| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.014109

ARTICLE

Dynamic Changes of Chemical and Mechanical Properties of Moso Bamboo (Phyllostachys edulis) Culms under Different Storage Conditions

1Southwest Forestry University, Kunming, 650224, China

2APFNet Kunming Training Center, Kunming, 650224, China

*Corresponding Author: Shuguang Wang. Email: stevenwang1979@126.com

Received: 31 August 2020; Accepted: 19 October 2020

Abstract: The durability of bamboo based on its chemical and mechanical properties is a crucial consideration for the wood-based industry due to its vulnerability to insects and microorganisms. We investigated the dynamic changes of chemical and mechanical properties of Phyllostachys edulis under air-dry and water storage conditions for 3, 6 and 12 months respectively. The chemical properties of P. edulis bamboo culms varied with culm age but insignificantly with culm height. The mechanical properties of P. edulis culms showed an increasing trend with culm age. Water storage condition decreased the ash, SiO2 and lignin content, but increased the ethanol-benzene extracts. It also created an anaerobic environment for bamboo culms in which only anaerobic respiration was possible contributing to reducing the content of soluble sugar and starch, thereby beneficial for decreasing the damage from insects and microorganisms. Moreover, the water storage conditions could maintain culm mechanical performance better. Therefore, the indigenous practice of local people to store bamboo culms in ponds has good science behind it and water storage practices of bamboo culms was recommended.

Keywords: Phyllostachys edulis; chemical properties; mechanical properties; storage conditions

Bamboo has become the most important non-wood material for the wood-based industry due to its easy propagation, fast growth and high productivity [1]. Bamboo use is wide-ranging from construction and reinforcing fibers, paper, textiles and boards, food and combustion and bioenergy applications [2]. The chemical and mechanical properties of bamboo timber are fundamental for its utilization as they affect the processing procedures and the performance of end products significantly [1]. Similar to the ratios reported in both softwood and hardwood, bamboo contains 40%–48% cellulose, 22%–27% hemicellulose and 25%–30% lignin, enhancing the mechanical properties of bamboo [2]. With such compressive, tensile and bending strengths equivalent to those of wood and steel commonly used for scaffolding, bamboo exhibits excellent compression and bending properties [3]. Furthermore, bamboo is widely used in light-frame buildings nowadays due to its better dimensional stability [4,5], larger axial tension and compression strength [4,6] as well as comparable thermal insulation performances compared to wood [7]. However, for industry use, especially in architectural application, the durability of bamboo is a crucial consideration due to its vulnerability to insects and microorganisms [8]. Low durability of bamboo is associated strongly with its chemical composition of high sugar and starch content, making it susceptible to mold, fungal infection and insect attack [9]. The durability of raw bamboo varies by species, age and preservation techniques [10]. In good storage or use conditions, raw bamboo is estimated to have a design life of 10–15 years [10]. In order to improve its properties, bamboo are commonly treated with preservatives used for wood, however, these preservatives have posed adverse influence on human health and environment [9].

In the vast rural areas of south of China, it is often not possible to transport bamboo culms to factories in time for processing and utilization after being logged. They are air-dried in situ temporarily but are susceptible to mold and fungal attack because of the high humidity environment. The traditional method of storing logs in local pond water to prevent wood borers and fungi is practiced. Researchers have conducted some related works based on this method on wood [11]. However, research on such storage practices of bamboo culms is rare. The chemical and mechanical properties of bamboo after water storage have not yet been fully studied and whether water storage is suitable for bamboo is yet to be explored.

Moso bamboo (Phyllostachys edulis) is most extensively distributed and cultivated in China and is widely used in construction materials, handicraft, pulp and paper, biomass energy, etc. In this study, we explored the dynamic changes of the chemical and mechanical properties, as well as the soluble sugar and starch contents of P. edulis culms after storing in pond water for 3, 6 and 12 months in comparison with the air dried culms. Our work could provide theoretical basis and references for the large-scale industrial processing and utilization of bamboo resources.

P. edulis bamboo culms were obtained from Xiangyin county of Yueyang City, Hunan Province of China (28°33′38″N, 112°48′44″E; Altitude: 81 m) in December, 2017, with the local annual mean temperature at 16.5°C (highest at 29°C in July and lowest at 5°C in January) and annual mean relative humidity at 79% (highest 84% in September and lowest 78% in July), respectively. 21 culms of moso bamboos in each of the three age class (1, 2, and 3 years old), totaling 63 culms, were cut. Internodes of each culm were consecutively numbered from the bottom to the top and were then divided into three portions, each with an equal number of internodes, i.e., 1st for bottom, 11th for middle and 22nd for top portion.

The control groups of 9 culms (3 culms in each of the 3 age groups) were used to analyze the chemical and mechanical properties, and the soluble sugar and starch contents. For analytical comparison, 27 culms (3 culms in each of the three age groups from three drying periods) were exposed for drying under natural climatic conditions (3, 6 and 12 months) and the rest 27 culms of three age groups were stored in pond water for the same time periods.

2.2.1 Determination of Chemical Properties

We oven-dried the internode strips at 60°C for 24 h and ground in a Wiley mill (FW100, China). Milled material passing a 40-mesh sieve but retaining on 60 mesh screen was used for chemical analyses, which were carried out in compliance with the Chinese National Standards for Testing and Materials. We carbonized the milled samples in a porcelain crucible on an electric stove and then in a muffle furnace at 575 ± 25°C for 2 h. Ash samples were then taken out, cooled to room temperature and weighted (Ash-GB/T 2677.3-93). And then, we added 5 mL of 6 mol/liter HCl which was evaporated in a steam bath. Based on three repetitions, distilled water was used to rinse the residue which was then filtered, and moved to the same muffle furnace and heated at 575 ± 25°C for 2 h and SiO2 weight was obtained (SiO2-GB/T7978). We packaged the milled samples using filter paper and loaded them in a Soxhlet extractor. Benzene alcohol solution (2:l) was applied for 6 h water-bath extraction and the extracts were weighed (Toluene–alcohol extractives-GB/T10741-89). The residue was unpackaged and moved into a conical flask for 2 h water-bath with 15 mL of sulfuric acid (72%). Then, we added distilled water to 560 mL, and after 4 h water-bath, we filtered the solution, rinsed the residue using distilled water, which was dried and weighed to determine acid-insoluble lignin content. Filtrate of the acid-insoluble lignin was metered by ultraviolet spectrophotometer (752 N Hengping) under the absorbance at 205 nm to be acid-soluble lignin (Lignin-GB/T 2677.8-94, GB/T 10337-2008). After 6 h water-bath for extraction, samples were loaded into a conical flask, and mixed with 65 mL distilled water, 0.5 mL acetic acid, and 0.75 g sodium chlorite. After 1 h water-bath at the constant temperature 75°C, and then mixed with 0.5 mL acetic acid and 0.75 g sodium chlorite. We obtained whitish materials after four repeated procedures. Filtering and rinsing with distilled water was practiced until filtrate from the solution presented no acidity. Lastly, we washed the residue 3 times using acetone, dried and holocellulose weight was obtained (Holocellulose-GB/T 2677.10-1995). Each test was triplicated.

2.2.2 Determination of Soluble Sugar and Starch Content

We determined the soluble sugar and starch contents using the phenol-sulfuric acid method [8]. Samples (0.2 g) were powdered in a mortar and pestle with liquid nitrogen, and then extracted with distilled water. The supernatants centrifugally collected at 6,000 rpm for 15 min, were mixed with 5% phenol and 98% sulfuric acid for 1 h. We used a spectrophotometer (752 N Hengping) to determine absorbance at 485 nm. The sediments were collected and used to determine the starch contents. Each test was triplicated.

2.2.3 Determination of Mechanical Properties

The samples for mechanical properties were derived from internodes 11 (middle portions of the culms), which were usually one of the longest internodes of the culms. These internodes were stored in a conditioning room maintained at 23°C and 65% relative humidity until moisture content (12%) was achieved. The procedures used for the determination of mechanical properties (compressing strength, tensile strength and bending strength) were conducted according to the Chinese National Standards for Testing Methods for Physical and Mechanical properties of bamboo (GB/T 15780-1995). Each test was triplicated.

3.1 Variation of Chemical Compositions under Different Storage Conditions

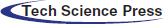

The average chemical compositions of the P. edulis culms control varied with age but insignificantly with culm heights (Tab. 1). Ash content decreased with culm age, with 1- and 2-year culms containing significantly higher ash content than that of 3-year culms. SiO2 content showed a downward and then upward trend, and reached its highest value at the 3rd year. The ethanol-benzene extract, lignin and holocellulose content slightly increased with age (Tab. 1).

Table 1: Chemical compositions of Phyllostachys edulis culms under different storage conditions (%)

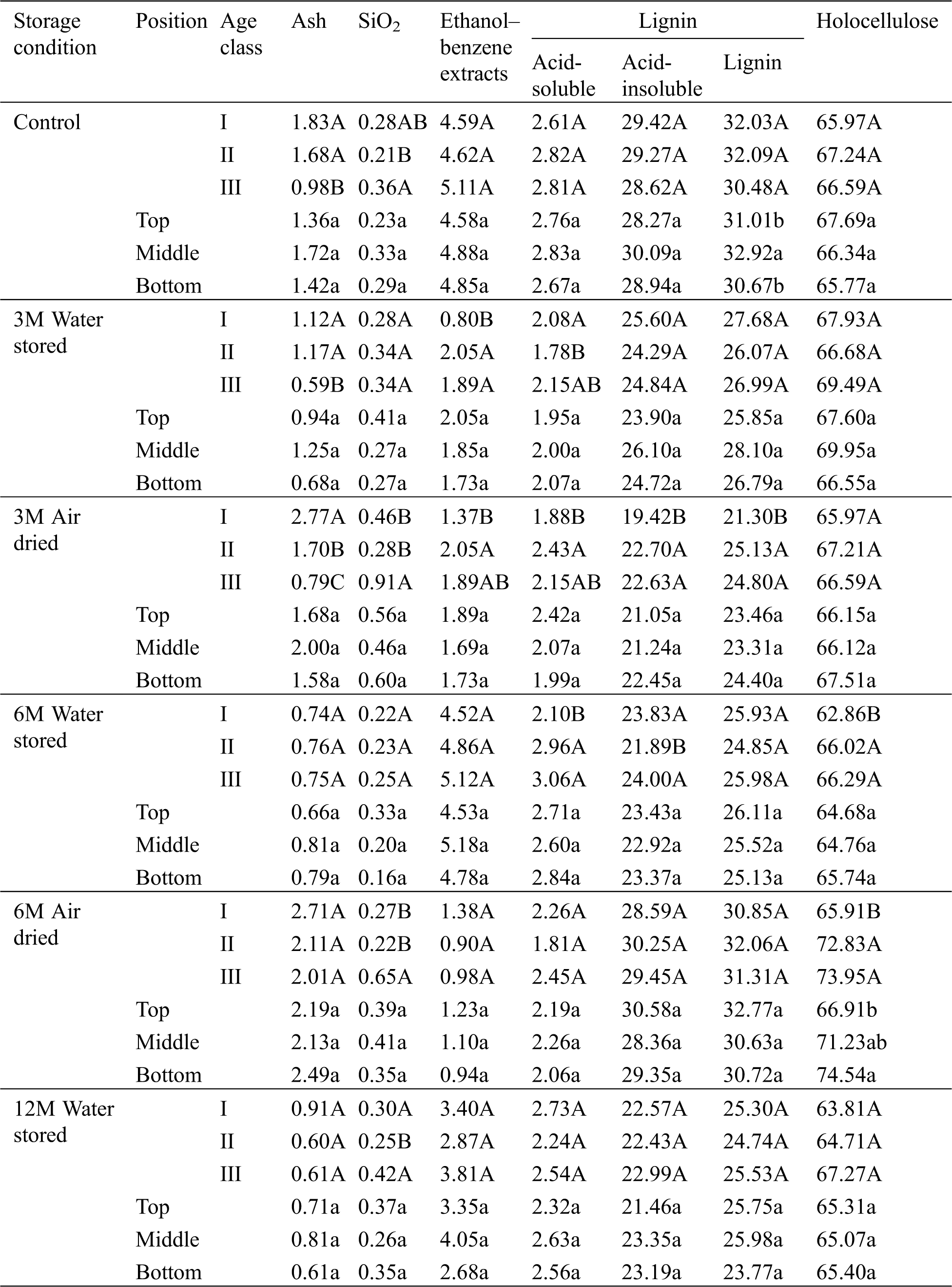

Under the air-dry condition, the average ash content of P. edulis culms showed increasing trend as compared to the control. It reached the highest value (2.27%) in the 6th month, but declined to the lowest (1.66%) in the 12th month. While under the water storage condition, the ash content declined to 0.96% in the 3rd month, significantly lower than those of the control and the air-dry ones, and it continued to decrease with storage time to 0.71% in the 12th month (Fig. 1). The mean ash content of P. edulis culms under the water storage condition was apparently lower than that under the air-dry condition as well as the control. Lower ash content indicates high pulp yield from pulping process [12] and help reduce the risks of environmental pollution to some extent. Moreover, high ash content for some bamboo species can adversely affect tool/knife wear during machining operations [13]. Therefore, the P. edulis culms stored in water for a period with lower ash content would benefit industry processing.

Figure 1: Ash variations of P. edulis culms under different storage conditions. Bars are mean values of the different age class of P. edulis culms in the chemical properties parameters from three replicates. Lower case letters (a, b, c after the values) denote the statistical difference of chemical properties under different conditions at P < 0.05 according to LSD tests (the same hereinafter)

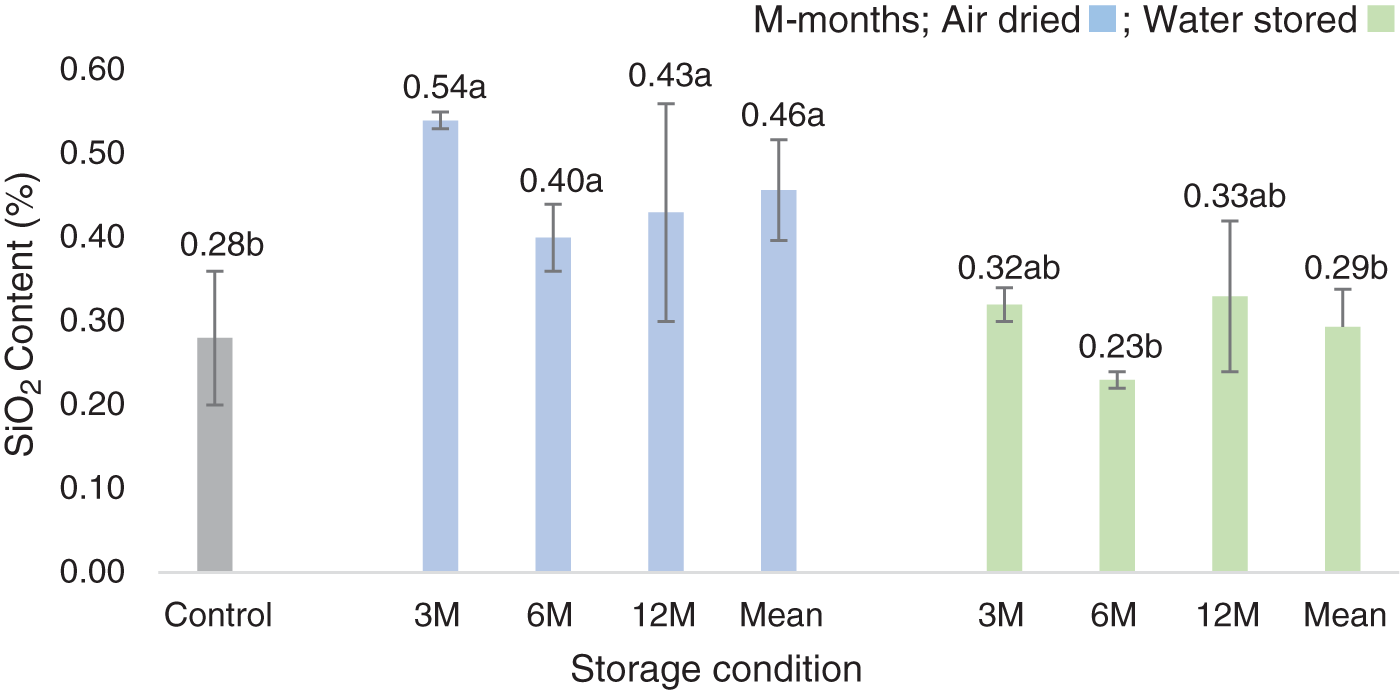

Under the air-dry condition, the SiO2 content of P. edulis culms increased to 0.54% in the 3rd month, which was significantly higher than that of the control, but deceased slightly in the 6th and 12th month. Whereas, under the water storage condition, the SiO2 content did not show obvious change compared with that of the control, but its mean value was significantly lower than that under the air-dry condition. The lowest value was found in the 6-month culm (0.23%), which might be caused by soluble silicon dissolution in water (Fig. 2).

Figure 2: SiO2 variations of P. edulis culms under different storage conditions

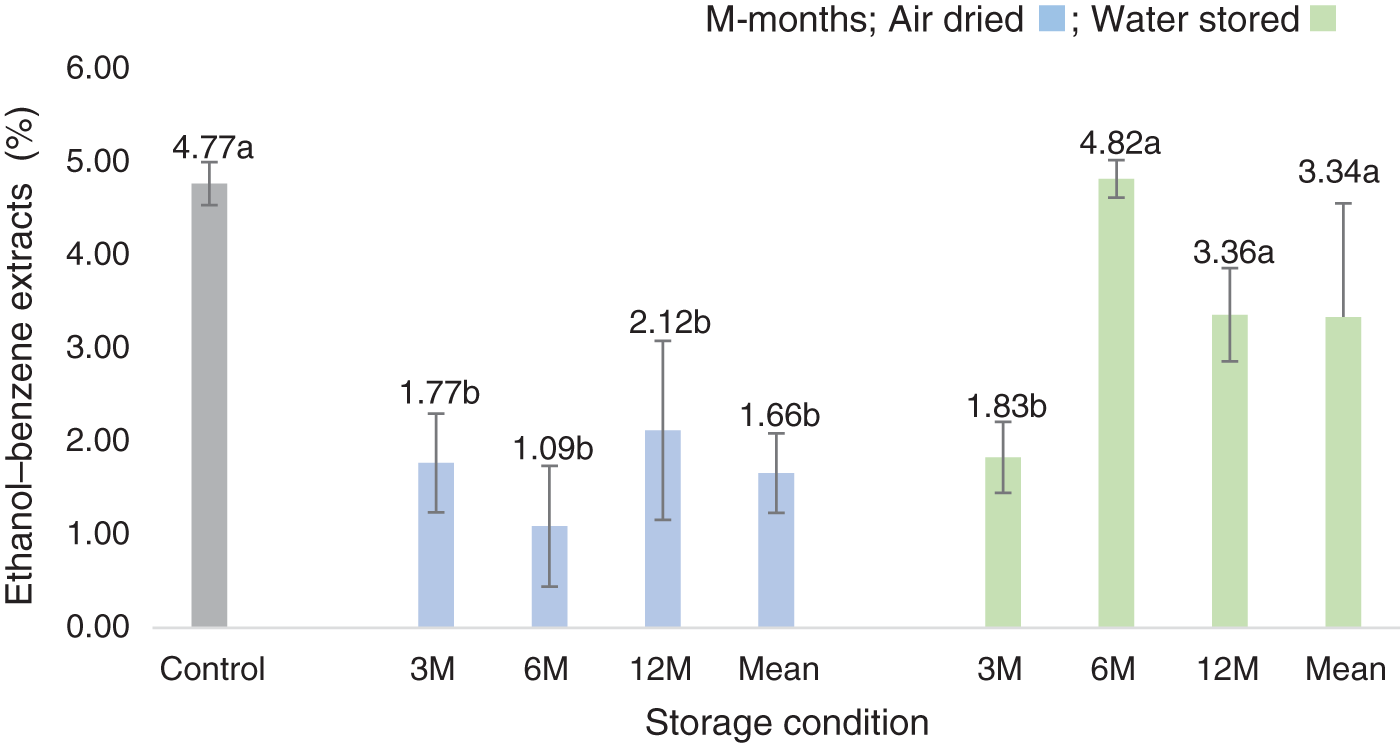

Under the air-dry condition, the ethanol-benzene extract of the culms showed an obviously decreasing trend, and the lowest value occurred in 6-month culm (1.09%). While under the water storage condition, the ethanol-benzene extract declined in the 3rd month, but did not show significantly decreasing trend in the 6th and 12th month (Fig. 3). The ethanol-benzene extract of the culms water stored for 6 and 12-month demonstrated insignificant difference as compared to the control. Water storage condition did not significantly affected the contents of ethanol-benzene extract in the culms (Fig. 3). Li et al. [14] reported extractives deposition increased with bamboo age and imparted greater decay resistance. Higher extractives contents might be advantageous for decay resistance and would provide good strength in fiber processing [15]. The air-dry ones showed relatively lower value on extracts than that of the control, which might have decomposed during storage. However, the ethanol-benzene extracts of the culms were preserved better under water storage conditions, which could help overcome its biologically perishable properties and be better for industrial application.

Figure 3: Ethanol-benzene extracts variations of P. edulis culms under different storage conditions

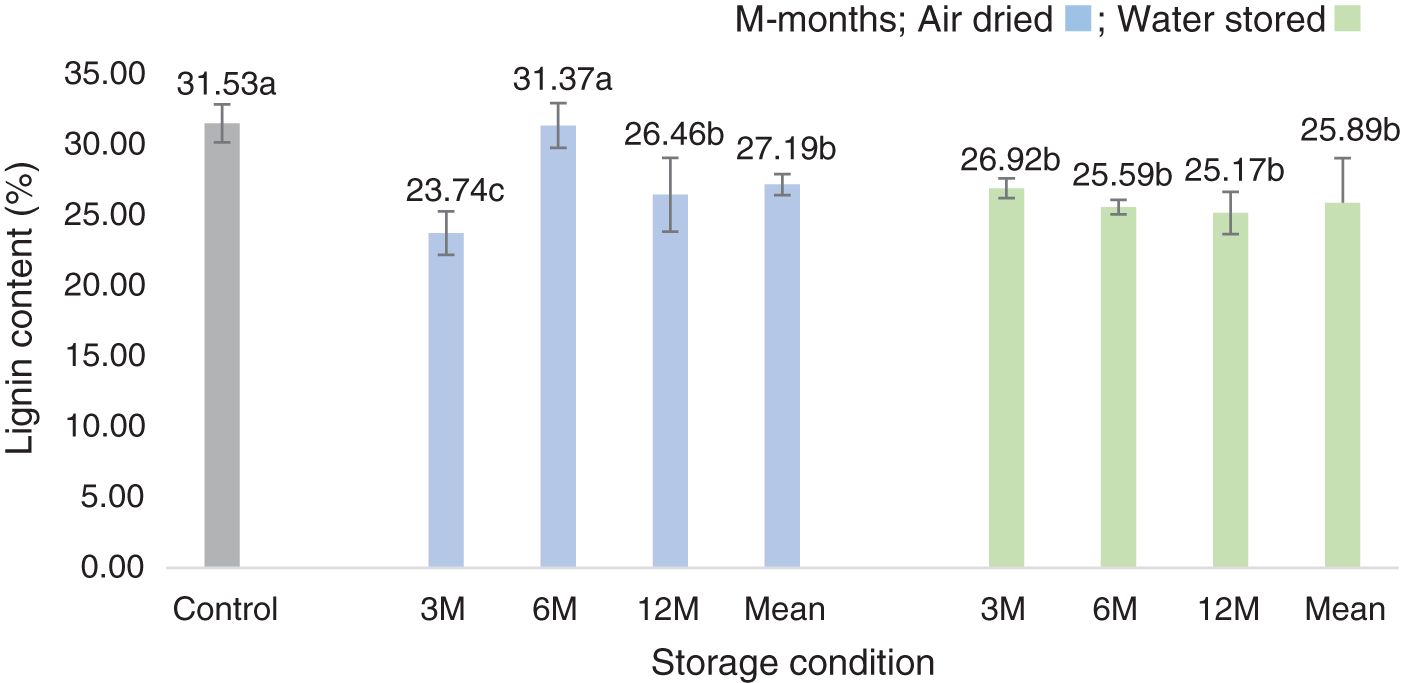

Under the air-dry condition, the lignin content of P. edulis culms decreased to 23.74% at the 3rd month, but increased in the 6th month and then decreased again in the 12th month. The 3 and 12-month-air-dry culms had significantly lower lignin content than that of the control. Under the water storage condition, the lignin content considerably declined with the increment time (Fig. 4), which would do good to the lignin removal during pulp manufacturing, but may not be conducive to architectural applications due to its weak mechanical strength, since lignin functions as an adhesive to bind cellulose together in the fiber, making the fiber strength greater and harder to break [16], contributing to improving the physical and mechanical strength of bamboo. However, lignin is an undesirable polymer, and its removal in pulping requires high amounts of energy and chemicals [15].

Figure 4: Lignin variations of P. edulis culms under different storage conditions

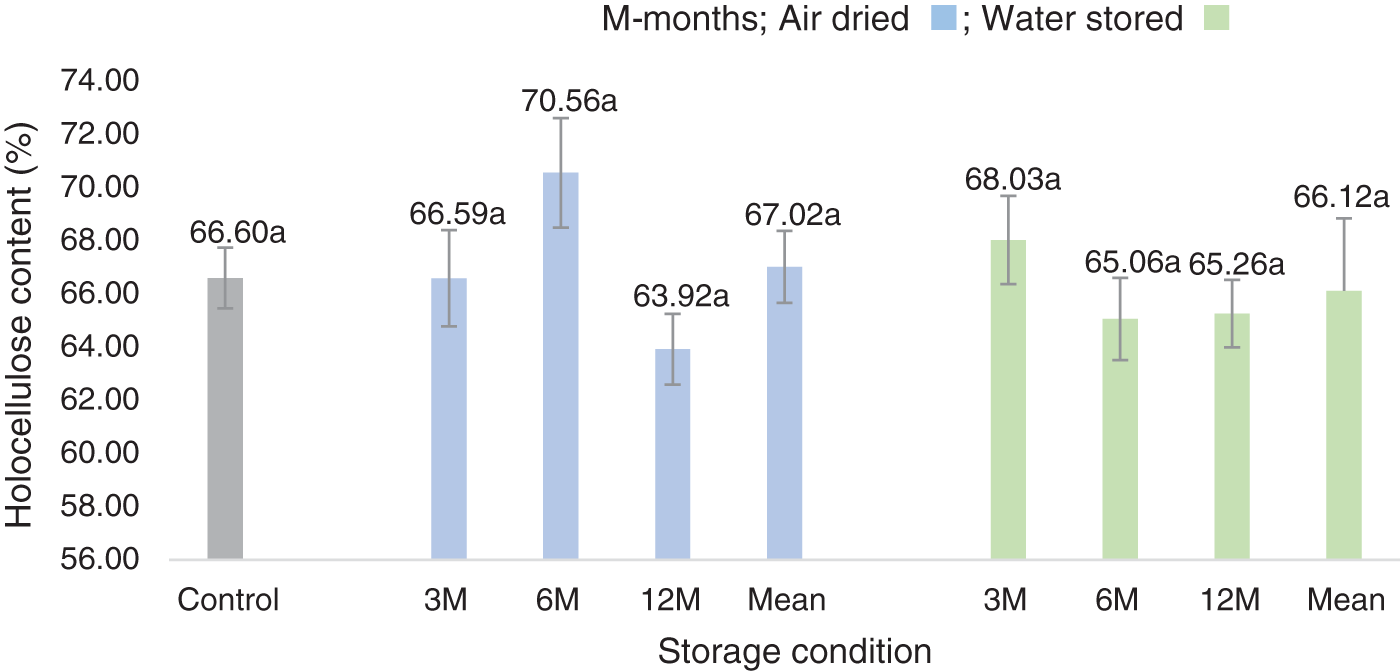

The holocellulose content was stable and showed no obvious difference under both the air-dry and water storage condition as compared to that of the control. In addition, no specific trend was found with the increment of storage time (Fig. 5), indicating different storage conditions had no pronounced effect on holocellulose content.

Figure 5: Holocellulose variations of P. edulis culms under different storage conditions

3.2 Variation of Starch and Soluble Sugar Content under Different Storage Conditions

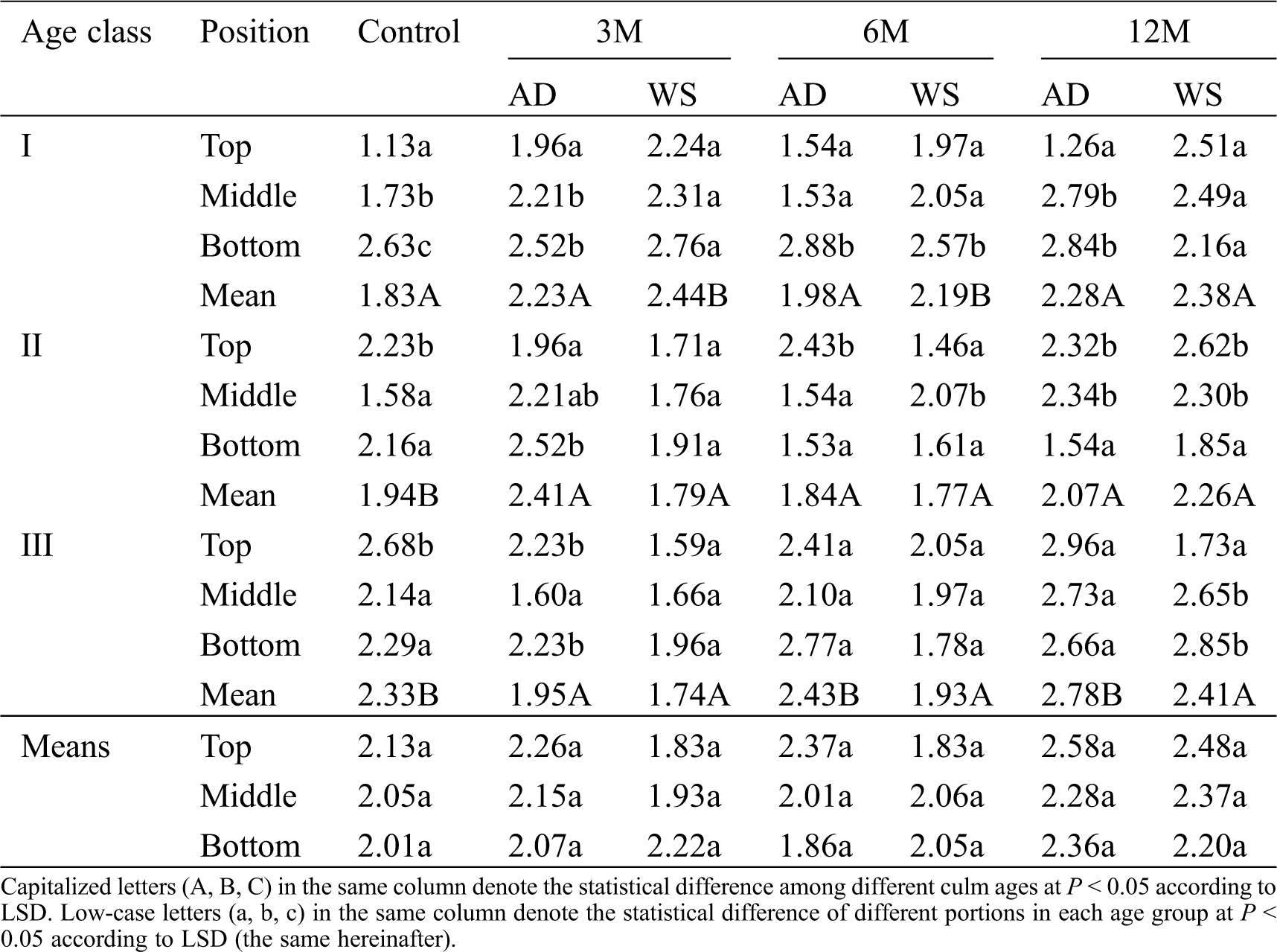

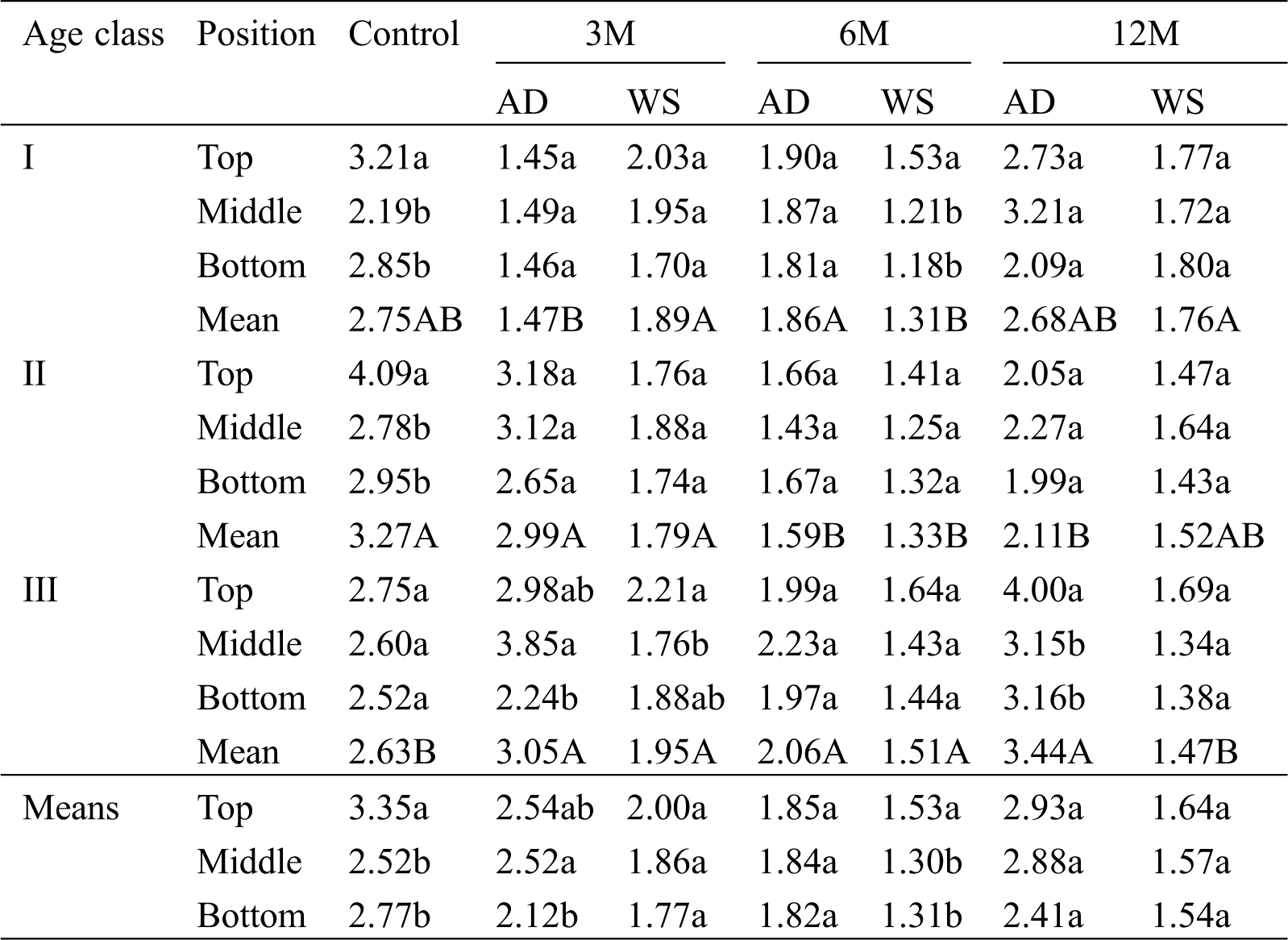

Soluble sugar and starch are the principal forms of carbohydrate storage in vegetative tissues of plants [15]. Soluble sugar is the substrate for starch synthesis. Starch accumulation in tissues occurs when carbohydrate supply is excess of demands [17]. The starch and soluble sugar content of the P. edulis culms control increased with culm age (Tabs. 2 and 3). Most carbohydrates of 1-year P. edulis culms came from their mother bamboo, while 2-year culm had flourish branches and leaves, could producing photoassimilates by photosynthesis. Therefore, the soluble sugar content increased with culm age reached the peak in 2-year culm. However, the soluble sugar content in 3-year culm decreased, while the starch content reached the highest average value indicating that the carbohydrate supply in 3-year culm was excess of demands. It could also be noted that the starch and soluble sugar was higher in the top portions (Tabs. 2 and 3). That’s because the top culm portion had flourish branches and leaves with better photosynthesis ability and more carbohydrates were produced.

Table 2: Starch content of Phyllostachys edulis culms under different storage conditions (%)

Table 3: Soluble sugar content of P. edulis culms under different storage conditions (%)

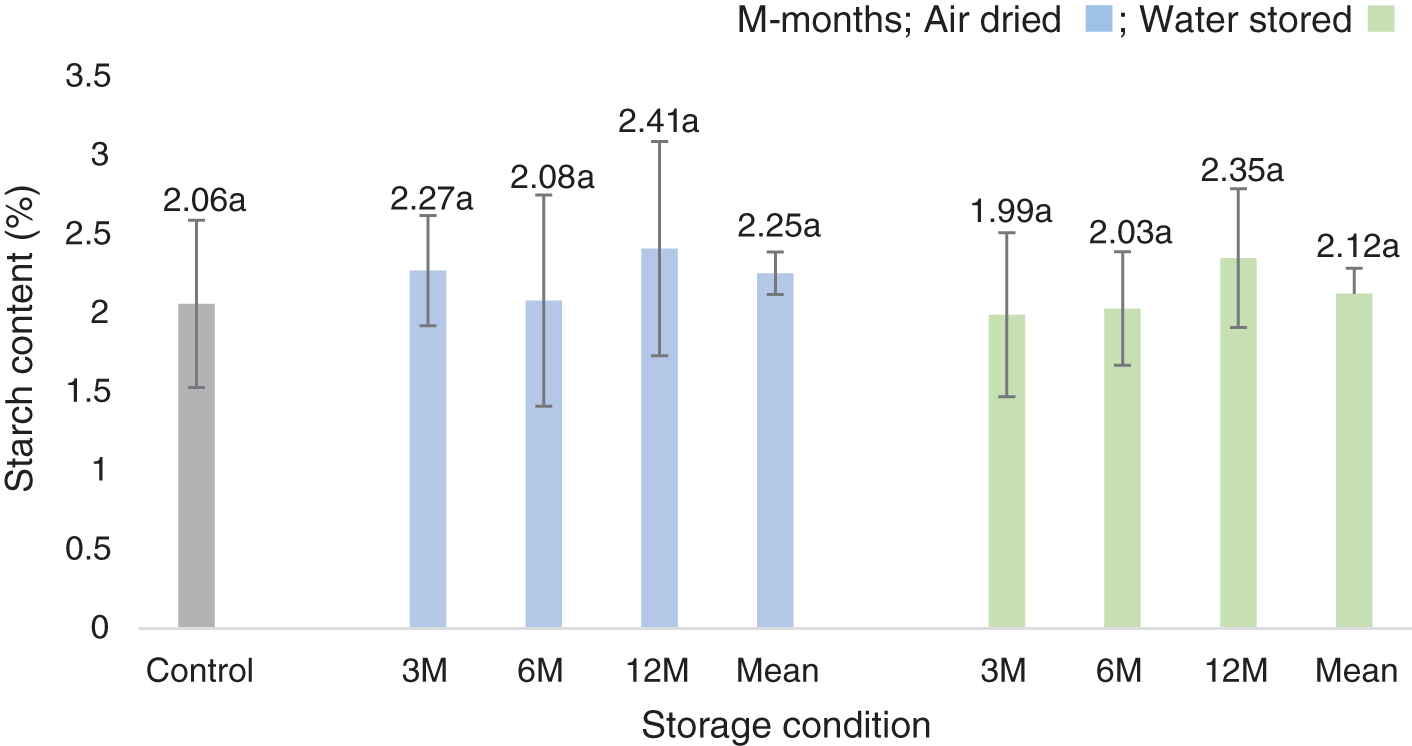

The biologically perishable properties of bamboos are assumed to be mainly caused by its high sugar and starch contents, which are excellent foods for fungi or insects [8]. Previous investigations into the damage by the insect Dinoderus minutus, which was a serious pest of bamboo, showed that the damage by the pest increased with the starch contents in the bamboo culms [18]. In the present research, under the air-dry condition, the average starch content of P. edulis culms slightly increased but did not show considerable difference compare with that of the control. Whereas, under the water storage condition, the starch content deceased minimally in the 3rd and 6th month, and then increased to 2.35% in the 12th month. It was noticed that the mean starch content of the P. edulis culms under the water storage condition was lower than those under the air-dry condition (Fig. 6).

Figure 6: Starch variations of P. edulis culms under different storage conditions

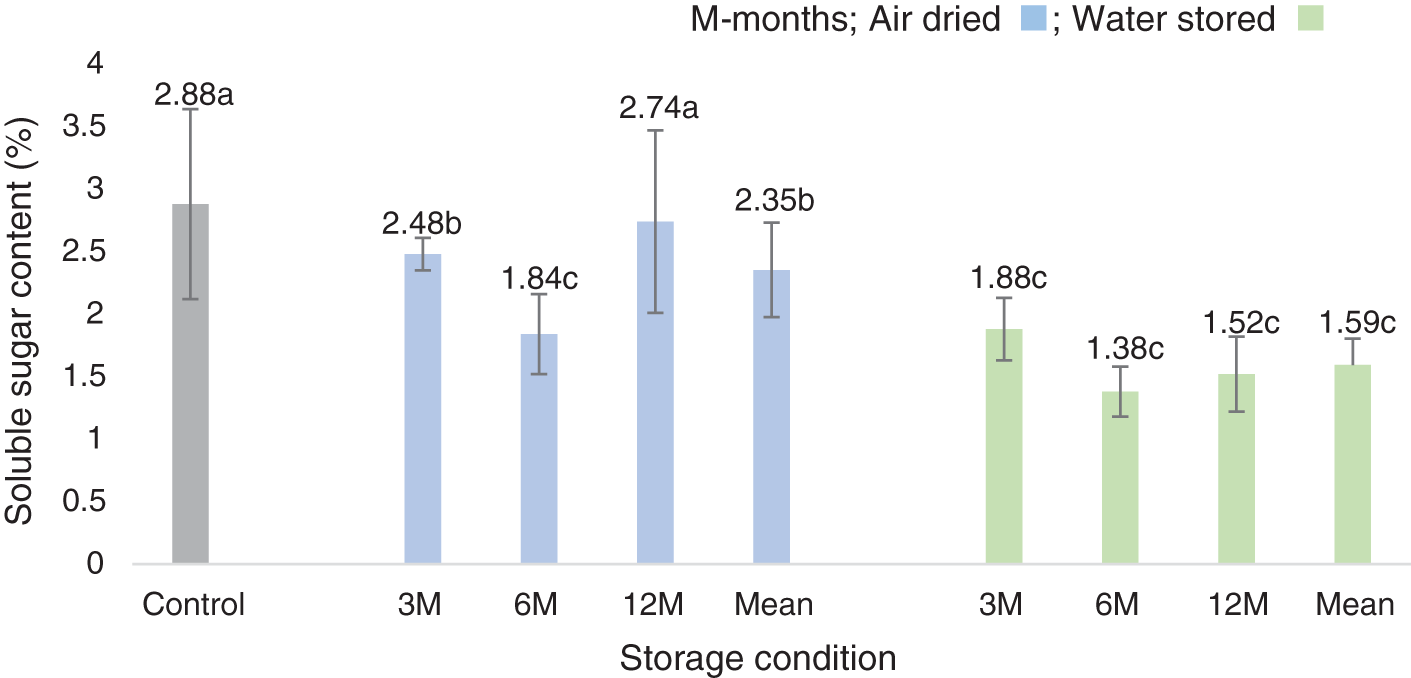

Under the air-dry condition, the soluble sugar content of P. edulis culms decreased as compared with that of the control. The culms in the 3rd month (2.48%) and 6th month (1.84%) had significantly lower soluble sugar content than that of the control (2.88%), indicating some soluble sugar might be decomposed in water. Under water storage condition, the soluble sugar also decreased and had considerable lower mean value than that of the control as well as that under the air-dry condition (Fig. 7).

Figure 7: Soluble sugar variations of P. edulis culms under different storage conditions

In our study, both the starch and the soluble sugar content of the P. edulis culms decreased under water storage condition. Water storage created an anaerobic environment for bamboo culms in which only anaerobic respiration was possible during the storage period. This would reduce the content of soluble sugar and starch, thereby beneficial for decreasing the damage from insects and microorganisms. This was the probable reason for the indigenous practice of local people to store bamboo culms in ponds.

3.3 Variation of Mechanical Properties under Different Storage Conditions

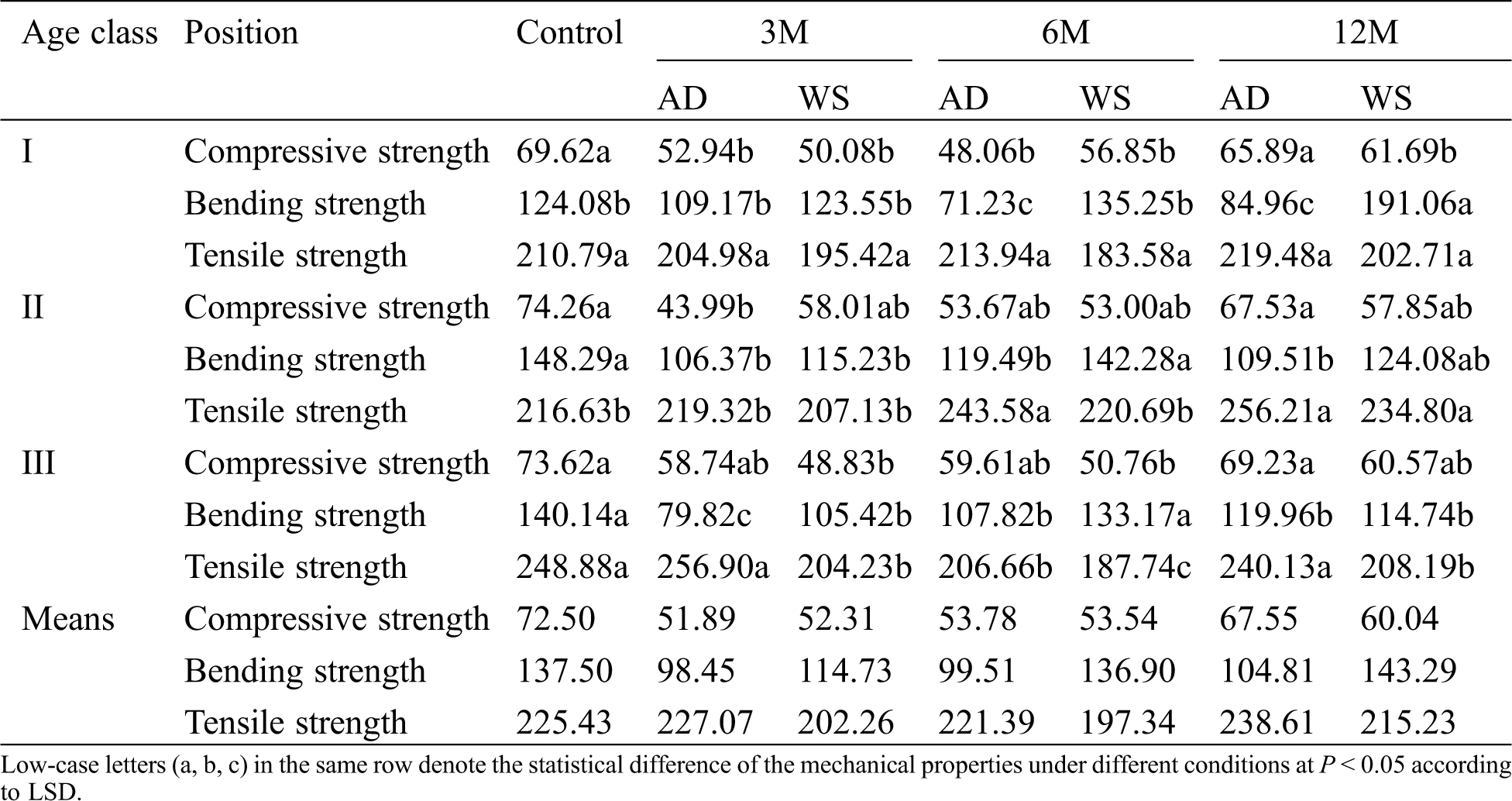

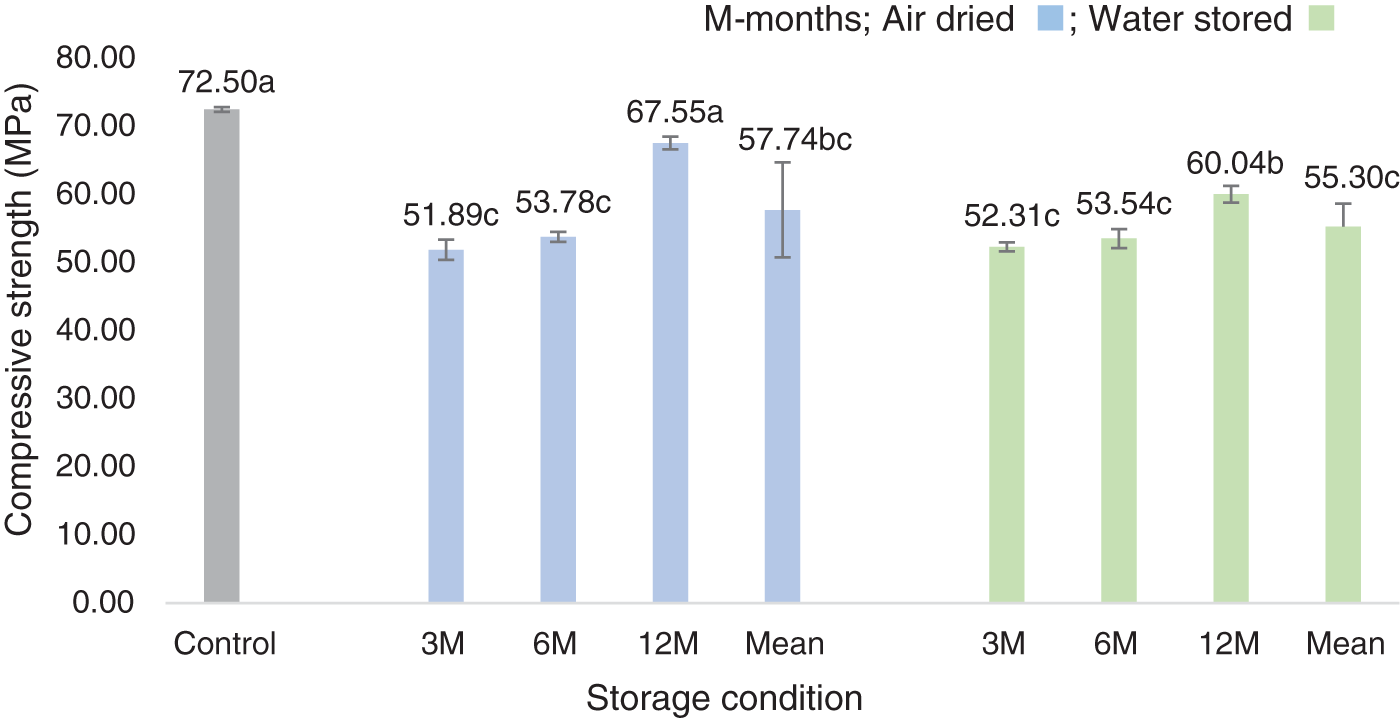

The physical and mechanical properties of bamboo depend on many factors such as species, season, soil, height, age, presence of node section, environmental conditions [19]. The higher the value was, the stronger the strength and the better the material properties are. The main mechanical properties of the P. edulis culms control were compressive strength 72.50 MPa, bending strength 137.50 MPa, and tensile strength 225.43 MPa (Tab. 4). Mechanical properties of the controlled P. edulis culms varied with culm age, confirming the previous findings [13,19]. The compressive strength increased to 74.26 MPa at 2-year culm, but degraded slightly to 73.62 MPa at 3-year culms. The bending strength also exhibited an increasing trend with culm age, and the 2 and 3-year culms of which was notably higher than that of 1-year culm. The tensile strength increased and attained the highest value of 248.88 MPa at 3-year (Tab. 4).

Table 4: Mechanical properties of P. edulis culms under different storage conditions (MPa)

The compressive strength of the P. edulis culms under different storage conditions decreased obviously as compared to that of the control. Under the air-dry condition, the compressive strength decreased to 51.89 MPa in the 3rd month, but increased to 67.55 MPa in the 12th month, which showed no significant difference as compared to that of the control. The compressive strength of the P. edulis culms under the water storage condition showed the same decreasing trend. The difference in compressive strength between the culms under the air-dry condition and the water storage condition was not significant (Fig. 8).

Figure 8: Compressive strength variations of P. edulis culms under different storage conditions

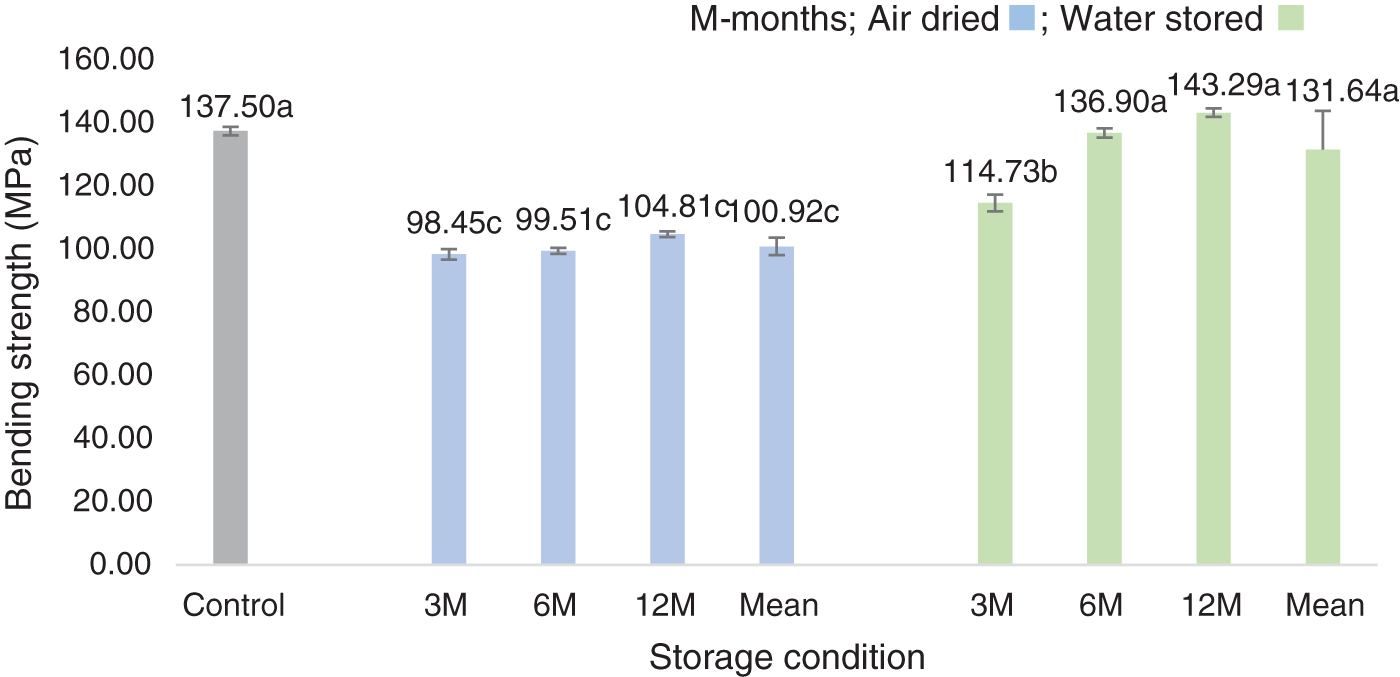

In terms of furniture manufacturing, bending strength appears to be an important material property of wood [20]. The bending strength of P. edulis culms demonstrated an increasing trend along with the increment time under different storage conditions. Under the air-dry condition, the bending strength decreased, significantly lower than that of the control, whereas those under the water storage condition for 6 and 12 months appeared insignificant difference as compared to that of the control (Fig. 9), indicating that the water storage condition could better maintain culm bending strength.

Figure 9: Bending strength variations of P. edulis culms under different storage conditions

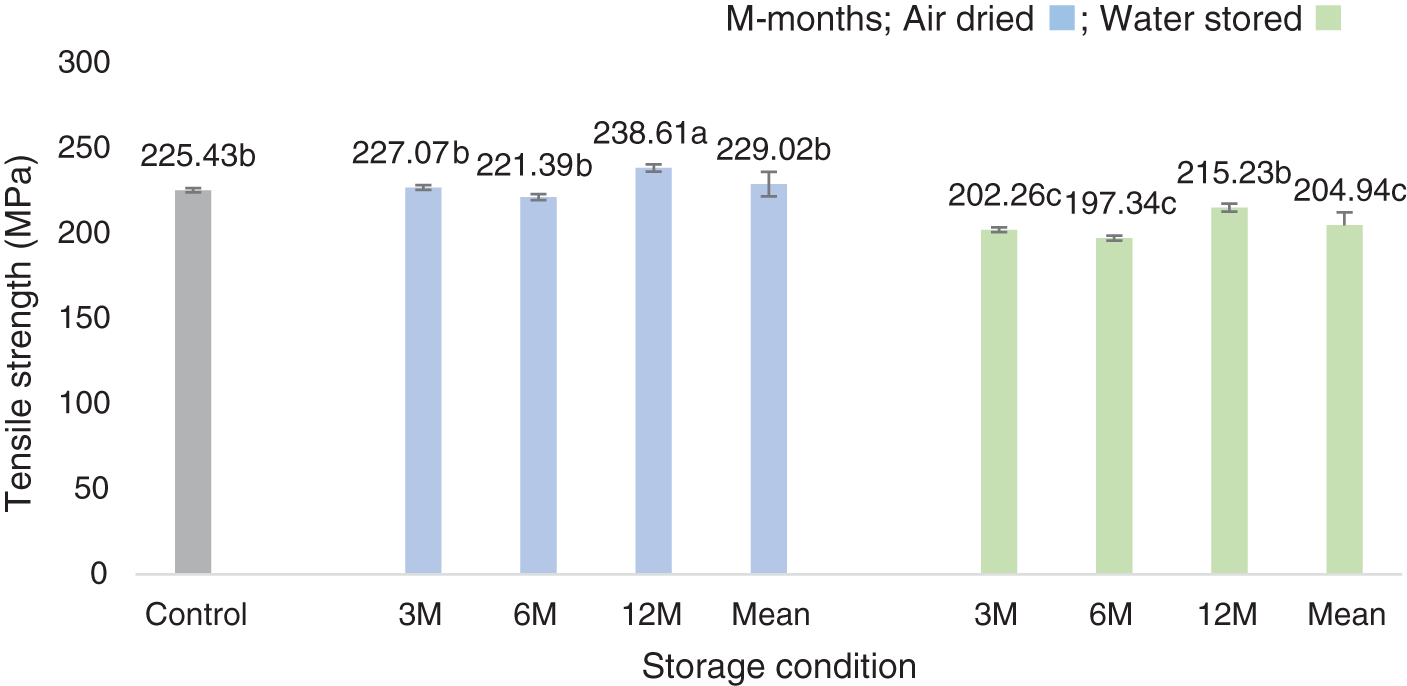

Under the air-dry condition, the mean tensile strength of the P. edulis culms did not show obvious change as compared to that of the control (Fig. 10). Whereas, under the water storage condition, with the increment of the storage time, the tensile strength degraded to 197.34 MPa in the 6th month, but increased to 215.23 MPa in the 12th month, showed no significant difference compared to that of the control, implying the tensile strength was less affected under different storage conditions.

Figure 10: Tensile strength variations of P. edulis culms under different storage conditions

There are some explanations for strength reduction based on earlier research, such as decreasing equilibrium moisture content of wood and volumetric expansion, degradation of wood components (cellulose and especially the hemicelluloses), and evaporation of extractives [20]. Strength changes were also caused by increase of crystallinity and increased size of crystals [20]. Our study showed different storage condition caused changes in chemical composition of the P. edulis culm, specifically the degradation of the ash, SiO2, extractives and lignin. Thus, the mechanical properties of P. edulis culm degraded, especially the compressive strength. Relatively speaking, water storage condition could better maintain their mechanical performance than the air-dry condition.

The chemical and mechanical properties of P. edulis bamboo culms varied under different storage conditions. The chemical properties of P. edulis bamboo culms varied with culm age, but insignificantly with culm height. Water storage condition decreased the ash, SiO2 and lignin content, but increased the ethanol-benzene extracts. It also created an anaerobic environment for bamboo culms in which only anaerobic respiration was possible contributing to reducing the content of soluble sugar and starch, thereby beneficial for decreasing the damage from insects and microorganisms. The mechanical properties of P. edulis culms showed an increasing trend with culm age. Water storage conditions could maintain the mechanical properties of the culm better. Accordingly, P. edulis culms stored under water were better than under the air-dry condition. The indigenous practice of local people to store bamboo culms in ponds has good science behind it and water storage practices of bamboo culms was recommended.

Author Contributions: Hui Zhan designed the experiment, ran the data analysis and wrote the paper; Zhaohui Niu and Lixia Yu performed the experiments; Maobiao Li revised the manuscript; Changming Wang and Shuguang Wang designed the experiment, supervised the research work and revised the manuscript.

Funding Statement: This work was jointly supported by Yunnan Fundamental Research Project of 2020 (202001AT070108); Yunnan Provincial Joint Special Project for Basic Research in Agriculture (No. 2017FG001-092); Scientific Research Start-up Fund Project of Southwest Forestry University (No. 111817) and Yunnan Provincial Department of Education Fund for Scientific Research (No. 2020J0413).

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Zhan, H., Tang, G., Wang, C., Wang, S. (2015). Chemical properties and fibers morphology of Fargesia fungosa at different culm ages and heights. Bioresources, 10(3), 5666–5676. DOI 10.15376/biores.10.3.5666-5676. [Google Scholar] [CrossRef]

2. Scurlock, J. (2000). Bamboo: An over-looked biomass resource? Biomass Bioenergy, 19(4), 229–244. DOI 10.1016/S0961-9534(00)00038-6. [Google Scholar] [CrossRef]

3. Chung, K., Yu, W. (2002). Mechanical properties of structural bamboo for bamboo scaffoldings. Engineering Structures, 24(4), 429–442. DOI 10.1016/S0141-0296(01)00110-9. [Google Scholar] [CrossRef]

4. Wang, J. S., Demartino, C., Xiao, Y., Li, Y. Y. (2018). Thermal insulation performance of bamboo- and wood-based shear walls in light-frame buildings. Energy and Buildings, 168, 167–179. DOI 10.1016/j.enbuild.2018.03.017. [Google Scholar] [CrossRef]

5. Ahmad, M. F., Kamke, A. (2005). Analysis of Calcutta bamboo for structural composite materials: Physical and mechanical properties. Wood Science and Technology, 39(6), 448–459 469. DOI 10.1007/s00226-005-0016-y. [Google Scholar] [CrossRef]

6. Ramage, M., Sharma, B., Bock, M., Gatoo, A., Mulligan, H. (2015). Engineered bamboo: State of the art. Construction Materials, 168(2), 57–67. DOI 10.1680/coma.14.00020. [Google Scholar] [CrossRef]

7. Fu, H., Ding, Y., Li, M., Cao, Y., Xie, W. et al. (2020). Research and simulation analysis of thermal performance and hygrothermal behavior of timber-framed walls with different external thermal insulation layer: Cork board and anticorrosive pine plate. Journal of Building Physics, 34(1), 174425912093672. DOI 10.1177/1744259120936720. [Google Scholar] [CrossRef]

8. Okahisa, Y., Yoshimura, T., Imamura, Y. (2006). Seasonal and height-dependent fluctuation of starch and free glucose contents in moso bamboo (Phyllostachys pubescens) and its relation to attack by termites and decay fungi. Journal of Wood Science, 52(5), 445–451. DOI 10.1007/s10086-005-0776-x. [Google Scholar] [CrossRef]

9. Lee, C. H., Yang, T. H., Cheng, Y. W., Lee, C. J. (2018). Effect of thermal modification on the surface and chemical properties of moso bamboo. Construction and Building Materials, 178, 59–71. DOI 10.1016/j.conbuildmat.2018.05.099. [Google Scholar] [CrossRef]

10. Xu, Q., Harries, K., Li, X., Liu, Q., Gottron, J. (2014). Mechanical properties of structural bamboo following immersion in water. Engineering Structures, 81, 230–239. DOI 10.1016/j.engstruct.2014.09.044. [Google Scholar] [CrossRef]

11. Johnson, G. C., Martin, A. K. (1992). Survival of wood-inhabiting fungi stored for 10 years in water and under oil. Canadian Journal of Microbiology, 38(8), 861–864. DOI 10.1139/m92-140. [Google Scholar] [CrossRef]

12. Lopez, D., Alfaro, A., Garcia, M. M., Diaz, M. J., Calero, A. M. et al. (2004). Pulp and paper from tagaste (Chaoaecytisus proliferusl LF. SSP. Palmesis). Chemical Engineering Research and Design, 82(8), 1029–1036. DOI 10.1205/0263876041580730. [Google Scholar] [CrossRef]

13. Abd Latif, M. (1993). Effects of age and height of three bamboo species on their machining properties. Journal of Tropical Forest Science, 5(4), 528–535. [Google Scholar]

14. Li, X. B., Shupe, T. F., Peter, G. F., Hse, C., Eberhardt, T. L. (2007). Chemical changes with maturation of the bamboo species Phyllostachys pubescens. Journal of Tropical Forest Science, 19(1), 6–12. [Google Scholar]

15. Abdul Khalil, H. P. S., Siti Alwani, M., Mohd Omar, A. K. (2006). Chemical composition, anatomy, lignin distribution, and cell wall structure of Malaysian plant waster fibers. Bioresources, 1(2), 220–232. DOI 10.15376/biores.1.2.220-232. [Google Scholar] [CrossRef]

16. Tran, A. V. (2006). Chemical analysis and pulping study of pineapple crown leaves. Industrial Crops and Production, 24(1), 66–74. DOI 10.1016/j.indcrop.2006.03.003. [Google Scholar] [CrossRef]

17. Scofield, G. N., Ruuska, S. A., Aoki, N., Lewis, D. C., Tabe, L. M. et al. (2009). Starch storage in the stems of wheat plants: Localization and temporal changes. Annals of Botany, 103(6), 859–868. DOI 10.1093/aob/mcp010. [Google Scholar] [CrossRef]

18. Ninomiya, S., Kotani, K. (2002). Feeding tests by Dinoderus minutus Fabricius on acetylated bamboo (in Japanese). Wood Protection, 28(4), 135–143. DOI 10.5990/jwpa.28.135. [Google Scholar] [CrossRef]

19. Lee, A. W. C., Bai, X., Peralta, P. N. (1994). Selected physical and mechanical properties of giant timber bamboo grown in South Carolina. Forest Products Journal, 44, 40–46. [Google Scholar]

20. Tankut, N., Tankut, A. N., Zor, M. (2014). Mechanical properties of heat-treated wooden material utilized in the construction of outdoor sitting furniture. Turkish Journal of Agriculture and Forestry, 38, 148–158. DOI 10.3906/tar-1211-9. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |