| Journal of Renewable Materials |  |

DOI: 10.32604/jrm.2021.014878

ARTICLE

Effect of Ultraviolet Aging on the Bonding and Tensile Properties of Polymer-Cement Composite

1Air Force Engineering University, Xi’an, 710038, China

2Northwest Polytechnic University, Xi’an, 710072, China

*Corresponding Author: Zhihang Wang. Email: wangzhihangafeu@163.com

Received: 05 November 2020; Accepted: 10 December 2020

Abstract: In this paper, the specimens of polymer-cement composites after 1 d, 7 d, 15 d, and 30 d aging without aging and UV aging are subjected to fixed extension test and tensile test. By observing the mode of the composite in the fixed-elongation test, and measuring the elastic recovery rate, tensile strength, elongation at break, peak tensile strain, tensile toughness and pre-peak tensile toughness of the composite, the effects of UV aging on the bonding and the tensile properties of the composite were studied. And combining with scanning electron microscopy experiments, the micro-mechanism of the effect of ultraviolet aging on the properties of composite was analyzed. The results showed that the composite had a good bonding property, and no damage was observed after UV aging for 30 days. The UV aging increased the elastic recovery rate and peak tensile within a certain range. The elastic recovery rate and peak tensile strain of the composite increased by 6.60% and 23.55% respectively after UV aging for 15 days. Therefore, the UV aging could enhance the tensile property and the tensile energy consumption performance of the composite. The tensile strength of the composite increased by 65.36% after UV aging for 30 days. The tensile toughness and pre-peak tensile toughness of the composite were increased by 43.29% and 101.83% respectively after UV aging for 15 days. The elongation at break of composite decreased continuously after UV aging due to the photo-oxygen reaction, as well as secondary hydration reaction and cross-linking curing reaction of cement.

Keywords: Polymer-cement composite; ultraviolet aging; bonding property; tensile property; failure mode; microstructure

Polymer-cement composite is a two-component polymer produced in reaction between polymer film formation and cement hydration, for which organic polymer and cement are mixed, with additive and filler added. This materials usually have the advantages of cement-based materials, such as good durability, high strength, low price and environmental protection, and polymer materials, such as high bonding strength and flexibility [1]. The polymer-cement composite prepared with styrene-acrylic emulsion and VAE emulsion as organic components is broadly used in building waterproofing, concrete pavement joint sealing, airport pavement joint engineering and etc. for low production cost, no pollution, as well as excellent cohesive deformation and waterproof properties [2–4]. Especially as applied in airport pavement joint engineering or pavement caulking, the polymer-cement composite may bond with cement concrete properly with excellent sealing and deformation performance, thus effectively preventing failures of joints, such as mud pumping, spalling, shatter and faulting of slab ends due to fracture or aging of the caulking material, and ensuring the safe operation of aircraft [5,6]. For airport pavement caulking material used in natural environment, the performance in mud pumping may be influenced by many environmental factors, such as solar radiation, ultraviolet light, temperature, humidity, rain, snow, and chemical medium. These factors will lead to degradation of the composite in macroscopic performance and reduce the service life of the caulking material [7].

Many scholars have studied the polymer-cement composite [8–11]. Choi et al. [12] studied the effect of ethylene-vinyl acetate polymer emulsion on the performance of polymer-cement composite, and found that ethylene-vinyl acetate polymer emulsion could improve the flexural strength and compressive strength of the composite, as well as the chloride ion penetration resistance. Tsukagoshi et al. [13] studied the influence of different humidity conditions (25%, 60%, 98%) for maintenance on the tensile property of waterproof coating for the polymer-cement composite, and established a numerical model for hydration–evaporation water loss and film formation by polymer coalescence in the polymer-cement composite system. Ohama studied the microstructure of polymer-cement composite, proposed a model to explain the reinforcement mechanism of polymer cement, which was then modified by Ma and Plank from different perspectives [14–16]. Melichar et al. [17] studied the proportioning of mixture for the polymer-cement composite at extreme temperatures, invented a polymer cement mortar used at extreme temperatures, which may also be applied to reinforced concrete structures as a repair mortar. Sokołowska et al. [18] studied the influence of acidic environment on the degradation of polymer cement concrete, and evaluated the resistance of polymer cement concrete to chemical erosion based on indexes like mass, compressive strength and flexural strength. Soufi et al. [19] systematically studied the effects of copolymer of ethyl acrylate and phenethyl acrylamide on durability indexes of modified repair mortar, e.g., permeability, capillary water absorption and chloride diffusivity, from the perspective of water migration. However, the above researches most focus on the influence of type, temperature, acidic environment of polymer on mechanical property of the composite, and seldom concern the bonding and tensile properties of the composite after UV aging. The airport pavement caulking material is not only used in the natural environment with complex conditions, but also bearing horizontal displacement and tensile stress from the seam slot of cement concrete pavement joint generated for the effects of aircraft wheel load and temperature. To meet the requirements for the use of relevant airport pavement caulking material, it is of great engineering value and theoretical significance to study the bonding and tensile properties of the composite after aging under environmental conditions.

In this study, the ultraviolet radiation of the composite was simulated by an artificial accelerated ultraviolet aging method based on the application of polymer-cement composite in airport joint engineering. The influence of ultraviolet radiation on bonding and tensile properties of the composite was studied through analyzing changes of the composite in failure mode, elastic recovery rate, tensile property, tensile deformation property and tensile energy consumption performance before and after ultraviolet aging, and the reasons for changes in properties of the composite were analyzed microscopically by scanning electron microscopy.

2.1 Raw Materials and Specimens Preparation

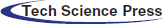

The main raw materials for preparation of polymer-cement composite are as follows: Polymer emulsions (styrene-acrylic emulsion and VAE emulsions), cement, inorganic fillers (talc powder, Heavy calcium carbonate), functional admixtures (dispersant, defoamer, Film forming aid, plasticizer, and silane coupling agent). Various materials are introduced as follows: Acronal S400F ap styrene-acrylic emulsion, viscosity: 400 to 1800 MPa·s, average particle size: 0.1 μm, solid content: 56 ± 1%; CELVOLIT 1350 VAE emulsion, viscosity: 1500 to 5000 MPa·s, average particle size: 1.5 m, solid content: 55 ± 1%; ordinary Portland cement 42.5, initial set: 141 min, final set: 296 min; ultrafine talc powder, pure white, fineness: 600 mesh, silica content: 99%; Heavy calcium carbonate, white powder, average particle size: 3 μm; SN-DISPERSANT 5040 dispersant, NOPCO NXZ defoamer, DN-12 Film forming aid, DOP plasticizer, and ND-42 silane coupling agent.

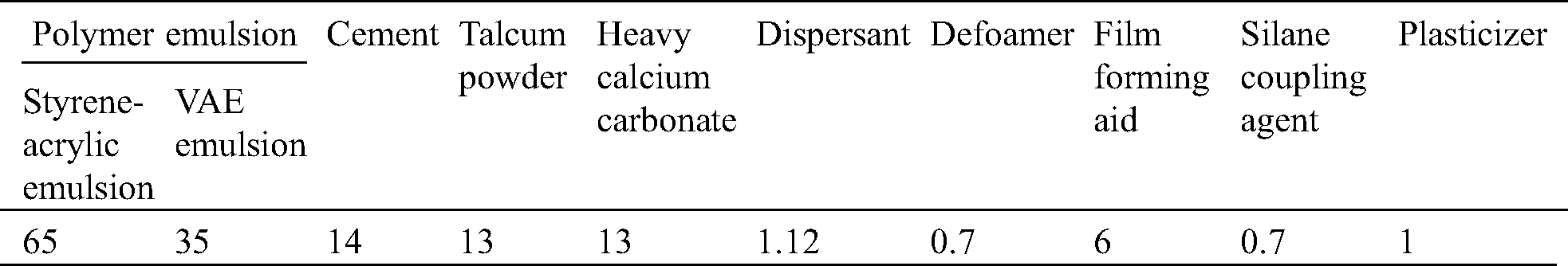

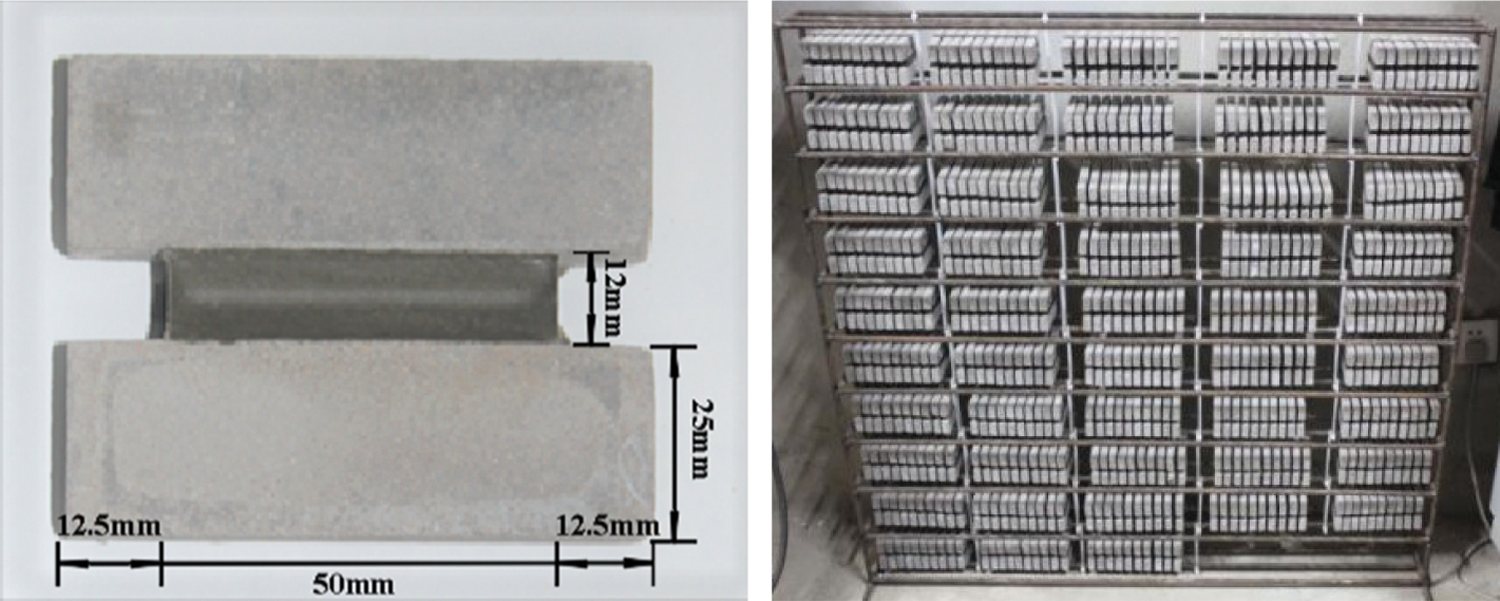

The polymer-cement composite was prepared according to the ratio given in Tab. 1. For details, see Fig. 1. After the preparation was completed, the specimen was obtained through pouring together with cement mortar based material, as shown in Fig. 2. The size of cement mortar based material was 75 mm × 25 mm × 12 mm, and of polymer-cement composite was 50 mm × 12 mm × 12 mm [20,21].

Table 1: Mix ratio of polymer-cement composite (unit: g)

Figure 1: Preparation process of polymer-cement composite

Figure 2: Specimen of polymer-cement composite

2.2 Experimental Equipment and Method

In accordance with the Standard GB/T 14522-2008, ultraviolet radiation was performed with a LZW-050A ultraviolet weather resistance test box at 40°C, wavelength: 315 to 400 nm. Samples were taken to test after UV aging for 1 d, 7 d, 15 d and 30 d.

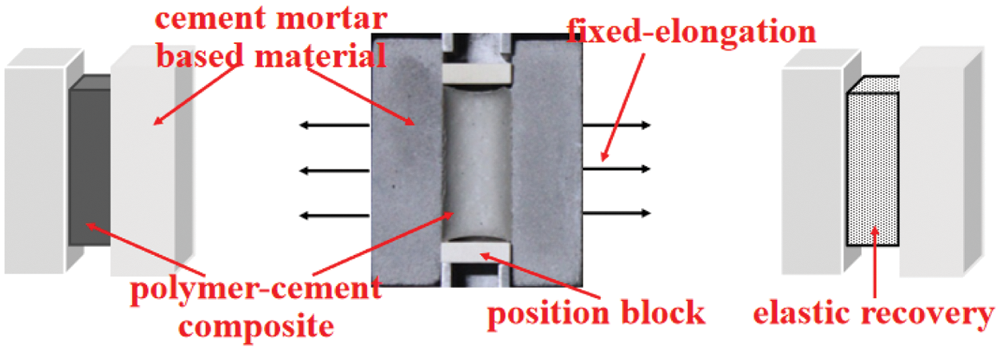

Fixed-elongation test with reference to ISO 11600, JC/T 881 and JC/T976 [22–24], place the prepared specimen in the fixed-elongation (fixed tensile displacement) test mold, stretch the specimen to 60% of the original seam width with speed of 5 mm/min, keep the fixed tensile displacement for 24 h, and then observe the forms of polymer-cement composite at the fixed tensile displacement, check the polymer-cement composite for cohesive failure. If no failure, remove the specimen and hold for 24 h. Measure the seam width after elastic recovery of the specimen with a vernier caliper, and calculate Re, the elastic recovery rate of the polymer-cement composite with Eq. (1). Each set of tests was conducted three times, and the results were averaged.

where w0, w1 and w2 are the initial seam width, the seam width at fixed elongation displacement, and the seam width after elastic recovery of the specimen respectively. The schematic diagram of the fixed-elongation test is shown in the Fig. 3, the specimen in fixed-elongation is shown in the Fig. 4.

Figure 3: The schematic diagram of the fixed-elongation test

Figure 4: The specimen in fixed-elongation

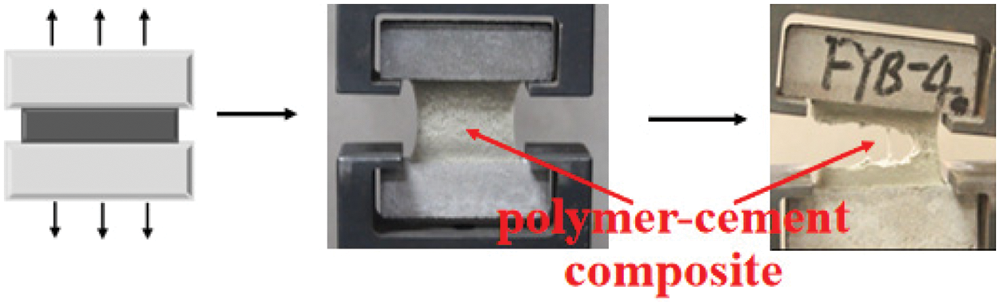

Tensile test with reference to JC/T 881, JT/T 589-2004 and GB/T 13477-2002 [25,26], HS-3001B electronic tensile test equipment was used for tensile test of specimens after different ultraviolet aging time. During the process, the specimens were loaded into the fixture, and then stretched to failure at a speed of 5 mm/min. Corresponding load and displacement data were recorded by the test equipment. Each set of tests was conducted three times, and the results were averaged. The schematic diagram of the tensile test is shown in the Fig. 5.

Figure 5: The schematic diagram of the tensile test

2.2.4 Scanning Electron Microscope Test

COX I EM-30 scanning electron microscope was used. The microsection specimen after gold spraying was placed in the chamber of scanning electron microscope for observation of microscopic morphology of the polymer-cement composite before and after ultraviolet aging under magnification of 500x.

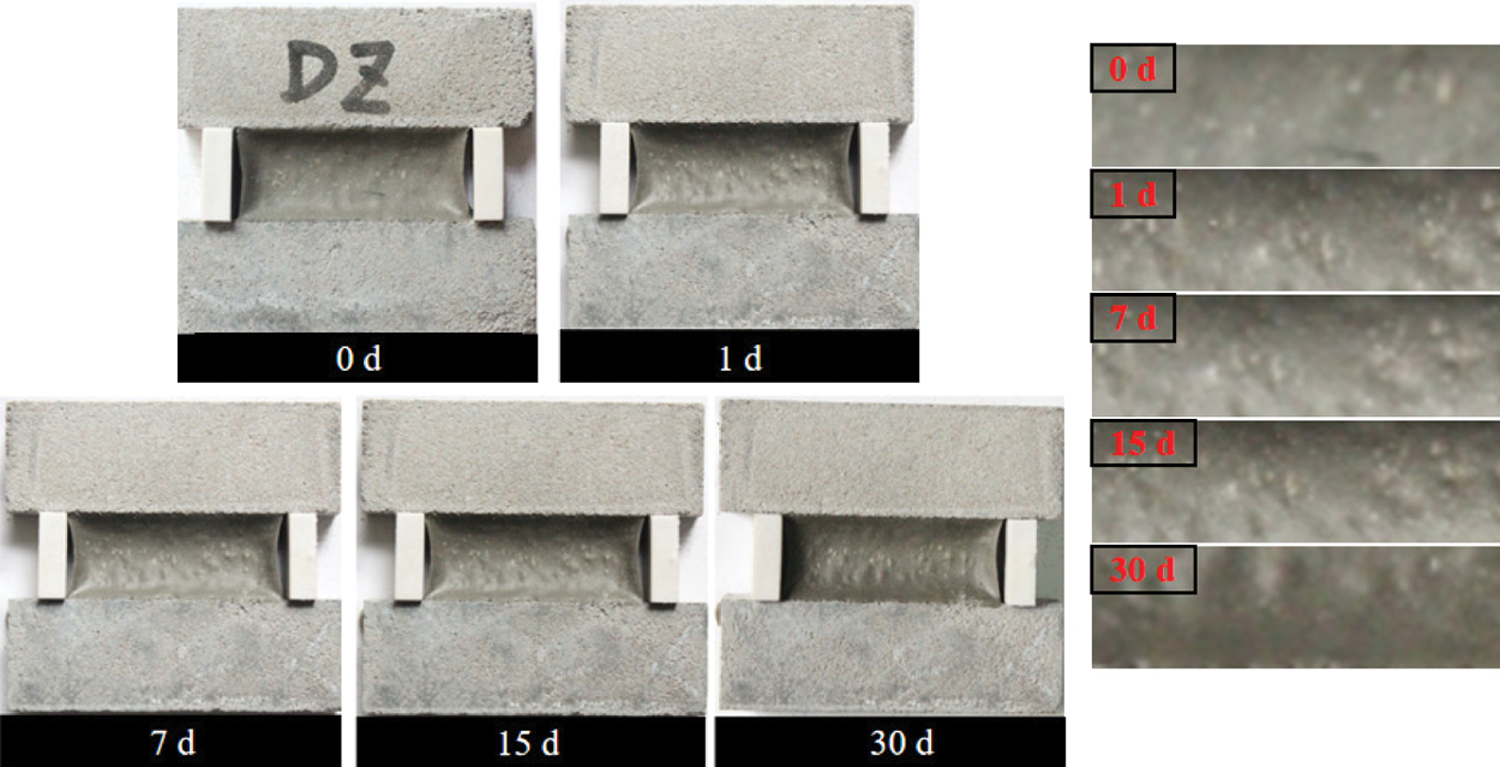

3.1 Failure Mode of Fixed-Elongation Test

The bonding property represents the cohesive property of the polymer-cement composite at a fixed-elongation, which is important for material design. The fixed-elongation failure form is an important qualitative index to reflect the bonding property of the material. The influence of ultraviolet aging on the failure mode of polymer-cement composite as joint filler in fixed-elongation test is as shown in Fig. 6. Obviously, no cohesive failure of polymer-cement composite occurred after UV aging for different days in the fixed-elongation test. The polymer-cement composite was not damaged even after UV aging for 30 days. Therefore, the polymer-cement composite has a good fixed- elongation cohesive property. With increasing of UV aging time, the color of polymer-cement composite was gradually deepened, and the distribution of deepened color gradually extended to the whole composite surface. The main reasons for this was that a UV-irradiation aging reaction of polymer molecules under UV radiation occurred, and the ultraviolet light broke the polymer molecular chain to form the active radical, which reacted with oxygen in the air, and generated a new chromophoric group changing the color of the test specimen. The cement and inorganic fillers in the composite are stable chemically, and so further damage for UV oxidation may be delayed [27,28].

Figure 6: The influence of ultraviolet aging on the failure mode of polymer-cement composite in fixed-elongation test

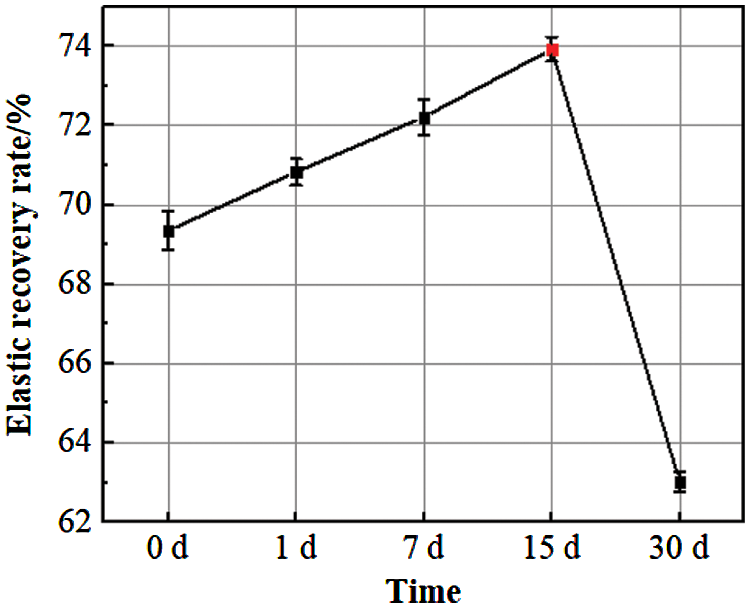

The elastic recovery rate is an important quantitative index to reflect the bonding property of materials. From Fig. 7, which showed the influence of UV aging on the elastic recovery rate of polymer-cement composite, obviously, the elastic recovery rate of polymer-cement composite first increased and then decreased with increasing of UV aging time. Within the first 15 days of UV aging, the elastic recovery rate of polymer-cement composite increased continuously, and was even greater than that of polymer-cement composite without UV aging. After UV aging for 15 days, the elastic recovery rate of the polymer-cement composite as joint filler was 73.93%, which was 6.60% higher than that of the polymer-cement composite without UV aging. After UV aging for 30 days, the elastic recovery rate of the polymer-cement composite decreased to 90.86% of that of the polymer-cement composite without UV aging. On the whole, the elastic recovery rate of polymer-cement composite after UV aging for different days was more than 60%, which met relevant requirements for use. So UV aging increased the elastic recovery rate and enhanced the bonding property within a certain range. The main reason for this was that a cross-linking reaction between the active radical on polymer molecular chain in the polymer cement composite and part of the cement hydration product occurred under UV irradiation, thus resulting in the increase of cross-linking density, which made the elastic recovery rate of the polymer-cement composite increase continuously within a certain UV aging time range [29]. However, prolonged ultraviolet aging caused degradation of polymer molecules for ageing, which broke the chain segment and reduced the of cross-linking density, thus reducing the elastic recovery rate.

Figure 7: Influence of UV aging on the elastic recovery rate of polymer-cement composite

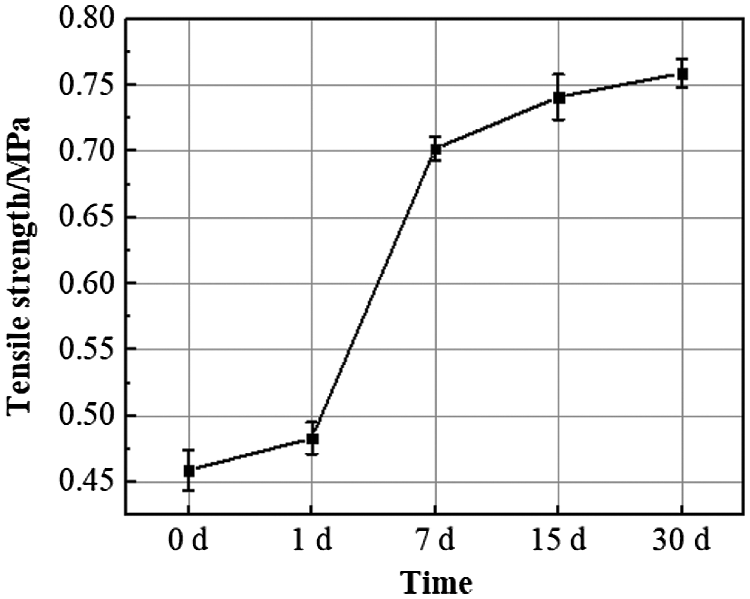

As an important index to characterize the tensile property of materials, tensile strength is the peak stress of polymer-cement composite specimens under the tensile load. The influence of UV aging on the tensile strength of polymer-cement composite is shown in Fig. 8. This figure shows that the tensile strength of polymer-cement composite increased with increasing of UV aging time. The tensile strength of polymer-cement composite was 0.48 MPa after UV aging for 1 day, which rose only by 5.23%, but increased significantly to 0.70 MPa after UV aging for 7 day. The tensile strength increased continuously with increasing of UV aging time. After UV aging for 30 days, tensile strength of the polymer-cement composite increased by 65.36%. Obviously, the ultraviolet aging increased the tensile strength of polymer-cement composite and improved its tensile property. And the longer the UV aging time is, the more obvious the effect will be.

The tensile strength of polymer-cement composite increased significantly with increasing of UV aging time for two reasons. First, under the UV radiation, a cross-linking reaction occurred inside the composite, the composite was cured, and thus, the integrity of the composite, as well as its tensile property, was improved [29]. Second, under the UV radiation, the unhydrated cement inside the composite was further hydrated, and thus, the skeleton for hydration network of cement inside the composite, as well as the tensile strength of the composite, was continuously strengthened [30].

Figure 8: Influence of UV aging on the tensile strength of polymer-cement composite

3.4 Tensile Deformation Property

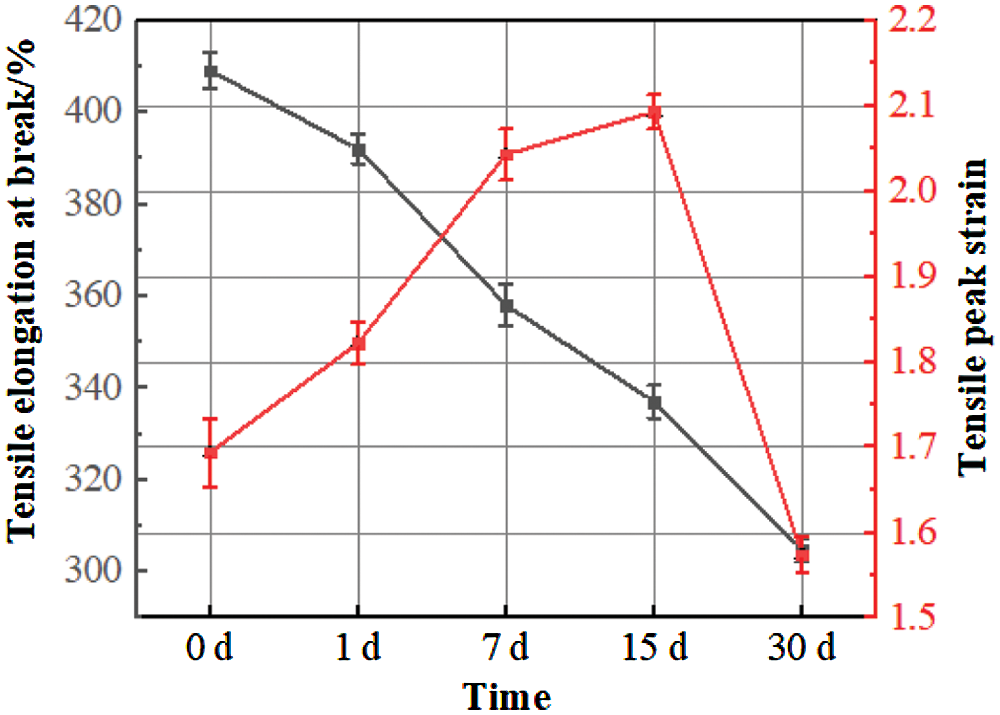

The tensile elongation at break and the peak strain are usually used to measure the tensile deformation property of materials. The tensile elongation at break is the ratio of the seam width at break to the initial seam width of the specimen of polymer-cement composite. The peak tensile strain is the strain when the peak stress of the polymer-cement composite specimen is reached during the tensile process. The influence of UV aging on the tensile deformation property of polymer-cement composite is shown in Fig. 9, the elongation at break of polymer-cement composite decreased continuously with increasing of UV aging time. After UV aging time for 15 days and 30 days, the elongation at break of polymer-cement composite was 337.09% and 304.89%, which were decreased by 17.60% and 25.62% respectively. With increasing of UV aging time, the peak tensile strain of polymer-cement composite increased first, and then decreased. When the UV aging time was up to 15 days, the peak tensile strain of the polymer-cement composite was at maximum, which was increased by 23.55%. After UV aging for 30 days, the peak tensile strain of the polymer-cement composite was decreased significantly, and even lower than that of the polymer-cement composite without UV aging time. The peak tensile strain decreased by 7.08%. Therefore, the UV aging influenced the elongation at break of polymer-cement composite greatly, and it reduced the elongation at break. And the UV aging increased the peak tensile strain of polymer-cement composite within a certain range.

The polymer molecular film was cured and the cement was further hydrated under UV radiation, thus improving the rigidity of polymer-cement composite, and reducing its viscosity as well [31]. As a result, the elongation at break of polymer cement composite decreased continuously. The peak tensile strain of polymer-cement composite was increasing with the rigidity. Prolonged ultraviolet aging made the molecular chain of the composite break, and thus, internal cracks were formed, and the structure became relaxed. At this point, the polymer-cement composite was damaged under a small peak tensile strain.

Figure 9: Influence of UV aging on the tensile deformation property of polymer-cement composite

3.5 Tensile Energy Consumption Performance

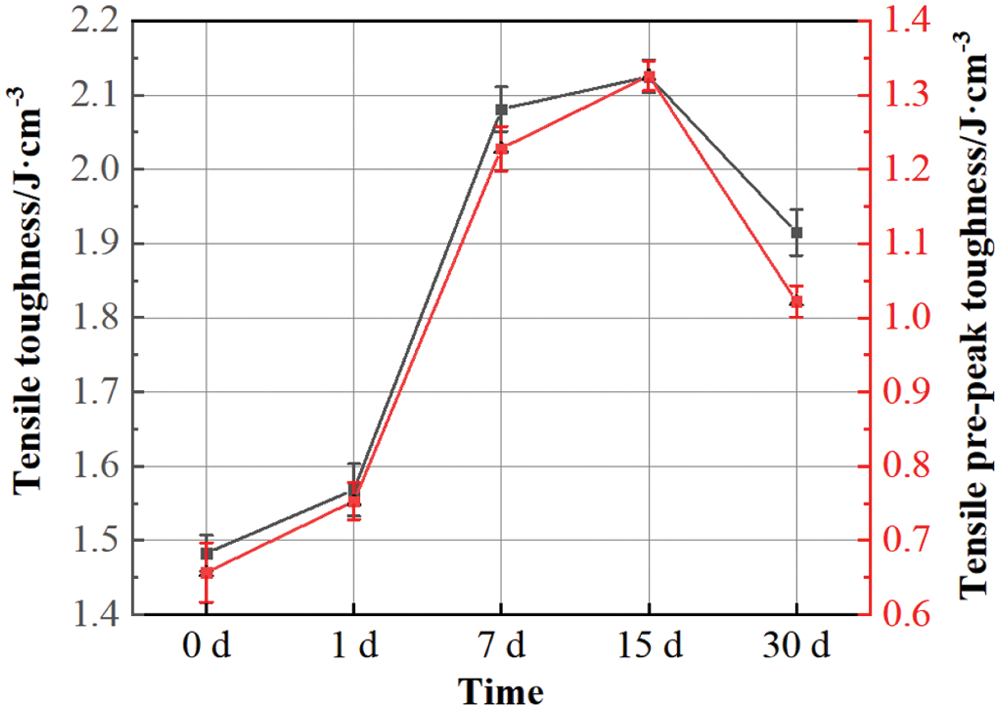

Compared with other emulsions such as styrene-butadiene emulsions, styrene-acrylic emulsions and VAE emulsions contain certain active groups, which is beneficial to improve the performance of polymer-cement composite. The energy consumption of materials under tensile load is usually quantitatively characterized by tensile toughness and pre-peak tensile toughness. The tensile toughness is to represent the amount of energy absorbed by the polymer-cement composite throughout the process of tensile loading while the pre-peak tensile toughness is to represent the amount of energy absorbed by the polymer-cement composite before it is damaged. The influence of UV aging on the tensile energy consumption performance of polymer-cement composite is shown in Fig. 10, with increasing of UV aging time, both the tensile toughness and the pre-peak tensile toughness of polymer-cement composite increased first, and then decreased. After UV aging for 15 days, the tensile toughness and the pre-peak tensile toughness of the polymer-cement composite were at maximum, which respectively are 2.13 J·cm−3 and 1.33 J·cm−3, increased by 43.29% and 101.83% respectively as compared with those of unaged polymer-cement composite. The tensile toughness and pre-peak tensile toughness of the polymer-cement composite decreased after UV aging for 30 days, but still increased by 29.13% and 55.56% respectively as compared with the those of polymer-cement composite. On the whole, UV aging enhanced the tensile energy consumption performance of polymer-cement composite obviously. After UV aging, the tensile toughness and the pre-peak tensile toughness of polymer-cement composite were significantly improved.

With ultraviolet aging time, the polymer molecular chain broke, and there were more cracks in the composite. Thus, more free pores were available for the polymer molecular chain to freely curl, flex, and rotate under external load. Pores of different sizes were also the basic conditions for absorbing and consuming a large amount of deformation and fracture energy [28]. Therefore, the tensile toughness and the pre-peak tensile toughness of the polymer-cement composite were increased. As the UV aging was further prolonged, the increased active groups formed by the fracture of polymer molecular chains and hydration products of unhydrated cement particles, as well as the cross-linking action between active groups and some hydration products, made some free pores filled, thus compromising the tensile energy consumption performance [30,31].

Figure 10: Influence of UV aging on the tensile energy consumption performance of polymer-cement composite

4 Microscopic Mechanism Analysis

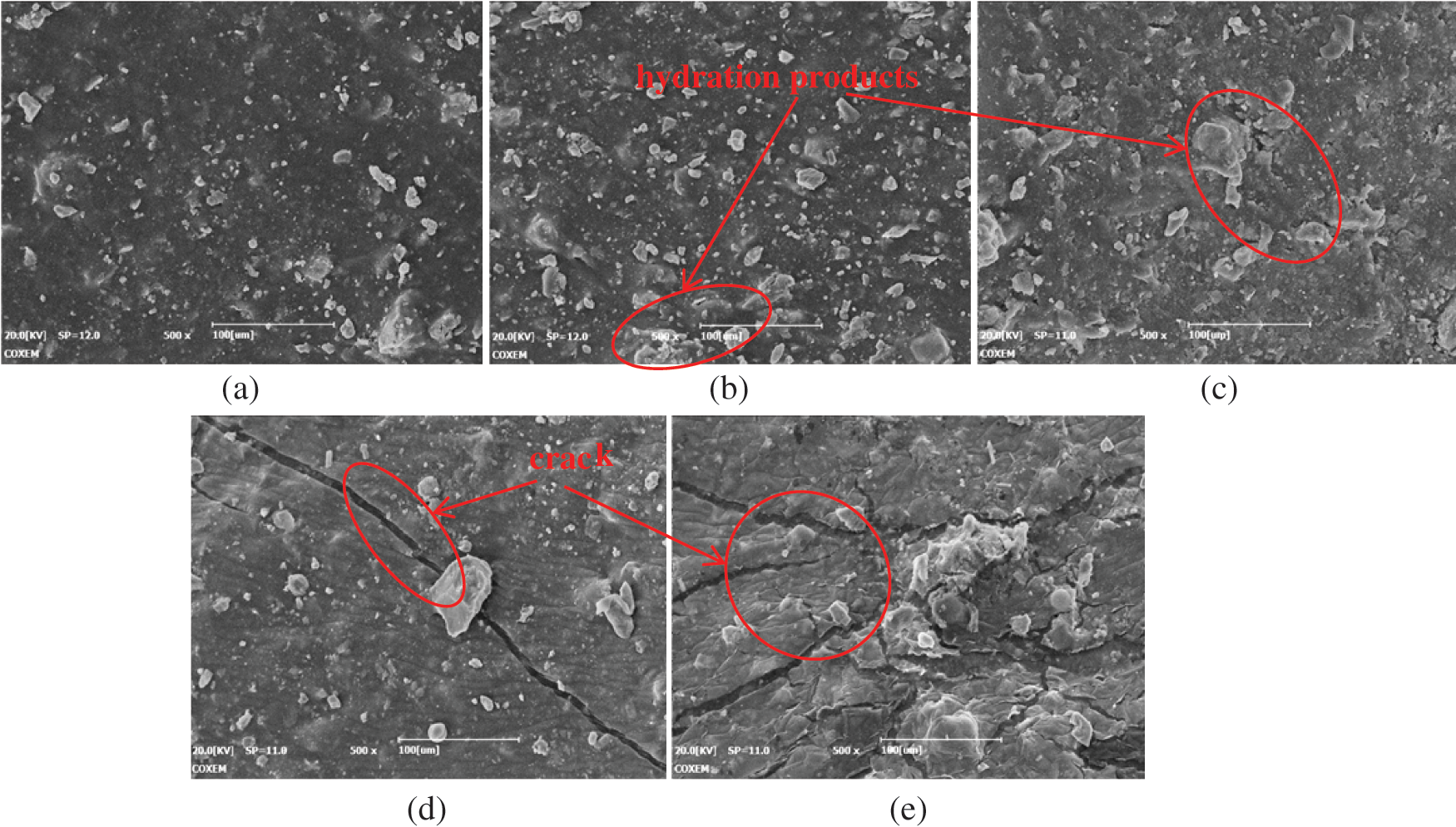

Polymer-cement composite is a heterogeneous multiphase system composed of polymer film, cement hydration products and other inorganic fillers, as well as water and air existing in pores, i.e., a three-phase porous body of solid-liquid-gas. The change of macroscopic property of the composite is essentially caused by the change of microstructure inside the composite system. Fig. 11 was the microtopography of polymer-cement composite after different days of UV aging. As shown in Fig. 11, the ultraviolet aging influenced the microstructure of polymer-cement composite significantly. The UV radiation energy was about 71.5 to 95.3 kcal/mol while the bond energy of covalent bond between polymer molecules was about 40 to 100 kcal/mol [27]. Thus, under the UV radiation, the polymer molecules of the composite absorbed the UV energy, which was gradually accumulated. As shown in Figs. 11b and 11c, after UV aging for 1 day, polymer molecules absorbed more energy, the molecular chains were cut off, and chemical bonds were broken, thus producing active radicals, which had a UV-irradiation reaction with oxygen in the air. After UV aging for 7 days, further UV-irradiation reaction occurred, the unhydrated cement particles in the polymer cement composite began to hydrate and form hydration products. As shown in Figs. 11d and 11e, after UV aging for 15 days, some of the polymer molecular chains on the surface of composite underwent chain UV-irradiation reactions of free radicals, which caused degradation of polymer molecules, as well as obvious cracks in the composite. At the same time, a crosslinking curing reaction between the active free radicals of the polymer chain and some of the hydration products occured. After UV aging for 30 days, the chain UV-irradiation reaction developed to inside the composite, for which the number and depth of cracks increased as the composite aged and deteriorated from the outside to the inside.

The UV aging influenced the property of polymer-cement composite from the following three aspects [28–31].

1. Photooxygen reaction, in which the polymer molecular chain absorbed the UV energy, broke and produced active free radicals, which had a photooxygen reaction with oxygen, thus making the composite aged.

2. The secondary hydration reaction of cement, in which the unhydrated cement in the composite was further hydrated under high energy of ultraviolet radiation, and so, the skeleton for hydration network of cement inside the composite was continuously strengthened.

3. The crosslinking curing reaction, i.e., the crosslinking curing reaction between the active groups of the polymer molecular chain and some of hydration products, which strengthened the composite totally.

In the early stage of UV aging, the UV-irradiation reaction was weaker than the secondary hydration reaction of cement, which was manifested as increasing elasticity recovery rate, tensile strength, peak tensile strain and tensile energy consumption of polymer-cement composite macroscopically. In the late stage of UV aging, the UV-irradiation reaction was stronger than the secondary hydration reaction of cement, which was manifested as decreased elasticity recovery rate, peak tensile strain and tensile energy consumption of polymer-cement composite macroscopically. At the same time, the tensile strength of polymer-cement composite continued increasing due to cross-linking reaction. The joint action of above three factors made the viscosity of the polymer-cement composite decrease gradually and the rigidity increase continuously, and thus, the elongation at break of the composite decreased continuously.

Figure 11: The microtopography of polymer-cement composite after different days of UV aging. (a) 0 d (b) 1 d (c) 7 d (d) 15 d and (e) 30 d

The UV aging had little influence on the failure mode of polymer-cement composite in the fixed-elongation test. The composite still had no cohesive failure after UV aging for 30 days, and it had a good bonding property.

The UV aging increased the elastic recovery rate of polymer-cement composite within a certain range. The elastic recovery rate of polymer-cement composite first increased and then decreased with increasing of UV aging time. When the UV aging time was up to 15 days, elastic recovery rate of the polymer-cement composite was at maximum, and when the UV aging time was up to 30 days, the elastic recovery rate of the composite decreased as compared with that before aging. On the whole, the elastic recovery rate of composite was more than 60%, which met relevant requirements for use.

The UV aging could enhance the tensile strength of polymer-cement composite. With increasing of UV aging time, the tensile strength of the composite increased continuously.

The elongation at break of composite decreased continuously after UV aging due to the photo-oxygen reaction, the secondary hydration reaction of cement, and the cross-linking curing reaction. With increasing of UV aging time, the peak tensile strain of polymer-cement composite increased first, and then decreased. When the UV aging time was up to 15 days, the peak tensile strain of the polymer-cement composite was at maximum.

The UV aging could enhance the tensile energy consumption performance of the polymer-cement composite. With increasing of UV aging time, both the tensile toughness and the pre-peak tensile toughness of polymer-cement composite increased first, and then decreased. After UV aging for 15 days, the tensile toughness and the pre-peak tensile toughness of the polymer-cement composite were at maximum. The tensile toughness and pre-peak tensile toughness of the polymer-cement composite decreased after UV aging for 30 days, but were still higher than before aging.

Acknowledgement: The authors would like to thank the National Natural Science Foundation of China (Grant No. 51208507) for the financial support.

Funding Statement: This research was funded by the National Natural Science Foundation of China, Grant No. 51208507.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Rashid, K., Wang, Y., Ueda, T. (2019). Influence of continuous and cyclic temperature durations on the performance of polymer cement mortar and its composite with concrete. Composite Structures, 215, 214–225. DOI 10.1016/j.compstruct.2019.02.057. [Google Scholar] [CrossRef]

2. Jiang, Y. J., Li, L., Wang, H. S. (2015). Influence of acrylic emulsion on polymer-cement waterproof coating. Advanced Materials Research, 1129, 263–269. DOI 10.4028/www.scientific.net/AMR.1129.263. [Google Scholar] [CrossRef]

3. Wang, D. Y., Fei, W. S. (2013). Joint issue discussion on cement concrete pavement. Advanced Materials Research, 671–674(2), 1179–1182. DOI 10.4028/www.scientific.net/AMR.671-674.1179. [Google Scholar] [CrossRef]

4. Banjo, A. A., Temidayo, E. O. (2017). Engineering properties of acrylic emulsion polymer modified bamboo reinforced cement bonded composites. Engineering Structures and Technologies, 9(3), 126–132. DOI 10.3846/2029882X.2017.1371085. [Google Scholar] [CrossRef]

5. Wang, W. X., Wang, M. F., Li, H. X. (2019). Pavement crack image acquisition methods and crack extraction algorithms: A review. Journal of Traffic and Transportation Engineering (English Edition), 6(6), 535–556. DOI 10.1016/j.jtte.2019.10.001. [Google Scholar] [CrossRef]

6. Bai, E. L., Liu, G. J., Xu, J. Y. (2020). Tensile properties of a flexible polymer-cement composite containing portland cement and VAE emulsion. Ceramics Silikaty, 64(1), 92–99. [Google Scholar]

7. Liu, Z. G., Xu, F. M., Cao, G. B. (2015). Study on cement concrete pavement treatment methods of common damage diseases. Applied Mechanics and Materials, 716−717, 307–309. DOI 10.4028/www.scientific.net/AMM.734.307. [Google Scholar] [CrossRef]

8. Yassene, A. M., Ismail, M. R., Afify, M. S. (2020). Physicomechanical properties of irradiated SBR latex polymer-modified cement mortar composites. Journal of Vinyl and Additive Technology, 26(2), 144–154. DOI 10.1002/vnl.21727. [Google Scholar] [CrossRef]

9. Asad, M., Dhanasekar, M., Zahra, T. (2019). Characterisation of polymer cement mortar composites containing 1 carbon fibre or auxetic fabric overlays and inserts under flexure. Construction and Building Materials, 224(10), 863–879. DOI 10.1016/j.conbuildmat.2019.07.120. [Google Scholar] [CrossRef]

10. Bai, E., Liu, G., Xu, J. (2020). Tensile and fixed elongation properties of polymer-based cement flexible composite under water/corrosive solution environment. Materials, 13(9), 2155. DOI 10.3390/ma13092155. [Google Scholar] [CrossRef]

11. Nguyen, M., Wang, Z. M., Rod, K. A. (2018). Atomic origins of the self-healing function in cement-polymer composites. ACS Applied Materials & Interfaces, 10(3), 3011–3019. DOI 10.1021/acsami.7b13309. [Google Scholar] [CrossRef]

12. Choi, J. Y., Joo, M. K., Lho, B. C. (2016). Effects of SilicaFume content and polymer-binder ratio on properties of ultrarapid-hardening polymer-modified mortars. International Journal of Concrete Structures and Materials, 10(2), 249–256. [Google Scholar]

13. Tsukagoshi, M., Kokami, Y., Tanaka, K. (2010). Influence of curing condition on film formation of polymer-cement waterproofing membrane. Journal of Structural and Construction Engineering (Transactions of AIJ), 75(652), 1057–1064. DOI 10.3130/aijs.75.1057. [Google Scholar] [CrossRef]

14. Ohama, Y. (1998). Polymer-based admixtures. Cement and Concrete Composites, (20), 189–212. DOI 10.1016/S0958-9465(97)00065-6. [Google Scholar] [CrossRef]

15. Mah, Y., Tian, Y., Li, Z. J. (2011). Interactions between organic and inorganic phases in PA- and PU/PA-modified-cement based materials. Journal of Materials in Civil Engineering, 23(10), 1412–1421. DOI 10.1061/(ASCE)MT.1943-5533.0000302. [Google Scholar] [CrossRef]

16. Plank, J., Gretz, M. (2008). Study on the interaction between anionic and cationic latex particles and Portland cement. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 330(2−3), 227–233. DOI 10.1016/j.colsurfa.2008.08.005. [Google Scholar] [CrossRef]

17. Melichar, T., Byd, O. J., Keprdová, Á. (2014). Study of parameters of new polymer-cement composites after exposure to extreme temperatures. Advanced Materials Research, 1000, 81–84. [Google Scholar]

18. Sokołowska, J. J., Woyciechowski, P., Adamczewski, G. (2013). Influence of acidic environments on cement and polymer-cement concretes degradation. Advanced Materials Research, 687, 144–149. DOI 10.4028/www.scientific.net/AMR.687.144. [Google Scholar] [CrossRef]

19. Soufi, A., Mahieux, P. Y. (2015). Influence of polymer proportion on transfer properties of repair mortars having equivalent water porosity. Materials and Structures, 49(1−2), 383–398. DOI 10.1617/s11527-014-0504-3. [Google Scholar] [CrossRef]

20. Yang, N., Bai, E., Xu, J. (2018). Study on tensile mechanical property of styrene-acrylic cement composite material. IOP Conference Series: Earth and Environmental Science, 153(2), 1–9. [Google Scholar]

21. Boxu, M., Jinyu, X., Chao, G. (2019). Effect of VAE latex powder addition on tensile and shear properties of styrene-acrylate based cement composite joint compound. IOP Conference Series: Earth and Environmental Science, 242(2), 1–8. DOI 10.1088/1755-1315/242/3/032063. [Google Scholar] [CrossRef]

22. ISO/DIS 11600-2000. Building construction-jointing products-classification and requirements for sealants. [Google Scholar]

23. National Bureau of Building Materials Industry. (2001). JC/T 881-2001 Sealant for joints of concrete buildings. Beijing: China Building Materials Industry Press. [Google Scholar]

24. National Development and Reform Commission of the People’s Republic of China. (2005). JC/T 976–2005 sealant for road and bridge caulking. Beijing: China Building Materials Industry Press. [Google Scholar]

25. Ministry of Communications of the People’s Republic of China. (2004). JT/T 589−2004 cement concrete pavement caulking sealing material. Beijing: People’s Communications Press. [Google Scholar]

26. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. (2002). GB/T 13477–2002 test method for building sealing materials. Beijing: China Quality Supervision and Inspection Press. [Google Scholar]

27. Fu, C., Ni, A., Wang, J. (2020). The effect of ultraviolet aging on the fatigue properties of glass fiber reinforced epoxy resin matrix composites. Composite Materials Science and Engineering, 135(7), 74–80. [Google Scholar]

28. Dong, S. (2002). Preparation of polymer cement-based waterproof coating and study of coating film performance and microstructure. Chongqing: Chongqing University. [Google Scholar]

29. Ding, S. (2006). Aging test and durability study of building sealing materials. Zhengzhou: Zhengzhou University. [Google Scholar]

30. Lou, C., Xu, J., Liu, S. (2020). Effects of external environments on the fixed elongation and tensile properties of the VAE emulsion-cement composite joint sealant. Materials, 13(14), 3233. DOI 10.3390/ma13143233. [Google Scholar] [CrossRef]

31. Bai, E. L., Liu, G. J. (2020). Tensile and fixed elongation properties of polymer-based cement flexible composite under water/corrosive solution environment. Materials, 13(9), 1–16. [Google Scholar]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |