| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.023548

ARTICLE

Research on the Bending Impact Resistance and Transverse Fracture Characteristics of Bamboo under the Action of Falling Weight

1Department of Biomaterials, International Centre for Bamboo and Rattan, Beijing, 100102, China

2SFA and Beijing Co-Built Key Laboratory of Bamboo and Rattan Science & Technology, State Forestry Administration, Beijing, 100102, China

*Corresponding Author: Fengbo Sun. Email: sunfengbo@icbr.ac.cn

Received: 01 May 2022; Accepted: 20 June 2022

Abstract: Drop weight impact tester was used to accurately measure the bending impact resistance of various parts of Phyllostachys edulis, commonly known as moso bamboo, with a growth cycle of 3–8 years. Cellulose crystallinity in the bottom (B), middle (M) and top (T) of bamboo at different ages was calculated using peak height analysis in X-ray diffraction. Heatmap of Spearman correlation analysis was used to represent the correlation between chemical composition and impact mechanics. The breaking load (BL), fracture energy (FE) and impact deflection (ID) of 3–8-year-old bamboo were found to be in the range of ~670–2120 N, ~5.17–15.55 J, and ~3.60–~17.76 mm, respectively. As the growth periodof bamboo rises, the cellulose crystallinity at the B and T decreases first and then increases, while that for the M increases first and then remains stable. Similarly, the bending impact performance of bamboo was found to become stable with its growth and age. The flexural impact and toughness of the 4-year-old bamboo base material were better than other specimens. The enhancement in the bending impact properties of bamboo at different growth periods was influenced by the lignin content, while the value of FE was mainly positively correlated with ash, cold and hot water extracts and benzyl alcohol content. However the content of holocellulose and pentosan, air-dry density and, base density negatively influenced the FE. With the change in the height of the bamboo, the correlation between its impact mechanical properties and chemical composition gradually decreased. This study provides data support and theoretical basis for the age-appropriate thinning and application of moso bamboo.

Keywords: Moso bamboo; lifespan; bending impact; breaking load; fracture energy; impact deflection; chemical composition; correlation

Nomenclature

| B | Bamboo bottom parts |

| M | Bamboo middle parts |

| T | Bamboo top parts |

| BL | Breaking load |

| FE | Fracture energy |

| ID | Impact deflection |

Phyllostachys edulis, commonly known as moso bamboo, is an economically important and abundant among varieties of bamboo, with advantage of one-time planting. Owing to its excellent physical and mechanical properties, it is considered to be one of the important biomass engineering materials in China [1,2]. Moso bamboo is rich in resources and is widely used in architectural decoration, pulp and paper, arts and crafts and other fields [3–6]. As material properties of moso bamboo are greatly dependent on rotation cycle, choice of appropriate growth period is of great significance to realize its material value to the fullest [7]. The application of materials should be applied to suitable places, which is an important way to exert its ecological value. However, most of the current applications of moso bamboo ignore the impact of rotation cycle and use site on the end use, and lack the processing concept of classification and graded utilization and reliable data support. It is known to inevitably bear the external forces of different impact loads during its use as building material. Therefore, it is vital to understand the extent of resistance to impact damage of original bamboo at different growth periods for the application of end products.

The change law of chemical composition content of moso bamboo can be divided into growth period (1–4 years), maturity period (5–7 years) and decline period (more than 8 years) [8]. Mo et al. [9] found that the pendulum impact flexibility of bamboo showed an increasing trend with the bamboo age (2–14 years), such that the impact toughness was higher for T compared to the B and M parts. Yet another study showed a quadratic parabolic relationship between properties of bamboo (such as basic density, compressive strength, tensile strength and other macroscopic mechanical properties) and bamboo age and this study concluded that the 4-year-old is the best, and the mechanical properties of the bamboo with a growth period of more than 8 years decreased gradually due to aging [10]. Wang et al. [11] analyzed the bending failure morphology of moso bamboo at the macroscopic and microscopic levels, and found that moso bamboo exhibited typical brittle failure under the combined stress of tension, shear and compression. The lightweight structure of composite maintains bamboo’s good structural stability while improving tensile, compressive, bending, and shear properties of bamboo [12–14]. The above-mentioned studies involve static load and detailed analysis discussion of the mechanical properties through pendulum test and chemical components of the original bamboo. However, the impact resistance data obtained through the pendulum test does not fully reflect the mechanical properties of natural bamboo for real-life applications. In addition to the side impact forces (pendulum), the bamboo might also experience vertical forces in some application domain. The falling hammer impact force on bamboo needs to be further studied so as to correlate between its chemistry and flexural impact properties.

In view of this, we intend to focus on the relationship between the cellulose crystallinity and chemical composition and impact mechanics of moso bamboo at different ages. We have studied the effect of cellulose crystallinity in different parts of moso bamboo on their impact toughness and fracture morphology, in order to provide a better understanding of the correlation between impact resistance of moso bamboo and growth period. Considering the two-carbon strategy, it is particularly important to determine the suitable rotation period for the comprehensive evaluation of the bamboo property value and ecological value of moso bamboo. Timely harvesting of mature timber frees up growth space for young bamboo, which can promote a win-win situation for bamboo timber-use and ecological value.

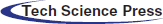

Fresh bamboo pieces (3–8 years old) were collected from Jian’ou Forest Reserve, Fujian Province of China, and from 2013 to 2021 of bamboos were collected on the same slope according to “degree” (1 year), and processed into two kinds of specimens (with and without bamboo node). After each bamboo piece was broken (12 parts per piece), taken and the specimen was sawed and cut with the dimension of 200 mm × 15 mm × t mm according to the B (1–7 segments) and the M (8–14 segments), and the T (sections 21–28) was divided into several segments (Fig. 1).

Figure 1: Schematic illustration of specimen sampling and bending impact

2.2 Methods and Characterization

The specimens were sawed according to the growth period (3–8 years) and parts (B, M, and T) of moso bamboo and the specimens with uniform size having dimensions of 200 mm × 15 mm × t mm (wall thickness) were obtained. The specimens were uniformly quenched and tempered in an environmental temperature condition of 20 ± 2°C and relative humidity of 65 ± 3% to a constant quality and finally air-dried (6.65 ± 0.16)%. According to Chinese standard GB/T 15780-1995 “Testing methods for physical and mechanical properties of bamboos”, the moisture content, air-dry density and basic density of 3–8 years old moso bamboo specimens were determined. Epson perfection V850Pro scanner (Seiko Epson Corporation) was used to measure the area and height dimensions of the specimen.

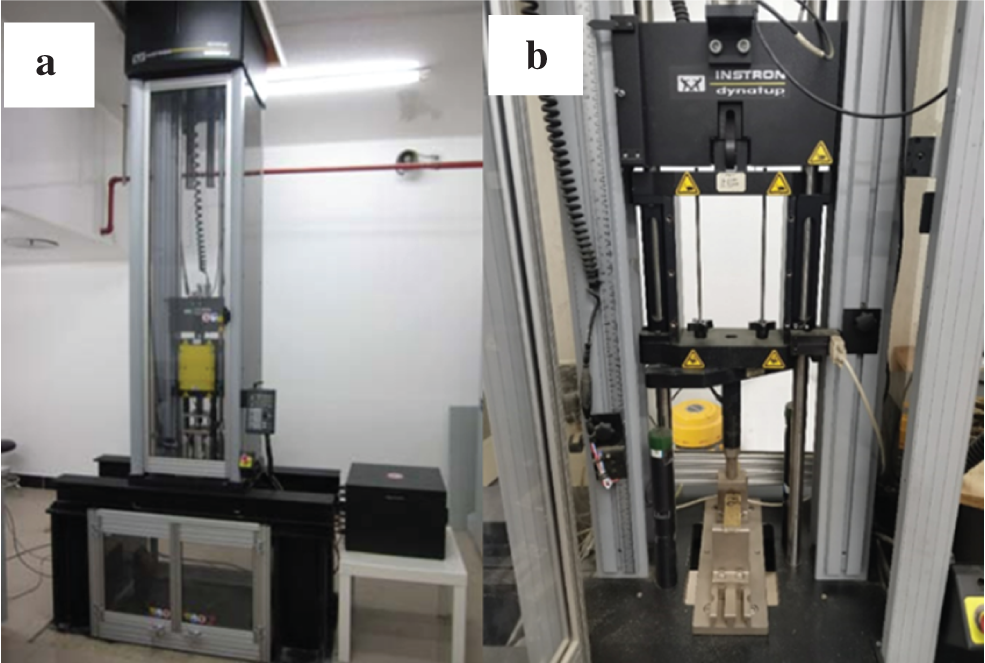

In general, the method of the drop weight impact test is used to realize the impact damage of the specimen by adjusting the height of the drop weight and the loading mass. Fully digital drop weight impact tester (Instron dynatup 9250HV, Instron, USA) was used to perform impact bending tests on all specimens. Herein, the weight of the drop weight was set to 18.28 kg, the total impact energy was set to 50 J, the height of the drop weight was set to be 0.277 m, and the impact test was carried out on each group of samples with the same impact energy. The force between the impact head and the test piece were detected by a piezoelectric sensor, and the impact speed was recorded by a velocity grating near the impact head. Transfer the drop weight to a preset height and release it. the three-point bending span was 18 cm, and the specimen was placed in the sample holder. The green side of the bamboo was impacted on the platform, and the mechanical testing machine was used to record the displacement load changes in the entire impact process in real time, and each sample was tested 12 times, and used a vernier caliper to record the stretched length of the fiber at the fracture interface. According to the formula of Newton’s second law, the impact load is calculated as shown in formula (1).

In the formula, m is the mass of the counterweight, and v(t) is the instantaneous velocity obtained during the test.

We used bamboo of different ages, removed the bamboo skin and pith ring, and grinded into 60 mesh powder. Crystal structures of the various allomorphs were analyzed by XRD (X PERTPRO-30X) with Ni-filtered Cu-Kα radiation (λ = 0.1542 nm), generated at 40 kV and 40 mA. Scans were in the range of 5°–60° (2θ) with scanning speed of 0.05° min-1. Blank sample holder was also scanned for further subtraction from the powder patterns of cellulose samples and in order to obtain the background diffractogram. The patterns were analyzed by using the pseudo-Voigt peak shape with Maud Rietveld software (Version 2.7) [15]. The crystallinity index (CrI) was calculated by using formula (2),

where Acrystal is the calculated peak of the crystalline cellulose pattern and Aamorph is the calculated amorphous curve under the non-crystalline cure.

Fracture morphology: The damaged part after impact was photographed using a digital camera, and the fracture damage state and fiber morphology near the incident surface and the exit surface of the test piece were observed.

Excel software was used for data statistics, and Duncan’s multiple test and correlation analysis were performed by one-way analysis of variance analysis of variance (ANOVA) of SPSS 25.0 software.

3.1 Effects of Growth Period and Material Location of Phyllostachys Pubescens on Bending Impact Mechanical Properties

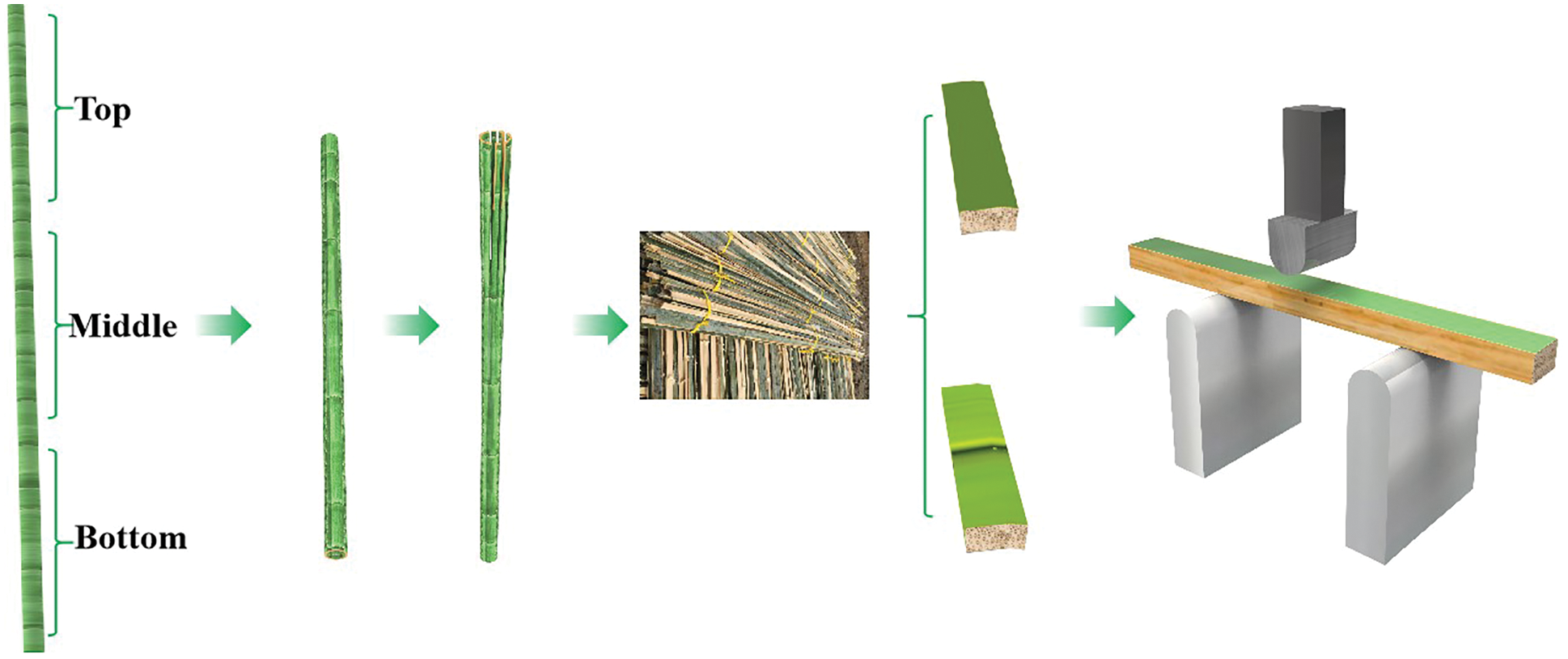

The flexure of the bamboo exhibits elastic–plastic and ductile characteristics. In particular, under impact velocity of 2 ms−1, it is very close to free fall flexural deformation [16]. Moso bamboo dominates the applications at this impact velocity. Therefore, the impact velocity of all specimens in this study was set to 2 ± 0.2 ms−1. With the extension of bamboo growth period (4–8 years), the ability of specimens to resist impact damage showed a trend of first decreasing and then increasing (Fig. 2). Four-year-old moso bamboo has reached maturity and exhibits good physical and mechanical properties, comparable to high-density broad-leaved wood and its B exhibits the largest impact load; however, the energy is slightly inferior to that of the eight-year-old specimen. The energy showed a trend of first decreasing and then increasing. The 6-year-old B showed the lowest energy. However, the impact strength was the largest under the ID of 0–5 mm. Moreover, the 6-year-old B showed strong stiffness, and the 4-, 7-, and 8-year-old B exhibited peak value increase in FE in the range of 0–10 mm ID. Consequently, 4-year-old B presents excellent mechanical properties when exposed to vertical impact forces. As a monocot, moso bamboo cannot renew the water-conducting vascular system by enlarging culm diameters every year as it occurs in dicotyledonous trees [17], which may lead to a gradually weakening water-conducting function in culms with increasing age. As a result, the bending impact mechanics no longer increase with the growth period. However, existing studies still have not answered whether culms of different ages respond variably (or similarly) to severe drought [18].

Figure 2: Schematic illustration of impact displacement load and energy of bamboo B in different growth periods

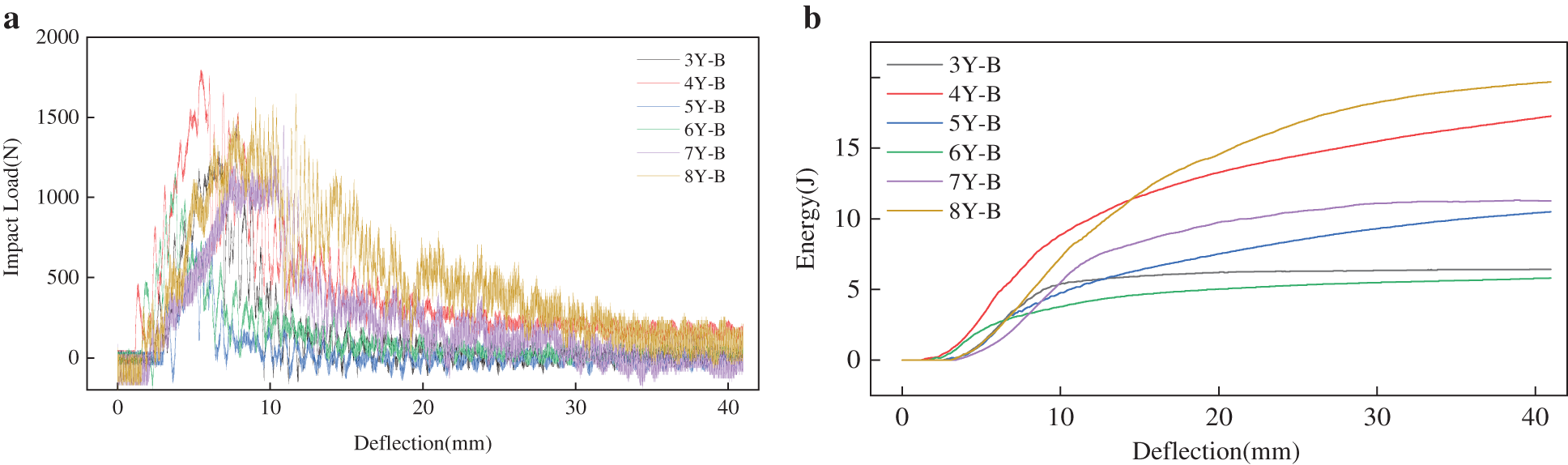

The 7–8-year-old M showed the highest impact load value. The maximum impact load of the 4-year-old M was found to be better than those of the 3-, 5-, and 6-year-old specimens. However, the displacement reaching the maximum load was generally greater than that of the M specimens of other differently-aged bamboo (Fig. 3). Noteworthy, the M of the 4-year-old bamboo shows excellent toughness. On the other hand, with the gradual increase of the growth period of moso bamboo, the energy shows a gradually increasing trend. The above-mentioned data conclude that the M has strong impact resistance in practical application sites; moreover, the M of 4-year-old moso bamboo exhibited deformation without damage after being impacted under the equivalent impact load.

Figure 3: Schematic illustration of impact displacement load and energy of bamboo M in different growth periods

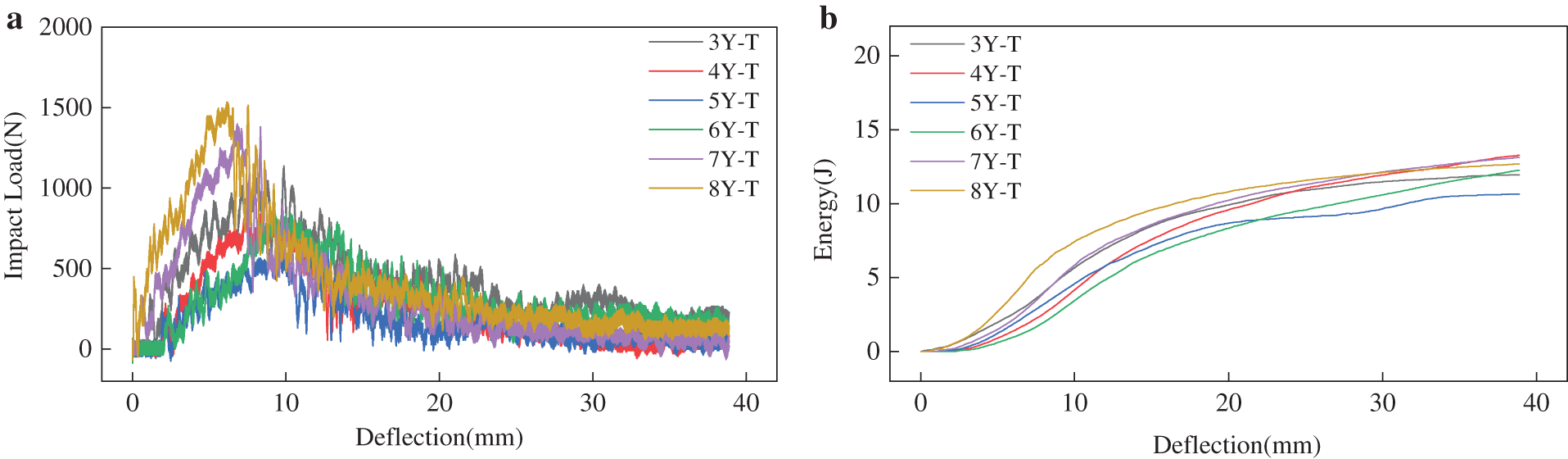

In general, the impact load of the T with different growth periods is lower than those of B and M. From large to small, T of 7–8 years old moso bamboo are more than 3 years, more than 4 years, and more than 5–6 years old, respectively (Fig. 4). The FE showed a trend of first decreasing and then increasing with the extension of the growth period. The FE of the 3-year-old T was better than that of the 4- and 6-year-old T within the ID range of 20 mm. The above-mentioned phenomenon suggest that the selection of T should be within the range of 7–8 growth period as far as possible, and the performance of bamboo T with 3-year growth period in terms of flexibility was found to be excellent.

Figure 4: Schematic illustration of impact displacement load and energy of bamboo T in different growth stages

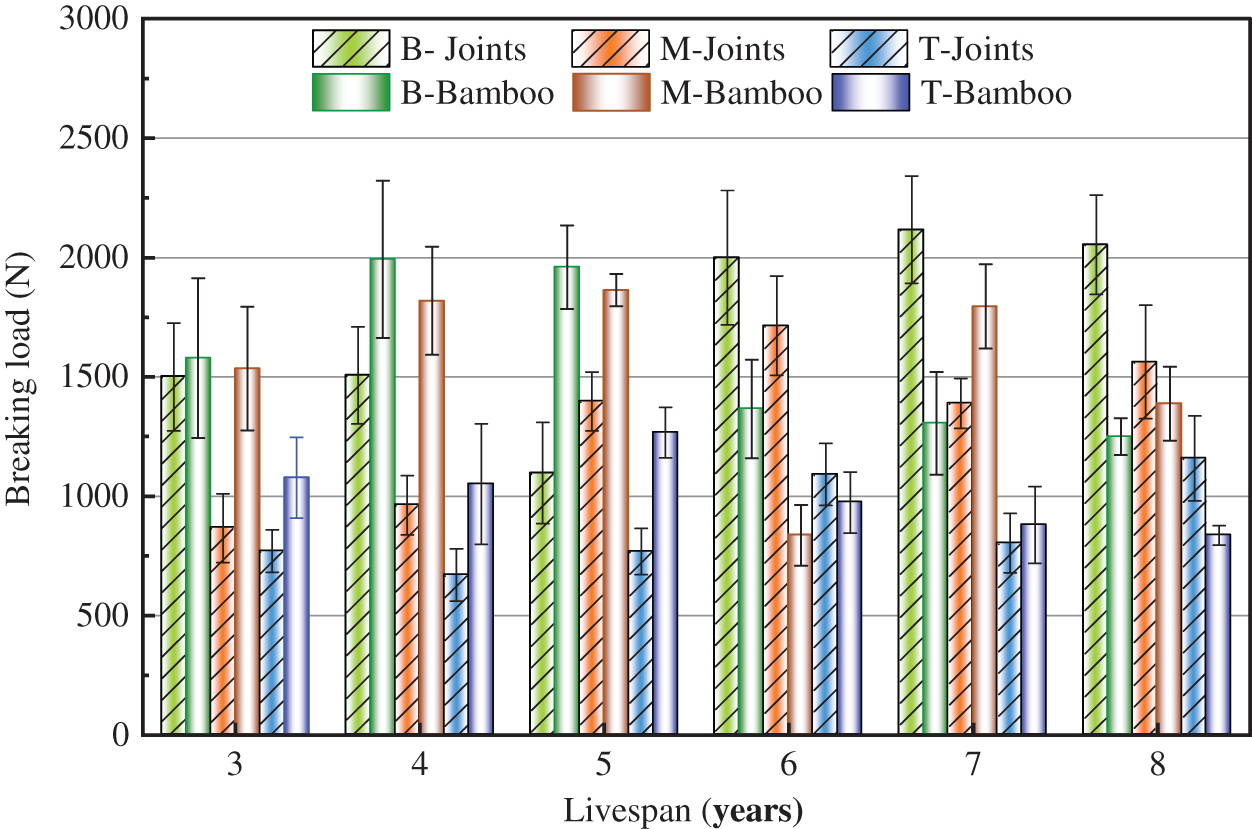

The age (1, 3, 5) of moso bamboo was positively correlated with the flexural strength and parallel-to-grain compressive strength and the mechanical strength increased with the increase in its age [19]. In general, with the increase of growth cycle, the damage load of moso bamboo chips to resist external impact first increases and then decreases slowly. The BL of the two types of specimens showed different trends with the increase of the growth period as a whole. Notably, variation in the diameter of the bamboo does not affect its responses to impact [20]. However, the responses of bamboo to the effects of bending impact performance at different growth stages and locations have rarely been addressed till date. The BL of bamboo (without node) in all parts showed a trend of first increasing and then decreasing significantly, and the changing trends of the BL of the bamboo specimens in the three parts were slightly different and the variability was relatively large. In other words, the B part shows a trend of first decreasing and then increasing, ranging from 1097 to 2117 N. The M shows a trend of first increasing and then slowly decreasing, and the BL trend of the T of bamboo is the lowest, showing a fluctuating trend (Fig. 5). The extraordinary mechanical properties of bamboo are mainly derived from its fiber components. According to the literature, in moso bamboo the tensile modulus and strength of fibers vary slightly across samples ranging from 0.5 to 4 years in age [21], and fiber mechanical strength exhibits a significant contribution to the flexural impact strength of bamboo. Although the absolute values change minimally with age, the effect of bamboo age on tensile strength is significant. Undeniably, a lot more systematic explorations are further demanded to determine whether these flexural shocks reaching a stable, near-optimal state at a young age (four ages) could have important implications for expanding the commercial application of these types of fibers.

Figure 5: Impact BL of moso bamboo in different growth periods

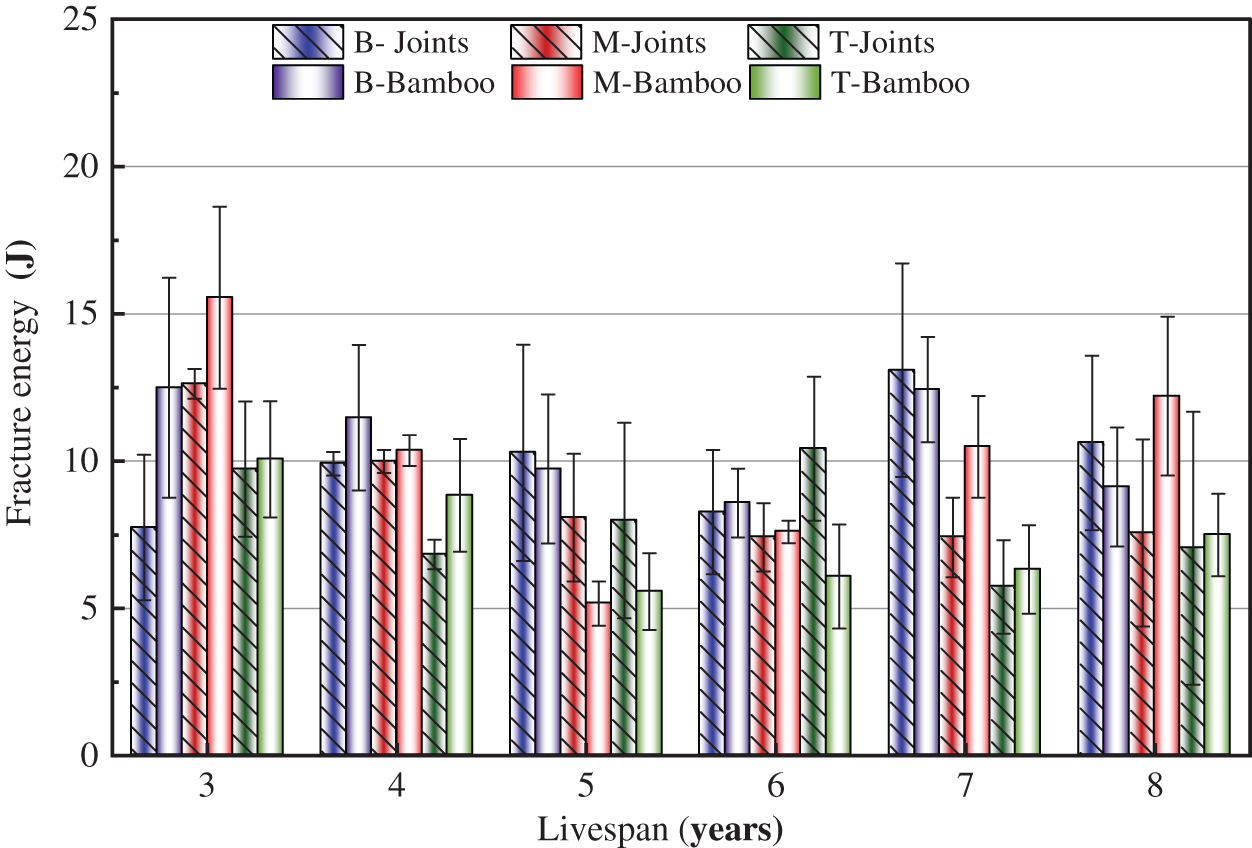

It can be seen from Fig. 6 that FE reflects the energy that the bamboo specimen needs to absorb when it is impacted by external force, and the stronger the toughness, the higher the impact energy. On the whole, in general, the FE of the T is lower than those of the B and M of bamboo specimens. The interlaminar FE of bamboo showed a trend of first decreasing and then increasing with the increase in the growth period, and that of B decreased to the lowest value of 8.57 J in the 6-year growth period. In the 5-year growth period, the values for the M and T dropped to a minimum of 5.17 and 5.57 J, respectively. The FE of the M exhibited a decreasing trend with the increase of the growth period (12.62–7.41 J), and coefficient of variation of FE of the B and T was relatively large.

Figure 6: Impact FE of moso bamboo in different growth periods

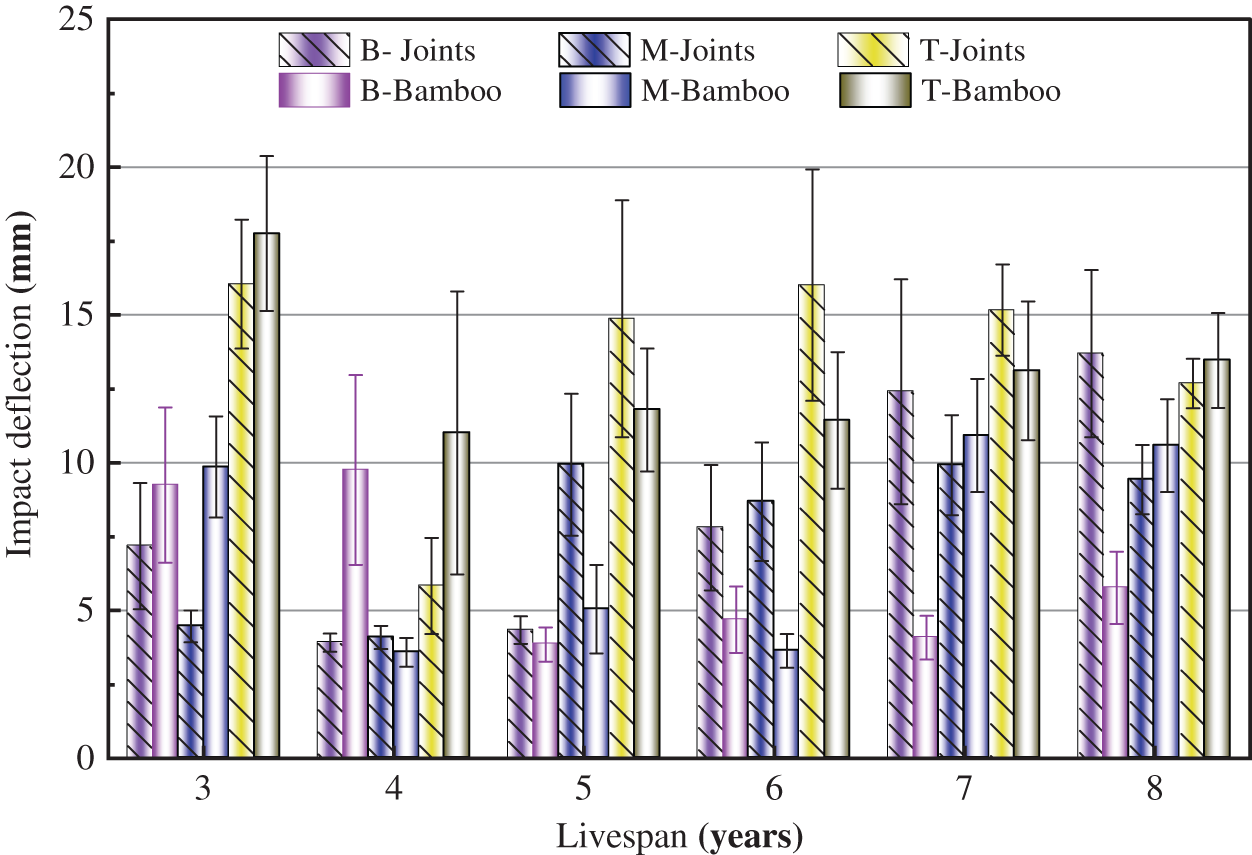

ID refers to the degree of bending deformation of the specimen when it is subjected to external force, which is measured by the distance from the center of each cross-section to the original axis after the specimen is bent. Age is an important factor dictating mechanical properties of bamboo [22]. The ID of bamboo joints in different growth periods is generally larger than that in bamboo interlayers, and the coefficient of variation is larger. This may be attributed to the presence of transverse vascular bundles at the bamboo joints of moso bamboo, and the force angle between the transverse vascular bundle and the falling weight is less than 90° during the impact of external force, thus the ID is generally greater than that of bamboo interlayers with only longitudinal vascular bundles. In general, the ID of the T is greater than those of the M and the B. The ID of B and the M exhibited a trend of first decreasing and then increasing with the increase of growth period (Fig. 7). In contrast, the T interlayer showed a trend of first decreasing and then fluctuating; and the ID value of 4-year-old bamboo joint was the lowest. The application in areas with high incidence of earthquake-prone can play a maximum protective role. Bamboo is a fast-growing plant, thus the most of it can be used in construction at the age of 4. According to the literature, the increase in the layer of parenchymal cells of bamboo continues for 3–5 years, as assessed by microscopic observation [23]. The contribution of the growth of parenchymal cells to the bending shock cannot be underestimated. With the increase in the age, the diameter of bamboo gradually increases. The variation in the diameter of the bamboo does not significantly affect the responses to impact, as revealed by ANOVA (P-value ≤ 0.05); and total deflection varies [20].

Figure 7: Impact ID of bamboo in different growth periods

3.2 The Effect of Cellulose Crystallinity in Bamboo Growth Period and Extraction Site on Bending Impact Properties

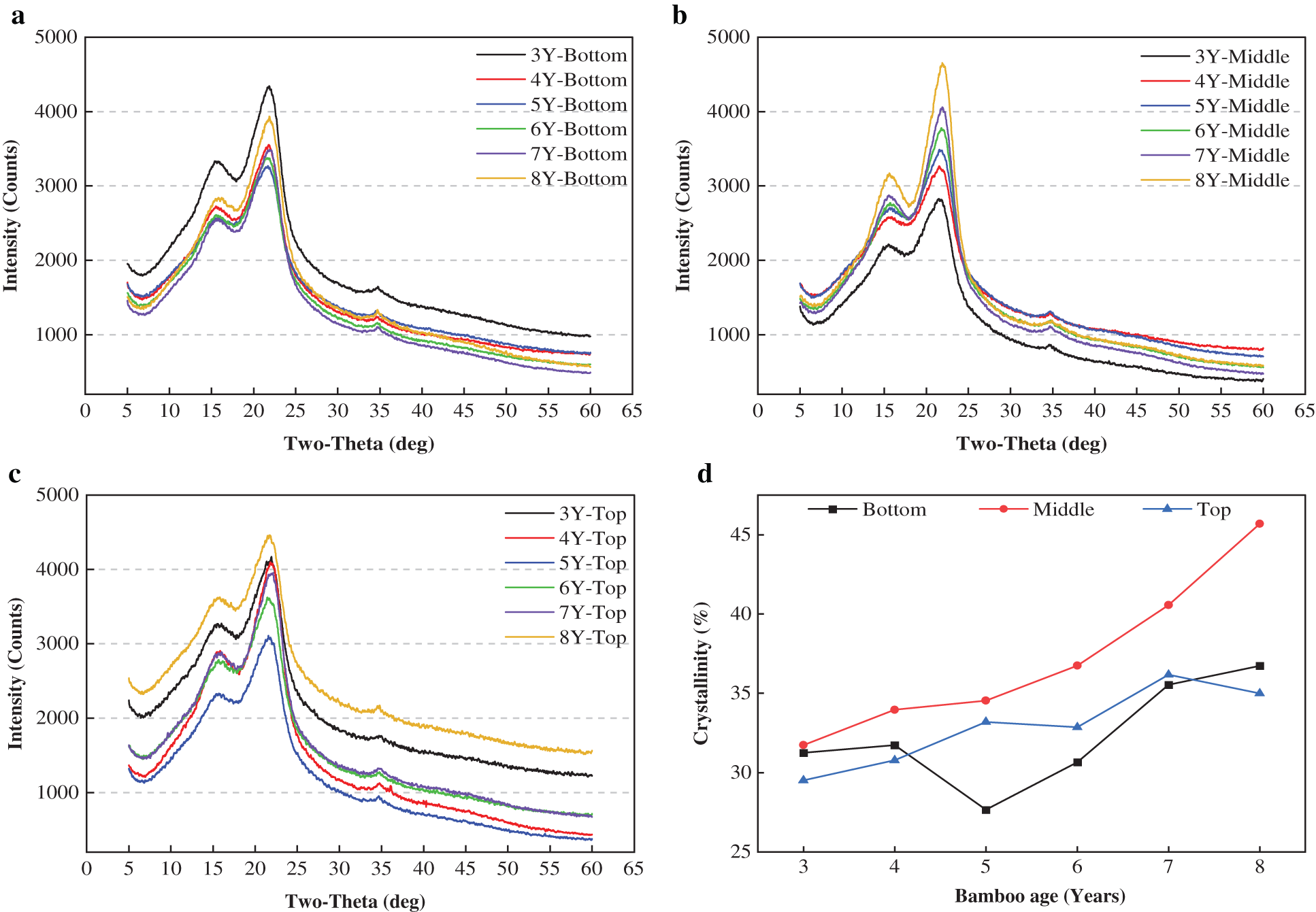

The degree of crystallinity of bamboo cellulose refers to the percentage of the crystalline area of cellulose in the entire cellulose content, which reflects the degree of crystallization when cellulose gets aggregated. Okahisa et al. [22] suggested that the age-dependent changes in the microfibril angles possibly affect these mechanical changes. In general, with the increase in the crystallinity of cellulose, the tensile strength of the fiber increases. Wang et al. [24] found that the angle and crystallinity of cellulose microfibrils of 4-year-old bamboo increased from the inside to the outside in the radial direction of the bamboo stem. This part reveals the changing trend of the crystallinity of bamboo cellulose at different bamboo ages (3–8 years) and in different parts (B, M, and T) (Figs. 8a–8c) and its influence on the bending performance of drop impact. B on the analysis of the physical properties (crystallinity) of the material itself, the impact on the mechanical properties of moso bamboo could be determined. The results show that all samples showed crystals near the 2θ angle maximum peak of surface diffraction. Calculation of crystallinity of moso bamboo in different growth stages was carried out by Segal method. Herein, it was found that the crystallinity of cellulose in the B, M, and T was quite different, and the overall performance indicates that the crystallinity of the M was greater than those of the B and T. The crystallinity of cellulose in the M and B of moso bamboo increased gradually with the extension of the growth period (Fig. 8c). Echoing the previous conclusion, the impact BL of M increases gradually with the increase of crystallinity. In contrast, the T crystallinity of the mature bamboo increased, then decreased, and then finally increased in the over-mature stage and then trend of the crystallinity of the T is similar to the FE. With the prolonging of bamboo growth period, along with the growth and development of cells, the change rule of the absorption peak intensity at 2θ angle is that the crystallinity of the B and T first decreases and then increases with the increase of bamboo age [25], which is minimum at the fifth year. The M shows a gradually increasing trend. According to the existing data, the impact FE of the B and T of the bamboo and the BL in the M are positively correlated with the change trend of the 2θ angle absorption peak, respectively. The above-mentioned discussion thus concludes that the cellulose crystallinity of the M of high bamboo age (7–8 years) is positively correlated to the bending impact mechanics. The cellulose crystallinity of the 4-year-old B and T is at a high level, showing good flexibility in bending mechanical strength. However, owing to the large coefficient of variation of the T, more sample data are required to verify the reliability of the conclusion.

Figure 8: Absorption peak intensity at 2θ angle and Cellulose crystallinity of moso bamboo in different growth periods

The Segal method was used to measure the crystallinity of bamboo cellulose. The results show that with prolonging livespan, the cellulose crystallinity of moso bamboo exhibited a gradually increasing trend as a whole. The figure illustrates that the cellulose crystallinity of the B and T is lower than that of the M, except that the cellulose crystallinity of the 5–6-year-old B is lower than that of the T, and the FE of the B in this growth period is at a low level.

3.3 Correlation Analysis between Chemical Composition and Impact Mechanical Properties of Moso Bamboo

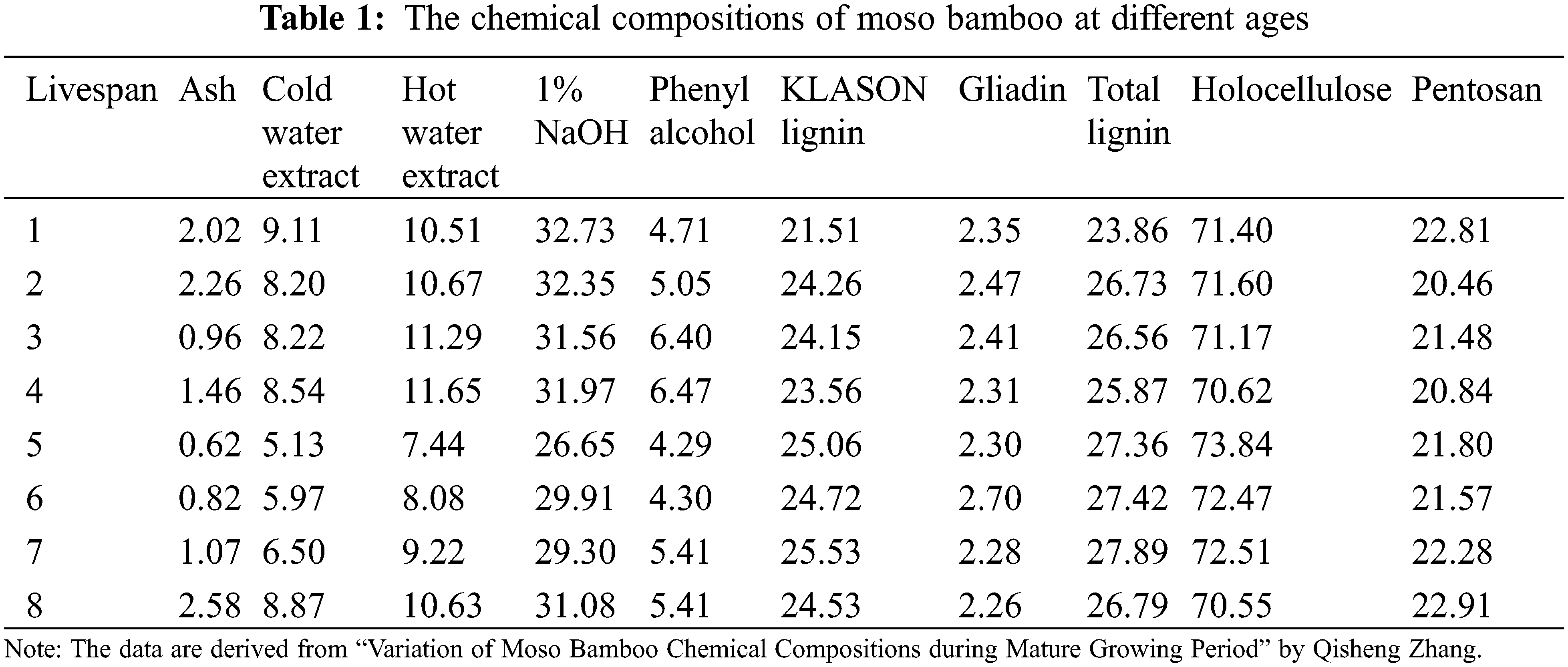

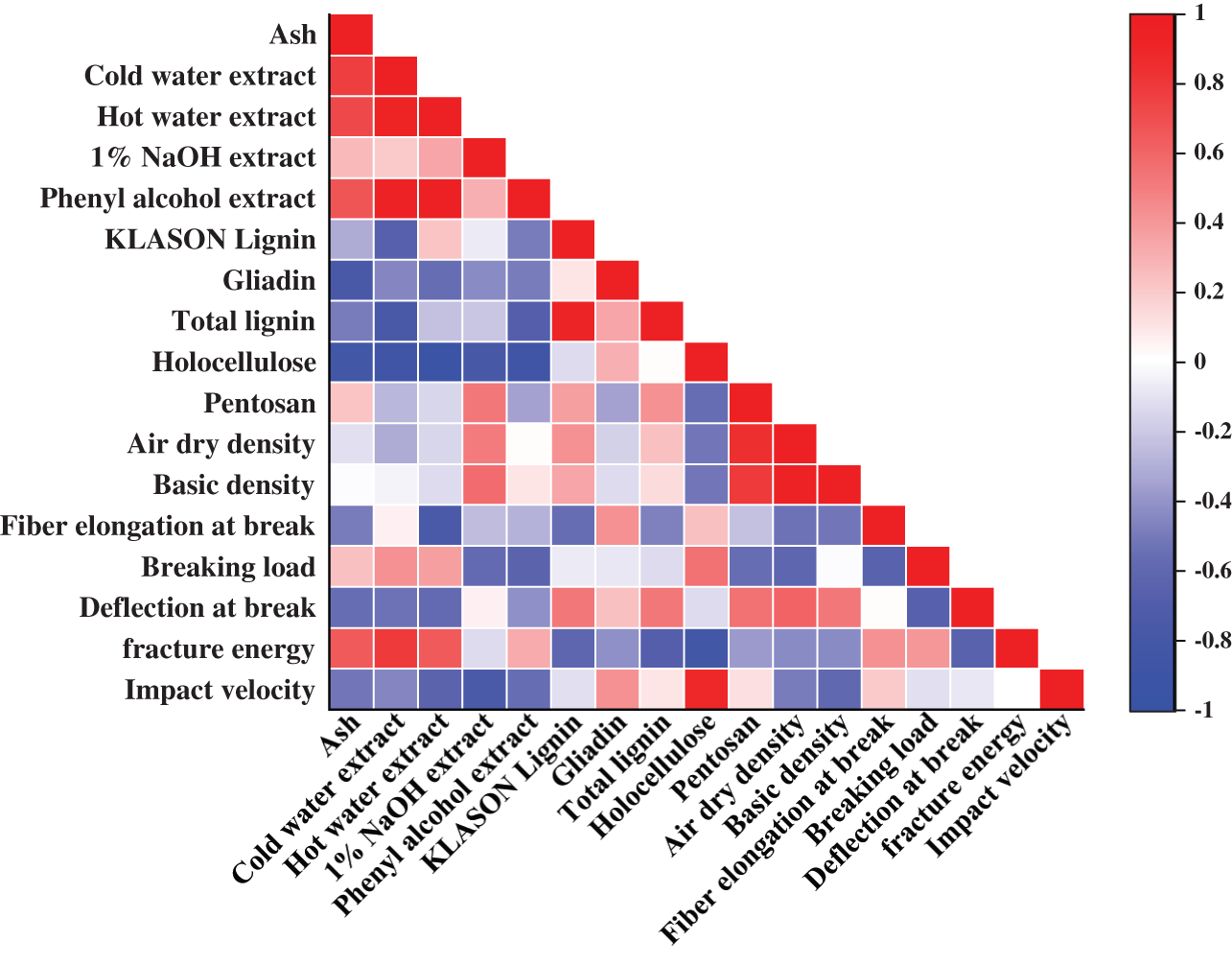

The chemical composition of moso bamboo showed different trends with the increase of growth period. Zhang et al. provided the content of chemical constituents of moso bamboo in different growth stages and different parts, and the corresponding results are presented in Tables 1 and 2. In Table 1, we find that Ash, cold and holt water extracts, and 1% NaOH extract showed a trend of first decreasing and then increasing with the extension of growth period. The lignin content increased gradually with the extension of the growth period. Holocellulose, pentosan, and phenyl alcohol extracts ranged within 2%. It can be seen from Table 2 that the lignin, total cellulose and pentosan of 4-year-old bamboo and 7-year-old bamboo have little change with the change of bamboo culm height, while the percentage content of these high molecular weight substances is basically unchanged. It shows that the macromolecules of bamboo poles are evenly distributed. The ash content of bamboo and the percentage content of the four kinds of extracts showed a trend of decreasing gradually from the root to the tip with the increase of the bamboo culm. At the same time, the relevant literature was also checked to confirm the reliability of the variation trend of the chemical composition data of moso bamboo in different growth periods. It was found that the content of lignin and pentosan increased year by year with the extension of growth period [26,27]. Lignin contents increased with an increase in bamboo age from one to five years, while the xylan content decreased [28]. Thus, a clear age dependence was observed in the yield of thioacidolysis products derived from β-O-4 lignin structures, and 3.5-year-old bamboo exhibits the highest content of sulfuric acid hydrolysate [29]. The ash content of moso bamboo within 5 years showed a decreasing trend, while the ash content of bamboos older than 5 years increased with the increase of bamboo age [30]. The holocellulose content of 5–7 years old bamboo was at a high level, the content of cold and hot water extracts was at a low level, and the four extracts (cold water extract, hot water extract, 1% NaOH extract, and percentage content of phenyl alcohol extract) showed a decreasing trend from the B to the T [8].

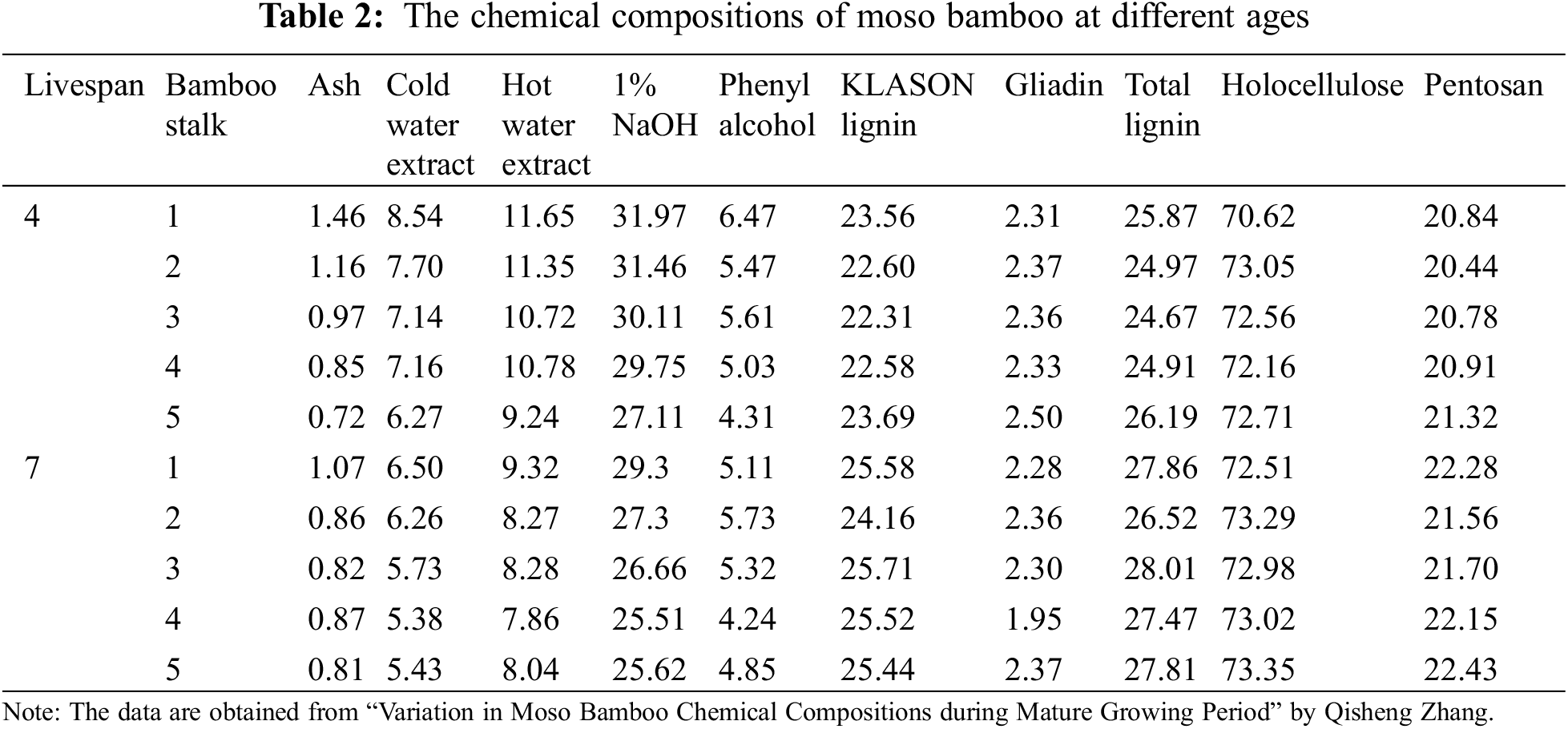

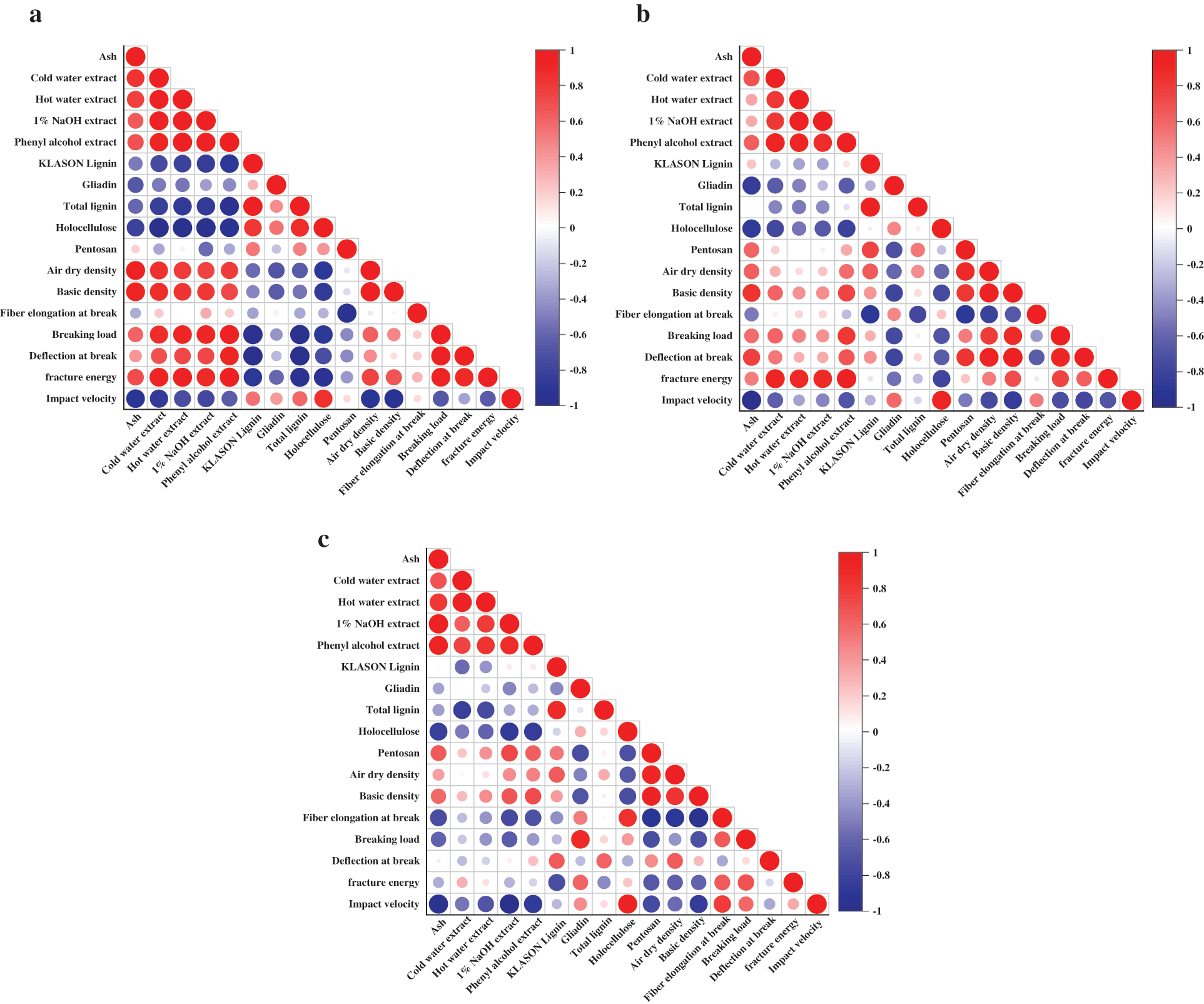

Bamboo density of the entire culm and the thickness of the cell wall also affect the mechanical properties of bamboo, and the variation in mechanical properties in bamboo may also be affected by some changes in lignin quality [31]. Nelson et al. [32] found that although direct correlations are observed between fiber volume and strength and stiffness, it is still unclear if these relationships hold independently from treatment type. The conclusions of this study show that the impact velocity is only positively correlated with alcohol-soluble lignin and holocellulose, not correlated at all with the total lignin content, and exhibits different degrees of negative correlation with other chemical components. The BL and FE of bamboo stripe are positively correlated with ash, cold, and hot water extracts and phenyl alcohol extracts, and are weakly negatively correlated with 1% NaOH extracts and three types of lignin. Moreover, BL and FE is significantly negatively with holocellulose, pentosan, air-dry density, and basic density. Noteworthy, the ID is inversely correlated with the above-mentioned indicators (Fig. 9). It is well known that the density of cortex side of bamboo is greater than that of pith bamboo. Bamboo gradient structure creates special flexural impact properties. Chen et al. [33] found that the inner (bamboo yellow) part of bamboo showed higher flexural ductility than the outer (bamboo green) part. The graded application of lightweight and high-strength raw materials may improve impact resistance. Therefore, the performance between the original bamboo and the bamboo-based composite material has its own advantages. On the other hand, the impact fracture fiber length of bamboo stripe exhibits a significant positive correlation with alcohol-soluble lignin and holocellulose, and shows a negative correlation with other chemical components and impact mechanical properties to varying degrees.

Figure 9: Correlation between chemical composition and impact mechanical properties of moso bamboo in different growth periods

For the further analysis of the relationship between chemical composition and impact mechanical properties of different parts of moso bamboo in different growth stages, herein, the bamboo materials in different growth stages were taken according to their parts (B, M, and T), and the correlation between their chemical composition and the mechanical properties under falling hammer impact was systematically analyzed, respectively (Figs. 10a–10c). In general, the correlations of the bamboo sheets in the three parts exhibit similar changing rules, and the significance level gradually decreases with the increase of the sampling parts, which may be related to the objective phenomenon that the coefficient of variation of the impact mechanical parameters of T is large. The correlation between the length of broken fibers and the ID of bamboo in different bamboo stalk gradually changed from positive to negative with the height of the sampling location increase. Noteworthy, the ash content and extractive yield of moso bamboo in different growth periods exhibit a very significant positive correlation with BL, ID, and FE. The extract content of the B shows a certain degree of contribution to its impact mechanical properties. Furthermore, the contribution rate gradually decreases with the increase of the bamboo culm height, and it is negatively correlated to the T. Importantly, impact velocity was not affected by the height of the bamboo culm, and impact mechanics were significantly negatively correlated with the ash content and the extraction rate. Noteworthy, knowledge about the effects of aging and related chemical composition changes of bamboo on mechanical properties of natural plant materials is valuable for developing new polymeric materials. In summary, Ash, cold, heat, phenyl alcohol extractive contents were significantly different for BL and FE. NaOH extract and three types of lignin content negatively affect BL and FE. ID negatively affects almost all chemical content tested. Alcohol-soluble lignin and total cellulose have positive effects on length of broken fibers. The above correlation degree gradually weakened with the increase of bamboo culm height. In particular, the contribution rate of the content of the four extracts to the impact mechanics gradually decreased.

Figure 10: Correlation between chemical composition and impact mechanical properties of moso bamboo in different parts

3.4 Analysis of Fracture Morphology

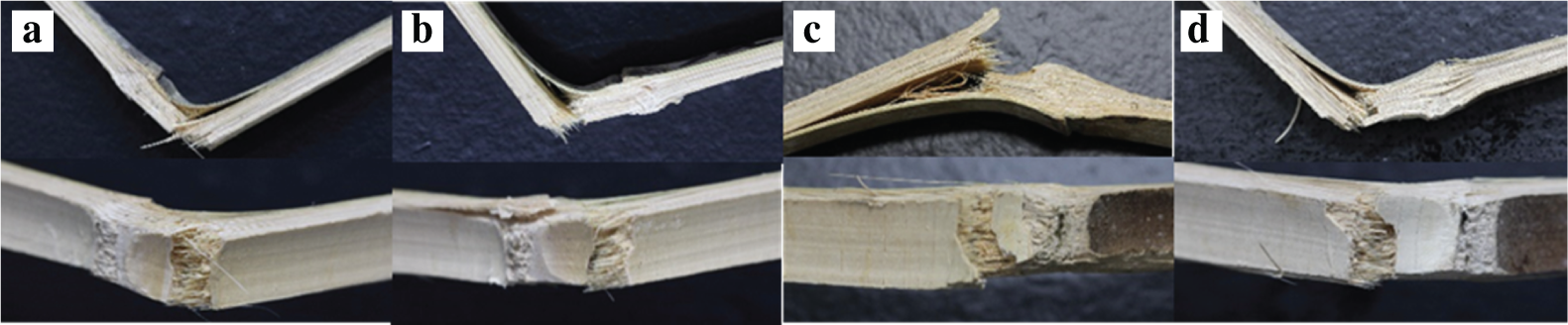

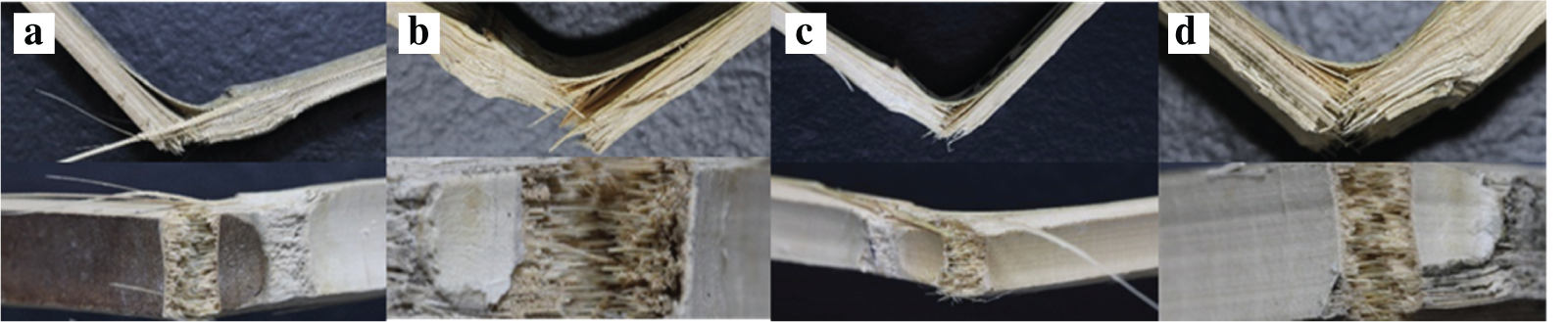

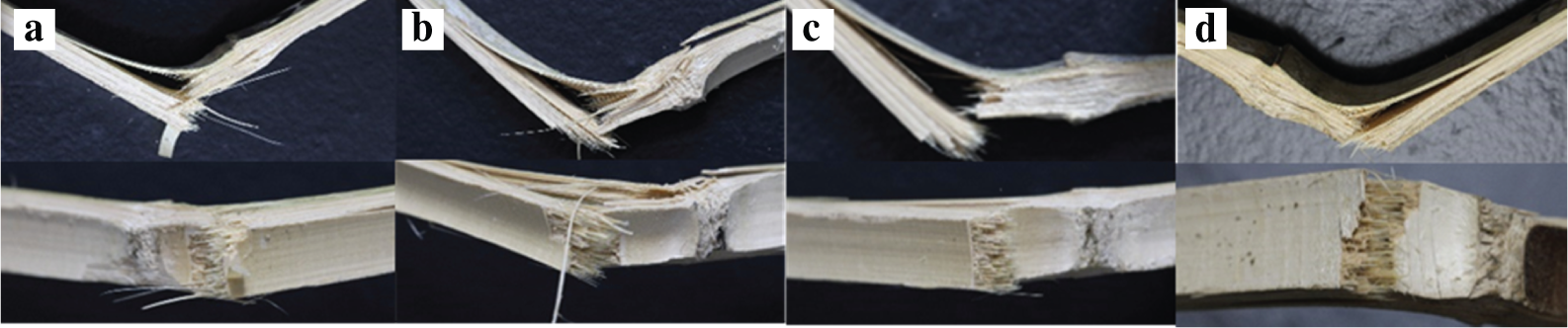

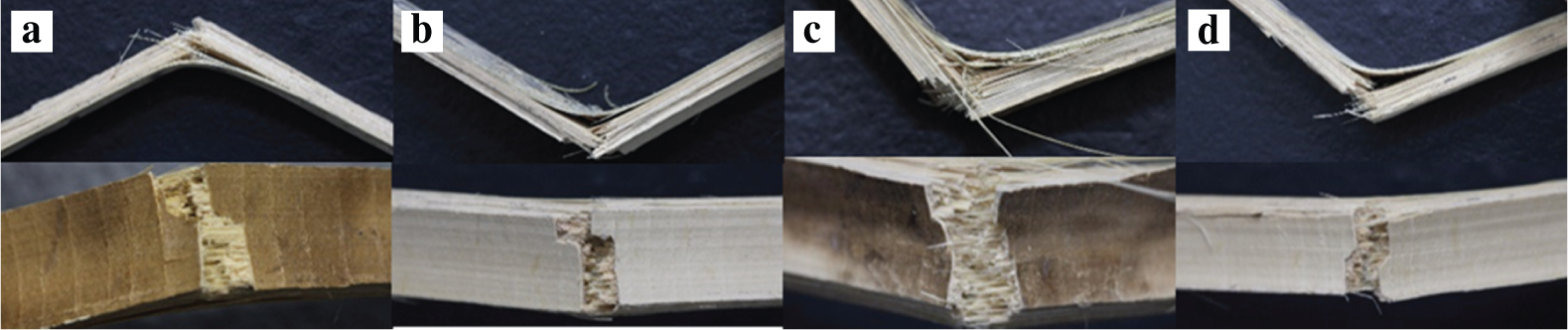

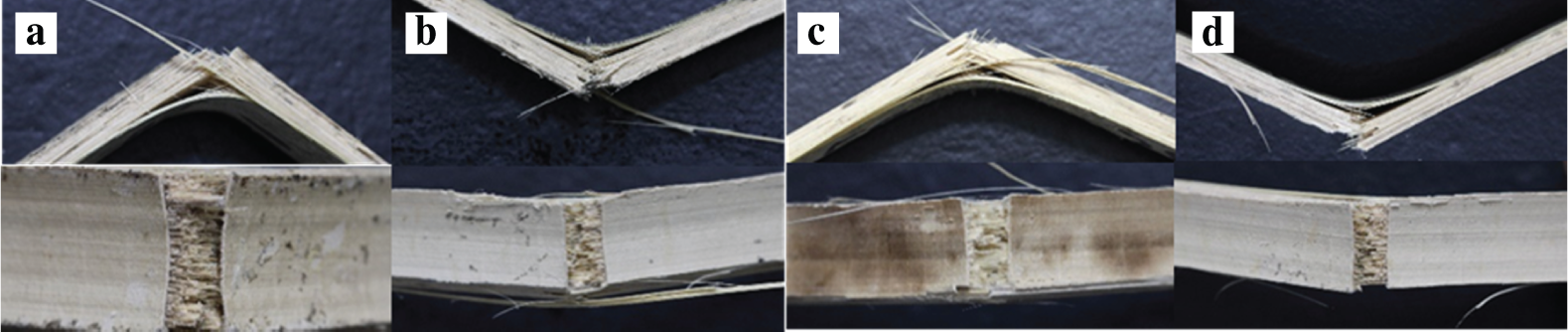

In the direction of the grain of bamboo, parenchyma cells account for about 52%, fibers account for about 40%, and the rest is conductive tissues (ducts, sieve tubes, companion cells). Therefore, bamboo can be regarded as a typical long fiber-reinforced uniaxial composite material in terms of macroscopic mechanical behavior [17,34]. Impact toughness of bamboo refers to the ability of moso bamboo to absorb energy during elastic deformation, plastic deformation, and fracture. Moso bamboo with high toughness does not suddenly undergo brittle fracture under the action of impact force. Obataya et al. [35] observed that the excellent flexural properties of bamboo were attributed to the perfect combination of fiber and parenchyma cells. Chen et al. [12,14] found that natural bamboo node samples that bent from two opposite radial directions displayed asymmetric flexural fracture process and behaviors. Three types of fracture behaviors, namely, parenchyma cells failure, fiber dissociation, and fiber breakage, are observed within bamboo node during the deformation and fracture process. Studies on fracture morphology analysis have been extensively carried out, in particular, at the cell wall scale [36]. In this study, the fracture morphology under flexural impact loading was calculated. Different ages and different parts of bamboo lead to different tissue ratios, showing different mechanical properties. The fracture behavior of fibers closer to the interior of bamboo yellow under tension is similar to brittle fracture; in contrast, the fracture behavior of fibers closer to the outside is similar to ductile fracture [24]. Under the action of falling hammer impact load, bamboo damage has time short, speed fast, stress-concentrated characteristics (Fig. 11). Under the action of the external impact force of the dropped hammer, the fracture morphology of the bamboo pieces resisting the impact force was different. On the whole, all the fracture surfaces of the specimens exhibited the phenomenon of fiber pullout and exposure, which reflected the excellent impact resistance performance of moso bamboo. According to the impact test of a large number of (2500) specimens, the fracture morphology of specimens with bamboo joints could be divided into unilateral cracking and uneven fracture at the impact point (Fig. 12). The impact point was unilateral delaminated cracking to level the fracture (Fig. 13), it was unilateral delaminated tearing with local convex fracture, and it was unilateral delamination tearing and local convex fracture (Fig. 14). The fracture morphology of the specimen without bamboo node could be divided into the impact point one-sided tearing “Z” type convex fracture on the green bamboo surface (Fig. 15), cracking on both sides of the bamboo cortex surface at the impact point “I” type smooth fracture (Fig. 16).

Figure 11: Schematic representation of drop weight impact mechanical test

Figure 12: Unilateral crack at the impact point and uneven fracture

Figure 13: Unilateral layered cracking at the impact point to level the fracture

Figure 14: Local convex fracture of unilateral delamination tear at impact point

Figure 15: One-sided tearing “Z”-shaped convex fracture of bamboo cortex surface at impact point

Figure 16: “I”-shaped flat fracture on both sides of the bamboo cortex surface at the impact point

Among the eight types of fractures, the flat and uneven fracture types of delaminated cracking mostly occur in the T. Notably, the specific manifestation is that the fracture surface on the bamboo pith is partially convex after the T is impacted by external force. Importantly, gradient structure leads to stronger fiber flexibility in T. The statistics of the test results show that the BL value of the T of the local convex fracture of the unilateral delamination tear was smaller than that of the linear fracture specimen and the impact resistance was reduced. Among the specimens without bamboo joints, there exist four fracture morphologies of moso bamboo when impacted. Among them, the “I” shape is the most common fracture form of moso bamboo subjected to drop hammer impact, and it is a transition type between flat fracture and inclined fracture. The fracture shows that the brittleness of the bamboo on impact accounts for less than 10%. Moreover, the appearance of more irregular fracture morphology indicates the excellent flexibility of the bamboo.

Research on the impact bamboo stripe tensile properties and failure mechanism of bamboo scrimber is helpful to its wide range of applications for structural materials [37]. Observation of the bamboo cortex indicates that the bamboo node specimens also have longitudinal splitting in addition to the transverse fracture; however, the bamboo interlayer exhibits many cracks. This is attributed to the presence of transverse vascular bundles at the bamboo node of moso bamboo. Under the impact of external force, signs of cracking along the transverse vascular bundles occur from time to time. Moso bamboo exhibits anisotropic characteristics. The impact mechanical strength is relatively weakened with the decrease of vascular bundle content [38,39]. When the specimen is impacted by external force, cracks are easily generated between the strong interface and the rough interface. Owing to the low strength of the interface between the bamboo parenchyma and the vascular bundle, the cracks gradually expand along the two interfaces. The part of the bamboo green surface fell off because the moment the bamboo sheet was impacted by the falling weight, the stress surface did not damage immediately, and the impact energy was transmitted inward, resulting in cracking and shedding between the stress surface and the subsurface. At present, there is no unified judgment standard for the mechanism and interrelationship among various morphologies of bamboo impact-resistant fracture morphology. This study investigates the impact-resistant fracture state of bamboo specimens to provide theoretical impact damage morphology and its principles for the practical processing and application of bamboo materials.

In this study, X-ray diffraction combined with peak-height method was used to characterize the cellulose crystallinity of bamboo. The chemical composition and impact mechanical properties of moso bamboo in different growth periods were systematically analyzed by Spearman correlation method, thereby revealing the changing trends and interrelationships of the two in different longitudinal positions at different growth periods. The obtained results show that with the increase of bamboo age (3–8 years), the BL of moso bamboo generally first increases and then decreases significantly. The cellulose crystallinity of the 4-year-old B and T material is at a high level, showing that it has good flexibility in bending mechanical strength.

The BL and FE of bamboo stripe are positively correlated with ash, cold and hot water extracts, and phenyl alcohol extracts, and significantly negatively correlated with holocellulose, pentosan, air-dry density, and basic density. The length of broken fiber is positively correlated with alcohol-soluble lignin and holocellulose, and negatively correlated with almost all chemical composition to varying degrees. With the change of bamboo culm height, the significance of the correlation between the impact mechanical properties and its chemical composition gradually weaken. Undeniably, this study has many limitations as well. For example, the influence of moso bamboo in different regions on the crosstalk of the overall correlation between chemical components and impact mechanics is not considered, and the climatic conditions of the research object correspond to only particular location; i.e., Jian’ou, Fujian. The effect of conditions on material properties may vary, which will be systematically explored in the future studies, and will be combined with static bending strength or other physical and mechanical properties to provide a more comprehensive theoretical basis and data support for bamboo harvesting time and application. Importantly, this study provides theoretical basis and data support for the application of bamboo materials in the downstream market, helps maximize the carbon sequestration potential of bamboo forests, and provides important ideas for balancing ecological and material values.

Acknowledgement: The authors gratefully acknowledge financial support from the Fundamental Research on Impact Toughness and Response Mechanism of Bamboo-Woven Structural Materials Funded of International Center for Bamboo and Rattan (1632020016).

Funding Statement: Fundamental Research on Impact Toughness and Response Mechanism of Bamboo-woven Structural Materials Funded of International Center for Bamboo and Rattan (1632020016).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Liese, W. (1987). Research on bamboo. Wood Science and Technology, 21(3), 189–209. DOI 10.1007/BF00351391. [Google Scholar] [CrossRef]

2. Suthon, S. (2018). Potential of three sympodial bamboo species naturally growing in Thailand for structural application. European Journal of Wood and Wood Products, 76(2), 643–653. DOI 10.1007/s00107-017-1218-3. [Google Scholar] [CrossRef]

3. Nkeuwa, W. N., Zhang, J., Semple, K. E., Chen, M. L., Xia, Y. L. et al. (2022). Bamboo-based composites: A review on fundamentals and processes of bamboo bonding. Composites Part B: Engineering, 235, 109776. DOI 10.1016/j.compositesb.2022.109776. [Google Scholar] [CrossRef]

4. Nugroho N., Ando N. (2001). Development of structural composite products made from bamboo II: Fundamental properties of laminated bamboo lumber. Journal of Wood Science, 47(3), 237–242. DOI 10.1007/BF01171228. [Google Scholar] [CrossRef]

5. Anwar, U. M. K., Paridah, M. T., Hamdan, H., Zaidon, A., Hanim, A. R. et al. (2012). Adhesion and bonding properties of low molecular weight phenol formaldehyde-treated-treated plybamboo. Journal of Tropical Forest Science, 24(3), 379–386. [Google Scholar]

6. Semple, K. E., Zhang, P. K., Smith, G. D. (2015). Hybrid oriented strand boards made from Moso bamboo (Phyllostachys pubescens Mazel) and Aspen (Populus tremuloides Michx.Species-separated three-layer boards. European Journal of Wood and Wood Products, 73(4), 527–536. DOI 10.1007/s00107-015-0914-0. [Google Scholar] [CrossRef]

7. Jiang, Z. H. (2002). World bamboo and rattan. China: Liaoning Science and Technology Press. [Google Scholar]

8. Zhang, Q. S., Guan, M. J., Ji, W. L. (2002). Variation of moso bamboo chemical compositions during mature growing period. Journal of Nanjing Forestry University(Natural Sciences), (2), 7–10 (in Chinese). [Google Scholar]

9. Mo, X. F., Guan, M. J., Zhu, Y. X., Mo, C. Z. (2010). Fracture pattern and toughness of maso bamboo. Journal of Forestry Engineering, 24(1), 45–47 (in Chinese). [Google Scholar]

10. Wang, X. Q., Li, X. Z., Ren, H. Q. (2010). Variation of microfibril angle and density in moso bamboo (Phyllostachys pubescens). Journal of Tropical Forest Science, 22(1), 88–96. [Google Scholar]

11. Wang, X. Y., Luo, X. Y., Ren, H. Q., Zhong, Y. (2022). Bending failure mechanism of bamboo scrimber. Construction and Building Materials, 326, 126892. DOI 10.1016/j.conbuildmat.2022.126892. [Google Scholar] [CrossRef]

12. Chen, G. W., Luo, H. Y. (2020). Effects of node with discontinuous hierarchical fibers on the tensile fracture behaviors of natural bamboo. Sustainable Materials and Technologies, 26, e00228. DOI 10.1016/j.susmat.2020.e00228. [Google Scholar] [CrossRef]

13. Kou Y. F., Tian L. M., Jin B. B. (2022). Axial compressive behavior of bamboo slices twining tube-confined concrete. European Journal of Wood and Wood Products, 80(1), 115–129. DOI 10.1007/s00107-021-01737-8. [Google Scholar] [CrossRef]

14. Chen, G. W., Luo, H. Y. (2021). Asymmetric flexural process and fracture behaviors of natural bamboo node with gradient discontinuous fibers. Composites Communications, 24, 100647. DOI 10.1016/j.coco.2021.100647. [Google Scholar] [CrossRef]

15. Lutterotti, L., Bortolotti, M., Ischia, G., Lonardelli, I., Wenk, H. R. (2007). Rietveld texture analysis from diffraction images. Zeitschrift Fur Kristallographie, 2007(suppl_26), 125–130. DOI 10.1524/zksu.2007.2007.suppl_26.125. [Google Scholar] [CrossRef]

16. Qiu, Z., Wang, J., Fan, H. (2021). Low velocity flexural impact behaviors of bamboo fiber reinforced composite beams. Polymer Testing, 94, 107047. DOI 10.1016/j.polymertesting.2020.107047. [Google Scholar] [CrossRef]

17. Liese, W., Bortolotti, M., Ischia, G., Lonardelli, I., Wenk, H. et al. (1998). The anatomy of bamboo culms. USA: International Network for Bamboo and Rattan. [Google Scholar]

18. Tong, C. Z., Zhang, X., Xie, J. B., Mei, T. T., Fang, D. M. et al. (2021). Water use strategies of different aged moso bamboo culms under summer drought. Forest Ecology and Management, 498, 119567. DOI 10.1016/j.foreco.2021.119567. [Google Scholar] [CrossRef]

19. Han, G., Li, R. R., Wang, C. (2021). Effects of three-layer structure and age on mechanical properties of moso bamboo. BioResources, 16(2), 2406–2415. DOI 10.15376/biores.16.2.2406-2415. [Google Scholar] [CrossRef]

20. Oliveira, L., Luiz, M., Tonatto, P., Luiza, G., Scarpa, F. (2021). Experimental and numerical assessment of sustainable bamboo core sandwich panels under low-velocity impact. Construction and Building Materials, 292, 123437. DOI 10.1016/j.conbuildmat.2021.123437. [Google Scholar] [CrossRef]

21. Huang, Y. H., Fei, B. H., Yu, Y., Zhao, R. J. (2012). Plant age effect on mechanical properties of moso bamboo (Phyllostachys heterocycla var. pubescens) single fibers. Wood and Fiber Science, 44(2), 196–201. [Google Scholar]

22. Okahisa, Y., Kojiro, K., Kiryu, T., Oki, T., Furuta, Y. et al. (2018). Nanostructural changes in bamboo cell walls with aging and their possible effects on mechanical properties. Journal of Materials Science, 53(6), 3972–3980. DOI 10.1007/s10853-017-1886-8. [Google Scholar] [CrossRef]

23. Banik, R. L. (2015). Chapter 7: Harvesting techniques. India: Springer International Publishing. [Google Scholar]

24. Wang, F. L., Shao, Z. P. (2020). Study on the variation law of bamboo fibers’ tensile properties and the organization structure on the radial direction of bamboo stem. Industrial Crops and Products, 152, 112521. DOI 10.1016/j.indcrop.2020.112521. [Google Scholar] [CrossRef]

25. Jiang, N. X. (2011). Study on chemical characterization in tissue cell of moso bamboo (phyllostachrs pubescens) at different age (in Chinese). Heilongjiang Province: Harbin, Northeast Forestry University. [Google Scholar]

26. Fei, B. H., Gao, Z. M., Wang, J., Liu, Z. J. (2016). Chapter 14-Biological, anatomical, and chemical characteristics of bamboo. secondary xylem biology, pp. 283–306. Boston: Academic Press. [Google Scholar]

27. Makwarela, M. O., Bada, S. O., Falcon, R. M. S. (2017). Co-firing combustion characteristics of different ages of Bambusa balcooa relative to a high ash coal. Renewable Energy, 105, 656–664. DOI 10.1016/j.renene.2016.12.059. [Google Scholar] [CrossRef]

28. Lu, J. J., Cheng, M. Y., Zhao, C., Shao, Q. J., Hassan, M. (2022). Combined oxidization and liquid ammonia pretreatment of bamboo of various ages and species for maximizing fermentable sugar release. Bioresource Technology, 343, 126085. DOI 10.1016/j.biortech.2021.126085. [Google Scholar] [CrossRef]

29. Okahisa, Y., Kojiro, K., Ashiya, H., Tomita, T., Furuta, Y. et al. (2020). Age-dependent and radial sectional differences in the dynamic viscoelastic properties of bamboo culms and their possible relationship with the lignin structures. Journal of Wood Science, 66(1), 66. DOI 10.1186/s10086-020-01914-y. [Google Scholar] [CrossRef]

30. Wang, H. (2010). Study the mechanism of moisture affecting the bamboo fibre cell walls and macroscopic mechanical behavior (in Chinese). Hunan China: Central South University of Forestry and Technology. [Google Scholar]

31. Kiryu, Y. T., Matsuda, N., Kojiro, K., Furuta, Y. (2017). The mechanism of improvement of physical properties of moso bamboo (Phyllostachys pubescens) with increasing age II. Relationship between dynamic viscoelastic properties and cell wall components. Mokuzai Gakkaishi, 63(1), 14–20. DOI 10.2488/jwrs.63.14. [Google Scholar] [CrossRef]

32. Nelson, J. W., Riddle, T. W. (2022). Comparison of analytical assessment of composite properties utilizing short discontinuous bamboo fibers. Composites Part C: Open Access, 8, 100262. DOI 10.1016/j.jcomc.2022.100262. [Google Scholar] [CrossRef]

33. Chen, M. L., Ye, L. H., Li, H., Wang, G., Chen, Q. et al. (2020). Flexural strength and ductility of moso bamboo. Construction and Building Materials, 246, 118418. DOI 10.1016/j.conbuildmat.2020.118418. [Google Scholar] [CrossRef]

34. Shao, Z. P., Fang, C. H., Tian, G. L. (2009). Mode I interlaminar fracture property of moso bamboo (Phyllostachys pubescens). Wood Science and Technology, 43(5), 527–536. DOI 10.1007/s00226-009-0265-2. [Google Scholar] [CrossRef]

35. Obataya, E., Kitin, P., Yamauchi, H. (2007). Bending characteristics of bamboo (Phyllostachys pubescens) with respect to its fiber-foam composite structure. Wood Science and Technology, 41(5), 385–400. DOI 10.1007/s00226-007-0127-8. [Google Scholar] [CrossRef]

36. Wang, D., Lin, L. Y., Fu, F. (2020). Fracture mechanisms of moso bamboo (Phyllostachys pubescens) under longitudinal tensile loading. Industrial Crops and Products, 153, 112574. DOI 10.1016/j.indcrop.2020.112574. [Google Scholar] [CrossRef]

37. Wang, M. T., Cai, X. F., Lu, Y. B., Noori, A., Chen, F. M. et al. (2021). Tensile mechanical properties and failure mechanism of bamboo scrimber under different strain rates. Construction and Building Materials, 299, 124258. DOI 10.1016/j.conbuildmat.2021.124258. [Google Scholar] [CrossRef]

38. Au, X. J., Yu, Y. (2013). Research progress of bamboo fracture property. World Forestry Research, 26(3), 70–73. [Google Scholar]

39. Liu, H. R. (2010). Study on the properties and mechanism of fracture in bamboo. Beijing, China: Chinese Academy of Forestry. [Google Scholar]