| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.018782

ARTICLE

Mechanical and Rheological Properties of Bamboo Pulp Fiber Reinforced High Density Polyethylene Composites: Influence of Nano CaCO3 Treatment and Manufacturing Process with Different Pressure Ratings

1International Centre for Bamboo and Rattan, Beijing, 100102, China

2Department of Mechanical and Energy Engineering, University of North Texas, Denton, 76203, USA

3Beijing Key Laboratory of Wood Science & Engineering, College of Material Science & Technology, Beijing Forestry University, Beijing, 100083, China

*Corresponding Author: Haitao Cheng. Email: htcheng@icbr.ac.cn

Received: 17 August 2021; Accepted: 24 September 2021

Abstract: In order to investigate the effect of the relative motion of nano CaCO3 reinforced bamboo pulp fiber (BPF)/HDPE composite components on the mechanical performance, a comparative study was performed. BPF was treated by nano CaCO3 blending (BM) and impregnation modification (IM) technology. The composites were produced using hot press (HPMP), extrusion (EMP) and injection molding process (IMP). The physical morphology of BPF was similar at different manufacturing processes. Compared to the samples manufactured by HPMP, a decrease in the (specific) flexural strength of BPF/HDPE composites and an increase in those of composites treated by nano CaCO3 manufactured by EMP and IMP were observed. The injection molded composites exhibited the best values in the (specific) impact strength, (specific) tensile properties. IM had a greater effect on the rheological behavior of the composites than BM, and nano CaCO3 treatment most effectively affected the performance of the extrusion molded composites.

Keywords: Nano CaCO3; bamboo pulp fiber; composites; manufacturing process; mechanical properties; rheological properties

As an abundant resource, the merits of natural fibers (e.g., bamboo fibers) exist inexpensive, biodegradability, non-hazardous, non-abrasive, light-weight, high specific strength and stiffness. These merits allow bamboo fibers to be used as one of excellent reinforcing materials for replacing conventional petroleum-based plastics, such as polypropylene (PP) and polyethylene (PE) to make useful structural or semi-structural composite materials, especially in lightweight applications [1–8]. Bamboo fiber composites possess good mechanical properties, good thermal properties, good acoustic insulation properties, good electrical resistance, high resistance to fracture, high fiber content for equivalent performance, and low environmental impacts, as well as the improved fuel efficiency, energy recovery and carbon credits at the end of life incineration of natural fibers [9–13]. Natural fiber composites have been widely applied in automotive, electronics, interior decoration and building industries [14–16].

Natural fiber composites are prepared by many different manufacturing processes, including hand lay-up, hot press molding (HPMP), extrusion molding (EMP), injection molding (IMP), vacuum assisted resin transfer molding (VARTM), filament winding and 3D printing, etc. [17–21]. The selection of the correct manufacturing process is often dependent on the materials being used and the target application of the product that is going to be produced. Each processing technique is that the manufacturing pressure varies among those processes, for instance, the HPMP only exerts several megapascal, where EMP requires dozens of megapascal and IMP needs several hundred megapascal. Bledzki et al. [22] adopted injection molding and compression molding to prepare wood fiber reinforced PP composites, and it was concluded that the injection molding showed better tensile, flexural, and impact resistance properties compared to the compression molding (containing same pressure). The charpy impact strength was increased to the maximum in the compression molding for hard-wood fiber-PP composites.

Currently, natural fibers are used to produce many types of products in various shapes that can be designed to fit a multitude of functions and applications. However, the interfacial compatibility between hydrophilic natural fibers and hydrophobic polymers used in these products is still a challenge, which puts restraints on the development and application of natural fiber composites. The improvement of the interfacial properties is key to develop natural fiber reinforced composites. Two treatments were reported to help improve the interfacial compatibility in natural fiber composites: (1) using a hydrophobic group to replace the hydroxy groups (-OH) on the natural fiber’s surface, which could improve the compatibility of the natural fiber with the hydrophobic polymer [23–25]; (2) by forming chemical bonds with the -OH on the surface of the natural fiber, the hydrophilic nature of the fibers was reduced [26–28], which was considered to be the more effective method. Although some modification methods possess good improvement effects, it is difficult for them to be popularized and applied in industry due to high cost and poor environmental benefit [29]. Nano CaCO3 can be used as a surface treatment method due to the low material cost, nano-scale, and ultra-fine solid structure. The nano CaCO3 impregnation modification technology is an effective method not only to improve the properties of single natural fiber, but also to develop the compatibility between natural fibers and polymer matrices. According to the previous research, the heterogeneous inorganic nanoparticle CaCO3 appeared on the surface of the impregnated fiber after the treatment. The root mean square of surface roughness increased by 5.8%, the hydrophilic nature of the retted fibers decreased by 59.4% and the Young’s modulus increased by 344% [30]. Nanoparticle CaCO3 was much more likely to fill voids of the fiber with an external pressure of 13.8 MPa and the impregnation efficiency for reducing the fiber porosity increased by 70.1% [31]. Moreover, studies have shown that nano CaCO3 did help to improve the properties of composites manufactured by these processing techniques. For example, Shi et al. [32] reported that the inorganic nanoparticle impregnation (INI) treatment improved the interfacial compatibility in kenaf fibers-polypropylene (PP) composites manufactured by the sheet molding compound process, which showed increases in the tensile modulus and tensile strength of the composites by 25.9% and 10.4%, respectively, when compared to the control samples. Xia et al. [33] concluded that the flexural modulus, flexural strength, tensile modulus, and tensile strength of kenaf fiber/polyester composites prepared by vacuum assisted resin infusion (VARI) process were improved by 33.1%, 64.3%, 22.3%, and 67.8%, respectively, when compared to that made from non-CaCO3-impregnated fibers. In our group’s previous work, nano CaCO3 treatment was used to improve the interfacial bonding and mechanical properties of composites manufactured by HPMP, EMP and VARI process.

Although there have been many studies focusing on the effect of natural fiber type, content, shape, size and the addition of additives on the properties of the composites produced from one of the previously described processing techniques, limited research has been completed for the comparison of different processing techniques and their effect on the properties of natural fiber reinforced composites. As of this point the interaction mechanism between CaCO3 nanoparticles and natural fibers, as well as the effect of inorganic nanoparticles impregnation on the rheological properties of the composites was explored in this study. The bamboo pulp fiber (BPF) was used as the reinforcement for high-density polyethylene (HDPE) to form a composite, which is also regarded as an economical and environment-friendly way to utilize the bamboo residues. Nano CaCO3 blending modification (BM) and impregnation modification (IM) technology were proposed as an effective method to improve the properties of the composite. In order to evaluate which nano CaCO3 treatment had a better effect on the mechanical properties of the composites, whether nano CaCO3 treatment could work for various process techniques (i.e., the HPMP, IMP and EMP), and how nano CaCO3 affected the interfacial properties of composites in the melting state, an experimental study on the mechanical properties, fracture morphology and rheological properties for the BPF reinforced HDPE composites was conducted.

The details and paramters of all materials used which included bamboo pulp fiber (BPF), high density polyethylene (HDPE), maleic anhydride grafted polyethylene (MAPE), PE-wax, ethylenediamine tetraacetic acid disodium salt (EDTA-2Na) and nano CaCO3 were illuminated in the previous study of our group [34].

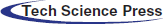

BPF were treated by two nano CaCO3 modification processes. The first modification was impregnation (IM) which followed the same procedure used by Wang et al. [34] to create IM-BPF, and the enhancement mechanism of IM on material can be seen in Fig. 1; the other process was nano CaCO3 blending modification (BM). In the BM process, in order to compare the effects of IM and BM on the property of composites, an equivalent content of nano CaCO3 was used to blend with BPF directly according to the loading of nano CaCO3 (L, wt%) in the process of IM (Eqs. (1) and (2)).

where, a (%) was the ash content which was tested according to the GB/T 742–2008 standard, m1 (g) was the initial mass of the BPF, m2 (g) was the mass after ashing, L (wt%) was calculated by looking at the difference of a between IM-BPF and BPF.

Figure 1: The enhancement mechanism of nano CaCO3 impregnation modification (IM)

2.3 Composites-Manufacturing Process

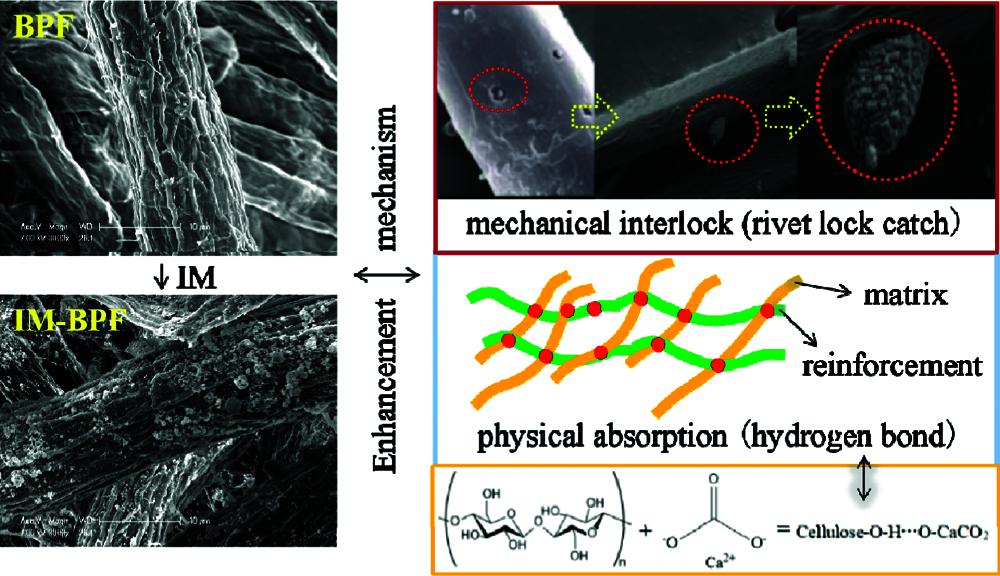

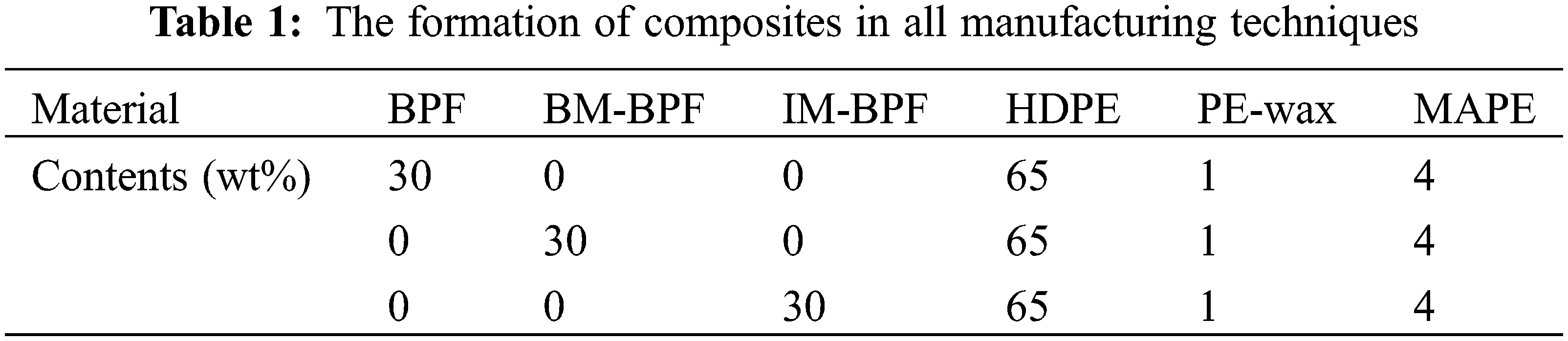

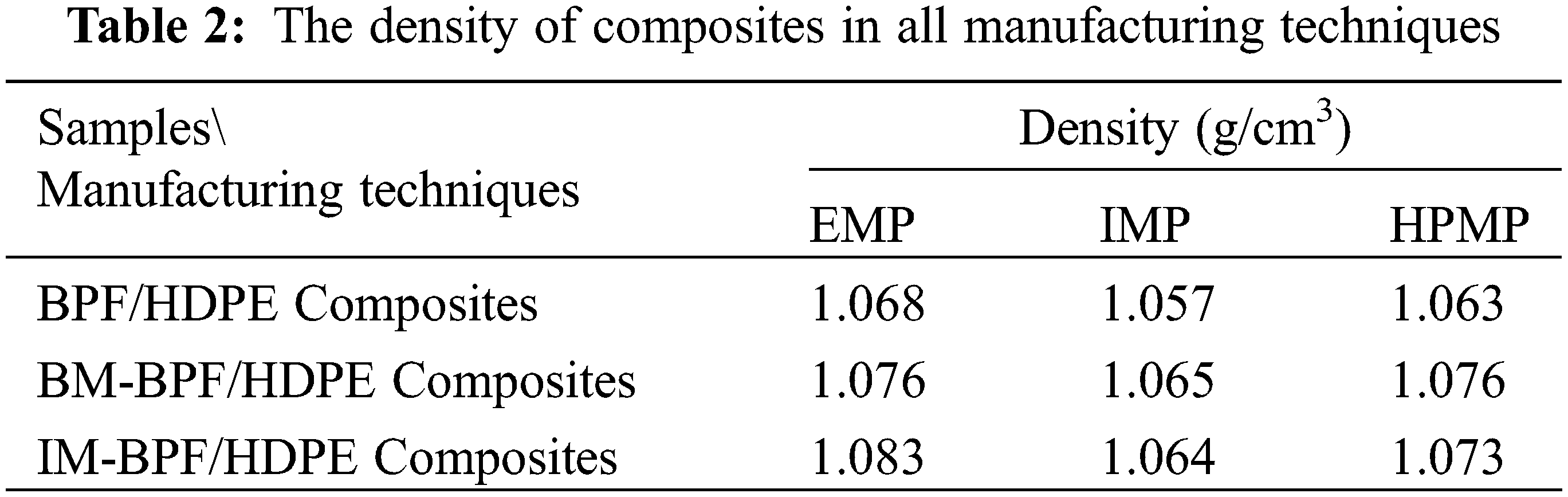

The composite samples used for this study were prepared using three separate manufacturing processes (Fig. 2). Prior to mixing, BPF, BM-BPF and IM-BPF were dried at 103°C in an air-circulating oven for 5 h (moisture content ≤2 wt%). After the fibers were dried, they were respectively mixed with PE-wax, HDPE, and MAPE in the device (SHR-25A) for 45 min at 40°C. The formation of composites was shown in Table 1. Upon being removed from the machine, the mixture then underwent melt mixing in a twin-screw extruder (SJZ45/90-YF110) where it was passed through the die of the extruder, forming the composites. Once the composite was extruded, it was granulated using a crushing machine (KCP150), and the composites pellets were obtained which were further used by hot press molding (HPMP), extrusion molding (EMP) and injection molding process (IMP).

Figure 2: Schematic diagram of manufacturing process of composites

2.3.1 Composites Manufactured Using HPMP

The composites pellets were subjected to hot-pressing at a temperature of 180°C under a pressure of 3.42 MPa, over a period of 30 min. The final dimension of the composite samples was 260 mm × 110 mm × 4 mm.

2.3.2 Composites Manufactured Using EMP

The composite pellets were melted then mixed in an extruder with a single-screw, after which they were cooled with water to produce the final composites with a cross section of 30 mm width by 4 mm thickness. The barrel temperatures used at different points of the extruder were 160°C, 170°C, 180°C and 175°C, and all of which were subjected to a die pressure of 20 ± 5 MPa.

2.3.3 Composites Manufactured Using IMP

Test samples with a thickness of 3 mm were molded using an injection process at a melting temperature of 185°C and injection pressure of 106.67 MPa.

2.4 Physical Morphology of BPF

Obtained from the granules, the BPF was prepared by a twin-screw extruder at different crushing times using the xylene extraction method as shown in the solid red box in Fig. 2. The residuum was washed by acetone and then filtered. Using deionized water, the residuum was washed and dried till the weight was a constant value. Once the weight of the samples stabilized, the length and width of BPF were then analyzed by fiber quality analyzer (FQA, LDA02), which was used to explore the influence of the extruder on physical morphology of BPF.

According to ASTM standard D792, the density of the composites was measured using a high precision density tester (MatsuHaKu) with a precision of 0.0001 g/cm3. Three replicate samples of each composite with masses ranging from 1–5 g were measured in accordance to the Archimedes principle (Table 2).

Flexural test was performed using a three-point bending test, which was in accordance with ASTM Standard D790-10. As indicated in the standard, a span of 16 to a depth of 1 (1.6 mm or greater in thickness) was used as the ratio. Flexural strength and modulus were determined using a loading speed of 17 mm/min.

Impact testing on the samples was performed following ASTM D6110 to evaluate the behavior of the materials subjected to sudden forces. Six replicate specimens with a dimension of 80 mm×12.7 mm (length by width) were tested at a speed of 2.9 m/s at room temperature (25°C) in order to obtain the breaking energy.

Tensile test was conducted using a universal mechanical testing machine (INSTRON 5848, USA) according to ASTM D638-10. Measurements were performed on standard type of dog-bone shaped samples at room temperature with a constant cross-head speed of 5 mm/min. A minimum of four specimens were tested for each composite.

2.6.4 Analysis of Variance (ANOVA)

ANOVA was carried out by IBM SPSS Statistics 19 package software in this research. And one-way ANOVA was a multiple comparison of Duncan (D) with a confidence interval of 0.05.

A Haake Polylab torque rheometer with a Rheomix 600 QC counter-rotating roller rotors mixing chamber was used to evaluate the melt viscosity of the composites. The velocity relation between rotors was 3/2, and the temperature was regulated by electric heating and air cooling. All tests were performed at 170°C and 40 rpm (4.196 rad/s), and the mixing chamber was loaded at 70% volume capacity. The addition of granules was calculated according to Eq. (3). The torque rheometer monitors torque varied as a function of time and temperature. The maximum and stabilized torques and mechanical energy of the composites were determined. Moreover, the processing behavior of composites can be reflected by fluctuation amplitude λ (Eq. (4)).

where, m (g) was the addition of granules, ρ (g) was the density of the material, vn (cm3) was the net cavity volume of rotor.

where, Tmax and Tmin were the maximum and minimum torque, λ was the fluctuation amplitude, which is related to the uniformity and rheological state of material.

A field emission environmental scanning electron microscope (ESEM; XL30 ESEM-FEG; FEI Co., USA) was used to analyze the surface of the IM-BPF and the fractured morphologies of the composites. The samples electrical conductivity was improved by coating them with platinum for a 90 s period. After being coated, the samples were then mounted into a vacuum chamber at a pressure of less than 5 × 10−5 Pa. The micrographs were collected at an accelerating voltage of 7 kV.

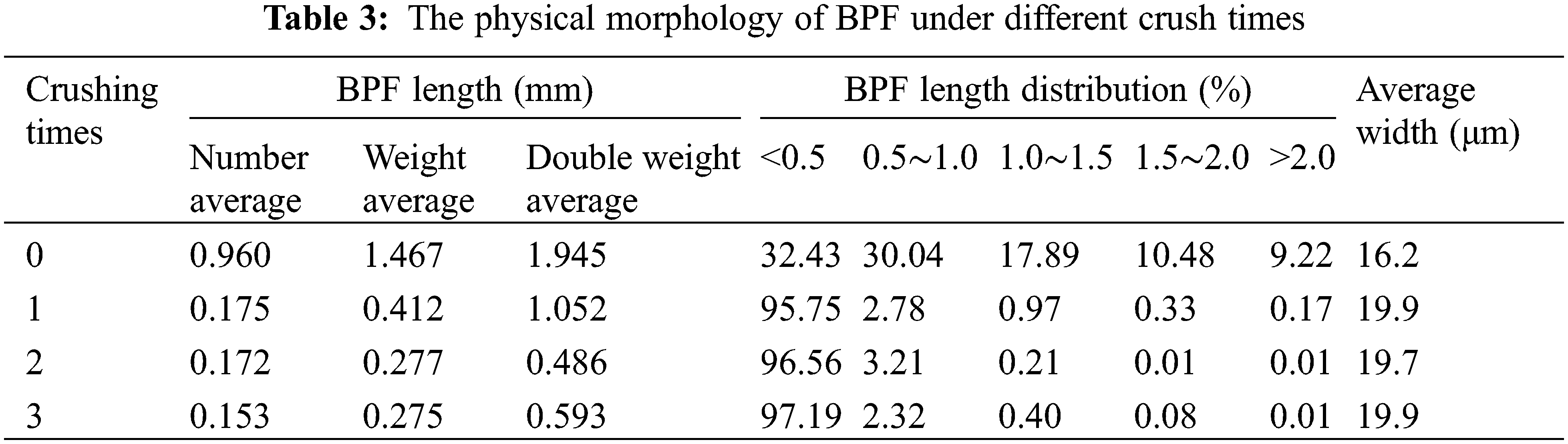

3.1 Physical Morphology of BPF under Different Crushing Times

Table 3 shows the physical morphological parameters of BPF at the different cycle numbers of pelleting-crushing. It was observed that the BPF length decreased with the increase of crushing times due to the shear action of the extruder. The BPF length was changed from 1.467 to 0.275 mm while the BPF width was swelled from 16.2 to 19.9 μm. Table 3 shows that the BPF length decreased by 71.91% and the BPF width increased by 22.84% when the crushing times increased from 0 to 1, indicating that the design structure of the screw had a dominant effect on the physical morphology of BPF. As the crushing time increased, the length of the BPF gradually decreased and the proportion of the BPF short fiber increased. However, the effect of the crushing time on the width of the BPF exhibited no large change. It was indicated that the crushing time had slight influence on the physical morphology of BPF during the extrusion and pelletizing process, revealing that the morphology of the BPF was not the cause of the property differences of the composites produced from the EMP, IMP and HPMP.

3.2 Surface Morphology of BPF Treated by IM

As shown in Fig. 1, there were pits and voids on the surface of BPF which can provide sites for CaCO3 to attach [35]. It also can be observed that CaCO3 was adhered to the surface of IM-BPF successfully, which reduced the force among IM-BPFs and made IM-BPFs arrange loosely. Based on Eqs. (1) and (3), the loading of CaCO3 was about 15 wt% which was the content of nano CaCO3 used in BM process.

3.3 Mechanical Properties of Composites in All Processes

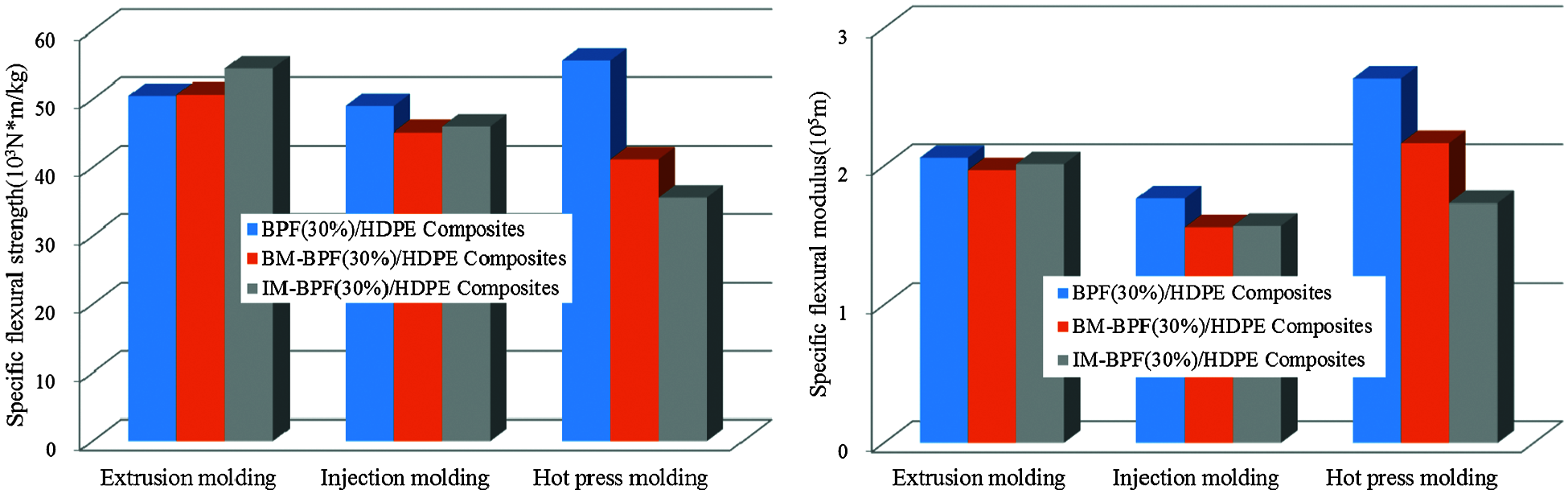

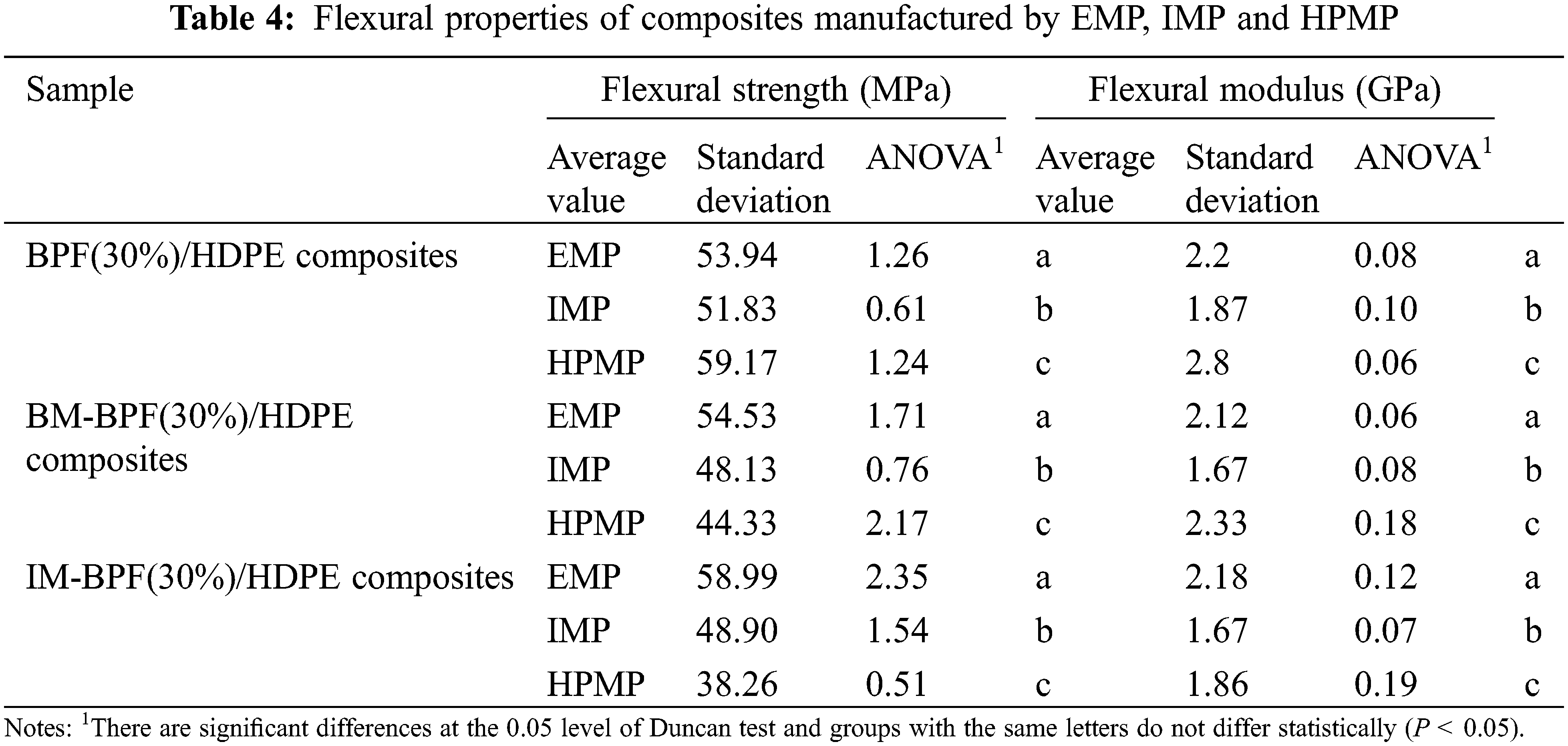

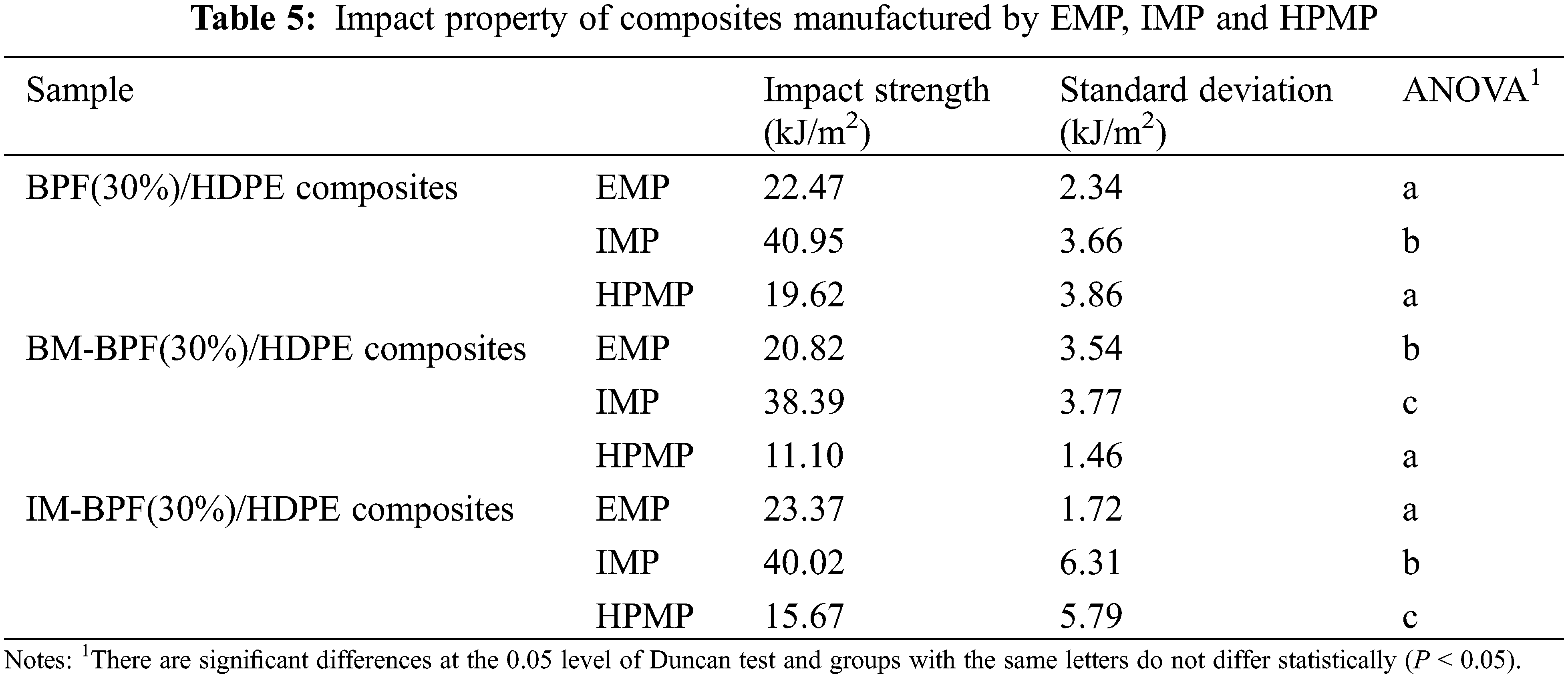

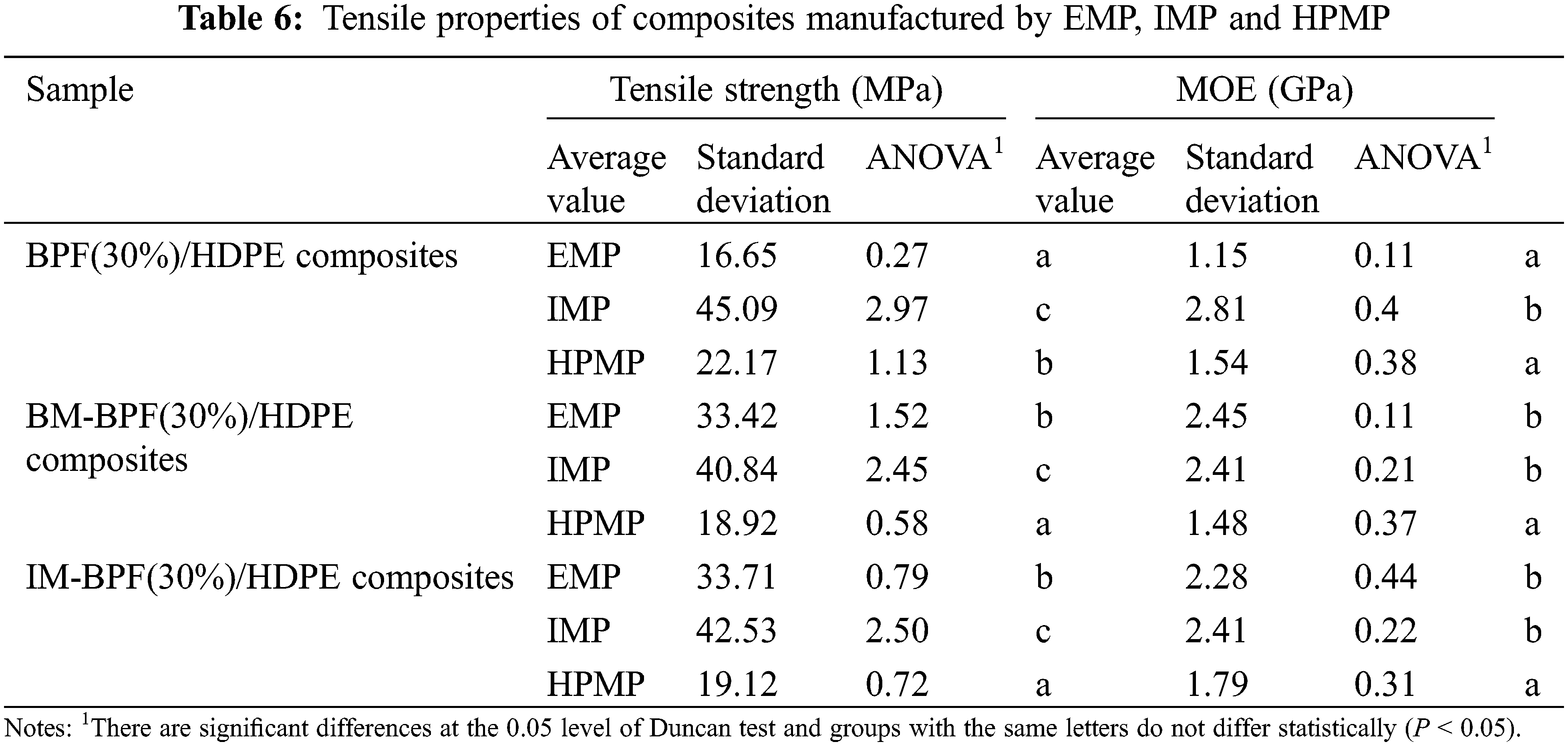

The mechanical properties (Tables 4–6 and Figs. 3–5) of BM-BPF and IM-BPF reinforced HDPE composites in all manufacturing processes were characterized and compared to the BPF(30%)/HDPE composites that were prepared as the control group in this study.

Figure 3: Specific flexural strength and specific flexural modulus of composites in all processes

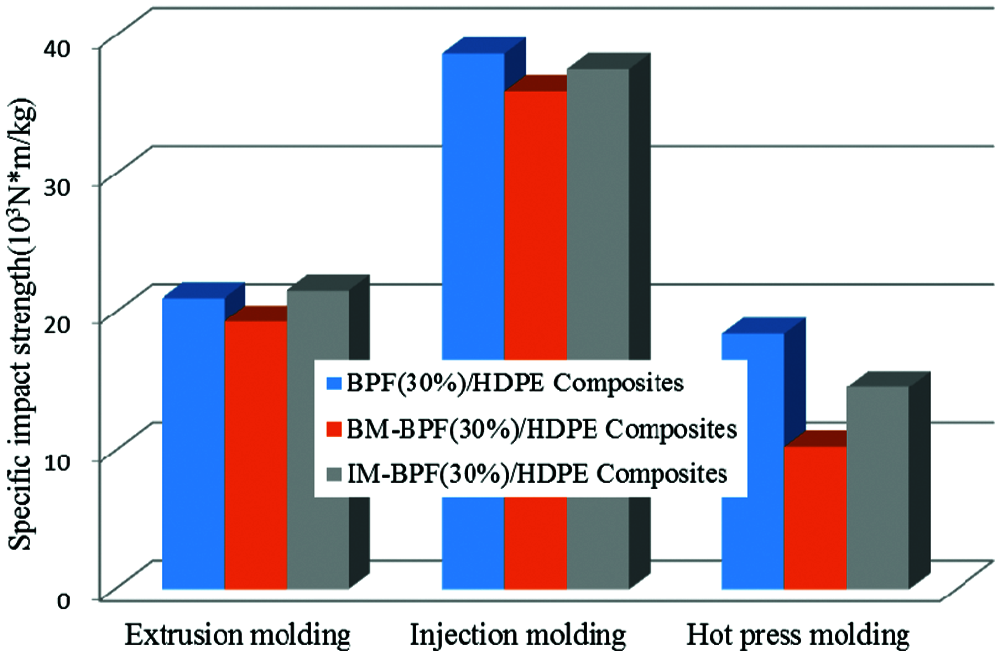

Figure 4: Specific impact strength of composites in all processes

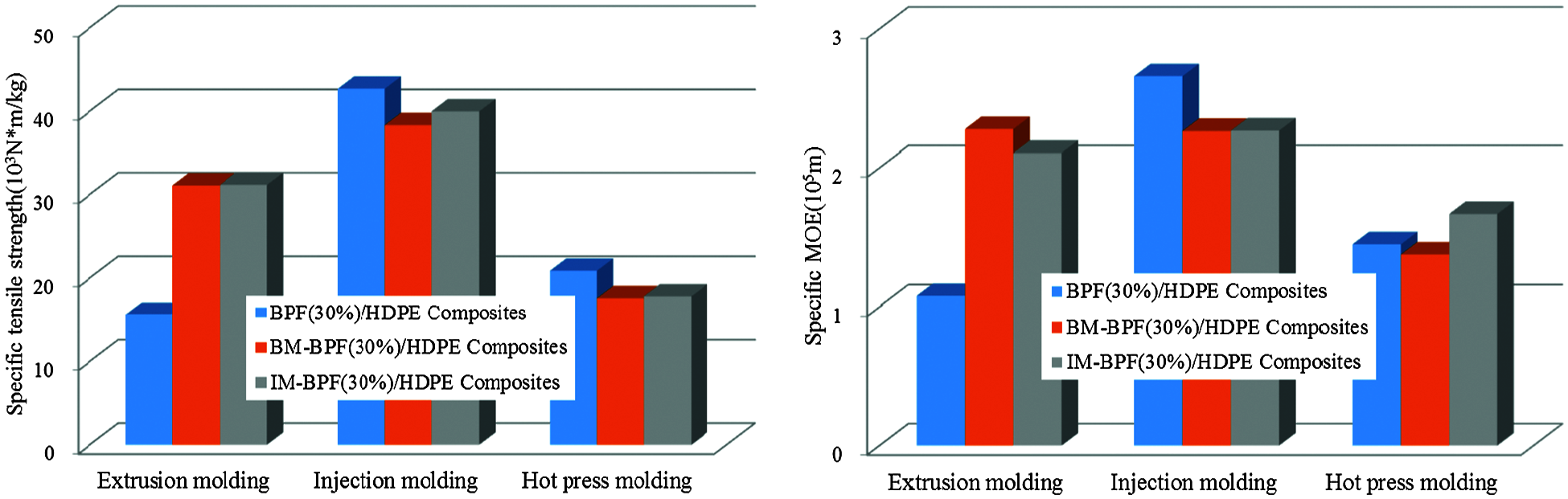

Figure 5: Specific tensile strength (left) and specific MOE (right) of composites in all processes

3.3.1 Flexural Properties and Specific Flexural Properties

Compared to the HPMP, the flexural strength (specific flexural strength) of the BPF/HDPE composites prepared by the EMP and IMP decreased by 8.84% (9.25%) and 12.40% (11.93%), respectively; the flexural strength (specific flexural strength) of BM-BPF/HDPE composites increased by 23.01% (22.96%) for the EMP and 8.57% (9.66%) for the IMP; The IM-BPF/HDPE composites’ flexural strength (specific flexural strength) increased by 54.18% (52.80%) for the EMP and 27.81% (28.88%) for the IMP (Table 4, Fig. 3). According to the ANOVA results, a significant difference among the flexural properties of the composite samples was observed. Generally, the composites showed an increasing trend in the mechanical properties with an increase in manufacturing pressure, however, the trends neither for the flexural strength nor specific flexural strength was in agreement with the manufacturing pressure. This is because the effect of reinforced fibers was most efficient along the axis that fibers were orientated within the fiber reinforced polymer composites and the preparation technology can determine the final distribution of the oriented fibers in the samples. Moreover, it has been reported that [36] using EMP to manufacture a fiberous anisotropic composite differed from that produced using HPMP and IMP. The BPF/HDPE samples that underwent BM and IM were produced using IMP and HPMP saw no increase in their flexural properties of strength and specific strencth when compared to untreated composites. Whereas it was observed that the flexural strength and specific flexural strength of the samples prepared by the EMP increased with the nano CaCO3 treatment. The highest flexural strength was observed in the IM-BPF/HDPE composite manufactured by EMP which was 8.18% higher than that of BM-BPF/HDPE composite, probably because of the better interfacial compatibility caused by stronger connections in the molecular chains. These stronger connections led to less slipping of the HDPE matrix and hence a higher flexural strength. Xia et al. [31] reported that the inorganic nanoparticle impregnation (INI) treatments could improve the compatibility between kenaf fibers and polypropylene matrix, resulting in increased mechanical properties of the composites reinforced with INI-treated fibers. This could be described by two reasons, the first was that nano CaCO3 treatment decreased voids caused by the BPF, which in turn reduced defects in the composite structure. This reduction of defects caused the increase in rigidity of the HDPE matrix and increase in storage modulus of the composites [37]. Secondly, nano CaCO3 was dispersed throughout the cellular structure of the BPF and the H-bond interaction may be formed between CaCO3 and surface hydroxy of BPF (Fig. 1). This bonding increased the interactions in the surface area. The increased interactions among HDPE, BPF and CaCO3 restricted the movement of the polymer chains, thus the flexural strength was improved. There was a significant difference between the flexural properties of the BM-BPF/HDPE and IM-BPF/HDPE composites prepared by the EMP, but slight difference was observed between the flexural modulus of the BM-BPF/HDPE and IM-BPF/HDPE composites. From the results, it can be inferred that nano CaCO3 treatment worked more effectively for composites produced using the EMP than those using the IMP and HPMP. It also can be inferred that IM had a greater effect on the properties of composites than BM.

3.3.2 Impact Strength and Specific Impact Strength

It was observed that the impact strength (Table 5) of the composites produced using the IMP was greater than the composites produced using the EMP and HPMP. This result was in alignment with previous study conducted by Bledzki et al. [22], in which it was concluded that the impact resistance in the IMP shows better performance, where in the HPMP, a large amount of initiation damage was observed. The specific impact strength (Fig. 4) of the composites had a trend similar to the impact resistance and these results were consistent with the preparation pressure. Compared with the injection molded composites, the impact strengths (specific impact strengths) of the extrusion molded BPF/HDPE, BM-BPF/HDPE and IM-BPF/HDPE composites were reduced by 45.13% (45.68%), 45.77% (46.34%), and 41.60% (42.60%), respectively. Compared to the injection molded composites, the impact strengths (specific impact strengths) of the hot press molded BPF/HDPE, BM-BPF/HDPE and IM-BPF/HDPE were reduced by 52.09% (52.34%), 71.09% (71.37%) and 60.84% (61.18%), respectively. It was observed that the impact strength of the composites was greater when produced using the EMP than that using the HPMP. According to the ANOVA results, a significant difference among the impact strength of the BM-BPF/HDPE (IM-BPF/HDPE) composite samples manufactured by EMP, IMP and HPMP was observed. Theoretically, according to “mixture rules” for the composite structures, the fiber characteristics become dominant and responsible for the huge drop on the impact strength of the composite [38,39]. However, it was illustrated in this study that there were no significant differences in the BPF/HDPE, BM-BPF/HDPE and IM-BPF/HDPE composites prepared by the IMP and EMP. It was observed that the BPF/HDPE composites presented the highest impact strength and specific impact strength among all composites produced by the HPMP, which were respectively 76.76% and 78.88% greater than the BM-BPF/HDPE composites and respectively 25.21% and 26.44% greater than the IM-BPF/HDPE composites (Table 5 and Fig. 4). The addition of nano CaCO3 made a significant difference in the impact strength between BPF/HDPE and BM-BPF/HDPE composites prepared by the HPMP. This can be attributed to the fact that the CaCO3 could well contact BPF directly when CaCO3 with a mass fraction of 15 wt% was incorporated into the composites. As a result, the stress cracks propagated much easier through the composites when impacted by an external force. Moreover, the hot press molded IM-BPF/HDPE composite had a higher impact strength than that of BM-BPF/HDPE composite, which might also be related to a better dispersion of the IM-BPF in the HDPE matrix.

3.3.3 Tensile Properties and Specific Tensile Properties

It is well known that the fiber reinforcing effect is most efficient along the fiber axis orientation. However, the processing technique will dictate the final fiber orientation distribution in the composite, which is one of the most important characteristics in determining the composites mechanical properties. Compared to the EMP and HPMP, the IMP could produce composites with greater tensile strength, modulus of elasticity (MOE), specific tensile strength, and specific MOE for each composite formulation used in this study (Table 6 and Fig. 5). These improved properties of the injection molded composites indicated that the effectiveness of this form of fiber reinforcement was also supported by the results of the impact strength and specific impact strength reported in this study. It was observed that the significant improvement in the tensile properties occurred in the samples that were produced with the modified BPF that underwent extrusion molding, but this improvement was not observed in other molding processes. The tensile strength and MOE of the extrusion molded BM-BPF/HDPE and IM-BPF/HDPE composites increased about 2-fold compared to the extrusion molded BPF/HDPE composites, thus enhanced the mechanical interlocking caused by the modification. The increases in tensile properties of extrusion molded composites were due to the effectiveness of the CaCO3 blending and impregnation modification of the fibers. It was indicated that nano CaCO3 treatment was more effective in the EMP than in the IMP and HPMP, which was also reported in a previous study [35], but it was not clear which nano CaCO3 treatment could yield greater properties.

ESEM was used to analyze the fiber surface, fiber pullout and fiber-matrix interface of the composites (Fig. 6). During the ESEM examination, it was observed that the fibers of each type of composite were still surrounded by HDPE at the fracture cross section of the samples. The HDPE could hold fibers after the sample was broken, indicating that a closer contact between the fiber and the matrix as well as a better wetting of the fibers was achieved. The contact between the matrix and fibers was improved, suggesting that the fibers were fully penetrated by the matrix, which explained the presence of matrix material on the fibers surface. Less fiber pullout was observed in the composites produced by the EMP and IMP, suggesting that there was less effective energy dissipation [40]. When the failure occurred at the fiber-matrix interface, extensive fiber pullouts from the matrix were observed. Then it can be supposed that the increase of the mechanical properties of the composite was the effect of the increase in the bonding at the fiber-matrix interface. Thus, by treating the BPF with nano CaCO3 using the BM and IM, the interfacial bonding between the fiber and matrix could be improved. When the fibers are vertical to the fracture surface, they play a vital role in arresting crack propagation in the HDPE matrix. The BPF can serve as nucleation sites for the deposition of CaCO3 to initiate crystalline formation [41], which can be attributed to a better interaction among CaCO3, BPF, and HDPE matrix. This type of interaction was caused by the friction and mechanical interlocking. As a result, when the composites were subjected external forces, the BM-BPF and IM-BPF were difficult to be pulled out from the HDPE matrix. This better interfacial interaction increased mechanical properties of composite, which was confirmed by the results of the mechanical properties test.

Figure 6: ESEM micrographs (×500) of BPF/HDPE, BM-BPF/HDPE IM-BPF/HDPE composites fracture surfaces subjected to manufacturing process, for (a) EMP; (b) IMP; (c) HPMP

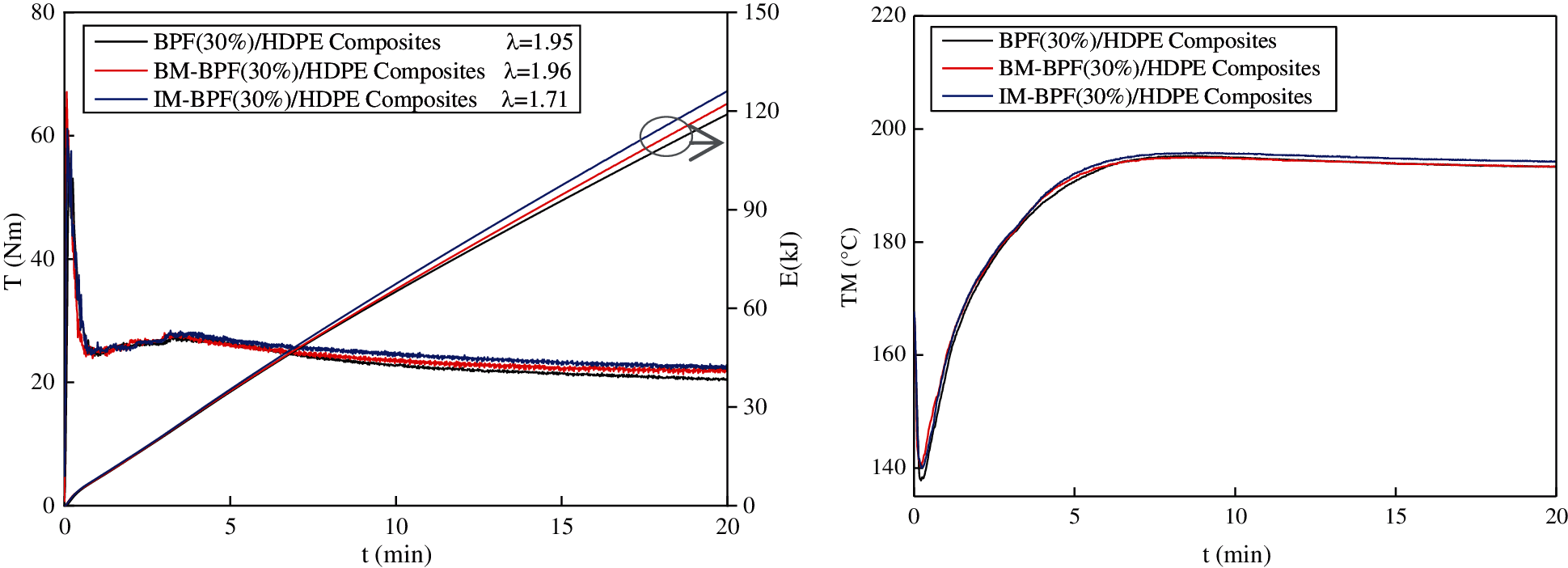

3.5 Rheological Properties of Composites

Rheology studies the flow of matter by measuring the change in the torque (T) & energy (E) at a constant rotational speed. Using this method, the quantitative and essential information of flow behavior of polymer blends, structural changes during processing, and the influence of various additives on new formulations can be examined, which is used for quality control and product development [42]. The polymer temperature can also be recorded using a torque rheometer, which varies over time due to the dissipation of the viscous energy being determined by inserting a thermocouple into the sample chamber. Polymer melts generally exhibit non-Newtonian viscosity, the torque exerted on each roller results from a distribution of viscosities [43].

Fig. 7 illustrates the rheological properties (torque (T), melt temperature (TM) and energy (E)) of BPF/HDPE, BM-BPF/HDPE and IM-BPF/HDPE composites. It can be seen from Fig. 7 that all the composites had the feeding peek and the T was highest (Tmax) due to the lower temperature of material at the initial time. The volume of material decreased because of compression when the material became softened by heat, causing the T reduce. As the time increased, the T and TM tended to balance torque (Tbal) and TMbal, respectively, which is because the material was gradually plasticized evenly. In addition, according to the fluctuation amplitude λ, it can be seen that IM made the material more homogeneous during processing. Using the information, the effect of nano CaCO3 on the rheological properties of composites was explored. It was observed that the Tmax, Tbal and TM values of BPF/HDPE, BM-BPF/HDPE and IM-BPF/HDPE composites did not show significant changes, whereas Emax increased from 119.05 kJ (BPF/HDPE composites) to 122.2 kJ (BM-BPF/HDPE composites) and 126.1 kJ (IM-BPF/HDPE composites). Results showed that nano CaCO3 caused a positive increment in torque properties, which was due to the improved interfacial adhesion and lower void content caused by the addition of nano CaCO3. It could be inferred from these results that nano CaCO3 treatment was an efficient method for improving interfacial properties of the composites. It was observed that the modification method of IM was superior to the method of BM.

Figure 7: Rheological properties of composites

The influence of the different preparation technologies (HPMP, EMP and IMP) on the mechanical properties, morphological observation, and rheological properties of the BPF, BM-BPF and IM-BPF reinforced HDPE composites was investigated. These tests helped to experimentally determine the effects of nano CaCO3 treatment methods (BM and IM) on different preparation technologies used to produce BPF/HDPE, BM-BPF/HDPE and IM-BPF/HDPE composites. The crushing times had a slight influence on the physical morphology of BPF that underwent extrusion and pelletizing process. As the crushing time used to granulate the composite material increased, the proportion of short BPF increased, and the BPF length decreased, whereas the BPF width had no major changes. All injection molded composites presented greater mechanical performance than the composites produced using EMP and HPMP due to the differences of the manufacturing pressure. Compared with the HPMP, the flexural strength (specific flexural strength) of the BPF/HDPE composites decreased by 8.84% (9.25%) and 12.40% (11.93%); BM-BPF/HDPE composites increased by 23.01% (22.96%) and 8.57% (9.66%); IM-BPF/HDPE composites increased by 54.18% (52.80%) and 27.81% (28.88%), in the EMP and IMP, respectively. Nano CaCO3 influenced the T and TM of the composites when compared to the control samples, particularly on E. It was observed that IM had a greater effect on the rheological properties of the composites than BM, and nano CaCO3 treatment most effectively affected the properties of the extrusion molded composites.

Funding Statement: This study is financially supported by the Basic Research Operating Expenses Program of International Centre for Bamboo and Rattan (1632021002).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Jawaid, M., Khalil, H. P. S. A. (2011). Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydrate Polymers, 86(1), 1–18. DOI 10.1016/j.carbpol.2011.04.043. [Google Scholar] [CrossRef]

2. Huda, M. S., Drzal, L. T., Mohanty, A. K., Misra, M. (2006). Chopped glass and recycled newspaper as reinforcement fibers in injection moulded poly (lactic acid) (PLA) composites: A comparative study. Composites Science and Technology, 66, 1813–1824. DOI 10.1016/j.compscitech.2005.10.015. [Google Scholar] [CrossRef]

3. Qiu, Z., Fan, H. (2020). Nonlinear modeling of bamboo fiber reinforced composite materials. Composite Structures, 238, 111976. DOI 10.1016/j.compstruct.2020.111976. [Google Scholar] [CrossRef]

4. Sathishkumar, T. P., Navaneethakrishnan, P., Shankar, S., Rajasekar, R. (2014). Mechanical properties and water absorption of short snake grass fiber reinforced isophthallic polyester composites. Fibers and Polymers, 15(9), 1927–1934. DOI 10.1002/app.38553. [Google Scholar] [CrossRef]

5. Sanjay, M. R., Yogesha, B. (2017). Studies on natural/glass fiber reinforced polymer hybrid composites: An evolution. Materials Today-Proceedings, 4(2), 2739–2747. DOI 10.1016/j.matpr.2017.02.151. [Google Scholar] [CrossRef]

6. Yusriah, L., Sapuan, S. M., Zainudin, E. S., Mariatti, M. (2014). Characterization of physical, mechanical, thermal and morphological properties of agro-waste betel nut (Areca catechu) husk fiber. Journal of Cleaner Production, 72, 174–180. DOI 10.1016/j.jclepro.2014.02.025. [Google Scholar] [CrossRef]

7. Soleimani, M., Tabil, L., Panigrahi, S., Opoku, A. (2008). The effect of fiber pretreatment and compatibilizer on mechanical and physical properties of flax fiber-polypropylene composites. Journal of Polymers and the Environment, 16, 74–82. DOI 10.1007/s10924-008-0102-y. [Google Scholar] [CrossRef]

8. Wielage, B., Lampke, T., Utschick, H., Soergel, F. (2003). Processing of natural-fibre reinforced polymers and the resulting dynamic-mechanical properties. Journal of Materials Processing Technology, 139(1–3), 140–146. DOI 10.1016/S0924-0136(03)00195-X. [Google Scholar] [CrossRef]

9. Vijaya Ramnath, B., Manickavasagam, V. M., Elanchezhian, C., Vinodh Krishna, C., Karthik, S. (2014). Determination of mechanical properties of intra-layer abaca-jute-glass fiber reinforced composite. Materials & Design, 60, 643–652. DOI 10.1016/j.matdes.2014.03.061. [Google Scholar] [CrossRef]

10. Sanjay, M. R., Arpitha, G. R., Yogesha, B. (2015). Study on mechanical properties of natural-glass fiber reinforced polymer hybrid composites: A review. Materials Today-Proceedings, 2(4–5), 2959–2967. DOI 10.1016/j.matpr.2015.07.264. [Google Scholar] [CrossRef]

11. Sanjay, M. R., Arpitha, G. R., Laxmana Naik, L., Gopalakrishna, K., Yogesha, B. (2016). Applications of natural fibers and its composites: An overview. Natural Resources, 7(3), 108–114. DOI 10.4236/nr.2016.73011. [Google Scholar] [CrossRef]

12. Deng, Y. L., Paraskevas, D., Tian, Y., Acker, K. V., Dewulf, W. et al. (2016). Life cycle assessment of flax-fibre reinforced epoxidized linseed oil composite with a flame retardant for electronic applications. Journal of Cleaner Production, 133(1), 427–438. DOI 10.1016/j.jclepro.2016.05.172. [Google Scholar] [CrossRef]

13. Joshi, S. V., Drzal, L. T., Mohanty, A. K., Arora, S. (2004). Are natural fiber composites environmentally superior to glass fiber reinforced composites? Composites Part A: Applied Science and Manufacturing, 35(3), 371–376. DOI 10.1016/j.compositesa.2003.09.016. [Google Scholar] [CrossRef]

14. Prabhakar, M. M., Gnanaraj, S. J. P., Allasi, H. L., Leno, I. J., Endro, S. et al. (2021). Mechanical property analysis on bamboo-glass fiber reinforced montmorillonite nano composite. Materials Today-Proceedings, 45, 6936–6940. DOI 10.1016/j.matpr.2021.01.392. [Google Scholar] [CrossRef]

15. Davoodi, M. M., Sapuan, S. M., Ahma, D., Aidy, A., Khalina, A. et al. (2012). Effect of polybutylene terephthalate (PBT) on impact property improvement of hybrid kenaf/glass epoxy composite. Materials Letters, 67(1), 5–7. DOI 10.1016/j.matlet.2011.08.101. [Google Scholar] [CrossRef]

16. Gupta, M. K., Srivastava, R. K. (2016). Mechanical properties of hybrid fibers-reinforced polymer composite: A review. Polymer Plastics Technology and Engineering, 55(6), 626–642. DOI 10.1080/03602559.2015.1098694. [Google Scholar] [CrossRef]

17. Wu, Y. J., Xia, C. L., Cai, L. P., Shi, S. Q., Cheng, J. T. (2018). Water-resistant hemp fiber-reinforced composites: In-situ surface protection by polyethylene film. Industrial Crops and Products, 112, 210–216. DOI 10.1016/j.indcrop.2017.12.014. [Google Scholar] [CrossRef]

18. Khondker, O. A., Ishiaku, U. S., Nakai, A., Hamada, H. (2006). A novel processing technique for thermo-plastic manufacturing of unidirectional composites reinforced with jute yarns. Composites Part A-Applied Science and Manufacturing, 37(12), 2274–2284. DOI 10.1016/j.compositesa.2005.12.030. [Google Scholar] [CrossRef]

19. Sojoudiasli, H., Heuzey, M. C., Carreau, P. J. (2014). Rheological, morphological and mechanical properties of flax fiber polypropylene composites: Influence of compatibilizers. Cellulose, 21(5), 3797–3812. DOI 10.1007/s10570-014-0375-3. [Google Scholar] [CrossRef]

20. Guo, G., Chen, J. C., Gong, G. (2017). Injection molding of polypropylene hybrid composites reinforced with carbon fiber and wood fiber. Polymer Composites, 39(9), 3329–3335. DOI 10.1002/pc.24350. [Google Scholar] [CrossRef]

21. Yan, L. B., Chouw, N., Yuan, X. W. (2012). Improving the mechanical properties of natural fiber fabric reinforced epoxy composites by alkali treatment. Journal of Reinforced Plastics and Composites, 31(6), 425–437. DOI 10.1177/0731684412439494. [Google Scholar] [CrossRef]

22. Bledzki, A. K., Faruk, O. (2004). Wood fiber reinforced polypropylene composites: Compression and injection molding process. Journal of Macromolecular Science Part D: Reviews in Polymer Process, 43(3), 871–888. DOI 10.1081/PPT-120038068. [Google Scholar] [CrossRef]

23. Kushwaha, P. K., Kumar, R. (2009). Studies on water absorption of bamboo-polyester composites: Effect of silane treatment of mercerized bamboo. Polymer Plastics Technology and Engineering, 49(1), 45–52. DOI 10.1080/03602550903283026. [Google Scholar] [CrossRef]

24. Kushwaha, P. K., Kumar, R. (2010). Studies on performance of acrylonitrile pretreated bamboo reinforced thermosetting resin composites. Journal of Reinforced Plastics and Composites, 29(9), 1347–1352. DOI 10.1177/0731684409103701. [Google Scholar] [CrossRef]

25. Kushwaha, P. K., Kumar, R. (2011). Influence of chemical treatments on the mechanical and water absorption properties of bamboo fiber composites. Journal of Reinforced Plastics and Composites, 30(1), 73–85. DOI 10.1177/0731684410383064. [Google Scholar] [CrossRef]

26. Kim, H., Okubo, K., Fujii, T., Takemura, K. (2013). Influence of fiber extraction and surface modification on mechanical properties of green composites with bamboo fiber. Journal of Adhesion Science and Technology, 27(12), 1348–1358. DOI 10.1080/01694243.2012.697363. [Google Scholar] [CrossRef]

27. Tran, D. T., Nguyen, D. M., HaThuc, C. N., Dang, T. T. (2013). Effect of coupling agents on the properties of bamboo fiber-reinforced unsaturated polyester resin composites. Composite Interfaces, 20(5), 343–353. DOI 10.1080/15685543.2013.806100. [Google Scholar] [CrossRef]

28. Qiu, R., Liu, W., Li, K. (2015). Investigation of bamboo pulp fiber-reinforced unsaturated polyester composites. Holzforschung, 69(8), 967–974. DOI 10.1515/hf-2014-0207. [Google Scholar] [CrossRef]

29. Yasim-Anuar, T. A. T., Ariffin, H., Norrrahim, M. N. F., Hassan, M. A., Tsukegi, T. et al. (2019). Sustainable one-pot process for the production of cellulose nanofiber and polyethylene/cellulose nanofiber composites. Journal of Cleaner Production, 207, 590–599. DOI 10.1016/j.jclepro.2018.09.266. [Google Scholar] [CrossRef]

30. Liang, K., Shi, S. Q., Wang, G. (2014). Effect of impregnated inorganic nanoparticles on the properties of the kenaf bast. Fibers, 2(3), 242–254. DOI 10.3390/fib2030242. [Google Scholar] [CrossRef]

31. Xia, C. L., Shi, S. Q., Cai, L. P., Nasrazadani, S. (2015). Increasing inorganic nanoparticle impregnation efficiency by external pressure for natural fibers. Industrial Crops and Products, 69, 395–399. DOI 10.1016/j.indcrop.2015.02.054. [Google Scholar] [CrossRef]

32. Shi, J., Shi, S. Q., Barnes, H. M., Horstemeyer, M. F., Wang, G. (2011). Kenaf bast fibers-part ii: Inorganic nanoparticle impregnation for polymer composites. International Journal of Polymer Science, 1, 2341–2348. DOI 10.1155/2011736474. [Google Scholar] [CrossRef]

33. Xia, C. L., Shi, S. Q., Cai, L. P. (2015). Vacuum-assisted resin infusion (VARI) and hot pressing for CaCO3 nanoparticle treated kenaf fiber reinforced composites. Composites Part B: Engineering, 78, 138–143. DOI 10.1016/j.compositesb.2015.03.039. [Google Scholar] [CrossRef]

34. Wang, C. C., Smith, L. M., Wang, G., Shi, S. Q., Cheng, H. T. et al. (2019). Characterization of interfacial interactions in bamboo pulp fiber/highdensity polyethylene composites treated by nano CaCO3 impregnation modification using fractal theory and dynamic mechanical analysis. Industrial Crops and Products, 141, 111712. DOI 10.1016/j.indcrop.2019.111712. [Google Scholar] [CrossRef]

35. Wang, C. C., Cai, L. P., Shi, S. Q., Wang, G., Cheng, H. T. et al. (2019). Thermal and flammable properties of bamboo pulp fiber/high-density polyethylene composites: Influence of preparation technology, nano calcium carbonate and fiber content. Renewable Energy, 134, 436–445. DOI 10.1016/j.renene.2018.09.051. [Google Scholar] [CrossRef]

36. Herrera-Franco, P. J., Valadez-González, A. (2005). A study of the mechanical properties of short natural-fiber reinforced composites. Composites Part B: Engineering, 36(8), 597–608. DOI 10.1016/j.compositesb.2005.04.001. [Google Scholar] [CrossRef]

37. Guo, M. L. (2002). Dynamic mechanical thermal analysis of polymer and composite, pp. 21–75. Beijing, China: Chemical Industry Press. [Google Scholar]

38. Bodur, M. S., Bakkal, M., Englund, K. (2016). Experimental study on the glass fiber/waste cotton fabric-reinforced hybrid composites: Mechanical and rheological investigations. Journal of Composite Materials, 51(23), 1–12. DOI 10.1177/0021998316685897. [Google Scholar] [CrossRef]

39. Afrifah, K. A., Hickok, R. A., Matuana, L. M. (2010). Polybutene as a matrix for wood plastic composites. Composites Science and Technology, 70(1), 167–172. DOI 10.1016/j.compscitech.2009.09.019. [Google Scholar] [CrossRef]

40. Haameem, J. A. M., Abdul Majid, M. S., Afendi, M., Marzuki, H. F. A., Fahmi, I. et al. (2016). Mechanical properties of napier grass fibre/polyester composites. Composite Structures, 136, 1–10. DOI 10.1016/j.compstruct.2015.09.051. [Google Scholar] [CrossRef]

41. Cheng, H. T., Gao, J., Wang, G., Shi, S. Q., Zhang, S. B. et al. (2015). Enhancement of mechanical properties of composites made of calcium carbonate modified bamboo fibers and polypropylene. Holzforschung, 69(2), 215–221. DOI 10.1515/hf-2014-0020. [Google Scholar] [CrossRef]

42. Cheng, B., Zhou, C., Yu, W., Sun, X. (2001). Evaluation of rheological parameters of polymer melts in torque rheometers. Polymer Testing, 20(7), 811–818. DOI 10.1016/S0142-9418(01)00008-3. [Google Scholar] [CrossRef]

43. Blyler, L. L., Daane, J. H. (2010). An analysis of brabender torque rheometer data. Polymer Engineering and Science, 7(3), 178–181. DOI 10.1002/pen.760070309. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |