| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.018755

ARTICLE

Study on Properties of Blue-Brick Masonry Materials for Historical Buildings

1Kaifeng Research Center for Engineering Repair and Material Recycle, School of Civil Engineering and Architecture, Henan University, Kaifeng, 475004, China

2College of Water Conservancy & Engineering, Zhengzhou University, Zhengzhou, 450001, China

*Corresponding Authors: Shaochun Ma. Email: scma@vip.henu.edu.cn; Peng Bao. Email: 10160068@vip.henu.edu.cn

Received: 15 August 2021; Accepted: 19 October 2021

Abstract: There are a large number of historic buildings which were mainly made of blue-brick masonry in today’s world. However, for the natural and man-made reasons, these historic buildings have been damaged in different degrees. In order to protect historic buildings more scientifically and learn about the preservation state of existing historic buildings, it is necessary to ascertain the material properties of blue brick in historic buildings. The article takes the blue bricks of historical buildings in Kaifeng area of the Central Plains as an example to study. Through the analysis of physical properties, X-ray fluorescence spectroscopy, X-ray diffraction and scanning electron microscopy of blue brick specimens, the physical properties such as the apparent density, moisture content, porosity, and material structure composition are understood. The results show that the apparent density of blue brick is 1.64 g/cm3, the moisture content is 10.23%, the 24 h atmospheric water absorption is 17.86%, and the porosity is 20.99%. The smaller the apparent density is, the larger the porosity is, and the water absorption performance is better. From the microscopic point of view, bonding ability between blue brick mineral particles is relatively weak. The pores between skeletons are large and the pore structure is obvious. From the perspective of material phase, the elements of blue brick are mainly O, Si, Al, Fe, and the composition of blue brick is mainly composed of quartz and feldspar. The softening coefficient of blue brick is 0.80, and the deformation and stability of the structure should be paid special attention in the rainy season or wet environment. Through the frost test, there are salt substances in the internal pores of the brick, and the surface of the blue brick is eroded and pulverized. In this paper, the experimental process and analysis methods for testing the material properties of blue brick can provide reference for the research on the material properties of the same kind of blue-brick masonry in historic buildings and masonry relics. The relevant material property parameters obtained in this paper can provide guidance for making protection schemes and scientific repairs for historic buildings in Central China, enrich the evaluation criteria for maintaining and reinforcing historic buildings, and provide theoretical support for studying the damage and health detection technology related to historic buildings.

Keywords: Historical buildings; blue brick; material properties; porosity; scanning electron microscopy; softening coefficient

Under the background of globalization, people gradually realize the importance and necessity of protecting traditional culture. Historical buildings witness the changes in culture and civilization, and it is the essence of the wisdom of working people. As one of the six ancient capitals in China, Kaifeng has a long history and culture after eight dynasties. There are many historical buildings with blue brick as the main building materials. They were successively rated as cultural relics protection units of different levels. The blue brick appeared in the Western Zhou Dynasty in China, after Qin and Han Dynasties, Sui and Tang Dynasties and Ming and Qing Dynasties three important stages of development. It bears thousands of years of history, culture, architectural technology development of the Chinese nation, and witnesses the development and progress of human civilization and society. Among many building materials, the blue brick material has the advantages of wide source of raw materials, low cost, convenient drawing and fire insulation, and it has become one of the main traditional building materials and has gradually become an important topic of research.

In recent years, as China has further strengthened the protection of historical buildings and cultural relics, many scholars have conducted a lot of research on the properties of historical building blue brick materials and have achieved some results. On the properties of blue brick materials, Gao et al. [1] carried out a series of physical properties tests on Xi’an City wall brick samples, and proposed that the decline of mechanical properties of city bricks is mainly related to factors such as long-term rain freeze-thaw and weathering. Li et al. [2] analyzed the physical properties, mineral composition and salt resistance of Pingyao ancient city blue brick, and proposed that capillary water rise was the main reason for wall deterioration. Liu et al. [3] conducted physical tests on the ancient brick samples of Ming and Qing Dynasties in Shanxi Province, and believed that the dynasties had little influence on the physical properties of the original components of ancient bricks, and the main components of ancient bricks were quartz and feldspar. On moisture absorption of blue brick materials, Maria et al. [4] found that the brick walls of historical buildings were limited in the level of craftsmanship at that time, and artificial masonry made the pores in the walls larger and easier to absorb water. Experiments were conducted on water-saturated walls, dry walls and similar materials, and it was proposed that saturated walls had better thermal conductivity and poor thermal insulation performance than dry walls. Wang et al. [5] analyzed the chemical elements, crystal composition and microstructure of the ancient blue brick, and proposed that the aluminum silicate content and sintering temperature were the main reasons for the difference in surface roughness and water absorption of the brick. Li et al. [6] pointed out that the rise of humidity will lead to deterioration and damage of blue brick materials in the historical buildings of blue brick masonry, and it will breed a series of hazards such as mold on the wall. It is proposed that the water rise in the wall is affected by the building type, masonry mode, environmental conditions and physical properties of masonry materials. Meanwhile, Li et al. [7] also studied the differences in isothermal moisture absorption characteristics of blue bricks in different ages and proposed that the isothermal moisture absorption capacity of blue bricks in the late Yuan and early Ming Dynasties was the largest when the relative humidity was 11%–97%. On the compressive strength of blue brick materials, Natthanan et al. [8] conducted a series of physical tests on ancient brick masonry and mortar in Thailand and proposed an empirical formula to predict the compressive strength of masonry with historical structures. Ding et al. [9] carried out the compressive test of blue brick masonry in the repair and protection project of modern cultural relics and ancient buildings with blue brick as the main building material in Hebei area. The compressive strength design value of blue brick masonry was determined by analyzing the test data, the stress-strain curve was established, and the reference value of elastic modulus suitable for this kind of masonry was recommended.

At present, some historical buildings in Kaifeng have undergone multiple repairs or renovations in different periods, and the original brick and the later replacement brick coexist. Whether the brick used for later maintenance or the original retained brick, there are unfavorable factors such as salt, spalling, powdering and material aging. The blue brick has a loose texture, higher porosity, strong water absorption capacity. Long-term exposure to the natural environment could make different degrees of deterioration [10]. With the passage of time, the deterioration continues to intensify.

Based on the above research, it is not difficult to find that many scholars have studied the properties of blue brick materials mainly including: water absorption, salt resistance and microstructure. Therefore, on the basis of this research, this article conducts a more in-depth study of the properties of blue brick materials. Not only the basic properties of blue bricks, such as apparent density, moisture content, 24 h atmospheric water absorption, porosity, softening coefficient, compressive strength, frosting, main component composition and micro-structure have a clear grasp. We also have further study of the relationship between basic performance. Such as the relationship between 24 h atmospheric water absorption and porosity, the relationship between softening coefficient and water absorption, and changes in the composition and internal structural characteristics of the blue brick under the frosted state. Through the frost cycle test, we have studied the influence of environmental factors on the pulverization, erosion and durability of blue brick. The test results enrich and broaden the comprehensive understanding of the performance of blue brick masonry materials. These research results can not only truly reflect the preservation status of historical buildings, but also provide an experimental basis and theoretical support for the protection of historical buildings in Central China. It provides guiding suggestions for the formulation of protection schemes of historical buildings and enriches the evaluation indexes of maintenance and reinforcement of historical buildings. It also lays the foundation for subsequent research on the influence of surrounding environment on the performance of blue brick materials, and provides theoretical support for the research of historical building damage and health detection technology. The purpose of scientific protection and repair of ancient masonry structure is realized.

2.1 Sample Source and Specimen Preparation

The blue brick used in the Central Plains Kaifeng City People’s Congress may be abandoned as old brick. Fig. 1 illustrates the Kaifeng People’s Congress, which was opened in 1928. Such historic buildings have these blue bricks with their unique rugged texture and blue-gray surfaces.

Figure 1: People’s Conference Hall of Kaifeng

According to the relevant regulations in “Basic Materials for Cultural Relics Building Maintenance” Blue Brick WW/T 0049-2014 [11] and “Test Methods for Wall Bricks” GBT 2542-2012 [12], the test samples were made as 50 mm × 50 mm × 50 mm cube samples. Thus, the experimental design comprised a total of 5 groups and 25 samples. These underwent a series of physical property tests such as apparent density, moisture content, 24 h atmospheric water absorption, compressive strength, softening coefficient, and frosting, in addition to comparative X-ray diffraction (XRD) and scanning electron microscopy (SEM) analyses on the ordinary and frosted samples. Fig. 2 shows the sample preparation.

Figure 2: Sample fabrication (a) Blue brick samples, (b) Sample finished products

2.2.1 Physical Properties Test

(1) Apparent density test

According to the relevant regulations in “Code for Rock Tests in Water and Hydropower Projects” SL/T 264-2020 [13] and “Test Methods for Wall Bricks” GBT 2542-2012 [12], the apparent density test helped understand the current performance of blue brick materials. Specimens without surface damage were selected, cleaned up the surface dust, put them into a 105°C blast oven, dried them to constant mass, and recorded this dry mass, and the Eqs. (1) and (2) led to determine the apparent density and porosity.

In the formula: ρ0 is the apparent density of blue brick material, the unit is g/cm3. m is the mass of specimen under natural state, the unit is g. V is the volume of the specimen, the unit is cm3.

In the formula: P is the porosity of blue brick material, the unit is %. ρ0 is the apparent density of blue brick material, the unit is g/cm3. ρ is specimen density, the unit is g/cm3.

(2) Moisture content and 24 h atmospheric water absorption test

In general, the mass of the blue brick material increased with water absorption, but the thermal insulation performance decreased. In addition, the durability and strength of the blue brick material were also affected to varying degrees. Excessive water absorption reduced the performance of blue brick materials impacting the materials’ service life [14–16]. Using waterproof materials to inhibit excessive water absorption depends on blue brick materials’ water content and 24 h atmospheric water absorption. Following the relevant regulations in “Test Methods for Wall Bricks,” GBT 2542-2012 [12] and “Fired Common Bricks” GBT 5101-2017 [17], the moisture content and water absorption of blue brick materials at an atmospheric temperature for 24 h were obtained using a 105°C blast drying oven to dry to constant mass, and recording the results. The dried specimen was placed in a container of water at a temperature of 10°C~30°C. After soaking for 24 h, a wet towel mopped excess surface moisture, and the wet mass was recorded. Eqs. (3) and (4) led to determining water content W1 and 24 h atmospheric water absorption W24.

In the formula: W1 is the water content of blue brick material, the unit is %. m is the mass of specimen under natural state, the unit is g. m0 is the dry mass of the blue brick specimen, the unit is g.

In the formula: W24 is the 24 h atmospheric water absorption of blue brick material, the unit is %. m24 is wet mass of specimen immersed for 24 h, the unit is g. m0 is the dry mass of the blue brick specimen, the unit is g.

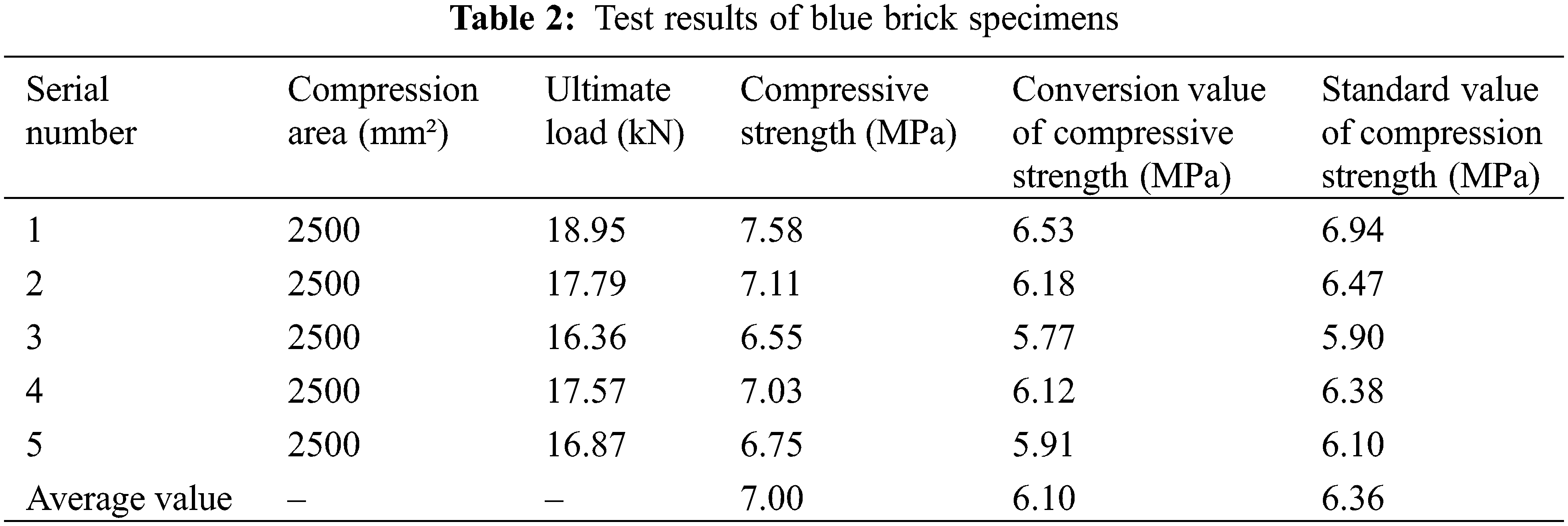

(3) Compressive strength test

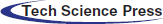

Blue brick served as a load-bearing building material. To utilize the characteristics of the material, people evaluate its bearing capacity and determine its strength grade. Therefore, it was necessary to assess the current mechanical properties of blue bricks to provide further reinforcement and maintenance of masonry structures. According to the relevant regulations in “Test Methods for Wall Bricks” GBT 2542-2012 [12], “Fired Common Bricks” GBT 5101-2017 [17] and “Basic Materials for Cultural Relic Building Maintenance” Blue Bricks WW/T 0049-2014 [11], a microcomputer-controlled electron universal testing machine WDW-600E was adopted. Its measurement accuracy was ±1%, and the maximum axial force was 600 kN. Fig. 3 gives further details.

Figure 3: Compressive strength test (a) Compression test device, (b) Destruction diagram of test piece

Cleaned up surface dust on the test piece and numbered them separately. Next, aligned and axially loaded, ensuring no eccentricity in loading. The loading rate was 1 mm/min. During the loading process, the microcomputer image and the specimen’s crack development trend until the specimen was destroyed and recorded the corresponding test phenomena and results.

The compressive strength Rp is calculated according to Eq. (5).

In the formula: Rp is the compressive strength of blue brick material, the unit is MPa. F is the maximum failure load, the unit is N. L and B are the length and width of the pressure surface, respectively, the unit is mm.

(4) Softening coefficient test

In hot, rainy, and humid areas, blue brick masonry buildings were often damp. To better protect such buildings. It was imperative to verify their water-resistance [18]. The softening coefficient was a parameter indicating the water resistance of the material. The higher the softening coefficient was, the better was the water resistance of the material. According to the relevant regulations in “Test Methods for Wall Bricks” GBT 2542-2012 [12]. The softening coefficient test suggested the specimen needed to be softened into the water at about 20°C for 96 h to obtain the saturated but dry surfaced specimen. For air-drying, the specimen was placed in an unventilated room set at a temperature not less than 10°C for 72 h. The compressive strength tests were carried out on the saturated surface dry and air-dried specimens, and the ratio of saturated surface dry compressive strength to air dry compressive strength was considered the softening coefficient as shown in Eq. (6).

In the formula: Kf is the softening coefficient of blue brick material. Rf is the dry compressive strength value of the saturated surface, the unit is MPa. R0 is the air dry compressive strength value, the unit is MPa.

(5) Frosting test

The frost phenomena were a consequence of the existence of soluble salt inside the brick material. Frost damage to the blue brick masonry building was numerous. First, it affected the appearance of the building and loosened the structure, shortening the life of the material. Secondly, it caused the cracking of blue brick materials and posed a severe threat to materials, components, and structures [19]. The test results and the surrounding environment better understood the current frosting degree of blue brick materials. Thus the results provided an essential reference for the development of protective measures for blue brick masonry structures, and it was significant for realizing the scientific protection of historic buildings. According to the relevant regulations in “Test Methods for Wall Bricks” GBT 2542-2012 [12]. For the frost test, the specimen was placed in a 105°C blast drying box for 24 h, and it was put into the shallow plate injected with distilled water, exposed to the specimen’s surface, and sealed with a thin film. After 168 h, the specimen was removed and dried. This cycle simulates the dry-wet alternate environments, and the experimental design had five such cycles. Finally, the specimens were placed in a 105°C blast ovens and dried to a constant mass, and the degree of frosting was determined and made appropriate conclusions.

2.2.2 X-Ray Fluorescence Spectrum Analysis Test

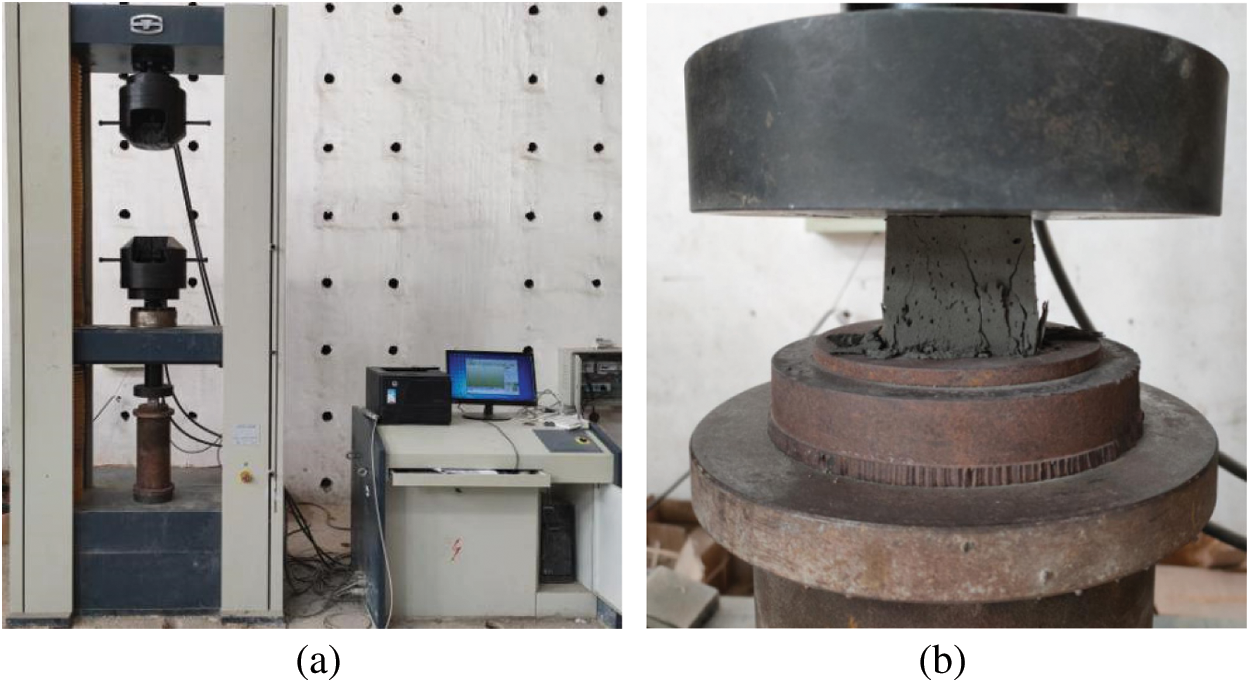

In studying the characteristics of blue brick materials, it was necessary to determine their chemical composition. Therefore, the chemical composition of ordinary samples and samples after frosting of blue brick was obtained by XRF analysis, which was used to analyze the variation of the main elements before and after the frosting of blue brick materials. Fig. 4 illustrates the ARL Perform’ X4200 spectrometer that analyzed the X-ray fluorescence spectrum, and the element analysis range was O-U. In the X-ray fluorescence spectrum analysis test, the blue brick specimens were ground into powder according to the requirements for specimen preparation and dried in a 105°C blast drying oven. The white frosting powder formed on the specimen’s surface was subsequently scraped off.

Figure 4: Experimental apparatus for X-ray fluorescence spectrometry

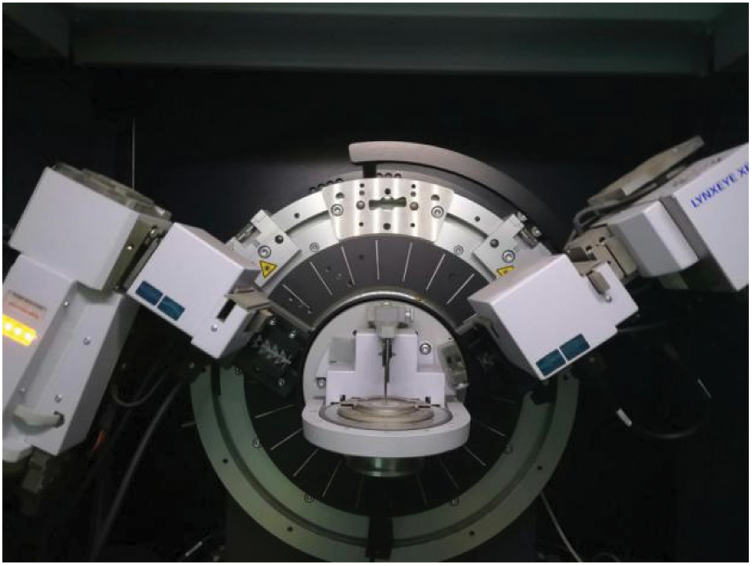

The compositions of the material shed helpful information to the characterization study of blue brick materials. The International Center for Diffraction Data published the diffraction data of various substances in PDF2-2004. The main material composition and the types of soluble salts in the materials were obtained through XRD analysis of the ordinary samples and the samples after frosting to analyze the variation of the material composition of blue brick before and after frosting. X-ray diffraction analysis used a D8-ADVANCE diffractometer (Fig. 5) with an angular accuracy of 0.0001°, and the scan range was 5°~90°. Blue brick specimens were ground into powder for the X-ray diffraction test as required and dried in the 105°C blast drying oven. Information as obtained from the typical samples of blue brick samples before and after frosting. A laser diffractometer provided the relevant XRD spectrum.

Figure 5: X-ray diffraction test device

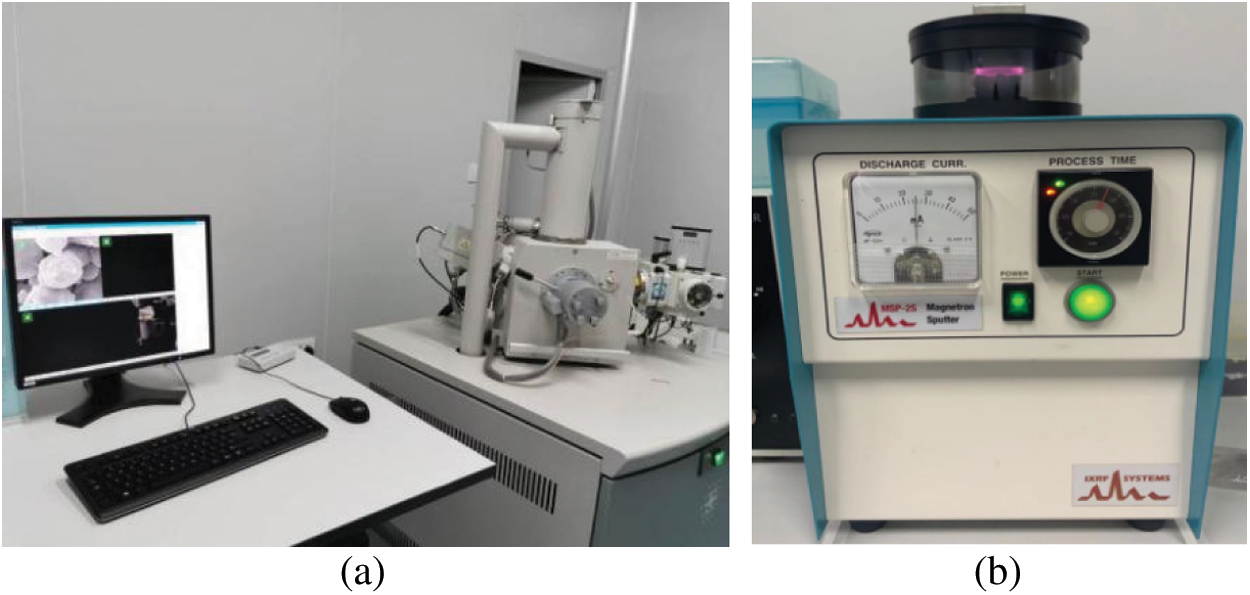

2.2.4 Scanning Electron Microscopy Test

According to the relevant regulations in “Analysis Methods of Rock Sample by Scanning Electron Microscope” SY/T 5162-2014 [20]. Scanning electron microscopy was used to observe the internal structure of blue brick materials. By studying the micro structural changes of specimens before and after frosting. The cross-sectional microstructure and pore characteristics of blue brick materials were observed. The microstructure analysis supported learning the attributes of blue brick materials and the compactness of the sample particles [21]. The SEM specimens of blue brick specimens were analyzed in a FEI Quanta 250 environmental scanning electron microscope. It is accelerating voltage was 50 kV, the beam current was 80100 Ma, and the resolution was 1.0 nm/15 kV, as shown in Fig. 6. In the SEM test, the size of the blue brick sample required was 5 mm × 2 mm × 2 mm. The specimens were dried in a 105°C blasts drying oven to constant mass, and the ordinary specimens and frosted specimens were thus obtained, respectively. After vacuum gold plating, the blue brick samples were electronic scanned and images appropriately magnified, creating conditions for the study of microscopic morphology.

Figure 6: Scanning electron (a) Scanning electron microscope test device; (b) Vacuum gold plating

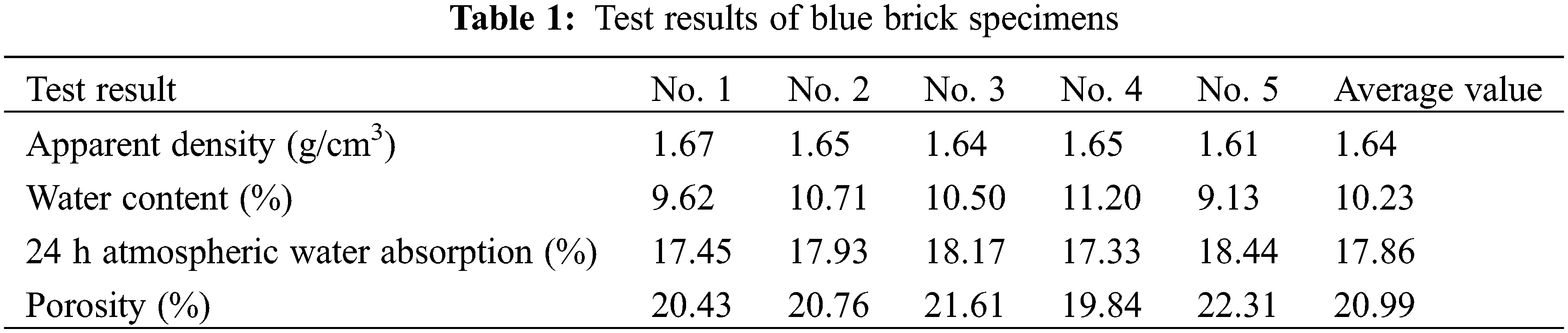

3.1 Test Results and Analysis of Physical Properties of Blue Brick

The apparent density can reflect the solidity of the blue brick masonry material. The water absorption rate represents the water absorption and permeability of the blue brick, and the porosity is an important indicator to measure the internal pore status of the blue brick. These three were usually used to check the quality of bricks, and to a certain extent. Reflect the existing conditions of historic buildings [2,3]. The determination of these indicators was the basis for studying the performance of blue brick materials and the prerequisite for the protection of blue brick masonry historic buildings and the subsequent maintenance and reinforcement.

Table 1 gives the test results of the blue brick used in the study. The apparent density of blue brick was about 1.64 g/cm3, which was lower than that of modern ordinary clay brick (1.70 g/cm3). Consequently, a study of the blue brick pores was developed. At the initial immersion stage, more bubbles were generated on the water surface, indicating more pores in the specimen. The lower the apparent density of blue brick, the larger the porosity was, meaning more internal pores, and the experimental results also confirmed this. The water content of blue brick ranged from 9.13% to 11.20%, with an average of 10.23%. The porosity of blue brick ranged from 19.84% to 22.31%, with an average of 20.99%. Compared with the porosity of blue brick in Xi’an City wall, the blue brick in Kaifeng had lower porosity, weaker water absorption, but better frost resistance and weathering resistance. These differences were mainly related to the geographical environment of Xi’ (dry, windy, and sandy). Blue brick was seriously eroded by weathering, and porosity was relatively large. When the maximum porosity of brick was 22.31%, the 24 h atmospheric water absorption rate also reached the maximum of 18.44%. When the minimum porosity of brick was 19.84%, the 24 h atmospheric water absorption rate also achieved the minimum value of 17.33%.

The apparent density, porosity, water content, and 24 h atmospheric water absorption rate of blue brick were thus closely related. Therefore, it was necessary to clarify the relationship between these indicators in the study of material properties. The porosity of brick had a significant correlation with the 24 h atmospheric water absorption of brick. With increased brick porosity, the 24 h atmospheric water absorption rate also showed an upward trend. With the proliferation of porosity, the 24 h atmospheric water absorption rate of blue brick increased gradually. When the porosity was relatively high, it became easier for water to migrate freely through capillary action. Therefore, the capillary water absorption capacity of the blue brick was better, and the internal water absorption performance was also relatively good. As a result, the water absorption and moisture absorption increased, and the material gained moisture content. The water absorption performance of the material was mainly affected by its internal porosity, and high porosity led to bricks quickly absorbing water because the more significant the porosity of the blue brick material, the more was the internal porosity of the material, the lower the apparent density. At the same time, the higher the 24 h atmospheric water absorption rate was, the greater the water absorption and water absorption of brick were. Therefore, for the blue brick material with large porosity. The water absorption of the material was reduced through improved compactness, avoiding the destruction of the internal structure of the material with an aqueous salt solution to enhance the quality of the brick.

3.1.1 Analysis of the Results of the Compressive Strength of Blue Brick

As far as the material was concerned, blue bricks were generally load-bearing material in historic buildings. The quality of the building was directly related to the bearing capacity of the building [22,23]. China has a long history of building protection, but many historic buildings with blue brick masonry had missed the protection. Most of these buildings had gone past a hundred years and urgently needed to repair due to natural or artificial reasons. According to the requirements of the principle of repairing the blue bricks of cultural relics, the material of the replacement blue bricks cannot be higher than the compressive strength of the original blue bricks. Therefore, an accurate assessment of its compressive strength was essential. Referring to the regression equation proposed by Ding et al. [9]. The regression equation was R1 = 0.7381R2+0.9311. R1 was the compressive strength, R2 was the conversion value of compressive strength. By converting compressive strength value of 50 mm × 50 mm × 5 mm cube specimens, the compressive strength conversion value was obtained according to the relevant regulations in “Test Methods for Wall Bricks” GBT 2542-2012 [12], and as shown in Table 2.

The test results were revised based on the research from relevant scholars. Compressive strength results were quite different because of the sources of bricks and the different storage environments. Nevertheless, the test results show that the standard value of the compressive strength of blue brick is 6.358 MPa, which is greater than 5 MPa and less than 6.5 MPa. According to the relevant provisions on the strength grade of blue brick in “Fired Common Bricks” GBT 5101-2017 [17], the strength grade of brick consisted of five grades; MU30, MU25, MU20, MU15, and MU10. Among them, MU10 required that the average compressive strength of brick needed to be greater than or equal to 10 MPa, and the standard compressive strength requirement was more significant than 6.5 MPa. However, the average compressive strength of blue brick after conversion was 6.102 MPa, and the required compressive strength value was 6.358 MPa. Therefore, the overall strength grade of the blue brick did not meet the minimum strength requirement of MU10. In this context of the actual material situation, this research believed that the deterioration of the blue brick material under the long-term outdoor environment and load contributed to the reduced performance and was detrimental to the stability and safety of the structure. Therefore, it was vital to study the historic building materials using this kind of blue brick data, to strengthen the maintenance and provide adequate protection of landmark building structures with the support of theoretical data.

The accuracy of the test instruments used in this research was 1%. Compared with previous experimental research methods and tests, these results were within the engineering error requirements. In addition, given the current research situation, the protection of ancient buildings and cultural relics was a popular research direction. However, there were limitations in research methods, research means, research depth, and test equipment. Through researching the blue brick’s material properties, developed test methods enriched and supplemented the testing plan. The research results guided the scientific repair and protection of ancient buildings and cultural relics and provided references to similar structures.

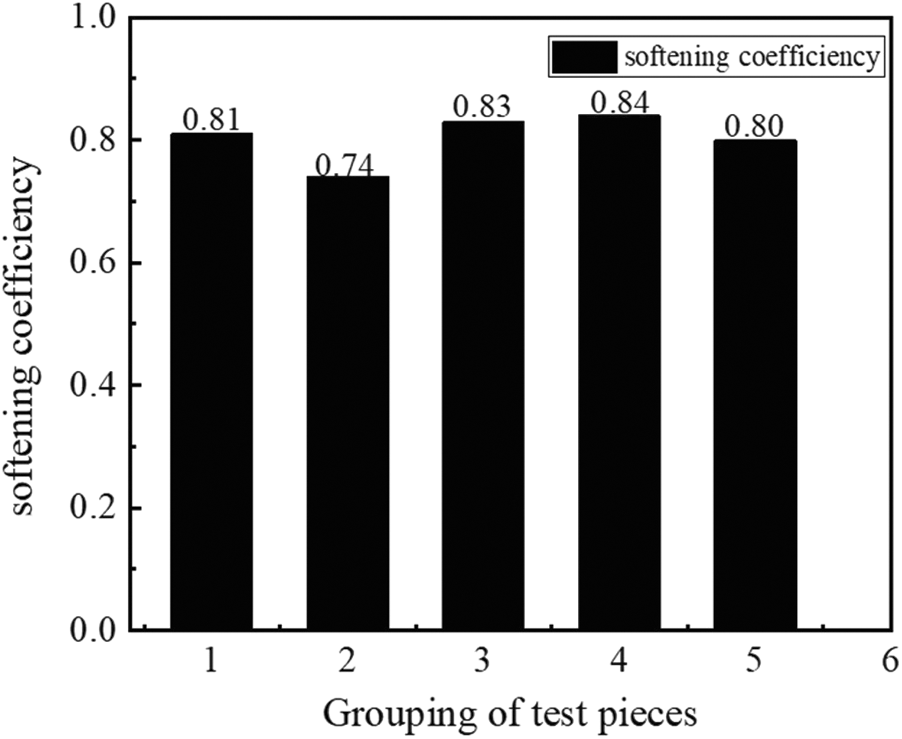

3.1.2 Analysis of Softening Coefficient Results

The softening coefficient showed the water resistance of blue brick materials and was adopted as an essential basis for material selection [24,25]. Generally, materials with softening coefficient greater than 0.85 were water-resistant materials. The softening coefficient must be greater than 0.85 for important constructions in moist environments or under long-term water. The softening coefficient must not be less than 0.70 for building materials with lighter or secondary structures subjected to moisture.

The mortar material that played a role in binding blue bricks in ancient buildings had a softening coefficient of 0.486 and poor water resistance [26]. Based on this research, this paper studied the blue brick materials. Fig. 7 illustrates the observations in the softening coefficient testing of blue brick, and the result indicated that the softening coefficient of blue brick was 0.80, between 0.70 and 0.85. Thus it showed that the water resistance of the blue brick was better than that of the mortar. Combined effects of the typical monsoon climate characteristics of high temperature and heavy rains in summer and cold and dry in winter over the central plain area, the long-term load and environment were the significant causes. The internal pores of the blue brick became more meaningful, and the coupling between particles became weaker. Finally, the water absorption became stronger, decreasing the strength and low softening coefficient of blue brick. Therefore, special attention was necessary to the deformation and stability of the structure in the rainy season or wet environment to establish the corresponding historic building environment observation in real-time. When the surrounding environment was in a long-term wet or polluted state, the instability of the building structure was predictable over time. Therefore, it was conducive to more scientific protection of historic buildings and cultural relics and provided a theoretical basis for studying damage to historic buildings and health observation techniques.

Figure 7: Softening coefficient of blue brick

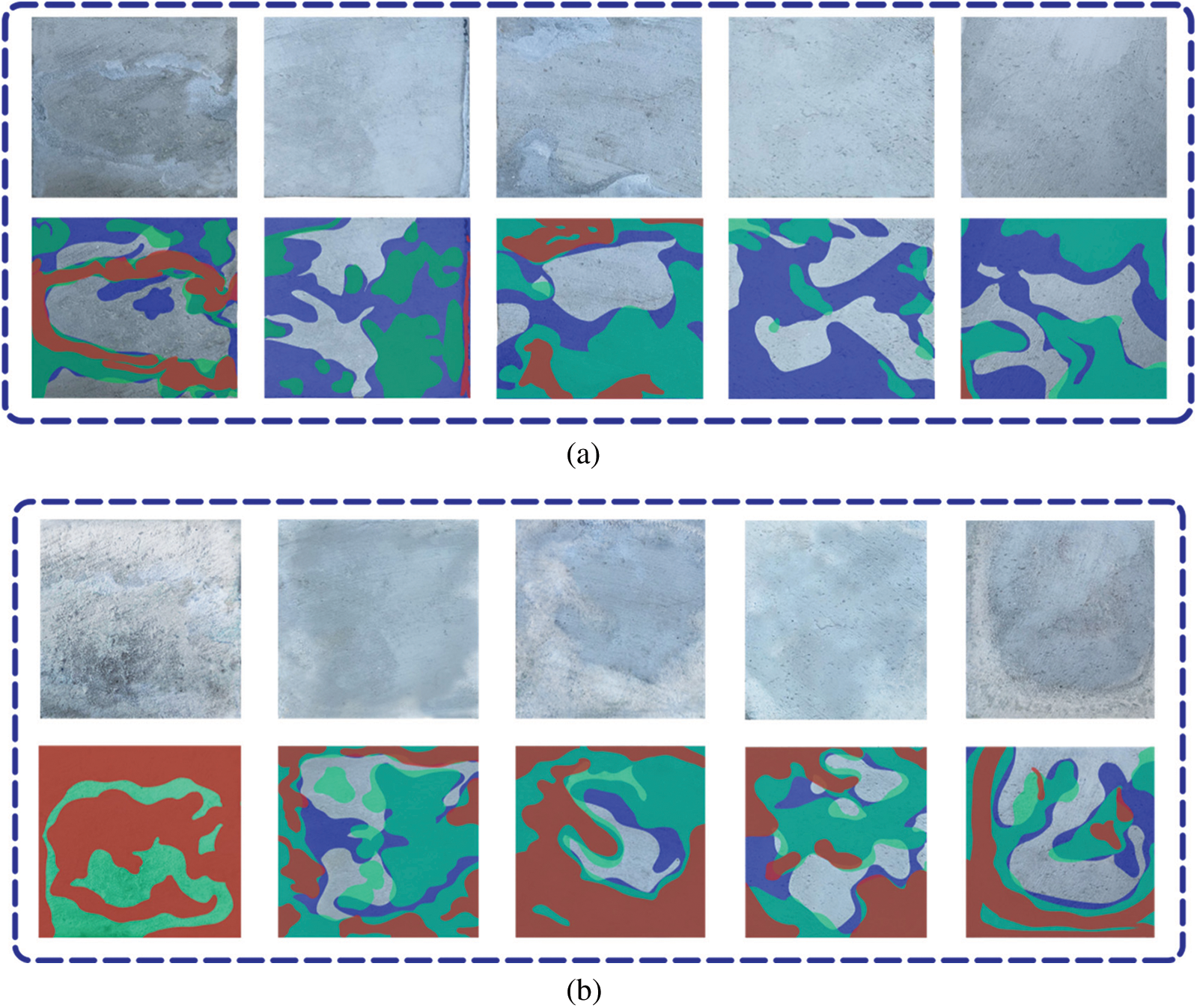

3.1.3 Results and Analysis of Flooding Frost

The frosting was a common durability damage phenomenon of blue brick. When water erodes bricks, the water’s soluble substances are transported to the surface through capillary tubes, crystallized, and remained on the surface during water evaporation. With the change of humidity, they dissolve and re-crystallized repeatedly. Soluble substances include inorganic materials and mineral materials, among which salt substances were considered the root of frost formation [27,28]. There were two sources of salt substances, namely the brick itself or the external environment. These salt affected historic buildings’ overall aesthetic feeling and reduced the mechanical strength of blue brick materials, resulting in shedding, crisp powder, and other damage, and even threatening to affect structures’ stability and safety [29]. The blue brick selected in the frost test was the most commonly used masonry material in the historical buildings in Central China. Combined with the climatic characteristics of high temperature and rainy summer, cold and dry winter, more rainfall, and pronounced seasonality in the Central Plains region. In addition, the cations in surface water and groundwater in the Central Plains were mainly Na+, and the anions are mainly HCO3−, followed by SO42−. These situations had the primary conditions of soluble salt formation. Therefore, it was vital to conduct a frosting test on blue brick.

The frosting test repeated a process five times. After the first cycle, slight frosting occurred. The phenomenon was not evident after the second to fourth cycles but remained similar to the first cycle results. At the end of the fifth cycle, the specimen became pulverized. As shown in the chart, the severity of the frost phenomenon, from severe to slight, was designated red, green, and blue. The results of one cycle are shown in Fig. 8a. A thin layer of white salt crystals with powder and membrane was precipitated on the surface of the blue brick. However, the surface of the brick was still clearly visible, and there were no erosion and pulverization phenomena. The results from five cycles are shown in Fig. 8b. With the cyclical alternation in the frost test, increasing white salt crystals were formed on the surface of the specimen. Crystal growth trend spreads from the edges to the middle and the upper surface of the lower. The color of the specimen also changed with increasing dry-wet cycles. The surface of the specimen was no longer smooth and flat, and erosion and pulverization also occurred. A slight surficial drop occurred at the corners of the specimen, and the original color of the brick also changed.

Figure 8: Comparison plot of the pan-frost test results (a) The Result of one cycle (b) The Result of five cycles

In general, the frosting was a quantifiable process. The alternating dry and wet simulate the natural environment of the historic building. The results of the frosting test not only proved the existence of soluble salts in the blue bricks but also provided clues to the source of blue brick and the impact of changes in environmental humidity on the durability of brick. The soluble salt in the pores of the blue brick will absorb water to form a crystalline salt with some crystal water. After the salt crystallized, the volume increased, causing an expansive force in the pores of the blue brick. With repeated changes of the environmental humidity, the soluble salt circulated back and forth within the interior and surface of the brick, and the expansion force formed in the pores of the blue brick was also increasing, which led to the phenomena of pulverization and erosion on the surface of the blue brick reducing the brick material. These material properties affected the durability of brick and eventually led to the cracking and even collapse of structural components. Therefore, to improve the durability of blue brick, on the one hand, historic buildings with the salting-out phenomenon were treated to retard the desalting to slow down the efflorescence and peeling of blue brick caused by the expansion of salt-forming crystals.

On the other hand, it was also necessary to block the migration of water and soluble salt into the interior of the brick. Therefore, it was essential to ensure the weather-resistant performance of brick and the desalting of soluble salt. At the same time, it was also necessary to protect and maintain historic buildings’ appearance as the fundamental principle to achieve harmony and unity of maintenance and protection.

The results of XRF primary element analysis of ordinary samples and frosted samples are shown in Table 3. The results show that the elements of standard samples were mainly O, Si, Al, and Fe, and the proportions were 55.64%, 26.95%, 4.83%, and 6.57%, respectively. Na, Mg, K, Ca, Mn, S content was relatively small. Due to the generation of carbonates, the contents of S and Ca in the samples after frosting were relatively high. The elements were mainly O, Si, S, and Ca, and the proportions were 53.69%, 23.45%, 8.17%, and 10.33%, respectively. The contents of Mg, K, Ca, Mn, and S were still relatively small.

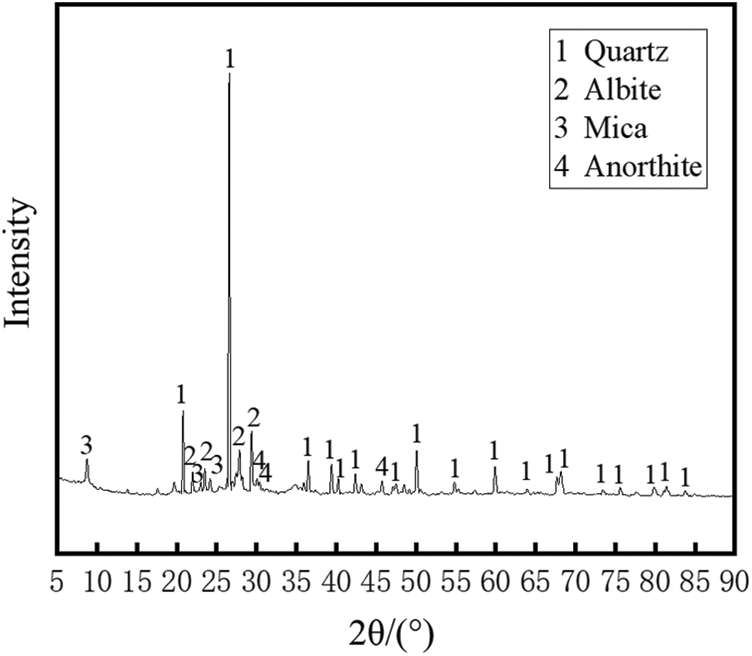

3.3 Analysis of the XRD Results

XRD analysis was carried out on the ordinary blue brick samples obtained and the frosted samples. By importing the obtained XRD spectrum to the data analysis software, the mineral composition was obtained. Fig. 9 shows the main mineral composition of the blue brick specimen. The coordinate axis was the diffractometer angle, and the curve in the figure reflected the abundance of mineral composition under different test angles. The No. 1 diffraction peak was that of the quartz (SiO2), with the peak at 26.8°. The No. 2 peak was albite (Na(AlSi3O8)), at 29.6°. The No. 3 diffraction peak was mica, appearing at 8.9°. The No. 4 diffraction peak was anorthite (Ca(AlSi3O8)), occurring at 29.8°. In general, the better the crystallinity of the crystal was, the sharper and more precise the corresponding diffraction peak was, and the peak value also represented the abundance of the substance. The results showed that the quartz content was the highest, followed by an albite, anorthite, and mica, and mica content was the lowest. Therefore, the composition of blue brick was mainly composed of quartz and feldspar.

Figure 9: XRD pattern of ordinary blue brick

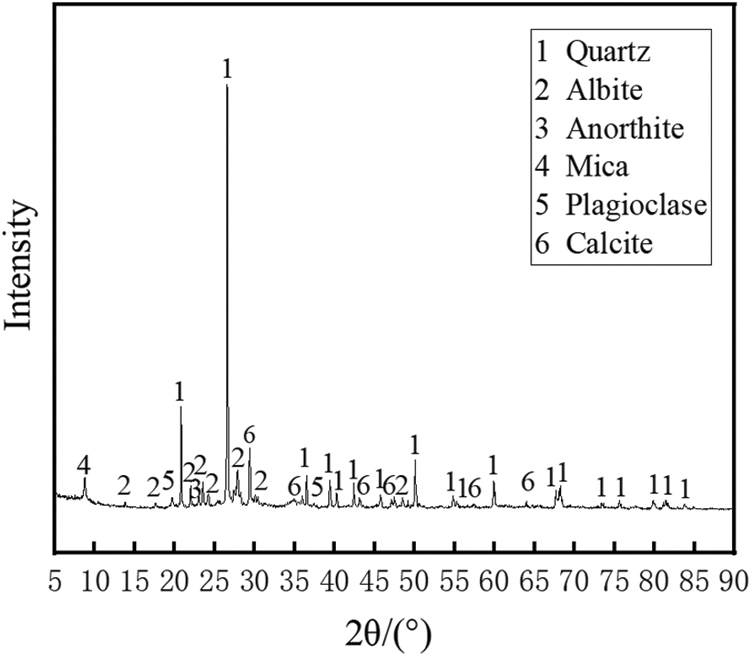

The main mineralogical composition of the frosted brick specimen is shown in Fig. 10. The No. 1 diffraction peak was that of quartz (SiO2), with a peak at 26.5°. The No. 2 diffraction peak belongs to albite (Na(AlSi3O8)), at 27.8°. The No. 3 diffraction peak at 22.8° was that from anorthite (Ca(AlSi3O8)). The diffraction peak No. 4 at 8.6° was that of mica. The No. 5 diffraction peaks at 19.6° and 37.3° were of plagioclase. The No. 6 diffraction peak was that of calcite (Calcium Carbonate) with a peak at 29.3°. Compared with the ordinary sample (without frosting), quartz and feldspar were still the main minerals when the test angle was between 20° and 35°. The difference was that calcite occurred. Calcite belongs to the carbonate mineral group, and its occurrence further confirmed the existence of salt substances in the internal voids of bricks, which caused the reaction of some new minerals interaction water. In this study, blue brick ordinary and frosted samples and Shanxi Ming and Qing ancient brick composition were similar and dominated with quartz and feldspar material [3], but with the frosted samples, calcite appeared. In the design of European brick, quartz was the main component, and feldspar was less [30].

Figure 10: XRD pattern of blue brick after frost

Based on the above analysis, we concluded that the frosting process was similar to the water washing process, which soaked the specimen with demonized water. However, after frosting, the peak value of feldspar materials became relatively weak; especially the peak value of calcium feldspar was no longer sharp as calcium carbonate was produced from the reaction of calcium feldspar and water, and calcium carbonate was not soluble in water. Therefore, after washing, the peak value of calcite was more prominent.

3.4 Analysis of the SEM Results

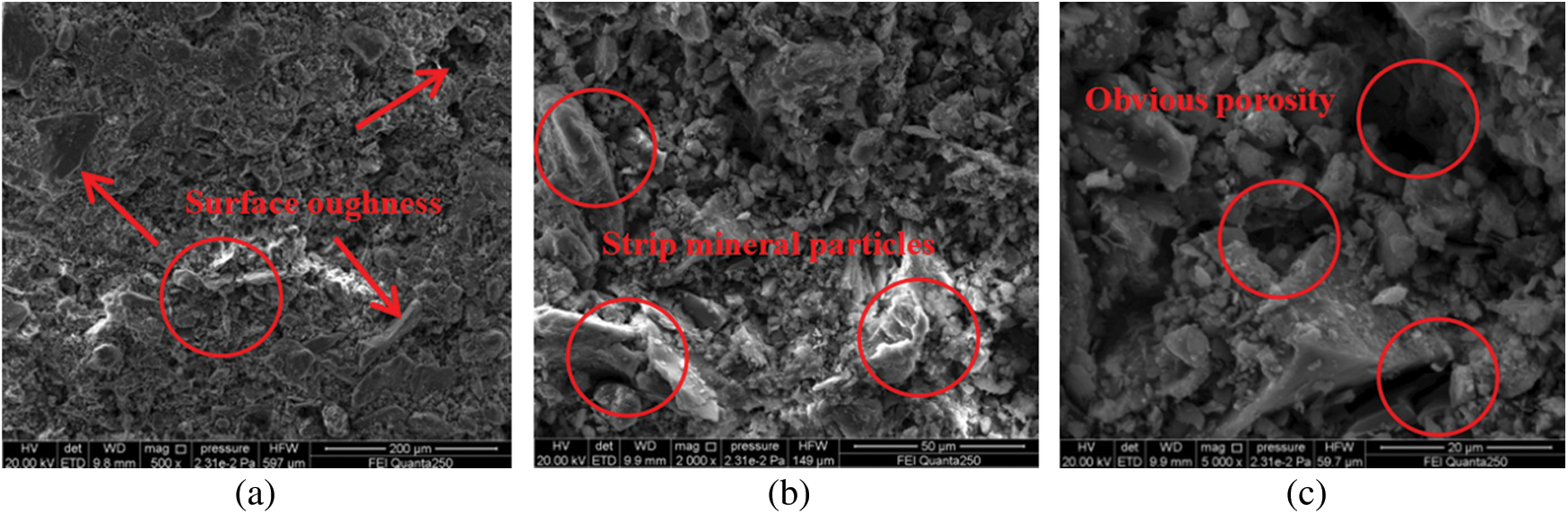

The interior of blue brick material was more intrusively studied when the specimen was scanned with the SEM. The microstructure of European brick is diverse [30], which is generally similar to that of ancient blue brick, showing prominent pore structure, rough surface, and weak inter-structure linkage [5]. On this basis, to study the change of microstructure of blue brick before and after frosting. SEM images of blue brick ordinary specimens and frosted specimens were viewed at magnifications of 500, 2000, and 5000 times. The internal microstructure, contact status between particles, and pore characteristics were observed [31].

3.4.1 Electron Microscopic Analysis of Ordinary Blue Brick Specimens

Fig. 11 displays the internal situation of ordinary blue brick specimens. The images showed that the texture of the blue brick was uniform. About 500 times magnifications, the microstructure of the sample was mainly a closely arranged tiny particle skeleton. The surface was relatively rough, and the overall structure was loose. At 2000 times magnification, many micron-sized mineral particles with different forms such as flake, strip, and block were evident. Smaller mineral particles surrounded by the larger particles, and the pores in the brick appeared abundant. At 5000 times magnification, the sample’s broken internal structure and the angularity of the crystals were apparent. Some grains appeared broken, the gap between mineral particles was large, the pore structure between skeletons was prominent, and the structural coupling power was relatively weak.

Figure 11: Scanning electron microscope (SEM) images of blue bricks (a) 500-fold magnification, (b) 2000-fold magnification, (c) 5000-fold magnification

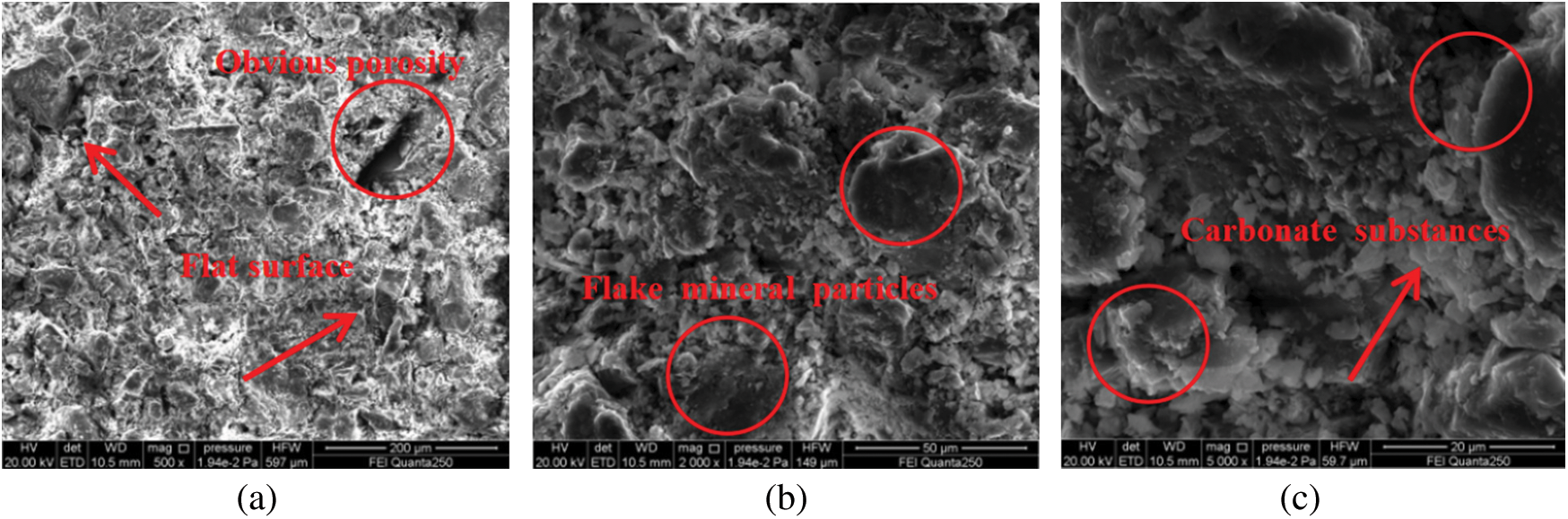

3.4.2 Electron Microscopic Analysis of Specimens after Frosting

Fig. 12 displays the internal status of the frosted specimens. The images showed that there were some soluble substances in the blue brick. Due to the effect of a moist environment and groundwater, these substances gradually precipitated and weakened the fusion between mineral particles in brick. The precipitated material remained within the pores or on the surfaces of the brick, and the interaction of the minerals with water formed more new minerals. These minerals within the brick’s pores eventually led to the brick’s collapse under the long-term repetitive crystallization pressure [31]. At 500 times magnification, fractures occurred within the frosted specimen, and noticeable pores appeared. Compared with ordinary samples, the arrangement of mineral particles was significantly different. A tiny particle skeleton no longer dominated the view, but the mineral particles were relatively closely arranged, incorporating carbonates between particles. At 2000 times magnification, the sample was relatively flat inside. No sharp strip-shaped mineral particles were visible, but many granular, flake and block-shaped mineral particles were visible. It was a consequence of the washing in the frosting process. At 5000 times magnifications, the sample was relatively flat and contained many dispersed particles. The space between mineral particles was small, and the coupling power was reasonably good. Compared with ordinary samples, the broken grains and pore structure between skeletons were not significant.

Figure 12: Scanning electron microscope (SEM) of blue brick frost samples (a) 500-fold magnification, (b) 2000-fold magnification, (c) 5000-fold magnification

In summary, compared with the ordinary samples (without frosting), the frosting caused carbonates to form within the blue brick. These products filled the bricks’ internal pores in the short term, making the brick skeleton tighter and improving the mineral particles’ binding forces. However, frost also broke the fusion between the original mineral particles within the brick body to expand these tiny particles. In addition, the emergence of new substances produced grain growth pressure, resulting in a gradual increase of crystallization pressure between minerals within the brick. The continuous changes in the surrounding environment and climate humidity in practical engineering induced the frost phenomenon. The presence of crystalline salt substances in the atmosphere led to new mineral particles within the brick, filling the internal pores in the brick. The crystalline material repeatedly circulated between the brick’s surface and interior, cracking and disintegrating the brick material and affecting the durability and safety of brick masonry buildings [32]. Desalination and moisture prevention in historic buildings with blue brick as the primary material was also a critical issue that needed urgent resolution in building protection.

The main conclusions drawn from the tests and analysis of the familiar blue brick materials in historic buildings were as follows:

1. The material property analysis ratified the current physical properties of blue brick specimens. The apparent density of blue brick was 1.64 g/cm3; water content was 10.23%, 24 h atmospheric water absorption was 17.86%, porosity was 20.99%. Thus, the low apparent density of blue brick responded to its higher porosity. Similarly, the higher porosity responded with a higher moisture absorption of the blue brick. Therefore, the water readily interacted freely within the brick through capillary action. In addition, the blue brick’s 24 h atmospheric water absorption increased, and so did its water content, with the water absorption performance being further improved.

2. Mechanical experiments referenced to the evaluation methods in relevant specifications showed that the existing strength grade of the blue brick did not meet the minimum strength requirement for MU10. Nevertheless, current mechanical properties of blue brick materials provided an essential basis for the maintenance and reinforcement of historic buildings to meet the principle that the strength of protective materials cannot exceed the strength of historic building materials. In addition, it also served to find the necessary modification scheme for blue bricks of the later period and provided a reference for the study of such masonry brick.

3. Frosting test analysis of blue brick showed that there were soluble salt substances within the brick. With the repetitive cycles of the frosting test, blue brick specimens were eroded and pulverized, demonstrating the influence of environmental drying and wetting cycles on the durability of brick. Therefore, it was necessary to desalt the historic buildings with frost to restrain the migration of water and its soluble salts inside the brick. Careful research was done on the weathering resistance of brick and the desalination of soluble salt. The experimental results enriched and broadened the comprehensive understanding of the performance of blue brick masonry materials.

4. The composition and microstructure study identified that the main mineral components of blue brick were quartz and feldspar. The elemental compositions of the samples before and after frosting were mainly O, Si, Al, and Fe, and the contents of S and Ca were relatively high after frosting. The microstructure of the samples after frosting showed that the pores between mineral particles were tiny, the bonding force was reasonably good, and the pore structure between broken grains and skeleton was not significant. Thus, these resulted from carbonate production.

Funding Statement: The authors would like to express heartfelt gratitude to the financial support by the Science Technology of the Ministry of Housing and Urban-Rural Development (No. 2018-K9-065), China Postdoctoral Science Foundation Funded Project (No. 2018M632805), Key Scientific and Technological Project of Henan Province (No. 212102310932), Key Scientific and Technological Project of Kaifeng City (No. 2001010).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Gao, H., Sun, S., Jin, P. J. (2020). Study on the composition, structure and properties of ‘Vanguard’ brick materials for Xi’an city walls in the Ming Dynasty. Journal of Building Materials, 23(1), 122–127. DOI 10.3969/j.issn.1007-9629.2020.01.018. [Google Scholar] [CrossRef]

2. Li, Y. H., Ma, Y., Xie, H. R., Li, J., Li, X. (2021). Cross validation of hygrothermal properties of historical Chinese blue bricks with isothermal sorption experiments. Frontiers of Architectural Research, 10(1), 164–175. DOI 10.1016/j.foar.2020.09.003. [Google Scholar] [CrossRef]

3. Liu, J. B., Zhang, Z. J. (2020). Characteristics and weathering mechanisms of the traditional Chinese blue brick from the ancient city of Ping Yao. Royal Society Open Science, 8(7), 1–19. DOI 10.1098/rsos.200058. [Google Scholar] [CrossRef]

4. Maria, S. C., Alejandro, C. P., Alfredo, L. A., Maria, P. S., Maria, P. S. et al. (2019). Brick walls of buildings of the historical heritage. Comparative analysis of the thermal conductivity in dry and saturated state. IOP Conference Series: Materials Science and Engineering, 471(8), 1–8. DOI 10.1088/1757-899X/471/8/082059. [Google Scholar] [CrossRef]

5. Wang, Y. S., Wu, X. M., Wu, G. L., Liu, X. (2021). Study on the factors influencing the surface quality of ancient blue bricks based on instrument analysis. Journal of Building Materials, 24(4), 7. DOI 10.3969/j.issn.1007-9629.2021.04.024. [Google Scholar] [CrossRef]

6. Li, Y. H., Kong, Z. Y., Xie, H. R., Hokoi, S. (2021). Construction type influences features of rising damp of blue-brick masonry walls. Construction and Building Materials, 284(2–4), 122791. DOI 10.1016/j.conbuildmat.2021.122791. [Google Scholar] [CrossRef]

7. Li, Y. H., Cai, Y. K., Xie, H. R., Zhang, J. (2020). Wenzhou Qiaolou site in different ages of blue brick isothermal moisture absorption characteristics comparison. Journal of Southeast University (Natural Science Edition), 50(2), 327–333. DOI 10.3969/j.issn.1001-0505.2020.02.017. [Google Scholar] [CrossRef]

8. Natthanan, W., Chainarong, A., Weerachart, T., Raktipong, S., Sutat, L. (2021). Ancient materials and substitution materials used in Thai historical masonry structure preservation. Journal of Renewable Materials, 9(2), 179–204. DOI 10.32604/jrm.2021.013134. [Google Scholar] [CrossRef]

9. Ding, W. (2020). Experimental study on compressive properties of handmade blue brick masonry with traditional mortar. Architectural Science, 36(11), 71–77. DOI 10.13614/j.cnki.11-1962/tu.2020.11.011. [Google Scholar] [CrossRef]

10. Cheraghcheshm, F., Javanbakht, V. (2021). Surface modification of brick by zinc oxide and silver nanoparticles to improve performance properties. Journal of Building Engineering, 34(25), 101933. DOI 10.1016/j.jobe.2020.101933. [Google Scholar] [CrossRef]

11. WW/T 0049-2014 (2014). Material of maintenance and conservation of historic architecture-Grey brick. Beijing, China: National Cultural Heritage Administration. [Google Scholar]

12. GBT 2542-2012 (2012). Test methods for wall bricks. Beijing, China: China Building Material Federation. [Google Scholar]

13. SL/T 264-2020 (2020). Code for rock tests in water and hydropower projects. Beijing, China: Ministry of Water Resources of the People’s Republic of China. [Google Scholar]

14. Cao, F., Wu, Y. Q., Wang, J. L. (2019). Determination of capillary water absorption of blue bricks in the Ming Great Wall of Beijing and its influencing factors. Science Technology and Engineering, 19(22), 286–292. DOI 10.3969/j.issn.1671-1815.2019.22.042. [Google Scholar] [CrossRef]

15. Alejandro, C., María, S. C., María, A. R., Alfredo, L. A., María, P. S. (2020). Moisture influence on the thermal operation of the late 19th century brick facade, in a historic building in the city of Zamora. Energies, 137(13), 1–14. DOI 10.3390/en13061307. [Google Scholar] [CrossRef]

16. Veronica, V., Roberto, C., Mercedes, D. R. M. (2020). Experimental research to evaluate the percentage change of thermal and mechanical performances of bricks in historical buildings due to moisture. Construction and Building Materials, 244(8), 118107. DOI 10.1016/j.conbuildmat.2020.118107. [Google Scholar] [CrossRef]

17. GBT 5101-2017 (2017). Fired common bricks. Beijing, China: China Building Material Federation. [Google Scholar]

18. Yuan, J. L., Yang, Y., Peng, S. N. (2015). Experimental study on the material and environmental property of ancient adobe brick. Advanced Materials Research, 1120–1121, 1485–1490. DOI 10.4028/www.scientific.net/AMR.1120-1121.1485. [Google Scholar] [CrossRef]

19. Swathy, M., Manu, S., Naresh, C. (2019). Performance and microstructure of bricks with protective coatings subjected to salt weathering. Construction and Building Materials, 226(7), 94–105. DOI 10.1016/j.conbuildmat.2019.07.180. [Google Scholar] [CrossRef]

20. SY/T 5162-2014 (2012). Analysis methods of rock sample by scanning electron microscope. Beijing, China: Standardization Administration, National Energy Administration. [Google Scholar]

21. Bie, Z. M. (2020). The evolution law of structural damage of blue brick masonry under freeze-thaw cycle. Journal of Shandong Agricultural University (Natural Science Edition), 51(4), 668–672. DOI 10.3969/j.issn.1000-2324.2020.04.017. [Google Scholar] [CrossRef]

22. Shahreza, S. K., Niklewski, J., Molnár, M. (2021). Experimental investigation of water absorption and penetration in clay brick masonry under simulated uniform water spray exposure. Journal of Building Engineering, 43(33), 1–14. DOI 10.1016/J.JOBE.2021.102583. [Google Scholar] [CrossRef]

23. Peerasit, M., Natthanan, W., Chainarong, A., Weerachart, T. (2020). Engineering properties of ancient masonry materials in Thailand and substitution materials for historical structures preservation. IOP Conference Series: Earth and Environmental Science, 463(1), 012077. DOI 10.1088/1755-1315/463/1/012077. [Google Scholar] [CrossRef]

24. Li, B., Du, H. X., Liu, X. X., Wang, C. B. (2020). Physical properties and composition analysis of Shanxi Ming and Qing ancient bricks. Bulletin of the Chinese Ceramic Society, 39(9), 2944–2949+2963. DOI 10.16552/j.cnki/issn1001-1625.2020.09.033. [Google Scholar] [CrossRef]

25. Mishra, A. K., Mishra, A., Anshumali (2021). Geochemical characterization of bricks used in historical monuments of 14–18th century CE of Haryana region of the Indian subcontinent: Reference to raw materials and production technique. Construction and Building Materials, 269(2), 121802. DOI 10.1016/j.conbuildmat.2020.121802. [Google Scholar] [CrossRef]

26. Yue, J. W., Wang, W. Z., Zhu, Y. D. (2021). Experimental study on the modification of ancient building mortar with MICP technology. Journal of Henan University (Natural Science Edition), 51(3), 289–298. DOI 10.15591/j.cnki.411100.2021.03.004. [Google Scholar] [CrossRef]

27. Hans, J., Jacek, C., Jan, E. (2020). Gypsum efflorescence on clay brick masonry: Analysis of potential efflorescence origins. Journal of Building Physics, 44(1), 37–66. DOI 10.1177/1744259119896083. [Google Scholar] [CrossRef]

28. Konior, J., Rejment, M. (2021). Correlation between defects and technical wear of materials used in traditional construction. Materials, 14(10), 2482. DOI 10.3390/ma14102482. [Google Scholar] [CrossRef]

29. Dario, B., Marco, L., Alexandra, T., John, G. (2021). Hygrothermal characterization of a fictitious homogenized porous material to describe multiphase heat and moisture transport in massive historic walls. Construction and Building Materials, 266(3), 121497. DOI 10.1016/j.conbuildmat.2020.121497. [Google Scholar] [CrossRef]

30. Buchner, T., Kiefer, T., Gaggl, W., Zelaya, Z., Fussl, J. (2021). Automated morphometrical characterization of material phases of fired clay bricks based on scanning electron microscopy, energy dispersive X-ray spectroscopy and powder X-ray diffraction. Construction and Building Materials, 288(10–11), 122909. DOI 10.1016/j.conbuildmat.2021.122909. [Google Scholar] [CrossRef]

31. Aït, O. Y., Pierre, A., El, M. F., Lepiller, V. (2021). Hygrothermal properties of an early 20th century clay brick from eastern France: Experimental characterization and numerical modelling. Construction and Building Materials, 273(2), 121763. DOI 10.1016/j.conbuildmat.2020.121763. [Google Scholar] [CrossRef]

32. Shimoda, I., So, S., Chan, V. (2021). Damage assessment and guidelines for restoration methods of ancient brick structures at Sambor Prei Kuk. Cambodia International Journal of Architectural Heritage, 27, 1–16. DOI 10.1080/15583058.2021.1884319. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |