| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.019989

ARTICLE

Study on the Structural Characteristics and Physical and Mechanical Properties of Phoebe bournei Thinning Wood

College of Materials Science and Engineering, Central South University of Forestry and Technology, Changsha, 410004, China

*Corresponding Author: Jianying Xu. Email: xujykyoto@163.com

Received: 28 October 2021; Accepted: 06 December 2021

Abstract: The artificial afforestation of precious Phoebe bournei has been carried out in China. During the cultivation process, thinning wood will be produced. The properties of thinning wood might vary greatly with matured wood and require evaluation for better utilization. The objective of the present study aims to determine the wood structure, fiber morphology, and physical and mechanical properties of the Phoebe bournei thinning wood to help us understand the wood properties and improve its utility value. Three 14-year-old Phoebe bournei were cut from Jindong Forestry Farm of Hunan Province, China. The wood structure and fiber morphology were observed and analyzed with a light microscope and scanning electron microscope. The physical and mechanical properties were tested according to the Chinese national standards. The results showed as follows: (1) The Phoebe bournei thinning wood has a beautiful wood figure and fine texture, whereas the heartwood has not yet formed. (2) It is a diffuse-porous hardwood with small and less pores as well as fine wood rays. (3) The wood fiber is medium length and extremely thin wall thickness. (4) It is low in density and has excellent dimensionally stability. (5) The wood mechanical properties belong to the low to medium class and the comprehensive strength of wood belongs to the medium-strength class. It is concluded that Phoebe bournei thinning wood is suitable for wood carving, handicraft, high-end furniture, and decorative furniture parts.

Keywords: Phoebe bournei; thinning wood; wood structure; fiber morphology; physical and mechanical property

Wood is a renewable biomass material. It has many excellent characteristics and has been widely used for thousands of years. There are many kinds of wood that differ in structure and properties. Some precious wood posse high strength and beautiful pattern, while other ordinary woods are not. Because of the limited availability of precious wood, people on one hand modify the ordinary wood materials to improve the strength and appearance to increase their utilization value [1–3], and on the other hand, carry out artificial cultivation of precious tree species (Phoebe bournei, Cyclobalanopsis glauca, etc.) to increase the yield of precious wood.

Phoebe bournei is an evergreen tree in the Lauraceae family, and one of the important species in subtropical broad-leaved forests. There are more than 100 species of Phoebe genus worldwide, of which 34 species (including Phoebe bournei) are distributed in China [4,5]. Historically, the Phoebe wood was one of the “Four Famous Woods” in the South of Yangzi River [4]. It has been extensively used in the manufacture of precious furniture and palace columns in the Ming and Qing dynasties [6]. The most famous and valuable Phoebe wood is called “wood with golden wire”, which comes from Phoebe bournei, Phoebe chekiangensis, Phoebe sheareri, Phoebe zhennan, and Phoebe lichuanensis [7], Phoebe bournei is mainly distributed in Hunan, Guizhou, Hubei, Jiangxi, Fujian, Zhejiang and other provinces in China [8]. Phoebe bournei is tall and straight, with a fragrant odor. It is an excellent material for high-end architecture, high-quality furniture, and carving craft attributed to its fine texture, wonderful dimensional stability, and resistance to insects and corrosion [9]. Moreover, the Phoebe bournei wood extractive has an inhibitory effect on leukemia, breast, and colon cancer cells [10]. Because of its huge economic value, Phoebe bournei has been a favorite tree species for a long time so that its wild resources have been destroyed extremely seriously [11]. It is currently protected as a rare and endangered secondary plant species in China and is on the IUCN Red List of Threatened Species, Near Threatened [12,13].

Phoebe bournei is a favorite wood material, however, its natural resources are scarce. In recent years, the artificial afforestation of Phoebe bournei has been carried out in the south of China. To improve the growth rate, some trees were cut to adjust the growth density of standing trees and improve wood quality, and thinning wood will be thus produced in this process. Thinning wood of common tree species is mainly used for wood-based panels production and papermaking [14]. Nevertheless, Phoebe bournei is a precious wood with excellent wood characteristics and high economic value. We need to make better use of it to increase its added value. Therefore, it is essential to understand the properties of Phoebe bournei thinning wood. So far, most studies in the field of Phoebe bournei have only focused on population structure [15], cultivation [16], and afforestation technology [17], and only very few on the wood properties. Chen et al. [18,19] studied its anatomical structure and fiber morphology variation, and Jiang et al. [20] studied the physical and mechanical properties of Phoebe bournei wood from both plantation and natural forest. Unfortunately, research on thinning wood of Phoebe bournei has not yet been reported. The value of wood is usually governed by its properties, such as texture, structure, density, strength and dimensional stability, etc. Accordingly, the anatomical structure, fiber morphology, and physical and mechanical properties of Phoebe bournei thinning wood were evaluated to increase its added value.

Three 14-year-old Phoebe bournei trees (10–12 cm of diameter at breast height) were cut from Jindong Forestry Farm of Hunan Province at 112°02′27″ to 112°07′01″ E and 26°8′45″ to 26°12′27″ N, which belongs to central subtropical southeast monsoon humid climate zone, with an annual average temperature of 16.3°C–17.7°C. The average sunshine time is 159.9 h, and the average annual precipitation is 1600–1900 mm. The blocks (1.8 m long) from breast height (1.3 m) upward to approximately 3.1 m height were cut for test material (except the material for testing fiber morphology, which is cut from the butt end of the log). All blocks were further shortened to about 600 mm long and stacked in a laboratory to dry naturally. A 30-year-old Cunninghamia (Chinese fir, a fast-growing tree species, its wood has been widely used in China) was cut for mechanical properties comparison.

2.2.1 Macrostructure Characteristics

The cross surface, radial surface, and tangential surface of Phoebe bournei thinning wood were sawn and planed to get smooth surfaces for macroscopic structure analysis. The color, luster, wood figure, texture, growth ring, and ray were observed under the naked eye. The annual ring width was measured (total ring width/ring number) according to the Chinese national standard GB/T 1930-2009 [21].

First of all, three 10 mm × 10 mm × 10 mm (R × T × L, radial × tangential × longitudinal) wood cubes from different positions of the wood were heated for about 80 min to soften. The cross section, radial section, and tangential section (10–15 μm thickness) of the Phoebe bournei cubes were cut with a sliding microtome (G.S.L.1, Switzerland). Subsequently, the sections were stained with 1% safranin solution for 10 h and were dehydrated using 50%, 70%, 85%, 95%, and 100% gradient ethanol for a few seconds. Finally, washed with 50% xylene, and mounted with a drop of Canada balsam to make permanent sections. After drying, the anatomical features were observed with a light microscope (Nikon H550S, Nikon Corporation, Tokyo, Japan). Anatomical features such as the diameter of the pores, the height and width of the rays, and proportions of vessels, fibers, rays, and axial parenchyma were measured by Image J software (National Institutes of Health, Bethesda, MD, USA).

The pore diameter, vessel wall thickness, and the width of the wood ray were measured on the cross section. The heights of wood rays were measured on the tangential section. The pores density (pores/mm2) and rays per millimetre were counted on the cross section and tangential section, respectively. The proportion of cell type was calculated on the cross section. The area of vessels, fibers, rays, axial parenchyma cells, and the image area were measured by Image J. The ratio of each type of wood cell area to the image area is the proportion of this cell type.

For the Scanning Electron Microscope (SEM) test, 2-mm thick wood slices in the cross, radial, and tangential directions were prepared and dried. Subsequently, the slices were coated with gold in an anion sputter coater (Quorumsc7620, Beijing, China) and were vacuumed. Finally, the slices were observed under a Scanning Electron Microscope (Zeiss sigma 300, Oberkochen, Germany) and the element composition of spherical material in wood rays was analyzed by Energy Dispersive Spectrometer (EDS) (Smart EDX, EDAX Inc., USA).

2.2.3 Fiber Morphology and Radial Variation

A 3-cm thick disc was taken from the butt-end of 14-year-old Phoebe bournei thinning wood, and a wood piece was then cut from the pith to the bark. Wooden sticks were collected in each odd-numbered annual ring (1, 3, 5, 7, etc.) and were boiled in separate test tubes until they were softened. Then nitric acid (30%) was added for further softening. Rinsed with distilled water until neutral, the samples were separated into fibers by shaking. Finally, temporary sections were made and the fiber morphology of the Phoebe bournei thinning wood was observed and analyzed with the light microscope.

The fiber length, fiber width, and fiber lumen diameter were measured (50 fibers were measured for each sample) by the Image J software. The fiber wall thickness (fiber width–fiber lumen), fiber length to width ratio, and fiber wall to lumen ratio were calculated and various fiber morphology variation patterns were drawn.

2.2.4 Physical and Mechanical Properties

For physical property evaluation, the density (air-dry density, oven-dry density, basic density), shrinkage rate, and swelling rate of Phoebe bournei thinning wood were tested, respectively, according to GB/T 1933-2009, GB/T 1932-2009, and GB/T 1934.2-2009 [22–24]. The dimensions of all specimens above are 20 mm × 20 mm × 20 mm (R × T × L) and the number of specimens is 12 for each property.

The air-dry density and oven-dry density of wood are the density in the air-dry state (25°C, 65% RH to achieve a constant weight) and oven-dry state, respectively. Basic density is the ratio of the weight of the oven-dried specimen to the volume of the water-saturated specimen. Shrinkage rates (radial, tangential, and volumetric) include air-dry shrinkage (from water-saturated state to air-dry state) and oven-dry shrinkage (from water-saturated state to oven-dry state). Swelling rates (radial, tangential, and volumetric) include oven-dry state to air-dry state and oven-dry state to water-saturated state.

The linear shrinkage (radial and tangential) was calculated according to (Ls–L0)/Ls, where Ls is the dimensions of the water-saturated or air-dried specimen in a given direction (radial or tangential), L0 is the distance between the same points of the specimen at oven-dry state. Volumetric shrinkage was determined according to (Vs–V0)/Vs, where Vs is the volume of the specimen in an air-dry or water-saturated state, V0 is the volume of the specimen at the oven-dry state. The linear swelling rate (radial and tangential) was calculated according to (Lw–L0)/L0, where the Lw is the length of the air-dry or water-saturated specimen in a given direction (radial or tangential). The volumetric swelling rate was determined according to (Vw–V0)/V0, where Vw is the volume of the specimen at the air-dry or water-saturated state.

For the mechanical properties, the modulus of rupture (MOR), modulus of elasticity (MOE), compressive strength parallel to grain, shearing strength parallel to grain, and hardness were tested by the mechanical test machine (MWW-100, Naier Testing Machine Co., Ltd., Jinan, China) in accordance with GB/T 1936-2-2009 [25], GB/T 1936-1-2009 [26], GB/T 1935-2009 [27], GB/T 1937-2009 [28], and GB/T 1941-2009 [29]. 12 specimens with the dimensions of 20 mm × 20 mm × 300 mm (R × T × L) were prepared for both MOE and MOR tests. 12 specimens with the dimensions of 20 mm × 20 mm × 30 mm (R × T × L) were prepared for the compressive strength parallel to grain test, each 10 specimens of 40 mm × 20 mm × 35 mm (T × R × L, R × T × L) were prepared for shearing strength parallel to grain (tangential, radial) and 9 specimens of 50 mm × 50 mm × 70 mm (R × T × L) were prepared for the hardness test. After the mechanical properties were tested, a 20 mm × 20 mm × 20 mm cube was taken at the end of each specimen to test its moisture content and the test results of mechanical properties were adjusted to the value at 12% moisture content according to the relevant standards [25–29].

3.1.1 Macrostructure Characteristics

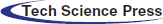

Fig. 1 is the cross surface, radial surface, and tangential surface of 14-year-old Phoebe bournei thinning wood.

Figure 1: The macrostructure of 14-year-old Phoebe bournei thinning wood (a) cross surface (b) radial surface (c) tangential surface

As shown in Fig. 1, the color of the Phoebe bournei thinning wood is yellowish-brown with greenish. On the cross surface (Fig. 1a), from the pith to the bark, the wood color is uniform and it is difficult to define the boundary of heartwood and sapwood. The growth ring is distinct under the naked eye. The shapes of growth rings are oval and round, and there exist false annual rings. The width of the growth rings decreased gradually from the pith to the bark, with an average of 4.99 mm. The transition from earlywood to latewood is gradual. Pores are invisible to the naked eye. The surface of the wood has a high luster. The planed wood surface is being felt something as smooth as silk to the touch. The wood rays are pronounced on the radial surface (Fig. 1b). The wood figure is beautiful and shows striking parabolic pattern on the tangential surface (Fig. 1c). The newly cut surface has a strongly fragrant odor. The wood grain is straight and the wood texture is fine.

3.1.2 Microstructure Characteristics

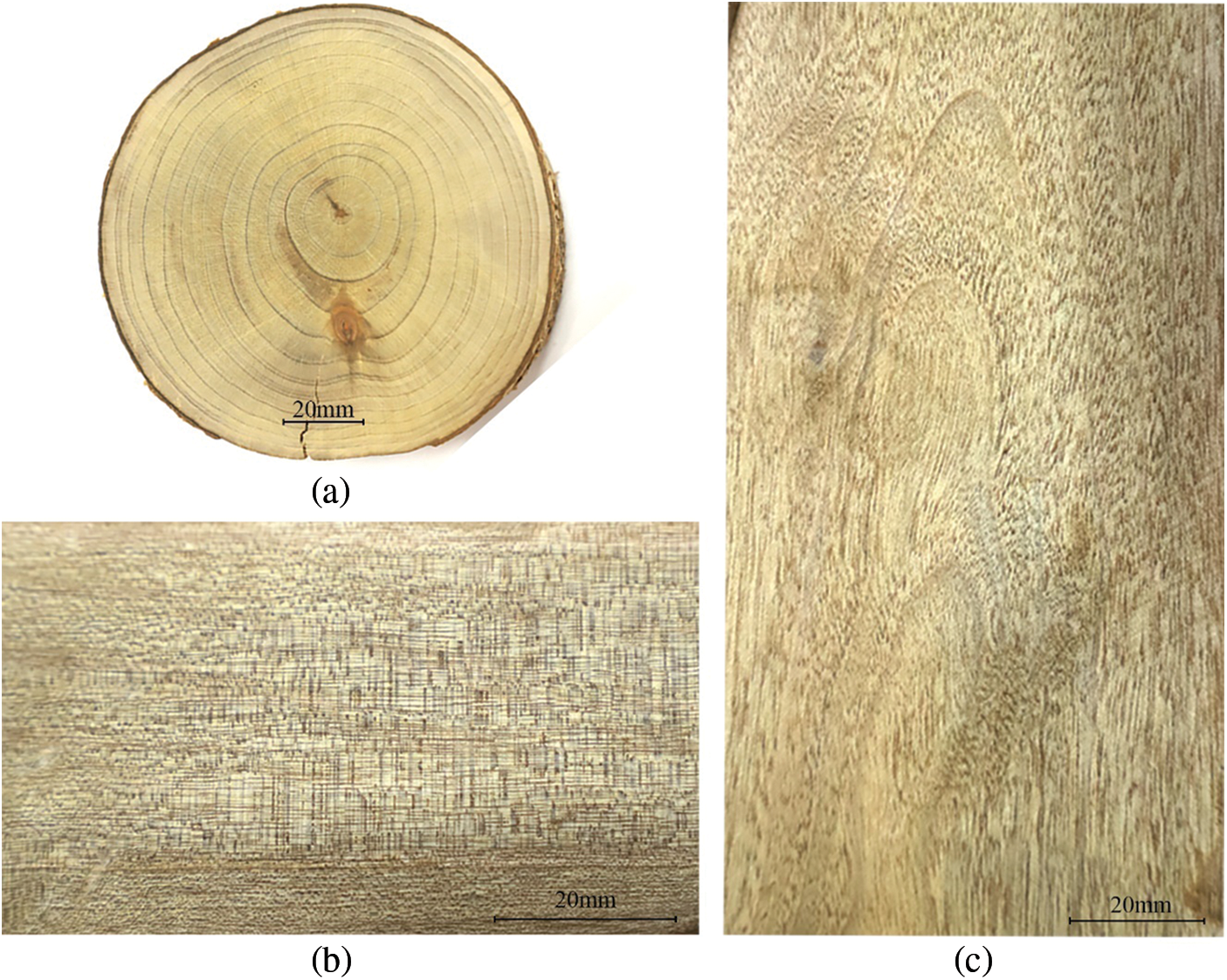

Like most hardwood, Phoebe bournei thinning wood is mainly composed of vessels, axial parenchyma, wood rays, and wood fibers. Fig. 2 is the cross, tangential and radial sections of the Phoebe bournei thinning wood, its microstructure characteristics were observed and analyzed with the light microscope.

Figure 2: Microscopic images of Phoebe bournei thinning wood: (a) Cross section (40×): solitary pore and multiple pores; (b) Cross section (100×): paratracheal parenchyma; (c) Cross section (200×): scalariform perforation of vessel element; (d) Radial section (40×): homogeneous rays; (e) Radial section (100×): heterogeneous rays with square marginal cells and recumbent cells; (f) Radial section (200×): scalariform pits between vessel and rays; (g) Tangential section (40×): wood rays of nonstoried structure; (h) Tangential section (100×): oil cells on the wood ray ends; (i) Tangential section (400×): alternate intervessel pitting

As shown in Fig. 2, the 14-year-old Phoebe bournei thinning wood is diffuse-porous. The vessels are mainly solitary pores and multiple pores, the clusters are occasionally seen (Figs. 2a and 2b). The pore shapes are mostly oval and circular (Figs. 2a and 2b). The pores density is around 19/mm2. The maximum tangential diameter of the pore is 111 μm, with an average of 72 μm. The vessel wall thickness is 5.163 μm and the proportion of vessels is 12.89%. Scalariform perforation of vessel element is observed in the pore of the cross section (Fig. 2c).

The axial parenchyma in the Phoebe bournei thinning wood is associated with the vessels. It is a paratracheal parenchyma (Figs. 2b and 2d) with the shape of oval and trapeziform on the cross section (Fig. 2b), and the proportion is 11.23%.

The proportion of rays is 10.24% and there are 7 rays per millimeter. The rays are mostly multiseriate heterogeneous rays (Figs. 2a, 2b and 2h) with rectangular, upright, and square cells (2e). The width of the uniseriate ray is 3–9 μm, with a mean of 6 μm, and the height of uniseriate ray is 54–179 μm, with the mean of 104 μm (2 to 5 cells). The width of the multiseriate rays is ranging from 14 to 37 μm (2 to 3 cells), with a mean of 22 μm. The height of the multiseriate rays is ranging from 81 to 726 μm (5 to 30 cells), with a mean of 275 μm. At the ends of wood rays, some oil cells are observed (Fig. 2h). Oil cell is a special kind of cell type found in the Lauraceae species, which may be related to its fragrant odor.

The wood fibers of the 14-year-old Phoebe bournei thinning wood are polygonal and circular in cross section, and the proportion is 64.83%. The fiber morphology would be illustrated in 3.2.

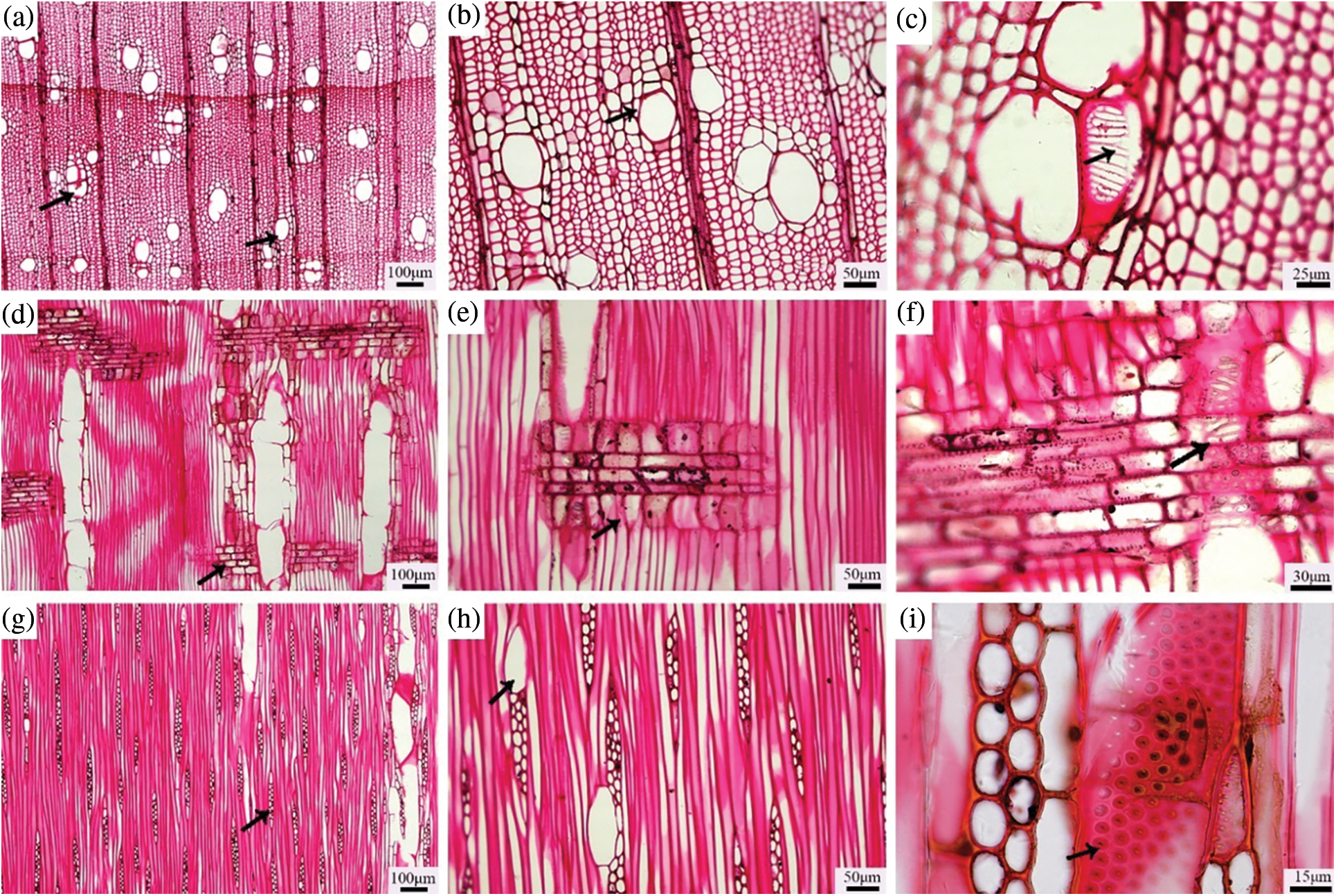

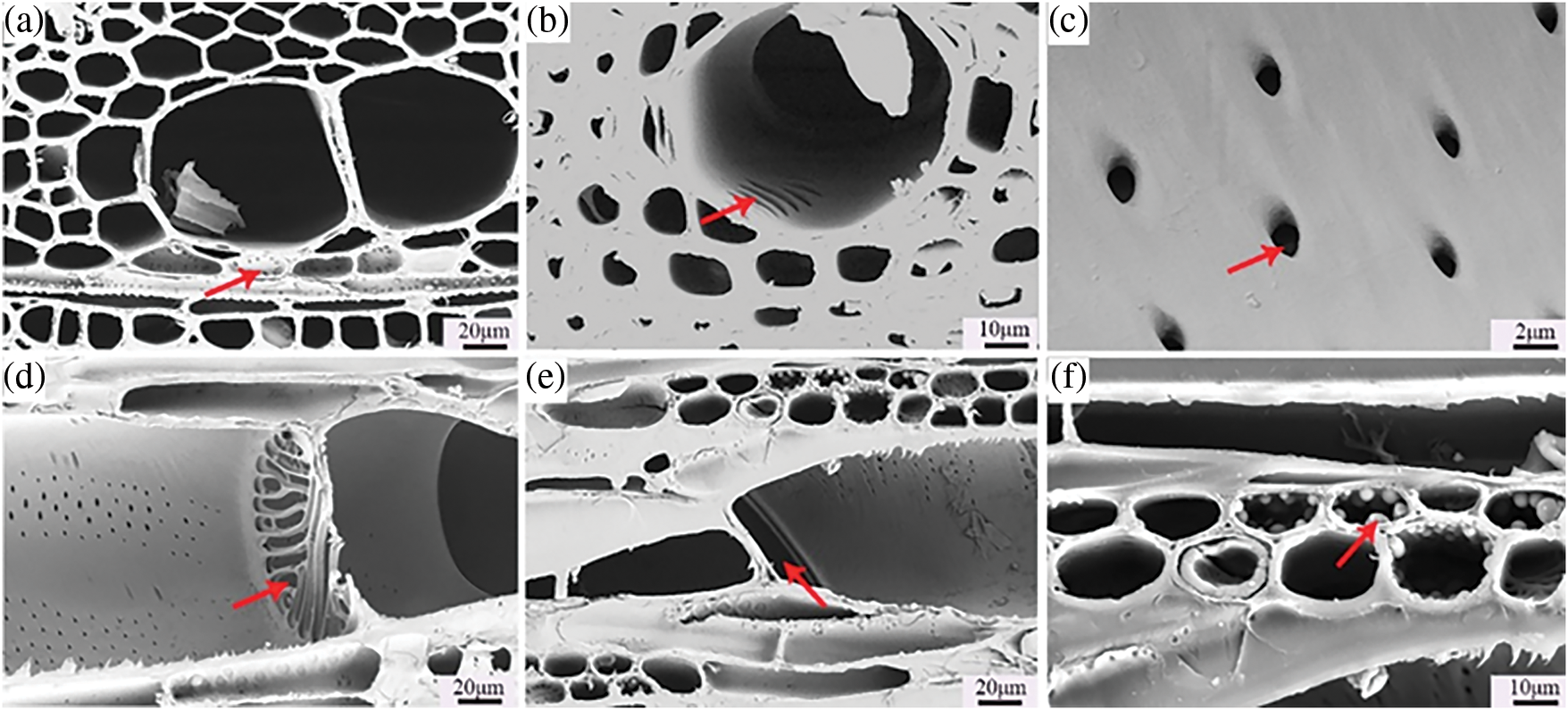

Fig. 3 is the ultramicrostructure of Phoebe bournei thinning wood observed by SEM. Vessels or pores, axial parenchyma, pits, rays, and perforations in the vessels are observed at different magnifications.

Figure 3: SEM images of 14-year-old Phoebe bournei thinning wood: (a) paratracheal axial parenchyma; (b) scalariform pits on the vessel wall; (c) included aperture in the fiber wall; (d) scalariform perforation in the vessel element; (e) simple perforation between the vessel elements; (f) starch granules in the ray cell

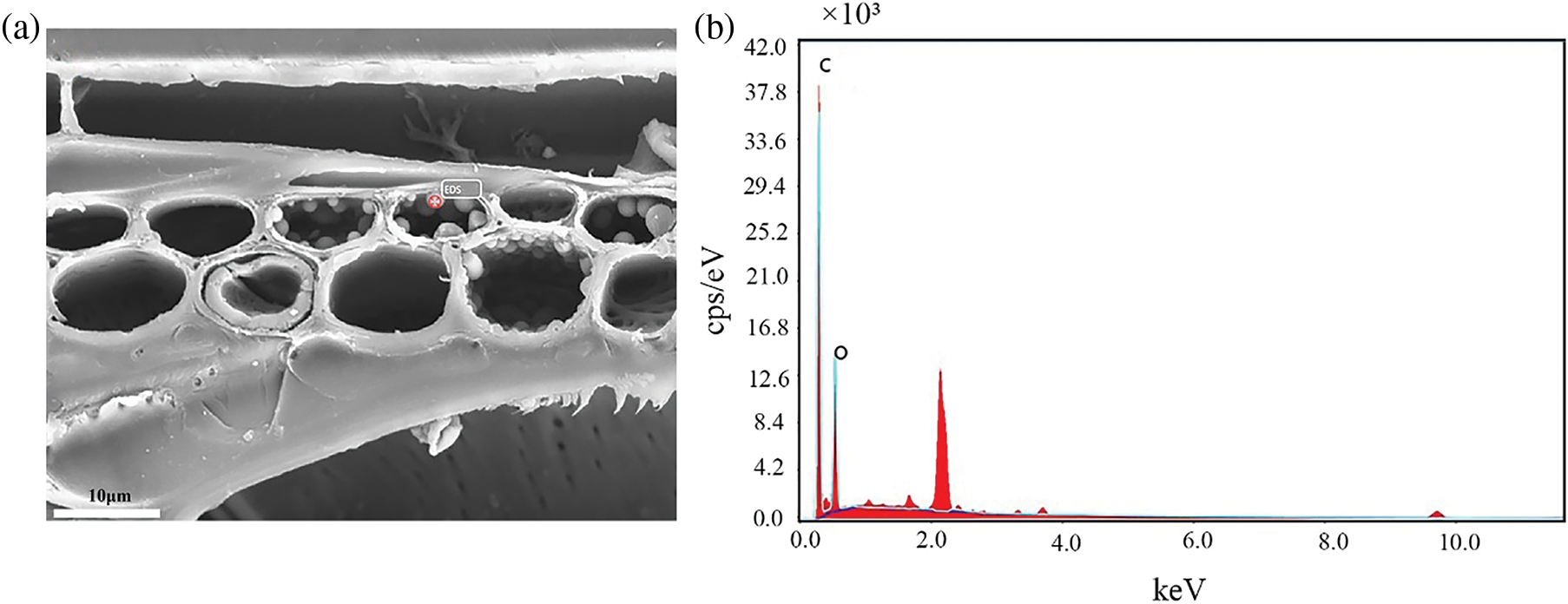

Paratracheal axial parenchyma (Fig. 3a) and scalariform pits (Fig. 3b) in the vessel wall are observed on the cross section. The pits in the fiber wall are included aperture (Fig. 3c). Scalariform perforation with bifurcate bars (Fig. 3d) and simple perforation (Fig. 3e) are observed in the vessel. Scalariform perforation is more primitive than simple perforation, the latter is evolved from the former when the bars on scalariform perforation fade away [30–32]. There are many spherical substances in the ray cells (Fig. 3f). The EDS analysis (Fig. 4) manifests that the main components of the spherical substances are carbon and oxygen, no calcium was detected, indicating that no calcium carbonate deposits are formed. According to the report by Seurfield et al. [33], these spherical substances might be some starch granules.

Figure 4: EDS analysis of the spherical substances in the ray cell: (a) SEM image and analysis point; (b) X-ray energy spectrum characteristics of the spherical substances in the ray cell

3.2 Wood Fiber Morphology and Radial Variation

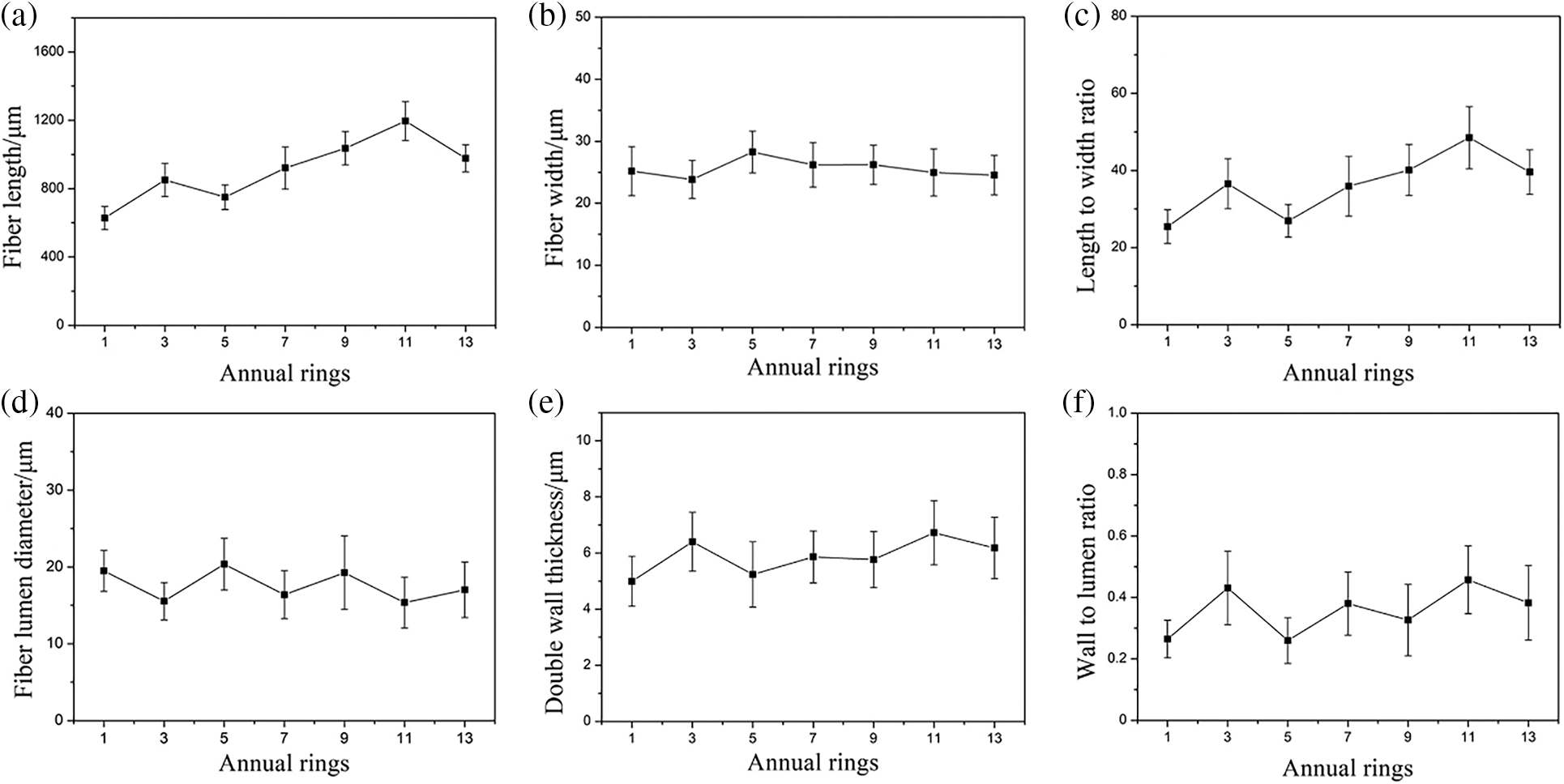

Wood fiber morphology characteristics, including fiber length, fiber width, fiber wall thickness, fiber lumen diameter, length to width ratio, and wall to lumen ratio are analyzed and the variation patterns are shown in Fig. 5. The average length, width, double wall thickness, and lumen diameter of all of the Phoebe bournei thinning wood fiber samples are 908.71, 25.60, 5.88, and 17.63 μm, respectively. The length to width ratio and wall to lumen ratio of fiber are 36.145 and 0.357, respectively.

Figure 5: Fiber morphology variation patterns from pith to the bark

From the pith to the bark, the average fiber length for each odd-numbered annual ring of Phoebe bournei thinning wood increases from 628.08 to 1195.92 μm, and it increases rapidly from Ring 5 and reaches a maximum at Ring 11 but then decreases at Ring 13 (Fig. 5a). The longest fiber length (Ring 11) is almost 2 times of the shortest one (Ring 1). However, the average fiber width at different annual rings does not show much difference. They range from 23.85 to 28.27 μm (Fig. 5b), which is only 18.53% in variation. The fiber length to width ratio is between 25.42 and 48.50. Because the fiber width does not change a lot with the increase of annual rings, the radial variation trend of the fiber length to width ratio is very similar to that of the fiber length, which increases significantly with the increasing of tree age (Fig. 5c). The fiber lumen diameter varies from 15.35 to 20.37 μm, with large fluctuations up and down (Fig. 5d). With the increase of annual rings, the fiber wall thickness increases gradually and then decreases slightly near the bark (Fig. 5e). The fiber wall to lumen ratio varies from 0.26 to 0.46, with irregular radial variations and fluctuations (Fig. 5f).

3.3 Physical and Mechanical Properties of Phoebe bournei Thinning Wood

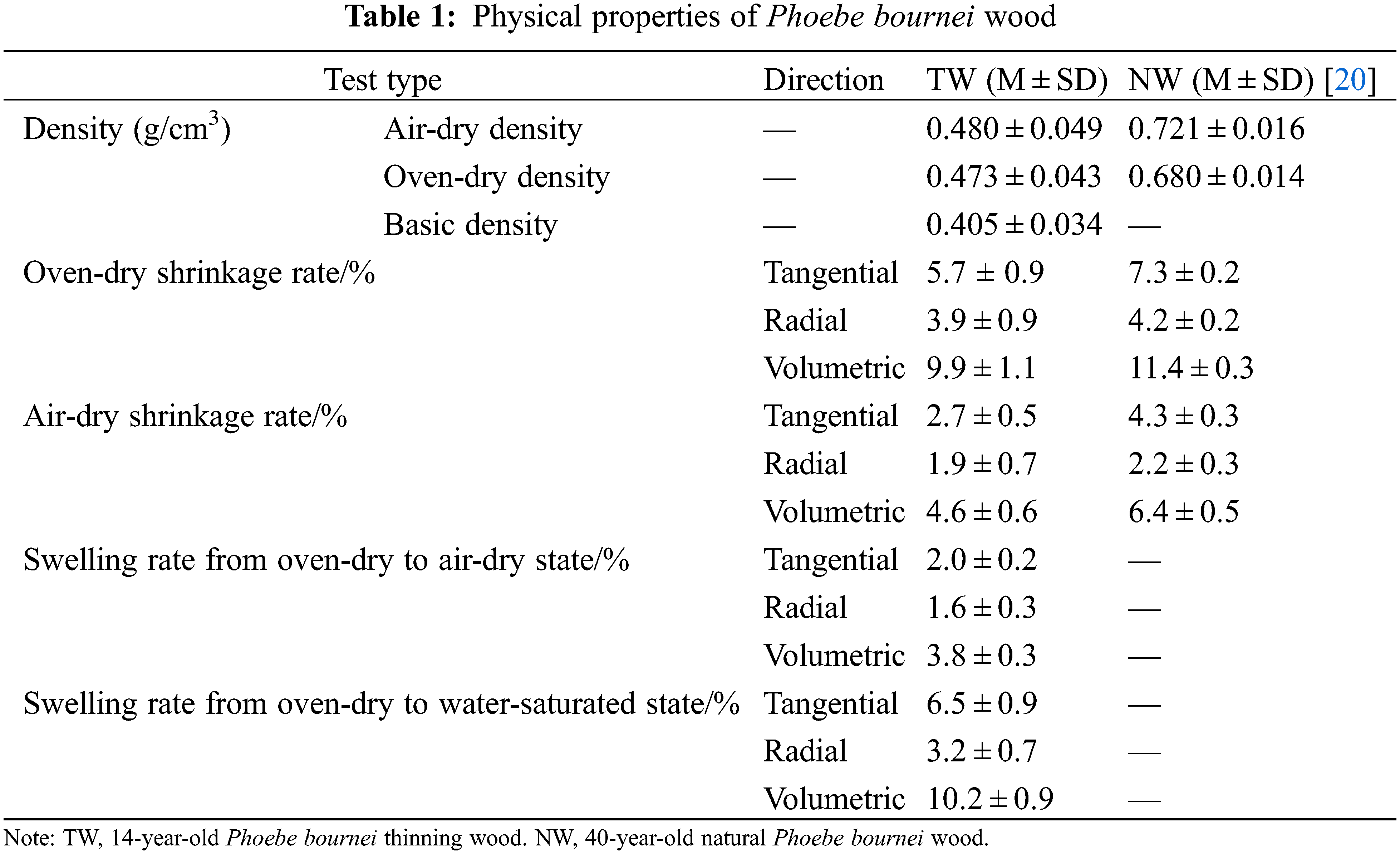

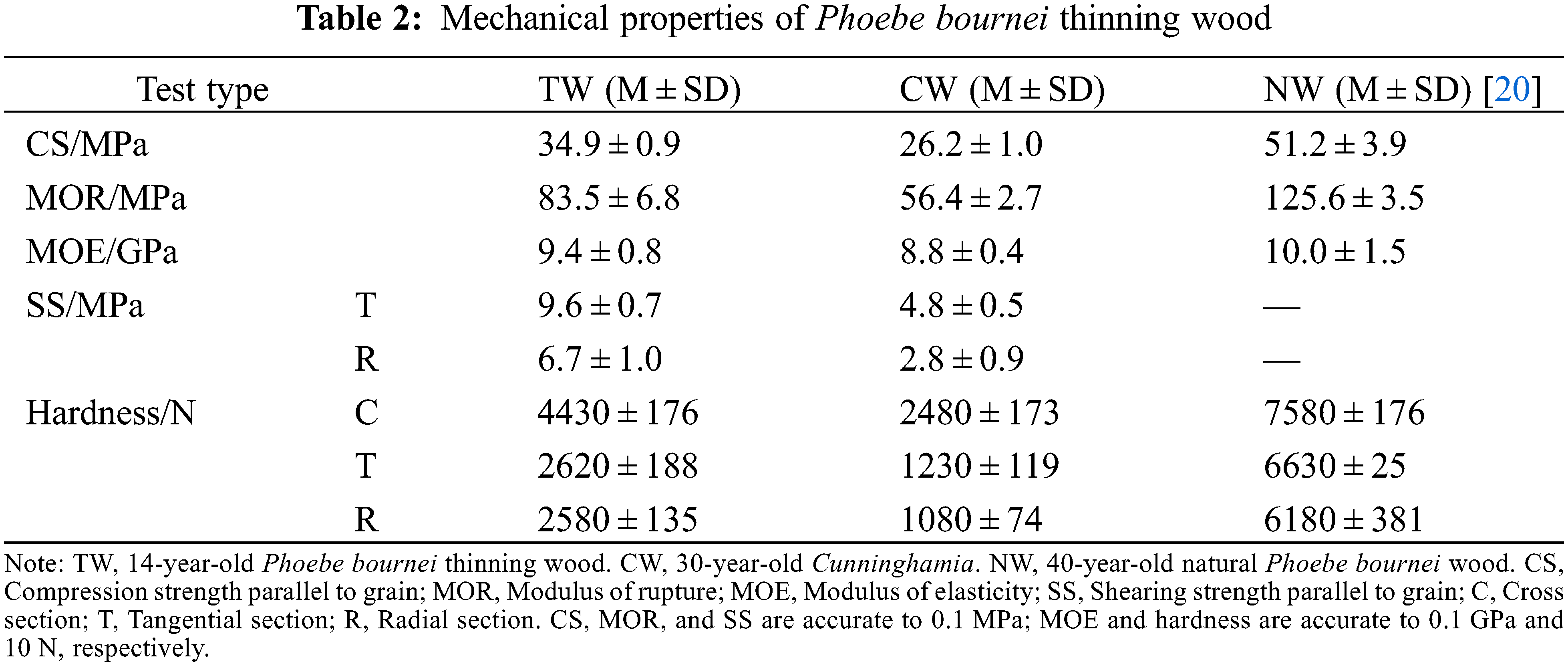

Tables 1 and 2 show the physical and mechanical properties of the 14-year-old Phoebe bournei thinning wood, respectively, the physical and mechanical properties of the 40-year-old natural Phoebe bournei wood studied by Jiang et al. [20] and 30-year-old Cunninghamia (Table 2) are also listed in the same table for comparison.

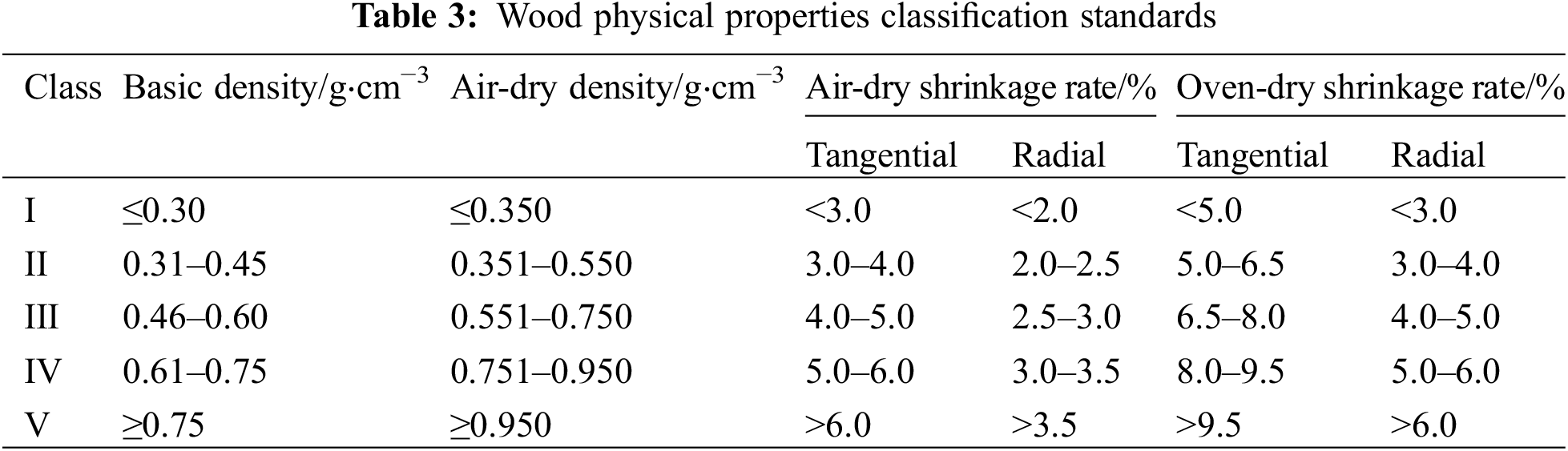

As shown in Table 1, the air-dry density and oven-dry density of 14-year-old Phoebe bournei thinning wood are 0.480 g/cm3 and 0.473 g/cm3, respectively, which are 30%–33% lower than that of 40-year-old natural Phoebe bournei wood. 14-year-old Phoebe bournei thinning wood also shows lower values on shrinkage rate, and they are all lower than 40-year-old natural Phoebe bourei wood. Swelling rate from oven-dry to air-dry state is 2.0% (tangential) and 1.6% (radial), while swelling rate from oven-dry to water-saturated state is 6.5% (tangential) and 3.2% (radial), respectively. From oven-dry to water-saturated state, the tangential swelling rate is 2 times of the radial.

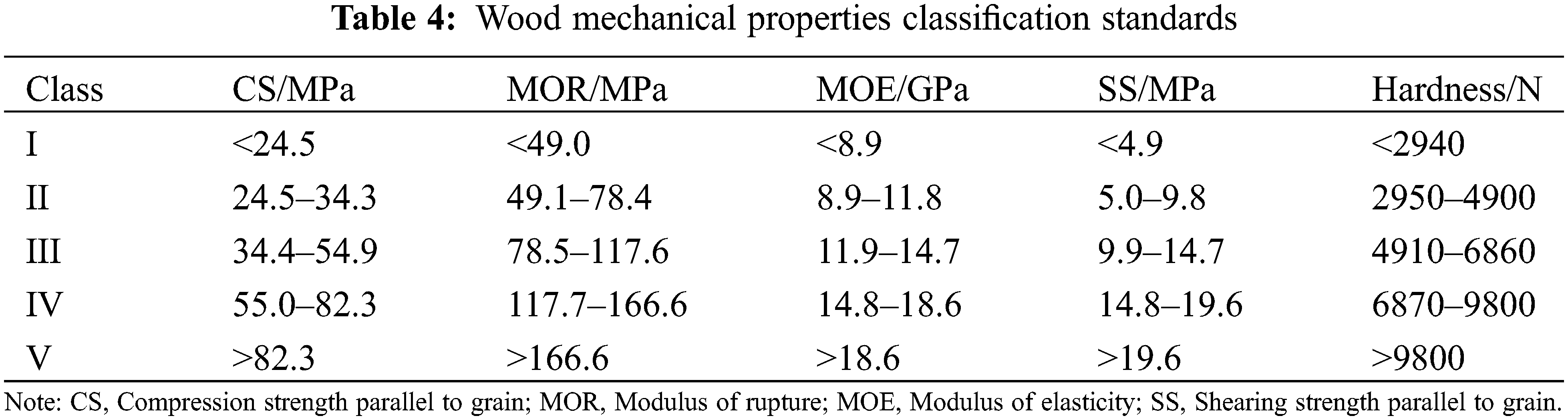

As shown in Table 2, under the condition of 12% moisture content, the compression strength parallel to grain of the 14-year-old Phoebe bournei thinning wood is 34.9 MPa, which is 32% lower than the natural Phoebe bournei but 33% higher than 30-year-old Cunninghamia wood. The MOR is 83.5 MPa, which is 34% lower than that of natural Phoebe bournei wood, whereas 32% higher than that of Cunninghamia wood. The MOE is 9.4 GPa, which is 12% lower than that of natural wood. The shearing strength parallel to grain in the tangential and radial direction is 9.6 MPa and 6.7 MPa, which is 2 and 2.4 times of Cunninghamia wood, respectively. The hardness of Phoebe bournei thinning wood on tangential and radial surfaces shows similar values. The end hardness (on the cross surface) is about 1.7 times of the side hardness (on the tangential and radial surface).

For most of the wood species, heartwood and sapwood can be clearly distinguished on the cross or radial section of a mature tree trunk. They have an inner core of dark-colored wood, heartwood, and an outer shell of light-colored tissue called sapwood. Nevertheless, observed from the cross surface of the 14-year-old Phoebe bournei thinning wood, the color is uniform from the pith to the bark and it is difficult to define the boundary between the heartwood and the sapwood.

According to a previous study [34], when a tree is young and growing vigorously, it often contains no heartwood. After the passage of a few years, however, heartwood begins to form near the center of the stem. For some species, many years may pass before heartwood development. Heartwood formation is a complex process. During the growth of trees, the parenchyma cells of the sapwood are still alive and conduct vigorous metabolic activities such as photosynthesizing (water and carbon dioxide combine to form sugars needed for tree growth to provide energy). The photosynthate is stored in the parenchyma cells in the form of starch grains and it can be easily observed with a microscope. The cells closer to the pith have a slower metabolic rate. As starch and sugar decrease, the cells of the sapwood gradually die and are filled with various deposits (pigment, tannin, resin or gum, calcium carbonate), tyloses is produced in the vessels of some wood species, and the wood color is darkened and the heartwood is formed (all cells have died in heartwood). After that, the water drainage system (vessel lumens) of the tree is blocked by the deposits, the density and mechanical strength of wood improve gradually. The 14-year-old Phoebe bournei thinning wood near the pith was observed to contain many starch substances in the ray cells, with no tyloses and gum in the pores. This implied cells still conduct vigorous metabolism. However, tyloses have been observed in the heartwood pore of the mature Phoebe bournei [19], which can block the water drainage system in the hardwood. Consequently, it is believed that the heartwood of 14-year-old Phoebe bournei has not formed.

Juvenile tree grows vigorously. Generally, the width of the growth ring of juvenile wood is wider than that of natural wood. So is Phoebe bournei. The average width of the growth ring of 14-year-old Phoebe bournei thinning wood (4.99 mm) in this study is much wider than the Phoebe bournei mature wood (3.5 mm) reported by Chen et al. [19].

For the anatomical structure, the pores in the Phoebe bournei thinning wood are small and less. The tangential diameter of pores is divided into 4 classes, which are ≤50 μm, 50–100 μm, 100–200 μm, and ≥200 μm [35]. The average tangential diameter of pores (72 μm) of Phoebe bournei thinning wood is between 50–100 μm. They are too small to be visible under the naked eye. The pores of mature Phoebe bournei wood, however, are distinct owing to their larger diameter than thinning wood. Pores density is divided into 5 classes, namely ≤5, 5–20, 20–40, 40–100, and ≥100 [35]. The Phoebe bournei thinning wood (19) is between 5–20, less than most trees, whereas more than mature wood (12) [34]. The proportion of vessels of 14-year-old Phoebe bournei thinning wood is 12.89%, less than that of angiosperms, which average 15% [36].

Whether wood rays are fine or not is related to rays per millimetre and the width of the rays. Rays per millimetre are divided into 3 classes, which are ≤4, 4–12, and ≥12 [35]. The Phoebe bournei thinning wood (7) is between 4–12, which is medium class. The width of the rays is divided into 5 classes, which are ≤50 μm, 50–100 μm, 100–200 μm, 200–400 μm, and ≥400 μm [37]. The average width of the uniseriate ray (6 μm) and multiseriate rays (22 μm) of Phoebe bournei thinning wood are both less than 50 μm, which are extremely fine. The heights of the uniseriate rays (104 μm) and multiseriate rays (275 μm) of Phoebe bournei thinning wood do not show much difference with that of Phoebe bournei mature wood (114, 248 μm).

4.2 Wood Fiber Morphology and Radial Variation

Fiber morphology affects the physical and mechanical properties of the wood [33]. Therefore, to better utilize the Phoebe bournei thinning wood, it is necessary to study their fiber morphology.

Fiber length is an important factor in the quality of wood products, as long fiber helps improve the MOR of wood [38]. Fiber length is divided into 3 classes, which are ≤900 μm, 900–1600 μm, and ≥1600 μm [35]. The mean fiber length of 14-year-old Phoebe bournei thinning wood is 908.71 μm, which is medium-class and slightly shorter than that of 50-year-old natural Phoebe bournei wood (1079 μm). According to a previous study [33], the wood cells are shorter when the tree grows fast. At the juvenile age of wood, the growth rate of the tree is so fast that it results in short fiber cells. From the pith to the bark, the fiber length of Phoebe bournei thinning wood increases significantly, which indicates that the tree age has an important influence on the fiber length. The mean fiber width (25.60 μm) is wider than that of 50-year-old natural Phoebe bournei wood (21.93 μm) [18]. The fiber width of the Phoebe bournei thinning wood does not vary greatly, and it gradually stabilizes after fluctuations in the first to the seventh year. The variation trend of length to width ratio is similar to that of the fiber length, which shows that fiber length is the main factor determining the fiber length to width ratio.

The fiber wall thickness of 14-year-old Phoebe bournei thinning wood (5.88 μm) belongs to “very thin” (fiber lumen diameter is 3 times of wall thickness) and thinner than the 50-year-old natural Phoebe bournei wood (7.31 μm) [18,37]. The fiber wall thickness and lumen diameter are important factors that govern the wood density. Compared with thick-walled cell species, wood with thin-walled cells always have lower density and strength [39]. It has been reported that the influence of fiber wall thickness on the density of the juvenile wood (account for 81%) is more significant than that of the mature wood (account for 34%) [40]. Therefore, the thin fiber wall of 14-year-old Phoebe bournei thinning wood results in lower density and strength than mature Phoebe bournei wood.

4.3 Physical and Mechanical Properties

Wood density is an important parameter of wood property and the difference in wood density will affect wood mechanical property [41–43]. Compared with the wood physical properties classification shown in Table 3 [44], the air-dry density (0.480 g/cm3) and the basic density (0.405 g/cm3) of 14-year-old Phoebe bournei thinning wood belong to Class II. In addition to the thinner fiber wall, the low density of Phoebe bournei thinning wood might be related to lacking deposits in the cells. In our study, neither tyloses in the pores nor calcium carbonate and other deposits have been formed in the Phoebe bournei thinning wood.

The shrinkage of Phoebe bournei thinning wood is low. Both the tangential (2.7%) and radial (1.9%) air-dry shrinkage rates of Phoebe bournei thinning wood belong to Class I, while the tangential (5.7%) and radial (3.9%) oven-dry shrinkage rates belong to Class II. The radial shrinkage of the wood is restrained by the horizontal distribution of wood rays, which makes the radial shrinkage of the wood smaller than that of the tangential shrinkage [34]. The oven-dry shrinkage in the tangential and radial directions is lower than that of American beech (11.9%, 5.5%) [39]. The lower shrinkage of Phoebe bournei thinning wood is attributed to their thinner cell walls which result in a smaller cell wall shrinkage than thick cell-wall mature Phoebe bournei wood. In summary, the Phoebe bournei thinning wood has excellent dimensional stability, which makes it uneasy to crack during drying.

Table 4 is the wood mechanical properties classification standards [44]. The compressive strength parallel to grain (34.9 MPa) and the MOR (83.5 MPa) of Phoebe bournei thinning wood are both belong to Class III, while the MOE (9.4 GPa) is rated to Class II. The MOR is lower than that of American beech (103 MPa) but higher than American basswood (60 MPa) and Sycamore (69 MPa), which are commercially important woods grown in the United States [39]. The tangential (9.6 MPa) and radial (6.7 MPa) shearing strengths parallel to grain belong to Class III and Class II, respectively. The end hardness (4430 N) belongs to Class II, while the tangential (2620 N) and radial (2580 N) hardness belong to Class I. Although the hardness of 14-year-old Phoebe bournei thinning wood is lower than 40-year-old natural Phoebe bournei wood, it is higher than the 30-year-old Cunninghamia, and more than twice that of Cunninghamia.

When wood is used as a load-bearing material, the “comprehensive strength” which is the sum of the MOR and compressive strength parallel to grain, is often used to evaluate its strength property. It is classified into low strength (≤107.8 MPa), medium strength (107.9–166.6 MPa) and high strength (≥166.6 MPa) [44]. The comprehensive strength of Phoebe bournei thinning wood is 118.4 MPa, which belongs to medium-strength tree species. This value is 30% higher than that of Cunninghamia which is 82.6 MPa and belongs to low strength tree species.

Cunninghamia is a fast-growing tree species with the largest artificial plantation area in China. The timber has the advantages of straight grain, no warping, and resistance to decay, and is widely used for furniture (desk, cabinet, wardrobe, bed board), constructions (beam, pillar, truss, door, and window), and bridge, etc. However, it is not applicable to the situation where heavy-load bearing or high shock resistance is needed [45,46]. Phoebe bournei thinning wood not only has a beautiful pattern but also has higher mechanical properties than Cunninghamia. Therefore, Phoebe bournei thinning wood might have wider applications than Cunninghamia wood.

The color of the Phoebe bournei thinning wood is yellowish-brown with greenish. It has a beautiful wood figure, fine texture, high luster, and a strongly fragrant odor. The planed wood surface is being felt something as smooth as silk to the touch. Because the tree age is juvenile, the heartwood of the 14-year-old Phoebe bournei thinning wood has not formed. The pore diameter is small and the wood is diffuse-porous. The wood rays are fine and mostly being multiseriate rays. The average fiber length is medium and the wall thickness of fiber is very thin. Fiber length increases with tree age while fiber width is less variable. The Phoebe bournei thinning wood has low density, low shrinkage rate, and moderate comprehensive strength. Although the mechanical properties of Phoebe bournei thinning wood are lower than that of 40-year-old natural Phoebe bournei wood, it is much higher than 30-year-old Cunninghamia and thus might have wider applications.

Owing to the above-mentioned properties, 14-year-old Phoebe bournei thinning wood might be used for wood carving, handicrafts, high-end furniture, and decorative furniture parts such as chair backrest, cabinet panel, screen, etc., 14-year-old Phoebe bournei thinning wood is a promising material that has high economic and use value.

Acknowledgement: We acknowledge Prof. Tiehua Li (College of Forestry, Central South University of Forestry and Technology) for providing Phoebe bournei thinning wood and Cunninghamia wood. We also acknowledge technical assistance from Mr. Dongnian Xu, Prof. Lisheng Xie, and Prof. Shangshang Chang (College of Materials Science and Engineering, Central South University of Forestry and Technology).

Funding Statement: This research was funded by the Postgraduate Scientific Research Innovation Project of Hunan Province (No. CX20210867), and the Scientific Innovation Fund for Postgraduates of Central South University of Forestry and Technology (No. CX202102030).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Cencin, A., Zanetti, M., Urso, T., Crivellaro, A. (2021). Effects of an innovative densification process on mechanical and physical properties of beech and Norway spruce veneers. Journal of Wood Science, 67(1), 1–14. DOI 10.1186/s10086-021-01948-w. [Google Scholar] [CrossRef]

2. Lou, Z., Yuan, T., Wang, Q., Wu, X., Hu, S. (2021). Fabrication of crack-free flattened bamboo and its macro-/micromorphological and mechanical properties. Journal of Renewable Materials, 9(5), 959–977. DOI 10.32604/jrm.2021.014285. [Google Scholar] [CrossRef]

3. Grosse, C., Noël, M., Thévenon, M., Rautkari, L., Gérardin, P. (2018). Influence of water and humidity on wood modification with lactic acid. Journal of Renewable Materials, 6(3), 259–269. DOI 10.7569/JRM.2017.634176. [Google Scholar] [CrossRef]

4. Li, Y., Xu, W., Zou, W., Jiang, D., Li, X. (2017). Complete chloroplast genome sequences of two endangered phoebe (lauraceae) species. Botanical Studies, 58(1), 1–10. DOI 10.1186/s40529-017-0192-8. [Google Scholar] [CrossRef]

5. Wu, Z., Peter, H., Hong, D. (2008). Flora of China. Beijing, China: Science Press. [Google Scholar]

6. Ding, Y., Zhang, J., Lu, Y., Lin, E., Lou, L. et al. (2015). Development of EST-SSR markers and analysis of genetic diversity in natural populations of endemic and endangered plant Phoebe chekiangensis. Biochemical Systematics and Ecology, 63, 183–189. DOI 10.1016/j.bse.2015.10.008. [Google Scholar] [CrossRef]

7. He, Y., Liang, R., Jiang, Y., Sun, B. (2013). Research progress of precious species Phoebe bournei and its development strategies. Guangxi Forestry Science, 42(4), 365–370. DOI 10.19692/j.cnki.gfs.2013.04.015. [Google Scholar] [CrossRef]

8. Zhang, W., Li, T., Wen, S., He, G., Shen, Z. et al. (2013). Inhibition effect of extraction from seed of Phoebe bournei. Advanced Materials Research, 2480(726–731), 4468–4472. DOI 10.4028/www.scientific.net/AMR.726-731.4468. [Google Scholar] [CrossRef]

9. Gao, J., Shang, H., Chen, Z., Tian, Y., Yu, H. (2016). Effects of elevated ozone on stoichiometry and nutrient pools of Phoebe bournei (Hemsl.) yang and Phoebe zhennan S. Lee et F. N. Wei seedlings in subtropical China. Foersts, 7(4), 78. DOI 10.3390/f11080824. [Google Scholar] [CrossRef]

10. Ding, W., Ning, L., Wei, S., Xing, H., Li, Z. (2019). Essential Oil extracted from wood of Phoebe bournei (Hemsl.) yang: Chemical constituents, antitumor, antibacterial, and hypoglycemic activities. Bioresources, 14(1), 858–869. DOI 10.15376/biores.14.1.858-869. [Google Scholar] [CrossRef]

11. Liu, B., Chen, C., Lin, D., Lin, S. (2014). Analyses of photosynthetic pigment content and chlorophyll fluorescence parameter in leaves of 21 provenances of Phoebe bournei. Acta Agriculturae Universitis Jiangxiensis, 36(1), 115–121. DOI 10.13836/jjau.2014018. [Google Scholar] [CrossRef]

12. Roberts, J., Drost, R., Carol, A. (2014). IUCN red list of threatened species. College & Research Libraries News, 75(7), 402. DOI 10.5860/crln.75.7.9167. [Google Scholar] [CrossRef]

13. Ge, Y., He, X., Wang, J., Jiang, B., Ye, R. et al. (2014). Physiological and biochemical responses of phoebe bournei seedlings to water stress and recovery. Acta Physiologiae Plantarum, 36(5), 1241–1250. DOI 10.1007/s11738-014-1502-3. [Google Scholar] [CrossRef]

14. Song, X. (2000). Wood properties and industrialized utilization of Chinese fir thinning wood. China Forestry Science and Technology, 14(2), 27–29. DOI 10.13360/j.issn.1000-8101.2000.02.010. [Google Scholar] [CrossRef]

15. Chen, Z., Cao, J., Yu, H., Shang, H. (2018). Effects of elevated ozone levels on photosynthesis, biomass and non-structural carbohydrates of Phoebe bournei and Phoebe zhennan in subtropical China. Frontiers in Plant Science, 9, 1764. DOI 10.3389/fpls.2018.01764. [Google Scholar] [CrossRef]

16. Li, T., Min, X. (2020). Dormancy characteristics and germination requirements of Phoebe bournei seed. Scientia Horticulturae, 260, 108903. DOI 10.1016/j.scienta.2019.108903. [Google Scholar] [CrossRef]

17. Tang, X., Liu, G., Jiang, J., Lei, C., Liu, X. (2020). Effects of growth irradiance on photosynthesis and photorespiration of Phoebe bournei leaves. Functional Plant Biology, 47(12), 1053–1061. DOI 10.1071/FP20062. [Google Scholar] [CrossRef]

18. Chen, G., Chen, Y., Feng, Q., Liang, R., Huang, T. et al. (2019). Radial variations of fiber morphology for Phoebe bournei wood from natural forest. Journal of Northwest Forestry University, 34(4), 217–222. DOI 10.3969/J.ISSN.1001-7461.2019.04.33. [Google Scholar] [CrossRef]

19. Chen, G., Huang, T., Lei, F., Liu, X., Chen, Y. et al. (2017). Research on the anatomical structure characteristics of Phoebe bournei wood. Guangxi Forestry Science, 46(4), 375–379. DOI 10.3969/j.issn.1006-1126.2017.04.007. [Google Scholar] [CrossRef]

20. Jiang, X., Xiao, F., Gong, B., Ye, J. (2008). Study on physical and mechanical properties of Phoebe bournei natural forest and plantation wood. Forest Research, 21(6), 862–866. DOI 10.13275/j.cnki.lykxyj.2008.06.024. [Google Scholar] [CrossRef]

21. GB/T1930-2009 (2009). Method for determination of the annual rings width and latewood rate of wood. Standards Press of China, Beijing. [Google Scholar]

22. GB/T1933-2009 (2009). Method for determination of the density of wood. Standards Press of China, Beijing. [Google Scholar]

23. GB/T1932-2009 (2009). Method for determination of the shrinkage of wood. Standards Press of China, Beijing. [Google Scholar]

24. GB/T1934.2-2009 (2009). Method for determination of the swelling of wood. Standards Press of China, Beijing. [Google Scholar]

25. GB/T1936-2-2009 (2009). Method for determination of the modulus of elasticity in static bending of wood. Standards Press of China, Beijing. [Google Scholar]

26. GB/T1936-1-2009 (2009). Method of testing in bending strength of wood. Standards Press of China, Beijing. [Google Scholar]

27. GB/T1935-2009 (2009). Method of testing in compressive strength parallel to grain of wood. Standards Press of China, Beijing. [Google Scholar]

28. GB/T1937-2009 (2009). Method of testing in shearing strength parallel to grain of wood. Standards Press of China, Beijing. [Google Scholar]

29. GB/T1941-2009 (2009). Method of testing in hardness of wood. Standards Press of China, Beijing. [Google Scholar]

30. Bailey, I. (1944). The development of vessels in angiosperms and its significance in morphological research. American Journal of Botany, 31(7), 421–442. DOI 10.1002/j.1537-2197.1944.tb08053.x. [Google Scholar] [CrossRef]

31. Yu, C. (1954). The relationship between xylem’s evolution and phylogeny of plants. Acta Botanica Sinica, 3, 183–195. [Google Scholar]

32. Thomposn, W. (1918). Independent evolution of vessels in Gnetales and angiosperms. Botanical Gazette, 65(1), 83–90. DOI 10.1086/332191. [Google Scholar] [CrossRef]

33. Seurfield, G., Miehell, A., Silva, S. (2008). Crystals in woody stems. Botanical Journal of the Linnean Society, 66(4), 277–289. DOI 10.1111/j.1095-8339.1973.tb02175.x. [Google Scholar] [CrossRef]

34. Liu, Y., Zhao, G. (2012). Wood science. China: Forestry Publishing House. [Google Scholar]

35. Wheeler, E., Baas, P., Gasson, P. (1989). IAWA list of microscopic features for hardwood identification. IAWA Journal, 10(3), 219–332. DOI 10.1163/22941932-90000496. [Google Scholar] [CrossRef]

36. Fichtler, E., Worbes, M. (2012). Wood anatomical variables in tropical trees and their relation to site conditions and individual tree morphology. IAWA Journal, 33 (2), 19–40. DOI 10.1163/22941932-90000084. [Google Scholar] [CrossRef]

37. GB/T33023-2016 (2016). Terminology relating to wood structure. Standards Press of China, Beijing. [Google Scholar]

38. Leeuwen, M., Hilker, T., Coops, N., Frazer, G., Wulder, M. et al. (2011). Assessment of standing wood and fiber quality using ground and airborne laser scanning: A review. Forest Ecology and Management, 261(9), 1467–1478. DOI 10.1016/j.foreco.2011.01.032. [Google Scholar] [CrossRef]

39. Service, F. (2010). Wood handbook. Forest Products Laboratory, USA: M Adison. [Google Scholar]

40. Denne, M. P. (1997). Variation in density of Picea sitchensis in relation to within-tree trends in tracheid diameter and wall thickness. Forestry, 70(1), 47–60. DOI 10.1093/forestry/70.1.47. [Google Scholar] [CrossRef]

41. Gindl, W., Teischinger, A. (2002). Axial compression strength of Norway spruce related to structural variability and lignin content. Composite Part A–Applied Science and Manufacturing, 33(12), 1623–1628. DOI 10.1016/S1359-835X(02)00182-3. [Google Scholar] [CrossRef]

42. Wahab, R., Mustafa, T., Shafiqur, R., Mohammed, S., Othman, S. et al. (2012). Relationship between physical, anatomical and strength properties of 3-year-old cultivated tropical bamboo Gigantochloa scortechinii. Journal of Agricultural and Biological Science, 7(10), 782–791. [Google Scholar]

43. Massayuki, M., Matoski, A., Magajewski, C., Machado, J. (2014). Shear strength parallel of the wood fiber stress by punching-proposed test. Revista Ingenieria de Construccion, 29(1), 46–60. DOI 10.4067/S0718-50732014000100003. [Google Scholar] [CrossRef]

44. Yin, S. (1996). Wood science. China: Forestry Publishing House. [Google Scholar]

45. Hong, L., Shu, B., He, Q., Ju, Z., Zhang, H. et al. (2021). Improving the properties of fast-growing Chinese fir by vacuum hot pressing treatment. Journal of Renewable Materials, 9(1), 49–59. DOI 10.32604/jrm.2021.013833. [Google Scholar] [CrossRef]

46. Luo, Q. (2014). Theory in song dynasty China fir and people’s social life (Master Thesis). Hunan University of Science and Technology, China. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |