Materials

| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.016255

ARTICLE

Preparation and Properties of Bio-Based Flame Retardant L-APP/Poly(L-lactic acid) Composites

1Hunan Engineering Laboratory for Preparation Technology of Polyvinyl Alcohol Fiber Material, Huaihua University, Huaihua, 418000, China

2National and Local Joint Engineering Laboratory for New Petro-Chemical Materials and Fine Utilization of Resources, Hunan Normal University, Changsha, 410081, China

*Corresponding Authors: You Shu. Email: shuyou1122@163.com; Shengpei Su. Email: shengpei_academi@sohu.com

Received: 21 February 2021; Accepted: 31 March 2021

Abstract: Poly(L-lactic acid) (PLLA) is a thermoplastic material with complete degradability, high biocompatibility and excellent mechanical properties. It can replace petroleum-based polymers are currently being used in the fields of packaging, agriculture, textiles, medical and so on. However, PLLA’s extremely flammability greatly limits its wider application. An bio-based flame retardant L-APP/PLLA composites was prepared by melt blending of the L-APP and PLLA. The morphology, impact properties, thermal properties and flame retardant properties of composites were investigated by field emission scanning electron microscope (SEM), impact tester, differential scanning calorimeter (DSC), thermogravimetric analyzer (TGA), limiting oxygen indexer (LOI) and horizontal-vertical burning tester. The results showed that the degree of crystallization (Xc) and LOI of L-APP/PLLA composites increased as increasing of L-APP content. What’s more, the impact strength first increased and then decreased, the glass transition temperature (Tg) and melting temperature (Tm) do not changed significantly. The impact strength of composites was 9.1 kJ/m2 at a 5 wt% loading for L-APP, which was the highest level. When the content of L-APP was 20%, the LOI was 30.8%, the Xc was 42.3% and the UL-94 level was V-0. This research can promote the value-added utilization of lignin and the application of PLLA in the fields of flame retardant materials.

Keywords: Bio-based flame retardant; lignin; ammonium polyphosphate; poly(L-lactic acid)

The theme of the current era is green and sustainable development. The reduction of resources and the aggravation of white pollution make people urgently need a kind of material that can be synthesized from biomass and can be fully degraded after the end of the use period to reduce environmental deterioration [1,2]. Poly(L-lactic acid) (PLLA) is a representative of this type of material. PLLA is a polymer obtained by polymerization of lactic acid. Lactic acid has a wide range of sources and can be extracted by fermentation of sugar-containing biomass sucrose, potato, corn, sugar beet, etc. [3–5]. PLLA with excellent mechanical properties, high transparency and biodegradability is regarded as a substitute for petrochemical-based polymer materials such as PP, PE, PS, etc. [6]. The preparation and application of flame-retardant PLLA material is an important research direction in the field of PLLA materials [7–9].

Adding intumescent flame retardants is the most convenient and effective method for flame retardant modification of PLLA [10]. Among them, ammonium polyphosphate (APP) has environmental protection characteristics such as halogen-free, low toxicity, and no corrosive gas. The intumescent flame retardant composed of APP used as an acid source and gas source and starch, lignin, and cyclodextrin used as a carbon source can achieve high-efficiency flame retardant modification of PLLA [11,12]. Wang et al. used polyurethane to microencapsulate APP (MCAPP), then combined with melamine (MA) and starch (Starch) to form a compound intumescent flame retardant for the flame retardant modification of PLLA, and the impact of flame retardant system components on the flame retardant properties of PLLA was discussed. The research results showed that when the flame retardant content was 30% (MCAPP:MA:Starch = 13:7:10), the LOI of PLLA/MCAPP/MA/Starch composite resin possessed high value as 41.0%, and the UL-94 rating was upgraded to V-0 level [13]. Reti et al. prepared flame-retardant PLLA composites by mixing lignin, APP and PLLA. The research results showed that the UL-94 rating of PLLA reached V-0 level when adding 30 wt% APP and 10 wt% lignin [14]. Feng et al. prepared flame-retardant PLLA composites by mixing β-cyclodextrin, APP and PLLA. The research results illustrated that the UL-94 rating of PLLA passed V-0 level and the LOI reached 29% when adding 10 wt% APP and 10 wt% β-cyclodextrin [15]. However, in most researches, the total content of flame retardants used was too high, or the toughness of PLLA cannot be effectively improved while obtaining flame retardant modified PLLA [16]. Generally, the toughness of the material would be further deteriorated due to the addition of flame retardants.

In order to overcome the above problems, an lignin-based ammonium polyphosphate (L-APP)/PLLA composites were prepared by blending L-APP and PLLA. The impact performance, thermal performance and flame retardancy of the L-APP/PLLA composites were tested. This strategy had simple process and low cost, and provided a new idea for expanding the application of PLLA.

PLLA (4032D, density 1.24, Tg 52.8°C) was bought from NatureWorks, USA. L-APP (lignin segment content, 20 wt%) was purchased from Hunan Lvshen Environmental Protection Technology Co., Ltd., China.

2.2 Production of Flame Retardant L-APP/PLLA

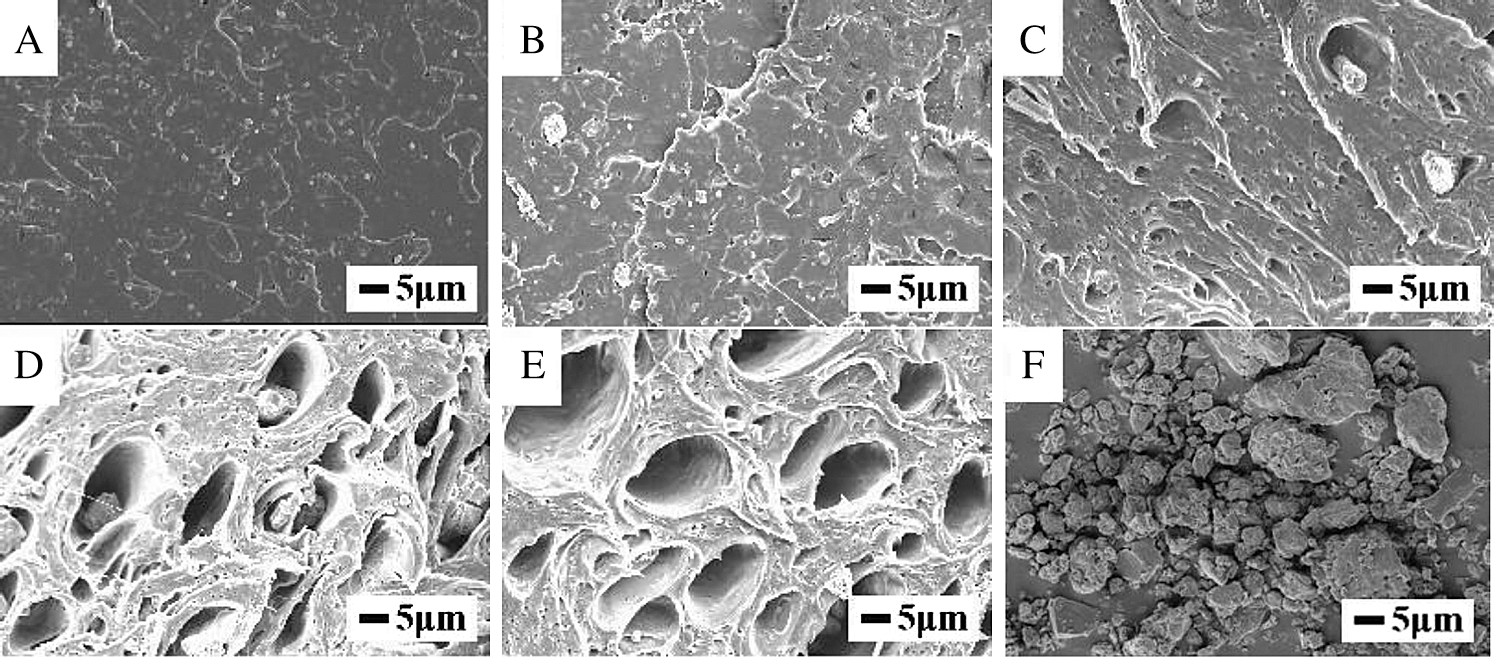

The PLLA and L-APP were uniformly mixed by a twin-screw extruder (MTS-20B, Nanjing Jieente Electromechanical Co., Ltd., China). According to the formula listed in Tab. 1. Then, the flame retardant L-APP/PLLA composites were prepared using an injection molding machine (ZH-88D, China Changsha Haibo Electromechanical Equipment Co., Ltd., China). The temperatures of extruder: one-zone 110°C, two-zone 130°C, three-zone 150°C, four-zone 160°C, five-zone 170°C, six-zone 175°C, and extrusion die of 170°C. The temperatures of injection molding machine as follows: one-zone 160°C, two-zone 170°C, three-zone 175°C, and four-zone 175°C.

2.3 Performance Testing and Structural Characterization

Zeiss-SIGMAHD SEM (Zhe Zeiss, Germany) was employed in the characterization. The surface of the samples were sprayed with gold before scanning and the voltage was set at 5.0 kV.

Impact performance was obtained by XBL-22 impact tester (China Shenzhen Kaiqiangli Experimental Instrument Co., Ltd., China) with V-notched samples and pendulum impact energy of 7.5 J was used. This test was carried out on the specimen accordance to the method as specified in GB/T 1843-2008.

A sample of 5 mg was sealed in an aluminum sample pan, then was placed in the differential scanning calorimeter (DSC) (200F3 type, NETZSCH Group of Germany). Samples were heated from 20°C to 200°C at a heating rate of 10 °C/min and kept for 5 min at 200°C to clear the thermal history. Thereafter, the samples were cooled down to room temperature at a rate of 10 °C/min and kept for 5 min, and then were run as the formed heating way for second time. The heating process was performed under a nitrogen atmosphere. The crystallinity of the composites was calculated in line with the following formula:

where ΔHm is the melting enthalpy of composites, ΔHcc is the cold crystallization enthalpy of composites, ФPLLA is the mass fraction of PLLA in the composites, and ΔHm0 is the melting enthalpy for 100% crystalline PLLA (93.6 J/g) [17].

Pyris Diamond type TG analyzer (PE Company, USA) was used in the test. A sample of 10 mg was heated from 30°C to 800°C at 20 °C/min in an air atmosphere.

The LOI was surveyed in the light of GB/T 2406.2-2009 employing a ZR-01 type LOI meter (Qingdao Shanfang Instrument Co., Ltd., China). The length, width, and thickness of the sample were 80 mm, 10 mm, and 4 mm, respectively.

Vertical burning test was carried out in line with GB/T 2408-2008 using a CZF-5 horizontal-vertical burning tester (Nanjing Yulei Instrument Equipment Co., Ltd., China). The length, width, and thickness of the sample were 120 mm, 13 mm, and 6 mm, respectively.

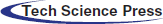

To investigate the dispersion of L-APP in PLLA substrate and the compatibility between L-APP and PLLA, the morphology of impact-fractured surfaces of PLLA and flame retardant L-APP/PLLA composites were observed by SEM, as shown in Fig. 1.

Figure 1: SEM images obtained from: (A) pure PLLA; (B) flame retardant PLLA with 5 wt% L-APP; (C) flame retardant PLLA with 10 wt% L-APP; (D) flame retardant PLLA with 15 wt% L-APP; (E) flame retardant PLLA with 20 wt% L-APP; (F) L-APP (X2000)

There were uneven pores caused by the shedding of L-APP in the impact-fractured surfaces of flame retardant L-APP/PLLA composites, and the size of the pores increased with the content of L-APP, which indicated that the compatibility between L-APP and PLLA was unsatisfactory, and L-APP agglomerated severely in the PLLA substrate.

The fractured surface of PLLA was smooth and flat, which was caused by its brittle fracture. It can be seen from Fig. 1F that L-APP was a sheet structure. As illustrated in Fig. 1B, when the content of L-APP was 5 wt%, the fractured surface of the composites was rough, and there were obvious filaments due to ductile rupture. It was because a little of L-APP has a heterogeneous nucleation effect in PLLA substrate, which refined the crystallization of the composites, thereby improving the toughness of the composites [18]. As known from Figs. 1C–1E that the fractured surface of the composites became more and more smooth again as the amount of L-APP continues to increase, which was due to the agglomeration of L-APP in PLLA substrate became more serious, and leaded to a gradual decrease in the toughness of the composites.

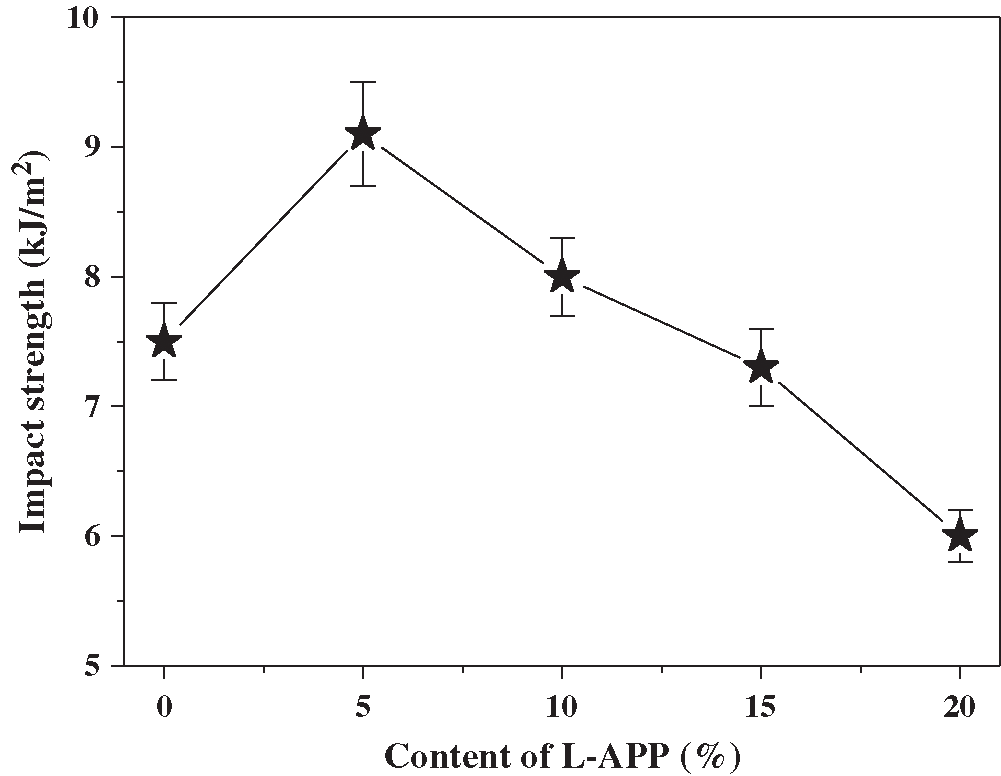

Impact properties is one of the most important properties of polymer materials. In this section, the impact performance of PLLA and flame retardant L-APP/PLLA composites were tested (Fig. 2).

Figure 2: Effect of L-APP content on the impact strength of flame retardant PLLA composites

The impact strength of PLLA was 7.5 kJ/m2, and the impact strength of flame retardant L-APP/PLLA composites increased first and then decreased with the L-APP content. When the L-APP content was 5 wt%, the impact strength of the composites was the largest, 9.1 kJ/m2, which was 20.7% higher than that of pure PLLA. When the content of L-APP was within 10 wt%, its heterogeneous nucleation effect was prominent, which refined the spherulites of the composites, increased the toughness of the composites, and then made the impact strength of the composites higher than that of pure PLLA [18]. When the content of L-APP was further increased, the impact strength of the composites was lower than that of pure PLLA, which caused by the serious agglomeration of L-APP in the composites and the heterogeneous nucleation effect of L-APP was weakened.

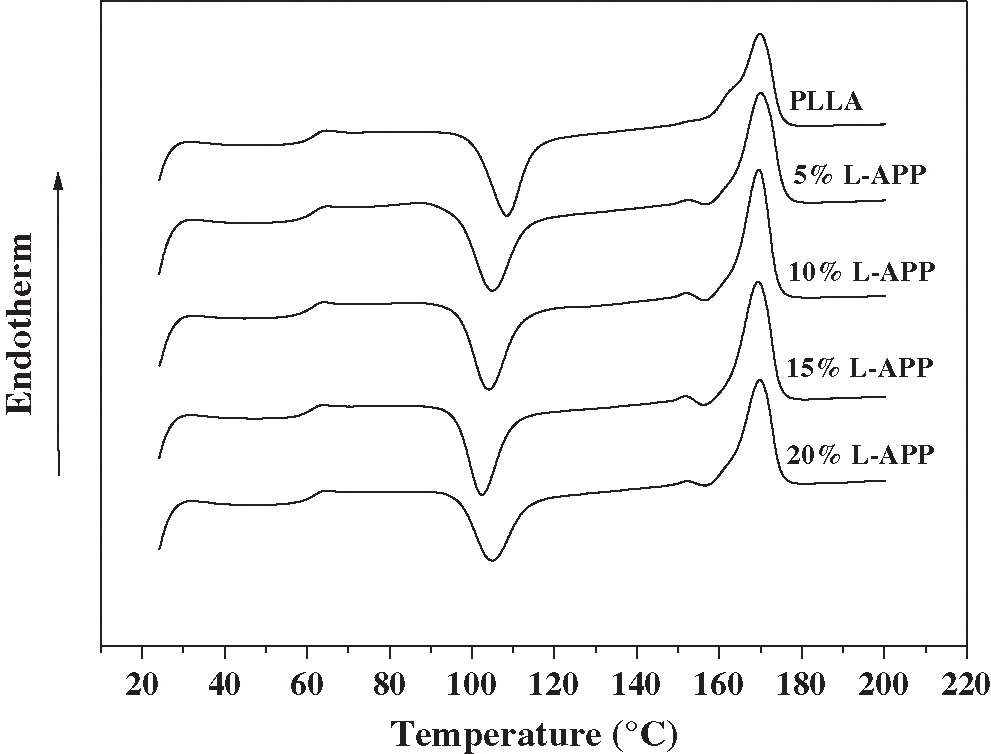

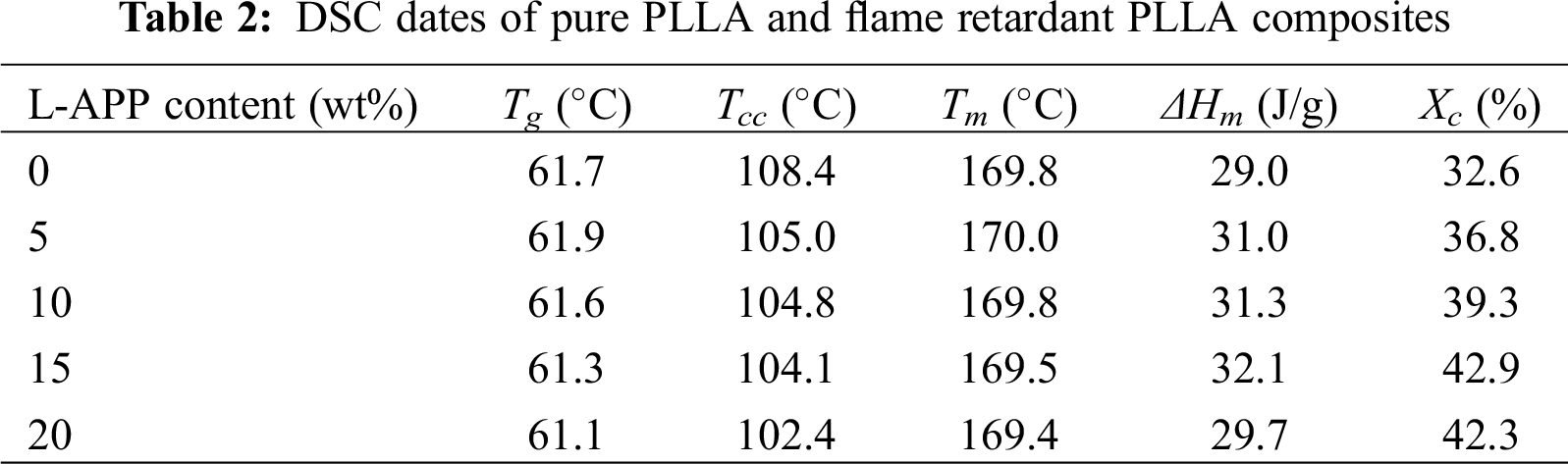

The thermal properties of PLLA and flame retardant L-APP/PLLA composites were studied by DSC, and the results were shown in Fig. 3 and Tab. 2.

Figure 3: DSC curves of pure PLLA and flame retardant PLLA composites

The Tg, Tcc, Tm, and Xc of PLLA were 61.7°C, 108.4°C, 169.8°C, 32.6%, respectively. As the content of L-APP increased, the Tcc of flame retardant L-APP/PLLA composites gradually decreased, and Xc shown an upward trend. It is because L-APP had a heterogeneous nucleation effect, which made the crystallization of composites easier. The change of Tg and Tm of flame retardant L-APP/PLLA composites was not very obvious with the increased of L-APP content. It may be the result of a balance between the positive effects of L-APP heterogeneous nucleation and the negative effects of L-APP agglomeration.

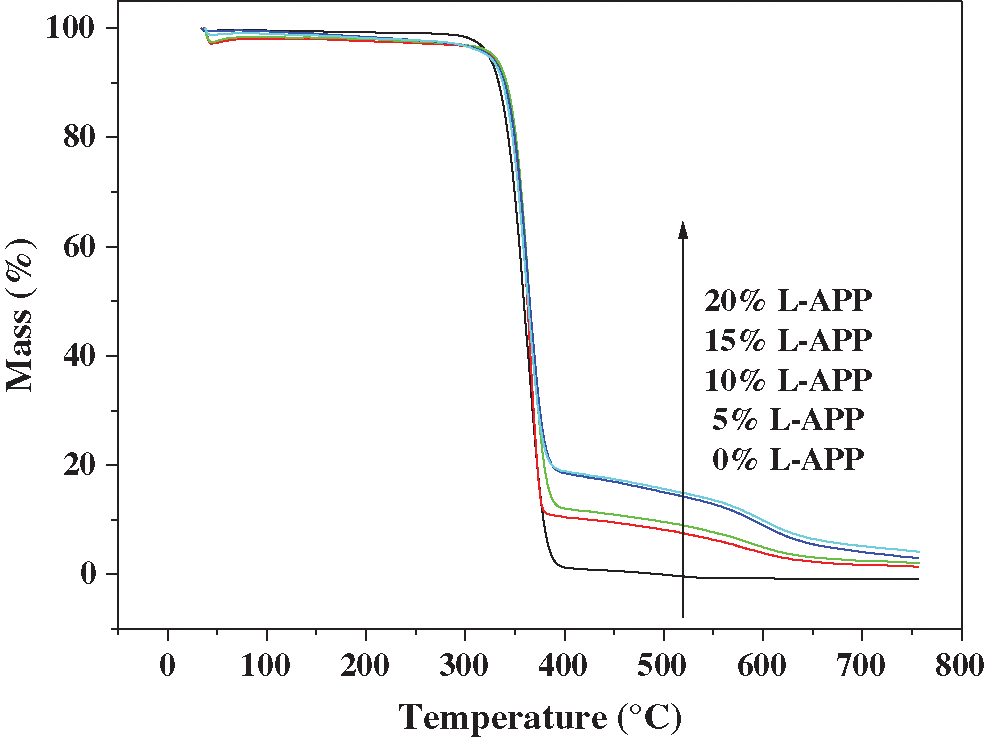

The thermogravimetric method is usually used to measure the relationship between the mass change of the sample and the temperature. In order to investigate the influence of L-APP on the thermal oxidative degradation of flame retardant L-APP/PLLA composites, thermogravimetric analysis of PLLA and flame retardant L-APP/PLLA composites was performed, the test result was shown in Fig. 4.

Figure 4: TG curves of pure PLLA and flame retardant PLLA composites

The mass loss of PLLA can be divided into three stages: there was a slight weight loss from room temperature to 330°C, which was caused by the evaporation of trace water and the decomposition of monomers remained in PLLA. 330∼395°C, the mass loss rate fastest, the mass loss rate in this region reached 93.0%, which was due to the decomposition of the macro-molecular chain segment of PLLA. It basically reached equilibrium after 400°C. The mass loss of flame retardant L-APP/PLLA composites can be roughly divided into four stages: there was a slight weight loss from room temperature to 330°C, which was caused by the evaporation of trace water and the decomposition of monomers remained in composites. 330∼395°C, the mass loss rate was the fastest, when the L-APP content were 5 wt%, 10 wt%, 15 wt%, and 20 wt%, the mass loss rates of the corresponding composites were 82.5%, 81.3%, 75.9%, 75.1%, respectively. It was due to the decomposition of PLLA macro-molecular segments and L-APP. The mass loss rate slowed down at 395∼700°C, which was caused by the gas released by the oxidation of the residual carbon layer burned in the previous stage of the composites. It basically reached equilibrium after 700°C.

It can also be seen from Fig. 4 that in the range of 395°C to 700°C, there was no residual carbon in the pure PLLA. The residual carbon content of the flame retardant L-APP/PLLA composites increased with L-APP content. It was because during the combustion process of the composites, the phospholipid bonds and lignin segments in L-APP can promote the formation of the carbon layer [19].

3.5 Flame Retardant Performance

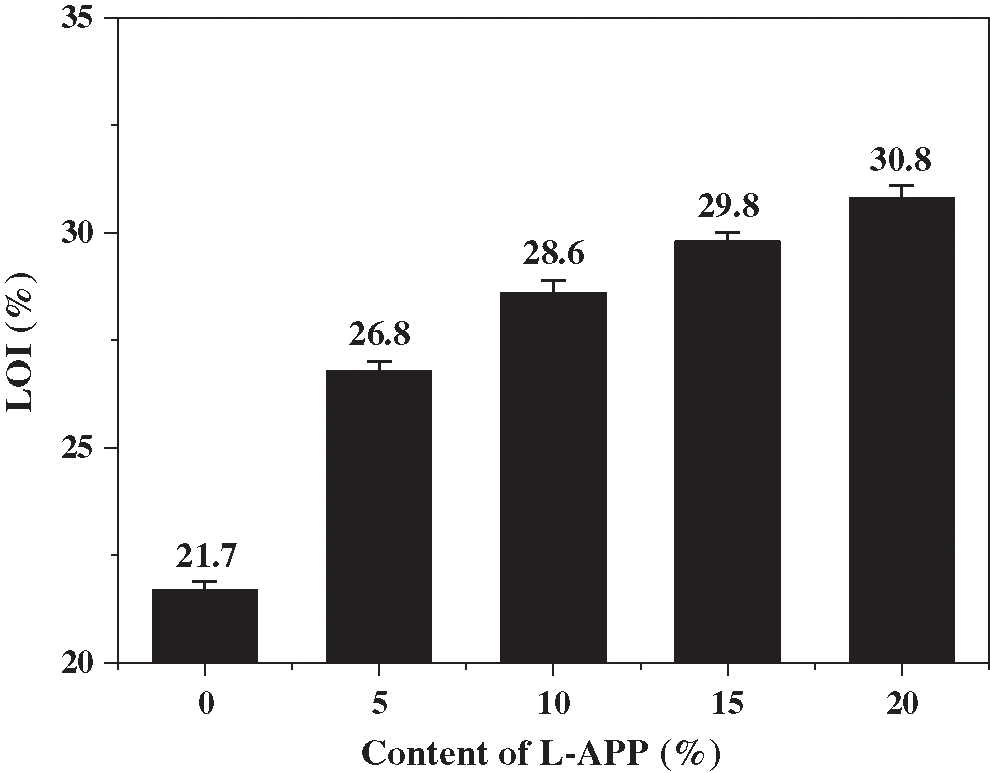

In order to investigate the impact of L-APP on the minimum oxygen concentration (LOI) required for the L-APP/PLLA composites to maintain combustion, the LOI of PLLA and flame retardant L-APP/PLLA composites were tested and the results were shown in Fig. 5.

Figure 5: Impact of the content of L-APP on LOI of flame retardant L-APP/PLLA composites

The LOI of the PLLA was 21.7%, indicating easy combustion. The test data showed that the LOI of flame retardant L-APP/PLLA composites could be enhanced by adding L-APP. The LOI of the composites was as high as 30.8% when the load of L-APP up to 20%. It was because of that the synergistic flame retardant function of phosphorus and nitrogen in L-APP and the char-formation effect of lignin segments strengthened insulation shield effect of composites to heat flux, oxygen and combustible pyrolysis products [20–22].

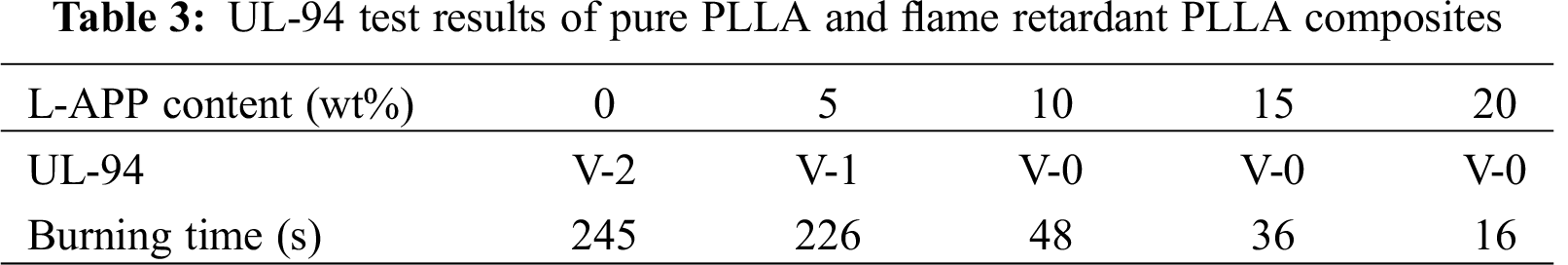

Vertical burning test was performed to investigate the influence of L-APP on the UL-94 fire hazard level of L-APP/PLLA composite materials. The test results were listed in Tab. 3.

The burning time of PLLA was 245 s, there being drips during the burning process, which fire up the cotton underneath, and the UL-94 level was V-2. When the portion of L-APP up to 10%, the burning time of flame retardant L-APP/PLLA composites was 48 s and no drip was produced during combustion, the UL-94 level of fire retardancy reached V-0. The burning time of composites decreased as the portion of L-APP, evidencing that flame retardancy of composites promoted [4].

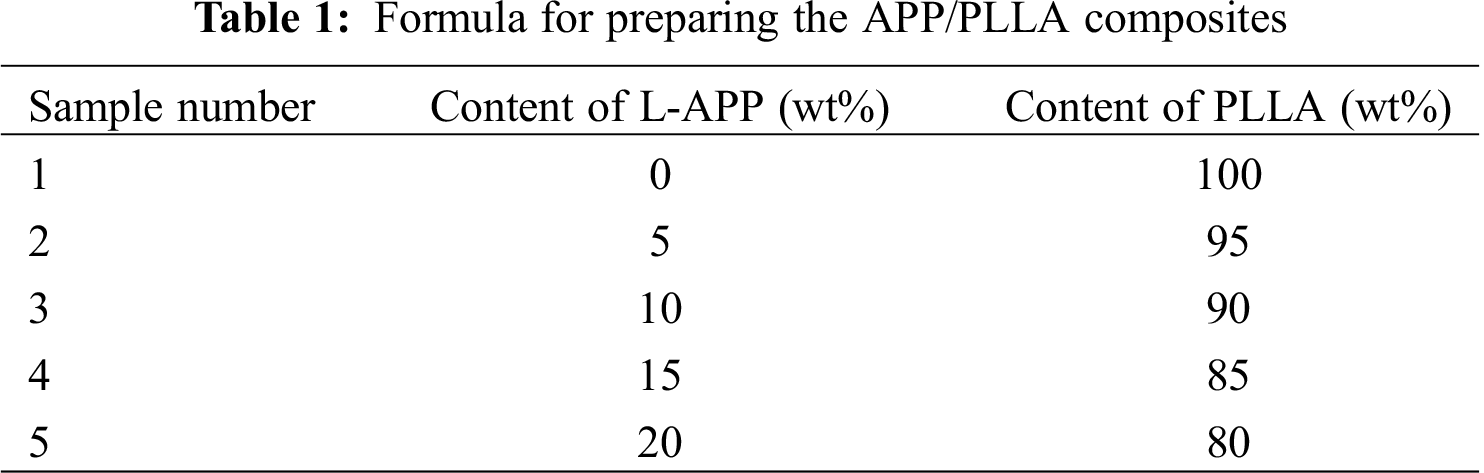

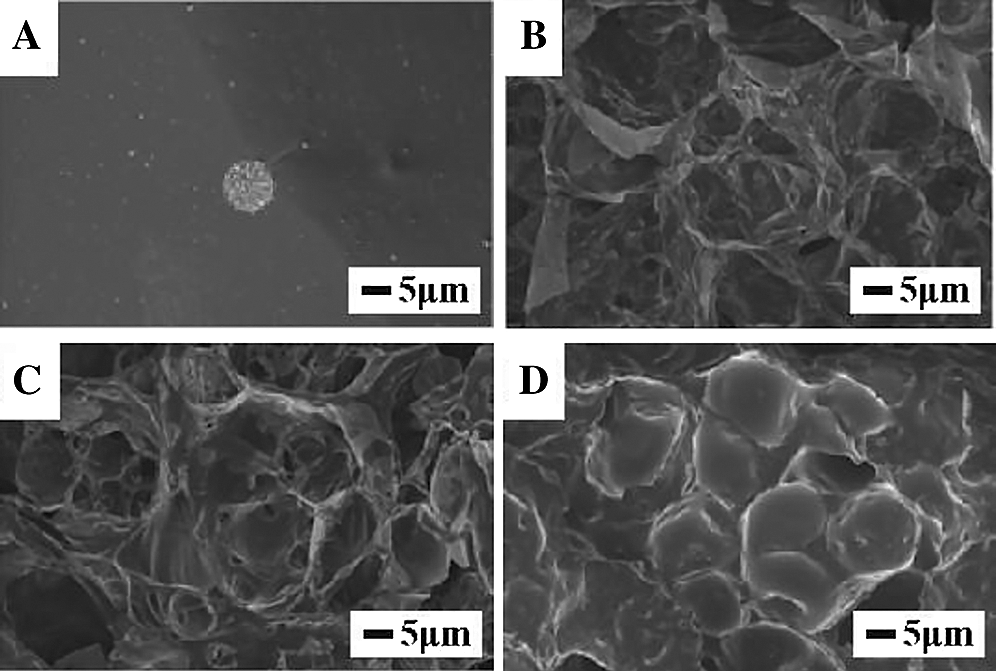

The carbon layer formed during combustion process can insulate heat and combustible gas, thereby preventing the polymer material from continuing to burn. The SEM was performed here to research the morphology of the burning carbon layer of PLLA and L-APP/PLLA composites (Fig. 6).

Figure 6: SEM images of residues: (A) pure PLLA; (B) composites of L-APP/PLLA with 5 wt% L-APP; (C) composites of L-APP/PLLA with 10 wt% L-APP; (D) composites of L-APP/PLLA with 20 wt% L-APP (X10000)

As shown in Fig. 6A, PLLA burnt relatively completely, with almost no carbon resided. After the L-APP was introduced, a significant carbon layer resided after the L-APP/PLLA composites burnt, and the carbon layer was honeycomb-shaped due to gas expansion. As illustrated in Figs. 6B–6D, the burning residual carbon layer of the composites became thicker than that of pure PLLA and there were plentiful of the honeycomb-like holes as increasing the content of L-APP. These results could be triggered by the intumescent flame retardant function of L-APP [23].

The Xc, thermal stability and impact strength of flame retardant L-APP/PLLA composites were found to be improved as the addition of a certain content of L-APP. When the load of L-APP up to 10%, the LOI, UL-94 level, impact strength and Xc of flame retardant L-APP/PLLA composites increased to 28.6%, V-0, 8.0 kJ/m2, 39.3%, respectively. The experimental date indicated that bio-based flame retardant L-APP/PLLA composites with fire retardancy and fine impact-resistance performance was successfully prepared. This work can accelerate the application of PLLA in the field of fire protection.

Funding Statement: This work was financially supported by the following funds: Hunan Provincial Natural Foundation of China (2019JJ50472), Opening Fund of National & Local Joint Engineering Laboratory for New Petro-chemical Materials and Fine Utilization of Resources (KF201802), Hunan Province Key Field R&D Program Project (2019GK2246), Education Department of Hunan Province Key Project (19A391),Key scientific research project of Huaihua University (HHUY2019-04), Special Project of Innovative Provincial Construction in Hunan Province (2020RC1013), Huaihua Key Laboratory for Preparation of Ceramic Materials and Devices and Science and Technology Plan Project of Huaihua City (2020R3101).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Li, J. H., Sun, J., Zhang, S. (2018). Domestic and overseas research progress of flame retardant poly(lactic acid). Plastics, 47(2), 89–92. [Google Scholar]

2. Kaseem, M. (2019). Poly(lactic acid) composites. Materials, 12(21), 3586. DOI 10.3390/ma12213586. [Google Scholar] [CrossRef]

3. Han, S. F., Li, Y., He, M., Tian, G., Yang, Z. Q. et al. (2019). Research progress on heat resistant modification of PLLA matrix composites. Engineering Plastics Application, 47(6), 143–147. [Google Scholar]

4. Zhao, P. C., Liu, Z. Q., Wang, X. Y., Pan, Y. T., Kuehnert, I. et al. (2018). Renewable vanillin based flame retardant for poly(lactic acidA way to enhance flame retardancy and toughness simultaneously. RSC Advances, 8(73), 42189–42199. DOI 10.1039/C8RA08531E. [Google Scholar] [CrossRef]

5. Zhang, N., Lu, X. (2018). Mechanical, thermal and combustion properties of intumescent flame retardant biodegradable poly(lactic acid) composites. Plastics, Rubber and Composites, 48(10), 1–10. DOI 10.1080/14658011.2018.1534391. [Google Scholar] [CrossRef]

6. Sun, Q. H., Zhang, B. C., Song, X. F. (2020). Advance research of flame retarded polylactic acid. Engineering Plastics Application, 48(7), 142–147. [Google Scholar]

7. Tang, D., Weng, Y. X., Diao, X. Q., Song, X. Y., Zhou, Y. X. et al. (2020). Research progress on toughening and modification of polylactic acid with environmentally friendly materials. Scientia Sinica Chimica, 50(12), 1769–1780. DOI 10.1360/SSC-2020-0054. [Google Scholar] [CrossRef]

8. Shu, Y., Hu, Y. J., Lin, H. W., Li, J. S., Wang, M. L. (2017). Effect of thermoplastic poly(vinyl alcohol) on structure and properties of poly(lactic acid). China Plastics, 31(12), 73–77. [Google Scholar]

9. Xue, Y., Zuo, X. H., Wang, L. K., Zhou, Y. C., Pan, Y. et al. (2020). Enhanced flame retardancy of poly(lactic acid) with ultra-low loading of ammonium polyphosphate. Composites Part B, 196, 108124. DOI 10.1016/j.compositesb.2020.108124. [Google Scholar] [CrossRef]

10. Wu, C., Yang, D. D., Wu, G., Chen, S. C. (2021). Flame retardant and toughening modification of poly(lactic acid) with phenylhypophosphate ionomer/ammonium polyphosphate. Acta Polymerica Sinica, 52(2), 176–185. [Google Scholar]

11. Zhan, J., Song, L., Nie, S. B., Hu, Y. (2009). Combustion properties and thermal degradation behavior of polylactide with an effective intumescent flame retardant. Polymer Degradation and Stability, 94(3), 291–296. DOI 10.1016/j.polymdegradstab.2008.12.015. [Google Scholar] [CrossRef]

12. Chen, C., Gu, X., Jin, X. D., Sun, J., Zhang, S. (2017). The effect of chitosan on the flammability and thermal stability of polylactic acid/ammonium polyphosphate biocomposites. Carbohydrate Polymers, 157, 1586–1593. DOI 10.1016/j.carbpol.2016.11.035. [Google Scholar] [CrossRef]

13. Wang, J. J., Ren, Q., Zheng, W. G., Zhai, W. T. (2014). Improved flame-retardant properties of poly(lactic acid) foams using starch as a natural charring agent. Industrial Engineering Chemistry Research, 53(4), 1422–1430. DOI 10.1021/ie403041h. [Google Scholar] [CrossRef]

14. Reti, C., Casetta, M., Duquesne, S., Bourbigot, S., Delobel, R. (2008). Flammability properties of intumescent PLLA including starch and lignin. Polymers for Advanced Technologies, 19(6), 628–635. DOI 10.1002/(ISSN)1099-1581. [Google Scholar] [CrossRef]

15. Feng, J. X., Su, S. P., Zhu, J. (2011). An intumescent flame retardant system using cyclodextrin as a carbon source in poly(lactic acid) (PLLA). Polymers for Advanced Technologies, 22(7), 1115–1122. DOI 10.1002/pat.1954. [Google Scholar] [CrossRef]

16. Yu, S. L., Hu, X. N., Tang, F. Y., Zhu, C. J., Xiang, H. X. et al. (2020). Flame-retardant poly(lactic acidAn overview and outlook. Chemical Industry and Engineering Progress, 39(9), 3421–3432. [Google Scholar]

17. Shu, Y., Luo, Q. L., Wang, M. L., Ouyang, Y. J., Lin, H. W. et al. (2020). Preparation and properties of poly(lactic acid)/ligninmodified polyvinyl acetate composites. Journal of Applied Polymer Science, 138(7), 49844. DOI 10.1002/app.49844. [Google Scholar] [CrossRef]

18. Zou, J., Shu, Y., Ma, T., He, W., Huang, F. R. (2010). Preparation and properties study of ultrafine talc filled poly(lactic acid) films. China Plastics Industry, 38(11), 13–16. [Google Scholar]

19. Wu, N. J., Yu, J. H., Lang, W. C., Ma, X. B., Yang, Y. (2019). Flame retardancy and toughness of poly(lactic acid)/GNR/SiAHP composites. Polymers, 11(7), 1129. DOI 10.3390/polym11071129. [Google Scholar] [CrossRef]

20. Zhang, Q. R., Lia, Z. W., Lia, X. H., Yu, L. G., Zhang, Z. J. et al. (2019). Zinc ferrite nanoparticle decorated boron nitride nanosheet: Preparation, magnetic field arrangement, and flame retardancy. Chemical Engineering Journal, 356, 680–692. DOI 10.1016/j.cej.2018.09.053. [Google Scholar] [CrossRef]

21. Nabipoura, H., Nieb, S., Wang, X., Song, L., Hua, Y. (2020). Zeolitic imidazolate framework-8/polyvinyl alcohol hybrid aerogels with excellent flame retardancy. Composites Part A: Applied Science and Manufacturing, 129, 105720. DOI 10.1016/j.compositesa.2019.105720. [Google Scholar] [CrossRef]

22. Shi, X. W., Ju, Y. Q., Zhang, M., Wang, X. L. (2018). The intumescent flame-retardant biocomposites of poly(lactic acid) containing surface-coated ammonium polyphosphate and distiller’s dried grains with solubles (DDGS). Fire and Materials, 42(2), 190–197. DOI 10.1002/fam.2479. [Google Scholar] [CrossRef]

23. Shu, Y., Luo, Q. L., Lin, H. W., Ouyang, Y. J., Zhang, X. M. et al. (2021). Preparation and properties of Bio-based flame retardant polyvinyl alcohol. Journal of Renewable Materials, 9(5), 909–921. DOI 10.32604/jrm.2021.014216. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |