| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.021761

ARTICLE

Engineered Wood/Bamboo Laminated Composites for Outdoor Hydrophilic Platforms: Structural Design and Performance

School of Art and Design, Zhejiang Sci-Tech University, Hangzhou, 310018, China

*Corresponding Author: Fei Rao. Email: raofei@zstu.edu.cn

Received: 03 February 2022; Accepted: 22 March 2022

Abstract: Landscape designers increasingly prefer to use wood/bamboo-based composites for outdoor hydrophilic platforms owing to their natural surface texture, high performance, and sustainability to facilitate extensive interaction between people and water and enable the full range of ecological functions of water resources. In this study, four laminated composite (LC) structures were designed and manufactured using fluffed bamboo and wood veneers. Their surface textures, profile densities, water resistances, and mechanical properties were then evaluated. The type of fluffed veneer of the surface layer determined the texture of the LC surface. The specific structures of fluffed bamboo and wood veneer laminations were found to affect the LC profile density variability, water resistance, and mechanical properties owing to the differences in the strength and interfacial properties of bamboo and wood fibers. Finally, the water resistance and mechanical properties of all four LCs were found to be much higher than the highest level specified in GB/T 20241-2006 for ‘‘laminated veneer lumber’’ and GB/T 30364-2013 for “bamboo scrimber flooring”, indicating that they are promising materials for structures and flooring, particularly for outdoor hydrophilic platforms.

Keywords: Wood/bamboo laminated composites; outdoor hydrophilic platform; surface texture; water resistance; mechanical properties

Nomenclature

| BLC | Laminated bamboo composite |

| LC | Laminated composite |

| MOR | Modulus of rupture |

| PF | Phenol-formaldehyde |

| TSR | Thickness swelling rate |

| WAR | Water absorption rate |

| WLC | Laminated wood composite |

| WSR | Width swelling rate |

Tourism development promotes the functioning of the landscape and the ornamental nature of the aquatic environment. Landscape designers seek to ensure the sustainable development of water resources through technical means, maximize the utilization of water resources, and facilitate human beings’ yearning to return to nature. As a result, designers often use floating bridges, water trails, viewing corridors, and other methods to enable tourist access to water areas, where tourists can observe flowers, fish, and coastal scenery.

Hydrophilic platforms provide a means of approach to aquatic animals and plants and can thus help to gain an understanding of the aquatic environment. Such platforms extend from the land over the water to engage with water resources such as parks, lakes, rivers, wetlands, and seashores. Wooden materials with natural textures and colors are considered ideal for manufacturing hydrophilic platforms. However, the outdoor environment and structural requirements of hydrophilic platforms pose a significant challenge to the water resistance and mechanical properties of most wooden materials.

In recent years, novel high-performance wood/bamboo-based composites with textures and colors similar to those of wood or bamboo have accordingly been fabricated using mechanical fluffing of wood veneer or bamboo culm, followed by resin impregnation, lamination, and molding recombination [1,2]. The bending, compressive, and shear strengths of a Radiata pine wood laminated composite (WLC) were found to be 308.11 MPa, 173.56 MPa, and 28.43 MPa, respectively, or approximately 2.3–4.0 times those of natural wood [3]. Furthermore, compared with a traditional poplar WLC fabricated using veneers without fluffing, a novel WLC constructed using fluffed veneers exhibited a slight decline in mechanical strength but significantly improved dimensional stability [4]. Additionally, denser WLCs have been observed to exhibited improvements in mechanical properties, dimensional stability, and surface properties [2,4,5]. Finally, the veneer thickness, mat formation, and resin solid content have also been found to have an important impact on the physical and mechanical properties of WLCs [6].

The bending strength and modulus of a bamboo laminated composite (BLC) with a density of 1.09 g/cm3 were found to reach 253.23 MPa and 26.35 GPa, respectively, and more importantly, the utilization rate of the Moso bamboo in this BLC was as high as 92.54% [1]. Furthermore, the water resistance of the BLC was observed to improve as its resin solid content and density increased [7]. The width swelling rate (WSR) and thickness swelling rate (TSR) of a BLC with a resin solid content of 20 wt% and density of 1.16 g/cm3 were 0.97% and 3.74%, respectively [8]. To further improve the dimensional stability of BLCs when used in outdoor environments, fluffed bamboo veneers are often heat-treated using industrial production processes such as saturated steam treatment or hot dry air treatment [9]. Zhang et al. found that when fluffed bamboo veneers were treated with a steam pressure of 0.40 MPa for 110 min, the WSR and TSR of the resulting BLC were significantly lower (26.545% and 11.26%, respectively) than those of the untreated control [10]. In addition, the modulus of rupture (MOR) of a BLC decreased by 45% after high-temperature steam treatment [11] owing to the accompanying change in the main chemical components of oriented bamboo fiber mat (OBFM) [10,12]. As a result of its excellent performance, a BLC prepared from heat-treated fluffed bamboo veneers have been used as a hydrophilic platform in wetland parks where it has maintained stable performance for several years, requiring only simple maintenance (Fig. 1).

Figure 1: Various applications of BLCs in outdoor hydrophilic platforms in Xixi National Wetland Park, China

This study therefore examined the influence of lamination design using fluffed bamboo and wood veneers on the mechanical properties of the resulting LCs for use as structural materials with excellent water resistance. Ensuring acceptable interfacial properties between the wood and bamboo veneers is critical for manufacturing these advanced composites [13,14]. A BBPBPBB layup (where B indicates a Neosinocalamus affinis bamboo veneer, and P indicates a poplar veneer) with a density of 0.886 g/cm3 was previously found to exhibit excellent properties (MOR⊥ = 240.80 MPa, modulus of elasticity (MOE)⊥ = 22.83 GPa, and shearing strength (SS)⊥ = 16.66 MPa) owing to the cooperation between the different materials [13]. However, when LCs are used in outdoor hydrophilic platforms, more attention should be paid to their dimensional stability.

In this study, four different LC structures were accordingly designed using fluffed bamboo and wood veneers to evaluate the suitability of their surface textures, profile densities, water resistances, and mechanical properties for use in outdoor hydrophilic platforms.

Four-year-old Neosinocalamus affinis bamboo (Bambusa emeiensis L. C. Chia & H. L. Fung) was obtained from the Hongya Forest Reserve, Sichuan Province, Southwest China. Poplar wood (Populus ssp.), 4–5 years of age, was obtained from Shandong Province, China. Low-molecular-weight phenol-formaldehyde (PF) resin with 47.91 wt% solid content, 35 cps viscosity, and pH 10–11 was supplied by Beijing Dynea Chemical Industry Co. Ltd.

2.2 Preparation of Bamboo and Wood Fluffed Veneers

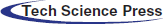

Fluffed bamboo [1,8] and wood [2,5] veneers were prepared according to the methods detailed in previously published literature. Specifically, the Neosinocalamus affinis bamboo culm was processed into two 2000 mm long semicircular bamboo bundles by transverse truncation and longitudinal splitting. Poplar wood veneers with a length, width, and thickness of 2000 mm, 20 mm, and 6 mm, respectively, were obtained through rotary cutting of poplar logs. The bamboo and wood veneers were then mechanically decomposed into continuous-oriented fluffed veneers (Fig. 2) using a multifunctional crushing machine [4,8]. The average thicknesses of the fluffed bamboo and wood veneers were 2.93 ± 0.27 mm and 5.94 ± 0.14 mm, respectively. The average water uptake rates of the fluffed bamboo and wood veneers were 85.67 ± 32.10% and 161.15 ± 10.68%, respectively, when immersed in water for 5 min at room temperature. After fluffing, many dot- and linear-shaped cracks were observed on the surface of the veneers, facilitating penetration by the water-soluble PF resin [2,8]. Finally, the fluffed veneers were dried to a moisture content (MC) of approximately 10 percent naturally.

Figure 2: Fluffed veneers of (A) Neosinocalamus affinis bamboo and (B) poplar wood

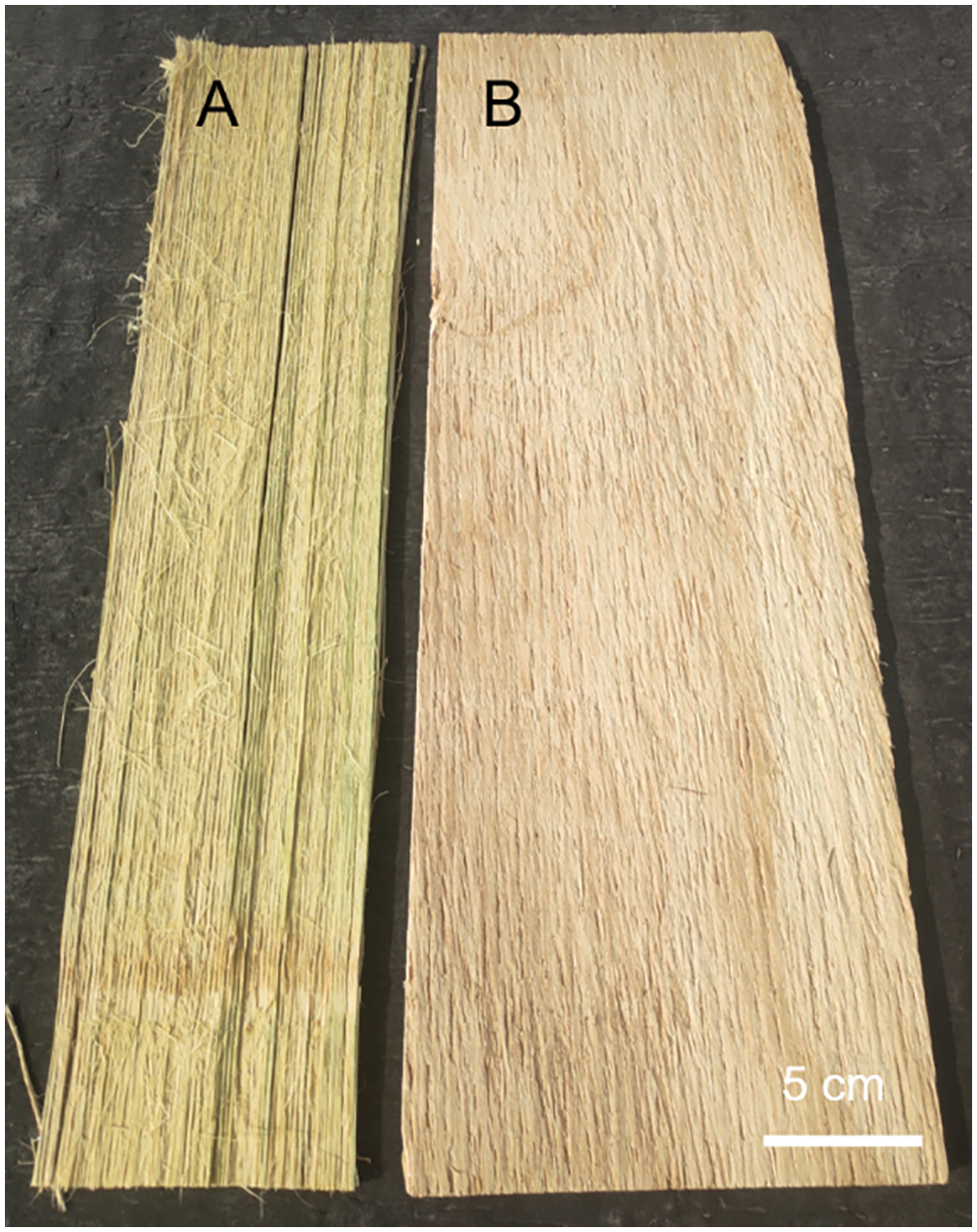

2.3 Structural Design and Manufacture of LCs

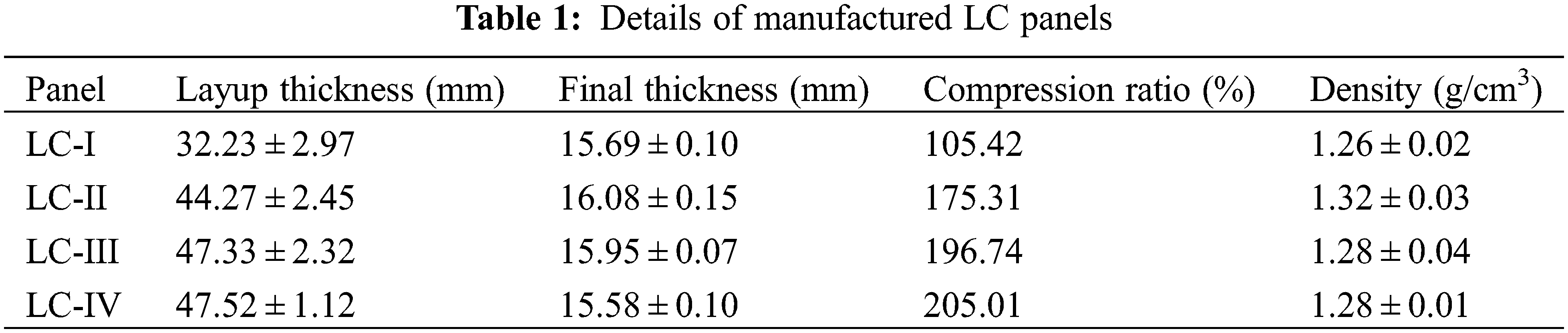

The fluffed veneers were impregnated with a PF resin solution to achieve 17% resin solid content and dried again to a moisture content of 10%–12%. They were weighed to confirm that the target density of 1.30 g/cm3 was obtained and then laminated along the grain direction in a 450 mm × 160 mm × 15 mm hot-pressing mold. Four LC panels made of various layup structures were constructed, named LC-I, LC-II, LC-III, and LC-IV, as defined in Fig. 3. The hot-pressing process consisted of holding a load at a hot-plate temperature of 150°C for 30 min (5 min for press closing and then 25 min of pressure at the target thickness), followed by unloading at a hot-plate temperature of 30°C–40°C. The pressure was kept at 3.5–7.0 MPa to cure the resin. Table 1 listed details of LC panels manufacturing. After two weeks of storage indoors at a temperature of 20°C and relative humidity of 65%, various LC test samples were prepared by sanding and cutting the completed panels.

Figure 3: Layup design of wood/bamboo LC panels, where green indicates a fluffed bamboo veneer and yellow indicates a fluffed poplar veneer

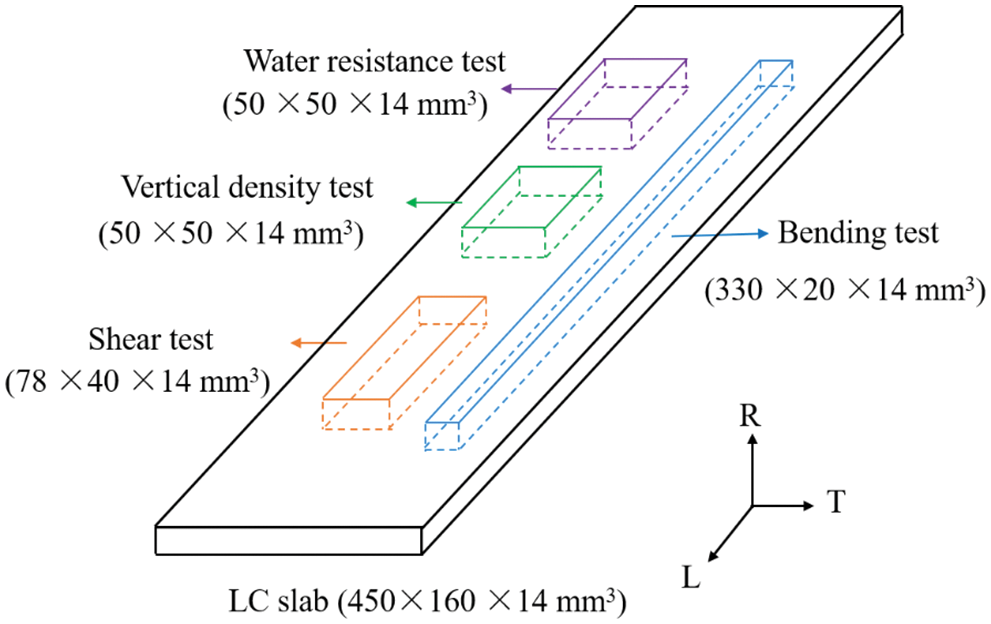

The samples for the density profile, water resistance, and mechanical property tests were taken from each LC panel as shown in Fig. 4.

Figure 4: Locations of LC panel sampling undertaken in this study

2.4.1 Density Profile Measurement

The vertical density profile of each LC panel was measured using an X-ray densitometer (Dense-Lab Mark3, EWS, Germany). The LC panel samples were 50 mm × 50 mm × 14 mm in size and were scanned at a speed of 0.1 mm/s along the thickness direction to measure their cross-sectional density distributions.

A 28-h treatment following test procedure GB/T 30364-2013 was used to determine the water absorption rate (WAR), WSR, and TSR of the LC panels [15]. The 28-h cycle treatment consisted of 4 h of immersion in boiling water, 20 h of oven-drying at 60 ± 3°C, and another 4 h of immersion in boiling water. Seven LC samples with dimensions of 50 mm × 50 mm × 14 mm were tested for each panel type.

The MOE and MOR of the LC panels were tested parallel to the face grains using a universal testing machine (MDW-W50, Jinan Time Testing Instrument Co., Ltd., Jinan, China) in the three-point bending mode according to the GB/T 17657-2013 standard [16]. Seven 330 mm × 20 mm × 14 mm samples were tested for each panel type at room temperature with a support span of 280 mm and loading rate of 10 mm/min.

Short-beam shear tests were performed in accordance with GB/T 20241-2006 using the same equipment as the bending test [17]. Eight 78 mm × 40 mm × 14 mm samples were tested for each panel type at a crosshead speed of 5 mm/min with a span of 52 mm.

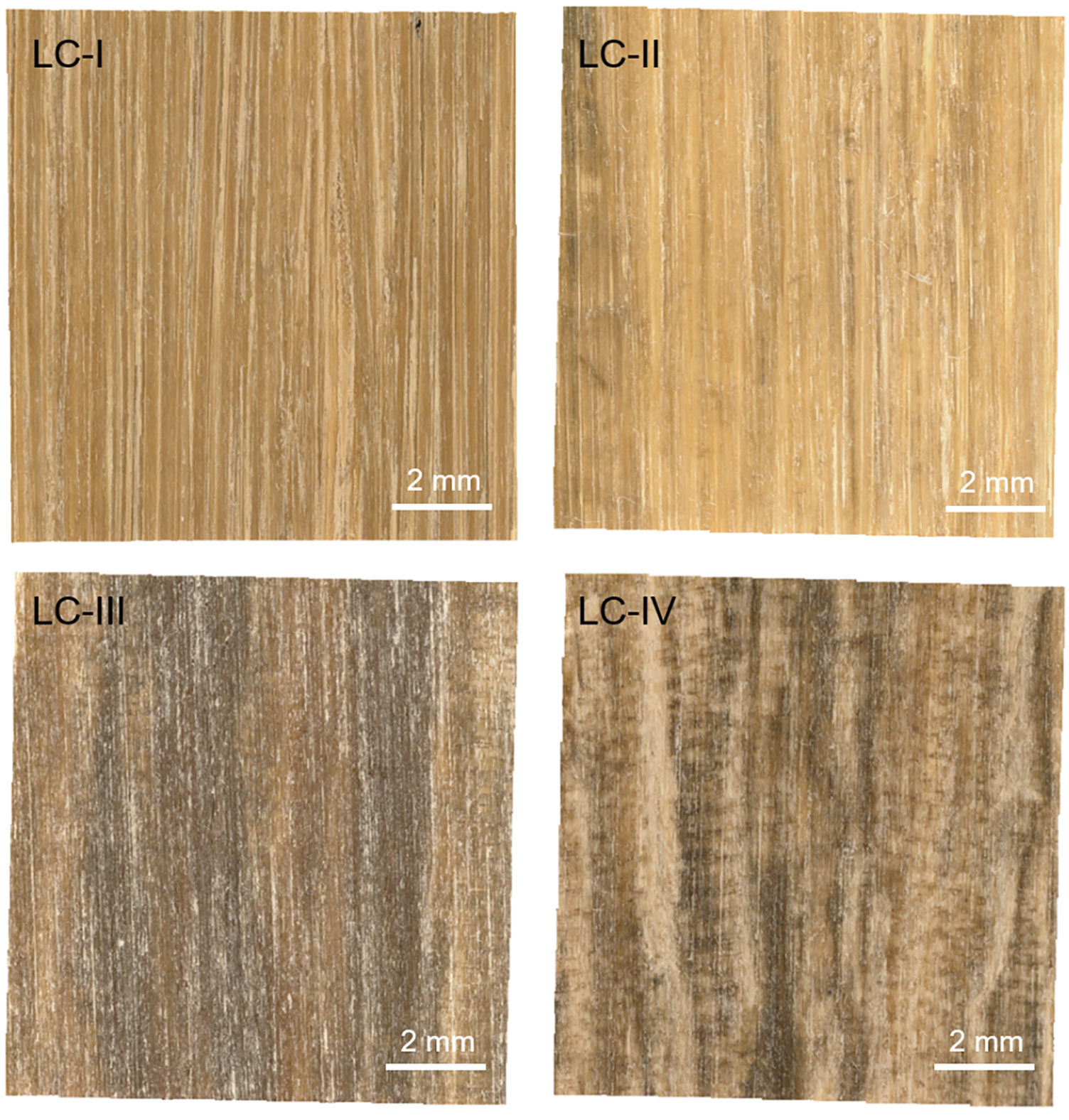

In Fig. 5, the surfaces of LC-I and LC-II show the texture of natural bamboo, whereas those of LC-III and LC-IV show the texture of wood according to the surface veneer of each LC panel. The bamboo tissue was composed of 49.5% (v/v) parenchyma cells, 45.0% (v/v) fiber cells, and 5.5% (v/v) metaxylem vessels [18]. The rigid fiber cells of the bamboo were found to be hardly affected after densification from an initial density of 0.72 g/cm3 to an LC with a density of 1.30 g/cm3. In contrast, the parenchyma cells and metaxylem vessels were severely compressed and deformed [19], leading to a denser texture of the fibers on the surfaces of LC-I and LC-II. Compared with color of

Figure 5: Surface textures of the LCs evaluated in this study

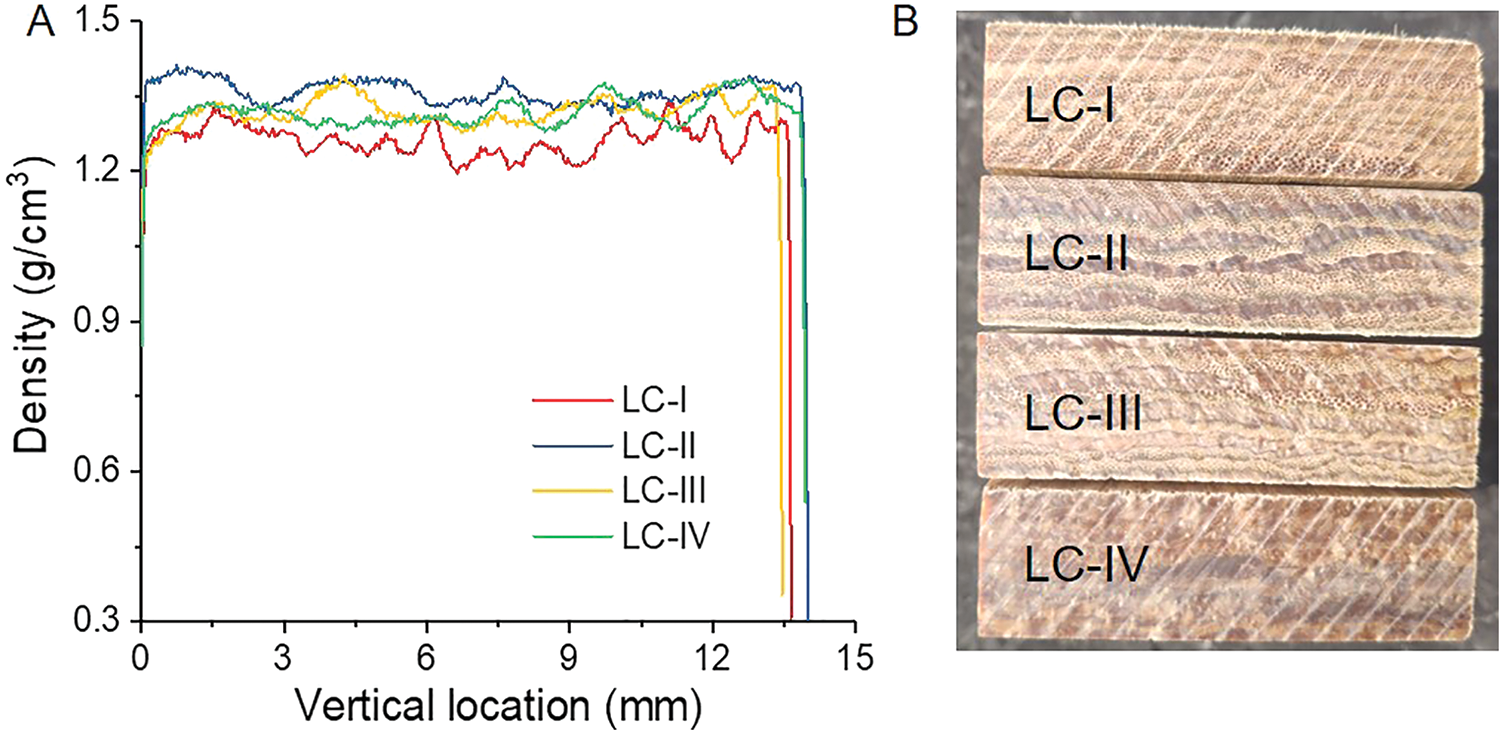

The vertical density profiles of the LCs were then investigated as shown in Fig. 6. The vertical density of LC-I presented a nearly regular fluctuation owing to the radial vascular bundle gradient of bamboo [20], whereas the vertical densities of LC-II and LC-III exhibited less variation than that of LC-IV, indicating that the degree of compression of the fluffed wood and bamboo veneers was balanced to a certain extent.

Figure 6: (A) Vertical density profiles and (B) test samples of the LCs

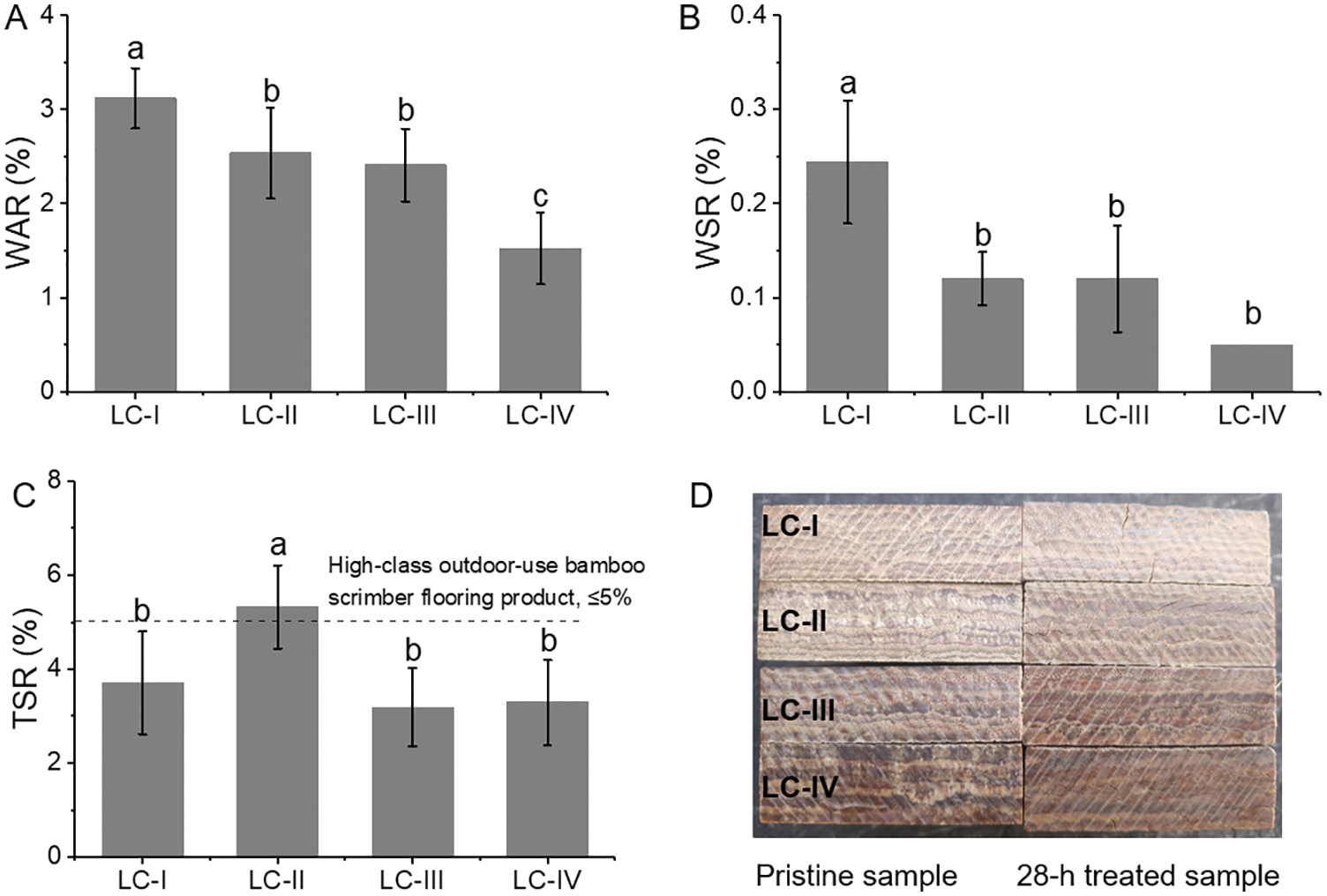

As LCs are intended for use in outdoor hydrophilic platforms, their water resistance is a critical consideration when determining their outdoor service life. The water-resistant properties of the different LCs were therefore investigated in this study with the results shown in Fig. 7. The WAR of the LCs generally decreased as the content of fluffed bamboo veneer decreased (Fig. 7A). Indeed, the WAR of LC-IV was less than 2%, which was significantly lower than those of other LCs, indicating that the resin penetrated the wood microstructure more easily than the bamboo microstructure. Furthermore, the WSR of LC-I was significantly higher than those of the other LCs (Fig. 7B). Cracks were mainly concentrated in the thickness direction of LC-I after 28 h of water resistance treatment (Fig. 7D), indicating that the transverse structure of the wood plays a positive role in inhibiting the width change of LCs under extreme hydrothermal conditions. The TSR of LC-II was 5.32%, significantly higher than those of the other LCs (≤4%) (Fig. 7C). The surface layers of the LCs were consistently the most severely compressed, and their vertical densities were accordingly higher (Fig. 6A). The four layers of fluffed poplar veneer in LC-II could not be completely compressed such that, coupled with its strong water absorption capacity, a large stress rebound was observed that led to cracks in the wood/bamboo bonding interface after 28 h of water resistance treatment (Fig. 7D). Notably, the WSR and TSR of LC-I, LC-III, and LC-IV obtained in this study achieved the GB/T 30364-2013 standard for high-class outdoor-use bamboo scrimber flooring products (WSR ≤ 3%, TSR ≤ 5%). These results indicate that the LCs exhibited excellent water resistance suitable for use in outdoor hydrophilic platforms.

Figure 7: (A) WAR, (B) WSR, (C) TSR and (D) test samples of the LCs

3.4.1 Bending Strength and Modulus

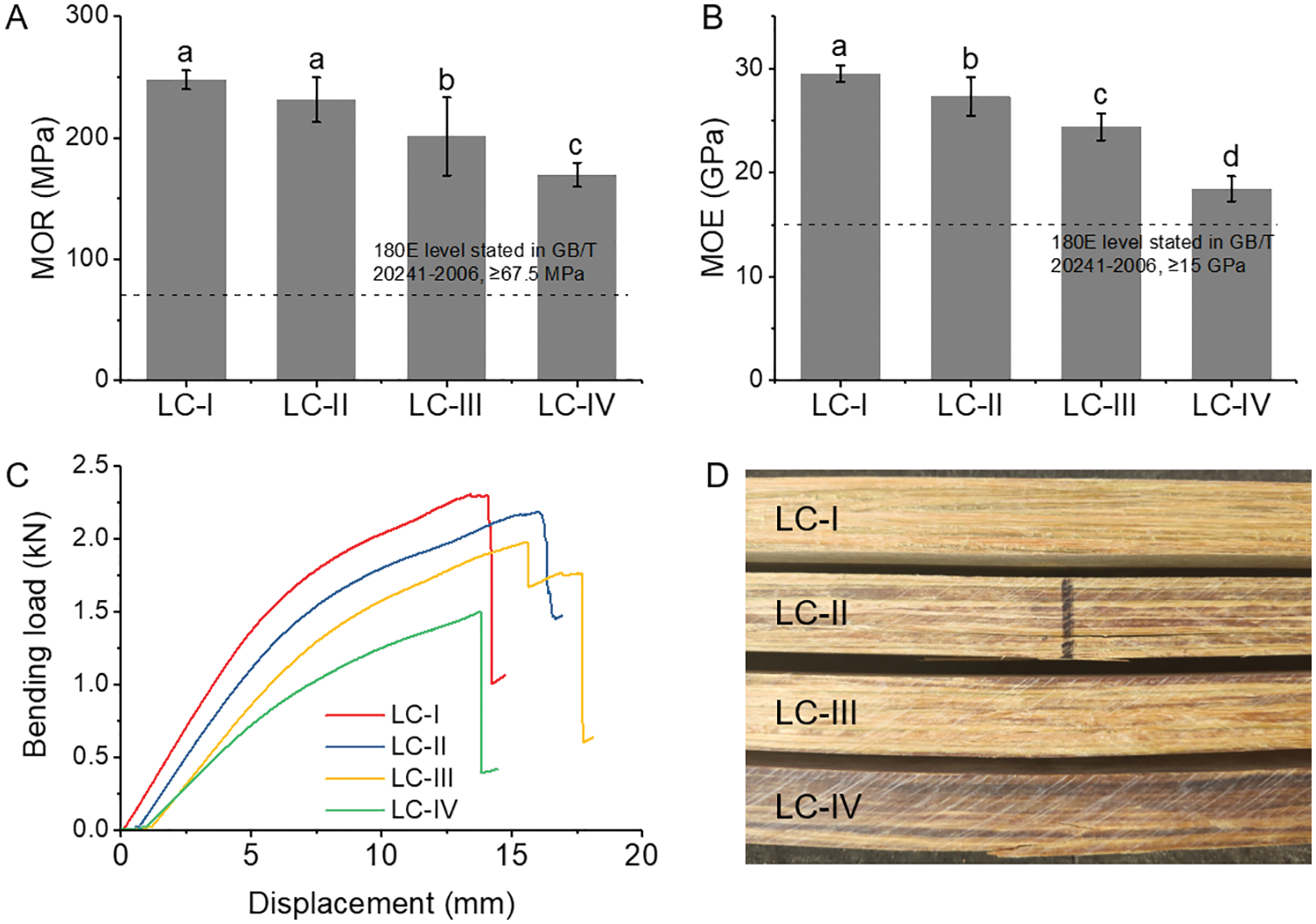

Fig. 8 shows the effect of the different lamination structures on the bending properties of the LCs they composed. The MORs of LC-I and LC-II were 248.01 and 231.41 MPa, respectively, significantly higher than those of LC-III and LC-IV (Fig. 8A). The MOEs ranged from 18.45 (LC-IV) to 29.50 GPa (LC-I) and decreased significantly with decreasing fluffed bamboo veneer content (Fig. 8B). The MOR and MOE of LC-I were 5.6 and 11.1 times that of wood–plastic composites (44.23 MPa and 2.65 GPa) [21], respectively. The elastic modulus and hardness of the poplar fiber cell walls were 12.5 and 0.39 GPa [22], while those of the Neosinocalamus affinis bamboo fiber were 22.91 and 0.56 GPa, respectively, and those of the bamboo parenchyma cell wall were 9.92 and 0.42 GPa, respectively [19]. This indicates that the fluffed bamboo veneer was a dominant factor influencing the transverse bending load in the LCs, while the fluffed wood veneer was a dominant factor in the bending deformation. However, for LC-I and LC-IV—which consisted entirely of fluffed bamboo and fluffed wood veneers, respectively—the substrates eventually failed under the bending load (Fig. 8D), resulting in smaller displacements than those observed for LC-II and LC-III (Fig. 8C), each of which contained a combination of fluffed bamboo and wood veneers. The results of the bending experiments demonstrated that the bending properties of all four LCs achieved the highest level strength index of 180E, as specified in GB/T 20241-2006 for “laminated veneer lumber,” indicating that they represent excellent engineered laminated veneer lumber products.

Figure 8: Bending test results: (A) MOR, (B) MOE, (C) bending load–displacement curves, and (D) failed LCs

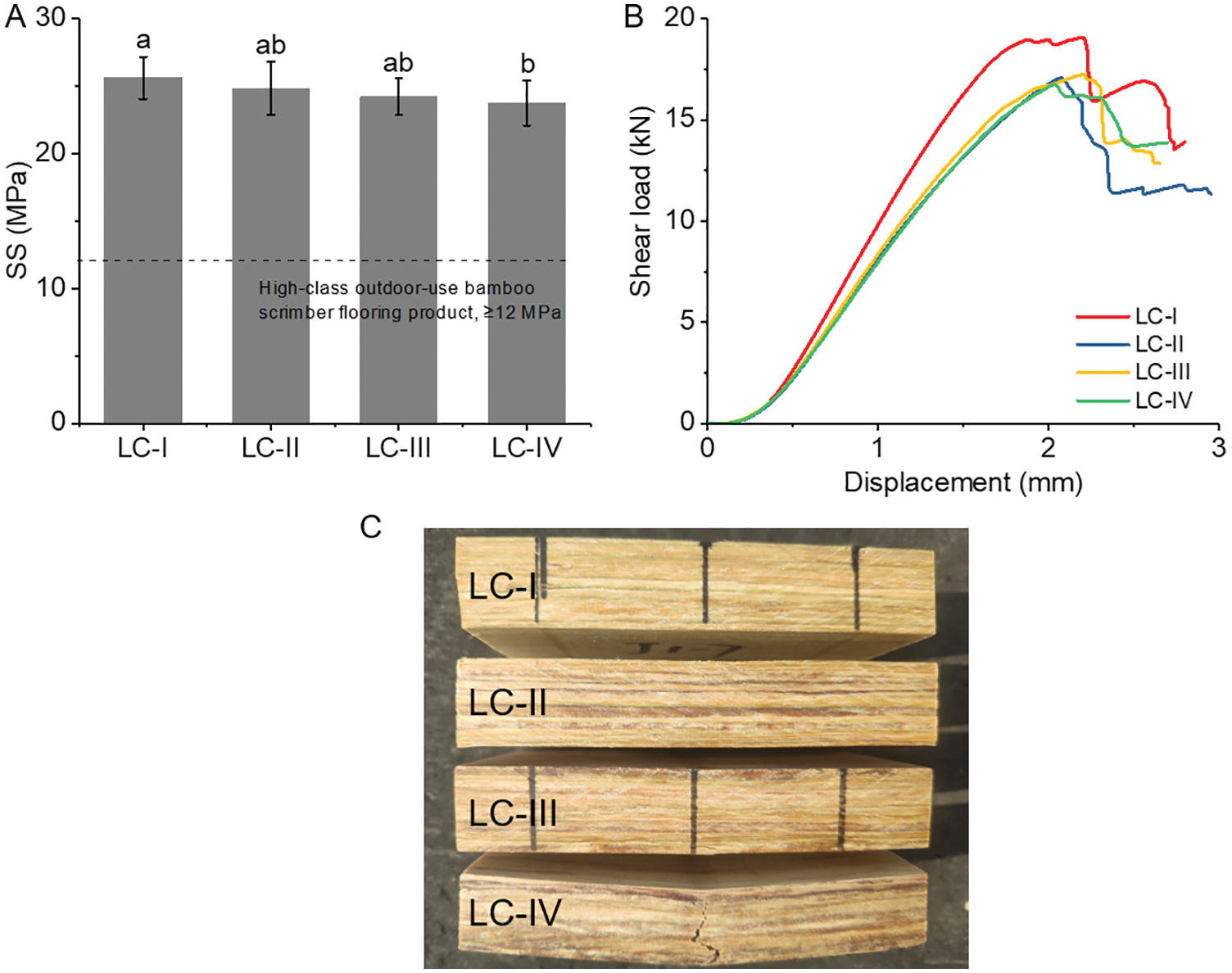

The shear strengths of the four LCs are compared in Fig. 9A, in which it can be seen that the shear strengths decreased from 25.62 GPa to 23.74 GPa with decreasing fluffed bamboo veneer content. However, these shear strengths are significantly higher than those obtained for Dipteryx panamensis in Costa Rica (19.3–19.6 GPa) [23]. Encouragingly, the shear strengths of all LC samples evaluated in this experiment were close to or greater than twice that required for high-class outdoor use, as stated in GB/T 30364-2013 for “bamboo scrimber flooring” (≥12 MPa). There was no significant difference between the shear strengths of LC-I, LC-II, and LC-III, indicating that the presence of fluffed wood veneer has little effect on the shear strength, or between those of LC-II, LC-III, and LC-IV, indicating that the presence of fluffed bamboo veneer has little effect. Fig. 9B shows that the shear load on each LC during the short-beam shear test exhibited a downward-stepping trend of varying degrees after reaching its maximum value. Fig. 9C shows that the short-beam test failure of LC-I, LC-II, and LC-III occurred in the layer-to-layer bonding interface, whereas that of LC-IV occurred in the substrate at the tension faces of the samples at mid-span. This result can be primarily attributed to the fact that the tensile strength of Neosinocalamus affinis bamboo fiber (1776 ± 25.67 MPa) [19] is much higher than that of poplar fiber (1776 ± 25.67 MPa) [24].

Figure 9: Shear test results: (A) shear strength, (B) shear load–displacement curves, and (C) failed LCs

In this study, LCs comprising fluffed bamboo and wood veneers were designed, and their physical and mechanical properties were evaluated. The fluffed veneer used in the surface layer was found to determine the appearance and texture of the LC surface. The lamination of fluffed bamboo and wood veneers together was observed to reduce the variation in the vertical density profiles of the LCs. The mechanical properties of the LCs decreased as their fluffed bamboo veneer contents decreased, whereas their water resistances improved, excluding the TSR. The water resistances and mechanical properties of LC-I, LC-III, and LC-IV were much higher than those specified in GB/T 20241-2006 and GB/T 30364-2013, indicating that these composites have considerable application potential in outdoor structures and flooring. By providing desirable bending strength, modulus, and water resistance, the poplar wood/bamboo LC investigated in this study represents a promising alternative to existing engineered bamboo and wood products for use in outdoor hydrophilic platforms. However, further research remains necessary to investigate novel technologies that can be applied to enhance the finish, weathering properties, and connection design for the proposed LC while maintaining its excellent physicomechanical properties.

Acknowledgement: The authors wish to thank Xiaoyan Li and Wanpei Cai for the experimental assistance. We would like to thank Editage (www.editage.cn) for English language editing.

Funding Statement: This work is supported by the Science and Technology Project of Zhejiang Province (2021C02012), the Science Foundation of Zhejiang Provincial Department of Education (113429A4F21070), and the Science Foundation of Zhejiang Sci-Tech University (11340031282014 and 11343132612052).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Yu, Y., Huang, X., Yu, W. (2014). A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Composites Part B: Engineering, 56, 48–53. DOI 10.1016/j.compositesb.2013.08.007. [Google Scholar] [CrossRef]

2. Zhang, Y., Zhang, Y., Yu, Y., Yu, W. (2018). Scrimber board (SB) manufacturing by a new method and characterization of SB’s mechanical properties and dimensional stability. Holzforschung, 72, 283–289. DOI 10.1515/hf-2017-0071. [Google Scholar] [CrossRef]

3. Wei, J., Rao, F., Zhang, Y., Yu, W., Hse, C. et al. (2019). Laminating wood fiber mats into a densified material with high performance. Materials Letters, 253, 358–361. DOI 10.1016/j.matlet.2019.06.097. [Google Scholar] [CrossRef]

4. Zhang, Y., Huang, Y., Qi, Y., Yu, W. (2018). Novel engineered scrimber with outstanding dimensional stability from finely fluffed poplar veneers. Measurement, 124, 318–321. DOI 10.1016/j.measurement.2018.04.051. [Google Scholar] [CrossRef]

5. Huang, Y., Qi, Y., Zhang, Y., Zhu, R., Zhang, Y. et al. (2019). Surface properties of novel wood-based reinforced composites manufactured from crushed veneers and phenolic resins. Maderas Ciencia y Tecnología, 21, 185–196. DOI 10.4067/s0718-221x2019005000206. [Google Scholar] [CrossRef]

6. Zhang, Y., Qi, Y., Huang, Y., Yu, Y. L., Yu, W. et al. (2018). Influence of veneer thickness, mat formation and resin content on some properties of novel poplar scrimbers. Holzforschung, 72, 673–680. DOI 10.1515/hf-2017-0188. [Google Scholar] [CrossRef]

7. Yu, Y., Liu, R., Huang, Y., Meng, F., Yu, W. (2017). Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Construction and Building Materials, 157, 1032–1039. DOI 10.1016/j.conbuildmat.2017.09.185. [Google Scholar] [CrossRef]

8. Rao, F., Ji, Y., Li, N., Zhang, Y., Chen, Y. et al. (2020). Outdoor bamboo-fiber-reinforced composite: Influence of resin content on water resistance and mechanical properties. Construction and Building Materials, 261, 120022. DOI 10.1016/j.conbuildmat.2020.120022. [Google Scholar] [CrossRef]

9. Yu, Y., Zhu, R., Wu, B., Hu, Y., Yu, W. (2015). Fabrication, material properties, and application of bamboo scrimber. Wood Science and Technology, 49, 83–98. DOI 10.1007/s00226-014-0683-7. [Google Scholar] [CrossRef]

10. Zhang, Y. M., Yu, W. (2013). Effect of thermal treatment on the properties of bamboo-based fiber composites. Scientia Silvae Sinicae, 49, 160–168. DOI 10.11707/j.1001-7488.20130521. [Google Scholar] [CrossRef]

11. Wu, B., Yu, Y., Qi, J., Yu, W. (2014). Effects of bamboo bundles treated with fine fluffing and carbonized treatment on the properties of bamboo scrimber. Journal of Nanjing Forestry University, 57, 115–120. DOI 10.3969/j.issn.1000–2006.2014.06.022. [Google Scholar] [CrossRef]

12. Meng, F., Wang, C., Xiang, Q., Yu, Y. (2019). Effect of hot dry air treated defibering bamboo veneer on properties of bamboo-based fiber composites. Scientia Silvae Sinicae, 55, 142–148. [Google Scholar]

13. Chen, F., Deng, J., Li, X., Wang, G., Smith, L. M. et al. (2017). Effect of laminated structure design on the mechanical properties of bamboo-wood hybrid laminated veneer lumber. European Journal of Wood and Wood Products, 75, 439–448. DOI 10.1007/s00107-016-1080-8. [Google Scholar] [CrossRef]

14. Chen, F., Wang, G., Li, X., Smith, L. M., Shi, S. Q. (2016). Laminated structure design of wood - bamboo hybrid laminated composite using finite element simulations. Journal Reinforced Plastics and Composites, 35, 1661–1670. DOI 10.1177/0731684416663852. [Google Scholar] [CrossRef]

15. CN-GB/T 30364-2013 (2013). Bamboo scrimber flooring, pp. 1–17. China. [Google Scholar]

16. CN-GB/T 17657-2013 Test methods of evaluating the properties of wood-based panels and surface decorated wood-based panels, pp. 1–113. China. [Google Scholar]

17. CN-GB/T 20241-2006 (2016). Laminated veneer lumber, pp. 1–17. China. [Google Scholar]

18. Yu, Y., Huang, X., Yu, W. (2014). High performance of bamboo-based fiber composites from long bamboo fiber bundles and phenolic resins. Journal of Applied Polymer Science, 131, 40371. DOI 10.1002/app.40371. [Google Scholar] [CrossRef]

19. Yu, Y., Huang, Y., Zhang, Y., Liu, R., Meng, F. et al. (2018). The reinforcing mechanism of mechanical properties of bamboo fiber bundle-reinforced composites. Polymer Composites, 40, 1463–1472. DOI 10.1002/pc.24885. [Google Scholar] [CrossRef]

20. Chen, M., Ye, L., Li, H., Wang, G., Chen, Q. et al. (2020). Flexural strength and ductility of moso bamboo. Construction and Building Materials, 246, 118418. DOI 10.1016/j.conbuildmat.2020.118418. [Google Scholar] [CrossRef]

21. Ratanawilai, T., Srivabut, C. (2022). Physico-mechanical properties and long-term creep behavior of wood-plastic composites for construction materials: Effect of water immersion times. Case Studies in Construction Materials, 16, e00791. DOI 10.1016/j.cscm.2021.e00791. [Google Scholar] [CrossRef]

22. Wang, X., Deng, Y., Wang, S., Min, C., Meng, Y. et al. (2014). Evaluation of the effects of compression combined with heat treatment by nanoindentation (NI) of poplar cell walls. Holzforschung, 68, 167–173. DOI 10.1515/hf-2013-0084. [Google Scholar] [CrossRef]

23. Rodríguez-Pérez, D., Moya, R., Murillo, O., Gaitán-Álvarez, J., Badilla-Valverde, Y. (2022). Variation and genetic control of the heartwood, sapwood, bark, wood color parameter, and physical and mechanical properties of Dipteryx panamensis in Costa Rica. Forests, 13, 106. DOI 10.3390/f13010106. [Google Scholar] [CrossRef]

24. Wu, D. (2013). Study on fiber morphology and properties of Salix Mongolia willow and polar (Master Thesis). Inner Mongolia Agricultural University. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |