| Sound & Vibration |  |

DOI: 10.32604/sv.2021.014916

ARTICLE

Acoustic Properties of Micro-Perforated Panels Made from Oil Palm Empty Fruit Bunch Fiber Reinforced Polylactic Acid

1School of Computer Science and Engineering, Taylor’s University, Subang Jaya, 47500, Malaysia

2Centre for Advanced Research on Energy, Universiti Teknikal Malaysia Melaka (UTeM), Melaka, 76100, Malaysia

3Fakulti Kejuruteraan Mekanikal, Universiti Teknikal Malaysia Melaka (UTeM), Melaka, 76100, Malaysia

*Corresponding Author: Vignesh Sekar. Email: svikiviki94@gmail.com

Received: 07 November 2020; Accepted: 22 July 2021

Abstract: This paper presents the development and performance of micro-perforated panels (MPP) from natural fiber reinforced composites. The MPP is made of Polylactic Acid (PLA) reinforced with Oil Palm Empty Fruit Bunch Fiber (OPEFBF). The investigation was made by varying the fiber density, air gap, and perforation ratio to observe the effect on the Sound Absorption Coefficient (SAC) through the experiment in an impedance tube. It is found that the peak level of SAC is not affected, but the peak frequency shifts to lower frequency when the fiber density is increased. This phenomenon might be due to the presence of porosity in the inner wall of the holes. Increasing or decreasing the air gap and perforation ratio shifts the peaks of acoustic absorption either way.

Keywords: Acoustics; micro-perforated panel; natural fiber reinforced composite; laser cutting; impedance tube

In this current time, noise pollution is one of the biggest problems faced by humankind since it involves mental, health, and psychological risks. Noise provoked from dynamic sources, such as crowds and traffic, is the major contribution to noise pollution in urban areas. Long-term exposure to noise higher than 85 dB can lead to health problems such as loss of hearing, sleep disorder, and cardiovascular disease [1]. A lot of workers are exposed to loud noise in their workplaces, such as mining, metal production, and manufacturing of food. Therefore, noise-induced hearing loss is labeled as the “fifteenth-most serious health problem” in the world. An estimation of 250 million people worldwide suffered from this disease, and the United States alone has an estimate of 10 million people who have noise-induced hearing loss [2]. As per the Malaysian Department of Environment’s Guidelines for Environmental Noise Limits and Control, the maximum acceptable noise levels for high, medium, and low-density residential places range from 60 dBA to 50 dBA [3]. However, a study conducted in 2018 near the intersection of roads leading to residential areas in Shah Alam records the highest noise level of around 90 dBA, which adequately overtakes the tolerance limit [4]. Furthermore, Malaysia has an approximate annual growth rate of 6%, corresponding to registered independent vehicles, which can contribute to noise pollution [5]. Consistent or continual exposure to sound might cause hearing damage, stimulation of various stress responses, and abnormality in circadian patterns. Hence, regulation of noise is much essential and has to be addressed immediately [6]. The use of material acoustics is one of the methods to control the noise. Apart from the conventional fibrous materials, this includes the micro perforated panels (MPP). The studies about MPP to improve its absorption bandwidth are still progressing with most recently, those deal with inhomogeneous hole arrangement [7,8]. Pan et al. studied the combination of perforated panels and two micro-perforated membranes made of transparent Methyl Methacrylate, which was shown to have a wideband sound absorption coefficient [9].

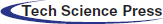

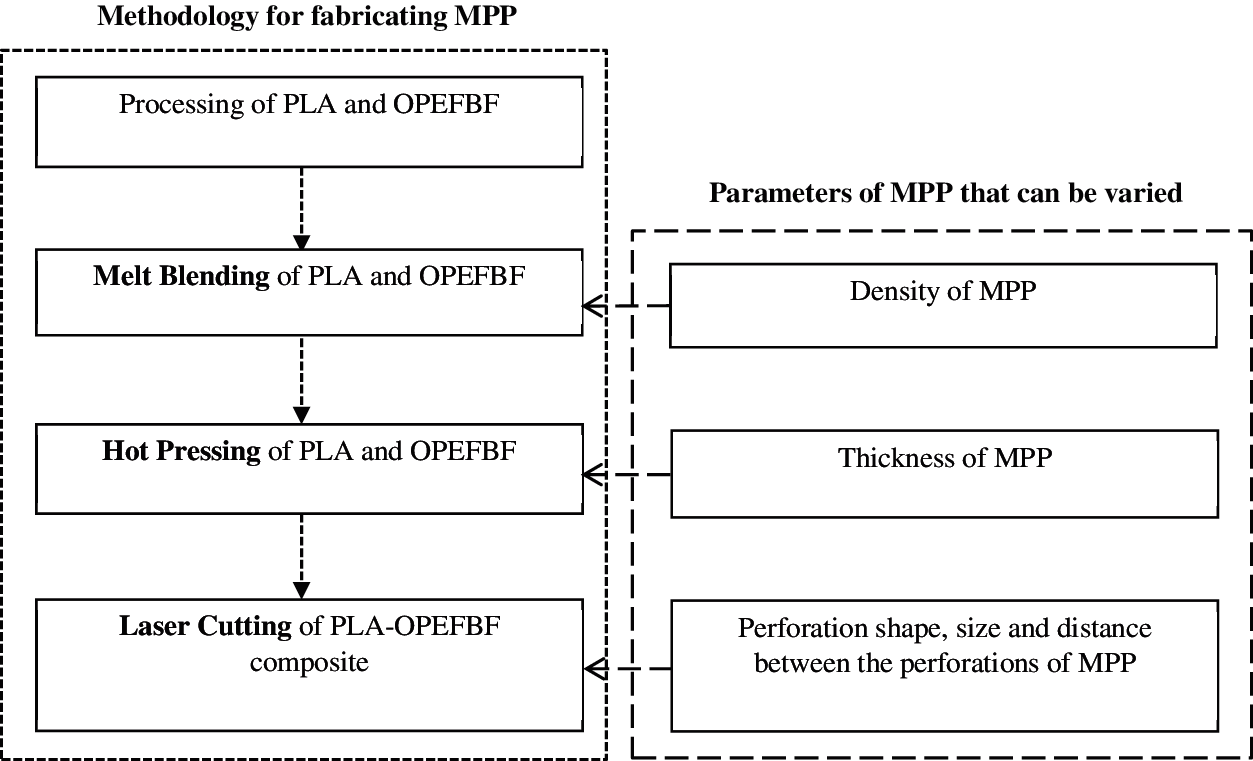

MPP is a panel (typically a thin one) with sub-millimeter perforations backed by an air gap and a rigid wall, as shown in Fig. 1. Several factors like thickness, the density of the MPP, size, shape of the perforations, perforation ratio, and the distance between perforations affect the acoustic absorption of the MPP.

Figure 1: Configuration of a micro-perforated panel (MPP)

The sound absorption coefficient (α) of an MPP backed with an air gap under normal incidence can be calculated theoretically by Eq. (1).

where R and X represent the resistance and reactance of the acoustic impedance of the MPP, ω = 2πf is the angular frequency (in rad/s), and f is the frequency (in Hz), D is the air gap (in mm), and c is the speed of sound (in m/s). The details for R and X for MPP can be referred in [10,11].

MPP are usually made from metallic materials such as steel and aluminium. However, metallic materials to produce MPP have an environmental impact on a larger scale and are not sustainable [12]. Moreover, the fabrication of MPP using metallic material is costlier due to the complicated process involved in producing sub-millimeter holes by jetting and etching [13]. The rising environmental concerns regarding MPP fabrication with metallic materials have fuelled the research on utilizing the natural fibers in the MPP.

Rusli et al. investigated the sound absorption of natural fibers, namely fibers from pineapple and oil palm coupled with acrylic MPP. The insertion of the natural fiber improved the performance of double-leaf MPP [14]. Sheng et al. [12] recently presented the performance of MPP made of PLA reinforced with coconut fibers. It was concluded that the natural fiber-reinforced composite MPP exhibits better sound absorption performance than the conventional MPP made of steel. Polylactic acid (PLA), which is eco-friendly and biodegradable, has become the rising star as a matrix for composite materials incorporated with natural fibers to produce MPP. Natural fiber composites have porous surfaces that can enhance sound dissipation [12], and other than that, natural fibers are found abundantly around the world, eco-friendly, low in cost, and biodegradable. The sound absorption of different natural fiber such as coir fibers, jute fiber, bamboo fiber, and tea leaf fiber has been studied, and they showed promising performance for sound absorption application [15].

Utilizing natural fibers in the fabrication of MPP would be beneficial to tropical countries, especially for Malaysia. This is because Malaysia is one of the largest oil palm production countries with an estimation of 5 million hectares of oil palm plantation. Palm oil export is one of Malaysia’s major economies; it generates around RM 60 billion in 2019 [16]. The huge amount of palm oil leads to many biomasses left behind after processing the palm oil. These biomasses can cause some environmental issue which cannot be ignored. Therefore, utilizing these biomasses to create valuable products can minimize the number of biomasses. Oil Palm Empty Fruit Bunch Fiber (OPEFBF) is one of the biomasses left after palm oil production, and it almost contributes more than 70% of fibrous biomass, which has not been used effectively [17]. This study applies these OPEFBF to construct the MPP. For the type of fibrous absorbers, OPEFBF has been demonstrated to have good sound absorption performance [18].

The performances of the test samples are studied by varying the densities of the fibers. Parameters of air gap and distance between the holes (perforation ratio) are also varied to complete the performance data of the proposed MPP made of OPEFBF composite.

Polylactic acid (PLA) pellets having a melt flow index of 6 g/10 min and a specific gravity of 1.24 with a grade of IngeoTM Biopolymer 2003D were used. The Oil palm empty fruit bunch fibers (OPEFBF) were obtained from a nearby palm oil mill, as shown in Fig. 2. The length of the fibers is within the range of 25 mm to 35 mm, with a diameter ranging from 0.25 mm to 0.55 mm.

Figure 2: Oil palm empty fruit bunch fibers used in this study

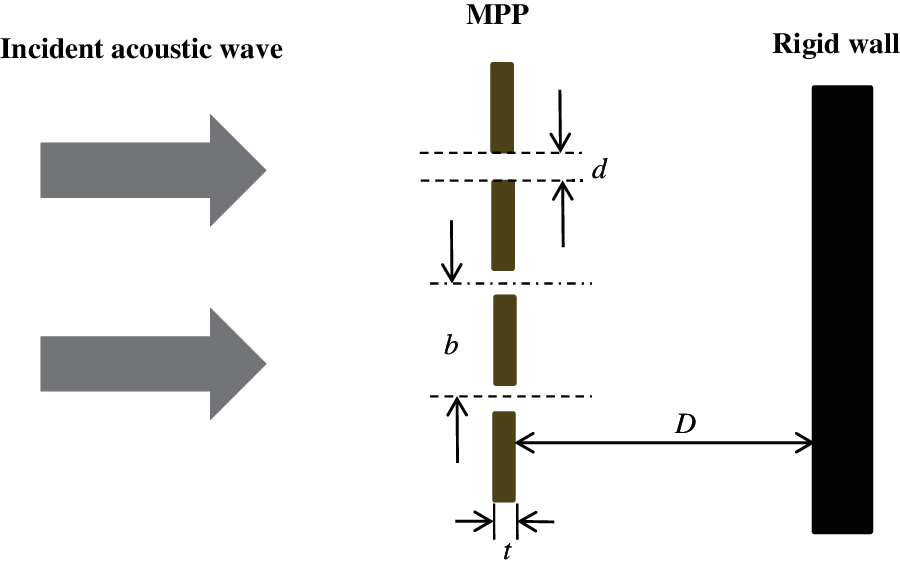

First, the OPEFBF were soaked, rinsed, and washed with normal tap water to remove any impurities. Then, the PLA pellets and OPEFBF were put into an oven for 24 h to minimize the moisture content. The OPEFBF were then grinded and sieved into a smaller size by filtering the OPEFBF through a 500 μm mesh. Later, the OPEFBF and PLA pellets were weighed to ensure the composition considering the weight ratio. After weighing, PLA pellets and OPEFBF were placed into an oven for melting. The oven temperature was set at 210°C, which is higher than the melting temperature of pure PLA to compensate for the convection inside the oven. Once the PLA pellets and OPEFBF were melted, the mixture was stirred well and kept inside an oven. This process was repeated until the materials are well mixed. At the end of this process, melt blended PLA-OPEFBF was collected as a lump. Before hot pressing the produced lumps, the machine was preheated for about 15 min at 180°C, considering the melting temperature of the pure PLA. Later, the melt blended PLA-OPEFBF composite lumps were hot-pressed for 2 min with 5 tons of load, followed by cold-pressed for 2 min with 5 tons of load. Lastly, the PLA-OPEFBF composites were laser cut into the required dimensions of the MPP, designed in SolidWorks software. The hole diameter was selected as 0.6 mm [0.5 mm (design input) + 0.1 mm (tolerance of laser cutting [19])] to offer better resistance [13]. The diagram is shown in Fig. 3. The methodology is summarized in the flow chart is shown in Fig. 4.

Figure 3: Detailed drawing of the MPP

Figure 4: Methodology for fabricating MPP made of PLA-OPEFBF composite

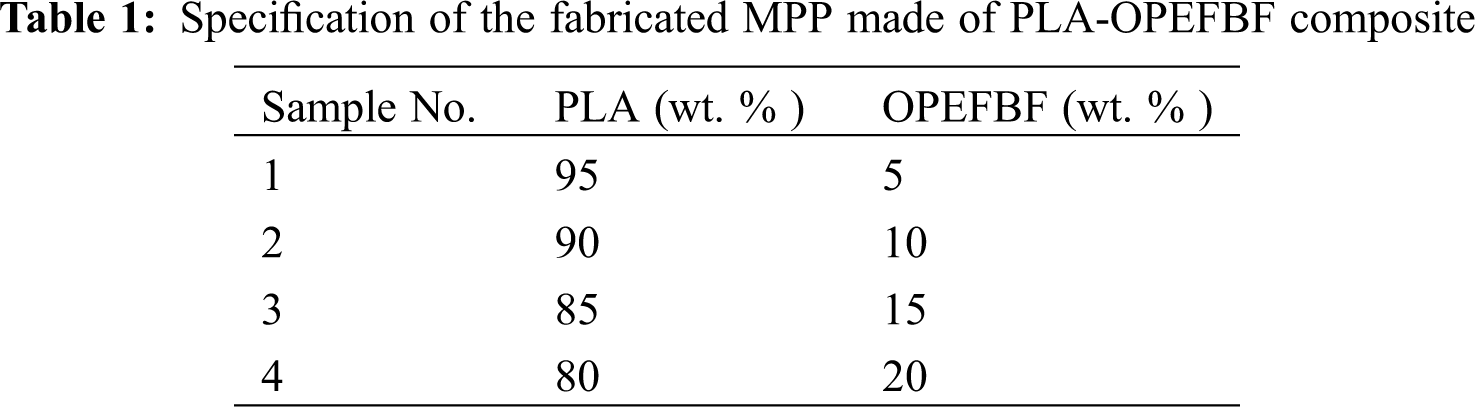

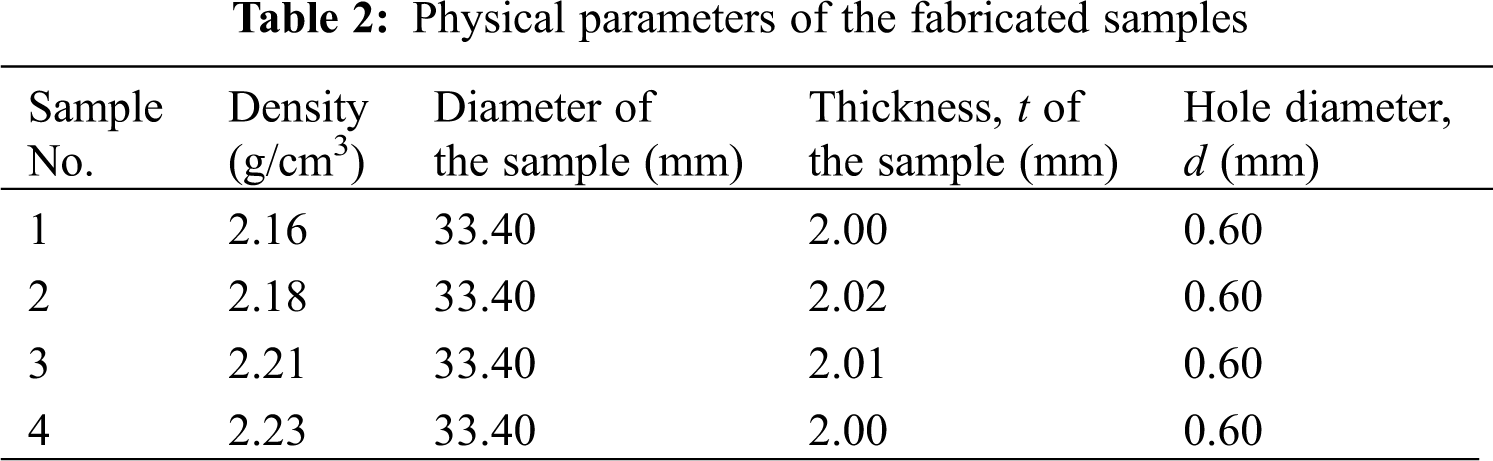

Tab. 1 shows the specification of the fabricated MPP made of PLA-OPEFBF composite, and Tab. 2 shows the physical parameters of all the fabricated samples.

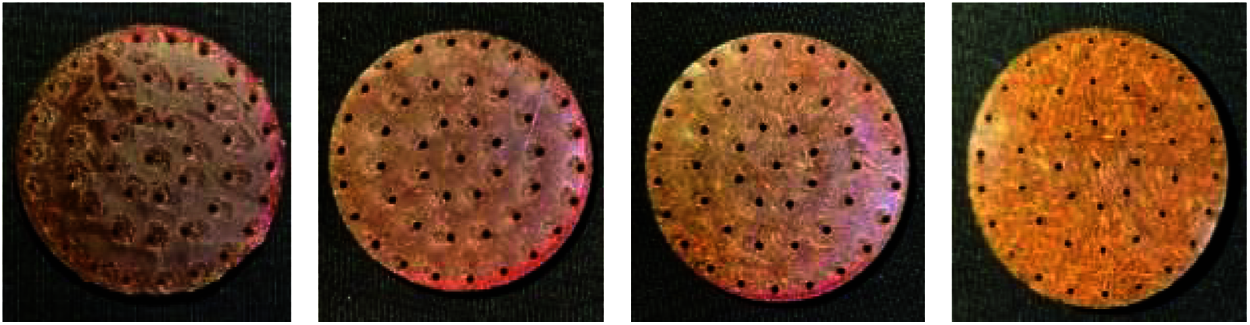

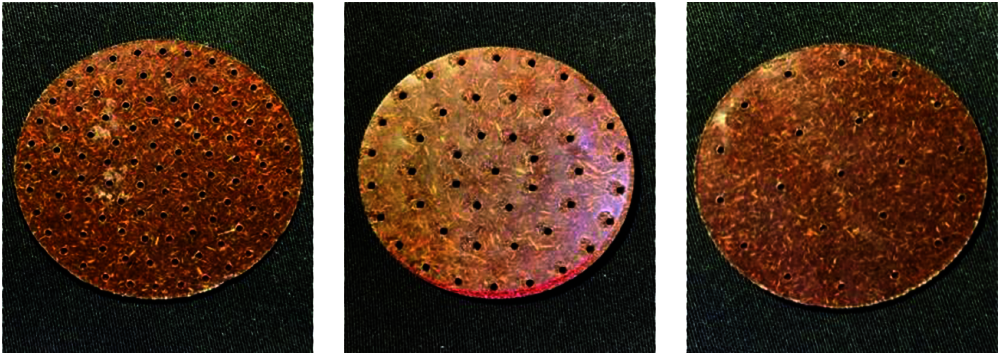

Fig. 5 shows the MPP made of PLA-OPEFBF fabricated with different OPEFBF content, and Fig. 6 shows the MPP made of PLA-OPEFBF fabricated with varying distances between the perforations.

Figure 5: MPP made of PLA reinforced with 5, 10, 15, and 20 wt. % of OPEFBF (left to right)

Figure 6: MPP made of PLA-OPEFBF with different distance between the holes, b = 3, 5, and 7 mm (left to right)

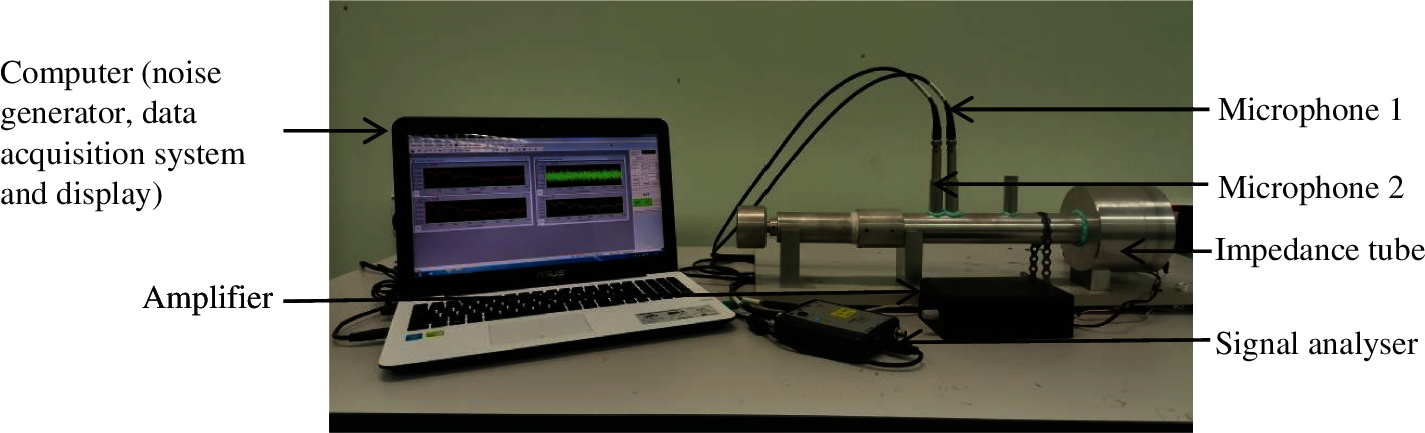

The Sound Absorption Coefficient (SAC) of the fabricated panels was measured by a two-microphone impedance tube method as per ISO 10534-2 standard [20]. Before the experiment, the microphones were calibrated with a sound calibrator to ensure the sound pressure inside the tube was accurately measured. To ensure repeatability, the measurement was repeated three times, and for each measurement, the sample was taken off and inserted back in the sample holder. The experiments were conducted under three cases, i) by varying OPEFBF content at 5 mm air gap, ii) by varying the air gap thickness, iii) by varying the distance between the holes. The results were presented within the frequency range of 500 Hz to 4500 Hz, valid frequency based on the tube diameter and the distance of the microphones. The experimental setup is shown in Fig. 7.

Figure 7: Experimental setup

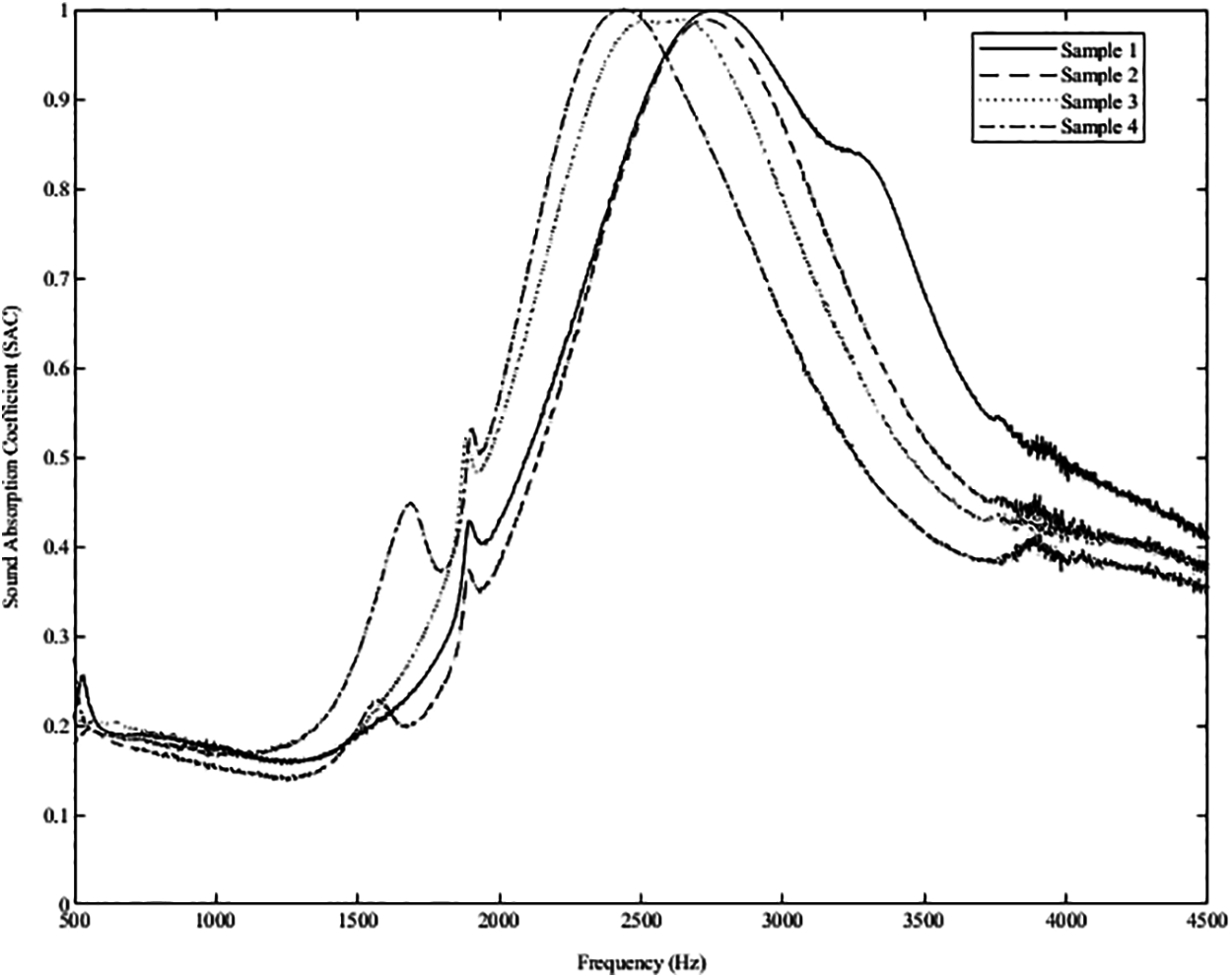

Fig. 8 shows the effect of varying densities on acoustic absorption of the MPP made of PLA-OPEFBF composite. It has been widely known that density played an important factor in affecting the sound absorption performance of a porous material. Based on the results obtained in Fig. 8, it can be seen that density affects the characteristic of sound absorption performance of the MPP composite. The increment of density causes the absorption peak to shift to a lower frequency. This phenomenon occurred mainly due to the increment in the number of small pores with the increment of sample density. The absorption mechanism of an MPP works through the viscous effect between the inner hole wall and the air (resistive part) and through the inertia of the air inside the hole (the reactive part). Combining with the stiffness of the air layer in the backed air gap and the perforation ratio (number of holes), these together determine the peak frequency and the bandwidth of absorption of MPP. In the study, when the MPP surface is attached with fabric [21], the peak frequency is maintained, only the frequency bandwidth is widening towards higher frequency, which is the absorption performance provided by a porous material.

Figure 8: Effect of varying densities on acoustic absorption of the MPP made of PLA-OPEFBF composite (air gap, D = 5 mm)

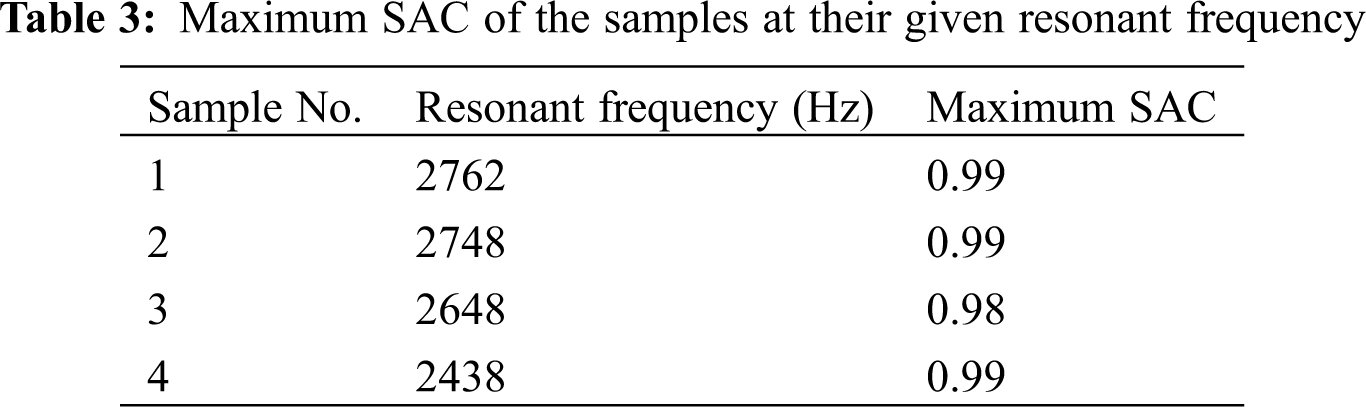

The results in Fig. 8 show an interesting phenomenon, where the peak frequency shifts consistently towards lower frequency as the amount of fibers is added in the composite. In these fabricated samples, the MPPs were finished with a clean surface (low porosity), and thus it is not the cause of the phenomenon. If the surface is porous, then it will increase only the bandwidth, as demonstrated in [18]. The only possibility of the frequency shifting is the presence of porosity on the inner wall of the holes, which contributes to adding the amount of air inside the hole (increasing the air mass) and thus lowering the resonant frequency. The findings are also similar to the study presented by Chin et al. [22]. Tab. 3 shows the maximum SAC of the samples with varying fiber content.

3.2 Effect of Air Gap and Perforation Ratio

The sound absorption performance of MPP based on the air gap and distance between holes (perforation ratio) is already well known. The approximated peak resonant frequency is given by Eq. (2) [10]

where P is the perforation ratio (in %), c = 344 m/s is the speed of sound, t, and D are the panel thickness and air gap (in mm). The perforation ratio is in relation with the hole distance, b can be determined by Eq. (3) [11]

where d is the hole diameter (in mm).

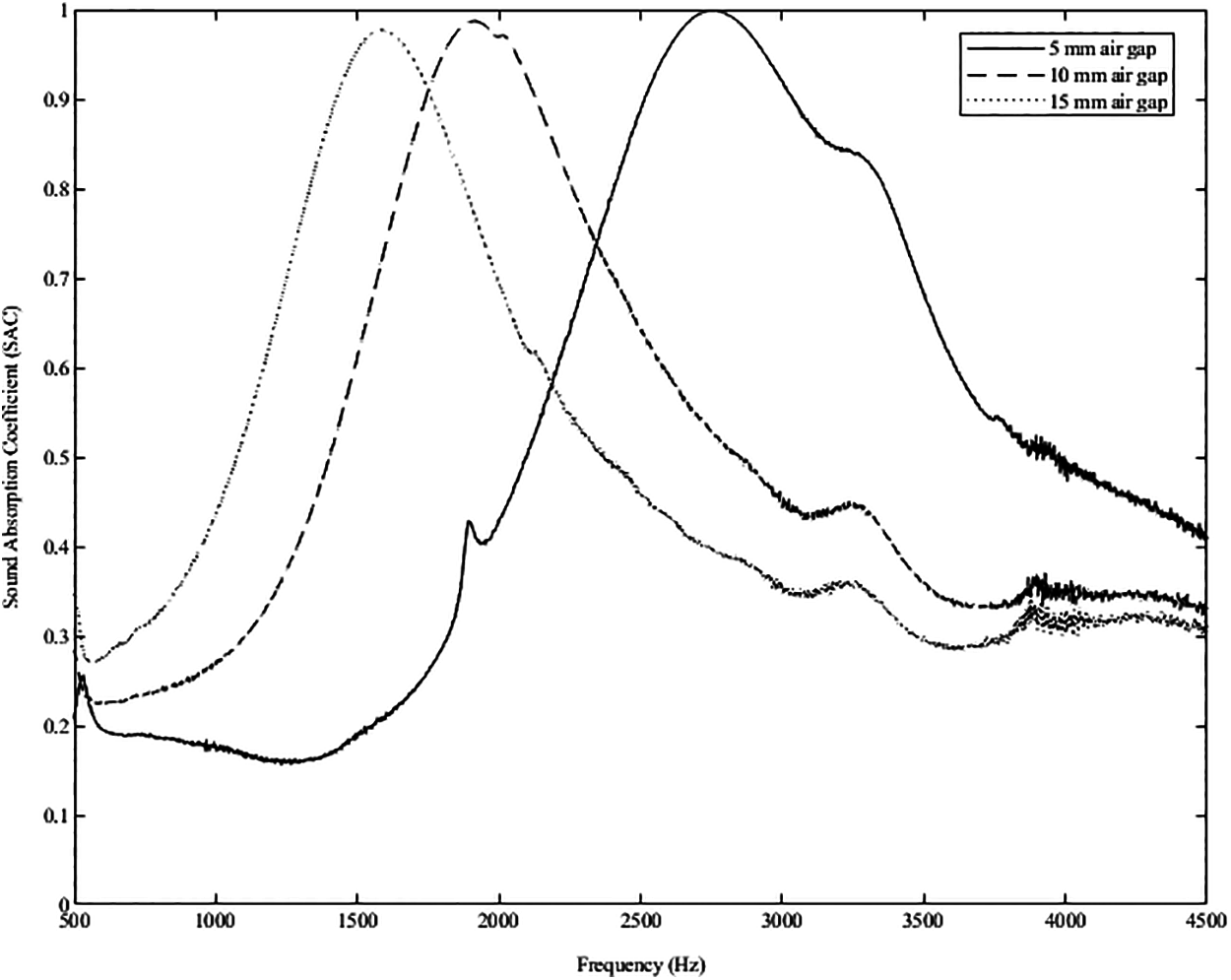

From Eq. (2), it can be predicted that by increasing the air gap, D the peak frequency will be reduced as seen in Fig. 9.

Figure 9: Effect of varying air gap on acoustic absorption of the Sample-1

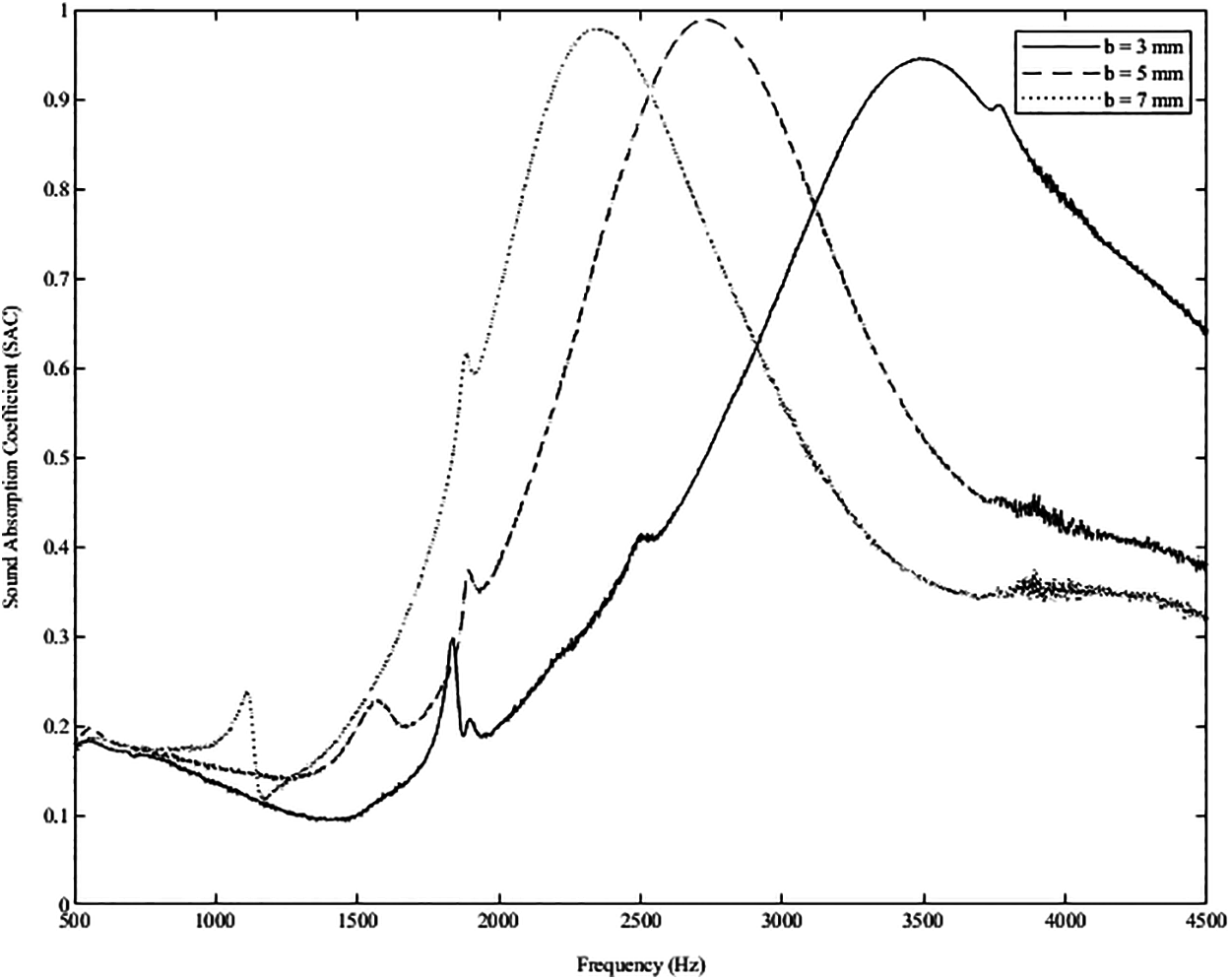

It can be seen from Fig. 9 that the peaks of acoustic absorption move towards the low-frequency spectrum when the air gap between the impedance tube and the sample increases. The air inside the holes serves as an acoustic mass (reactance), whereas the air layer in the back air gap acts as an acoustic spring. As the gap behind the MPP is increased, its stiffness decreases, hence shifting the peaks (natural frequency) of the acoustic absorption towards the low-frequency spectrums. By using Eq. (2) for a solid MPP (without the effect of porosity), the peak frequency in Fig. 9 can be seen to shift to low frequency due to the presence of porosity discussed for the results in Fig. 8. And by increasing the perforation ratio, P (or decreasing the distance between the hole, b), from Eq. (2), it can be predicted that the peak frequency will be increased, as seen in Fig. 10.

Figure 10: Effect of varying distance between holes on acoustic absorption of the Sample-2 (air gap, D = 5 mm)

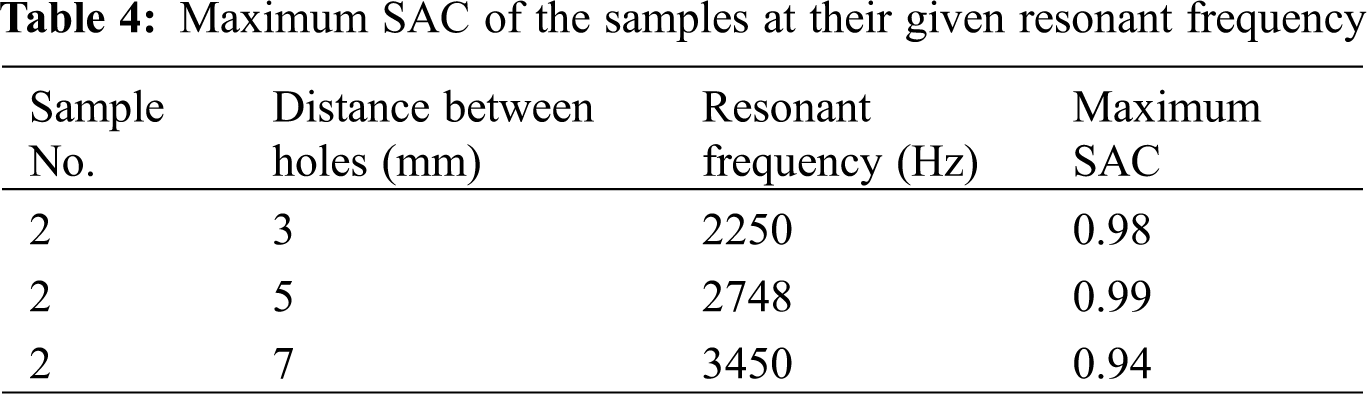

Tab. 4 shows the maximum SAC and the corresponding resonant frequency of the samples with varying distances between the holes. Again with the effect of porosity in the inner surface of the holes, the resonant frequencies in Tab. 4 are lower than those obtained from the prediction using Eq. (2).

There were a few small resonant peaks noticed in Figs. 8–10. This could be due to the eigenmode caused by the air inside the impedance tube, which was not free to undergo movement (as impedance tube is a closed-ended tube) and was forced to resonate the sample within the tube [23].

MPP composites made of PLA reinforced OPEFBF have been successfully fabricated, and the acoustic performance has been discussed. This study reveals that the peak frequency of the absorption coefficient shifts to a lower frequency when the content of fibers is increased in the composite. This could be because of the presence of porosity in the inner wall of the holes, which adds the oscillating mass and hence reduces the resonance frequency. This study can be extended by increasing the fiber density in the composite and possibly constructing an MPP with a certain degree of porosity across the panel. Also, the methodology provided in this study can show the interest for the designers and researchers to develop MPP made of natural fibers reinforced composites and to vary its parameters based on the required acoustic spectrum.

Acknowledgement: The author is thankful to the Taylor’s University for funding scholarship during this research work. The experiment using the impedance tube method is in collaboration with Universiti Teknikal Malaysia Melaka (UTeM).

Funding Statement: This work was partially sponsored by Taylor’s University Flagship Research Grant TUFR/2017/001/05.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Molaeifar, H., Khajehnasiri, F., Nikeghbal, K., Zamanian, Z. (2020). Assessment of effects of concomitant exposure to sound, heat, and physical workload changes on physiological parameters in five different combination modes, a controlled laboratory study. Sound & Vibration, 54(3), 140–148. DOI 10.32604/sv.2020.08810. [Google Scholar] [CrossRef]

2. Nelson, D. I., Nelson, R. Y., Concha-Barrientos, R. Y., Marilyn Fingerhut, M. (2005). The global burden of occupational noise-induced hearing loss. American Journal of Industrial Medicine, 48(6), 446–458. DOI 10.1002/ajim.20223. [Google Scholar] [CrossRef]

3. Guidelines for Environmental Noise Limits and Control. (.2019) Department of Environment Ministry of Energy, Science, Technology, Environment and Climate Change (MESTECC) [Google Scholar]

4. Isa, I. I. M., Zaki, Z. Z. M., Kassim, J. (2018). Traffic noise pollution at residential area. International Journal of Engineering & Technology, 7(3.11), 250–253. DOI 10.14419/ijet.v7i3.11.16019. [Google Scholar] [CrossRef]

5. Solah, M. S., Hamzah, A., Ariffin, A. H., Paiman, N. F., Hamid, A. et al. (2017). Private vehicle roadworthiness in Malaysia from the vehicle inspection perspective. Journal of the Society of Automotive Engineers Malaysia, 1(3), 262–271. [Google Scholar]

6. Elahishirvan, H., Ghotbi-ravandi, M., Zare, S., Ahsaee, M. G. (2020). Using audiometric data to weigh and prioritize factors that affect workers’ hearing loss through support vector machine (SVM) algorithm. Sound & Vibration, 54(2), 100–112. DOI 10.32604/sv.2020.08839. [Google Scholar] [CrossRef]

7. Ibrahim, A., Putra, A., Ramlan, R., Prasetiyo, I., Esraa, A. (2019). Theoretical model of absorption coefficient of an inhomogeneous MPP absorber with multi-cavity depths. Applied Acoustics, 146, 409–419. DOI 10.1016/j.apacoust.2018.11.002. [Google Scholar] [CrossRef]

8. Mosa, A. I., Putra, A., Ramlan, R., Esraa, A. (2020). Wideband sound absorption of a double-layer microperforated panel with inhomogeneous perforation. Applied Acoustics, 161, 107167. DOI 10.1016/j.apacoust.2019.107167. [Google Scholar] [CrossRef]

9. Pan, L., Martellotta, F. (2020). A parametric study of the acoustic performance of resonant absorbers made of micro-perforated membranes and perforated panels. Applied Sciences, 10, 1581. DOI 10.3390/app10051581. [Google Scholar] [CrossRef]

10. Maa, D. Y. (1987). Microperforated-panel wideband absorbers. Noise Control Engineering Journal, 29, 77–84. DOI 10.3397/1.2827694. [Google Scholar] [CrossRef]

11. Maa, D. Y. (1975). Theory and design of microperforated panel sound-absorbing constructions. Scientia Sinica, 18(1), 55–71. DOI 10.1360/ya1975-18-1-55. [Google Scholar] [CrossRef]

12. Sheng, D. D. C. V., Yahya, M. N. B., Din, N. B. C. (2020). Sound absorption of microperforated panel made from coconut fiber and polylactic acid composite. Journal of Natural Fibers. DOI 10.1080/15440478.2020.1821290. [Google Scholar] [CrossRef]

13. Liu, Z., Zhan, J., Fard, M., Davy, J. L. (2017). Acoustic properties of multilayer sound absorbers with a 3D printed micro-perforated panel. Applied Acoustics, 121(2017), 25–32. DOI 10.1016/j.apacoust.2017.01.032. [Google Scholar] [CrossRef]

14. Rusli, M., Nanda, R. S., Dahlan, H., Bur, M. (2020). Sound absorption characteristics of sandwich panel made from double leaf micro-perforated panel and natural fiber. IOP Conference Series Materials Science and Engineering, 815, 12011. DOI 10.1088/1757-899X/815/1/012011. [Google Scholar] [CrossRef]

15. Sekar, V., Fouladi, M. H., Namasivayam, S. N., Sivanesan, S. (2019). Additive manufacturing: A novel method for developing an acoustic panel made of natural fiber-reinforced composites with enhanced mechanical and acoustical properties. Journal of Engineering, 2019(3), 19. DOI 10.1155/2019/4546863. [Google Scholar] [CrossRef]

16. Parveez, G. K. A., Hishamuddin, E., Loh, S. K., Ong-Abdullah, M., Salleh, K. M. et al. (2020). Oil palm economic performance in Malaysia and R&D progress in 2019’. Journal of Oil Palm Research, 32(2), 159–190. DOI 10.21894/jopr.2020.0032. [Google Scholar] [CrossRef]

17. Sekar, V., Zarrouq, M., Namasivayam, S. N. (2020). Investigating the effect of size and shape of perforations on natural frequency of an acoustic panel made of natural fiber reinforced composites by modal analysis. AIP Conference Proceedings, 2233, 20023, 1–11. DOI 10.1063/5.0005447. [Google Scholar] [CrossRef]

18. Or, K. H., Putra, A., Selamat, M. Z. (2017). Oil palm empty fruit bunch fibres as sustainable acoustic absorber. Applied Acoustics, 119, 9–16. DOI 10.1016/j.apacoust.2016.12.002. [Google Scholar] [CrossRef]

19. Dikova, T. (2012). Factors influencing on the dimensions accuracy in laser cutting. Advanced Materials Research, 445(2012), 430–435. DOI 10.4028/www.scientific.net/AMR.445.430. [Google Scholar] [CrossRef]

20. ISO 10534-2 (2001). Acoustics-Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes International Standardization. International Organization for Standardization. [Google Scholar]

21. Putra, A., Jamil, M. H., Prasetiyo, I., Ismail, R., Kassim, D. H. (2020). Effect of fabric layer on sound absorption of micro-perforated panel. International Journal on Engineering Applications, 8(2), 41–46, 2020. DOI 10.15866/irea.v8i2.17976. [Google Scholar] [CrossRef]

22. Chin, D. D. V. S., Yahya, M. N. B., Din, N. B. C., Ong, P. (2018). Acoustic properties of biodegradable composite micro-perforated panel (BC-MPP) made from kenaf fibre and polylactic acid (PLA). Applied Acoustics, 138, 179–187. DOI 10.1016/j.apacoust.2018.04.009. [Google Scholar] [CrossRef]

23. Horoshenkov, K. V., Khan, A., Bécot, F. X., Jaouen, L., Sgard, F. et al. (2007). Reproducibility experiments on measuring acoustical properties of rigid-frame porous media (round-robin tests). Journal of the Acoustical Society of America, 122(1), 345–353. DOI 10.1121/1.2739806. [Google Scholar] [CrossRef]

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |