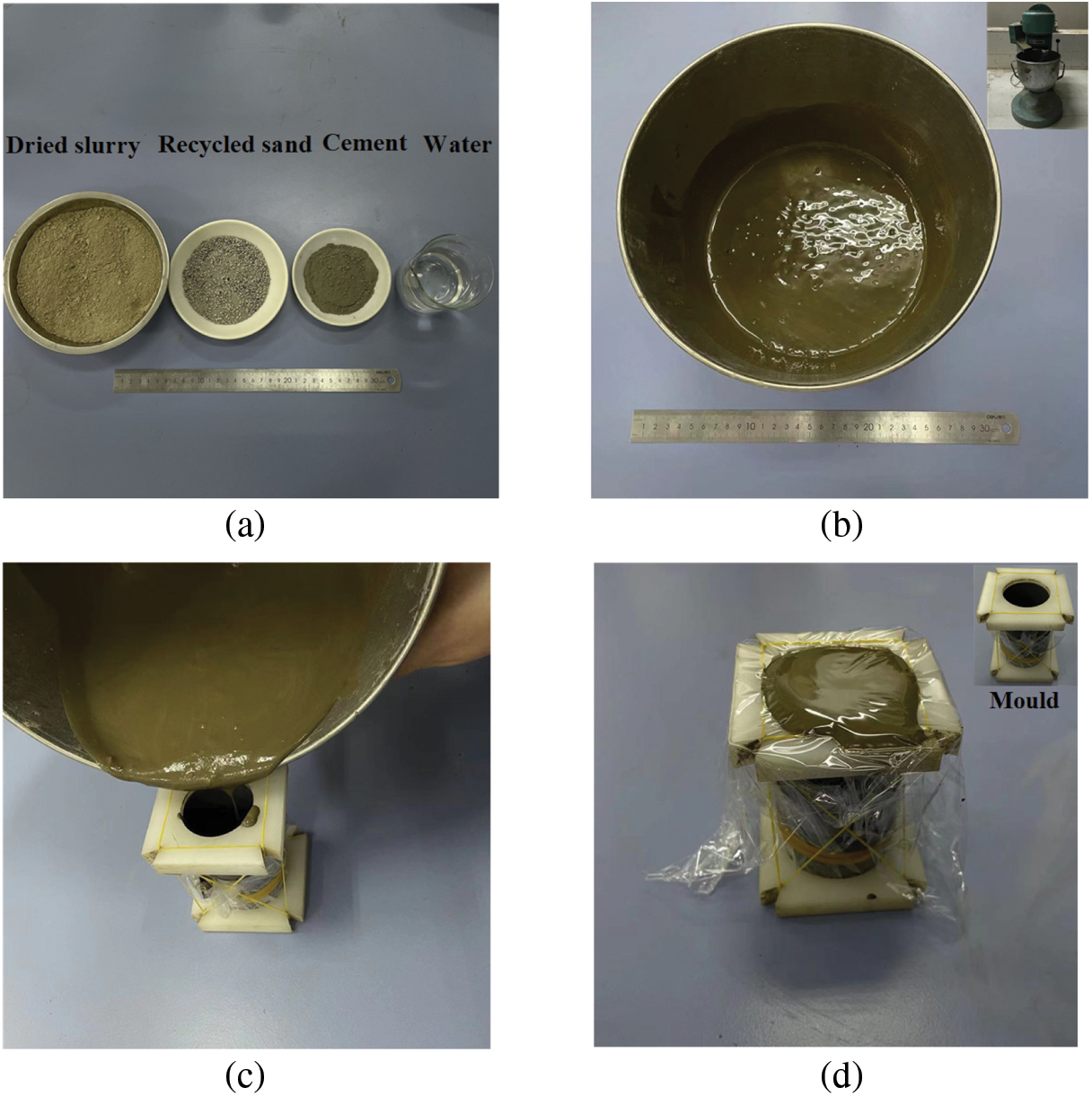

According to the “Standard for Soil Test Methods” (GB/T 50123-2019) [19], the sample preparation process of the unconsolidated and undrained triaxial test can be mainly divided into the following four steps:

1. After drying the construction waste slurry, a 2 mm aperture standard sieve was used to remove large particles.

2. After drying the recycles sand, large particles were removed by a standard sieve with an aperture of 3 mm, as shown in Fig. 1.

3. According to the mixing ratio, the test materials were weighed and mixed evenly. And a cylinder sample with a diameter of 39.1 mm and a height of 80 mm was made with a mold. After standing for 3–4 h, the two ends of the bearing plates of the sample were removed, and the filter paper was fixed on both ends of the mold cylinder with a rubber ring.

4. The sample was immersed in water for water-saturated curing for 7 d, then the mold cylinder was removed, and the sample was made. The detailed sample preparation process can be seen as shown in Fig. 2.

Figure 1: Standard sieve with 3 mm aperture

Figure 2: Sample preparation process (a) Experiment material, (b) Mix and stir, (c) Vibrate, (d) Forming, (e) Maintenance, (f) Standard sample

1. Triaxial UU test. The TKA-TTS-3S automatic triaxial instrument was used to perform unconsolidation and undrainage (UU) shear tests on RCWS samples. The shear rate was set to 1 mm/min, and the test was stopped when the axial strain reached 15%. The sample was placed on a metal sampling table with a smooth bottom, and an epoxy indenter at the top to minimize the end effect.

2. SEM test. JSM-6360LV tungsten filament high and low vacuum scanning electron microscope instrument was used to conduct the test. After the reference RCWS samples with different recycled sand content were made, the samples were sprayed with crystal, and finally the SEM image was taken.

3. XRD test. PIXcel3D X-ray diffractometer was applied to this test. The RCWS samples were first crushed into powder particles, and then placed in the groove of the sample holder until the entire sample tank was filled, and finally the sample was placed in the sample chamber for diffraction testing.

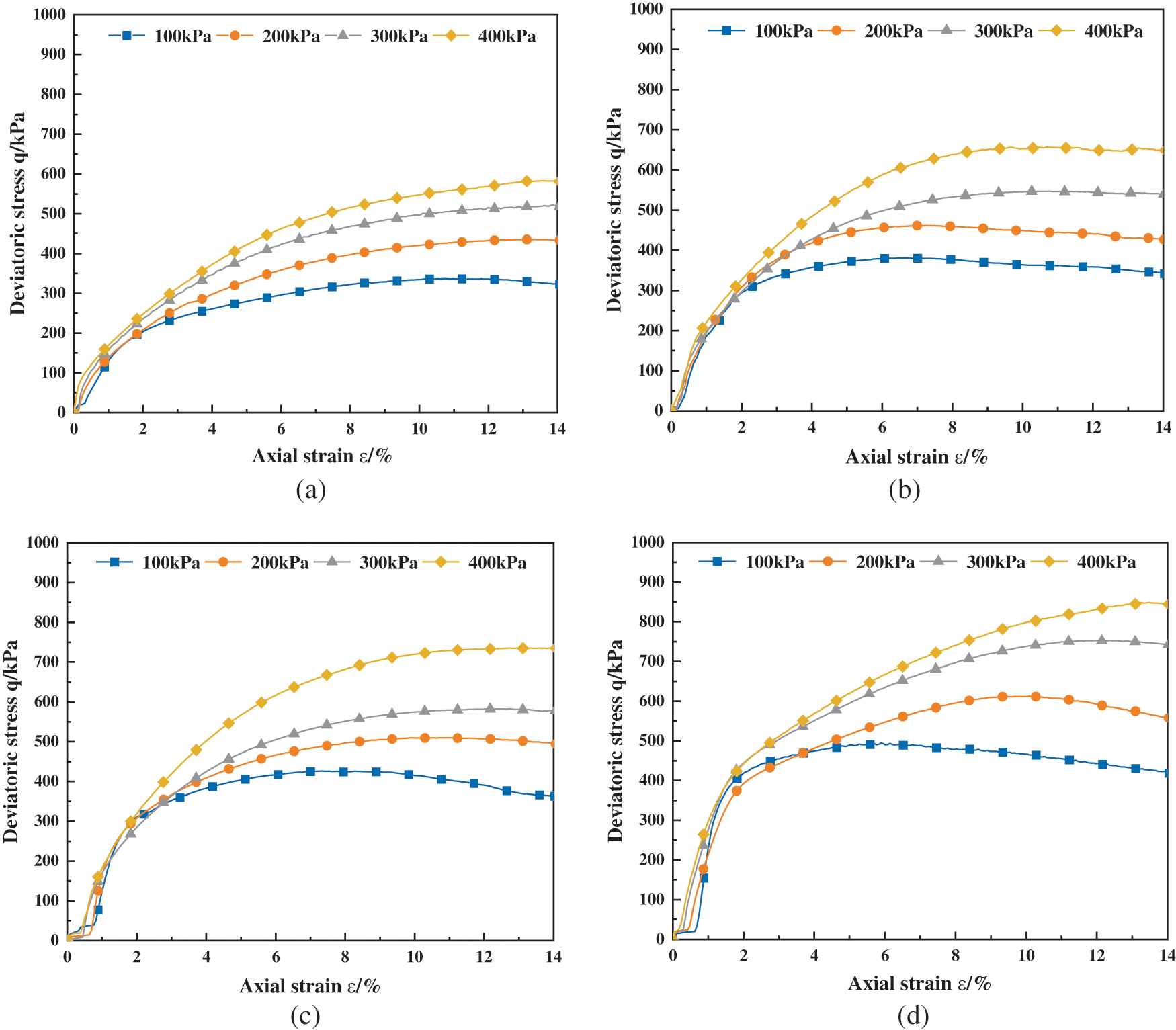

3.1 Deviatoric Stress–Strain Curve

The relation curves between the deviatoric stress q and the axial strain ε (hereinafter referred to as the deviatoric stress–strain curve) of RCWS samples with six recycled sand content were obtained through triaxial test. The deviatoric stress–strain curves of a typical sample with recycled sand content of S = 0%, 10%, 30%, 50% are shown in Fig. 3. According to the “Standard for Soil Test Methods” (GB/T 50123-2019) [19], 14% was taken as the maximum axial strain in this study. It can be seen from Fig. 3 that the deviatoric stress–strain curve of pure CWS samples is of strain hardening type, with no obvious downward trend. With the increase of recycled sand content, the deviatoric stress–strain curve of RCWS samples gradually transforms to the softening type, and the transformation trend is more obvious under low confining pressure. This is because the incorporation of recycled sand makes the CWS sample contain aggregates similar to those found in concrete, so it can be regarded as “concrete-like”, and the more recycled sand, the more similar the structure of RCWS and concrete. Therefore, its stress–strain curve will be similar to that of concrete, and the stress will gradually decrease with the increase of strain, that is, it will gradually change from the hardened type to the softened type. At the same time, because the CWS sample is difficult to break under the condition of low stress level, and the particle shape is complex, it is difficult to transpose between the particles, and the resistance is large, which makes the sample easy to dilate during the shearing process, thus showing the characteristics of strain softening. So the transition trend is more obvious under low confining pressure [20].

Figure 3: Deviatoric stress–strain curves of RCWS with different recycled sand contents (a) S = 0%, (b) S = 10%, (c) S = 30%, (d) S = 50%

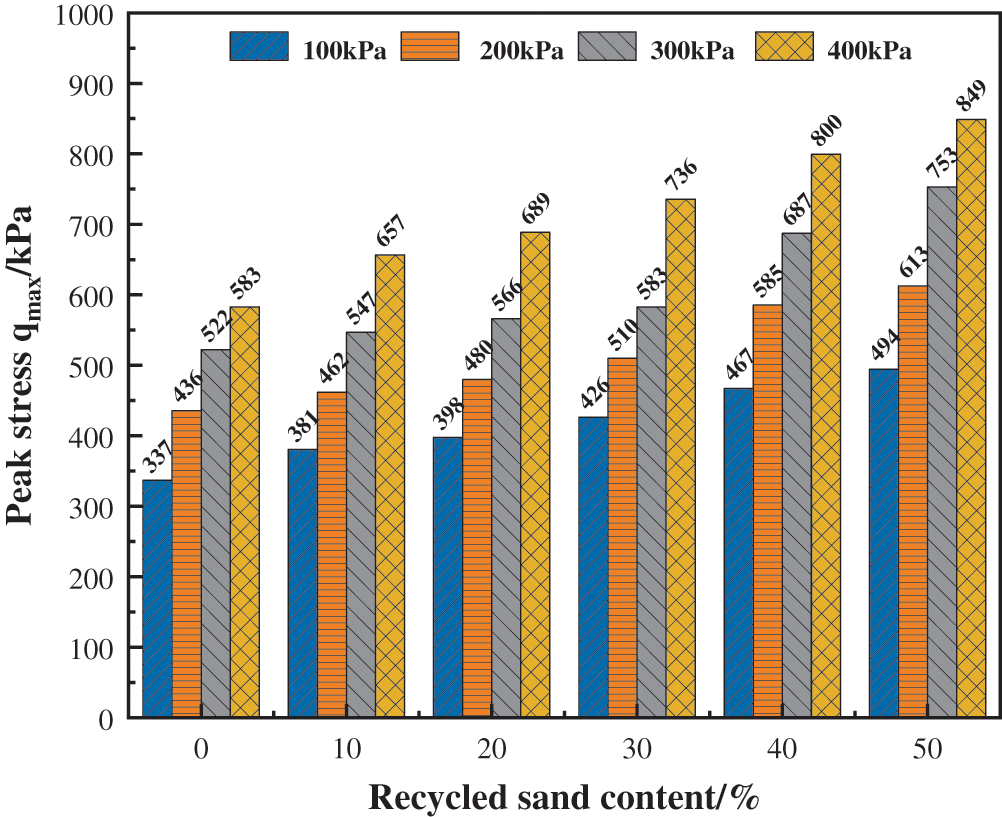

According to the stress and strain test results, the peak stress qmax of RCWS samples can be obtained. The specific stress value is shown in Fig. 4.

Figure 4: Peak stress of RCWS with different recycled sand contents

It can be seen from Fig. 4 that with constant recycled sand content, the peak stress of RCWS samples gradually increases with the increase of confining pressure. Under the same confining pressure, the peak stress of RCWS samples increases with the increase of recycled sand content. When the recycled sand content is 50%, the peak stress of RCWS samples reaches the maximum. Under the four confining pressures, the peak stress of RCWS samples with 50% recycled sand content is increased by 47%, 41%, 44%, and 46% respectively compared with that of RCWS samples with 0% content.

Incorporating a certain amount of recycled sand can increase the strength of CWS, which can be explained from the following two aspects: the incorporation of recycled sand makes CWS contain aggregates similar to those in concrete, and the increase in strength is due to the role of recycled sand acting as a skeleton in CWS, which further increase the shear strength of CWS and limits the further development of CWS failure surface. At the same time, under the combined action of cement and recycled sand, the hydrated calcium silicate (C-S-H) gel produced by the cement hydration reaction greatly improves the connection between the slurry particles and the recycled sand particles, thereby improving the overall compactness and shear strength of CWS.

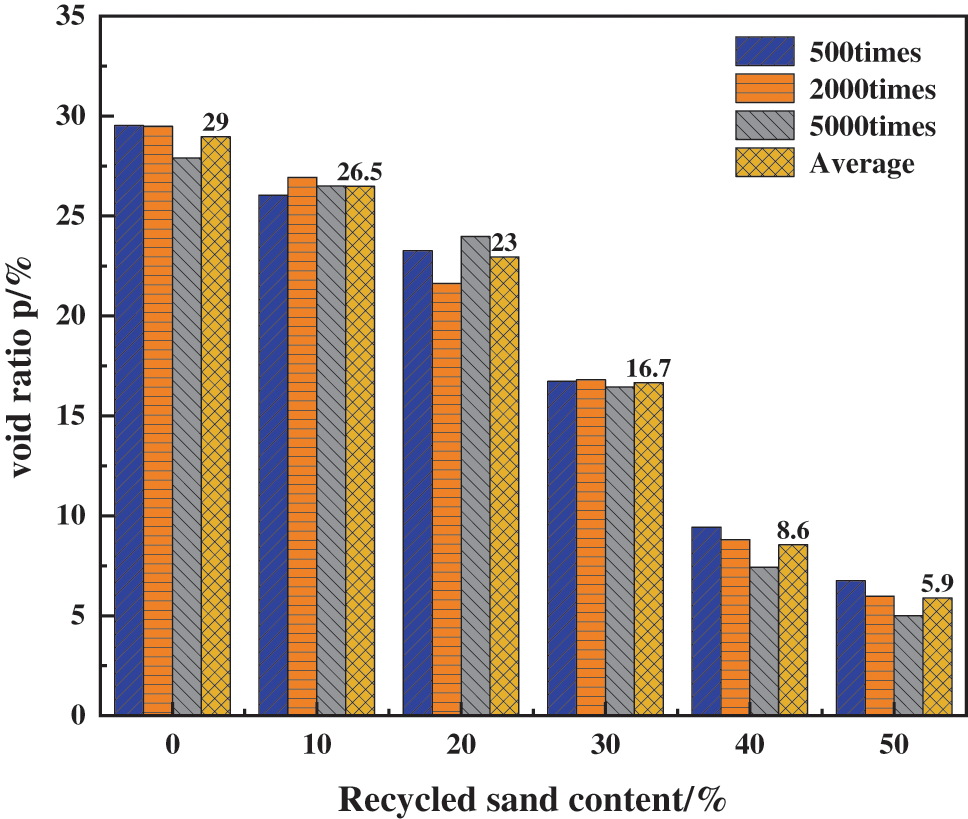

3.3 Strength Curve and Shear Strength Parameters

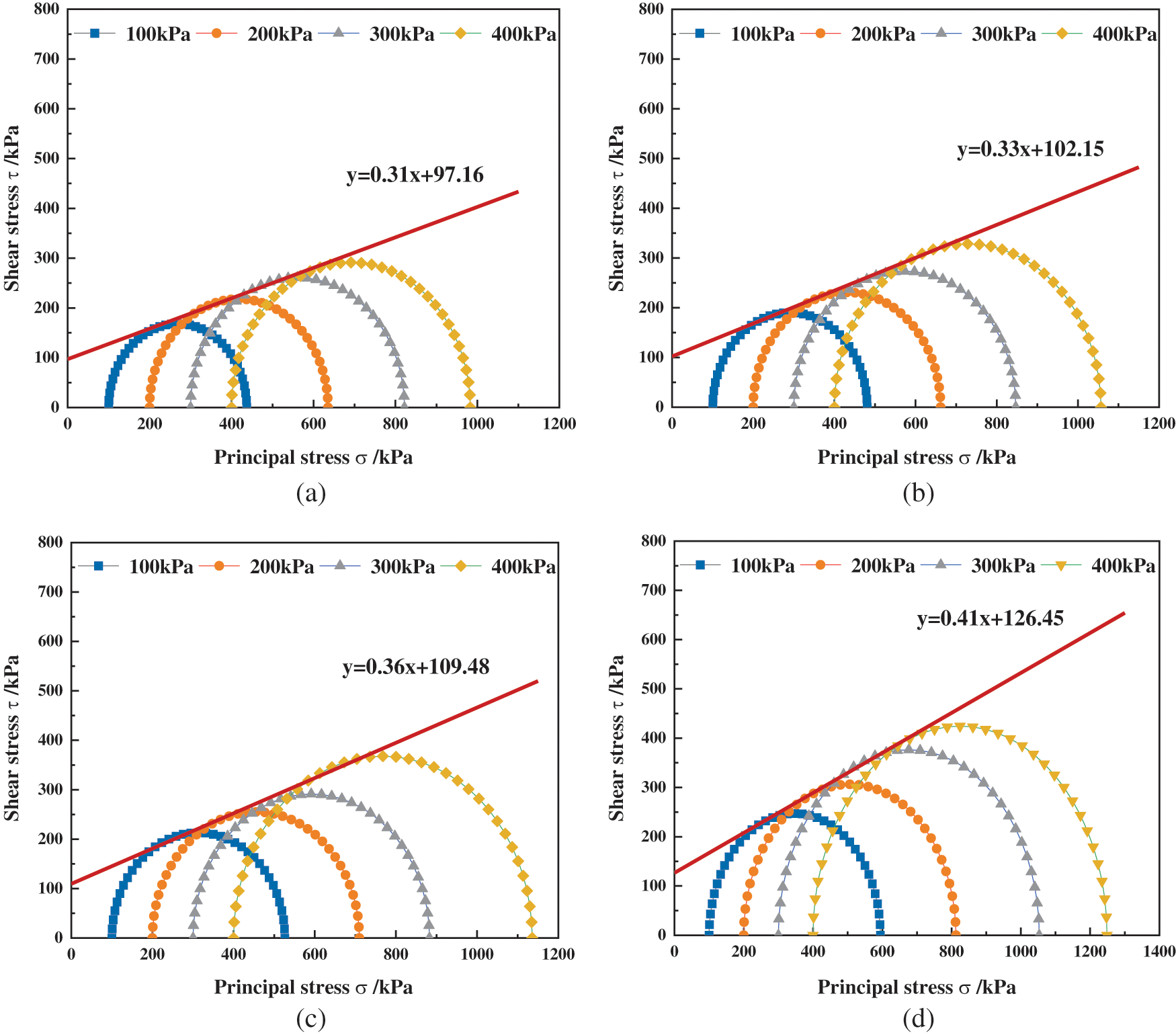

According to the deviatoric stress–strain curve, the normal stress σ is taken as the x-coordinate and the shear stress τ is taken as the y-coordinate, and the Mohr failure stress envelope with different recycled sand contents can be drawn on the τ-σ stress plane diagram. The shear strength envelope of the sample can be drawn, and the c and φ data with different recycled sand contents were calculated. Typical Mohr envelopes with 0%, 10%, 30%, and 50% recycled sand content are shown in Fig. 5. The values of c and φ with each content are shown in Table 4.

Figure 5: Mohr failure stress envelope of RCWS with different recycled sand contents (a) S = 0%, (b) S = 10%, (c) S = 30%, (d) S = 50%

It can be seen from Fig. 5 that the shear strength envelope obtained in this study has a certain inclination, which is different from the horizontal shear strength envelope obtained by the traditional UU test. This is mainly because the cement hydration products fill and seal the pores in the cement soil. There are closed pores in the cement soil, which affects the saturation of the cement soil. The cement soil is in a low saturation state in the test [21]. When the soil in the low-saturation state is subjected to the UU test, the change in the confining pressure cannot be offset by the equivalent pore water pressure, and the peak stress of the soil will increase with the increase of the confining pressure [22].

It can be seen from Table 4 that, with the increase of recycled sand content, the cohesion and internal friction angle of CWS samples gradually increase. When the recycled sand content is 50%, the cohesion and internal friction angle reach the maximum, which are 126.45 kPa and 22.10°, respectively. Compared with RCWS samples with 0% recycled sand content, the cohesion and internal friction angle are increased by 30.1% and 29.9%, respectively, with a significant improvement effect. This is because the cement content is constant, the slurry has greater fluidity, and has no shear strength, the incorporation of cement can improve its cohesion [23,24]. With the increase of recycled sand content, the friction and bite force between particles increases, the cohesion and internal friction angle of RCWS samples also increase [25], which indicates that recycled sand can enhance the shear strength of RCWS samples by simultaneously increasing their cohesion and internal friction angle.

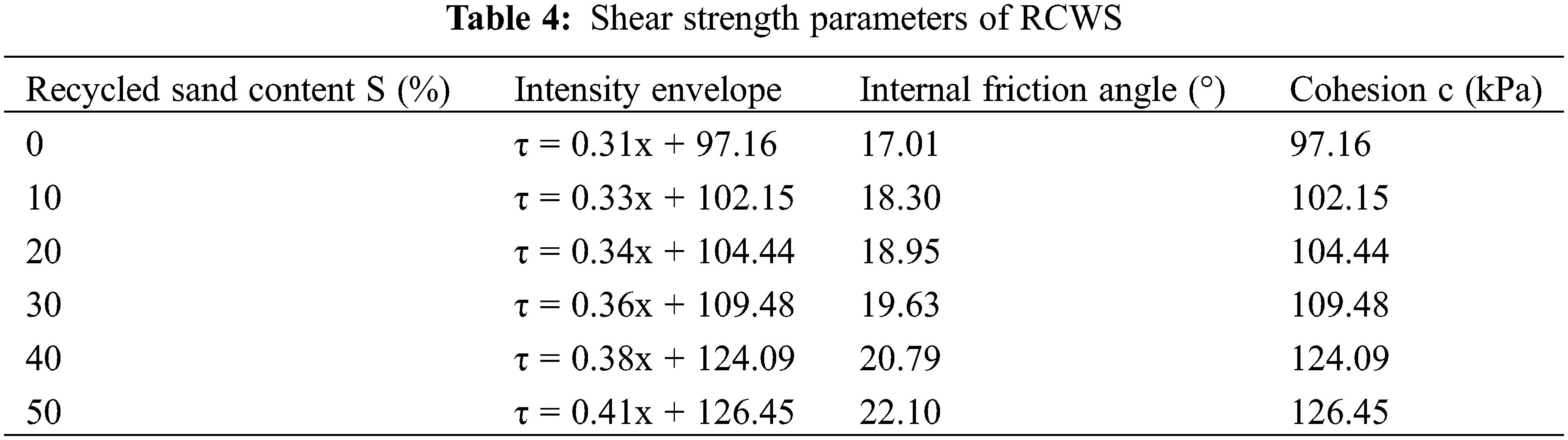

In order to further explore the strength increase mechanism of RCWS, RCWS samples with different recycled sand contents were tested by SEM, using three different magnifications of 500 times, 2000 times and 5000 times. Fig. 4 shows the SEM images of RCWS samples at 2000 and 5000 times magnification.

As shown in Figs. 6a and 6b, RCWS samples with 0% recycled sand content have a large number of relatively large pores. The hydration product C-S-H gel content is less, the connection between the sample unit is poor, and the whole sample is relatively discrete. Figs. 6c and 6d show the SEM images of RCWS samples with 50% recycled sand content. It can be clearly seen that there are only small cracks in the RCWS samples, the pores are significantly reduced. In addition, there are a large number of cement-coated recycled sand particles in the pores of the sample, which form more effective bonding through the acicular C-S-H gel, and the connection between the units is denser. The overall structure is significantly improved compared with the RCWS sample with 0% recycled sand content, so the strength has increased significantly [26]. At the same time, small-size recycled sand particles fill the tiny pores in the sample to make the structure denser, thereby improving its shear strength.

Figure 6: SEM microstructure of RCWS with different recycled sand contents (a) S = 0%, 2000 times, (b) S = 0%, 5000 times, (c) S = 50%, 2000 times, (d) S = 50%, 5000 times

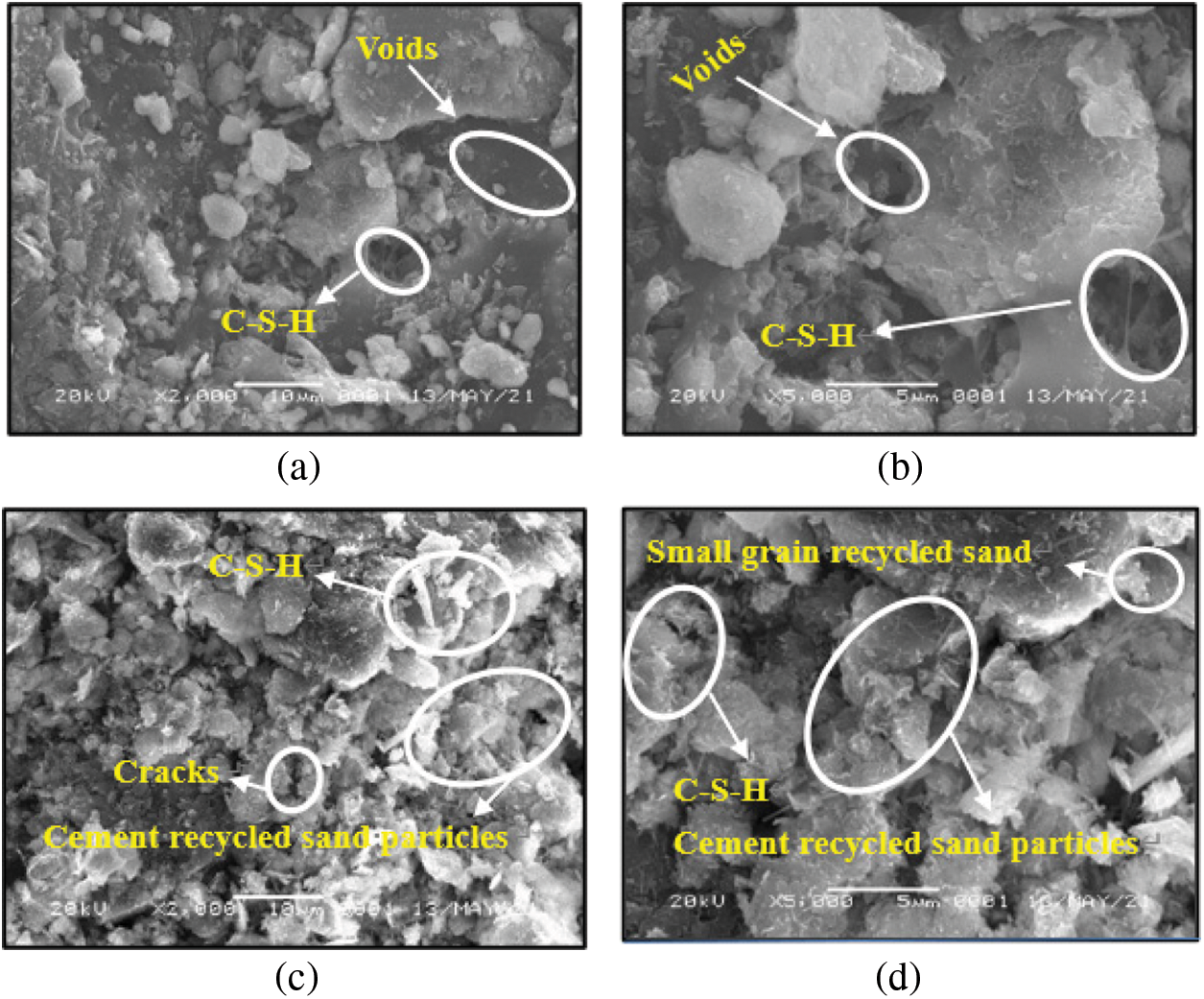

In order to further quantitatively analyze the void ratio of RCWS samples, the SEM images of six groups of RCWS samples under three magnifications were binarized to obtain a black and white binarization image, and the void ratio was obtained by weighted average, as shown in Fig. 7 [27]. Fig. 7 shows that the void ratio of RCWS samples with 0% recycled sand content is the largest, which is 29%. With the increase of recycled sand content, the void ratio of RCWS samples gradually decreases. When the recycled sand content is 50%, the void ratio reaches the minimum value of 5.9%, which is 79.7% lower than that with 0% recycled content. With the increase of recycled sand content, the void ratio of RCWS samples decreases obviously mainly because when the recycled sand is not added, the fluidity of the slurry prevents the cement from having a good bonding effect, so there is a large number of pores. The incorporation of recycled sand makes the slurry to contain solid particles of different sizes, which can be cemented with clay and cement in the slurry to form a compact structure, and the friction and bite force between the recycled sand particles are also beneficial to improve the compactness of CWS. With the increase of recycled sand content, the effect of cementation, the friction between particles and the bite force becomes greater. The higher recycled sand content with a relatively small particle size is also conducive to filling the pores and further reducing the void ratio of RCWS samples.

Figure 7: Comparison chart of void ratio of RCWS samples

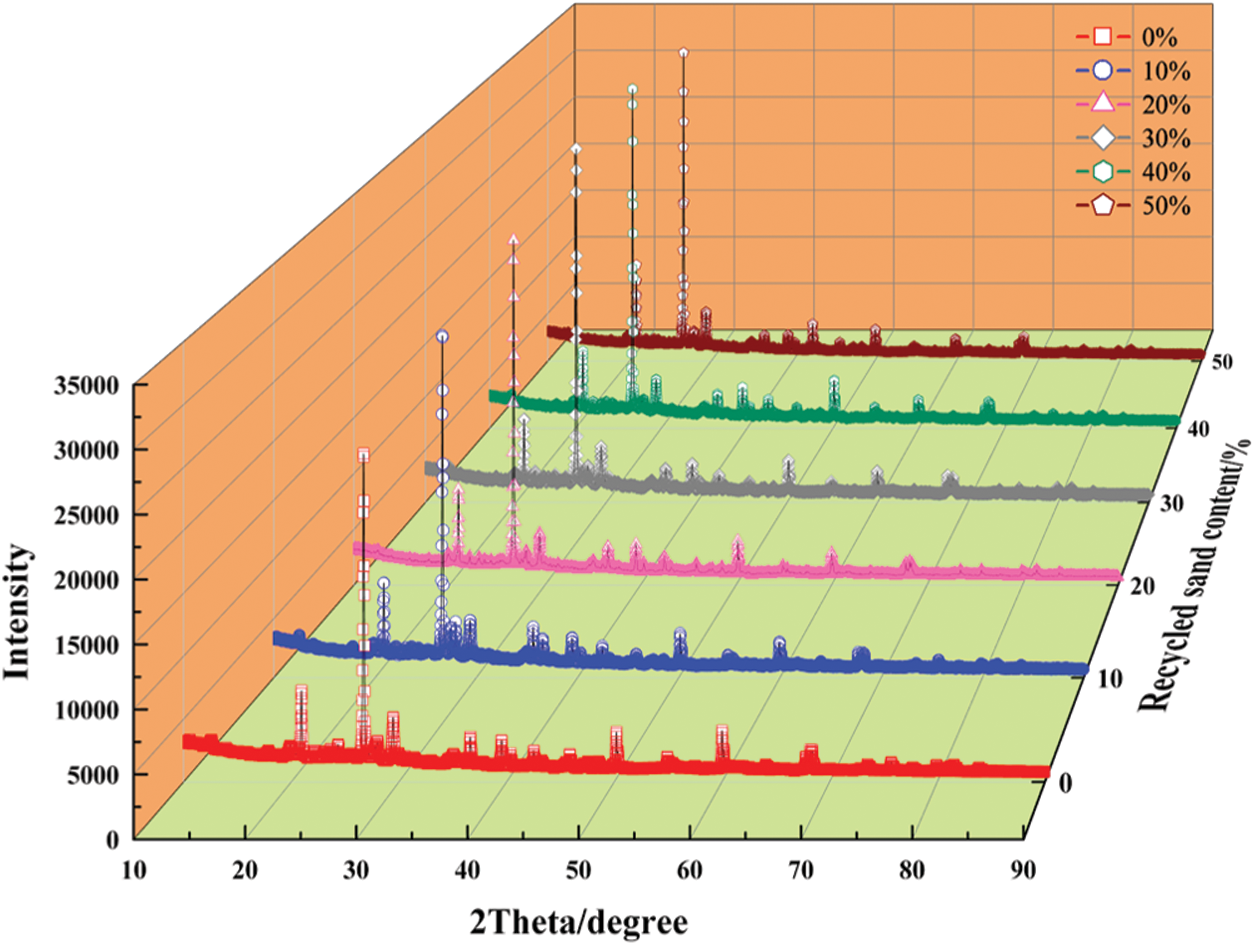

Fig. 8 shows the XRD patterns of RCWS samples with different recycled sand contents. The incorporation of recycled sand has no obvious effect on the diffraction peak intensity of cement hydration product CH crystals in CWS. The main reason is that recycled sand mainly plays a skeleton role in CWS and cannot react with cement and its hydration products. Thus, it will not have a great influence on the content of CH crystals in CWS.

Figure 8: XRD pattern of RCWS

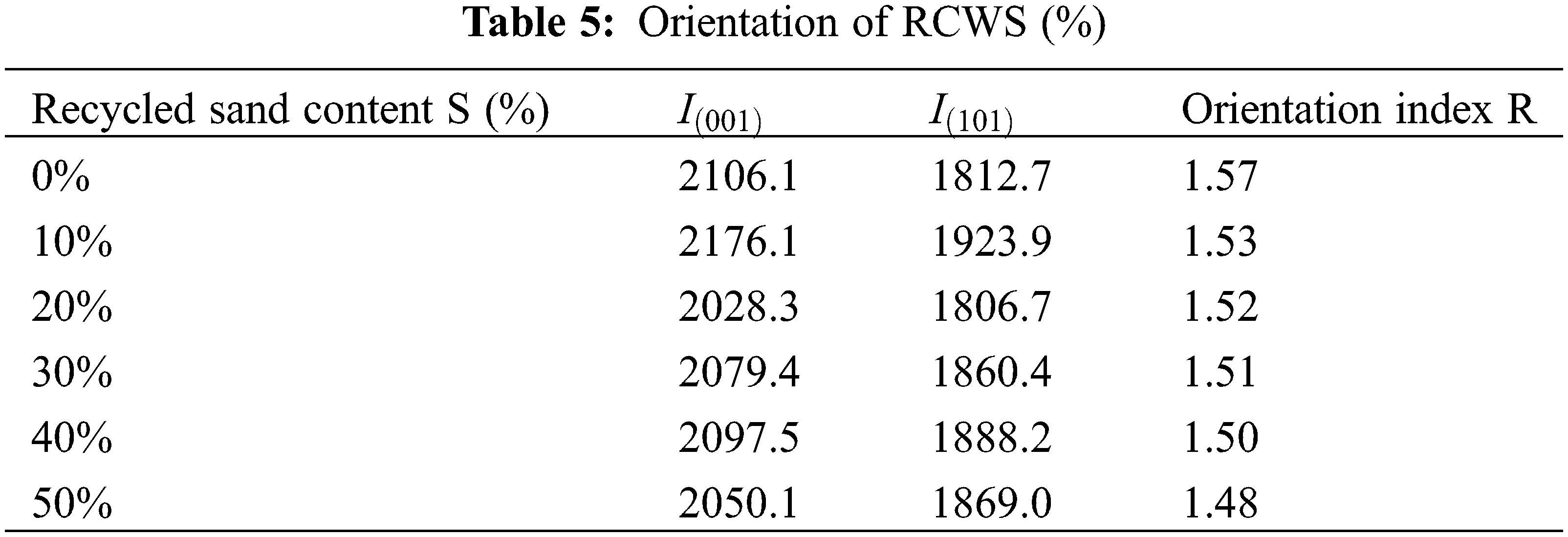

Grandet and Ollivier proposed the concept of CH crystal orientation index to evaluate the interfacial properties of cement-based composites [28]. The main hydration products of cement-based materials are needle-shaped hydrated calcium silicate (C-S-H gel) and plate-shaped calcium hydroxide crystals (CH crystals). Taking the (101) and (001) crystal planes of CH crystals as reference planes, the growth and structural compactness of cement-based CH crystals can be revealed by the orientation index. The lower the orientation index, the denser the material structure. The mathematical expression of the orientation index R of CH crystal is shown in Eq. (1) [29]:

where, R represents the orientation index of CH crystal, I(001) represents the diffraction peak intensity of CH (001) crystal plane, and I(101) represents the diffraction peak intensity of CH (101) crystal plane. Table 5 shows the orientation index of RCWS.

It can be seen from Table 5 that the incorporation of recycled sand has a greater impact on the orientation index of CH crystals of cement hydration products in CWS. With the increase of recycled sand content, the orientation index of RCWS samples shows a downward trend, and the overall trend is relatively slow. When the recycled sand content is 50%, the orientation index reaches the minimum value of 1.48; compared with RCWS samples with 0% recycled sand content, the orientation index decreases by 5.73%. This indicates that the incorporation of recycled sand can promote the growth of CH crystals to a certain extent. This is because recycled sand improves the particle gradation of CWS, increases the density of CWS, and then promotes the growth of CH crystals, making RCWS samples denser. This also can be further explained through UU test that recycled sand can significantly improve the shear strength of RCWS samples. At the same time, this is highly consistent with the void ratio change measured by SEM test.

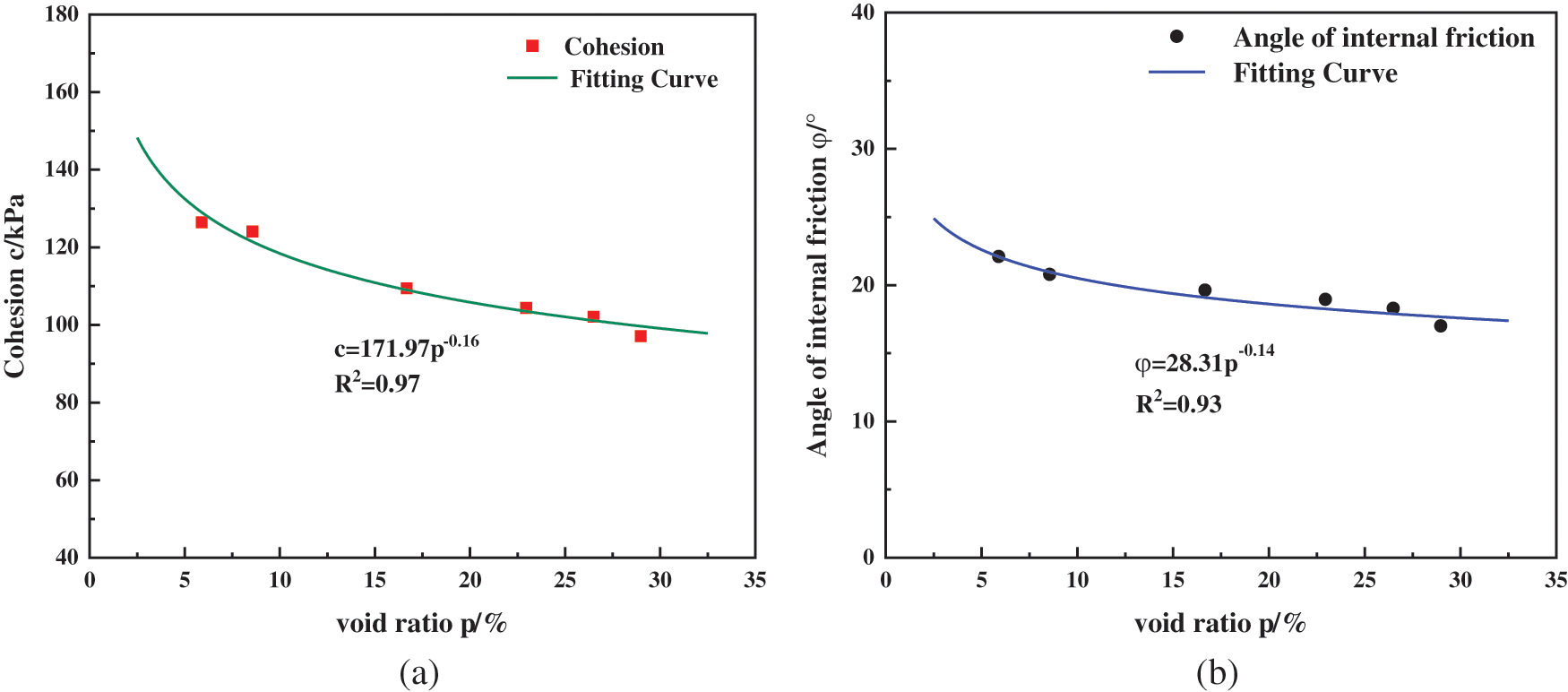

The above analysis shows that SEM test can qualitatively explain the influence of void ratio change caused by different recycled sand content on the shear strength parameters of cohesion and internal friction angle of RCWS samples, but it is still not enough to provide a design reference for engineering applications. For this reason, it is necessary to further establish an empirical formula between void ratio and shear strength parameters for quantitative description. The shear strength parameters in Table 4 are mathematically fitted, and the fitting results are shown in Fig. 9. The mathematical equation of cohesion and void ratio of RCWS samples is shown in Eq. (2), and the mathematical equation of internal friction angle and void ratio is shown in Eq. (3), where:

It can be seen from the fitting results that the cohesion, internal friction angle and void ratio of RCWS samples all have a power function relationship with negative exponents. The fitting results are in good agreement with the measured data, which can provide a good mathematical description for the change law of the shear strength parameters of RCWS samples.

Figure 9: Shear strength parameter and void ratio fitting curve, (a) Cohesion and void ratio, (b) Angle of internal friction and void ratio

1. The deviatoric stress–strain curve of pure CWS samples is strain hardening type. With the increase of recycled sand content, the deviatoric stress–strain curve of RCWS samples gradually transforms to the softening type. The peak stress of RCWS samples increases with the increase of recycled sand content. When the confining pressure is 100 kPa, 200 kPa, 300 kPa, and 400 kPa, the peak stress increases by 46.6%, 40.6%, 44.3% and 45.6% of the RCWS sample with 0% recycled sand content, respectively, which has a larger increase. The incorporation of recycled sand can increase the cohesion and internal friction angle of RCWS samples at the same time. When the recycled sand content is 50%, the cohesion and internal friction angle reach the maximum. Compared with the RCWS sample containing 0% recycled sand, the cohesion and internal friction angle are increased by 30.1% and 29.9%, respectively.

2. With the increase of recycled sand content, the porosity of the RCWS sample gradually decreases. When S = 50%, the porosity reaches the minimum value, which is 79.7% lower than the porosity of S = 0%. The incorporation of recycled sand can effectively reduce the void ratio of CWS samples, thereby improving the shear strength parameters of RCWS samples. It broadens the application scope of waste building slurry as recycled engineering materials.

3. The internal friction angle, cohesion and void ratio of RCWS samples all have a power function relationship with negative exponents. The increase of recycled sand content does not significantly increase the content of CH crystals of cement hydration product, but it has a certain effect on the orientation index. The orientation index of RCWS samples decreases with the increase of recycled sand content. When the recycled sand content is 50%, the orientation index reaches the minimum value. Compared with the RCWS sample when the recycled sand content is 0%, the orientation index decreases by 5.73%. The more the recycled sand content is, the denser the RCWS sample is.

1. Only consider the impact of recycled sand content on the mechanical properties of CWS when the cement content is 20% under the short age of 7 d. The mechanical properties of RCWS under different cement content and longer ages such as 28 d and 56 d have yet to be followed research.

2. This study only explores the mechanical properties of RCWS specimens under UU test conditions, and the mechanical properties of RCWS specimens under CU and CD conditions are yet to be studied.

Authors’ Contribution: Conceptualization, B.L.; formal analysis, N.L.; investigation, H.K.; writing—original draft preparation, Y.W.; writing—review and editing, W.W.

Funding Statement: This research was funded by the National Natural Science Foundation of China (41772311, 52179107), College Student Xinmiao Plan of Zhejiang Province (15002001007), and Student Research Fund Funded Project of Shaoxing University.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Liang, Z., Yang, C., Gao, H., Wu, Z. (2016). Experimental study on rapid separation between water and slurry from construction engineering. Journal of Southeast University (Natural Science Edition), 46(2), 427–433. DOI 10.3969/j.issn.1001-0505.2016.02.031. [Google Scholar] [CrossRef]

2. Gao, S., Chen, Y., Chen, L., Cheng, X., Chen, G. (2018). Experimental and field study on treatment waste mud by in-situ solidification. Proceedings of the Institution of Civil Engineers—Municipal Engineer, 173(4), 237–245. DOI 10.1680/jmuen.18.00021. [Google Scholar] [CrossRef]

3. Chen, Y., Wang, J., Han, J. (2014). Research on the solidification treatment technology of Hainan red clay waste mud. Natural Science Journal of Hainan University, 32(1), 74–79. DOI 10.15886/j.cnki.hdxbzkb.2014.01.012. [Google Scholar] [CrossRef]

4. Peng, L., Chen, B. (2021). Study on the basic properties and mechanism of waste sludge solidified by magnesium phosphate cement containing different active magnesium oxide. Construction and Building Materials, 281, 122609. DOI 10.1016/j.conbuildmat.2021.122609. [Google Scholar] [CrossRef]

5. Zhang, W., Chen, Y., Zhao, L., Chen, L. (2017). Mechanical behavior and constitutive relationship of mud with cement and fly ash. Construction and Building Materials, 150(5), 426–434. DOI 10.1016/j.conbuildmat.2017.05.163. [Google Scholar] [CrossRef]

6. Shi, Z., Xue, D., Peng, M., Chen, Y. (2018). Experiment on modified-curing and strength properties of waste mud from slurry shield tunnel. Journal of Engineering Geology, 26(1), 103–111. DOI 10.13544/j.cnki.jeg.2018.01.012. [Google Scholar] [CrossRef]

7. Cheng, Q., Han, B., Zhou, W., Zhu, X., Chen, X. (2020). Triaxial tests study on lime-stabilized disposal mud. Science Technology and Engineering, 20(15), 6191–6195. DOI 10.3969/j.issn.1671-1815.2020.15.043. [Google Scholar] [CrossRef]

8. Xiao, J. (2018). Recycled aggregate concrete. In: Recycled aggregate concrete structures, pp. 65–98. Berlin, Heidelberg: Springer. [Google Scholar]

9. Zou, S., Xiao, J., Ding, T., Duan, Z., Zhang, Q. (2021). Printability and advantages of 3D printing mortar with 100% recycled sand. Construction and Building Materials, 273, 121699. DOI 10.1016/j.conbuildmat.2020.121699. [Google Scholar] [CrossRef]

10. Li, L., Zhan, B. J., Lu, J., Poon, C. S. (2019). Systematic evaluation of the effect of replacing river sand by different particle size ranges of fine recycled concrete aggregates (FRCA) in cement mortars. Construction and Building Materials, 209, 147–155. DOI 10.1016/j.conbuildmat.2019.03.044. [Google Scholar] [CrossRef]

11. Ozbakkaloglu, T., Gholampour, A., Xie, T. (2018). Mechanical and durability properties of recycled aggregate concrete: Effect of recycled aggregate properties and content. Journal of Materials in Civil Engineering, 30(2), 04017275. DOI 10.1061/(ASCE)MT.1943-5533.0002142. [Google Scholar] [CrossRef]

12. Bao, J., Li, S., Peng, Z., Zhao, T. (2020). Effect of recycled coarse aggregate after strengthening by silane impregnation on mass transport of concrete. Acta Materiae Compositae Sinica, 37(10), 2602–2609. DOI 10.13801/j.cnki.fhclxb.20200316.002. [Google Scholar] [CrossRef]

13. Xiao, J., Lu, D., Ying, J. (2013). Durability of recycled aggregate concrete: An overview. Journal of Advanced Concrete Technology, 11(12), 347–359. DOI 10.3151/jact.11.347. [Google Scholar] [CrossRef]

14. Ying, J., Zhou, B., Xiao, J. (2017). Pore structure and chloride diffusivity of recycled aggregate concrete with nano-SiO2 and nano-TiO2. Construction and Building Materials, 150, 49–55. DOI 10.1016/j.conbuildmat.2017.05.168. [Google Scholar] [CrossRef]

15. Nepomuceno Miguel, C. S., Isidoro Rui, A. S., Catarino José, P. G. (2018). Mechanical performance evaluation of concrete made with recycled ceramic coarse aggregates from industrial brick waste. Construction and Building Materials, 165, 284–294. DOI 10.1016/j.conbuildmat.2018.01.052. [Google Scholar] [CrossRef]

16. Siempu, R., Pancharathi, R. K. (2018). Pull-out behaviour of recycled aggregate based self compacting concrete. Computers and Concrete, 21(3), 249–259. DOI 10.12989/cac.2018.21.3.249. [Google Scholar] [CrossRef]

17. Fan, Y., Niu, H., Zhang, X. (2020). Impact of the properties of old mortar on creep prediction model of recycled aggregate concrete. Construction and Building Materials, 239(1), 117772. DOI 10.1016/j.conbuildmat.2019.117772. [Google Scholar] [CrossRef]

18. Ge, X., Chu, H. (2020). Mechanical properties of ultra-high performance concrete with recycled sand. Journal of Building Materials, 23(4), 810–815. DOI 10.3969/j.issn.1007-9629.2020.04.011. [Google Scholar] [CrossRef]

19. Ministry of Water Resources of People’s Republic of China (2019). Standard for geotechnical testing method. GB/T50123-2019. [Google Scholar]

20. Yan, C., Long, Z., Zhou, Y., Kuang, D., Chen, J. (2020). Investigation on the effects of confining pressure and particle size of shear characteristics of calcareous sand. Rock and Soil Mechanics, 41(2), 581–591+634. DOI 10.16285/j.rsm.2019.0346. [Google Scholar] [CrossRef]

21. Song, X. (2010). Study on determination of permeability coefficient of cement soil based on conventional triaxial apparatus. Jianghuai Water Resources Science and Technology, 30(6), 19–21, 25. DOI 10.3969/j.issn.1673-4688.2010.06.009. [Google Scholar] [CrossRef]

22. Miu, L. (2012). Mechanical properties of soft soil and engineering practice. Beijing: Science Press. [Google Scholar]

23. Wu, Y., Wei, X., Tang, J. (2018). Effects of initial water content and sand content on dredger fill settlement. Journal of Shanghai University (Natural Science), 24(2), 278–286. DOI 10.12066/j.issn.1007-2861.1798. [Google Scholar] [CrossRef]

24. Liu, P., Xiao, S., Wang, Q. (2005). Mechanism of improvement of dredger fill serous fluid with additive. Journal of Engineering Geology, 2005(2), 285–288. DOI 10.3969/j.issn.1004-9665.2005.02.027. [Google Scholar] [CrossRef]

25. Fang, L. I. (2018). Experimental analysis of the influence of sand content on the Duncan-Chang model parameters of cement mortar pile. Journal of Railway Science and Engineering, 15(3), 645–650. DOI 10.19713/j.cnki.43-1423/u.2018.03.014. [Google Scholar] [CrossRef]

26. Sun, H., Wang, W., Ling, D. (2021). Mechanical properties and microstructure of solidified soil with low cement content. Journal of ZheJiang University (Engineering Science), 55(3), 530–538. DOI 10.3785/j.issn.1008-973X.2021.03.013. [Google Scholar] [CrossRef]

27. Wang, W., Liu, J., Li, N., Ma, L. (2022). Mechanical properties and micro mechanism of Nano-SiO2 modified coastal cement soil at short age. Acta Materiae Compositae Sinica, 39, 1–16. DOI 10.13801/j.cnki.fhclxb.20210702.001. [Google Scholar] [CrossRef]

28. Grandet, J., Ollivier, J. (1980). Etude de la formation du monocarboaluminate de calcium hydrate au contact d’un granulat calcaire dans une pate de ciment portland. Cement and Concrete Research, 10(6), 759–770. DOI 10.1016/0008-8846(80)90004-6. [Google Scholar] [CrossRef]

29. Liu, J., Fu, J., Yang, Y., Gu, C. (2019). Study on dispersion, mechanical and microstructure properties of cement paste incorporating graphene sheets. Construction and Building Materials, 199(6), 1–11. DOI 10.1016/j.conbuildmat.2018.12.006. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |