| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.022624

REVIEW

A Review on the Mechanical Behaviour of Bamboo Reinforced Concrete Beams

1College of Civil Engineering, Nanjing Forestry University, Nanjing, 210037, China

2Joint International Research Laboratory for Bio‑composite Building Materials and Structures, Nanjing Forestry University, Nanjing, 210037, China

3University College London, London, WC1E 6BT, UK

*Corresponding Author: Haitao Li. Email: lhaitao1982@126.com

Received: 17 March 2022; Accepted: 21 April 2022

Abstract: In light of the increasing demand for sustainable building materials, the effectiveness of bamboo utilization in various fields has become the object of scientists’ close attention. The increased interest in bamboo is explained by its sustainable characteristics, which make it the most preferred material for environmentally friendly and cost-effective construction compared to conventional ones. Applicability of bamboo is vast and diverse: from decoration and furniture to structural members and reinforcement. Due to the low price, rich resources, and high elasticity, bamboo culms have also been used as an alternative to steel reinforcement in concrete structures. Extensive research has been done to assess feasibility of bamboo reinforcement in structural elements made of concrete. This article discusses the mechanical properties of three types of structural bamboo reinforced concrete (BRC) beams. Existing original papers on the mechanical behaviour of structural BRC members were studied, and the fundamental properties including typical failure modes, reasons of failure, load-displacement relationships, and influencing factors were discussed and described. Observations and conclusions of the review will contribute to deep understanding of structural feasibility of BRC beams and serve as a base for future research.

Keywords: Concrete; bamboo; bamboo reinforced concrete; mechanical behaviour

With the development of sustainable design and construction technologies [1], such as Passive Housing, Low Energy Buildings [2], and Net-zero Energy Buildings, the requirements for building materials have increased dramatically. According to recent studies on sustainable construction [3–5], building materials are responsible for 60%–80% of emissions and energy consumption due to the depletion of non-renewable resources, energy-intensive production, and transportation [6]. The development of resilient building materials has become one of the essential tasks to improve the sustainability of the construction sector. Over the past decade, original bamboo has received much attention due to its sustainability and strength [7–9]. The mechanical characteristics of bamboo may vary depending on the species and moisture content. In general, the mechanical properties of original bamboo can be compared with that of mild steel [10], cast iron, aluminium alloys, and wood [11–16]. Considering the excellent mechanical properties of bamboo, many scientists have studied its use as reinforcement for concrete structures in order to reduce the environmental impact of steel reinforcement without reducing strength. Table 1 shows the tensile properties of bamboo compared to conventional reinforcing materials [17,18].

Concrete is one of the most widely used building materials in the world. Unlike wood and bamboo, concrete is an isotropic material, and its mechanical properties are uniform in any direction. Despite its increasing strength over time, concrete is brittle and weak under tensile loads [28]. Due to the non-renewable aspect and high cost of steel, many researchers have developed various ways to increase the ductility of concrete by reinforcing it with natural fibres such as coir, malva, sugarcane, kenaf bast, bamboo, banana, pineapple leaf, date, sisal, vakka, palm, jute, hemp, elephant grass, Hibiscus cannabinus, abaca leaf, ramie bast, flax, sansevieria leaf, and wheat straw [28–32]. Since 1950, bamboo has been used for concrete reinforcement [33].

The mechanical properties of bamboo reinforced concrete (BRC) were compared with plain concrete (PC) and steel-reinforced concrete (SRC). It was reported that the strength of the BRC members increased twice compared to PC and constituted 35% of the strength of SRC [33]. Various BRC members were tested, including beams, columns, and slabs. Ghavami [34] conducted a review on BRC application in structures, and Archila et al. [35] gave a critical assessment of the applicability of BRC based on a case study. Both authors highlighted the advantages and disadvantages of the material in terms of environmental friendliness, durability, and mechanical properties, comparing it with SRC. However, there is still no review of the current state of the art in BRC research focusing on fundamental mechanical properties and failure mechanisms.

The current study attempted to review existing literature on the mechanical properties of BRC structural beams. The review is not all-encompassing and includes selected original articles that focus on the mechanical properties of BRC members, particularly beams, which were published over the past ten years and included in the ScienceDirect and Engineering Village databases. The research boundaries include concrete beams reinforced with bamboo bars and their structural performance in particular failure mechanisms, reasons for failure, influencing factors, load-deflection, and stress-strain relationships. The summary of the paper will contribute to a better understanding of the mechanical properties of BRC structural beams and serve as a base for future research.

In the engineering sector, steel is preferred as a reinforcing material due to its yielding characteristics, which helps to inform people in the building about its impending destruction. In contrast to steel, bamboo, as well as concrete, are brittle materials [36,37]. Numerous studies recommended applying excessive reinforcement or a lower workload than the strength limit of the composite [38]. Despite the lower ductility of bamboo, its elasticity, superior durabillity when compared to steel, and its ability to absorb energy, have made it a fairly strong alternative for concrete reinforcement [39,40].

The production of bamboo bars is not much different from bamboo strips for laminated bamboo lumber and has similar stages of sampling, processing, and treatment [41–45]. However, at the stage of drying and treatment, the preparation of bamboo bars ends, while bamboo strips for laminated bamboo lumber undergo further bleaching or carbonization with subsequent gluing and pressing [46–48].

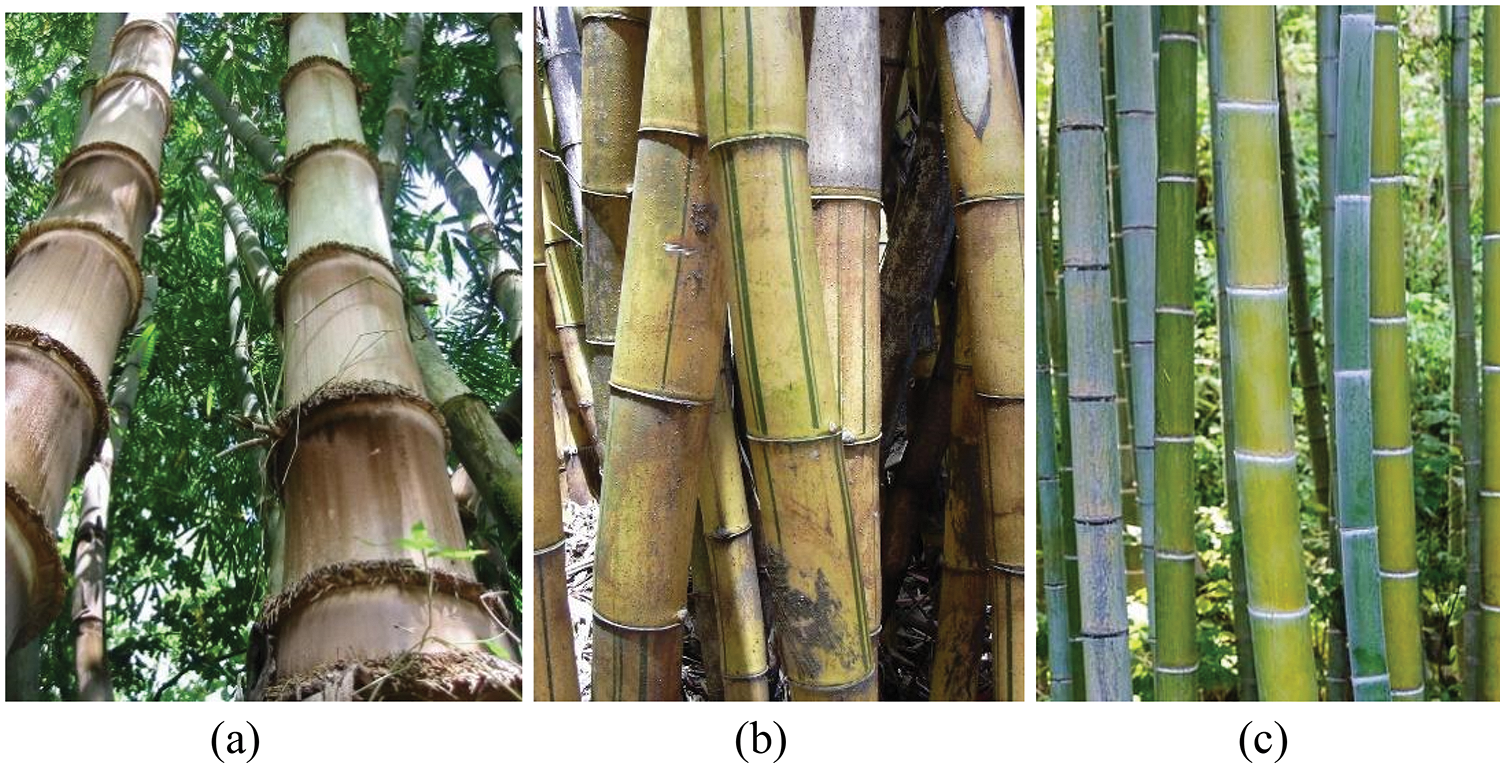

According to the articles reviewed, the bamboo species of Dendrocalamus and Bambusa were often chosen as reinforcing material (Fig. 1). It is known that the strength of bamboo depends on the bamboo species. In their study, Yeh et al. [49] compared the mechanical properties of bamboo species Phyllostachys pubescens (Moso) and Dendrocalamus latiflorus (Ma) (Fig. 1).

Figure 1: Bamboo species (a) Dendrocalamus; (b) Bambusa; (c) Phyllostachys (taken from [50–52])

According to the results of bending tests, the modulus of rupture (MOR) of Moso bamboo strips was 48.7% higher than that of Ma bamboo. It was explained by the difference in bamboo density; Moso bamboo was 21% higher in density than Ma bamboo. However, the effect of this factor on the bending properties of BRC beams was not taken into account in the reviewed studies.

Similar to the production of laminated bamboo lumber, 3–4-year-old bamboo culms of brown colour are selected to produce bamboo bars. It is necessary to avoid using green culms of freshly cut bamboo from March to June since this type of bamboo absorbs more moisture and has a low strength capacity [39]. It should be noted that the bigger the diameter of the bamboo culm, the stronger it is [39].

After harvesting, the culms are cut into bamboo strips and processed. Full culms are not recommended for use as concrete reinforcement, as they are hollow and less resistant to swelling than bamboo strips.

Bamboo strips are seasoned outdoors for two to four weeks. The seasoning is carried out to reduce the moisture content in bamboo before using it. This is also known as the bamboo drying process. This step is carried out to prevent insect and fungi attacks and to reduce problems that may appear during further processing of bamboo, such as warping or smoking [39,53,54]. The outdoor seasoning process is traditional and differs from oven drying, in which moisture is removed at high temperatures.

After drying, bamboo strips are leached to remove the juice after cutting the bamboo. This process is carried out by photosynthesis or mechanical processing.

The durability of bamboo depends on changes in its chemical composition in cellulose, hemicellulose, and lignin, which are breeding grounds for bacteria, fungi, mold, and food for insects [35]. When bamboo reaches maturity, its tissues and cells begin to decompose. At the same time, the outer part of the bamboo culm is stronger and more durable than its inner part [21]. Such strength grading of bamboo also needs to be considered when designing a BRC composite.

Over the past decade, scientists have conducted several studies to increase the durability of bamboo for reinforcing cement materials using various methods. Many studies have looked into the effect of an alkaline environment on the durability of bamboo previously. According to the experimental results, the highly alkaline medium destroys the cells of lignocellulose materials, such as bamboo and wood, and promotes the best adhesion to the concrete mixture [39,55–57]. To protect against insects, scientists have proposed chemical treatment with a solution of tap water and calcium hydroxide [39].

Bamboo is also susceptible to rotting and this contributes to cracks in the concrete due to the bamboo’s ability to absorb and release moisture [34]. Moisture absorption contributes to the swelling of bamboo strips and pushes back the walls of concrete. With the evaporation of moisture, bamboo shrinks in size, leaving voids leading to the appearance of cracks. This problem occurs when curing concrete (Fig. 2).

Figure 2: Dimensional changes of bamboo in concrete: (a) bamboo strip in concrete; (b) swelling of the bamboo strip; (c) shrinking of the bamboo strip (reproduced from Javadian et al. [58])

In addition, the differential coefficient of thermal expansion (CTE) of bamboo can also lead to cracking concrete. According to previous studies, the CTE of bamboo was five times lower than that of concrete or steel in the axial direction and two times higher in the transverse direction [35]. It was reported, that the longitudinal CTE of bamboo was from 2.5 to 10 × 10−6/C, while transverse CTE was about an order of magnitude larger [35,59]. Researchers have proposed a number of measures to improve the water-resistance of bamboo reinforcement while improving the adhesion between bamboo and concrete and the friction properties of the bamboo surface. The types of treatments proposed by the researchers include epoxy coating followed by sand spraying, processing with asphalt paints, tar-based paints, and specific bituminous materials [60].

The international or national standards are used for concrete mix design, such as IS 10262, [60,61], and the mix proportions vary from the purpose of the study and can be seen in Table 3. The bamboo must be properly tied down before the concrete can be poured. Bamboo should be fixed in a logical sequence to prevent it from floating up in the concrete during the placement and vibration [62]. Fig. 3 shows the steps of the BRC manufacturing process.

Figure 3: BRC material production process

The strength of the BRC beams depends primarily on the bond strength, which is determined by the following factors: the adhesion strength of bamboo reinforcement with concrete mix, the water-repellent properties of bamboo, and the friction properties at the bamboo-concrete interface. To study the bond strength of the BRC specimens, the researchers conducted a series of shear pull-out experiments considering different types of treatments and bamboo surface modifications (Fig. 4).

Figure 4: Pull-out test of the bamboo-concrete specimen

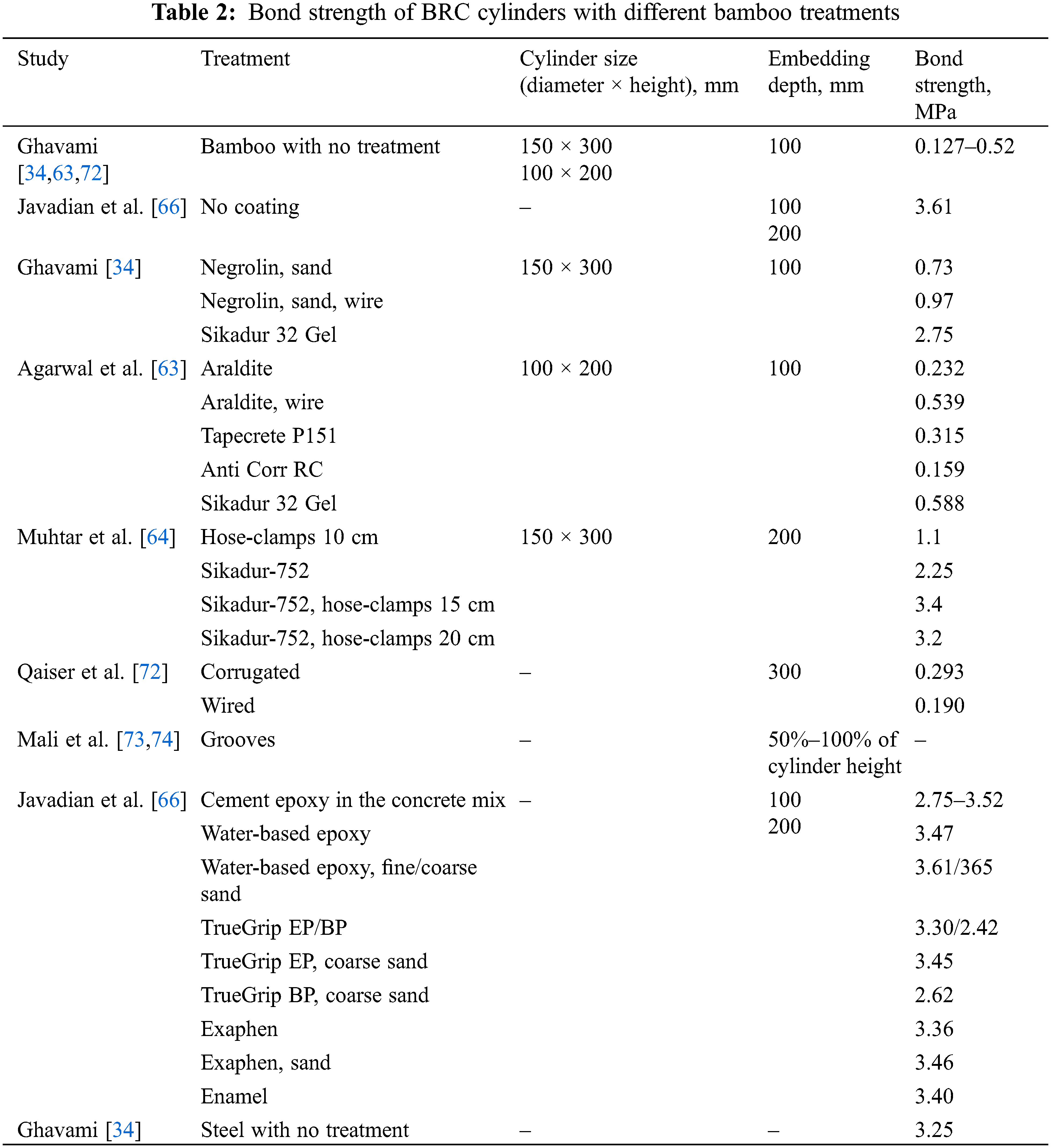

Ghavami [34] examined the bond strength of bamboo-concrete specimens. Part of the bamboo bars were treated with Negrolin (bituminous product), wrapped with wire of 1.5mm diameter, and coated with sand. Another part was coated with Sikadur 32 Gel. All the specimens were subjected to pull-out tests, and according to the results (Table 2), the specimens with bamboo bars treated with Sikadur 32 Gel showed the best performance with increased bond strength by 5.29 times.

Agarwal et al. [63] examined the interfacial performance of bamboo-concrete specimens treated with different adhesives, including Araldite (epoxy glue), Araldite with binding wire, Tapecrete P-151 (acrylic-based polymer), Anti Corr RC, and Sikadur 32 Gel (epoxy glue). Similar to the findings of Ghavami [34], specimens treated with Sikadur 32 showed the highest strength (Table 2), while Araldite with binding wire showed similar strength. According to the results, most of the specimens failed due to the slipping of bamboo bars from the concrete cylinders (Fig. 5a).

Figure 5: Failure patterns of bamboo-concrete specimens in pull-out tests: (a) slipping of bamboo; (b) concrete cone failure; (c) bamboo tensile failure (extracted from Javadian et al. [58] and Muhtar et al. [64])

Javadian et al. [58,65,66] considered the effect of several coatings and embedding lengths of 100 and 200 mm on the bonding between the bamboo and concrete. Treatment included a waterproof vapour barrier membrane, a bio-based epoxy resin (Exaphen), a two-part epoxy resin (TrueGrip EP/BP), and a two-part epoxy resin with and without sand coating. According to the results, bamboo bars with an embedment length of 200 mm and treated with waterproof vapour barrier membrane and sand particles showed a similar bond strength as plain Glass Fibre Reinforced Polymer (GFRP) in normal strength concrete. The enhancement in bond strength was explained by the water and moisture repellent property of the coating. The addition of sand helped improve the roughness of the bamboo surface, resulting in improved mechanical interlock with concrete matrix aggregates.

Similar to previous studies, Kumar et al. [39] and Mengistu [67] stated that epoxy-based adhesives increase the bonding strength of the bamboo with the concrete. Terai et al. [68] reported that bamboo treated with synthetic resin and synthetic rubber enhanced the bond stress capacity of the BRC composite twice compared to the plane specimen. According to Jung [69], an increase in bond strength could be achieved by keeping bamboo at a distance of 1.5 inches from the center of the specimen. Santos et al. [70] attempted to increase the bonding strength of bamboo by a pozzolanic reaction between the silica (SiO2) contained in bamboo and the Ca (OH)2 in Portland cement. However, the increase in bond strength turned out to be negligible since silica located in the epidermic of bamboo culms or splints could not be exposed to the concrete properly to ensure the successful pozzolanic reaction.

3.2 BRC with Surface Modification

Considering the weak bonding performance of bamboo strips with concrete matrix, most studies developed new approaches, including grooving, wire wrapping, hose-clamping, and other modifications to the bamboo surface (Fig. 6).

Figure 6: Modification of bamboo surface: (a) bamboo bars with hose-clamps; (b) bamboo bars with semi-rectangular grooves; (c) bamboo bars with semi-circular corrugations; (d) bamboo bars with wire wrappings (extracted from Muhtar et al. [71], Qaiser et al. [72], and Mali et al. [73])

Qaiser et al. [72] examined the pull-out strength of bamboo bars with different surface modifications, including semi-circular corrugations with a pitch of 5–25 mm depth, binding wire of 2 mm thick wrapped at a distance of 10–25 mm. According to the results, corrugated bamboo strips showed better bonding due to concrete filling into pitches (Table 2). Wired bamboo showed higher (17%) resistance to slipping than plain bamboo specimens. However, both plain bamboo and wired bamboo exhibited low bonding strength and failed due to slipping, while corrugated bamboo increased pull-out strength by 80% when compared to plain ones and broke outside the cylinder since it could not be pulled out from the concrete (Fig. 6c).

Similar to the previous study, Mali et al. [73,74] examined the bond behaviour of grooved bamboo bars coated with Bond Tite 26 adhesive and sand and wrapped with steel wire. The authors considered different parameters affecting the bond strength of the bamboo-concrete cylinders, such as groove shapes (V-notch, rectangular, semi-circular), embedded lengths (50%, 75%, 100% of cylinder height), and the ratio of groove size to its spacing (1:1, 1:2, 1:3). Based on the results, the specimens with semi-circular grooves, 50% embedding length, and a ratio of 1:1 exhibited the highest bond strength due to the mechanical interlock. However, the processing of bamboo strips with semi-circular grooves was practically difficult. Instead, bamboo bars with rectangular grooves were suggested since they were easy to corrugate. Based on the results of pull-out tests, bamboo bars with rectangular grooves of 10 mm width and 5 mm depth made in a zigzag manner at 20 mm distance showed the highest bond with concrete mix.

Muhtar et al. [64] carried out shear pull-out tests on bamboo-concrete specimens with the following treatments: a hose-clamp of 10 cm span, Sikadur-752, Sikadur-752 with a hose-clamp of 15 cm span, and Sikadur-752 with a hose-clamp of 20 cm span. Based on the results, bamboo bars treated with Sikadur-752 having hose-clamps of 15 and 20 cm spans and coated with sand increased the bond strength by 214% and 200%, respectively. Specimens coated with epoxy glue and sand without hose clamps showed a 125% increase in bond strength. Bamboo bars with hose-clamps including a 10 cm span with no glue and sand coating increased the pull-out strength by only 8%. The specimens showed different failure patterns corresponding to the treatment type [64]. Specimens with Sikadur-752, hose-clamps, and sand failed in bond and concrete cone failure (Fig. 5b), showing excellent attachment of bamboo to the concrete matrix. Although specimens with Sikadur gel and sand showed strong bond strength, the specimens failed due to the slipping of bamboo bars from concrete (Fig. 5a). Specimens with hose clamps only showed weak bond strength and failed due to bond-slipping. The authors stated that the bond-slip failure pattern occurred due to the swelling and shrinking of bamboo during concrete curing. Water absorbed by bamboo caused dimensional changes, which led to a loosening of the hose clamps and a corresponding weak bond between bamboo and concrete.

Table 2 shows the changing trends in the bond strength values corresponding to the bamboo treatment type.

Overall studies on the shear pull-out behavior of bamboo reinforcement in concrete cylinders recommend using waterproof coatings of bamboo to ensure moisture barrier that protects the bamboo from dimensional changes, increases the attachment of bamboo to the concrete matrix, and improves the physical and mechanical properties. As shown in Table 2, bamboo surface grooving, wrapping with binding wire, corrugation, and adding hose clamps improve the frictional properties of bamboo, leading to a better bond with the concrete through the mechanical interlock. Without waterproof coating, the idea of bamboo surface modification has no significant effect due to the water absorption of bamboo.

4 The Mechanical Behaviour of BRC Beams

The review covered the following questions: what the fundamental mechanical properties of BRC structural members in terms of flexural and compression strength are; and what are the most typical failure mechanisms, modes, load-deflection behaviour, and influencing factors.

Beams are structural elements that are subjected to bending forces. Over the past decade, most research has been done on the mechanical properties of the BRC beams compared to other structural elements. For this part, 12 experimental studies on the flexural behaviour of the BRC beams of different sizes were selected. Table 3 shows the details of selected studies on bending performance. The review focuses on research conducted over the last decade, from 2011 to 2021. The review also included a survey undertaken in 2005.

4.1 Failure Modes of BRC Beams

One of the first attempts to evaluate the fundamental flexural characteristics of BRC beams was made by Ghavami [34]. The investigation focused on the structural performance of BRC beams considering different q. For the bending test, BRC beams with the size of 120 mm × 300 mm × 3400 mm were prepared. The reinforcement system was made of split bamboo culms of 30 mm wide, wrapped with 1.5 mm wire at a distance of 10 mm. The reinforcement was coated with an impermeable layer and sand to improve bamboo’s water resistance and bonding performance. The q was set as 0.75%–5.00%. The purpose of the study was to find out the optimum q for BRC beams. Before the experiment, BRC beams were curried for 28 days. According to the 4-point bending test results, all beams failed due to the tensile failure of bamboo and concrete. There were three failure modes: when the beam was under-reinforced and failed in bending, when the beam was over-reinforced and failed in compression, and when both concrete and bamboo collapsed simultaneously. Terai et al. [75] also evaluated the flexural behaviour of BRC beams with dimensions of 125 mm × 250 mm × 1500 mm considering different shear to span ratios (0.6–2.0). According to the results of 4-point bending tests, the beams had the same failure behaviour as SRC beams, characterised by the crack appearance on the bottom of the beam,propagating to the top layer.

Karthik et al. [76] investigated the effect of manufactured sand (m-sand) and mineral admixtures on the flexural performance of BRC beams. The research included three types of mixes for the specimens: conventional mix 1:2:4 of cement, sand, and granite; mix 2 was composed of m-sand, granite, and cement as the binder; mix 3 was made of m-sand, granite, 75% of cement, 12.5% of fly ash, and 12.5% of Ground Granulated Blast-furnace Slag (GGBS). The reinforcement matrix contained four bamboo bars of 10 mm × 10 mm × 480 mm; the bamboo bars were wrapped by binding wire (y6@300), and their surface was greased to improve water resistance and increase bond strength. The dimension of the beams was 100 mm × 100 mm × 500 mm; the curing period was 28 days. Based on the 4-point bending test results, the failure mode of the conventional mix of BRC beams was similar to previous studies and characterised by diagonal tension failure at the middle part (Fig. 7a). In contrast, both mixes exhibited brittle mode failure due to the poor bonding of bamboo and concrete (Fig. 7b).

Figure 7: Failure patterns of BRC beams: (a) conventional BRC beam; (b) Mix 1/2 BRC beam; (c) BRC beam with Sikadur 32 Gel (extracted from Karthik et al. [76] and Agarwal et al. [63])

In most studies, the authors mentioned that the smooth surface of bamboo led to a poor bond between reinforcement and concrete matrix, which negatively affected the flexural strength and failure mode of BRC beams. Considering the weak bond between bamboo interface and concrete, Agarwal et al. [63] and Mishra et al. [77] used the adhesive Sikadur 32 Gel to improve the bonding strength and overall flexural performance of BRC beams. The dimensions of BRC beams were 75 mm × 150 mm × 1000 mm and q = 1.49%. The reinforcement was composed of 2 longitudinal bamboo bars with an area of 70 mm2 each. According to the 4-point bending test results, BRC beams with untreated bamboo reinforcement failed due to bond failures and were characterised by cracks appearing along the bamboo bars. In contrast, BRC beams with treated bamboo bars failed due to the simultaneous effect of shear and bending loads which led to crack formation on the bottom of the beam. The following crack propagation to the top surface of the beam and spalling of concrete caused the beam’s failure (Fig. 7c) [63,77].

Muhtar et al. [64] suggested the hose clamping approach. The experimental part included 75 mm × 150 mm × 1100 mm beams with two bamboo bars installed as tensile reinforcement. The reinforcement area constituted 140, 200 and 450 mm2. The distance between hose clamps was 150, 200, and 250 mm (Fig. 6a). With finite element modeling, the authors gave a better understanding of the failure modes in BRC beams. Similar to previous studies, the initial cracks appeared on the tensile surface, i.e., in the middle span of the bottom of the beam. The major cracks branched into small cracks in the position of bamboo bars and propagated right, left, and upward following the bamboo reinforcement direction (Fig. 8a). Hose-clamps worked as barriers that transferred the load to the concrete.

Figure 8: Failure patterns of the beams: (a) BRC beam with hose-claps; (b) SRC beam (extracted from Muhtar et al. [64])

Qaiser et al. [72] suggested open-loop stirrups to improve the BRC beams’ flexural performance. The size of the beams was 230 mm × 230 mm ×1880 mm, q = 4%. In addition, the authors considered the effect of different thicknesses of bamboo bars 10, 15 and 20 mm. The bamboo strips were subjected to 2 types of modifications to achieve a better bonding with the concrete matrix: bamboo bars with semi-circular corrugations having a pitch, width, and depth of 25, 10 and 5 mm, respectively; bamboo bars wrapped by 2 mm wire with 25 mm pitch and 10 mm extension (Figs. 6c and 6d) [72]. According to the results, all beams failed in pure flexure caused by the propagation of cracks from the bending zone (Fig. 9) [72].

Figure 9: Failure patterns of the beams: (a) SRC beam; (b) grooved BRC beam; (c) wired BRC beam; (d) PC beam (extracted from Qaiser et al. [72])

Mali et al. [73] evaluated the flexural performance of BRC beams with longitudinal bamboo reinforcement ratios of 2.8% (BV) and 3.8% (BO). Similar to Muhtar et al. [64], the authors improved the bond strength of bamboo bars by making semi-circular grooves of 10 mm in width and 5 mm in depth made in a zigzag manner (Fig. 7b). BRC specimens were divided into the following groups: untreated plain (UP), untreated grooved (UG), treated plain (TP), and treated grooved (TG). The treatment included coating with a Bond Tite chemical adhesive and sand particles. BV type of BRC beams stands for q = 2.8%, BO for q = 3.8%. The BV beams failed due to shear cracks, which were caused by a weakening of the bamboo stirrups capacity (Fig. 10a), while the BO beams failed due to shear cracks that occurred on the tensile part of the beam and propagated to the top layer. It should be noted that the BO beams with untreated grooved bamboo bars failed in the middle of the 1/3 span due to flexural crack (Fig. 10b) [73].

Figure 10: Failure pattern of BRC beams: (a) BRC beams (q = 2.8%); (b) BRC beams (q = 3.8%) (extracted from Mali et al. [73])

Researchers have considered their use in reinforced structural elements with the increased development of biocomposites made of bamboo fibres and adhesives. For instance, Wen et al. [78] combined bamboo fibres and bamboo bars to enhance the flexural performance of bio-beams. The manufacturing process of bio-beams includes sands and discrete, randomly distributed fibres treated by MICP that develop cementation between soil particles. The detailed manufacturing process of bio-beams can be found in the respective research [78]. For the experiment, the following types of bio-beams were manufactured: unreinforced bio-beams, bamboo fibre reinforced (BF) bio-beams, bamboo bars reinforced (BA) bio-beams, and bio-beams reinforced with bamboo fibres and bamboo bars (BFBA). The size of bio-beams was 38.1 mm × 76.2 mm × 177.8 mm, q = 0.83%, 0.93%, and 1.24%, and the proportion of fibres was 0.1%, 0.2%, 0.3% and 0.4% by weight of dry sand. BA bio-beams were reinforced longitudinally by 2, 3, 4, and 6 bamboo bars on the tensile side. BA bio-beams mostly failed under a 4-point bending load due to shear cracks that appeared on the bottom of the beams (Fig. 11).

Figure 11: Failure modes of the BA bio-beams: (a) q of 0.83%–0.93%; (b) q of 1.24% (extracted from Wen et al. [78])

BA bio-beams represented the beams that collapsed in a major failure mode with q of 0.83% and 0.93% (Fig. 11a). The specimens with a q of 1.24% did not show any significant changes in flexural behaviour. The beams that failed before the bamboo reinforcement could contribute to any improvement by spalling sandy soil from bamboo bars and the bottom of the beams (Fig. 11b) [78].

Another research by Javadian et al. [66] used bamboo-composite made of fibre bundles and epoxy as concrete reinforcement. The bamboo-composite reinforcement is shown in Fig. 12b. The detailed processing method of the material can be found in the respective study [66].

Figure 12: Bamboo-composite reinforced concrete (BCRC) beam: (a) bamboo-composite (b) bamboo-composite reinforcement; (c) failure of the BCRC beam (extracted from Javadian et al. [65,66])

BCRC beams prepared for the study had a size of 160 mm × 160 mm × 1300 mm. The cross-section of bamboo composite bars was 10 mm × 10 mm (Fig. 12a). The number of bottom reinforcements constituted 2 and 4 bars and q = 0.93% and 1.86%. The system had shear reinforcement, including different spacings (6@70, 4@115, 8@50); the reinforcement system was coated with water and an alkaline resistant layer. BCRC beams with 2 reinforcement bars broke due to reinforcement failure, while specimens with 4 bars failed in the compression side of the beam due to concrete crushing (Fig. 12b).

Depending on the type of bamboo treatment, the BRC beams were destroyed in 3 modes–bonding failure between bamboo and concrete, pure bending, and shear failures. Destruction in the mode of bonding failure was typical for beams in which bamboo reinforcement was not subjected to additional treatment to improve adhesion to concrete. It is worth noting that the addition of admixtures such as fly ash, granite, and ground granulated blast-furnace slag (GGBS) worsened the adhesion to the concrete matrix. As a result, the overall behavior of beams with untreated bamboo and admixtures was weak and brittle.

Failure in pure bending mode occurred in beams that had bamboo bars with a modified surface in the form of grooves or binding with wire. This behavior was caused by better adhesion between bamboo reinforcement and concrete due to the mechanical interlock, leading to a better ductility similar to the behavior of SRC beams. At the same time, beams with bamboo reinforcements were covered with adhesives, and BRC beams with bamboo fibres and hose-clamping collapsed in shear mode. The grooves and the wire contributed to the improved ductility of the beam due to the mechanical lock, while the hose-clamping turned out to be a kind of bridge transmitting stress from bamboo bars to cement. It is worth noting that the beams reinforced with bamboo composite bars collapsed in the form of shear, compression, and reinforcement rupture in tension.

According to the results, BCRC beams with q = 1.86% improved ultimate failure load and modulus of rupture constituting 42.2 kN and 10.84 MPa, respectively. The authors stated that BCRC beams showed better initial cracking load and ultimate load-bearing capacity and could substitute GFRP and steel in concrete reinforcement. However, the authors did not compare the tested beams’ flexural performance values with the materials mentioned above [66]. In the subsequent investigation, Javadian et al. [65] tested BCRC beams with two types of bamboo-composite reinforcement: longitudinal and transverse. BCRC beam was prepared based on recommendations of ACI 440.1R-15 with dimensions 160 mm × 160 mm × 1200 mm. During the experimental investigation, three parameters were considered: the number and spacing of the stirrups (4@75, 4@115, 6@70) and the distance between loading points (350, 600). The beams failed in three modes: reinforcement rupture in tension, compression failure, and shear failure [65].

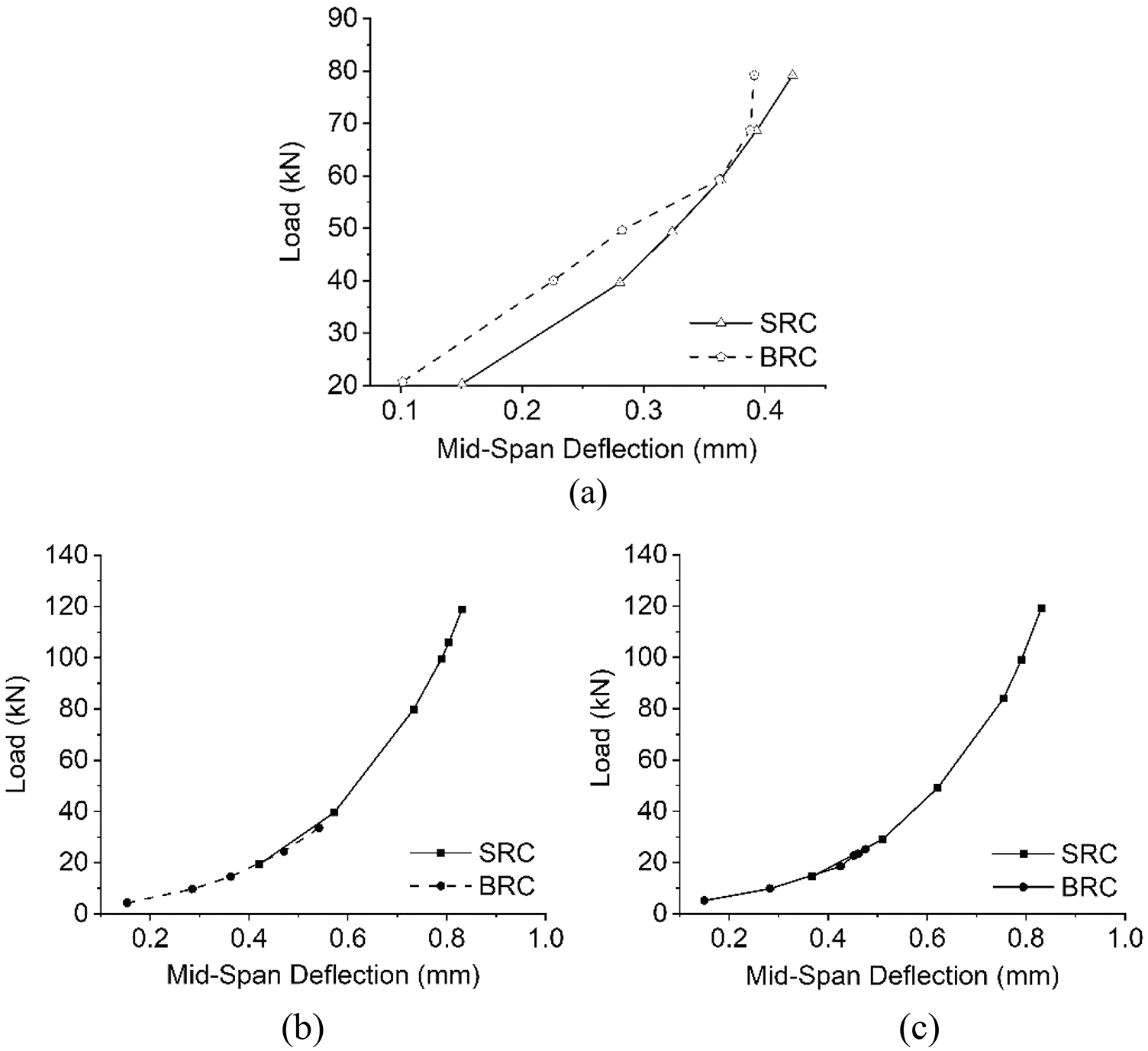

According to reviewed articles, the following factors can affect the beams’ strength: reinforcement material, materials composition, reinforcement ratio, span-to-depth ratio, bamboo bar treatment or modification method, and size of coarse aggregate. Ghavami et al. [34] found that the beams with q = 3% showed the best flexural performance among BRC beams with q of 0.75%–5.00%. The ultimate bearing capacity of the beams increased by 400% compared to that of the PC beams [34]. Mishra et al. [77] compared load-deflection relationships of BRC (q = 1.49%), PC, and SRC beams (q = 1.07%) (Fig. 13a).

Figure 13: Load-displacement relationships of beams: (a) PC, BRC (1.49%), and SRC (1.07%) beams; (b) PC, untreated BRC, treated BRC, and SRC beams (reproduced from Mishra et al. [77] and Agarwal et al. [63])

As can be seen, BRC beams could bear more deflection than SRC and PC beams and were more ductile. According to the results, the first cracks of BRC beams appeared at 80% of the ultimate load. The study’s goal was to investigate the feasibility of the neural-network approach (ANN) for predicting the flexural capacity of the beams. The results obtained from ANN matched the experimental values by 99%, proving the method’s reliability (Fig. 13a) [77].

The bamboo reinforcement treated by Sikadur 32 Gel showed improved bending capacity compared to untreated specimens (Fig. 13b) [63]. BRC beams with bamboo bars treated with Sikadur 32 Gel showed higher energy absorption and a much higher deflection than PC beams. BRC beams with untreated bamboo bars showed negligible improvement in flexural behaviour due to the low bond between reinforcement and concrete. It should be noted that treated BRC beams exhibited a comparable bending capacity and ductility to SRC beams with the same size and q of 0.89%. Average ultimate load and deflection at failure constituted 10.136 kN and 0.36 mm, 9.838 kN and 1.68 mm, 13.117 kN and 2.18 mm, 12.521 kN and 1.97 mm for PC, untreated BRC, treated BRC and SCR beams, respectively. As a result, the treatment with Sikadur 32 Gel showed a better bonding strength at the bamboo-concrete interface than other adhesives such as Tapecrete P-151, Araldite, and Anti Corr RC. The following improvement of the load-carrying capacity constituted 29.41% showing almost the same strength and behaviour as SRC beams with q = 0.89% [63].

The surface modification of bamboo bars can positively affect the flexural strength of BRC beams, provided the bamboo bars are treated with a coating that improves the bond strength and water resistance. If the load-deflection diagram of the SRC beam had pronounced elastic, elasto-plastic, and plastic areas, the behaviour of BRC beams was close to linear. The friction bond limit of the BRC beam occurred at 0.2 of the ultimate loads, which was twice lower than that of the SRC beam. The authors stated that the presence of hose-clamps did not significantly improve the flexural performance of BRC beams without additional treatment by water-resistant layers like Sikadur 32 Gel and coating by sand. For instance, BRC beams with a reinforcement area of 450 mm2 and hose clamps exhibited higher deflection, higher energy absorption, and lower stiffness than that of the SRC beams with q = 0.89% (Fig. 14a) [64].

Figure 14: Load-deflection diagram of BRC beams and SRC beams: (a) BRC beams with hose-clamps; (b) BRC beams with grooves and wires (reproduced from Muhtar et al. [64] and Qaiser et al. [72])

For future research, the authors suggested evaluating larger distances between hose clamps and considering the theory of confined concrete and shear reinforcement to improve the stiffness of BRC beams [64]. Fig. 14b shows the load-deflection relationship of the corrugated and wired BRC beams compared to other types of beams [72]. It should be noted that bamboo bars were not coated by adhesive or water-resistant layers. The first crack appeared in BRC beams when the load reached 12–14 kN. Compared to PC beams, wired and corrugated BRC beams improved ultimate capacity by 11% and 80%, respectively. However, q and other parameters of SRC beams were not available to adequately compare and evaluate the capacity of BRC beams. From the comparison between the load-deflection behaviour of hose-clamping and the corrugated beams, it can be seen that both have comparable flexural strength and could sustain similar deflection (Fig. 14). At the same time, the latter had more pronounced elastic, elastic-plastic, and plastic regions than the former. The authors recommended the utilization of corrugated and wired BRC beams in temporary or low-cost structures since their ductility, and ultimate capacity was far lower than that of SRC beams [72].

BRC beams improved flexural strength with grooved bamboo reinforcement treated with Bond Tite chemical adhesive and sand particles. Fig. 15 shows the average load-deflection curves of grooved BRC beams compared to PC and SRC beams (q = 1.2%). As can be seen, BRC beams with q = 3.8% and grooved treated bamboo bars showed higher flexural strength and could sustain more deflection compared to PC and BRC beams with q = 2.8%. However, SRC beams with q = 1.24% showed the best flexural performance [73].

Figure 15: Load-deflection diagram of BRC, PCC, and SRC beams (reproduced from Mali et al. [73])

According to the results of 4-point bending tests, the average values of maximum ultimate load obtained in these beams were 21, 63, 35 and 48 kN for PC, SRC, BRC with treated plain strips of q = 2.8%, and BRC with treated grooved strips of q = 3.8%. The BRC beam of q = 2.8% resulted in flexural strength that was 67% higher than that of PC beams and 44% lower than that of SRC beams. BRC beams of q = 3.8% exhibited flexural strength 37% higher than BRC of q = 2.8% with treated plain strips but 24% lower than SRC beams. Overall, the ultimate load and energy absorption capacity of 3.8% BRC beams with treated grooved strips were close to that of SRC beams and were lower by 3% and 17% than that of SRC beams. Moreover, shear strength and flexural strength of 3.8% BRC with treated grooved strips were comparable to SRC beams [73].

The results obtained by testing BRC beams made of alternative materials and admixtures are noteworthy. BRC beams made of mineral admixtures and 10 mm bamboo bars showed low flexural strength (Figs. 16b and 16c), which was twice lower than that of SRC beams reinforced with 10 mm steel. This was explained by poor bonding between bamboo and admixture. At the same time, BRC beams with 10 mm greased bamboo bars improved bending strength by 6.5% due to the perfect bond between bamboo and concrete matrix compared to SRC beams (Fig. 16a) [76].

Figure 16: Load-deflection relationship: (a) conventional BRC beam; (b) Mix 1; (c) Mix 2 (reproduced from Karthik et al. [76])

Adom-Asamoah et al. [79] investigated the performance of bamboo longitudinal reinforcement in self-compacted concrete (BRSCC) considering the following factors: the shear span-to-depth ratio (1.5–2.5), the longitudinal q (1.6%–3.1%), tensile reinforcement level (L as lower and H as higher) and the size of coarse aggregate (10, 14 mm). The beam size was 110 mm × 275 mm × 2000 mm with bamboo bars of 15 mm × 12 mm in cross-section. The transverse reinforcement of the BRSCC beams included mild steel (r8@100) since it was more cost-effective than cane or bamboo. Based on the results of 4-point bending tests, the authors draw the following conclusions: an increase in shear span-to-depth ratio increased the ultimate bending moment, the average increase constituted 94%–122% for ratios 1.5%–2.5%; an increase in q from 2.1% to 2.6% improved the normalised flexural, service and shear loads. However, when q > 2.6%, the structural performance of the beams decreased due to the insufficient bonding strength of bamboo reinforcement and self-compacted concrete. At the same time, q = 3.1% showed better cracking performance under monotonic loading. An increase in the size of the coarse grain aggregate increased the displacement ductility, post-yielding flexural resistance, and post-yielding energy resistance by 22.4%, 16.0%, and 44.5%, respectively. It was concluded that BRSCC could be used in structures for rural areas. However, the seismically active regions require improvements in the ductility of BRSCC.

The concrete beams with bamboo-composite reinforcement also showed improved flexural strength values [65]. Based on the results, the ductility of the BCRC beam was greatly improved. However, both PC and BCRC beams showed brittle characteristics compared to SRC beams, in which the yielding behaviour of steel ensured the greater ductility of the beam. Compared to the PC beams, BCRC beams had higher ultimate load capacity and better stiffness. The experimental part of this study was based on ACI 440.1R-15; the authors mentioned the suitability of this standard for the application of bamboo-composite reinforcement in concrete beams. Considering the low ductility of BCRC beams, the authors recommended its utilization in low-cost and low-rise buildings, where the failure of the secondary elements ensures the adequate warning of potential collapse [65].

One of the main tasks involved in construction is to ensure the safety of structures, which is achieved by improving the ductility of members and joints under loads. Based on the reviewed studies, BRC beams are still inferior to the ductility and strength of SRC beams. According to the study results, the bonding strength, reinforcement ratio, and stirrups were the determining factors of ductility and strength of BRC beams. The treatment of bamboo with adhesives, bamboo surface modification, an increase in the reinforcement ratio, and stirrups led to an improvement in ductility and overall structural performance.

4.3 Stress-Strain Relationship

It is worth noting that most studied BRC beams showed improved ductility, except for the beams in which bamboo bars were not treated. Ghavami [34] identified 3 regions in the stress-strain relationship of BRC beams (Fig. 17) [34].

Figure 17: Stress-strain relationship in BRC beams (reproduced from Ghavami [34])

The stress-strain relationship was characterised by a linear elastic stage, followed by the nonlinear behaviour and plastic stage with failure [34].

Bamboo reinforcement also increased the bending strength of bio-beams created with MICP. Fig. 18 shows stress-strain relationships of BA bio-beams compared to fibre-reinforced and unreinforced bio-beams [78].

Figure 18: Stress-strain relationship of bio-beams: (a) BA beams compared to unreinforced beams; (b) BABF bio-beams compared to BA and BF bio-beams; (c) BF beams compared to unreinforced beams (extracted from Wen et al. [78])

As shown in Fig. 18a the unreinforced bio-beams showed a brittle behaviour while the BA bio-beams’ performance was ductile. Furthermore, the flexural strength of BA bio-beams with q = 1.24% was higher than that of unreinforced bio-beams by 78%. At the same time, the authors evaluated the flexural performance of bio-beams reinforced with bamboo fibres. They concluded that the BF bio-beams with a fibre ratio of 0.3% improved ductility, flexure strain, and increased peak strength by 34% compared to unreinforced bio-beams (Fig. 18c). It should be additionally noted that the supplementation of more fibres to BRC (0.4% and higher) led to a decrease in flexural performance since the fibres filled the pores between the particles and reduced the bond strength. Based on these results, 0.3% of bamboo fibres and bamboo bars reinforcement with q = 1.24% were combined to enhance the flexural performance of bio-beams (BABF). The result can be seen in Fig. 18b, which shows stress-strain relationships of BABF bio-beams compared to BA and BF bio-beams [78]. As can be seen, BA bio-beams and BABF bio-beams had a better bending strength than BF specimens, showing great potential for the combined use of bamboo fibres and bamboo bars reinforcements to improve the flexural performance of the composite material [78].

Based on the results of the reviewed studies, BRC beams with bamboo treated with adhesives or surface modification, and BRC beams with bamboo fibres, showed the most obvious nonlinear behavior consisting of three stages – elastic, elastic-plastic, and plastic. The beams with treated bamboo showed better behavior compared to PC beams but performed worse compared to SRC beams. Nevertheless, the possibility of using BRC beams in lightweight structures of low-rise buildings is justified.

In this paper, the structural behavior of BRC beams was reviewed, particularly the common failure modes, reasons for failure, load-deflection curves, stress-strain relationship, and the factors influencing the fundamental mechanical properties of the beams. In addition, the bonding behavior of BRC material was considered and discussed. Based on the reviewed studies, the following conclusions were drawn.

5.1 Bonding Performance of BRC

An effective water-repellent treatment is necessary to improve the adhesion between bamboo bars and the concrete matrix. According to reviewed studies, the impermeability of bamboo is affected by three factors: the adhesive properties of the coating applied to bamboo and concrete, the water-repellent properties of the coating, and the friction behaviour regarding the bamboo-concrete interface. One of the most effective methods is the epoxy treatment of bamboo, followed by coating with fine sand. Additional bamboo surface modification can increase bond strength through the mechanical interlock.

5.2 Mechanical Behavior of BRC Beams

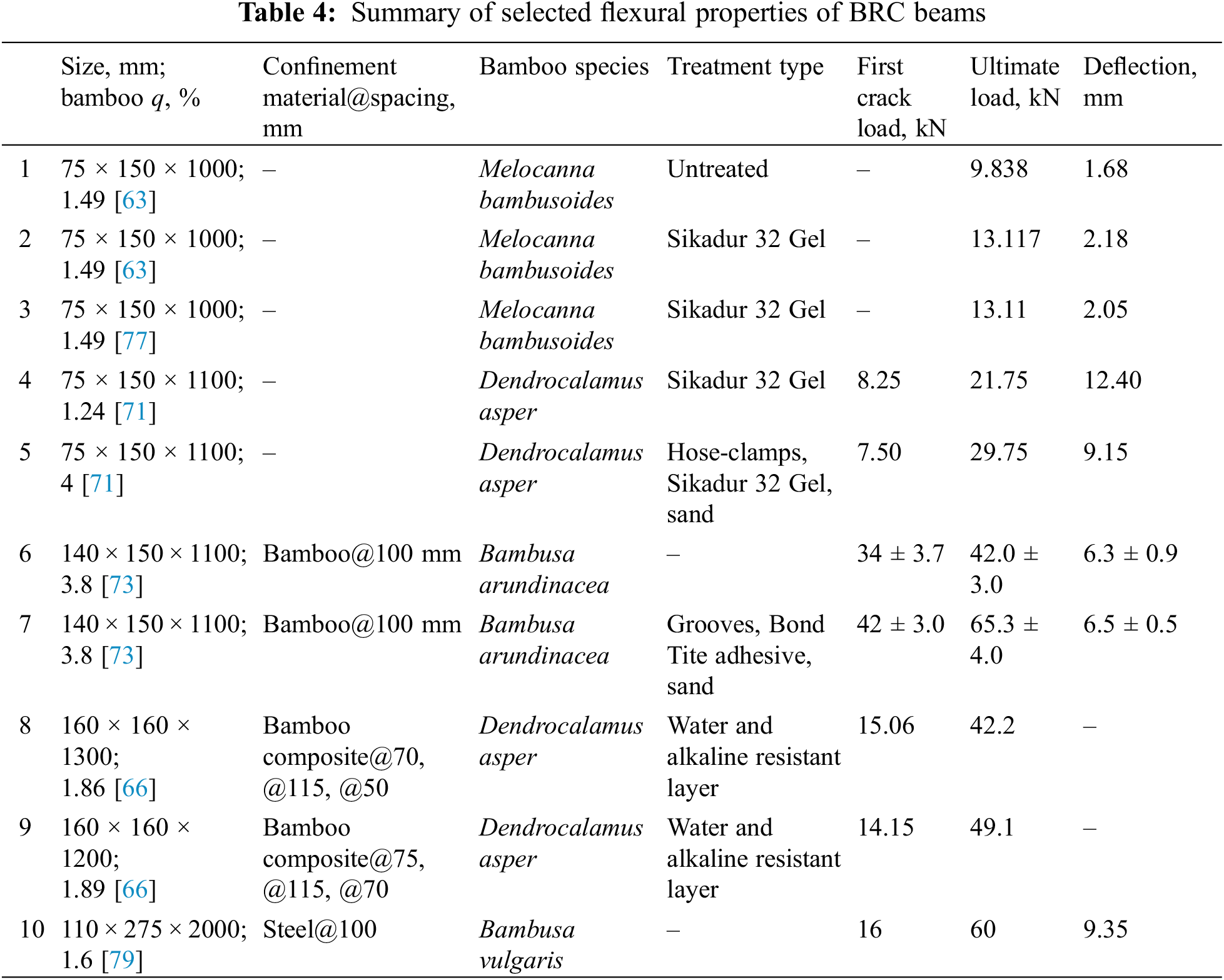

Different reinforcement systems were adopted for the experimental evaluation in the reviewed studies: longitudinal reinforcement with 2 bamboo bars; longitudinal reinforcement with 4 bamboo bars and bamboo, binding wire, and steel as confinement. The following influencing factors were considered: reinforcement material, reinforcement ratio, confinement material, bamboo treatment and modification type, and admixtures. Table 4 shows the summary of the selected mechanical properties of BRC beams.

As can be seen from Table 4, the first crack load and the ultimate load increased with the treatment of bamboo reinforcement. BRC beams #2, 3, and 4 have the same q and treatment with Sikadur 32 Gel, but beam #4 shows better mechanical properties than #2 and 3. This may be caused by the difference in bamboo species used for reinforcement and the grade of concrete. The beams significantly improved flexural behaviour by adding lateral reinforcement and surface modification. For instance, the first crack load, the ultimate load, and deflection of beam #7 with grooves, adhesive, and sand constituted 42 kN, 65.3 kN, and 6.5 mm, while the same properties of beam #6 with the same size and reinforcement ratio but no treatment included 34 kN, 42.0 kN, and 6.3 mm. It should be noted that an increase in reinforcement ratio also affects the flexural performance of the beams positively. For instance, the initial crack load, ultimate load, and deflection of beam #2 with q = 1.49% were 8.25 kN, 21.75 kN, and 12.40 mm, while beam #6 with q = 3.8% improved these values up to 34 kN, 42.0 kN, and 6.3 mm, respectively. At the same time, all the beams having lateral reinforcement exhibited better flexural performance and improved strength values compared to that with no confinement.

According to the reviewed studies, the beams failed in different modes depending on bamboo treatment, surface modification type, and the presence of admixtures. The BRC beams with untreated bamboo reinforcement were destroyed in the direction of the reinforcement due to the bond rupture and slippage of bamboo. The BRC beams with bamboo reinforcement treated with Sikadur 32 Gel showed better adhesion to cement, and the failure mode was characterised by the appearance of shear cracks on the tensile part of the beam and their spread to the top of the beam. The beams with hose-clamping of bamboo reinforcement had the same mode of destruction. The only difference was in the branching of the major cracks into small cracks that grew upwards and in the direction of bamboo reinforcement. The failure mode of the beams with grooved and wired bamboo bars was the closest to that of the SRC beams, characterised by pure bending destruction. Bio-beams with bamboo reinforcement also collapsed in the shear mode despite the different material compositions. At the same time, beams with fly ash, granite, and GGBS as admixtures showed brittle failure due to poor adhesion to the reinforcement system. In contrast, beams with bamboo-composite reinforcement showed 3 types of destruction: shear, compression, and reinforcement rupture in tension.

The behaviour of the bamboo beams can be characterised by 3 regions: elastic, elastic-plastic, and plastic. Several studies attempted to predict the flexural behaviour of the beams. Muhtar [80] developed a calculation model for predicting local slip in BRC beams through the curvature moments and bond stress with 6% of uncertainty, proving the proposed model’s high reliability. Muhtar [81] and Mishra et al. [77] adopted FEM and ANN methods to predict stiffness reduction and deflection values for BRC beams, respectively. The validation of the proposed models constituted 85%–93% and 99% for each study, respectively.

Based on the results of the reviewed articles, bamboo bars have a fairly convincing potential as a replacement for steel in the reinforcement of concrete beams going into the future. However, several factors need to be considered when using bamboo in reinforcement. According to the conducted studies, the BRC beams show the best bending behaviour and can withstand more deflection and bending loads, providing 3% of the reinforcement ratio, as well as bamboo surface modification by grooves in a zigzag manner, followed by coating with chemical adhesives such as Sikadur 32 Gel, Bond Tite and sand particles to improve adhesion between reinforcement and concrete matrix. Moreover, most researchers agreed that this type of composite is recommended for use in lightweight concrete structures of low-rise and low-cost buildings in regions with limited access to steel. Compared to SRC, BRC beams were less ductile and had a higher energy absorption capacity.

5.3 Potential of BRC Beams in Structural Application

With the invention of bamboo composites, such as laminated bamboo lumber [82–87], glubam [88–92], parallel strand bamboo [93–97], and their combinations with AFRP, CFRP [98,99], and other materials, the possibility of using bamboo as reinforcement for concrete is significantly expanding. Multiple studies have been done on new types of bamboo-based and concrete composites, such as engineered bamboo-concrete sandwich panels, bamboo particle concrete, bamboo fibre concrete, bamboo tube grid concrete panels, etc., showing wide possibilities of utilization of bamboo variations in composites with concrete [100,101]. Optimised bamboo processing methods, such as densification, also positively affect the tensile strength of bamboo [12], thereby opening a new direction for further study of its use in concrete reinforcement. Moreover, the mechanical properties of bamboo vary depending on the bamboo species, and the performance of its laminated version depends on the processing methods, the number of layers, lamina arrangement, and adhesive type. Various materials, such as fly ash, fibres, and bacteria, were used in the concrete mixture, which positively affected the mechanical properties of the BRC members.

According to the reviewed articles, bamboo reinforcement has a good potential to replace steel in concrete reinforcement. However, the factors mentioned above are worthy of further study, so as to further improve the mechanical properties of BRC members and their application in the construction sector. Scientists have made impressive progress in improving the adhesion strength between bamboo and cement by using adhesives, surface modification, and sand coating. One of the main purposes of using bamboo as a reinforcement and adding admixtures to replace cement and sand is to improve the environmental friendliness of obtained reinforced concrete while maintaining load-bearing capacity. Nevertheless, the methods of improving bond strength between bamboo and cement are energy-intensive, and the environmental friendliness of adhesives used for processing bamboo is also questionable. Furthermore, the recyclability of obtained concrete with bamboo reinforcement and admixtures is unknown.

The sustainability of BRC members was examined by Archilla et al. [35] using Life cycle assessment (LCA) [102] with the intergovernmental panel on climate change (IPCC) 2013 method for evaluating environmental impacts [103], the software OpenLCA [104], Ecoinvent V3 database [105], and data on bamboo-based construction materials and transport distances [106–108]. Surprisingly, carbon emissions from the production of the BRC material were almost twice the emissions caused by the production of the SRC. Increased carbon emissions were explained by an increase in the concrete amount to meet the load carrying requirements of the functional unit. Another environmental evaluation made by Zea Escamilla et al. [108] showed that the contribution of bamboo reinforcement to emissions was negligible. Still, the bamboo transportation emissions were greater than the material savings achieved by replacing steel. Despite the promising potential of bamboo as concrete reinforcement, there are still several problems, such as low ductility, poor adhesion to cement, water absorption, insect attacks, energy-intensive production, use of environmentally friendly adhesives, which need to be studied and optimised to justify the use of bamboo in the reinforcement of concrete structures.

In this article, the structural behaviour of BRC beams with bamboo reinforcement was considered. The most frequent failure modes, reasons for failure, and load-deflection relationship were identified, while factors affecting the behaviour of BRC structural beams were described. According to the review, the following conclusions were made. Failure of BRC flexural members was caused by shear and bending forces. In contrast to steel reinforcement, bamboo reinforcement is prone to rupture; it has low ductility and high energy absorption capacity. At the same time, the ductility of bamboo reinforced concrete members is higher than that of plain concrete members. The behaviour and strength of BRC members depend on the following factors: bond strength between bamboo and cement, the reinforcement ratio, the application of confinement, the presence of admixtures, and the strength of concrete. An increase in reinforcement ratio, confinement, treatment of bamboo bars with adhesives, sand and grooving, and the replacement of cement and sand with polymer admixtures increases the ductility and bearing capacity of the members. In general, the ultimate load and deflection of BRC beams without any treatment and 1.49% reinforcement ratio constituted 9.838 kN and 1.68 mm. In contrast, the exact parameters of the beams treated with Sikadur 32 Gel were around 13.11 kN and 2.05–2.18 mm. The deflection and limited load of the beams with bamboo reinforcement bars of q = 3.8%, which were coated by adhesive and grooved, were 6.5 mm and 65.3 kN showing a significant improvement in flexural performance. However, bamboo reinforcement is not inferior to the ductility and strength of steel reinforcement. Energy-intensive treatment of bamboo and the unknown recyclability raises the question of the environmental friendliness of the composite. Currently, this type of reinforcement is suitable for low-rise and low-cost buildings in seismically safe zones. Even though bamboo has the potential to replace steel in concrete structures, there are still certain areas where more research must be conducted to exploit the benefits of bamboo in the construction industry fully.

Funding Statement: The research work presented in this paper is supported by the National Natural Science Foundation of China (Nos. 51878354 & 51308301), the Natural Science Foundation of Jiangsu Province (Nos. BK20181402 & BK20130978), Six Talent Peak High-Level Projects of Jiangsu Province (No. JZ029), and Qinglan Project of Jiangsu Higher Education Institutions. Any research results expressed in this paper are those of the writers and do not necessarily reflect the views of the foundations.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Zhou, Y., Huang, Y., Sayed, U., Wang, Z. (2021). Research on dynamic characteristics test of wooden floor structure for gymnasium. Sustainable Structures, 1(1), 000005. DOI 10.54113/j.sust.2021.000005. [Google Scholar] [CrossRef]

2. Ponzo, F. C., Antonio, D. C., Nicla, L., Nigro., D. (2021). Experimental estimation of energy dissipated by multistorey post-tensioned timber framed buildings with anti-seismic dissipative devices. Sustainable Structures, 1(2), 000007. DOI 10.54113/j.sust.2021.000007. [Google Scholar] [CrossRef]

3. Dauletbek, A., Zhou, P. (2022). BIM-based LCA as a comprehensive method for the refurbishment of existing dwellings considering environmental compatibility, energy efficiency, and profitability: A case study in China. Journal of Building Engineering, 46(10), 103852. DOI 10.1016/j.jobe.2021.103852. [Google Scholar] [CrossRef]

4. Bueno, C., Fabricio, M. M. (2018). Comparative analysis between a complete LCA study and results from a BIM-LCA plug-in. Automation in Construction, 90(2), 188–200. DOI 10.1016/j.autcon.2018.02.028. [Google Scholar] [CrossRef]

5. Soust-Verdaguer, B., Llatas, C., García-Martínez, A. (2017). Critical review of bim-based LCA method to buildings. Energy and Buildings, 136(1), 110–120. DOI 10.1016/j.enbuild.2016.12.009. [Google Scholar] [CrossRef]

6. van der Lugt, P., van den Dobbelsteen, A. A. J. F., Janssen, J. J. A. (2006). An environmental, economic and practical assessment of bamboo as a building material for supporting structures. Construction and Building Materials, 20(9), 648–656. DOI 10.1016/j.conbuildmat.2005.02.023. [Google Scholar] [CrossRef]

7. Dauletbek, A., Li, H., Lorenzo, R. (2022). A Review of basic mechanical behavior of laminated bamboo lumber. Journal of Renewable Materials, 10(2), 273–300. DOI 10.32604/jrm.2022.017805. [Google Scholar] [CrossRef]

8. Dauletbek, A., Li, H., Xiong, Z., Lorenzo, R. (2021). A review of mechanical behavior of structural laminated bamboo lumber. Sustainable Structures, 1(1), 000004. DOI 10.54113/j.sust.2021.000004. [Google Scholar] [CrossRef]

9. Kewei, L., Jayaraman, D., Yongjiu, S., Harries, K., Yang Jun, J. W. et al. (2022). Bamboo: A very sustainable construction material-2021 international online seminar summary report. Sustainable Structures, 2(1), 00015. DOI 10.54113/j.sust.2022.000015. [Google Scholar] [CrossRef]

10. Ashraf, M., Hasan, M. J., Al-Deen, S. (2021). Semi-rigid behaviour of stainless steel beam-to-column bolted connections. Sustainable Structures, 1(1), 000002. DOI 10.54113/j.sust.2021.000002. [Google Scholar] [CrossRef]

11. Mahdavi, M., Clouston, P. L., Arwade, S. R. (2011). Development of laminated bamboo lumber: Review of processing, performance, and economical considerations. Journal of Materials in Civil Engineering, 23(7), 1036–1042. DOI 10.1061/(ASCE)MT.1943-5533.0000253. [Google Scholar] [CrossRef]

12. Li, Z., Chen, C., Mi, R., Gan, W., Dai, J. et al. (2020). A strong, tough, and scalable structural material from fast-growing bamboo. Advanced Materials, 32(10), 1906308. DOI 10.1002/adma.201906308. [Google Scholar] [CrossRef]

13. Huang, Z. R., Chen, Z. F., Huang, D. S., Zhou, A. P. (2016). The ultimate load-carrying capacity and deformation of laminated bamboo hollow decks: Experimental investigation and inelastic analysis. Construction and Building Materials, 117, 190–197. DOI 10.1016/j.conbuildmat.2016.04.115. [Google Scholar] [CrossRef]

14. Jin, X. B., Jiang, Z. H., Wen, X. W., Zhang, R., Qin, D. C. (2017). Flame retardant properties of laminated bamboo lumber treated with monoammonium phosphate (MAP) and boric acid/Borax (SBX) compounds. Bioresources, 12(3), 5071–5085. DOI 10.15376/biores.12.3.5071-5085. [Google Scholar] [CrossRef]

15. Yang, G., Wang, K. (2020). Evaluation on the application of GLB structures. Journal of Materials Science and Chemical Engineering, 8(5), 21–37. DOI 10.4236/msce.2020.85003. [Google Scholar] [CrossRef]

16. Su, J., Li, H., Xiong, Z., Lorenzo, R. (2021). Structural design and construction of an office building with laminated bamboo lumber. Sustainable Structures, 1(2), 000010. DOI 10.54113/j.sust.2021.000010. [Google Scholar] [CrossRef]

17. Liang, R., Hota, G. (2021). Development and evaluation of load-bearing fiber reinforced polymer composite panel systems with tongue and groove joints. Sustainable Structures, 1(2), 000008. DOI 10.54113/j.sust.2021.000003. [Google Scholar] [CrossRef]

18. Meng, X., Zhang, D., Feng, P., Hu, N. (2021). Review on mechanical behavior of solar cells for building integrated photovoltaics. Sustainable Structures, 1(2), 000009. DOI 10.54113/j.sust.2021.000009. [Google Scholar] [CrossRef]

19. Adewuyi, A. P., Otukoya, A., Olaniyi, O., Olafusi, O. (2015). Comparative studies of steel, bamboo and rattan as reinforcing bars in concrete: Tensile and flexural characteristics. Open Journal of Civil Engineering, 5(2), 228–238. DOI 10.4236/ojce.2015.52023. [Google Scholar] [CrossRef]

20. Li, D., Thomas, J., Leroux, P. (2020). Yield and tensile strength of steel and aluminum. https://www.researchgate.net/publication/340003398_Yield_and_Tensile_Strength_of_Steel_and_Aluminum. [Google Scholar]

21. Chen, Z., Wagoner, R., Gandhi, U., Lee, J. (2016). Variation and consistency of young’s modulus in steel. Journal of Materials Processing Technology, 227, 227–243. DOI 10.1016/j.jmatprotec.2015.08.024. [Google Scholar] [CrossRef]

22. Rosyidah, A., Sucita, I. K., Hidayat, F. (2018). The bond strength of glass fiber reinforced polymer (GFRP) reinforcement with monolith concrete. International Journal on Advanced Science, Engineering and Information Technology, 8(2), 495–500. DOI 10.18517/ijaseit.8.2.4346. [Google Scholar] [CrossRef]

23. Weber, A., Caspari, C., Pahn, M. (2022). Tensile tests at GFRP rebars, pp. 918–927. Cham: Springer International Publishing. [Google Scholar]

24. Zhang, X., Zou, G., Shen, Z. (2008). Experimental research on continuous basalt fiber and basalt-fibers-reinforced polymers. Proceedings of SPIE–The International Society for Optical Engineering, 7375. DOI 10.1117/12.839375. [Google Scholar] [CrossRef]

25. Truong, G. T., Tran, H. V., Choi, K. K. (2019). Tensile behavior of carbon fiber-reinforced polymer composites incorporating nanomaterials after exposure to elevated temperature. Journal of Nanomaterials, 2019(1), 4139208. DOI 10.1155/2019/4139208. [Google Scholar] [CrossRef]

26. Wardle, M. (2000). Aramid fiber reinforced plastics—Properties. Comprehensive Composite Materials. [Google Scholar]

27. Kampmann, R., Telikapalli, S., Ruiz Emparanza, A., Schmidt, A. E., Dulebenets, M. (2021). Tensile properties of basalt fiber-reinforced polymer reinforcing bars for reinforcement of concrete. ACI Materials Journal, 118(1), 111–126. DOI 10.14359/51729288. [Google Scholar] [CrossRef]

28. Farooqi, M. U., Ali, M. (2018). Contribution of plant fibers in improving the behavior and capacity of reinforced concrete for structural applications. Construction and Building Materials, 182(4), 94–107. DOI 10.1016/j.conbuildmat.2018.06.041. [Google Scholar] [CrossRef]

29. James, I. D., Gopalaratnam, V., Galinat, M. A. (2002). State-of-the-art report on fiber reinforced concrete. Manual Concr Practice, 21, 2–66. [Google Scholar]

30. Bheel, N., Tafsirojjaman, T., Liu, Y., Awoyera, P., Kumar, A. et al. (2021). Experimental study on engineering properties of cement concrete reinforced with nylon and jute fibers. Buildings, 11(10), 454. DOI 10.3390/buildings11100454. [Google Scholar] [CrossRef]

31. Chen, D., Deng, J. J., Cheng, B. Q., Wang, Q., Zhao, B. J. (2021). New anticracking glass-fiber-reinforced cement material and integrated composite technology with lightweight concrete panels. Advances in Civil Engineering, 2021(3), 1–17. DOI 10.1155/2021/7447066. [Google Scholar] [CrossRef]

32. da Gloria, M. Y. R., Toledo, R. D. (2021). Innovative sandwich panels made of wood bio-concrete and sisal fiber reinforced cement composites. Construction and Building Materials, 272(8), 121636. DOI 10.1016/j.conbuildmat.2020.121636. [Google Scholar] [CrossRef]

33. Liu, W., Liu, C., Liu, M., Xu, F., Li, Z. (2021). Investigation on interfacial properties and calculation models of bamboo scrimber-to-concrete bonding joint. Construction and Building Materials, 313(6), 125530. DOI 10.1016/j.conbuildmat.2021.125530. [Google Scholar] [CrossRef]

34. Ghavami, K. (2005). Bamboo as reinforcement in structural concrete elements. Cement and Concrete Composites, 27(6), 637–649. DOI 10.1016/j.cemconcomp.2004.06.002. [Google Scholar] [CrossRef]

35. Archila, H., Kaminski, S., Trujillo, D., Zea Escamilla, E., Harries, K. A. (2018). Bamboo reinforced concrete: A critical review. Materials and Structures, 51(4), 102. DOI 10.1617/s11527-018-1228-6. [Google Scholar] [CrossRef]

36. Xiao, J., Liu, H., Ding, T., Ma, G. (2021). 3D printed concrete components and structures: An overview. Sustainable Structures, 1(2), 000006. DOI 10.54113/j.sust.2021.000006. [Google Scholar] [CrossRef]

37. Corbi, O., Baratta, A., Corbi, I., Tropeano, F., Liccardo, E. (2021). Design issues for smart seismic isolation of structures: Past and recent research. Sustainable Structures, 1(1), 000001. DOI 10.54113/j.sust.2021.000001. [Google Scholar] [CrossRef]

38. Correal, J. (2016). Bamboo design and construction. Woodhead Publishing. [Google Scholar]

39. Kumar, P., Gautam, P., Kaur, S., Chaudhary, M., Afreen, A. et al. (2021). Bamboo as reinforcement in structural concrete. Materials Today: Proceedings, 46(4), 6793–6799. DOI 10.1016/j.matpr.2021.04.342. [Google Scholar] [CrossRef]

40. Lima, H., Willrich, F., Barbosa, N., Rosa, M., Cunha, B. (2008). Durability analysis of bamboo as concrete reinforcement. Materials and Structures, 41(5), 981–989. DOI 10.1617/s11527-007-9299-9. [Google Scholar] [CrossRef]

41. Sharma, B., Bauer, H., Schickhofer, G., Ramage, M. H. (2017). Mechanical characterisation of structural laminated bamboo. Proceedings of the Institution of Civil Engineers-Structures and Buildings, 170(4), 250–264. DOI 10.1680/jstbu.16.00061. [Google Scholar] [CrossRef]

42. Sharma, B., Gatoo, A., Bock, M., Ramage, M. (2015). Engineered bamboo for structural applications. Construction and Building Materials, 81(2), 66–73. DOI 10.1016/j.conbuildmat.2015.01.077. [Google Scholar] [CrossRef]

43. Sharma, B., Gatoo, A., Ramage, M. H. (2015). Effect of processing methods on the mechanical properties of engineered bamboo. Construction and Building Materials, 83(2), 95–101. DOI 10.1016/j.conbuildmat.2015.02.048. [Google Scholar] [CrossRef]

44. Sharma, B., Shah, D. U., Beaugrand, J., Janecek, E. R., Scherman, O. A. et al. (2018). Chemical composition of processed bamboo for structural applications. Cellulose, 25(6), 3255–3266. DOI 10.1007/s10570-018-1789-0. [Google Scholar] [CrossRef]

45. Verma, C. S., Sharma, N. K., Chariar, V. M., Maheshwari, S., Hada, M. K. (2014). Comparative study of mechanical properties of bamboo laminae and their laminates with woods and wood based composites. Composites Part B: Engineering, 60(7), 523–530. DOI 10.1016/j.compositesb.2013.12.061. [Google Scholar] [CrossRef]

46. Reynolds, T. P. S., Sharma, B., Serrano, E., Gustafsson, P. J., Ramage, M. H. (2019). Fracture of laminated bamboo and the influence of preservative treatments. Composites Part B: Engineering, 174(4), 107017. DOI 10.1016/j.compositesb.2019.107017. [Google Scholar] [CrossRef]

47. Takeuchi, C. (2012). Design and construction of housing with structural elements of bamboo (Guadua) laminated. Key Engineering Materials, 517, 179–183. DOI 10.4028/www.scientific.net/KEM.517.179. [Google Scholar] [CrossRef]

48. Takeuchi, C. P., Estrada, M., Linero, D. L. (2018). Experimental and numerical modeling of shear behavior of laminated Guadua bamboo for different fiber directions. Construction and Building Materials, 177(1), 23–32. DOI 10.1016/j.conbuildmat.2018.05.040. [Google Scholar] [CrossRef]

49. Yeh, M. C., Lin, Y. L. (2012). Finger joint performance of structural laminated bamboo member. Journal of Wood Science, 58(2), 120–127. DOI 10.1007/s10086-011-1233-7. [Google Scholar] [CrossRef]

50. Starr, F., Starr, K. (2003). Bambusa vulgaris Schrad. ex J.C. Wendl. Common Bamboo. https://www.biolib.cz/en/taxonimage/id51220/?taxonid=127720. [Google Scholar]

51. Lucas, S. (2006). Dendrocalamus asper. https://www.flickr.com/photos/worldbamboo/4809816348/. [Google Scholar]

52. How to grow bamboo in the open ground. https://agronomu.com/bok/6941-kak-vyrastit-bambuk-v-otkrytom-grunte.html. [Google Scholar]

53. Forest Products Laboratory (2010). Wood handbook, wood as an engineering material. Madison, WI: U.S. Department of Agriculture. [Google Scholar]

54. Liese, W., Tang, H. (2015). Preservation and drying of bamboo. Springer, Cham. [Google Scholar]

55. Pacheco-Torgal, F., Jalali, S. (2011). Cementitious building materials reinforced with vegetable fibres: A review. Construction and Building Materials, 25(2), 575–581. DOI 10.1016/j.conbuildmat.2010.07.024. [Google Scholar] [CrossRef]

56. Vo, L. T. T., Navard, P. (2016). Treatments of plant biomass for cementitious building materials–A review. Construction and Building Materials, 121, 161–176. DOI 10.1016/j.conbuildmat.2016.05.125. [Google Scholar] [CrossRef]

57. Pickering, K. L., Efendy, M. G. A., Le, T. M. (2016). A review of recent developments in natural fibre composites and their mechanical performance. Composites Part A: Applied Science and Manufacturing, 83(10), 98–112. DOI 10.1016/j.compositesa.2015.08.038. [Google Scholar] [CrossRef]

58. Javadian, A., Wielopolski, M., Smith, I. F. C., Hebel, D. E. (2016). Bond-behavior study of newly developed bamboo-composite reinforcement in concrete. Construction and Building Materials, 122(5), 110–117. DOI 10.1016/j.conbuildmat.2016.06.084. [Google Scholar] [CrossRef]

59. Ashby, M. F., Cebon, D. (1993). Materials selection in mechanical design. J. Phys. IV France, 3(C7), C7-1–C7-9. DOI 10.1051/jp4:1993701. [Google Scholar] [CrossRef]

60. Sutharsan, R., Ramprasanna, S., Gnanappa, S., Ganesh, C. (2020). Experimental study on bamboo as a reinforcing material in concrete. AIP Conference Proceedings, vol. 2204, no. 1, 020024. [Google Scholar]

61. Rahman, M., Rashid, H., Hossain, M. A., Hasan, M. (2011). Performance evaluation of bamboo reinforced concrete beam. International Journal of Engineering & Technology, 11(4), 142–146. [Google Scholar]

62. Nayak, A. (2013). Replacement of steel by bamboo reinforcement. IOSR Journal of Mechanical and Civil Engineering, 8(1), 50–61. DOI 10.9790/1684-0815061. [Google Scholar] [CrossRef]

63. Agarwal, A., Nanda, B., Maity, D. (2014). Experimental investigation on chemically treated bamboo reinforced concrete beams and columns. Construction and Building Materials, 71(2), 610–617. DOI 10.1016/j.conbuildmat.2014.09.011. [Google Scholar] [CrossRef]

64. Muhtar, Dewi, S. M., Wisnumurti, Munawir, A. A. (2019). Enhancing bamboo reinforcement using a hose-clamp to increase bond-stress and slip resistance. Journal of Building Engineering, 26, 100896. DOI 10.1016/j.jobe.2019.100896. [Google Scholar] [CrossRef]

65. Javadian, A., Smith, I. F. C., Hebel, D. E. (2020). Application of sustainable bamboo-based composite reinforcement in structural-concrete beams: Design and evaluation. Materials, 13(3), 696. DOI 10.3390/ma13030696. [Google Scholar] [CrossRef]

66. Javadian, A., Smith, I. F. C., Saeidi, N., Hebel, D. E. (2019). Mechanical properties of bamboo through measurement of culm physical properties for composite fabrication of structural concrete reinforcement. Frontiers in Materials, 6, 353. DOI 10.3389/fmats.2019.00015. [Google Scholar] [CrossRef]

67. Mengistu, F. (2010). Investigation of the flexural and bond strengthes of bamboo using different splits (Forms) in cocrete members (Master Thesis). Addis Ababa University. [Google Scholar]

68. Terai, M., Minami, K. (2012). Research and development on bamboo reinforced concrete structure. [Google Scholar]

69. Jung, Y. (2007). Investigation of bamboo as reinforcement in concrete (Master Thesis). The University of Texas at Arlington in Partial Fulfillment. [Google Scholar]

70. Santos, H. A., Pesce, G. L., Ansell, M. P., Ball, R. J. (2015). Limeboo: Lime as a replacement for cement in wall-framing systems with bamboo-guadua (Bahareque Encementado). [Google Scholar]

71. Muhtar, M., Dewi, S., Wisnumurti, Munawir, A. A. (2019). The flexural behavior model of bamboo reinforced concrete beams using a hose clamp. MATEC Web of Conferences, 276, 01033. DOI 10.1051/matecconf/201927601033. [Google Scholar] [CrossRef]

72. Qaiser, S., Hameed, A., Alyousef, R., Aslam, F., Alabduljabbar, H. (2020). Flexural strength improvement in bamboo reinforced concrete beams subjected to pure bending. Journal of Building Engineering, 31(2), 101289. DOI 10.1016/j.jobe.2020.101289. [Google Scholar] [CrossRef]

73. Mali, P. R., Datta, D. (2020). Experimental evaluation of bamboo reinforced concrete beams. Journal of Building Engineering, 28(7), 101071. DOI 10.1016/j.jobe.2019.101071. [Google Scholar] [CrossRef]

74. Mali, P., Datta, D. (2019). Experimental study on improving bamboo-concrete bond strength. Advances in Concrete Construction, 7(3), 191–201. [Google Scholar]

75. Terai, M., Minami, K. (2011). Fracture behavior and mechanical properties of bamboo reinforced concrete members. Procedia Engineering, 10, 2967–2972. DOI 10.1016/j.proeng.2011.04.492. [Google Scholar] [CrossRef]

76. Karthik, S., Rao, P. R. M., Awoyera, P. O. (2017). Strength properties of bamboo and steel reinforced concrete containing manufactured sand and mineral admixtures. Journal of King Saud University-Engineering Sciences, 29(4), 400–406. DOI 10.1016/j.jksues.2016.12.003. [Google Scholar] [CrossRef]

77. Mishra, M., Agarwal, A., Maity, D. (2019). Neural-network-based approach to predict the deflection of plain, steel-reinforced, and bamboo-reinforced concrete beams from experimental data. SN Applied Sciences, 1(6), 584. DOI 10.1007/s42452-019-0622-1. [Google Scholar] [CrossRef]

78. Wen, K., Bu, C., Liu, S., Li, Y., Li, L. (2018). Experimental investigation of flexure resistance performance of bio-beams reinforced with discrete randomly distributed fiber and bamboo. Construction and Building Materials, 176(4), 241–249. DOI 10.1016/j.conbuildmat.2018.05.032. [Google Scholar] [CrossRef]

79. Adom-Asamoah, M., Osei Banahene, J., Obeng, J., Antwi Boasiako, E. (2017). Bamboo-reinforced self-compacting concrete beams for sustainable construction in rural areas. Structural Concrete, 18(6), 1000–1010. DOI 10.1002/suco.201600205. [Google Scholar] [CrossRef]

80. Muhtar (2021). The measurement of the local slip in bamboo-reinforced concrete beams using moment-curvature and bond-stress. Journal of Renewable Materials, 9(9), 1631–1646. DOI 10.32604/jrm.2021.015452. [Google Scholar] [CrossRef]

81. Muhtar (2020). The prediction of stiffness reduction non-linear phase in bamboo reinforced concrete beam using the Finite Element Method (FEM) and Artificial Neural Networks (ANNs). Forests, 11(12), 1313. DOI 10.3390/f11121313. [Google Scholar] [CrossRef]

82. Ameh, O., Shittu, K. (2021). Laminated bamboo board: A sustainable alternative to timber board for building construction. LAUTECH Journal of Civil and Environmental Studies, 6(1), 104–115. [Google Scholar]

83. Chen, G., Yu, Y. F., Li, X., He, B. (2020). Mechanical behavior of laminated bamboo lumber for structural application: an experimental investigation. European Journal of Wood and Wood Products, 78(1), 53–63. DOI 10.1007/s00107-019-01486-9. [Google Scholar] [CrossRef]

84. Chow, A., Ramage, M. H., Shah, D. U. (2019). Optimising ply orientation in structural laminated bamboo. Construction and Building Materials, 212(18), 541–548. DOI 10.1016/j.conbuildmat.2019.04.025. [Google Scholar] [CrossRef]

85. Correal, J., Echeverry, J., Yamin, L., Ramirez, F. (2014). Experimental behaviour of structural size Glued Laminated Guadua bamboo members. World Conference on Timber Engineering. [Google Scholar]

86. Estrada, M., Linero, D. L., Takeuchi, C. (2019). Numerical model of cracking pattern in laminated bamboo specimens under tensile and shear loads. Frattura ed Integrita Strutturale, 13(48), 348–356. DOI 10.3221/IGF-ESIS.48.33. [Google Scholar] [CrossRef]

87. Guan, X., Yin, H. N., Liu, X. S., Wu, Q. R., Gong, M. (2018). Development of lightweight overlaid laminated bamboo lumber for structural uses. Construction and Building Materials, 188(10), 722–728. DOI 10.1016/j.conbuildmat.2018.08.107. [Google Scholar] [CrossRef]

88. Li, Z., Zhang, J., Wang, R., Monti, G., Xiao, Y. (2020). Design embedment strength of plybamboo panels used for glubam. Journal of Materials in Civil Engineering, 32(5), 04020082. DOI 10.1061/(ASCE)MT.1943-5533.0003128. [Google Scholar] [CrossRef]

89. Shan, B., Chen, C. Q., Deng, J. Y., Li, T. Y., Xiao, Y. (2021). Assessing adhesion and glue-line defects in cold-pressing lamination of glubam. Construction and Building Materials, 274(2), 122106. DOI 10.1016/j.conbuildmat.2020.122106. [Google Scholar] [CrossRef]

90. Tang, Z., Shan, B., Li, W. G., Peng, Q., Xiao, Y. (2019). Structural behavior of glubam I-joists. Construction and Building Materials, 224(9), 292–305. DOI 10.1016/j.conbuildmat.2019.07.082. [Google Scholar] [CrossRef]

91. Xiao, Y. (2010). Progress report on development of glue-laminated bamboo (Glubam) structures. Proceedings of the First International Conference on Sustainable Urbanization (ICSU 2010), pp. 51–60. Hong Kong, China. [Google Scholar]