| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2022.022684

REVIEW

Research Progress of Eco-Friendly Portland Cement Porous Concrete: A Review

1College of Water Conservancy and Hydropower Engineering, Hohai University, Nanjing, 210000, China

2College of Mechanics and Materials, Hohai University, Nanjing, 210000, China

3Jiangsu Jiuding Green Concrete Corporation, Yangzhou, 225000, China

4China Three Gorges Corporation, Beijing, 100000, China

*Corresponding Author: Xingwen Guo. Email: xwguo@hhu.edu.cn

Received: 21 March 2022; Accepted: 24 May 2022

Abstract: With the great impetus of energy conservation and emission reduction policies in various countries, the proposal of concepts such as “Sponge City” and “Eco-City”, and the emphasis on restoration and governance of ecological environment day by day, portland cement porous concrete (PCPC), as a novel building material, has attracted more and more attention from scientific researchers and engineers. PCPC possesses the peculiar pore structure, which owns numerous functions like river embankment protection, vegetation greening as well as air-cleaning, and has been of wide application in different engineering fields. This paper reviews the salient properties of PCPC, detailedly expounds the research progress of domestic and foreign literature about this subject in the past ten years (2010–2020), conducts the statistical analysis of the distribution rule of its major properties around the world, combines with the engineering application to summarize the excellent properties of PCPC, and makes a forecast of future research direction.

Keywords: Portland cement porous concrete (PCPC); penetrating quality; mechanical properties; durability; photocatalysis; endothermic function; slope protection with vegetation

With the development of the global economy, as well as resource scarcity and environmental deterioration due to the increasing population, the adverse effect of concrete, an indispensable man-made building material, on the environment cannot be neglected [1]. Thus, researchers often not only focus on the structural properties (Mechanical properties and durability properties) of concrete, but also attach importance to functional research on environmental protection and ecological balance [2]. Protecting the global environment and following the path of sustainable development has become a common concern all over the world. The pavement of conventional concrete brings a lot of convenience and security assurance to mankind, but it will not only generate a great deal of carbon dioxide during the production process, but also impede the natural process of the hydrologic cycle, easily leading to runoff and water contamination [3]. In the meantime, the solar heat absorption of the road will dramatically elevate the temperature of the area [4]. Over the past few decades, various countries in the world have researched and developed many substitutive approaches to ease these environmental issues, especially in water treatment. On this background, concepts such as Sustainable Urban Drainage System (SUDS) as well as rain and sewage diversion have been proposed one after another, and PCPC has emerged as a novel material in the engineering field [5]. As an important material basis for sponge city, PCPC has good water permeability, which can effectively relieve the flood discharge pressure of urban drainage system, and at the same time reduce groundwater, and alleviate geological disasters such as geological subsidence and surface collapse caused by groundwater overmining. PCPC can not only meet the requirements of human activities for the use of hardened ground, but also has the same ecological advantages as natural lawn and soil ground, reflecting the concept of sustainable development of symbiosis with the environment.

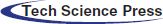

In terms of composition materials, PCPC, similar to normal concrete, is also made up of aggregates, cement, water, admixtures, and additives; from the view of bonding, it consists of a thin layer of cement mortar wrapped around the surface of the coarse aggregate, which cements the coarse aggregate together [6]. Due to the splendid ecological efficiency of PCPC, it is currently principally used in pervious roadbed and slope protection projects to come true functions such as vegetation greening, coexistence of organisms, off-gas absorption, water quality purification, and remission of the urban heat island effect, satisfying the demands of modern green engineering [7]. On account of the above factors, the fundamental purpose of this paper is to review the salient properties and applications of PCPC, including preparation process, penetrating quality, mechanical property, durability, and environmental (heat absorption, air-cleaning, and water quality) characteristics (Fig. 1). Thus, this paper conducts an extensive review and summary of the related research on PCPC in the past ten years and determines the major trend and research orientation for the future development of this field on the strength of scientific statistics, discussion, and analysis.

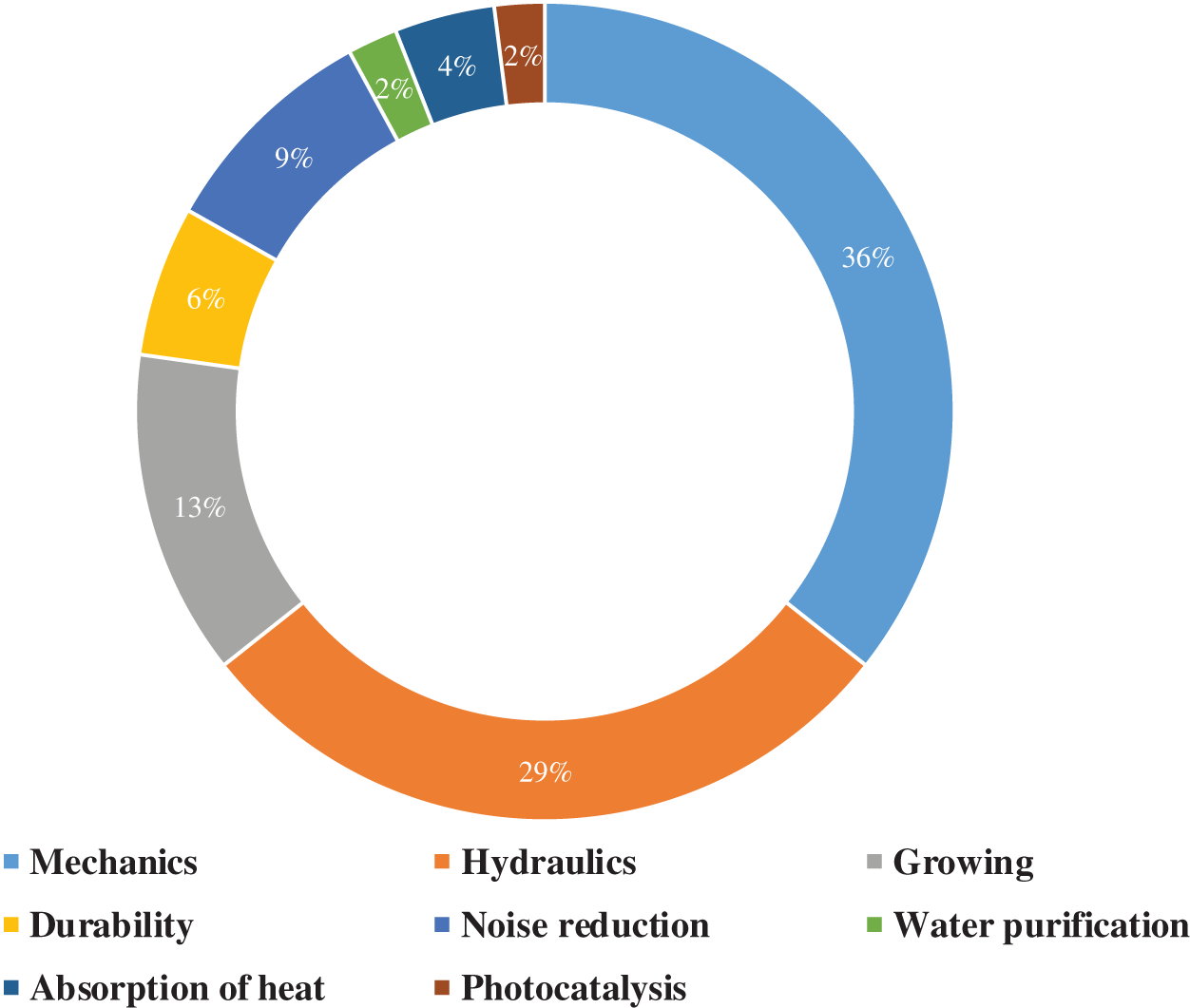

Figure 1: Main functions of PCPC

2 Literature Review and Engineering Application

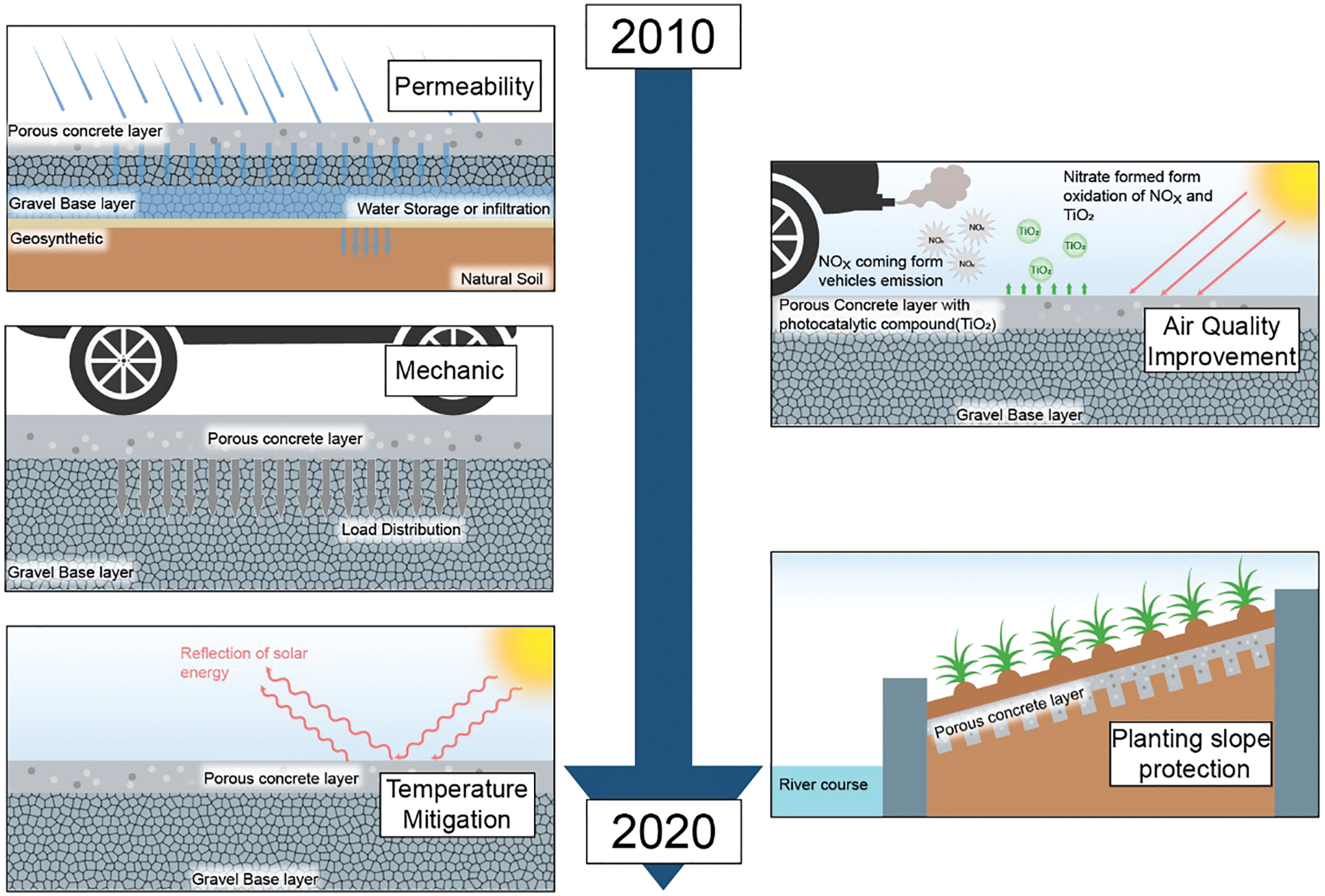

This section collects the primary research on PCPC in the past decade, referring to 14 aspects (Table 1). These properties and functions represent the dominant factors that can be analyzed in the application of PCPC in roadbed and side slope, and are also some of the functional properties that scientific researchers are most interested in in the past decade, including permeability, mechanical property, and environmental effects [8].

Hydraulic property refers to the excellent capacity of PCPC to penetrate or reserve water due to the continuous, interconnected pores [9]. Durability refers to the structural damage of PCPC due to the influence of the external environment during the use in pavement and side slopes. For example, when PCPC is used in slope protection of river embankment, its surface is in the alternation of wetting and drying for a long time as the tide rises and falls, and PCPC is liable to the damage of freezing and thawing cycle [10]. Mechanical properties are chiefly divided into four aspects: compressive strength, tensile strength, bending strength, and fatigue properties. The environmental field mainly contains five aspects, such as photocatalysis and vegetation greening. The proportion of publications is increasing with each passing year, which means that scientific researchers are paying more and more attention to the environmental field. It is also the goal that various countries in the world are struggling for carbon neutrality [11].

All literature achievements in this paper are derived from Scopus database and CNKI database (to avert repetition, Chinese literature is excluded during Scopus database indexing, and only Chinese literature is searched in CNKI database), and the literature from 2010 to 2020 is obtained by searching keywords. A total of 3318 publications were found, of which 2811 are from Scopus database and 507 from CNKI database. The total number of publications applied to the engineering field is 864. From Scopus, the number of publications related to pavement engineering, side slope engineering, and vegetation greening engineering is 517, 49, and 26, respectively. From CNKI, the number of publications related to pavement engineering, side slope engineering, and vegetation greening engineering is 113, 51, and 109, respectively. It is not difficult to find that in the known publications, American and European countries principally use PCPC for pavement permeation, which is what we often call “pervious concrete pavement (PCP)”. However, Southeast Asian countries represented by China chiefly apply PCPC to side slope protection, on this basis, combining with soil matrix and vegetation planting to form “porous vegetation concrete (PVC)” [12]. The formation of this phenomenon is principally caused by the geographic location differences of the two regions: there are many plains in America and Europe, and the population is dense in cities and towns, so the requirements for urban drainage are relatively high; plains in Southeast Asia are relatively few, and the distribution of rivers and lakes is wide, so there are many studies on the slope protection of river embankment [13,14]. The literature in this paper principally synthesizes several characteristic research and seeks the relationship between them. For instance, some literature verifies the relationship between the compressive strength and porosity of PCPC via experiments and set the target porosity to optimize and gain the mix proportion with optimal mechanical properties [15]. In summary, domestic and foreign scholars have done the most research on the mechanical properties, hydraulic characteristics, and corresponding numerical simulations of PCPC in the past decade. To describe PCPC better, this paper divides PCPC into the following three categories in terms of function: PCP; PVC; WPC (water purification concrete). The paper mainly reviews PCP and PVC.

According to the results in the literature review, this section analyzes and discusses the relationship among published countries, corresponding years, and relevant characteristics of publications about PCPC.

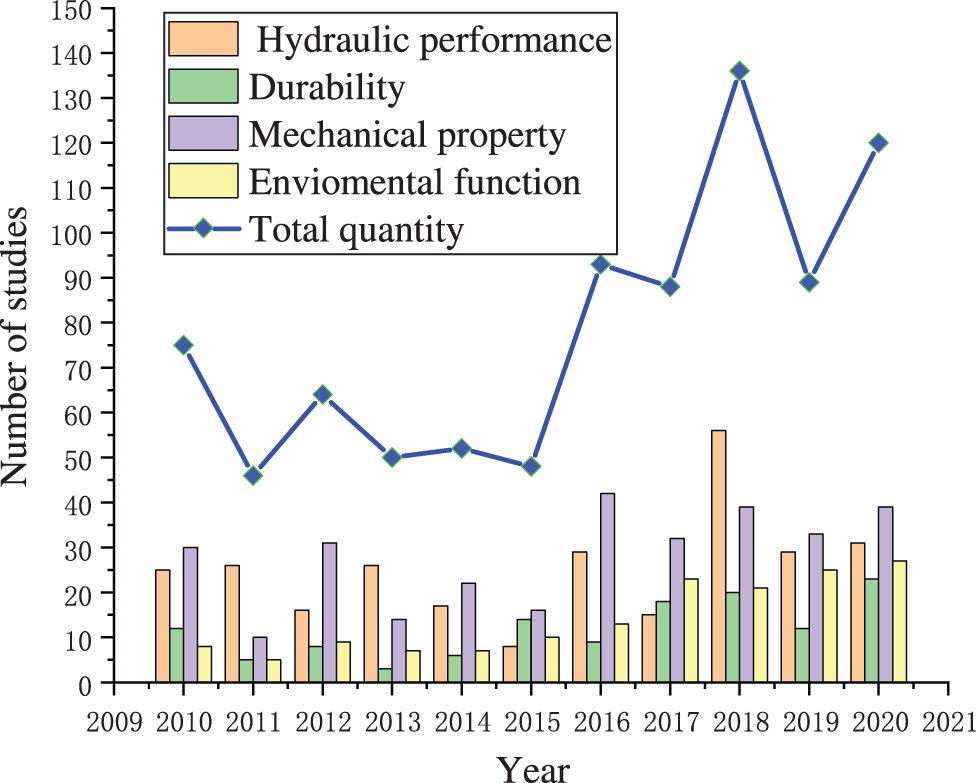

In the past decade, the major research on PCPC has focused on five fields: hydraulic performance, mechanical property, durability, environmental effect, and numerical simulation. Fig. 2 shows the 864-literature found in Scopus database and CNKI database since 2010. The distribution of years is shown according to the traits of the fields they study. Hydraulic property is the most extensively studied factor in this direction, and mechanical property is in second place. Specifically speaking, among the 864 papers found in the two databases, 36% of the papers refer to the study of the hydraulic property of PCPC, 29% of the papers involve the study of its mechanical property, and 13% of the papers are related to its function of vegetation slope protection, as shown in Fig. 3. As many as 185 papers have investigated the relationship between compressive strength and permeability in an attempt to obtain maximum infiltration capacity without affecting the compressive strength of pavements via adopting different kinds of additives, aggregates, and water cement ratios. In other words, about 85% of the literature studying the mechanical properties of PCPC relates to water permeability and gives priority to water permeability all the time. Additionally, research on environment and security features is still deficient, but these features are considered vital, as shown in Fig. 3. Only 6% of publications involve durability, 4% refer to the mitigation of heat island effect, and 2% are related to photocatalysis.

Figure 2: Time distribution of the number of publications on the main properties of PCPC

Figure 3: Research on characteristics of PCPC in recent ten years

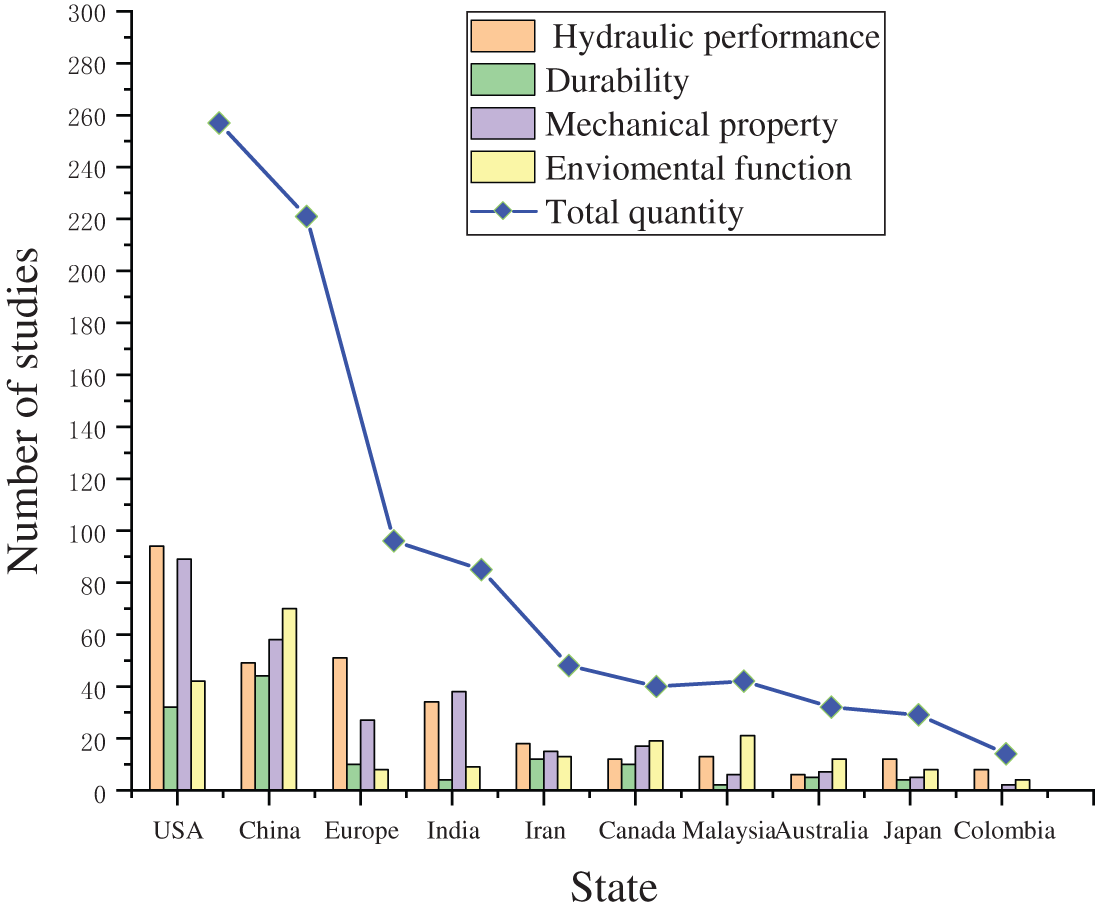

Fig. 4 shows the 10 countries possessing the most publications on PCPC. There into, most publications on the subject come from America and China. The difference, however, is that these properties studied by China are dispersive, yet America primarily focuses on hydraulic and mechanical properties. This may be related to China’s vigorous development of ecological construction in the past few years. These environmental issues make people start to pay attention and seek corresponding solutions.

Figure 4: Spatial distribution of the number of publications on the main characteristics of PCPC

PCPC is a novel concrete that can protect the ecological environment and ensure harmonious development between humans and nature. The application of this material in side slope protection not only enhances the capacity of watercourse side slopes to resist current scour, but also realizes vegetation greening, protecting and ameliorating the river ecosystem. The application of this material in pavement engineering and constructed wetland engineering can come true functions such as ventilation and water permeability, as well as water quality purification.

In the project of side slope protection, the internal pores of the PCPC have a large size and can interconnect. After the plants attached to its surface take root and sprout, their roots can penetrate the concrete and reach the underneath soil, creating conditions for the continued survival of plants. In the previous pavement application, the PCPC surface is relatively coarse and possesses a continuous pore structure, which makes the pavement have functions such as ventilation, water permeability, skid resistance, and water quality purification, effectually maintaining the balance of groundwater resources.

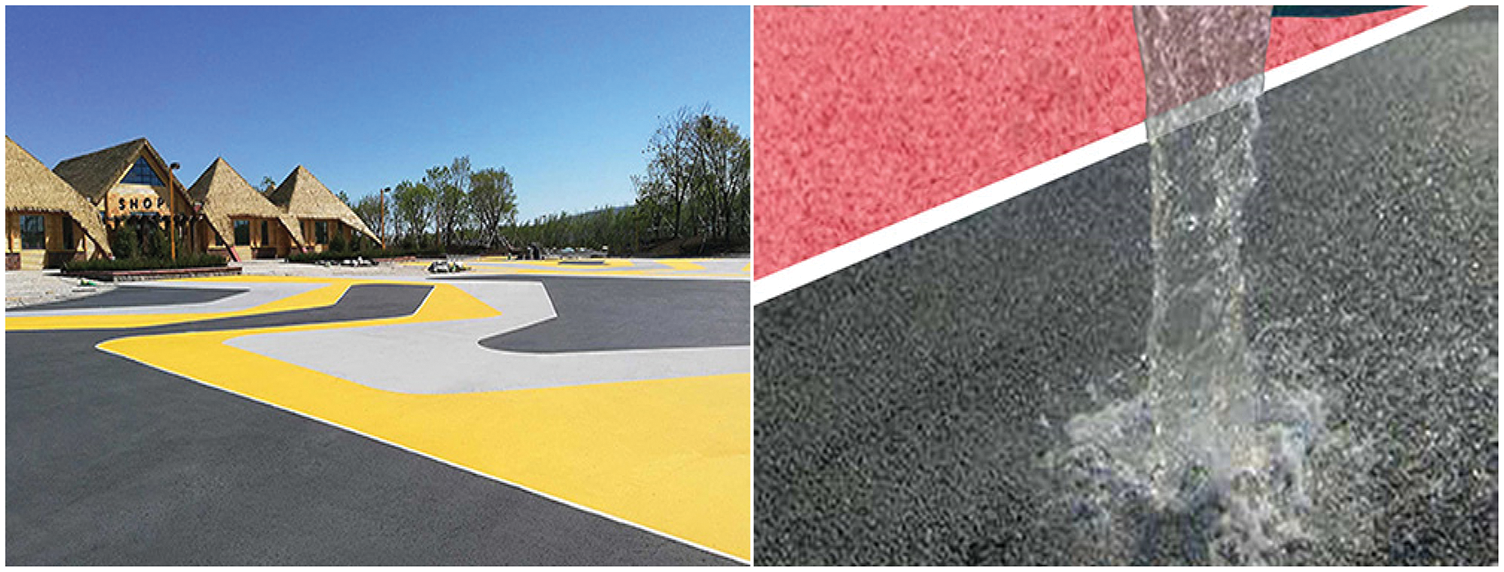

2.2.1 Pervious Pavement (Fig. 5)

(1) The colored antiwear layer on the surface of the PCP will not clog the pores, with excellent water permeability. Even on rainy days, there is no water-logging, guaranteeing the security and comfort of pedestrians.

(2) The PCP is bright in color and long in service life, which strengthens the landscape effect of the pavement.

Figure 5: Pervious pavement

2.2.2 Ecological Parking Spot of Sponge City (Fig. 6)

(1) PVC possesses strong water permeability, which can efficaciously filter and purify rainwater, remove detrimental impurities generated by water bodies, and elevate the ecological environment within the scope of the engineering.

(2) It has the effect of dust decrease, noise reduction, and purification on vehicle exhaust.

(3) The overall greening effect is sound, playing a positive, exemplary role in the construction of a sponge city.

Figure 6: Ecological parking space

2.2.3 Ecological Slope Protection (Fig. 7)

(1) The PVC possesses excellent ventilation and water permeability, and can carry out free drainage, so the porous concrete itself and the slope surface have preferable stability.

(2) In this project, the factors of the current scour are taken into account, and the aggregate grading and cement dosage are reasonably determined. Currently, the concrete itself has no great damage except that the partial soil body of the vegetation side slope is scoured.

(3) The effect of vegetation greening is well, and all technical indicators gratify the engineering requirements.

Figure 7: Application of PVC in ecological slope protection

3 Preparation Technology and Pore Characteristics

PCPC is a peculiar engineering structural material. In practical engineering applications, other than the strength factors, it is also necessary to take into account properties such as water permeability and freezing resistance, which are closely related to the physical properties of PCPC (porosity and pH) and the nature of raw materials.

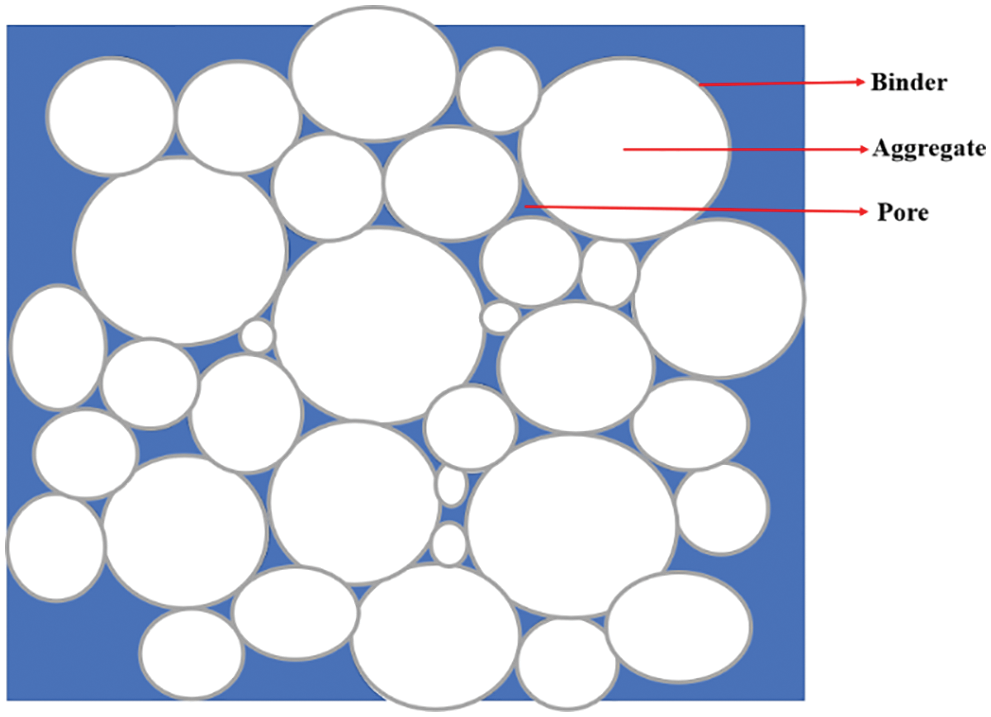

PCPC is composed of three parts: aggregate, cement mortar, and pores. Therefore, some scholars regard it as a three-phase composition. The solid-state component is coarse aggregate, the liquid-state component is cement mortar, and the gaseous-state component is pores. According to the features of pore structure, PCPC can be reviewed as the composition of coarse aggregates in a close packing state evenly wrapped by a thin layer of cement mortar [16]. Thus, the key part of the preparation principle of PC is to control the thickness of the thin layer of cement mortar. Around 1 mm is optimum. The thin layer makes the surface of coarse aggregate particles bond together, forming a honeycomb structure after hardening. And the pores between aggregates can interconnect [17].

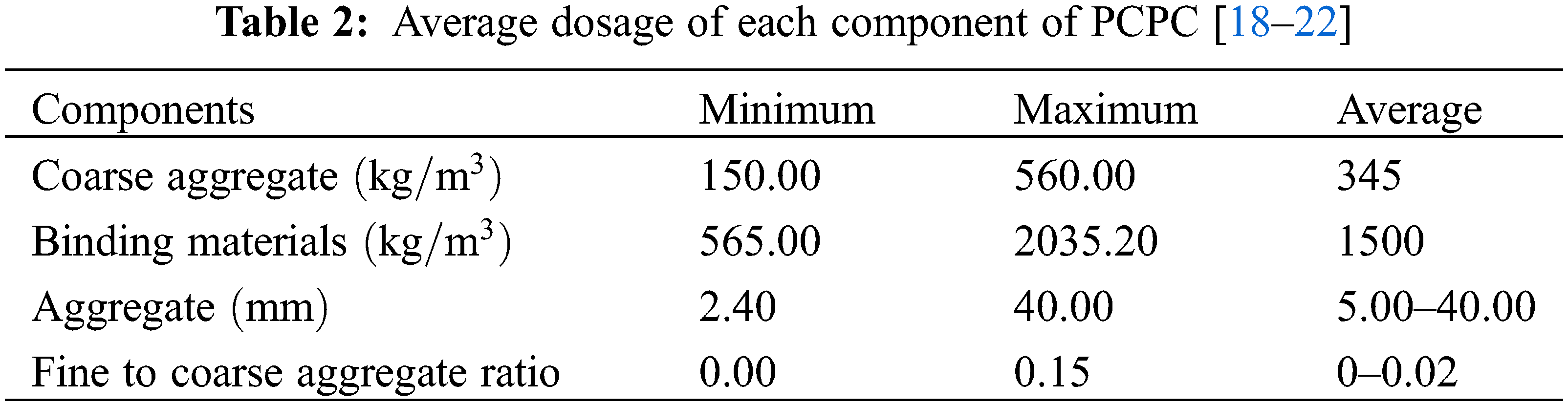

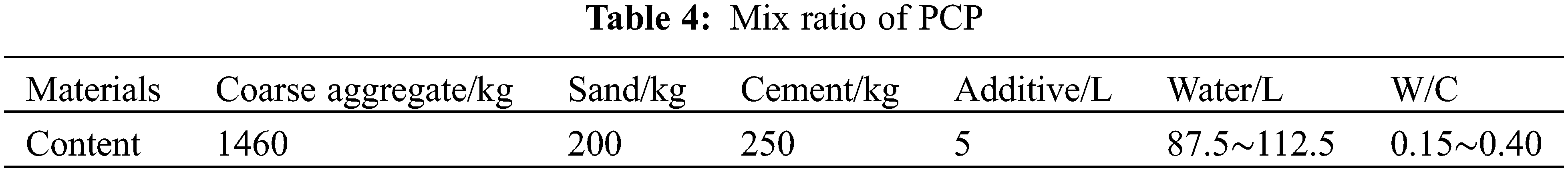

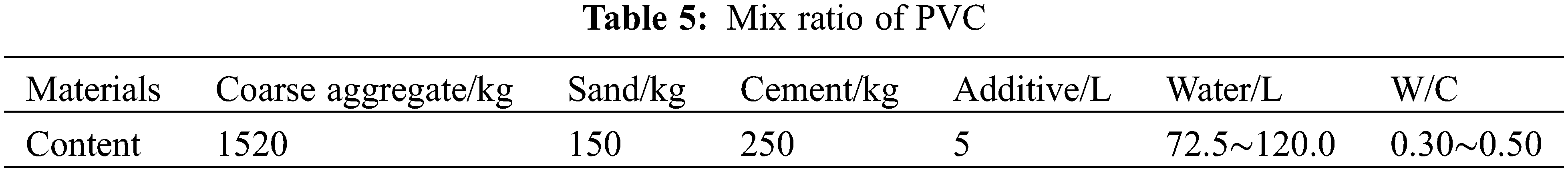

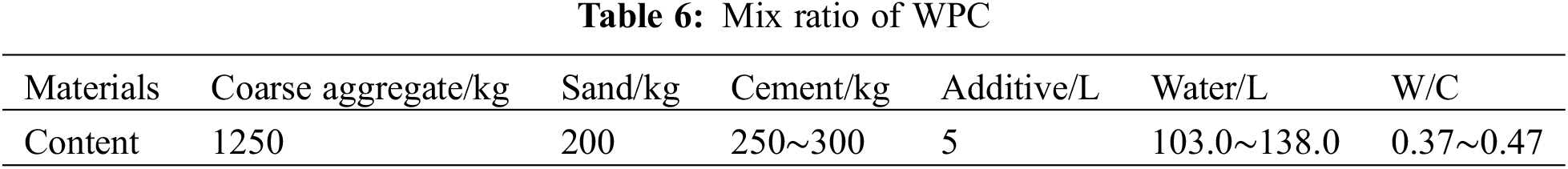

Due to the need to guarantee the connectivity of pores and meet the strength index, the preparation process and performance of PCPC are more stringent compared with those of normal concrete. The mean dosage of the components of PCPC is shown in Table 2.

PCPC often adopts the coarse aggregate as follows: broken stone, cobble, ceramsite, recycled aggregate prepared from waste concrete, and the like. In the case of the same aggregate grain diameter and grading, the broken stone has large porosity, excellent water permeability, a coarse surface that is easy for hanging grout, and cheap price, so it should be the first choice; cobble owns a relatively smooth surface, which is not suitable for hanging slurry, so it can be applied to PVC with low requirement for strength; the industrial and mineral waste residue aggregates, such as ceramsite, recycled aggregate prepared from waste concrete, and coal gangue, should be distinguished the types. Special selection or partial substitution with broken stone can be adopted to come true resource utilization of waste. Meanwhile, the appropriate application site should be taken into account [23]. And the influence of factors like hydroscopicity, rock flour content, and weathered stone on the performance of porous ecological concrete should also be considered.

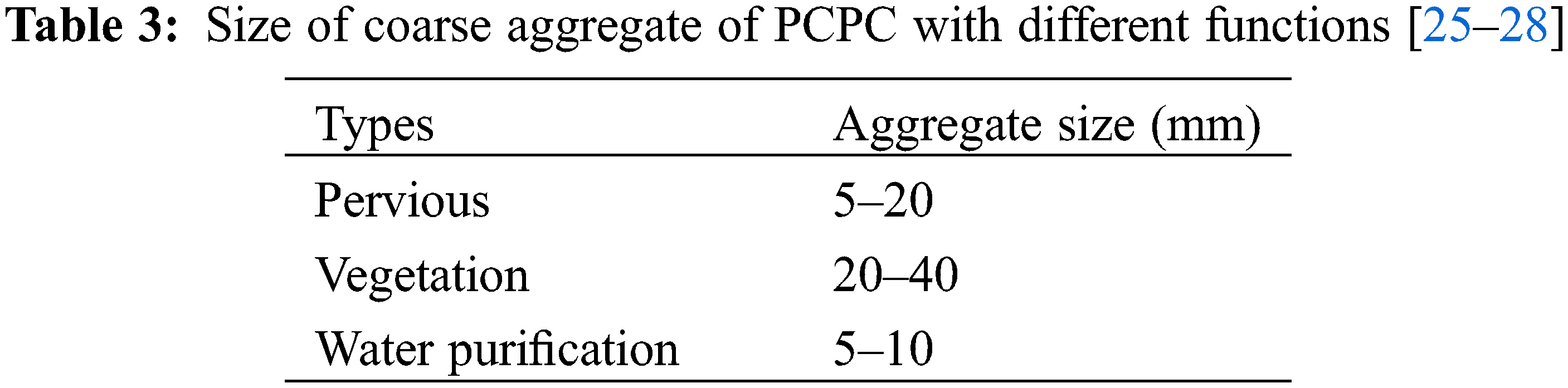

The maximum grain diameter of PCPC commonly does not exceed 40 mm. Distinct aggregate grain diameters are selected on the grounds of different functions of PCPC, as shown in Table 3. Coarse aggregates are classified into continuous grading, interrupted grading, and single grading. From the perspective of water permeability, single grading is superior to interrupted grading and continuous grading; from the angle of mechanical properties, single grading is inferior to interrupted grading and continuous grading [24]. In practical engineering applications, the option should be made according to the specific circumstance. Generally, single grading is the priority selection, and interrupted grading can also meet the conditions. But continuous grading usually does not satisfy the requirements. Screening should be conducted before use. The selected coarse aggregate should account for 40% of the total volume in the stacking state

For PCPC, the normal silicate cement that met the requirements of national standards is usually selected. For the preparation of concrete above C30, cement with a strength grade of P.O. 42.5 and above should be selected. In practical engineering applications, cement with a strength grade of P.O. 42.5 is generally chosen to assure the strength requirements and convenience for use. Some scholars also choose low alkalinity sulphoaluminate cement in order to facilitate the growth of plants in the PVC, but the promotion and use cannot be conducted due to the high cost.

To effectively guarantee the porosity of PCPC, no or small amount of fine aggregate is added in the preparation process (The addition of fine aggregate is easy to cause the pore blockage of PCPC, resulting in the complete failure of its water seepage function).

The major admixtures of PCPC are flyash, mineral powder, and silica fume. These three admixtures can replace cement in a certain proportion to lessen the cost of materials. Meanwhile, they can also improve the workability of PCPC and lift the durability.

(1) Fly ash

Fly ash is the dust collected from flue gas after pulverized coal is burned in coal-fired power plants. The main components of fly ash are silicon dioxide, alumina, ferric oxide, calcium oxide and sulfur oxide. Fly ash can replace cement in a certain proportion, reduce material consumption and cost, improve workability of PCPC, optimize interface transition zone, and improve later hardening strength and durability.

(2) Silica fume

Silica fume is absorbed and reused by industrial silicon in the process of production. Silica fume is the main component of silica, the content of 85%–95%. Silica powder has a high activity, and it can be used with high efficiency water reducing agent at the same time, which can effectively improve the compressive strength and wear resistance of PCPC, especially in the condition of sulfate erosion, which can significantly improve the durability of the material.

(3) Ore powder

The main components of ore powder are silicon dioxide, alumina and calcium oxide. Adding a certain amount of mineral powder into porous coagulation can greatly reduce the cost and improve the strength.

(4) Other admixtures

The modification of PCPC by admixtures has become a hot research field and is also one of the main aspects of PCPC research. In addition to the three conventional admixtures mentioned above, the main admixtures in existing studies are as follows: rubber, fiber, polymer, shell powder, etc. Most of the research is still in the experimental stage, mainly aimed at optimizing the mix ratio of PCPC and improving its strength and durability without affecting its water permeability.

Currently, polycarboxylate superplasticizer is widely used, which can efficaciously promote the hydration reaction of cement and strengthen the adhesive property between cement mortar and coarse aggregate.

According to the literature, the current design methods for the mix proportion of normal concrete principally include the gravimetric method, the specific surface area method, and the volumetric method. In accordance with the pore structure traits of PCPC, most researchers adopt the volumetric method to calculate the mix proportion, namely [29]:

In the formula,

Based on the characteristics of large pores and low strength of PCPC, the modification of porous concrete by admixtures has become a research hotspot, and it is also the main aspect of PCPC research. The main admixtures in the existing literature are: fly ash, mineral powder, silica fume, fiber, slag, recycled aggregate, shell powder, asphalt, polymer, etc.

Sun [34] studied the performance of fly ash and silica fume modified PCP by orthogonal test. The final parameters of the test results were as follows: when the target porosity was 16%, the water-binder ratio was 0.32, the silica fume content was 5%, and the fly ash content was 10%, the compressive strength of PCP could reach 30 MPa, and the permeability coefficient was 1.24 mm/s. Aoki et al. [35] studied the compressive strength and permeability of fly ash PCP. The results showed that the compressive strength of 20% fly ash modified PCP decreased by 12.7%, but had no significant influence on permeability. According to the relationship between porosity and strength of PVC, Huang et al. [36] studied the influence of different mineral admixtures, different particle size aggregates and different porosity on the strength of PVC. The results show that the enhancement of three kinds of admixtures on planting concrete is silica fume > fly ash > mineral powder, and fly ash can effectively improve the workability of PVC. Tang et al. [37] prepared PVC with ordinary Portland cement, low-alkali sulphoaluminate cement and ordinary Portland cement-straw powder. The results showed that the compressive strength of PVC prepared with low-alkali sulphoaluminate cement was not weaker than that of ordinary Portland cement, and the concrete under the condition of reducing alkali was more suitable for plant growth. The compressive strength of ordinary Portland cement-straw powder modified was lower than that of ordinary Portland cement, but the straw powder could provide certain nutrients for plant growth in the later stage. Wu [38] studied the strength and permeability of rubber aggregate PCP. The rubber particles with an average particle size of 1 mm were added by the external mixing method. The test results showed that the strength of PCP increased by 11.9% and 18.4% with the addition of 25 and 50 kg/m3 rubber particles, respectively. Yu et al. [39] studied the compressive strength and permeability coefficient of PCP mixed with steel slag and fly ash. The composite use of fly ash, steel slag and cement on the test surface as cementing materials promoted the hydration reaction of various materials. When the fly ash content was 15% and the steel slag content was 10%, the 28-day compressive strength and permeability coefficient of PCP were high. Singh et al. [40] added 0.33%, 0.65% and 1% of glass fiber and carbon fiber into PCP, respectively. The test results show that the flexural strength can be increased by about 2% and 5% respectively by adding 0.33% of glass fiber and 1% of carbon fiber, and the tensile strength can be reduced by 21% and 9%–16%, respectively. The compressive strength of glass fiber modified PCP can be increased by 10%–23% on the original basis, and the compressive strength of carbon fiber modified group is reduced by 6% compared with the control group. Sun [41] adopted lightweight clay ceramsite and high-strength ceramsite as aggregate, cement paste and resin as aggregate binder, respectively. The compressive strength and permeability coefficient of PCP were tested and studied. The results showed that the compressive strength of PCP under the same cementation condition was as follows: high-strength ceramsite > crushed stone aggregate > lightweight ceramsite, and the permeability coefficient was as follows: lightweight ceramsite > high-strength ceramsite > crushed stone aggregate. Giustozzi [42] did experimental research on four kinds of polymer modified PCP. The results showed that the incorporation of surface polymer significantly improved the flexural strength and stiffness of PCP, but had no effect on the porosity and permeability. The modification effect of vinyl acetate was the best, followed by ethylene-vinyl acetate.

In summary, many scholars have studied the mechanical properties of PCPC modified by admixtures, and analyzed the influence of different admixtures as cementitious materials on the basic physical and mechanical properties of PCPC. The particle size of fly ash and silica fume is smaller than cement, and the content is low, which has little effect on the permeability of PCPC, but can significantly improve the strength of PCPC; rubber can improve the deformation capacity and mechanical properties of PCPC; mineral powder, recycled aggregate, steel slag and shell powder are mainly considered from the perspective of waste recycling, and there are inconsistent conclusions on the influence of them on the mechanical properties of concrete. Fiber modified PCPC has good strength performance.

For indoor tests, the molding of PCP specimens generally adopts three compaction methods: vibration, static pressure and beating. When static pressure molding is adopted, the porosity in PCP specimens increases from bottom to top, because the aggregate is embedded and extruded from top to bottom under static pressure. When vibration molding is used, the porosity of the specimen decreases from top to bottom, and the difference between the porosity of the lower part and the porosity of the upper part is large. The porosity of the lower part of the specimen is mostly less than 5%, and the blockage phenomenon is serious, which seriously affects the permeability of PCP. Due to the dry hardness of PCP mixture, the large holes that may exist in the specimen during beating molding are not easy to become smaller, and the strength is difficult to control. However, compared with the other two methods, this method is not easy to precipitate, and the porosity is guaranteed. Therefore, it is generally applicable to the molding of PVC. Therefore, the molding of PCP is generally carried out by static pressure molding. At this time, the coarse aggregate is squeezed into each other, and the contact points between them are significantly increased. Under the occlusion of the displacement of coarse aggregate and the deformation of cement mortar layer, the PCP has a pore structure with connected pores and relatively uniform distribution of pores.

At present, there are few reports on pore structure characteristics of PCPC. It can be seen from the Fig. 8 that the structure of PCPC is mainly composed of aggregate, cement paste and pores. The cement paste evenly encapsulates the coarse aggregate and fully binds it. However, the pore structure characteristics of general concrete and rock materials have been studied deeply. Through relevant investigations, it is found that there are two main methods for pore structure model simulation of concrete materials [43]: One is to establish random aggregate model of concrete materials by using random bone placement algorithm; Second, using digital image processing technology, Construct the real meso model of concrete materials. The pore structure of porous eco-concrete plays an important role in its physical and mechanical properties, permeability and durability. Therefore, the determination of internal pore structure parameters is a prerequisite to study the relationship between microscopical and macroscopic properties of PCVC and to explore the influence of external erosion environment on its properties. The pore structure parameters of PCPC mainly include porosity, aggregate spacing, pore shape, pore size and pore connectivity.

Figure 8: Section structure of PCPC

Based on the random aggregate model is round, the rules of the internal random porous materials on the spherical pore (simulated aggregate) or other shapes, and there is bigger difference, the actual characteristics of the aggregate PCPC internal cannot reflect the actual mesoscopic structure, numerical simulation of its mechanical certainly cannot restore its true condition. Therefore, relevant scholars proposed the use of digital image processing technology to establish the pore structure model of concrete materials, and then basically carried out mechanical numerical simulation. For example, Qin et al. [44] applied digital image technology and MATLAB image processing tools to study boundary extraction of two-dimensional concrete aggregate, and established a mesoscale concrete calculation model by using ABAQUS to simulate aggregate. Xu [45] proposed the pore structure parameters of PCPC, measured the pore size of PCPC, analyzed the change of pore size distribution in PCPC under different porosity, water-cement ratio and gradation, and extracted the coarse aggregate boundary and cement slurry boundary by digital image method, and established a numerical aggregate model. The distribution of aggregate, porosity and cement mortar in PCPC is reflected. Therefore, in order to truly characterize the internal microscopic pore structure of PCPC and accurately study the macroscopic properties of PCPC, the two-dimensional and three-dimensional structure models of PCPC are constructed based on image processing technology. The model constructed by image processing technology is more similar to the pore structure of the actual PCPC, and accurately describes its internal pore structure characteristics. It provides an effective model for the finite element method to study the pore structure, mechanical properties, water permeability and plant growth of PCPC. It provides an effective method for numerical simulation of mechanical properties of PCPC.

4 Pervious Concrete Pavement (PCP)

PCP is a sort of PCPC. Generally, PCP refers to the PCPC used for ground pavement, which meets the pavement construction performance and requirements. Pervious pavement usually has 15%∼25% connected pores. When the PCP is used for ground pavement, under normal circumstances, the amount of water permeability can achieve

The permeability of PCP is one of its most significant properties, and is an indirect way to qualitatively determine how internal pores connect (see Fig. 9). In general, the water permeability capacity of PCP is usually measured by the permeation coefficient, which is one of the most important indicators. However, the assay approaches of permeation coefficient are not unified at home and abroad [48]. The existing concrete permeability test device is only suitable for ordinary concrete with low permeability (flow rate is less than 0.01

Figure 9: PCP drainage capabilities

The porosity of PCP refers to the remaining part of the total volume of concrete after deducting the actual part. It consists of three parts: connected pores, semi-connected pores, and sealed pores. Connected pores are the pores connected with each other; sealed pores are those that are disconnected and isolated from other pores; semi-connected pores are also called dead pores, which are connected to other pores at one end, and closed at the other end [51]. From the angle of drainage, pores are divided into effective pores and ineffective pores. Effective pores refer to the pores that can go through water and discharge water. From the perspective of water flow, just pores interconnected and not occupied by water are effective. The water in the semi-connected pores is relatively stagnant. But the semi-connected pores act as the buffer when draining, so they are also effective. Thus, the effective pores are composed of connected pores and semi-connected pores, and the sealed pores are ineffective pores [52].

For the indoor experiment, three compaction approaches including vibration, static pressure, and flapping are usually used for the moulding of PCP test specimen. When static pressure moulding is adopted, the porosity in the test specimen of PCP increases successively from bottom to top, because the aggregates are embedded and squeezed from top to bottom under the action of static pressure. When vibration moulding is used, the porosity of the test specimen becomes smaller from top to bottom, the difference value of porosity between the lower part and the upper part is large. The porosity of the lower part of the test specimen is usually less than 5%, and the phenomenon of clogging is severe, which seriously influences the water permeability of PCP. Due to the dry and hard nature of the PCP admixture, the large pores that may exist inside the test specimen are not easy to become smaller during moulding through flapping, and the strength is difficult to control. However, compared with the other two approaches, this approach is less liable to appear slurry sinking phenomenon, which guarantees the porosity, so it is generally appropriate for moulding of PVC. Thus, for the moulding of PCP, the approach of static pressure moulding is often adopted. At the moment, the coarse aggregates are squeezed and embedded into each other, and the contact points between them significantly increase. Under the interlocking action of coarse aggregate displacement and cement mortar layer deformation, PCP gains interconnected pores as well as the evenly distributed pore structure [53].

For pervious pavement engineering, PCP is extensively used on sidewalks and low-load roads. According to relevant statistical materials, this approach can augment the surface pervious area of existing urban regions by 6%. But, as time goes on, foreign particles lower the permeability of roads, ultimately leading to blockages [54]. Thus, cleaning and removal of deposit sediment at regular intervals is also one of the ways to ensure the sustainable function of PCP.

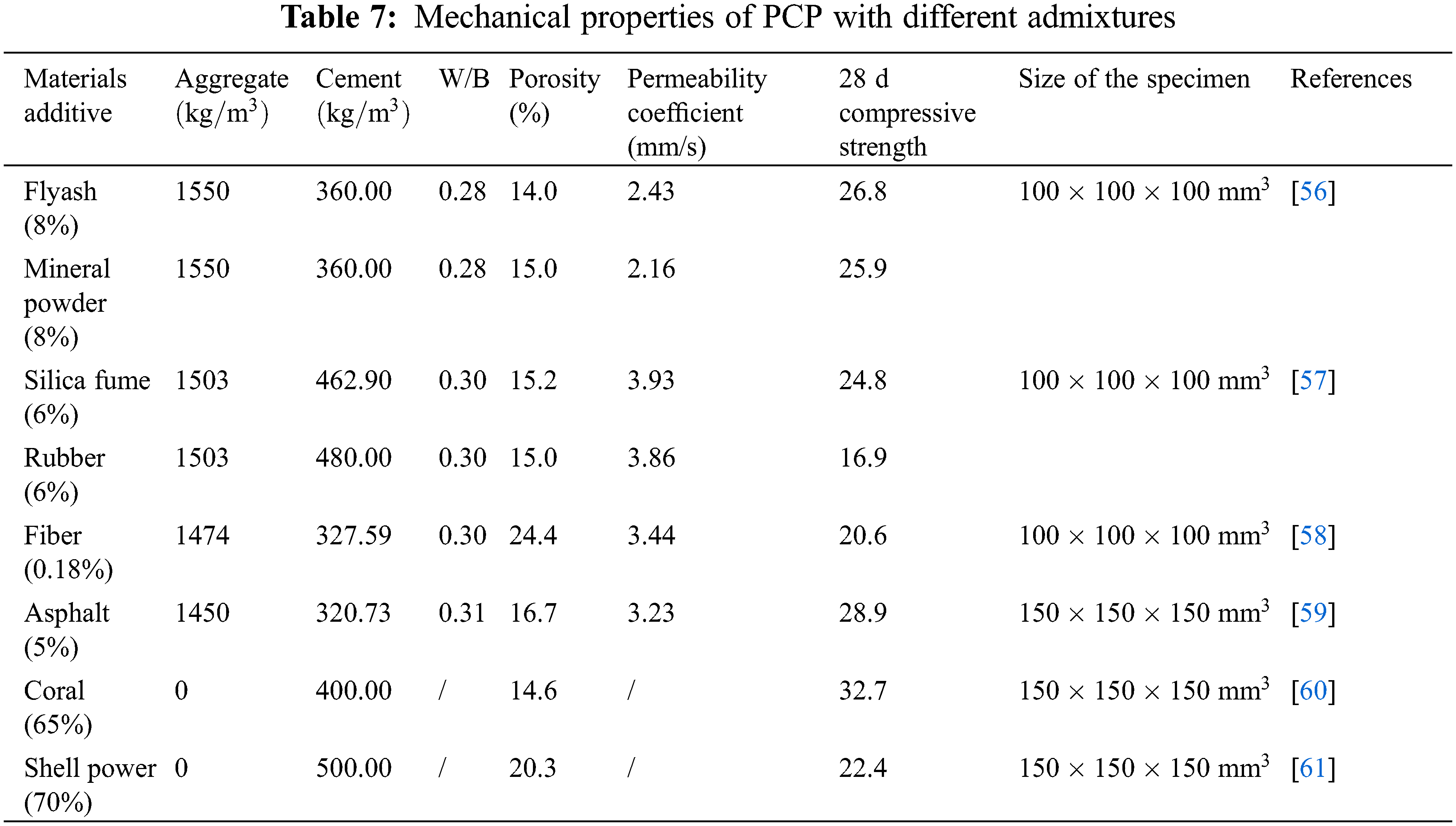

Under the condition of gratifying a certain capacity of water permeability, PCP must also meet the requirements of fundamental mechanical properties, which will determine its development prospects in pavement engineering. For normal concrete, once the strength of the aggregate is determined, the bottommost measure to enhance the strength of the concrete is improving the slurry strength of the cementing material; for PCP, due to its point-contact porous structure, the aggregate itself is high in strength, and the cementing layer between aggregate is relatively weak, which limits the strength of concrete. In other words, compared with normal concrete, the enhancement of slurry strength makes relatively little contribution to the improvement of the overall strength of concrete. The strength of PCP is affected by multiple factors, and the major factors are: (1) the thickness of the slurry layer wrapping the aggregate; (2) the strength of the aggregate; (3) the strength of the slurry; (4) the grading of the aggregate; (5) preparation technology [55]. Table 7 sums up the mechanical properties of PCP with different admixtures in recent years.

Except for the load, the PCP used for the pavement also suffers the deterioration effect of the environment, such as current scour, solarization, erosion of rain, snow, wind, frost and water, as well as the effects of freezing, aridity and humidity, and acid and alkaline [62]. Thus, PCP should not only meet the general load-bearing of pavement, but also own certain durability. From the angle of practical engineering application, PCP suffers the most severe damage of freezing and thawing cycle. Under the action of the freezing and thawing cycle, the microstructure of PCP will alter, affecting its macro-mechanical properties. The long-term accumulation of freezing and thawing damage will ultimately lead to destruction.

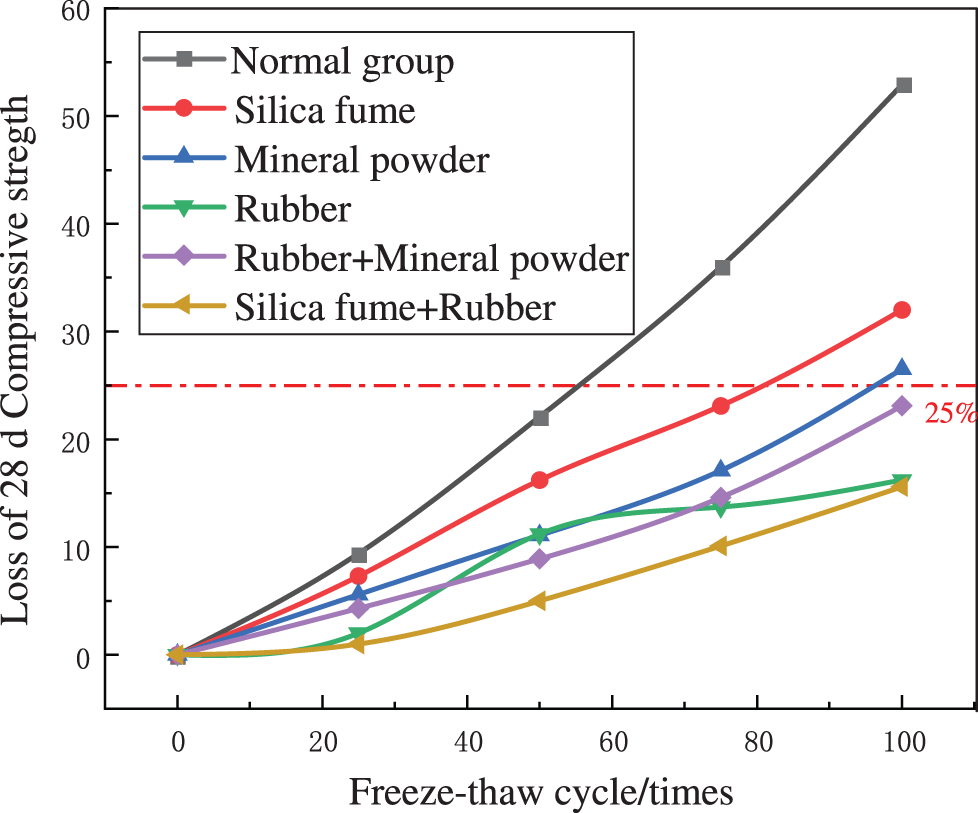

Now, the durability of PCP is chiefly evaluated by the test of anti-frost property in the globe, but no engineering test standard has been formed. The research on the durability of PCP mostly remains in the indoor lab, and the experiment just targets a single factor. For example, the optimal mix proportion that can satisfy the freezing resistance of PCP can be acquired by controlling the admixture amount of different materials via the orthogonal experiment. As shown in Fig. 10, the 28-day compressive strength of pervious Portland cement porous concrete under different times of freezing and thawing cycles was tested by adding the PCP of the benchmark group with single-doped mineral powder, silica fume, and rubber, as well as double-doped silica fume and mineral powder, and silica fume and rubber, respectively. With the increase of freezing and thawing cycle period, the loss ratio of compressive strength rose little by little. After 25 freezing and thawing cycles, the loss ratio of the 28-day compressive strength of the benchmark group reached around 10%. After 50 freezing and thawing cycles, the loss ratio of compressive strength of the benchmark group test specimen achieved 22.1%, which was about twice the strength loss ratio of the double-doped silica fume and mineral powder group. After 75 freezing and thawing cycles, the strength loss ratio of the test specimen in the benchmark group reached 36%, far beyond the 25% required by the standard, yet the strength loss ratios of the other single-doped and double-doped groups were all less than 25%. After 100 freezing and thawing cycles, it could be found that the test specimens of most groups had been entirely destructed or approximately destroyed, whereas the strength loss ratio of the double-doped silica fume and rubber group was just 15.6%. From strong to weak, the sequence of the freezing resistance of the six groups of PCP was: double-doped silica fume and rubber group

Figure 10: Relationship between the number of freeze-thaw cycles and compressive strength loss rate of PCP [63–67]

As pavement material, PCP will be subjected to repeated vehicle loads, and its fatigue performance is an important part of its durability. At present, there are few studies on the fatigue durability of PCP. Zhou et al. [68] studied the bending fatigue characteristics of polymer modified PCP. The aggregate used in the test was 27.5, 32.5 and 37.5 mm, the water-binder ratio was 0.32, and the polymer content was 10% of the water consumption.65 trabeculars were made for static bending test and fatigue bending test, the stress level was 0.65–0.85, and the stress ratio was 0.08, 0.2 and 0.5. The test results show that the fatigue life of specimens accords with two-parameter Weibull distribution, and the fatigue life equation coefficient is proposed. With the increase of aggregate particle size, the static strength and fatigue life of PCP decrease gradually. Zheng et al. [69] through indoor trabecular bending fatigue test, such as bending fatigue properties of PCP is studied, the study found that, the two parameter weibull distribution can be used to describe the permeable concrete fatigue life distribution, and thus established the fatigue life under the condition of different stress level and equivalent fatigue life equation, to calculate the fatigue stress coefficient and bending tensile strength structure coefficient. Wang et al. [70] using the acrylic class-poly carboxylic acid type water-soluble modifier on the single particle size of PCP modified and its properties of PCP three-point bending fatigue analysis, the effect of using weibull distribution with two parameters to simulate the distribution of fatigue life, and at the same time under the condition of different failure probability is established PCP fatigue life equation, the addition of modifier increases the fatigue life of PCP.

Chandrappa et al. [71] studied the influence of stress level and frequency on the fatigue life of PCP beams and established the fatigue life model of PCP beams. In the test, the fatigue load frequency is 2–10 Hz, and the stress level is 0.70, 0.75 and 0.80. Four-point bending fatigue test is adopted. The test results show that the fatigue life of PCP decreases with the increase of stress level under a certain load frequency, and there is a good functional relationship between the fatigue life and stress level. Compared with the load frequency, the fatigue life of PCP is more dependent on the stress level and flexural stiffness. The effect of load frequency on fatigue life is very small. The fatigue test data accord with three-parameter Weibull distribution and lognormal distribution. It can be seen from the strain curve of fatigue test that the failure strain of PCP is higher than that of ordinary concrete. Chandrappa et al. [72] also studied the influence of pore size and porosity on the fatigue performance of PCP and established a stiffness attenuation model of PCP. The results show that the crack surface porosity has a greater effect on fatigue life and stiffness than the volume porosity. The effect of large aperture on fatigue life is more significant than that of small aperture. Pindado et al. [73] conducted compression fatigue tests on polymer modified PCP with cylindrical specimens. The addition of polymer significantly improved the fatigue behavior at high stress levels, but the improvement was reduced at low stress levels. Chen et al. [74] studied the fracture toughness and fatigue performance of SJ-601 polymer modified pervious concrete. Under various stress levels, both fracture toughness and fatigue performance of polymer modified PCP were effectively improved.

Under the action of solar radiation, the evaporation process of water in the PCP of the road surface is similar to that of water in the soil. The water in the PCP overbrims the pavement surface. One type is the direct evaporation of the water on the pavement surface, and the other type is the evaporation of the water inside the connected pores of the pavement. The water evaporation of PCP pavement relies not only on the water content and internal structure of the pavement, but also on meteorological factors such as temperature, humidity, and wind speed. Some studies have discovered that, under the same environmental conditions, due to the coarse surface of PCP, the lighter weight of the same volume, and the larger connected pores, the temperature decrease rate of PCP is faster than that of conventional concrete, and the surface temperature range ability is also higher than that of conventional cement concrete. The coefficient of thermal conductivity, specific heat capacity, and density of PCP are small, resulting in a small coefficient of thermal storage [75].

Furthermore, the reflectivity of PCP is also lower than that of conventional concrete. Generally speaking, material reflectivity ranges from 0 to 1, the higher the indicator, the higher the solar reflectivity of the material. The reflectivity of traditional concrete is about 0.50, whereas the highest reflectivity of PCP can reach 0.29 (porosity of 17% and maximum aggregate size of 9.5 mm), which is conducive to reducing the heat island effect [76].

PCP containing photocatalysts possesses the capacity of removing air pollutants. Similar to photosynthesis in plants, photocatalytic compounds can be used to capture and absorb organic and inorganic particles in the air and remove detrimental pollutants, such as oxynitride (NOx) [77]. Titanium dioxide (TiO2) is one of the photocatalytic materials that have been studied most. Because its cost is low and it can rapidly react without chemical reactants. Titanium dioxide can decompose gaseous pollutants in sunlight, therefore, it can be applied to the pavement, to efficaciously remove pollutants emitted by vehicles on the road. Additionally, due to the coarse surface and high porosity of PCP, it has a high specific surface area and can retain more titanium dioxide particles, helping PCP gain a better photocatalytic air-cleaning effect on sunny days [78].

Now, photocatalysts are mainly made into coatings on the market, which are applied to traditional concrete pavements. Some researchers have attempted to test the purifying effects of three coatings: plaster, whitewash, and transparent coating. Compared with the latter two (52% NOx removal rate of varnish, and 40% NOx removal rate of white paint), plaster obtains the best effect when using in pavement concrete (81% NOx removal rate) [79]. Although these experimental results are from studies of conventional concrete pavements, applying PCP to pavements is deemed to retain photocatalytic compounds better due to its higher porosity ratio. However, PCP for pavement may lose some of this capacity over time, as it is more susceptible to abrasion and current scour. However, the application of photocatalytic coatings on the PCP of pavement is not extensive, and most stay in the indoor test stage, so some scholars have begun to study the innovative applications of directly adding titanium dioxide into the mixture. One of them is to evenly mix water with a certain amount of titanium dioxide. Then paint the PCP surface. This method has been proved that can absorb and reduce a large amount of NO (97.14%), methylbenzene (91.98%), and tetramethylbenzidine (TMB, 96.34%) [80]. However, the coating was found to be fragile and easily scoured by water. Another approach is called the cement-water slurry method, which consists of a thinner layer of cement slurry and contains small amounts of cement and titanium dioxide. Through this method, the removal rate of NO, methylbenzene, and TMB can reach 96.94%, 78.82%, and 97.26%, respectively. Nevertheless, this approach leads to a substantial reduction in permeability [81].

5 Porous Vegetation Concrete (PVC)

PVC, one type of PCPC, is concrete with large pores, with porosity of 20%∼35%. Most pore diameters are above 10 mm. The skeleton composed of cementing materials and aggregates is its load bearing part, and the pores are the spaces in which plant roots grow. Most pores are ventilated, pervious, connected, and large, allowing the root system that grows in them to reach the underneath soil layer (see Fig. 11) [82]. PVC can be divided into normal PVC and light PVC according to its use. The former has a certain load bearing capacity and is mostly used for slope protection of river embankments, dams, canals and roads, as well as parking lots. The latter is chiefly used for vegetation rooftops. The raw materials, structures, and performance indicators of PVC for different purposes are quite different.

Figure 11: PVC root development [83]

For PVC, the core principle of its design is to enlarge the water permeability of PVC, decrease water loss, and guarantee the growth of green plants on the premise of assuring the basic mechanical properties of the structure, to reach a state of natural ecological balance.

The permeation coefficient is a direct, efficacious indicator to characterize the water permeability of the PVC. The water permeability, on the one hand, reflects the capacity of the PVC to absorb rainwater and snow water for plant growth, and on the other hand, it can also reflect the capacity of the PVC to meet the nutrient exchange between the plant root system and the ambient environment. The permeation coefficient should not be too large. If it is too large, the filling soil and the nutrients in the filling soil will easily run off; if it is too small, the water-holding capacity and water exchange capacity of the PVC will bring down. Keeping a rational permeation coefficient can ensure the needs of plant growth and reduce the alkalinity of pores.

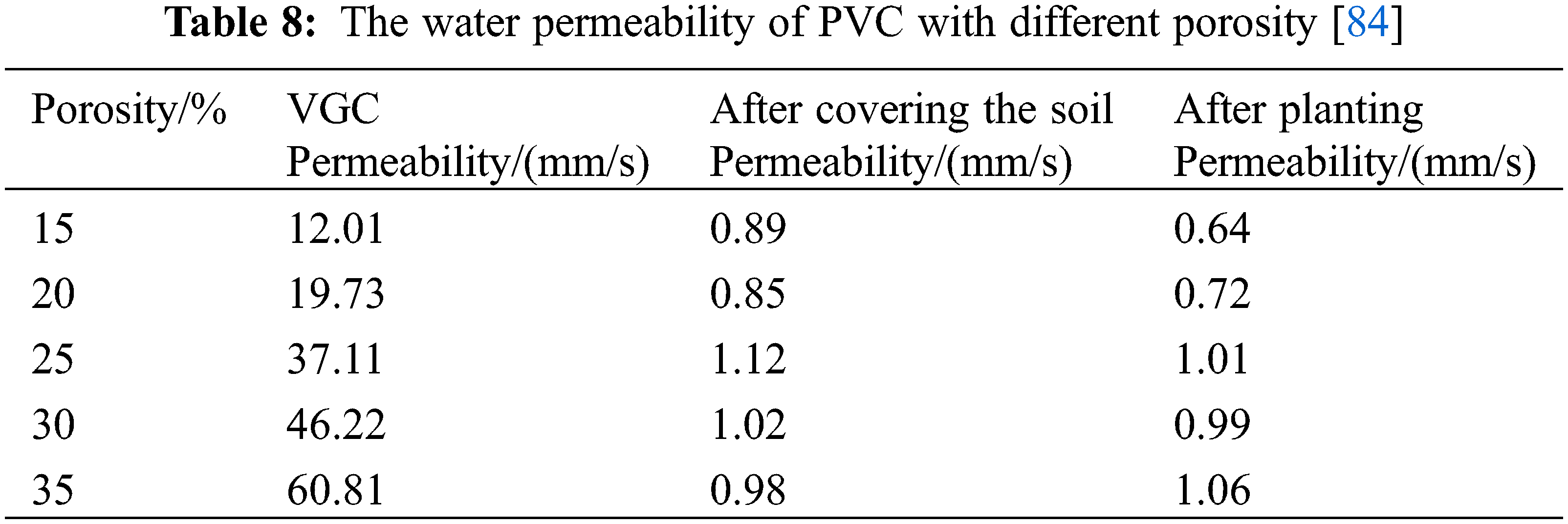

To study the influence of the planting process on the PVC, some scholars set up test experiments under distinct porosity and aggregate grading. The permeation coefficient of PVC, the permeation coefficient after perfusing pore vegetation substrate and covering 2 cm surface layer substrate, and the permeation coefficient after 30-day plant growth were tested step by step. The water cement ratio is 0.25, and the test specimen is a cylinder with a bottom diameter of 100 mm and a height of 150 mm, as shown in Table 8.

According to the table, the permeation coefficient of PVC shows a significant uptrend with the increase of porosity. Hence, the design of porosity is one of the significant factors influencing the permeation coefficient of PVC. Moreover, the permeation coefficient of concrete dropped dramatically after covering the soil. The permeability after planting was almost the same as that after covering soil, and in both cases, the phenomenon that the permeation coefficient rose with the increase of porosity was not significant. Generally, for the PVC after planting, the permeation coefficient must reach more than 1 mm/s, so as to offer the necessary water and nutrients for plant root growth, and to possess the functions including water retention, drainage, and ventilation.

In different engineering applications, the emphasis on the mechanical properties of PVC is distinct. In the situation of pavement or in the case that needs to meet a certain load, the requirements for compressive strength and flexural strength are high, yet the demands for tensile strength are low. Generally, on two sides of the watercourse side slope, only the compressive strength is taken as the design index.

These mechanical properties are often closely bound up with the mix proportion of the PVC. Its porous structure is formed by the point-to-point force between the coarse aggregate inside the concrete and the cement mortar. The strength of the cement mortar directly affects the strength of the concrete. Influencing factors such as water cement ratio, water-binder ratio, and additives can all alter the strength of concrete. In the meantime, the porosity also restricts the strength properties of the PVC. In engineering applications, the rhizomes of plants play a penetrating and connecting role on the surface matrix soil layer and the PVC over time, which results in the reinforcement effect on the whole concrete structure. To a certain extent, the mechanical properties and stability are improved [85].

In general, the original intention of the design of PVC is mainly embodied in the function like vegetation greening, with low requirements for mechanical properties. In current engineering applications, the 28-day compressive strength of PVC is generally 10∼20 Mpa, and the 28-day flexural strength is usually between 1.5 and 2.5 Mpa.

The structure of PVC is different from normal concrete. Its durability damage simultaneously occurs inside and outside, and the damage degree is much greater than that of normal concrete. The number and volume of internally interconnected pores in PVC restrict the growth and development of the plant root system, and plant growth also influences the essential performance and durability of PVC. The plant root system, at a certain stage after its formation, grows rapidly and becomes stronger quickly, which can easily make the concrete deform and cause structural damage.

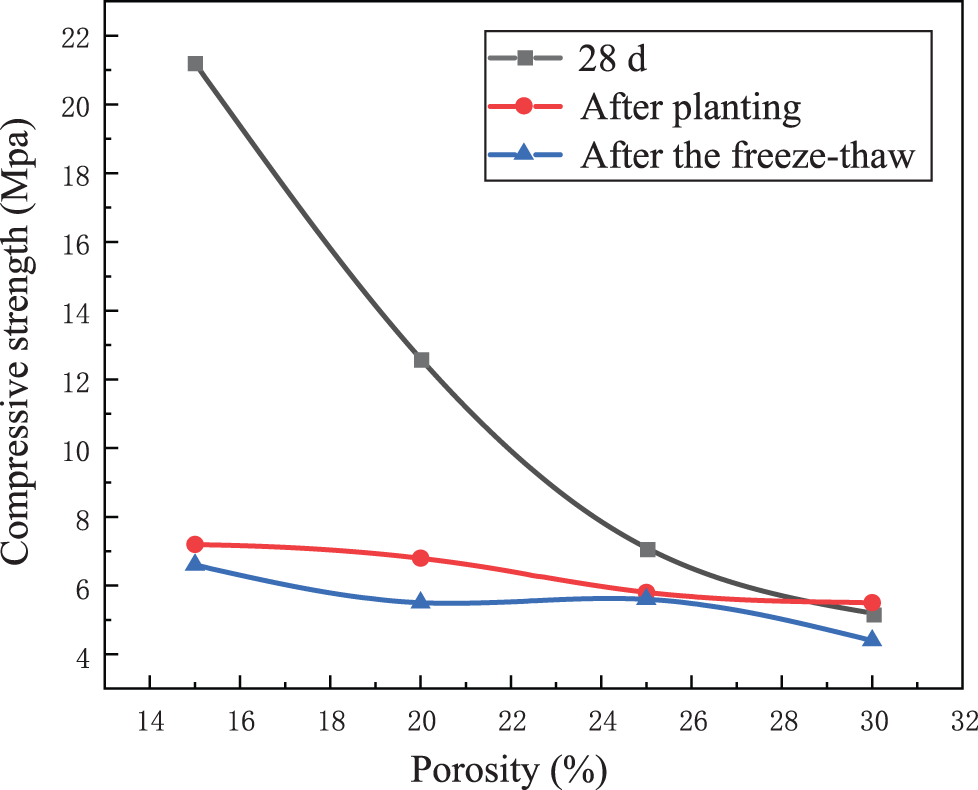

According to the existing research results, aggregate grain diameter and porosity have little effect on the freezing resistance of PVC. After planting, the damage of freezing and thawing is no longer the major factor affecting the compressive strength of PVC. The distribution test of experiments is used to measure concrete test specimens in three different pores. The water cement ratio is 0.25, and the size is

Figure 12: Effect of porosity on freezing resistance of PVC

According to the experiment results, when the porosity is 15% and 20%, the initial compressive strength of the PVC is high, and the strength declines sharply after the lawn is planted; while the porosity is 25% and 30%, the primary strength of the PVC reduces, and the strength drops less after the lawn is planted; so the greater the porosity, the less reduction of concrete strength by plants; after planting, the damage of freezing and thawing is no longer the major factor affecting the compressive strength of PVC.

Furthermore, the filling soil in the PVC is weakly acidic, and its acidity mainly derives from the organic acids in the humus and the microorganisms in the soil. In the soil solution, H+ dissociates from the acidic substances of the soil. And H+ occurs neutralization reaction with Ca(OH)2 dissolved from the cement stone. On the one hand, the alkalinity of the cement stone is sharply dropped. The hydrate calcium silicate and hydrate calcium aluminate lose their stability, hydrolyze, and dissolve, leading to a continuous decrease in the strength of the concrete. On the other hand, the corrosion products it produced have poor stability and are easily dissolved, which accelerates the corrosion process.

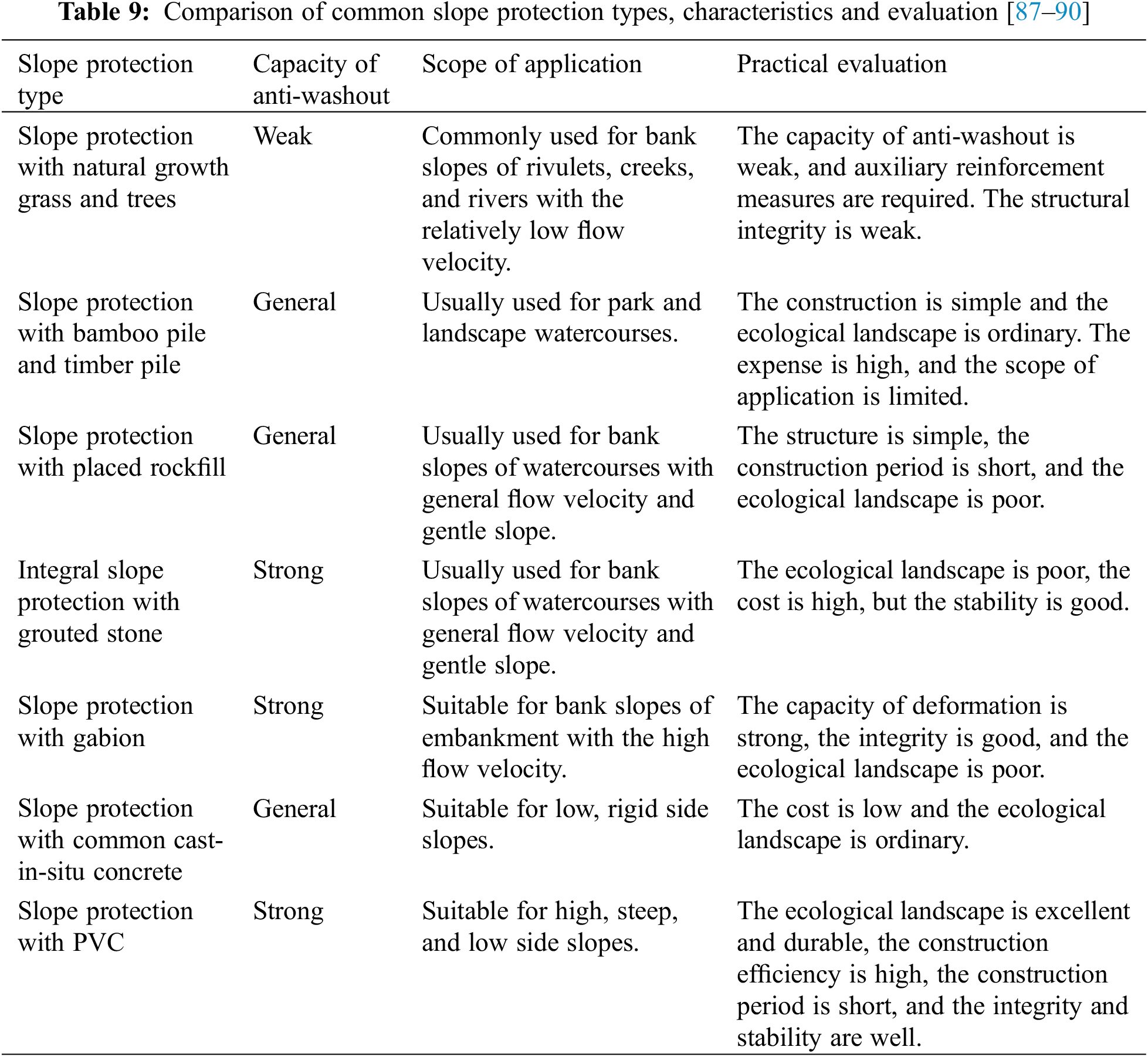

5.4 Function of Slope Protection with Vegetation

The theoretical foundation of slope protection with PVC is principally based on the theories of drainage and slope stabilization as well as stable protection of hydraulics and engineering mechanics, the theoretical basis of the vegetation ecology like restoration ecology and landscape ecology, and the fundamental theory of edaphology; the principle of slope protection with PVC mainly contains slope stabilization and conservation of water and soil. The water and soil conservation function of PVC is chiefly manifested in two aspects: one is to slow down the impact of runoff scouring the slope; the other is that plants alter the soil structure to enhance the erosion resistance of the soil. Common slope protection types, characteristics and evaluation are shown in Table 9.

The function of plants to stabilize slope is mainly embodied in the soil holding effect of the root system. Namely, the root system can enhance the cohesion strength of the soil body and the friction force between the root system and the soil body via reinforcement and anchoring, aggrandize the friction strength of the soil body, and then improve the shear strength and stability of the soil body. This is the fundamental theory of fixing soil via root system [91].

Vegetation plays a crucial role in controlling water and soil loss, and also cuts down the perniciousness of soil erosion. The practice has attested that there is a certain correlation between the total amount of soil erosion and vegetation coverage. The runoff generation amount and water and soil loss amount of the sloping fields with luxuriant grassland are less than that of bare lands, less than 6% and 12% of that of bare land, respectively. When the vegetation coverage rate is cut down to less than 75%, the runoff generation amount and water and soil loss amount soar [92]. Plant roots are confined by numerous factors when enhancing the overall stability of slopes. In a general way, the vegetation traits and environmental issues are the most essential.

On account of the above summary and analysis, this paper reviews the research and evaluation of relevant properties of PCPC at home and abroad in the past ten years. In short, research and attention on PCPC have been increasing in recent years, for instance, the evaluation of new properties to alleviate the climate and environmental issues that society is handling. In the past decade, the application of PCPC has been studied worldwide, but most of the research has been conducted in America and China. Moreover, it is possible to design high-performance PCPC for specific applications. However, these properties conflict with each other, so further study is needed to optimize the design of the corresponding mix proportion, to satisfy the performance such as hydraulic performance, mechanical performance as well as durability, and ultimately come true the combination of environmental function and security feature. In effect, aside from the well-known hydraulic and mechanical properties, many countries have not yet explored these environmental supplementary benefits, such as noise reduction, air-cleaning, and the like. This gives prominence to the necessity for continued study and promotion of PCPC as a multifunctional application material, particularly in overpopulated cities, which will confront major environmental issues, like air pollution, heat island effect, flood, and water contamination. In line with the quantitative analysis of publications, future trends show that there will be more and more applications of PCPC in the greening of sidewalks and side slopes in the next few years, contributing to solving the issues triggered by climate change and urban expansion.

PCPC is an important part of ‘sponge city construction’, which has excellent water permeability and plays an important role in urban ecological environment. However, the porous structure of PCPC leads to relatively poor durability of its mechanical properties, which seriously restricts its engineering application. In this paper, according to the literature in the past ten years, the number of literatures in various fields of PCPC is counted. The research focuses and reasons of different countries and years in different fields are analyzed. Combined with engineering applications, the domestic and foreign research on raw materials, mixing ratio, preparation and pore characteristics of PCPC are summarized. According to the different engineering characteristics of PCP and PVC, the research results in permeability, mechanical properties, durability, photocatalysis, heat absorption and plant slope protection are systematically reviewed. In general, PCPC is currently mainly used in ‘light load’ permeable pavement and slope greening. Low strength, pore clogging and poor durability are the three most critical issues of PCPC, which to some extent limit the large-scale promotion of PCPC. The conclusions drawn from the literature review are as follows:

(1) From the function, this paper has divided PCPC into the following three categories: PCP; PVC; water purification concrete. At present, it is mainly used for water permeability of pavement and side slope greening in the engineering field.

(2) In the light of different application fields, the permeability coefficient of PCPC is around 1.0–4.0 mm/s, the porosity is between 5% and 45%, and its porous structure basically meets the property of preferable water permeability.

(3) The 28-day compressive strength of PCP is generally above 15.0 Mpa, the tensile strength is 1.5–3.0 Mpa, and the bending strength is above 3.0 Mpa. The 28-day compressive strength of PVC is generally above 10.0 Mpa, the tensile strength is 0.8–1.8 Mpa, and the bending strength is above 2.0 Mpa.

(4) The mechanical properties and durability of the PCP and the water purification concrete are better than those of the PVC. For the PCP with the benchmark mix proportion, its frost resistance is as follows: double-doped silica fume and rubber

(5) The reflectivity of PCP is lower than that of conventional concrete, which is conducive to retard the urban heat island effect.

(6) The slope protection with PVC owns superior anti-washout capacity, is appropriate for various side slopes such as high, steep, and low slopes, and can meet the dual effects of “Ecology and Security”.

(7) The application of photocatalysts like titanium dioxide to PCP can effectively remove air pollution. However, due to the limitation of its validity period, it cannot be popularized and applied at present.

(8) Around the world, America and China have the most and widest research on PCPC. The literature chiefly focuses on hydraulic and mechanical performance, yet the literature on durability and environmental function accounts for a small proportion. As climate change and urban expansion trigger some issues, the rapid development of sponge cities conforms to the development strategy of China. PCPC, as the novel and green material, will play an important role in projects including water permeability of urban pavement and side slope greening.

Though PCPC, as a sustainable novel material, obtains more and more recognition, further study is needed to advance its extensive application in engineering:

During the preparation process of PCPC, different researchers adopt distinct mix proportions, and the unified design criterion is deficient. It is necessary to guarantee preferable mechanical properties and durability under the premise of meeting penetrating quality.

(1) Now, there are few studies on the microstructure and mesostructure of PCPC at home and abroad, so further research is required to enhance the understanding of the pore characteristics of PCPC.

(2) Different admixtures and additives have a significant influence on the performance of PCPC. Based on distinct engineering applications, from the angle of the economy and environmental protection, the effects of various substitute materials (such as fiber, rubber, and mineral powder) on the performance of PCPC are studied and the sustainable benefits over the design life are explored.

(3) The high porosity of PCPC plays an active role in its seepage, but this structure is also prone to cause pore blockage. Thus, more research approaches are needed to pledge that the efficacious pore structure of PCPC is not blocked. Quantitative models can be set up to predict the hydraulic power and mechanical properties of PCPC in the case of blockage.

(4) PVC possesses fine ecological benefits, but it involves multi-disciplinary crossover, which can be further studied in the aspects of alkali reduction, soil holding stability of roots, and vegetation performance.

Acknowledgement: Thanks to the help provided by Teacher Cai Xin of the college of Mechanics and Materials from Hohai University.

Funding Statement: This work was supported by the Jiangsu Water Conservancy Science and Technology Project of China (2016036).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Zhou, X. X., Yang, Z. Z., Xu, Y. J., Wang, L., Sun, H. B. et al. (2019). A review on waterproofing agent of lightweight porous concrete. Materials Reports, 33(15), 2546–2551. [Google Scholar]

2. Sun, Q. R., Wang, C. Y., Zhu, B. Y., Xue, B. (2017). Research status and prospect of key problems of planting concrete. China Energy and Environmental Protectio, (1), 20–24. DOI 10.19389/j.cnki.1003-0506.2017.01.001. [Google Scholar] [CrossRef]

3. Li, C. L., Yan, B., Zhang, Y. Q., Wang, Y. (2017). Research progress on water purification effect of aquatic plants and porous concrete. Bulletin of the Chinese Ceramic Society, 36(11), 3691–3696. DOI 10.16552/j.cnki.issn1001-1625.2017.11.019. [Google Scholar] [CrossRef]

4. Wang, H., Li, H., Liang, X., Zhou, H., Xie, N. et al. (2019). Investigation on the mechanical properties and environmental impacts of pervious concrete containing fly ash based on the cement-aggregate ratio. Construction and Building Materials, 202, 387–395. DOI 10.1016/j.conbuildmat.2019.01.044. [Google Scholar] [CrossRef]

5. Xu, T., Huang, P., Lei, L., Luo, C., Feng, Z. (2014). Additive material effects on geotechnical performance of pervious concrete. Electronic Journal of Geotechnical Engineering, 19, 6625–6633. [Google Scholar]

6. Yu, F., Sun, D., Sun, G., Ling, S., Hu, M. et al. (2021). A modified mix design method for pervious concrete based on Mohr-Coulomb failure criterion. Construction and Building Materials, 269, 121801. DOI 10.1016/j.conbuildmat.2020.121801. [Google Scholar] [CrossRef]

7. Kuruppu, U., Rahman, A., Rahman, M. A. (2019). Permeable pavement as a stormwater best management practice: A review and discussion. Environmental Earth Sciences, 78(10), 327. DOI 10.1007/s12665-019-8312-2. [Google Scholar] [CrossRef]

8. Guan, X., Wang, J., Xiao, F. (2021). Sponge city strategy and application of pavement materials in sponge city. Journal of Cleaner Production, 303, 127022. DOI 10.1016/j.jclepro.2021.127022. [Google Scholar] [CrossRef]

9. Goldberg, S. (2013). Permeable pavers expand: More uses for an ecofriendly solution. Erosion Control, 206, 36–41. [Google Scholar]

10. Sang, Z. H. (2017). Research on the durability of eco porous concrete. Central South University of Forestry & Technology. [Google Scholar]

11. Elizondo-Martínez, E. J., Andrés-Valeri, V. C., Jato-Espino, D., Rodriguez-Hernandez, J. (2020). Review of porous concrete as multifunctional and sustainable pavement. Journal of Building Engineering, 27, 100967. DOI 10.1016/j.jobe.2019.100967. [Google Scholar] [CrossRef]

12. Wang, G. L., Wang, L. Z., Zhang, H. X., Cui, X., Song, S. H. (2013). Meaning technology index and research emphases of planting eco-concrete. Concrete, (1), 105–109+113. [Google Scholar]

13. Huang, J. P. (2011). Research on preparation and properties of planting concrete of the slope protection adaptive to urban rivers in South China. South China University of Technology. [Google Scholar]

14. Faiz, H., Ng, S., Rahman, M. (2023). A state-of-the-art review on the advancement of sustainablevegetation concrete in slope stability. Construction and Building Materials, 326, 112–126. DOI 10.1016/j.conbuildmat.2022.126502. [Google Scholar] [CrossRef]

15. Yang, J., Zhou, L., Ou, Z. F. (2011). Experimental study of connected porosity of porous concrete and its effect on pressure strength. Coal Ash, 23(4), 35–37+39. [Google Scholar]

16. Sonebi, M., Bassuoni, M., Yahia, A. (2016). Pervious concrete: Mix design, properties and applications. RILEM Technical Letters, 1, 109–115. DOI 10.21809/rilemtechlett.2016.24. [Google Scholar] [CrossRef]

17. Han, J. (2014). Study on the compression strength and water permeability of vegetation-type ecological regenerate brick concrete. Shandong Agricultural University. [Google Scholar]

18. Wang, Y., Yan, B., Li, C. L. (2017). Review on preparation and properties of permeable concrete. Shenyang Agricultural University, 36(3), 864–869. DOI 10.16552/j.cnki.issn1001-1625.2017.03.018. [Google Scholar] [CrossRef]

19. Park, J. H., Kim, Y. U., Jeon, J., Wi, S., Chang, S. J. et al. (2021). Effect of Eco-friendly pervious concrete wtih amorphous metallic fiber on evaporative colling performance. Journal of Environmental Management, 297(22143–166. [Google Scholar]

20. Liu, R., Chi, Y., Chen, S., Jiang, Q., Meng, X. et al. (2020). Influence of pore structure characteristics on the mechanical and durability behavior of pervious concrete material based on image analysis. International Journal of Concrete Structures and Materials, 144, 627–642. DOI 10.1186/s40069-020-00404-1. [Google Scholar] [CrossRef]

21. Xie, X. S., Tang, W., Wang, J. Y. (2008). Experimental study on strength and porosity ratio of porous ecological concrete. Advanced Engineering Sciences, 40(6), 19–23. [Google Scholar]

22. Dai, Z., Li, H., Zhao, W. Z., Wang, X. P., Wang, H. B. et al. (2020). Multi-modified effects of varying admixtures on the mechanical properties of pervious concrete based on optimum design of gradation and cement-aggregate ratio. Construction and Building Materials, 233, 9. DOI 10.1016/j.conbuildmat.2019.117178. [Google Scholar] [CrossRef]

23. Cui, X., Ou, J., Zhang, N., Gao, Z., Sui, W. (2013). Strength-permeability model of pervious cement concrete. Tumu Jianzhu Yu Huanjing Gongcheng/Journal of Civil, Architectural and Environmental Engineering, 354, 114–120. DOI 10.11835/j.issn.1674-4764.2013.04.018. [Google Scholar] [CrossRef]

24. Dong, Q., Wu, H., Huang, B., Shu, X., Wang, K. (2013). Investigation into laboratory abrasion test methods for pervious concrete. Journal of Materials in Civil Engineering, 257, 886–892. DOI 10.1061/(ASCE)MT.1943-5533.0000683. [Google Scholar] [CrossRef]

25. Zhao, H., Yang, L. M., Li, F. X., Zhang, J. L., Yu, Q. J. (2014). Study on the thickness of cover layer of aggregate and its influence on properties of porous concrete. Concrete, (2), 29–32. DOI 10.3969/j.issn.1002-3550.2014.02.008. [Google Scholar] [CrossRef]

26. Fu, T. C., Yeih, W., Chang, J. J., Huang, R. (2014). The influence of aggregate size and binder material on the properties of pervious concrete. Advances in Materials Science and Engineering, 2014, 963971. DOI 10.1155/2014/963971. [Google Scholar] [CrossRef]

27. Wang, Y. J., Qu, A. L., Gao, T., Zao, A. L., Qi, Y. G. (2016). Experimental studies on strength and water permeability of recycles brick aggregate porous concrete. Concrete, (2), 90–95+98. [Google Scholar]

28. Li, C., Zeng, L. X., Lyu, X. H. (2011). Research progress and application of eco-concrete applied to wastewater treatment. Concrete, (9), 125–127+130. [Google Scholar]

29. Zhang, X. C. (2012). Research on mix proportion design and evaluation on life cycle environmental system of high performance permeable concrete. Central South University. [Google Scholar]

30. Zhu, X. Y., Chen, X. D., Shen, N., Tian, H. X., Fan, X. Q. et al. (2018). Mechanical properties of pervious concrete with recycled aggregate. Computers and Concrete, 216, 623–635. DOI 10.12989/cac.2018.21.6.623. [Google Scholar] [CrossRef]

31. Shang, X. (2016). Mixing ratio design and experimental studies of high-performance porous concrete strength. Chemical Engineering Transactions, 51, 1099–1104. DOI 10.3303/CET1651184. [Google Scholar] [CrossRef]

32. Sabaruddin, M., Tjaronge, W., Ali, N., Djamaluddin, R. (2016). Multilayer testing experimental study on pavement made of porous asphalt and concrete. ARPN Journal of Engineering and Applied Sciences, 1111. 7174–7179. [Google Scholar]

33. Qin, X. (2017). Study on pavement performance and water purification characteristics of pervious concrete surface layer and cement stabilized macadam base layer based on sponge cities. Chongqing Jiaotong University. [Google Scholar]

34. Sun, H. Y. (2016). Mix proportion design and experimental study of pervious concrete based on orthogonal test method. Southwest Jiaotong University. [Google Scholar]

35. Aoki, Y., Sri, R., Khabbaz, H. (2012). Properties of pervious concrete containing fly ash. Road Materials and Pavement Design, 13, 1–11. DOI 10.1080/14680629.2011.651834. [Google Scholar] [CrossRef]

36. Huang, K. J., Wang, J. Y., Lu, J. H., Wang, Y. G. (2016). Mechanical performance of eco-concrete with large porosity used in slope protection. Concrete, (6), 80–83. [Google Scholar]

37. Tang, R., Liu, Y. L., Chen, D. G., Fan, S. J. (2017). Experimental study on preparation and phytic properties of eco-concrete. China Concrete and Cement Products, (10), 18–23. DOI10.19761/j.1000-4637.2017.10.005. [Google Scholar] [CrossRef]

38. Wu, C. L. (2010). Experimental study on basic properties of pervious concrete with rubber aggregate. Tianjin University. [Google Scholar]

39. Yu, C. H., Zhang, Z. G. (2014). Influence of steel slag and fly ash on pervious concrete. Journal of Shijiazhuang Tiedao University (Natural Science Edition), 7(3), 47–49. DOI 10.13319/j.cnki.sjztddxxbzrb. [Google Scholar] [CrossRef]

40. Singh, A., Charak, A., Biligiri, K. P., Pandurangan, V. (2022). Glass and carbon fiber reinforced polymer composite wastes in pervious concrete: Material characterization and lifecycle assessment. Resources, Conservation and Recycling, 182, 106304. DOI 10.1016/j.resconrec.2022.106304. [Google Scholar] [CrossRef]

41. Sun, B. (2017). Study on preparation and properties of new permeable concrete pavement paving materials. Jilin University. [Google Scholar]

42. Giustozzi, F. (2016). Polymer-modified pervious concrete for durable and sustainable transportation infrastructures. Construction and Building Materials, 111, 502–512. DOI 10.1016/j.conbuildmat.2016.02.136. [Google Scholar] [CrossRef]

43. Wang, Z. M. (1996). Crack propagation and macroscopic calculation strength and deformation of inhomogeneous materials (Concrete). Tsinghua University. [Google Scholar]

44. Qin, W., Du, C. B., Sun, L. G. (2011). Concrete meso-level mechanical modeling based on digital image technology. Journal of Hydraulic Engineering, 42(4), 431–439. [Google Scholar]

45. Xu, R. J. (2018). Corroision test and damage mechanism analysis of porous eco-concrete considering environment effects. Jiangsu University. [Google Scholar]

46. Yang, Z. F. (2008). Study on material composition design and properties of porous concrete pervious base. Wuhan University of Technology. [Google Scholar]

47. Zhang, J., Sun, J., Huang, J. M., Cui, X. Z., Li, J. et al. (2019). Application technology of pervious concrete in sponge city. China Water & Power Press. [Google Scholar]

48. Liu, J. H. (2019). Study on water treatment and plugging performance based on RC01 sand-based permeable brick. Huazhong University of Science and Technology. DOI 10.27157/d.cnki.ghzku.2019.001455. [Google Scholar] [CrossRef]

49. Liu, R., Meng, X., Chi, Y., Wu, K., Jiang, Q. et al. (2021). Physical and mechanical properties of pervious concrete with multi-admixtures. Magazine of Concrete Research, 739, 448–463. DOI 10.1680/jmacr.19.00145. [Google Scholar] [CrossRef]

50. Lee, M. G., Huang, T., Huang, Y., Peng, C. P., Su, Y. M. (2017). Preliminary study of pervious concrete on pavement and seawall. Journal of Testing and Evaluation, 451, 249–259. DOI 10.1520/JTE20160156.10.1080/10298436.2021.1884861. [Google Scholar] [CrossRef]

51. Zhou, H., Li, H., Abdelhady, A., Liang, X., Wang, H. et al. (2019). Experimental investigation on the effect of pore characteristics on clogging risk of pervious concrete based on CT scanning. Construction and Building Materials, 212, 130–139. DOI 10.1016/j.conbuildmat.2019.03.310. [Google Scholar] [CrossRef]

52. Li, S. C., Zheng, Z., Liu, R. T., Feng, X., Sun, Z. Z. et al. (2015). Analysis of diffusion of grout in porous media considering infiltration effects. Chinese Journal of Rock Mechanics and Engineering, 34(12), 2401–2409. DOI 10.13722/j.cnki.jrme.2014.1624. [Google Scholar] [CrossRef]

53. Zhang, J., She, R., Dai, Z., Ming, R., Ma, G. et al. (2018). Experimental simulation study on pore clogging mechanism of porous pavement. Construction and Building Materials, 187, 803–818. DOI 10.1016/j.conbuildmat.2018.07.199. [Google Scholar] [CrossRef]

54. Akkaya, A., Çağatay, İ. H. (2021). Experimental investigation of the use of pervious concrete on high volume roads. Construction and Building Materials, 279, 122430. DOI 10.1016/j.conbuildmat.2021.122430. [Google Scholar] [CrossRef]

55. Aliabdo, A. A., Abd Elmoaty, M., Fawzy, A. M. (2018). Experimental investigation on permeability indices and strength of modified pervious concrete with recycled concrete aggregate. Construction and Building Materials, 193, 105–127. DOI 10.1016/j.conbuildmat.2018.10.182. [Google Scholar] [CrossRef]

56. Wang, P. X., Huang, H. C., Gui, M. M., Quan, M., Liu, J. et al. (2014). Influence factor and mechanical properties study on pavement pervious concrete. China Concrete and Cement Products, (3), 1–4. DOI 10.19761/j.1000-4637.2014.03.001. [Google Scholar] [CrossRef]

57. Luo, J. B. (2020). Research on mechnical properties and durability of crumb rubber and silica fume composite modified pervious concrete in seasonal frozen area. Jilin University. DOI 10.27162/d.cnki.gjlin.2020.000024. [Google Scholar] [CrossRef]

58. Chen, S. K., Lu, P., Li, B. L., Wang, L. X., Guo, L. et al. (2022). Influence and evalution analysis of different fibers on the performance of recycled aggregate pervious concrete. Journal of Basic Science and Engineering, 30(1), 208–218. DOI 10.16058/j.issn.1005-0930.2022.01.017. [Google Scholar] [CrossRef]

59. Shukhov, V. G., Yadykina, V. V., Aghamyan, B. S. (2016). Research of shear and crack resistance of asphalt concrete with porous mineral fillers Dmitriy Alekseevich Kuznetsov. International Journal of Pharmacy and Technology, 84, 24717–24725. [Google Scholar]

60. Lu, Y., Wang, Y. J., Wang, H. C., Sun, H. S., Wang, Q. (2019). Experim entalstudy on the mechanical properties of modified sea watersea sand coral concrete. Concrete, (4), 150–154. [Google Scholar]

61. Wang, D. M., Yang, C., Zhao, Q. X., Li, T., Yang, F. F. etal. (2020). Frost resistance of shell waste pervious vegetation-growing concrete. Journal of Yangtze River Scientific Research, 37(12), 152–156+182. [Google Scholar]

62. Zhang, W., Dong, Y., Peng, N., Gao, Y. (2020). Analysis on mechanical properties of pervious recycled concrete by damage under freeze-thaw cycles. Jianzhu Cailiao Xuebao/Journal of Building Materials, 232, 292–296. DOI 10.3969/j.issn.1007-9629.2020.02.008. [Google Scholar] [CrossRef]

63. Li, C., Zhao, S., Liu, H. Z., Zhang, Y. (2019). A review of research progress of vegetation concrete on coastal highway slope. Journal of Coastal Research, 9494, 367–371. DOI 10.2112/SI94-075.1. [Google Scholar] [CrossRef]

64. Xue, D. J., Liu, R. G., Xu, R. J., Yin, J., Liu, R. et al. (2014). Experimental study on pervious eco concrete in freezing-thawing circumstance. Bulletin of the Chinese Ceramic Society, 33(6), 1480–1484. DOI 10.16552/j.cnki.issn1001-1625.2014.06.065. [Google Scholar] [CrossRef]

65. Lund, M. S. M., Kevern, J. T., Schaefer, V. R., Hansen, K. K. (2017). Mix design for improved strength and freeze-thaw durability of pervious concrete fill in pearl-chain bridges. Materials and Structures/Materiaux et Constructions, 50(1), 42. DOI 10.1617/s11527-016-0907-4. [Google Scholar] [CrossRef]

66. Anderson, I., Dewoolkar, M. M. (2015). Laboratory freezing-and-thawing durability of fly ash pervious concrete in a simulated field environment. ACI Materials Journal, 1125, 603–611. DOI 10.14359/51687921. [Google Scholar] [CrossRef]

67. Nassiri, S., AlShareedah, O., Rodin, H., IIIEnglund, K. (2021). Mechanical and durability characteristics of pervious concrete reinforced with mechanically recycled carbon fiber composite materials. Materials and Structures/Materiaux et Constructions, 54(3), 107. DOI 10.1617/s11527-021-01708-8. [Google Scholar] [CrossRef]

68. Zhou, J. L., Zheng, M. L., Wang, Q., Yang, J. G., Lin, T. F. (2016). Flexural fatigue behavior of polymer-modified pervious concrete with single sized aggregates. Construction and Building Materials, 124, 897–905. DOI 10.1016/j.conbuildmat.2016.07.136. [Google Scholar] [CrossRef]

69. Zheng, M. L., Wang, B. G., Hu, C. Z. (2004). Study on fatigue performance of porous concrete. China Journal of Highway and Transport, (1), 11–15. [Google Scholar]