| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.021066

ARTICLE

Study on the Effect of Two-Step Saturated Steam Heat Treatment Process on the Properties of Reconstituted Bamboo

1Jiangsu Co-Innovation Center of Efficient Processing and Utilization of Forest Resources, Nanjing Forestry University, Nanjing, China

2Zhejiang Academy of Forestry Sciences, Hangzhou, China

3Key Laboratory of National Forestry and Grassland Administration/Beijing for Bamboo & Rattan Science and Technology, Beijing, China

4College of Materials Science and Engineering, Nanjing Forestry University, Nanjing, China

*Corresponding Authors: Yanjun Li. Email: nfcm2018@163.com; Zhichao Lou. Email: zc-Lou2015@njfu.edu.cn

Received: 26 December 2021; Accepted: 03 March 2022

Abstract: With the aim of utilizing reconstituted bamboo as a carbon cycle-oriented material, the improvement of physical and mechanical properties has been actively studied to solve using problems. The saturated steam heat treatment process has been widely used in worldwide. With the development and exploration of this technology, two-step saturated steam heat treatment process appears in some practical production, that is, after a period of saturated steam heat treatment at a lower temperature, the bamboo bundles are taken out and seasoned for a period of time, and then put back into the heat tank again, and heated at a higher temperature for another period of time. During the two-step saturated steam heat treatment, the physical and mechanical properties of bamboo changed. However, the mechanism of two-step saturated steam heat treatment has not been thoroughly discussed. For purpose that this paper all discuss and find out the mechanism of two-step saturated steam heat treatment on the change of physical and mechanical properties of reconstituted bamboo. In this work, the one and two-step saturated steam heat treatments were carried out according to the actual production parameters, and the physical and mechanical properties of the reconstituted bamboo board made of treated bamboo bundles were analyzed, including the color change, the thickness swelling (TS), modulus of elasticity (MOE), modulus of rupture (MOR) and shear strength. The results indicate that two-step saturated steam heat treatment is better than one-step. Based on the detailed study of the chemical composition, crystallinity and micro-morphological characteristics of the heated bamboo bundles, it is further revealed that during two-step saturated steam heat treatment, oxygen air is added to the reaction system between the two heat treatment processes to further catalyze the oxidation of hemicellulose and enhance the crystallinity of cellulose, so as to improve the properties of the final products. Our work has optimized the saturated steam heat treatment process which is widely used in industry, pointing out a new idea in the experimental and theoretical basis for the development of recombinant bamboo manufacturing industry.

Keywords: Modulus of elasticity; modulus of rupture; thickness swelling; oxidation

With the rapid economic growth and the continuous improvement of people’s living standards, home furnishing and building decoration industry put forward higher requirements for the use of green eco-friendly materials [1,2]. Bamboo is a raw material for engineering structural decoration materials because of its abundant reserves, fast growth, high strength and rigidity, good processing performance and local availability [3]. Especially in China, bamboo forest area accounts for 1/3 of the world’s total area, making bamboo become an important sustainable and renewable non-wood resource [4–6]. Among various bamboo-based products, reconstituted bamboo is widely used in many fields including construction, furniture and flooring [7,8]. Therefore, it is a key issue to develop a kind of reconstituted bamboo with good physical and mechanical properties and dimensional stability [9,10].

In view of the above problems, people have carried out a lot of work to explore [11]. Studies have shown that low molecular weight adhesives can enter a large number of broken cell cavities causing by the defibering process, which contributes to immobilize parenchyma cells in the subsequent process of hot pressing. Thus, it is beneficial for the adhesive strength. However, the low molecular weight adhesives penetrate the cell wall directly into the cell cavity, resulting in several weak links at the interface that lack adhesive lines. Therefore, the chemical bond reaction on the interface between the adhesive and the bamboo bundle is meaningless and the adhesive strength is affected [12,13]. Heat treatment, as a candidate way to improve the properties of bamboo, has attracted extensive attention recently [14]. At present, the heat treatment of bamboo bundles mainly includes hydrothermal treatment, oil heat treatment and gas phase heat treatment [15,16]. However, the downsides such as low efficiency and the induced environmental pollution limit the industrial application of the first two methods [17,18].

Comparatively, the gas phase heat treatment uses saturated steam as the medium. The moisture adsorbed inside the bamboo can be transferred efficiently during this heat treatment process, thus improving the physical and mechanical properties and removing nutrients. However, the traditional one-step saturated steam heat treatment process generally requests high temperature of 180°C–200°C. The saturated steam heat treatment temperature and corresponding absolute pressure are shown in Table S1. Under such conditions, cellulose which acts as frameworks for mechanical support in biomass materials, should degrade, followed by the decrease of the physical and mechanical properties of the treated samples. In addition, according to the practical industrial production in factories, we found bamboo bundles softened and collapsed. We analyze the problems of uneven color and unstable performance, but there are no relevant references.

The two-step saturated steam heat treatment method is developed based on the traditional one-step saturated steam heat treatment process. The expectation of two-step saturated steam heat treatment is to reduce the temperature. When the temperature is reduced, the energy consumption of the of the factory will be greatly reduced. Therefore, the temperature of two-step saturated steam heat treatment is 140°C–160°C. During the two-step saturated steam heat treatment, the physical and mechanical properties of bamboo changed. However, the mechanism of two-step saturated steam heat treatment has not been thoroughly discussed. For purpose that this paper all discuss and find out the mechanism of two-step saturated steam heat treatment on the change of physical and mechanical properties of reconstituted bamboo.

Four-year-old moso bamboo from the Lishui County, Zhejiang Province in China was cut off, peeled off the green outside and the yellow inside, and rolled to get completely released bamboo bundles. The obtained bamboo bundles were transverse, unbroken, and longitudinal unconsolidated.

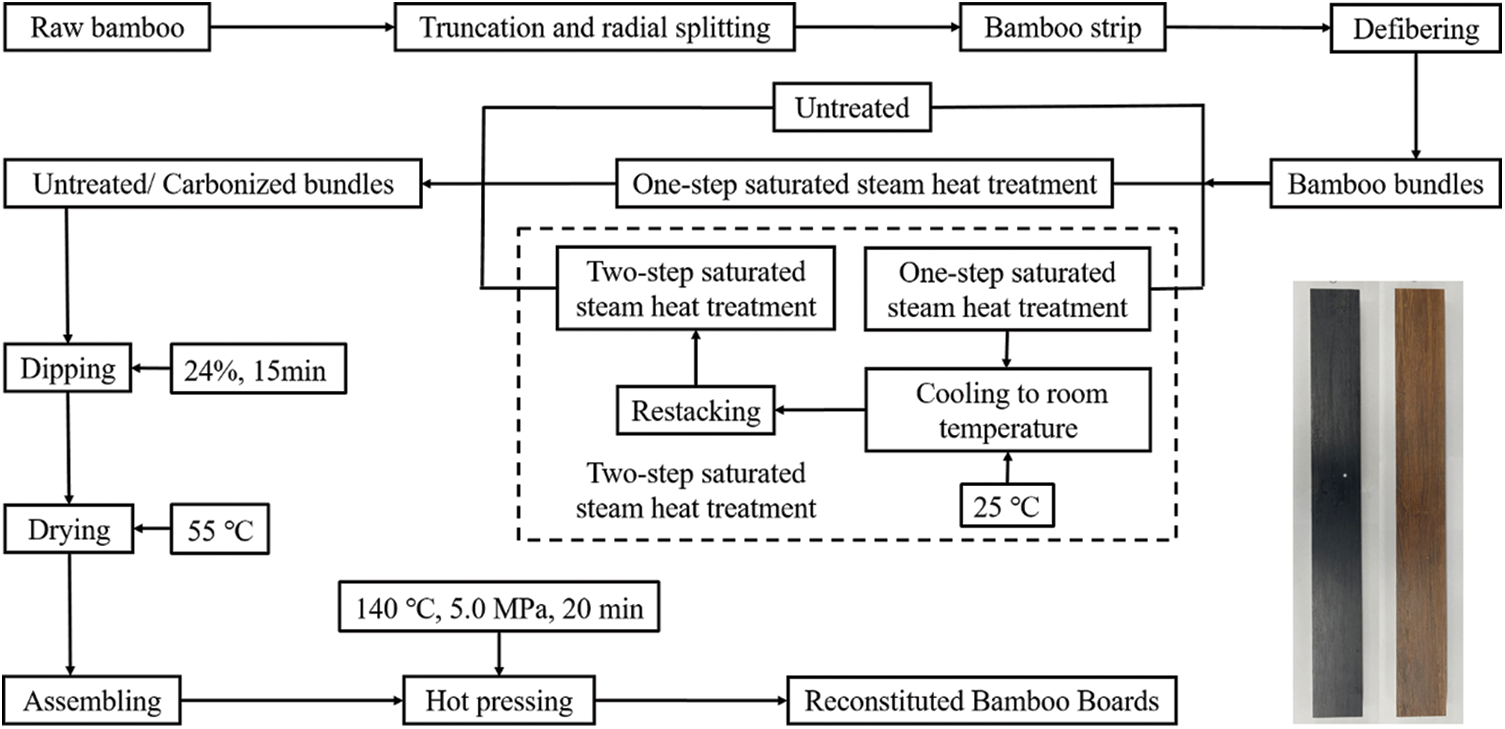

2.2 Fabrication of Reconstituted Bamboo Boards

Taking saturated steam heat treatment as medium. The bamboo bundles were divided into 31 groups. The first group was untreated as control group. The other 3 groups were subjected to a one-step heat treatment by saturated steam (temperature was 180°C, time were 10, 20 and 30 min, respectively). And another 27 groups were subjected to a two-step heat treatment by saturated steam. First, the bamboo bundles were subjected to the first heat treatment process (the first heat treatment temperature (T1) were 140°C and the first heat treatment time (τ1) were 1, 2 and 3 h, respectively). Taking out the bamboo bundles after one-step heat treatment. Then natural conservation and cooling to room temperature of 25°C, and restacking. Next, the bamboo bundles were subjected to the second heat treatment process (the second heat treatment temperature (T2) were 140°C, 150°C and 160°C, and second the heat treatment time (τ2) were 1, 2 and 3 h, respectively). Based on Table S2, named Table S2, as shown in Table S2.

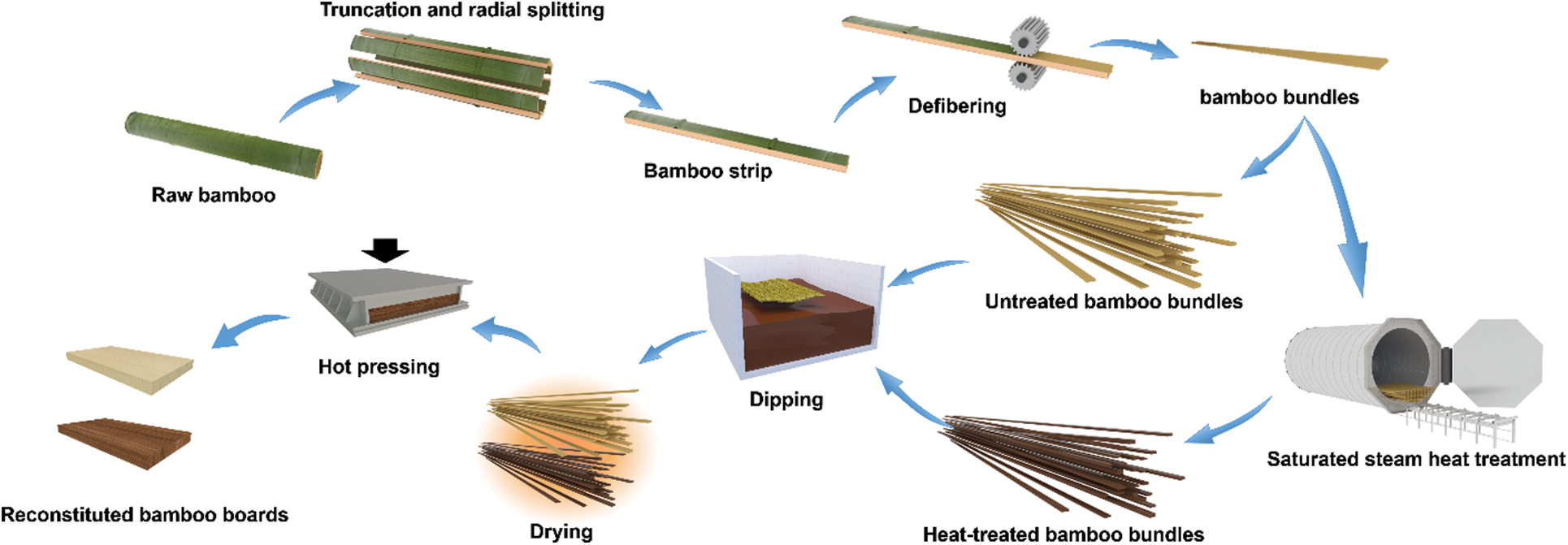

The bamboo bundles were impregnated in phenolic resin (the phenolic resin was obtained from Taier adhesive) for 15 min. The bamboo bundles were dried to a moisture content of 12% at 55°C, followed by parallel lay-up and being hot pressed into boards at 140°C with 5.0 MPa for 20 min. Reconstituted bamboo boards with a density of 1.1 g/cm3 were successfully fabricated. Fig. 1 shows the process figure for the preparation of reconstituted bamboo boards. Fig. 2 shows the Flowchart for the preparation of reconstituted bamboo boards.

Figure 1: Process figure for the preparation of reconstituted bamboo boards

Figure 2: Flowchart for the preparation of reconstituted bamboo boards

2.3 X-Ray Diffraction (XRD) Analysis

A step-by-step scanning method with powder X-ray diffractometer T-6000 (Malvern Panalytical, UK) was used. The scanning angle was 5° to 50° and the scanning speed was 2°/min. The crystallinity (CrI) and lattice spacing of cellulose before and after saturated steam heat treatment was calculated by Segal method (Eqs. (1) and (2)).

where CrI is the relative crystallinity. d is the lattice spacing. I002 is the maximum intensity of diffraction peak of crystal (002) plane. Iam is the diffraction intensity of amorphous. n = 1 is the diffraction series. λ is the wavelength of X-ray, which is 0.15406 Å, and θ is the peak position.

2.4 Chemical Compositions Analyses

The spectra were determined by the VERTEX-80 V (Bruker, Germany) infrared spectrometer. Before determination, the dried bamboo powder was mixed with KBr and pressed into a thin sheet. The scanning range was 500–4000 cm−1, and the scanning times were 32 and the resolution is 4 cm−1. The thin sheet was placed in the Fourier infrared spectrometer for determination. Finally, the infrared spectrum was drawn for analysis.

The contents of three major components (cellulose, hemicellulose and lignin) in bamboo before and after treatment were determined by reported method [19]. The sugar content in the supernatant was determined by high-performance liquid chromatography (HPLC). H2SO4 solution was used as eluent at a flow rate of 0.6 mL/min.

2.5 Physical and Mechanical Properties Test

The thickness swelling (TS), modulus of elasticity (MOE), modulus of rupture (MOR) and shear strength of the obtained reconstituted were tested using a DNS50 electronic universal testing machine, referring to the Chinese national standard “Testing methods for physical and chemical properties of wood-based panels and veneered wood-based panels” [20].

Commission International de l’Éclairage (CIE) L*, a* and b* standard colorimetric system was used for analysis [21]. The value L* indicated the brightness in the range of 0 to 100 (0∼100, 0 for black, 100 for perfect reflection of light). The value a* indicates the red-green feature in the color value (−60∼+60, −60 for green, +60 for red). And the value b* indicated the yellow-blue feature in the color (−60∼+60, −60 for blue, +60 for yellow). Calculate the measured mean value according to the Eqs. (3)–(6).

L0, a0 and b0 are the data of control group respectively. ΔL*, Δa* and Δb* are the corresponding change difference. ΔE* is the total color difference before and after treatment.

2.7 Statistical Product and Service Solutions Analyses (SPSS)

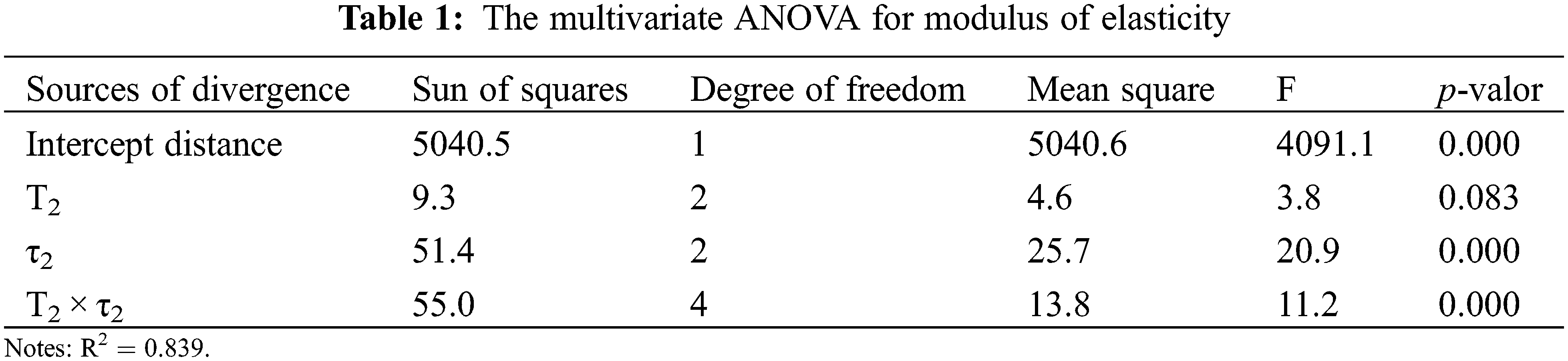

SPSS was used to analyze the test results. In order to further analyze the significance of the experimental effects, multivariate analysis of variance (ANOVA) test was used. Sig < 0.05 was considered to indicate a statistically significant difference. The specific corresponding relationship is shown in Table S3.

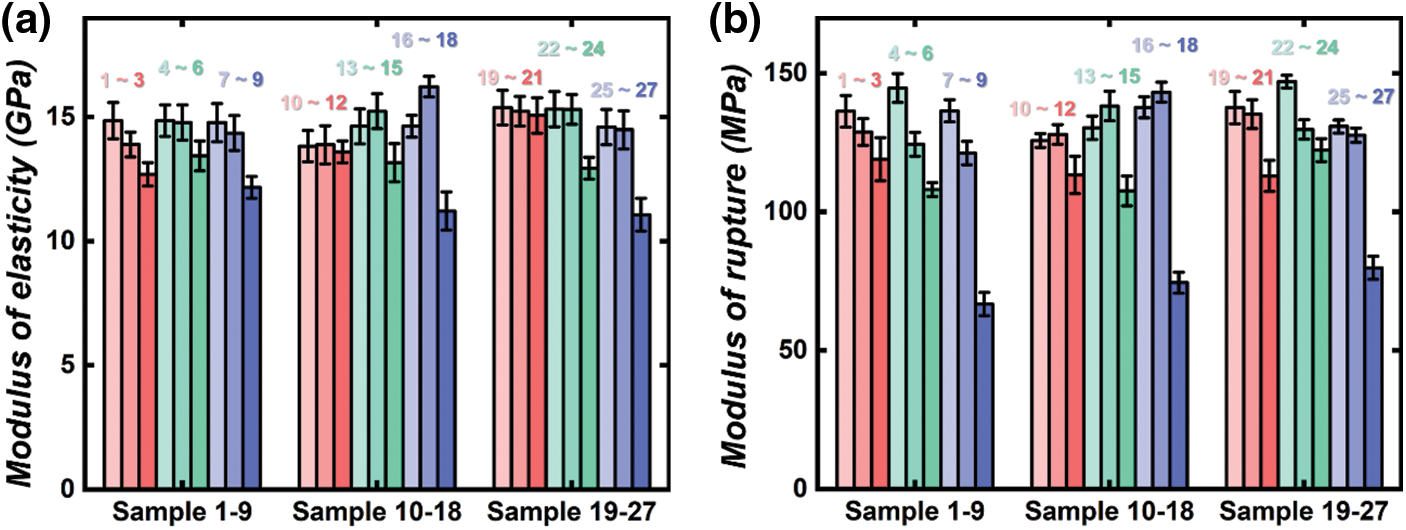

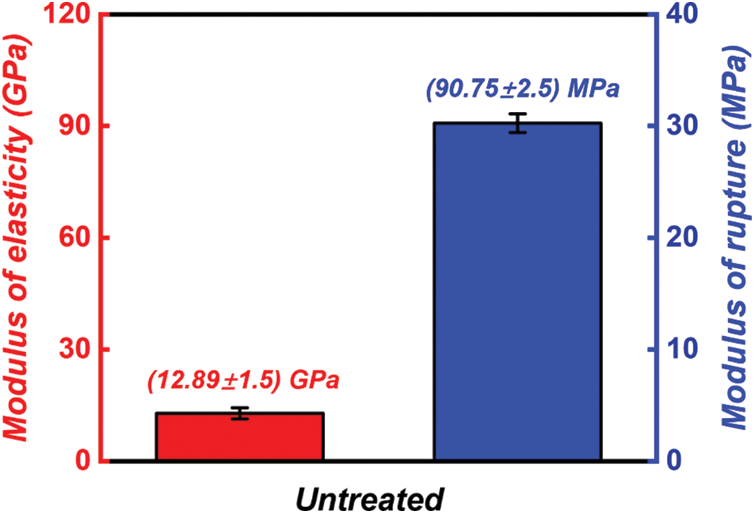

3.1 Modulus of Elasticity and Modulus of Rupture of Reconstituted Bamboo Boards

Figs. 3a and 3b show the MOE and MOR of reconstituted bamboo which was fabricated with the two-step heated bundles, respectively. Fig. S1 shows the MOE and MOR of untreated sample. The mean values of MOE and MOR of the untreated sample are 12.89 GPa and 90.75 MPa. As shown in Fig. 3a, the MOE of most heat-treated samples are higher compared with untreated sample. From Sample 1 to Sample 27, the MOE shows an overall decreasing trend. In particular, form Sample 10 to Sample 12, Sample 13 to Sample 15 and Sample 16 to Sample 18, the MOE first increases and then decreases. For Sample 17, the MOE reaches the maximum value of 16.23 GPa. Compared with Sample 8, Sample 17 and Sample 26, the MOE (Sample 9, Sample 18 and Sample 27) dramatically decreases by 62.74%, 56.89% and 45.41%, respectively. In particular, for Sample 27, MOE reaches the lowest of 11.07 GPa and is lower than untreated sample. The MOR is consistent with the change rules of MOE.

Figure 3: (a) The modulus of elasticity and (b) the modulus of rupture of reconstituted bamboo which was fabricated with the two-step heated bundles

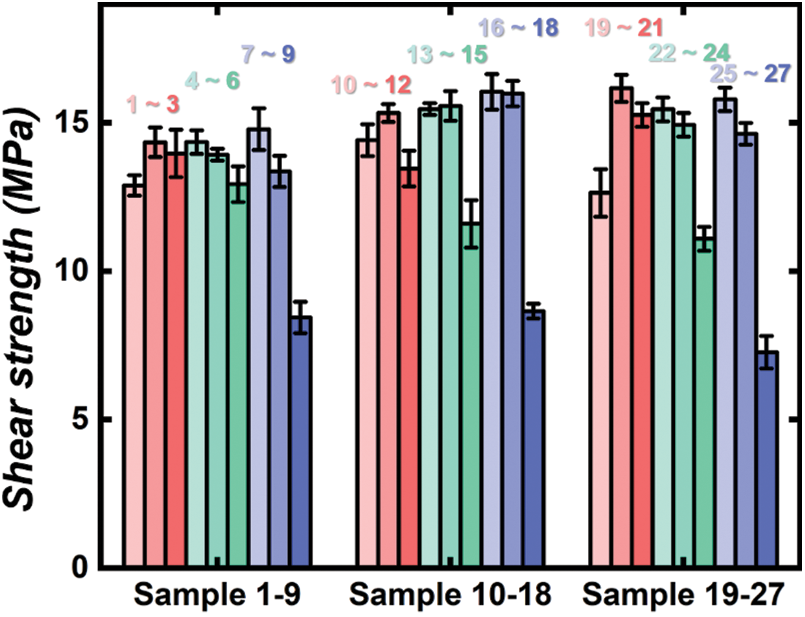

3.2 The Shear Strength of Reconstituted Bamboo Boards

Fig. 4 shows the shear strength of reconstituted bamboo which was fabricated with the two-step heated bundles. Fig. S2 shows the shear strength of the untreated sample. As shown in Fig. 4, the shear strength of most heat-treated samples is higher compared with untreated sample (11.02 MPa). Especially, compared with Sample 8, Sample 17 and Sample 26, the shear strength (Sample 9, Sample 18 and Sample 27) occurring a significant decrease in shear strength. For Sample 9, Sample 18 and Sample 27 decreasing by 35.3%, 33.1%, and 43.8% compared with untreated sample, respectively. From Sample 1 to Sample 9, Sample 10 to Sample 18 and Sample 19 to Sample 27, the shear strength shows an overall decreasing trend. In particular, from Sample 1 to Sample 3, Sample 10 to Sample 12 and Sample 19 to Sample 21, the shear strength first increases and then decreases. For Sample 16, the shear strength reaches the maximum with a mean value of 16.57 MPa.

Figure 4: The shear strength of reconstituted bamboo which was fabricated with the two-step heated bundles

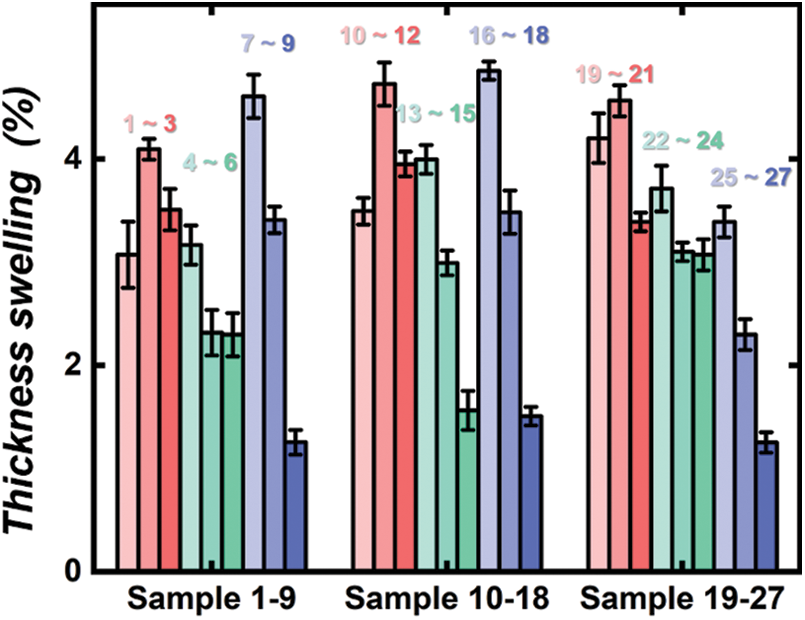

3.3 The Thickness Swelling (TS) of Reconstituted Bamboo Boards

Fig. 5 shows the TS of reconstituted bamboo which was fabricated with the two-step heated bundles. Fig. S2 shows the TS of untreated sample. The mean value of TS of untreated sample is 1.25%. As shown in Fig. 5, from Sample 1 to Sample 27, the TS shows an overall decreasing trend. For Sample 27, the TS reaches the minimum value of 1.51%, indicating the best dimensional stability under this heat treatment condition. For Samples 10–18, the TS values of the heat-treated samples increases except for Sample 15 and Sample 18. Specifically, the TS values of Sample 15 and Sample 18 decrease by 45.3% and 47.4% compared with untreated sample, respectively. Form Sample 8 to Sample 9, sample 17 to Sample 18 and Sample 26 to Sample 27, the TS dramatically decreases by 62.74%, 56.89% and 45.41%, respectively.

Figure 5: The thickness swelling of reconstituted bamboo which was fabricated with the two-step heated bundles

3.4 The Color of Reconstituted Bamboo Boards

Table S4 shows the change in color of untreated sample and reconstituted bamboo which was fabricated with the two-step heated bundles. The mean values of a*, b*, L* of untreated sample are 3.5, 25 and 60, respectively. Comparing with the untreated sample, the a* of heat-treated samples increases, indicating that the color of heat-treated samples turns red. For Sample 7, Sample 16 and Sample 25, a* decreases significantly. As shown in Table S4. The treatment process parameters negatively affect the b* and L* values. From Sample 1 to Sample 27, b* and L* decrease indicating the color of the heat-treated samples turns blue and dark. In other words, the heat-treated samples change from light yellow to reddish brown. Especially, for Sample 27, b* and L* reach the minimum values of 25 and 60, respectively.

As shown in Table S4, when T2 and τ2 are constant, T1 and τ1 have no influence on the changes of Δa*, Δb*, ΔL* and ΔE*. From Sample 1 to Sample 27, the value of Δ a* is in the range of 0.2–2.3. Δa* > 0 indicates the color of reconstituted bamboo boards turns red [22]. As shown in Table S4, the Δb* and ΔL* are negative and the values of Δb* and ΔL* are higher than Δa*. Δb* and ΔL* show a decreasing trend, indicating that the color of heat-treated samples turns blue and dark. For Sample 27 ΔL* reaches the maximum value of 43.69. It is indicated that the color difference between heat-treated samples and untreated sample is increasing.

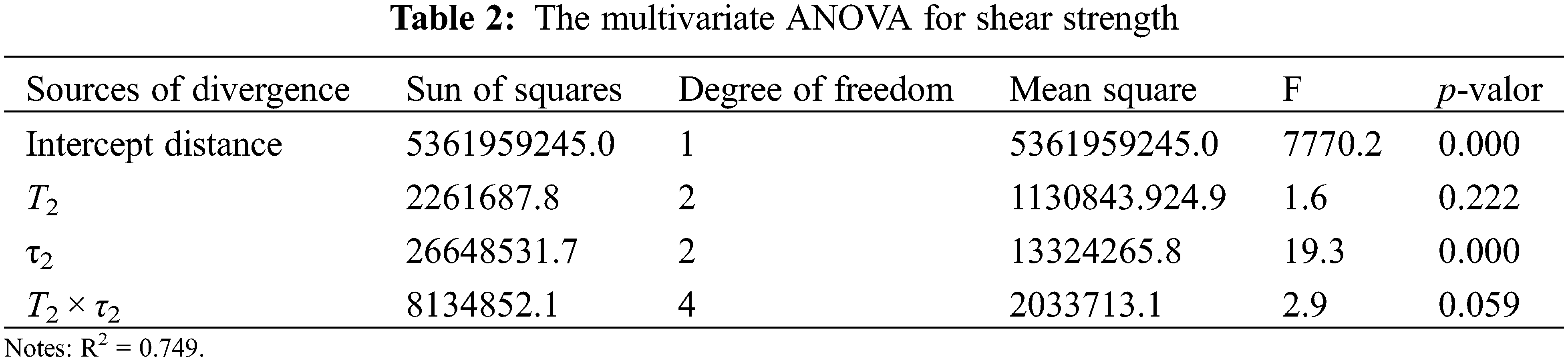

From Figs. 3–5 and Table S4, it can be seen that the T1 and τ1 have no effect on the physical and mechanical properties and the color. Therefore, Tables 1 and 2 show T2 and τ2 and interactions (T2 × τ2) on the MOE and shear strength multivariate ANOVA, respectively. As shown in Table 1, τ2 has more significant effect on the MOE of treated samples (p < 0.05). In contrast, the T2 and (T2 × τ2) have no significant effect on MOE of treated samples (p > 0.05). As shown in Table 2, T2 has no significance effect on the shear strength of the heat-treated samples (p > 0.05). The τ2 and (T2 × τ2) have significant effects on the shear strength of the heat-treated samples (p < 0.05).

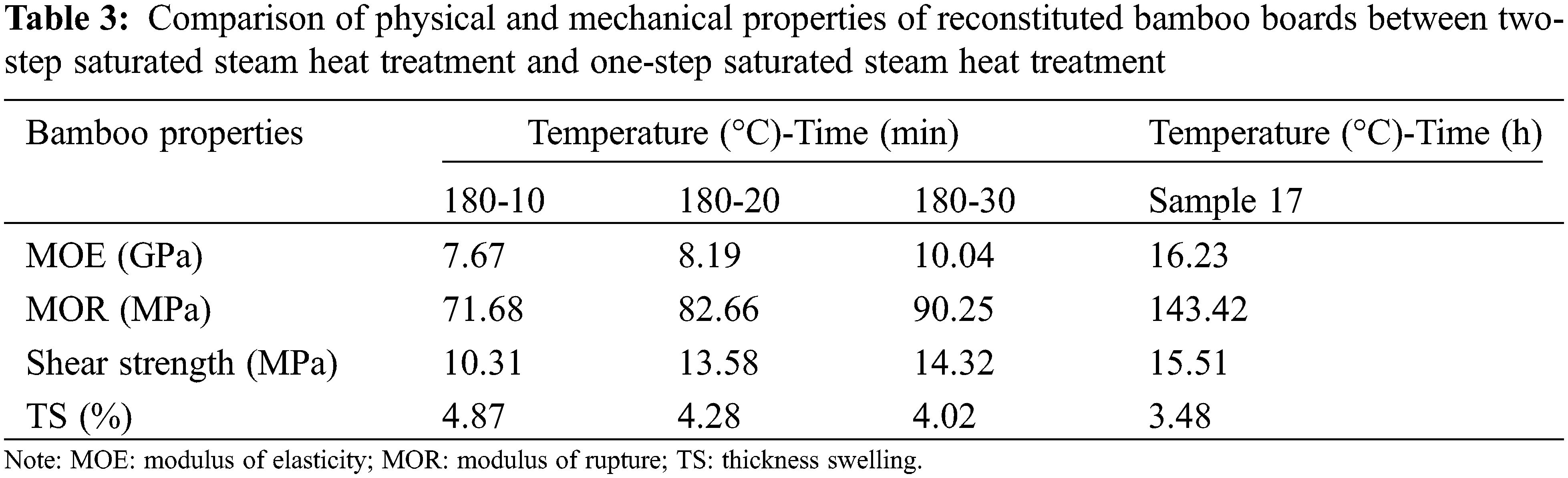

3.6 Comparison of One-Step and Two-Step Saturated Steam Heat Treatment

At present, the commonly used one-step saturated steam heat treatment temperature is 180°C and time is 10 min, 20 min and 30 min. As shown in Table 3. The MOE, MOR and the shear strength of one-step heat treatment saturated steam increase with the time increases. The TS decreases with the increase of one-step heat treatment time. When the one-step heat treatment temperature is 180°C, time is 30 min (180-3), the mechanical properties of the heat-treated samples reaches the highest which the MOE is 10.04 GPa, MOR is 90.25 MPa, and the shear strength is 14.32 MPa. In the meantime, the TS reaches the minimum of 4.02%, the dimensional stability is the best. Thus, the optimal one-step heat treatment process is 180-3.

According to the variation and conclusion of Figs. 3–5 and Table S4, it can be concluded that the optimal two-step saturated steam heat treatment process is Sample 17. Comparison of the optimal process of two-step saturated steam heat treatment and one-step saturated steam heat treatment is shown in Table 3. The result indicates that the two-step saturated steam heat treatment not only improves the physical and mechanical properties, but also improves the dimensional stability. Besides, in the industrialized production of bamboo industry, the two-step saturated steam heat treatment of 140°C and 160°C relative to the high temperature of 180°C of one-step heat treatment greatly reduces the energy consumption of production.

Fig. 6 shows the SEM images of untreated sample, one-step and two-step heat treated bamboo bundles. The cross section and longitudinal section of untreated sample are shown in Figs. 6a–6d, respectively. Figs. 6a–6d show typical bamboo microstructure. Figs. 6e–6h show the microstructure of longitudinal section of one-step and two-step heat treated, respectively. As shown in Figs. 6e–6h, the edge of parenchyma cells become smooth and the cell walls become thinner of heat-treated samples. However, the whole longitudinal microstructure still keeps the original rules.

Figure 6: SEM images of untreated sample, one-step and two-step saturated steam heat treatment bamboo bundles. (a), (b) Cross section of untreated sample, (c), (d) Longitudinal section of untreated sample, (e), (f) Longitudinal section of one-step saturated steam heat treatment and (g), (h) Longitudinal section of two-step saturated steam heat treatment, respectively

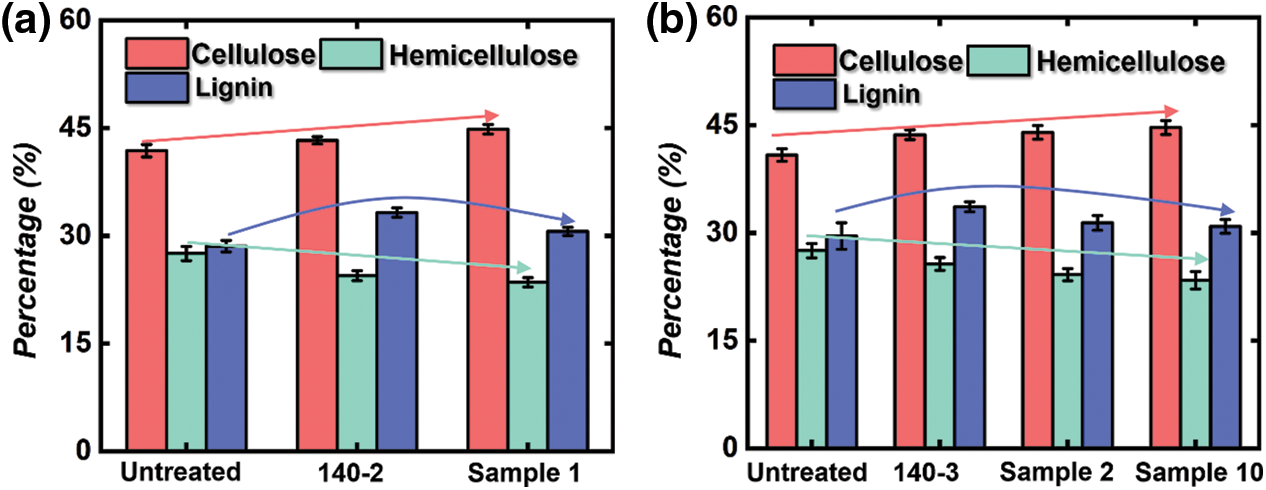

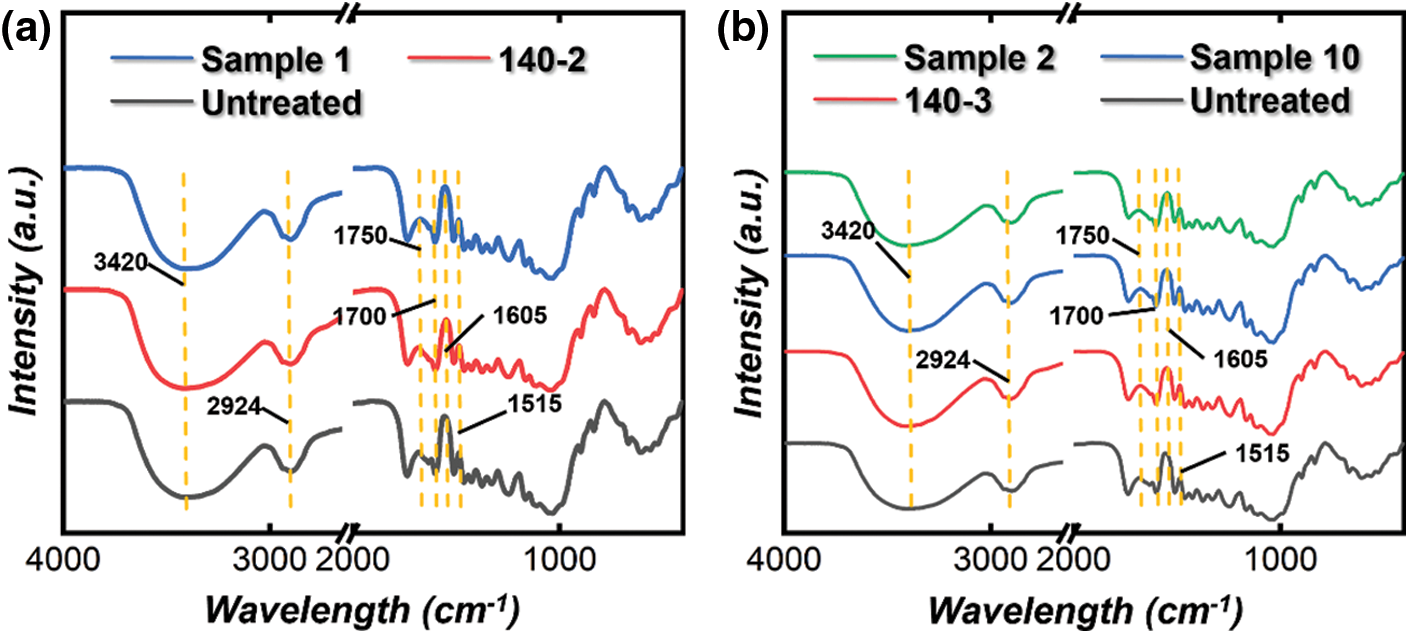

In order to reveal the difference between one-step saturated steam heat treatment (The treatment temperature is 140°C, the treatment time is 2 h and 3 h) and two-step saturated steam heat treatment (Sample 1, Sample 3 and Sample 10). We compare the three major components and FTIR of continuous and discontinuous treatment for 2 h and 3 h. As shown in Fig. 7, compared with untreated sample, the hemicellulose content of heat-treated samples decreases and the cellulose and lignin of heat-treated samples increases. As shown in Fig. 8, 3420 cm−1 is near the hydroxyl absorption peak. 1700–1750 cm−1 is the acetyl absorption peak of hemicellulose xylan, where 1605 cm−1 represents the lignin C=O and C=C aromatic skeletal vibrational bands, and the 1515 cm−1 represents the lignin aromatic ring. Compared with untreated sample, the absorption peaks (1605 cm−1 and 1515 cm−1) of heat-treated samples are higher than untreated sample [23,24]. And the absorption peaks (1700–1750 cm−1) of heat-treated samples is lower than untreated sample.

Figure 7: The percentage of cellulose, hemicellulose and lignin of the one-step and two-step heated bamboo bundles. (a) 2 h, (b) 3 h

Figure 8: FTIR spectra of the untreated sample, one-step and two-step heated bamboo bundles. (a) 2 h, (b) 3 h

As mentioned in Figs. 6e–6h, the smooth and thin parenchyma cells of heat-treated samples may be related to the degradation of the three components. As supposed, the heat treatment time and temperature are constant, the resulted contents of three major components and absorption peaks of components should be the same for one-step and two-step processes. However, as shown in Fig. 7a, we may see that the content of hemicellulose of Sample 1 is lower than that of 140-2. And as shown in Fig. 8a, the acetyl absorption peak of hemicellulose xylan of Sample 1 is lower than that of 140-2. The same trend can be observed for the heat treatment time of 3 h in Figs. 7b and 8b. To explain this, the further oxidation of hemicellulose should be considered.

Because there is a natural conservation during the two-step saturated steam heat treatment process, a large amount of O2 enters into the gap of bamboo bundles. Compared with the continuous one-step saturated steam heat treatment, O2 is supplemented. The increase of O2 content makes the hemicellulose undergo violent oxidation reaction again. Fig. 9 summarizes the different routes of hemicelluloses oxidation. One can see that the hemicelluloses oxidation is very complex. And a series of reaction routes is proposed. First of all, a predominant route is the fragmentation. The sugars hydrolyzed hemicelluloses are randomly fragmented and fragmented-oxidized into organic alcohols (C2–C4) and acids (C3–C6), respectively. Then side reactions such as oxidation are occurred among available organic alcohols and acids. Besides, the larger molecular fragments of sugars are formed by oxidation, fllowed by self-lactonization [25].

Figure 9: Different routes of hemicellulose oxidation [25]

The cellulose in the three major components of bamboo is a linear polymer with uniform chain structure, which is synthesized by the polymerization of dehydrated glucopyranose units. Therefore, cellulose plays a supporting role in the main components of the bamboo cell wall, endowing bamboo with elasticity and strength. The relative crystallinity is the percentage of cellulose crystalline regions in total, with the increase of relative crystallinity, the MOE and MOR of heat-treated samples are improved [26]. Due to the branched-chain structure and amorphous structure, polysaccharides in hemicellulose have low thermal stability at high temperature, which makes hemicellulose easier to decompose than other chemical components in bamboo. In addition, lignin is the main component of the interlayer, and the crosslinking of lignin polymer enhances the strength of the intermediate layer and affects the strength nature of cell wall.

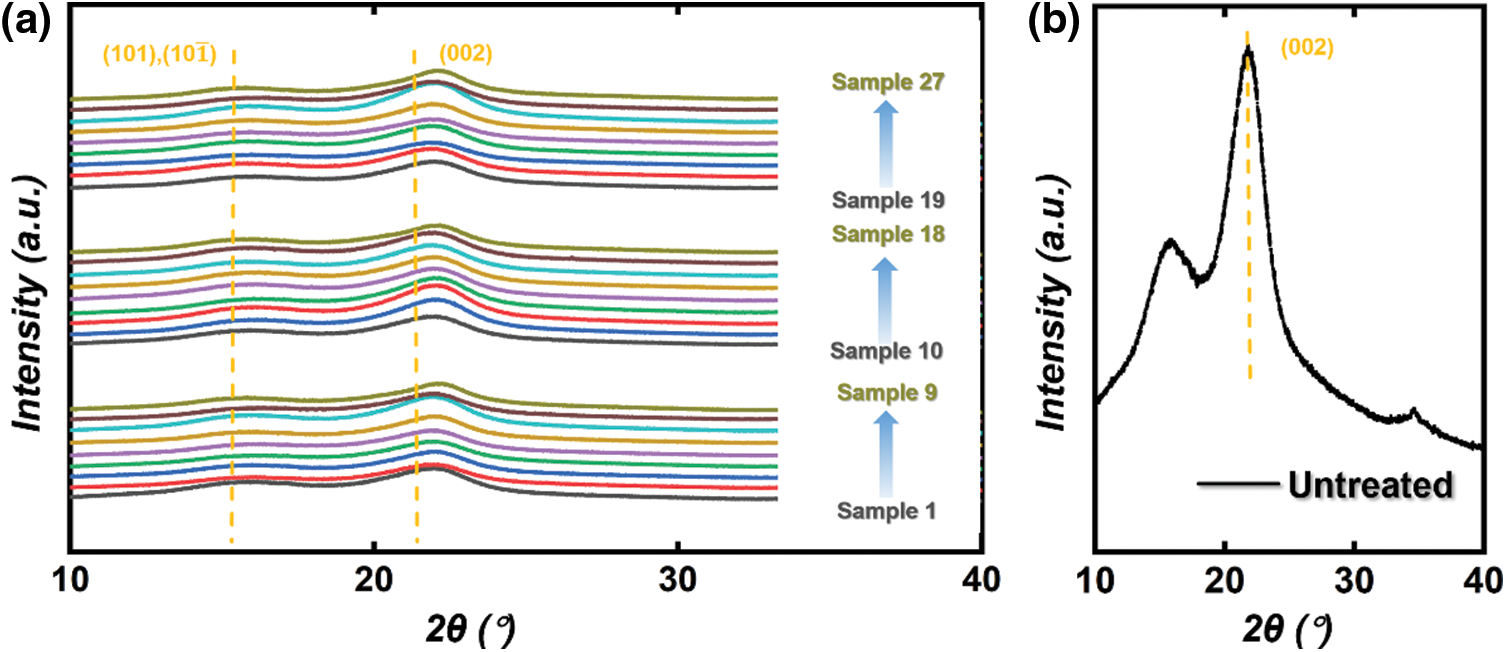

The XRD diffraction patterns of untreated sample and the two-step heated bamboo bundles are shown in Fig. 10. The XRD patterns of heat-treated samples are basically consistent, which show two characteristic peaks. An obvious high diffraction peak at 2θ = 22.00° corresponds to the (002) plane of cellulose crystal. The peak at 2θ = 15.60° corresponds to the (101) and (10

Figure 10: The XRD diffraction patterns of (a) two-step heated bamboo bundles and (b) untreated sample

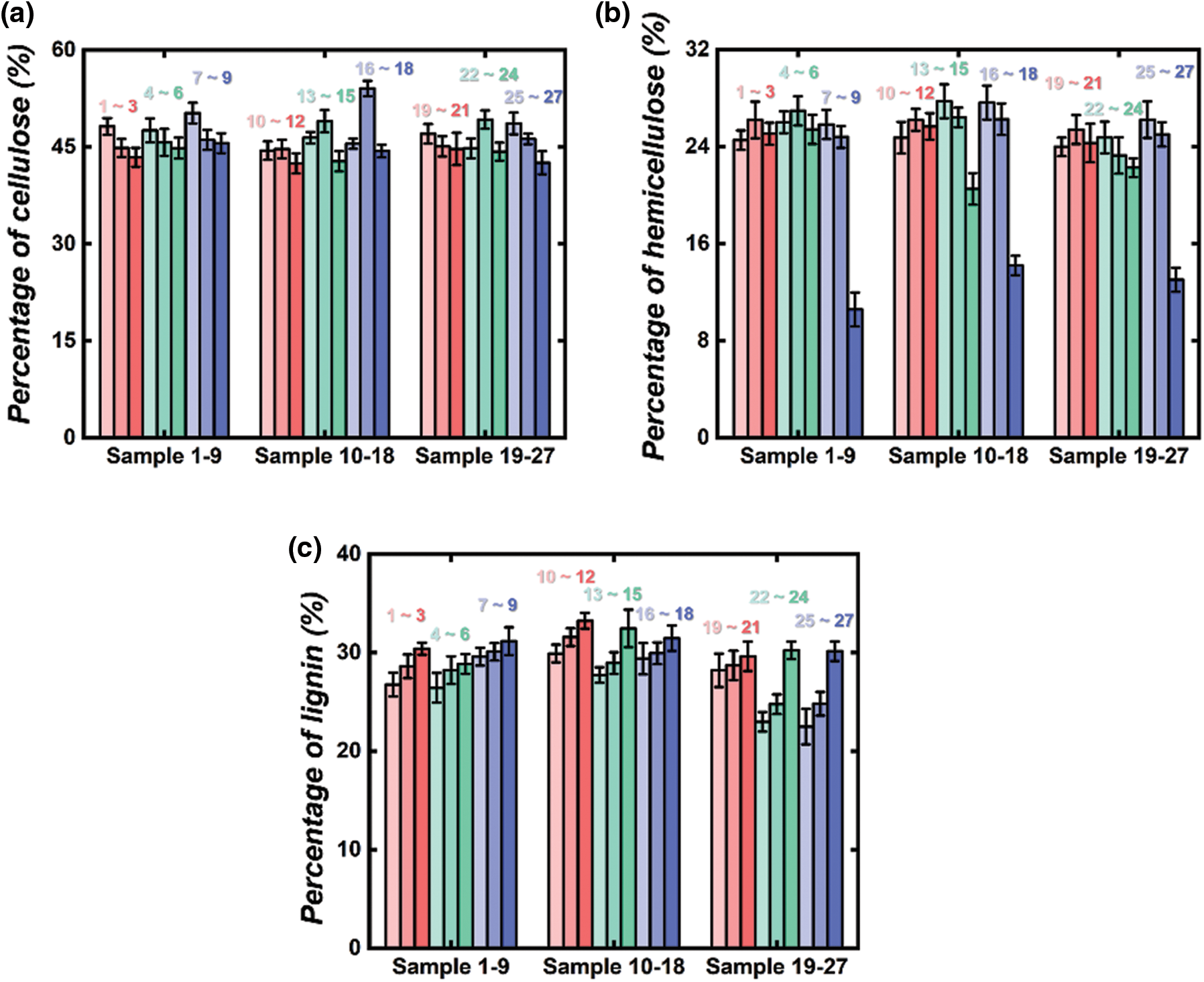

4.4 Three Major Components Analyses

The changes in cellulose content of untreated sample and heat-treated samples are shown in Fig. 11a. Fig. S3 shows the three element contents of untreated sample. As shown in Fig. 11a, the cellulose content of most heat-treated samples is higher than untreated sample. The relative crystallinity obtained in Table S5 is consistent with the change trend of cellulose content. With the development of saturated steam heat treatment, the -OH between the cellulose molecular chains in the amorphous region undergo “Bridge reaction” to form ether bonds [29]. Formation of ether bond increases the relative crystallinity. At the same time, the cellulose content increases due to the closer arrangement between microfibrils.

Figure 11: The percentage of (a) cellulose, (b) hemicellulose and (c) lignin of the two-step heated bamboo bundles

From Sample 1 to Sample 27, the cellulose shows an overall decreasing trend. In particular, form Sample 10 to Sample 12, Sample 13 to Sample 15 and Sample 16 to Sample 18, the cellulose first increases and then decreases. For Sample 17, the cellulose and relative crystallinity reach the maximum value, the values of cellulose and relative crystallinity are 54.05% and 57.12%. This is due to that the dehydration of the cellulose in the presence of saturated steam, which reduces the distance between microfibrils and increases the intermolecular forces in the non-crystalline region of the cellulose [30,31]. Furthermore, closer arrangement of the microfibrils leads to the cellulose content increases. Then, with the increase of heat treatment time, a large amount of hemicellulose is degraded to produce a large amount of acetic acid. And the cellulose in the amorphous region is degraded in acidic environment, resulting in the decrease of cellulose content [32–34]. These are consistent with the change trends of MOE and MOR.

The increase of lignin relative content has a positive effect on the strength and hardness of reconstituted bamboo. The change in lignin content of reconstituted bamboo which was fabricated with the two-step heated bundles is shown in Fig. 11c. The lignin of heat-treated samples is increase compared with untreated sample. For Samples 10 – 18, the lignin increases from Sample 10 to Sample 12, Sample 13 to Sample 15 and Samples 16 to 18. The degradation of polysaccharide substances during the heat-treated resulting in an increase in the relative lignin content. The lignin content decreases from Sample 12 to Sample 13 and Samples 15 to 16. This is because that the heat treatment temperature increases further, the lignin occurs a degree of thermal degradation, resulting in a decrease in the relative lignin content [35].

Hemicellulose, one of the three major components of bamboo, endowing bamboo shear strength. The change of hemicellulose content of reconstituted bamboo which was fabricated with the two-step heated bundles is shown in Fig. 11b. The hemicellulose content of heat-treated samples decreases compared with untreated sample. The acetyl group of hemicellulose begins to hydrolyze and produces acetic acid, which makes the content of hemicellulose gradually decrease [36]. The decrease of hemicellulose leads to the decrease of shear strength of reconstituted bamboo. Besides, with the development of saturated steam heat treatment, the formation of ether bond between cellulose leads to the decrease of hydrogen bonds. And that is also one of the reasons why the shear strength of reconstituted bamboo decreases rapidly at the Sample 9, Sample 18 and Sample 27.

Bamboo is a porous material with high porosity and high specific surface area and there are abundant hydroxyl groups on the cell wall. Therefore, bamboo has high water absorption. Swelling coefficient is a key parameter to measure the dimensional stability of bamboo products [37]. The hemicellulose content of reconstituted bamboo which was fabricated with the two-step heated bundles is shown in Fig. 11b. From Sample 1 to Sample 27, the hemicellulose decreases. Volatilization of free water and extract and a reduction of hydrophilic groups on the hemicellulose main and side chains, resulting in hemicellulose content of heat-treated samples lower than untreated sample. In particular, from Sample 1 to Sample 27, the cellulose shows an overall decreasing trend, due to the continuous increase of temperature and the extension of heat treatment time, the thermal degradation of hemicellulose generates formaldehyde and furfural substances. Formaldehyde and furfural substances have worse water absorption than hemicellulose, which can effectively reduce the moisture absorption of bamboo and improve the dimensional stability [38,39].

The color change is partly caused by the pyrolysis of hemicellulose and polysaccharides [40]. The hemicellulose content of reconstituted bamboo which was fabricated with the two-step heated bundles is shown in Fig. 11b. A large amount of hemicellulose is degraded during the two-step saturated steam heat treatment process, making the color of reconstituted bamboo turns red. With the reaction proceeds, the volatile organic compounds produced by the closed-vapour pressure system polymerise with the reconstituted bamboo, thereby inhibiting further a* enhancement [18,41]. In addition, the heat treatment process is accompanied by the degradation of oxygen-containing groups of hemicellulose such as acetyl and carboxyl groups. At the same time, there is also the occurrence of lignin side chain condensation reaction, which generates new β-β and β-5 condensed structures and new conjugated double bonds, and the conjugated system becomes longer. The shift of the ultraviolet (UV) absorption band to the visible region makes b* and L* decrease, which leads to the color of heat-treated samples becomes blue and dark [42].

In this work, the one-step and two-step saturated steam heat treatments were carried out according to the actual production parameters, and the physical and mechanical properties of the reconstituted bamboo board made of treated bamboo bundles were analyzed, including the color change, modulus of elasticity (MOE), modulus of rupture (MOR), the shear strength and the thickness swelling (TS). Based on the analysis of the test results, the following conclusions can be drawn.

1. In the two-step saturated steam heat treatment process, with the increase of heat treatment temperature time, the content of cellulose and hemicellulose decreases overall due to the acidolysis and dehydration condensation. The degradation of polysaccharide substances during the heat-treated resulting in an increase in the relative lignin content.

2. When the first heat treatment temperature is 140°C, the time is 2 h, the second heat treatment temperature is 160°C, the time is 2 h (Sample 17), the reconstituted bamboo which was fabricated with the two-step heated bundles has the optimal performance. The MOE is 16.23 GPa, the MOR is 143.20 MPa, the shear strength is 15.99 MPa, the TS is 3.48% and the color is light brown.

3. Compared with the one-step saturated steam heat treatment, the two-step saturated steam heat treatment has better performance. Besides, in the industrialized production of bamboo industry, the two-step saturated steam heat treatment of 140°C and 160°C relative to the high temperature of 180°C of one-step heat treatment greatly reduces the energy consumption of production.

Funding Statement: This research was funded by Financial support from the National Natural Science Foundation of China (No. 31971740), Key University Science Research Project of Jiangsu Province (17KJA220004), Jiangsu Agricultural Science and Technology Independent Innovation Fund (CX(20)3041), Science and Technology Program of Fujian Province (2019N3014), Open Fund of Key Laboratory of National Forestry and Grassland Administration/Beijing for Bamboo & Rattan Science and Technology (ICBR-2020-08).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Lou, Z., Wang, Q., Sun, W., Zhao, Y., Wang, X. et al. (2021). Bamboo flattening technique: A literature and patent review. European Journal of Wood and Wood Products, 79(5), 1035–1048. DOI 10.1007/s00107-021-01722-1. [Google Scholar] [CrossRef]

2. Liu, P., Xiang, P., Zhou, Q., Zhang, H., Tian, J. et al. (2021). Prediction of mechanical properties of structural bamboo and its relationship with growth parameters. Journal of Renewable Materials, 9(12), 2223–2239. DOI 10.32604/jrm.2021.015544. [Google Scholar] [CrossRef]

3. Lou, Z., Yuan, T., Wang, Q., Wu, X., Hu, S. et al. (2021). Fabrication of crack-free flattened bamboo and its macro-/micro-morphological and mechanical properties. Journal of Renewable Materials, 9(5), 959–977. DOI 10.32604/jrm.2021.014285. [Google Scholar] [CrossRef]

4. Lou, Z., Wang, Q., Kara, U., Mamtani, R., Zhou, X. et al. (2022). Biomass-derived carbon heterostructures enable environmentally adaptive wideband electromagnetic wave absorbers. Nano-Micro Letters, 14(1), 25–28. DOI 10.1007/s40820-021-00750-z. [Google Scholar] [CrossRef]

5. Lou, Z., Wang, Q., Zhou, X., Kara, U., Mamtani, R. et al. (2021). An angle-insensitive electromagnetic absorber enabling a wideband absorption. Journal of Materials Science & Technology, 129(5), 97–104. DOI 10.1016/j.jmst.2021.11.007. [Google Scholar] [CrossRef]

6. Bari, E., Pizzi, A., Schmidt, O. (2021). Differentiation of fungal destructive behaviour of wood by the white-rot fungus fomes fomentarius by MALDI-TOF mass spectrometry. Journal of Renewable Materials, 9(3), 381–397. DOI 10.32604/jrm.2021.015288. [Google Scholar] [CrossRef]

7. Lou, Z., Han, X., Liu, J., Ma, Q., Yan, H. et al. (2021). Nano-Fe3O4/bamboo bundles/phenolic resin oriented recombination ternary composite with enhanced multiple functions. Composites Part B-Engineering, 226, 109335. DOI 10.1016/j.compositesb.2021.109335. [Google Scholar] [CrossRef]

8. Lou, Z., Yuan, C., Li, Y., Shen, H., Yang, L. et al. (2020). Effect of saturated steam treatment on the chemical composition and crystallinity properties of bamboo bundles. Journal of Forestry Engineering, 11(5), 740–748. DOI 10.13360/j.issn.2096-1359.201905014. [Google Scholar] [CrossRef]

9. Sulaiman, O., Hashim, R., Wahab, R., Ismail, Z., Samsi, H. et al. (2006). Evaluation of shear strength of oil treated laminated bamboo. Bioresource Technology, 97(18), 2466–2469. DOI 10.1016/j.biortech.2005.10.026. [Google Scholar] [CrossRef]

10. Yang, K., Li, X., Wu, Y., Zheng, X. (2021). A simple, effective and inhibitor-free thermal treatment for enhancing mold-proof property of bamboo scrimber. European Journal of Wood and Wood Products, 79(5), 1049–1055. DOI 10.1007/s00107-021-01655-9. [Google Scholar] [CrossRef]

11. Nie, S. D., Ran, S., Wu, D., Chen, J., Wang, H. et al. (2022). Mechanical properties of mmoso bamboo connections with external clamp steel plates. Journal of Renewable Materials, 10(2), 487–510. DOI 10.32604/jrm.2022.017275. [Google Scholar] [CrossRef]

12. Huang, Y., Fei, B., Yu, Y., Zhao, R., Wang, X. (2012). Effect of phenol-formaldehyde-modified on mechanical properties of tracheids cell wall. Scientia Silvae Sinicae, 48(2), 89–92. DOI 10.11707/j.1001-7488.20121214. [Google Scholar] [CrossRef]

13. Guan, M., Yong, C., Wang, L. (2014). Microscopic characterization of modified phenol-formaldehyde resin penetration of bamboo surfaces and its effect on some properties of two-ply bamboo bonding interface. Bioresources, 9(2), 1953–1963. DOI 10.15376/biores.9.2.1953-1963. [Google Scholar] [CrossRef]

14. Yang, T., Lee, C., Lee, C., Cheng, Y. (2016). Effects of different thermal modification media on physical and mechanical properties of moso bamboo. Construction and Building Materials, 119(2), 251–259. DOI 10.1016/j.conbuildmat.2016.04.156. [Google Scholar] [CrossRef]

15. Zhou, K., Li, H., Dauletbek, A., Yang, D., Xiong, Z. et al. (2022). Slenderness ratio effect on the eccentric compression performance of chamfered laminated bamboo lumber columns. Journal of Renewable Materials, 10(1), 165–182. DOI 10.32604/jrm.2021.017223. [Google Scholar] [CrossRef]

16. Wang, X., Song, L., Cheng, D., Liang, X., Xu, B. (2019). Effects of saturated steam pretreatment on the drying quality of moso bamboo culms. European Journal of Wood and Wood Products, 77(5), 949–951. DOI 10.1007/s00107-019-01421-y. [Google Scholar] [CrossRef]

17. Yu, H., Pan, X., Wang, Z., Yang, W., Zhang, W. et al. (2018). Effects of heat treatments on photoaging properties of moso bamboo (Phyllostachys pubescens mazel). Wood Science and Technology, 52(6), 1671–1683. DOI 10.1007/s00226-018-1042-x. [Google Scholar] [CrossRef]

18. Tomak, E., Topaloglu, E., Ay, N., Yildiz, U. (2012). Effect of accelerated aging on some physical and mechanical properties of bamboo. Wood Science of Technology, 46(5), 905–918. DOI 10.1007/s00226-011-0454-7. [Google Scholar] [CrossRef]

19. Ling, Z., Tang, W., Su, Y., Huang, C., Lai, C. et al. (2022). Stepwise allomorphic transformations by alkaline and ethylenediamine treatments on bamboo crystalline cellulose for enhanced enzymatic digestibility. Industrial Crops & Products, 177, 114450. DOI 10.1016/j.indcrop.2021.114450. [Google Scholar] [CrossRef]

20. GB/T 17657-2013 Testing Methods for Physical and Chemical Properties of Wood-Based Panels and Veneered Wood-Based Panels. GB Standards, China. [Google Scholar]

21. Commission Internationale de L’Éclairage-CIE. (1986). Colorimetry. Part 4: CIE 1976 (L*a*b*) System, 2. ed. Vienna; (CIE, 15.2). a. [Google Scholar]

22. Lou, Z., Yang, L., Zhang, A., Shen, H., Liu, J. et al. (2020). Influence of saturated steam heat treatment on the bamboo color. Journal of Forestry Engineering, 5(4), 38–44. DOI 10.13360/j.issn.2096-1359.201906044. [Google Scholar] [CrossRef]

23. Sivonen, H., Maunu, S., Sundholm, F., Jamsa, S., Viitaniem, P. (2002). Magnetic resonance studies of thermally modified wood. Holzforschung, 56(6), 648–654. DOI 10.1515/HF.2002.098. [Google Scholar] [CrossRef]

24. Todorović, N., Popović, Z., Milić, G. (2020). Quality evaluation of heat-treated sessile oak ( Quercus petraea L.) wood by colour and FT-NIR spectroscopy. Wood Material Science & Engineering, 54, 1847188. DOI 10.1080/17480272.2020.1847188. [Google Scholar] [CrossRef]

25. Gao, Y., Wang, H., Guo, J., Peng, P., Zhai, M. et al. (2016). Hydrothermal degradation of hemicelluloses from triploid poplar in hot compressed water at 180°C–340°C. Polymer Degradation and Stability, 126(6), 179–187. DOI 10.1016/j.polymdegradstab.2016.02.003. [Google Scholar] [CrossRef]

26. Chung, M., Wang, S. (2017). Effects of peeling and steam-heating treatment on basic properties of two types of bamboo culms (Phyllostachys makinoi and Phyllostachys pubescens). Journal of Wood Science, 63(5), 483. DOI 10.1007/s10086-017-1647-y. [Google Scholar] [CrossRef]

27. Dixon, P., Ahvenainen, P., Aijazi, A. (2015). Comparison of the structure and flexural properties of moso, guadua and Tre Gai bamboo. Construction and Building Materials, 90(2), 11–17. DOI 10.1016/j.conbuildmat.2015.04.042. [Google Scholar] [CrossRef]

28. Lou, Z., Wang, Q., Sun, W., Liu, J., Yan, H. et al. (2022). Regulating lignin content to obtain excellent bamboo-derived electromagnetic wave absorber with thermal stability. Chemical Engineering Journal, 430, 133178. DOI 10.1016/j.cej.2021.133178. [Google Scholar] [CrossRef]

29. Tang, T., Chen, X., Zhang, B., Liu, X., Fei, B. (2019). Research on the physico-mechanical properties of moso bamboo with thermal treatment in tung oil and its influencing factors. Materials, 12(4), 587–599. DOI 10.3390/ma12040599. [Google Scholar] [CrossRef]

30. Saikia, P., Dutta, D., Kalita, D., Bora, J., Goswami, T. (2015). Improvement of mechano-chemical properties of bamboo by bio-chemical treatment. Construction and Building Materials, 101(6), 1031–1036. DOI 10.1016/j.conbuildmat.2015.10.106. [Google Scholar] [CrossRef]

31. Tang, A., Huang, Y., Zhang, W., Yu, Y., Yang, Y. et al. (2021). Effect of the nano-titanium dioxide (nano-TiO2) coating on the photoaging properties of thermally treated bamboo. Wood Material Science & Engineering, 23(2), 1–10. DOI 10.1080/17480272.2021.1972334. [Google Scholar] [CrossRef]

32. Lv, H., Ma, X., Zhang, B. (2019). Microwave-vacuum drying of round bamboo: A study of the physical properties. Construction and Building Materials, 211(5), 44–51. DOI 10.1016/j.conbuildmat.2019.03.221. [Google Scholar] [CrossRef]

33. Behr, G., Bollmus, S., Gellerich, A., Militz, H. (2018). Improvement of mechanical properties of thermally modified hardwood through melamine treatment. Wood Material Science & Engineering, 13(5), 262–270. DOI 10.1080/17480272.2017.1313313. [Google Scholar] [CrossRef]

34. Patcharawijit, A., Yam, R., Choodum, N. (2020). Superheated steam treatment of rubberwood to enhance its mechanical, physiochemical, and biological properties. Wood Material Science & Engineering, 15(5), 261–268. DOI 10.1080/17480272.2019.1594364. [Google Scholar] [CrossRef]

35. Yang, Y., Fahmy, M., Pan, Z., Zhan, Y., Wang, R. et al. (2020). Experimental study on basic mechanical properties of new BFRP-bamboo sandwich structure. Construction and Building Materials, 264, 120642. DOI 10.1016/j.conbuildmat.2020.120642. [Google Scholar] [CrossRef]

36. Li, T., Cheng, D., Avramidis, S., Walinder, M., Zhou, D. (2017). Response of hygroscopicity to heat treatment and its relation to durability of thermally modified wood. Construction and Building Materials, 144(6), 671–676, DOI 10.1016/j.conbuildmat.2017.03.218. [Google Scholar] [CrossRef]

37. Su, N., Fang, C., Zhou, H., Tang, T., Zhang, S. et al. (2021). Hydrophobic treatment of bamboo with rosin. Construction and Building Materials, 271, 121507. DOI 10.1016/j.conbuildmat.2020.121507. [Google Scholar] [CrossRef]

38. Sheikh, A., Tom, M., Margot, S., Blom, A. (2017). Effect of oil impregnation on water repellency, dimensional stability and mold susceptibility of thermally modified european aspen and downy birch wood. Journal Wood Science, 63(1), 74–82. DOI 10.1007/s10086-016-1595-y. [Google Scholar] [CrossRef]

39. Zhang, Y., Yu, Y., Lu, Y., Yu, W., Wang, S. et al. (2021). Effects of heat treatment on surface physicochemical properties and sorption behavior of bamboo (Phyllostachys edulis). Construction and Building Materials, 282, 122683. DOI 10.1016/j.conbuildmat.2021.122683. [Google Scholar] [CrossRef]

40. Yao, C., Fang, Y., Gao, J., Li, H. (2012). Coloring characteristics of in situ lignin during heat treatment. Wood Science of Technology, 46(1), 33–40. DOI 10.1007/s00226-010-0388-5. [Google Scholar] [CrossRef]

41. Esteves, B., Velez Marques, A., Domingos, I., Pereira, H. (2008). Heat-induced colour changes of pine (Pinus pinaster) and eucalypt (Eucalyptus globulus) wood. Wood Science and Technology, 42, 369–384. DOI 10.1007/s00226-007-0157-2. [Google Scholar] [CrossRef]

42. Lee, C., Yang, T., Cheng, Y., Lee, C. (2018). Effects of thermal modification on the surface and chemical properties of moso bamboo. Construction and Building Materials, 178(6), 59–71. DOI 10.1016/j.conbuildmat.2018.05.099. [Google Scholar] [CrossRef]

Appendix A:

The following formulas are the calculation formulas of the sum of squares (Eqs. S(1)–S(6)).

p-valor indicates whether the source of variance has a significant effect on the test results, where when the significance is less than 0.05, it means that the source of variance has a significant effect on the experimental results.

The above equation is the mathematical model of the two-factor interaction test ANOVA. yijk is the kth observation value of the combination of the i-th level of influencing factor A and the j-th level of influencing factor B. μ denotes the total average of the observed values without considering the influence of factors A and B, and it is the constant term (intercept) of the model. αi is the effect of level Ai. βj is the effect of level Bj. γij represents the interaction effect of the level I of the influencing factor A and the j level collocation of the influencing factor B. εijk is the random error of the kth observation value in the combination of the i-th level of influencing factor A and the j-th level of influencing factor B.

Figure S1: Modulus of elasticity and modulus of rupture of the untreated sample

Figure S2: Shear strength and thickness swelling of untreated sample

Figure S3: Three major components of untreated sample

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |