| Sound & Vibration |  |

DOI: 10.32604/sv.2022.011838

ARTICLE

A Suitable Active Control for Suppression the Vibrations of a Cantilever Beam

1Mathematics Department, Science Faculty, Zagazig University, Zagazig, Egypt

2Basic Sciences Department, Modern Academy for Engineering and Technology, Cairo, Egypt

3Basic Sciences Department, Higher Technological Institute, 10th of Ramadan City, Egypt

*Corresponding Author: M. N. Abd EL-Salam. Email: mansour.naserallah@yahoo.com

Received: 31 May 2020; Accepted: 24 December 2021

Abstract: In our consideration, a comparison between four different types of controllers for suppression the vibrations of the cantilever beam excited by an external force is carried out. Those four types are the linear velocity feedback control, the cubic velocity feedback control, the non-linear saturation controller (NSC) and the positive position feedback (PPF) controller. The suitable type is the PPF controller for suppression the vibrations of the cantilever beam. The approximate solution obtained up to the first approximation by using the multiple scale method. The PPF controller effectiveness is studied on the system. We used frequency-response equations to investigate the stability of a cantilever beam. We notified that, there is a good agreement between the analytical solution and the numerical solution.

Keywords: Cantilever beam; cubic velocity feedback control; linear velocity feedback control; non-linear saturation controller (NSC); positive position feedback (PPF) controller

Many types of controllers are used for suppressing the vibrations of different non-linear dynamical systems such that, negative linear velocity feedback, negative cubic velocity feedback, non-linear saturation controllers (NSC), non-linear Integral Positive Position Feedback Controllers (NIPPF), the Integral resonant controllers (IRC) and time delay control. The technique of multiple time scales used to investigate the micro-beams non-linear vibrations for two different resonance cases (super-harmonic and harmonic resonances). From this investigation, there is a clear effect of the boundary conditions on the micro-beams vibrations [1]. Recently, the vibrations of many vibrating systems [2–7] has been studied. Because of the time delayed and active controls springiness [8–14] in controlling many vibrating system, many papers used time delay for suppressing the vibrations of non-linear systems. Abdelhafez et al. [15] investigated the effectiveness of time delays when the positive position controllers are used for suppressing the vibrations of a self-exited non-linear beam. They notified that, the time margin depends on the overall delays of the system

Since the aim of most studies is to suppress the vibrations, one of the important types of control to vibrating systems is the PPF, which, described by a single degree of freedom system that, its frequency tuned to one of the structural frequencies. El-Ganaini et al. [17] presents the effectiveness of the PPF controller for decreasing the vibrations of nonlinear system at primary resonance and one-to-one internal resonance. They concluded that, PPF controller successful for systems that, has a small natural frequency. El-sayed et al. [18] achieved good results in decreasing the vibrations of vertical conveyor subject to external excitations by using PPF controllers such that, the vibrations in first mode reduced about 99.88% and the vibrations in the second mode reduced about 99.97% from its values without controllers. Ferrari et al. [19] offered an experimentally studying for the effectiveness of the PPF controllers on suspended the vibrations of sandwich plate. Niu et al. [20] realized the fractional-order positive position feedback (FOPPF) controller. They found that, the FOPPF controller gives better results comparing with PPF controller. Omidi et al. [21,22] presented three kinds of control to suppress the vibrations of vibrating systems such that, the Integral resonant controllers (IRC), PPF controllers and the non-linear Integral Positive Position feedback (NIPPF). The eminent type of decreasing the vibrations is NIPPF type. PPF controller and multimode modified positive position feedback (MMPPF) controllers are used for deceasing the vibrations of a flexible beam and a collocated structure, respectively [23,24].

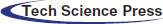

In this article, four types of active vibrations controllers the linear velocity feedback control, the cubic velocity feedback control, NSC and PPF controller used to suppression the vibrations of a cantilever beam containing the cubic and fifth nonlinearity terms excited by an external force. The positive position feedback controller (PPF) is the suitable active control type for decreasing the cantilever beam’s vibrations. The approximate solution obtained applying the method of multiple scales up to first approximation. The stability of the cantilever beam investigated at the simultaneous resonance conditions (1:1 internal and primary). The behavior of the cantilever beam without and with PPF controller is simulated numerically. The influence of some chosen coefficient is illustrated numerically. The rapprochement between numeric and analytic solution is offered.

The equation of motion of a cantilever beam described by the following differential equation [15]:

where, x is the displacement of the cantilever beam. The damping coefficient represented by

The negative linear velocity feedback:

The negative cubic velocity feedback:

The non-linear saturation controller:

The positive position feedback controller:

where,

Figure 1: The flowchart diagram of the main system with PPF controller

2.1 Time History with Numerical Simulation

Numerically, the cantilever beam’s differential Eq. (1) was studied using Runge-Kutta 4th order method at the worst resonance case (One-to-one internal and primary resonance) at the following values of parameters:

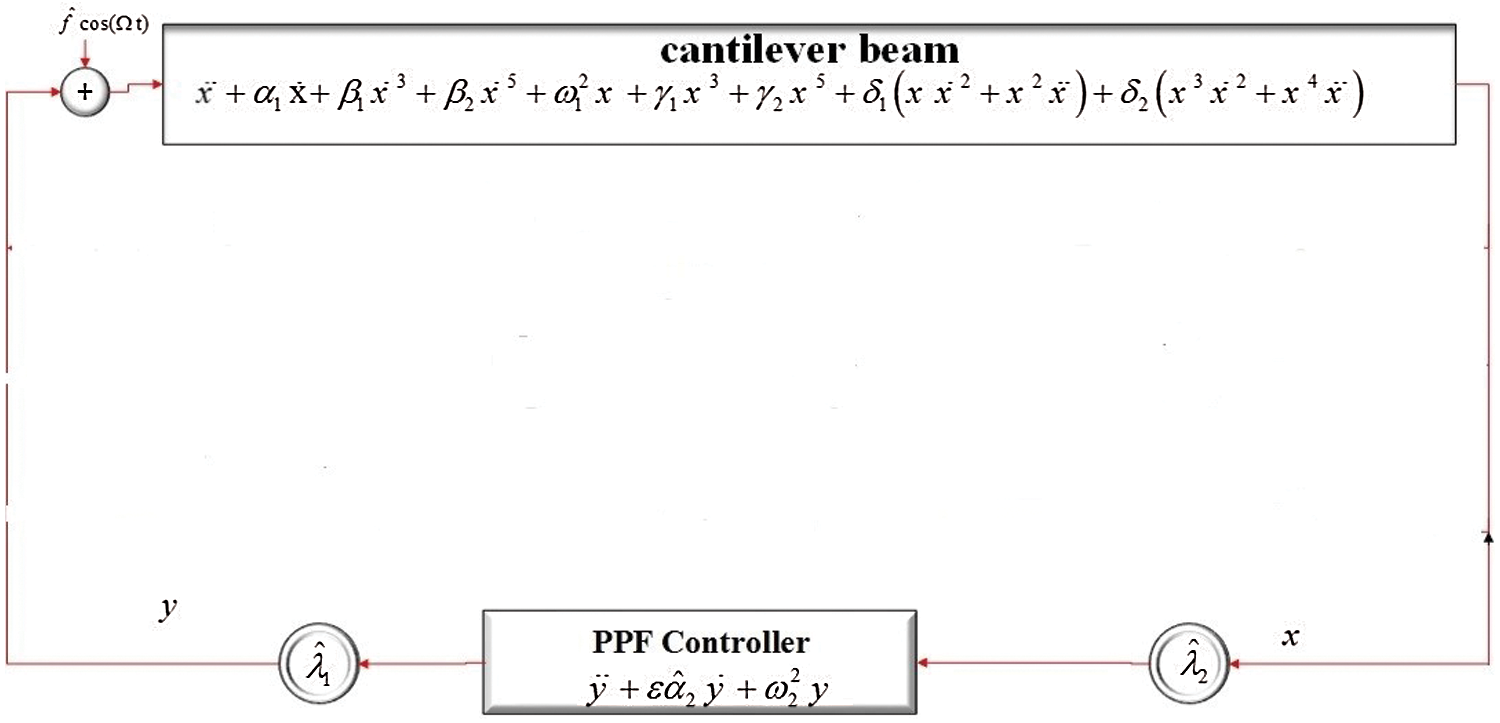

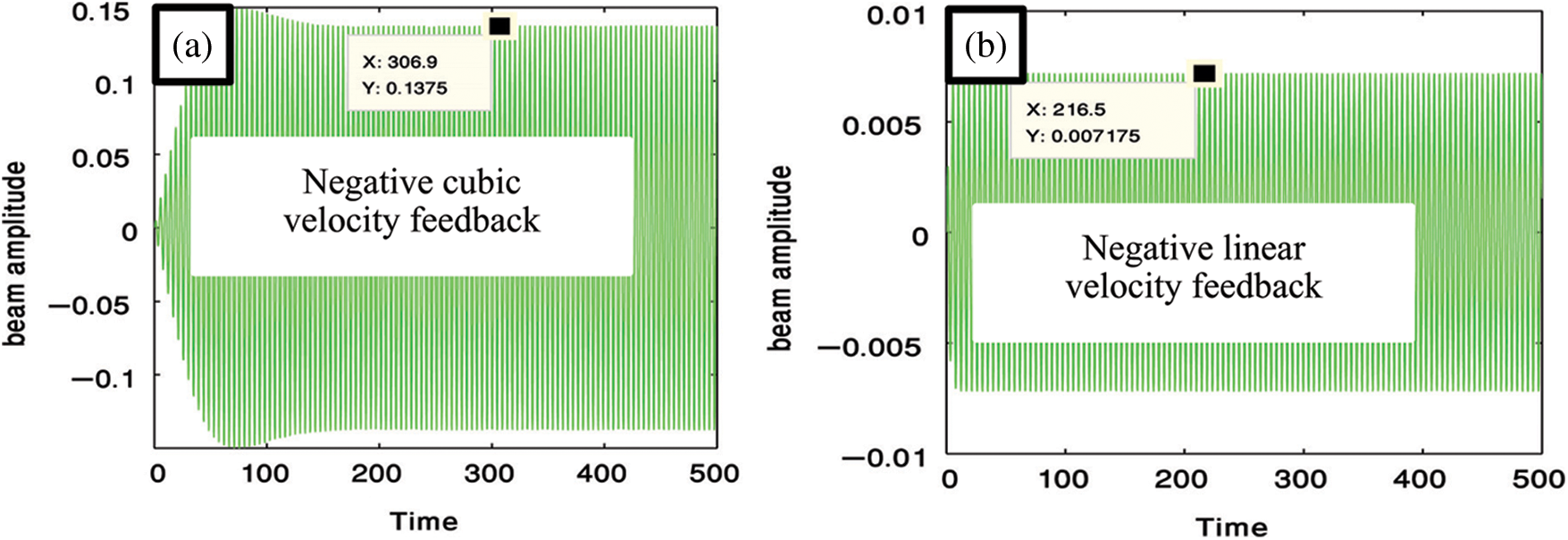

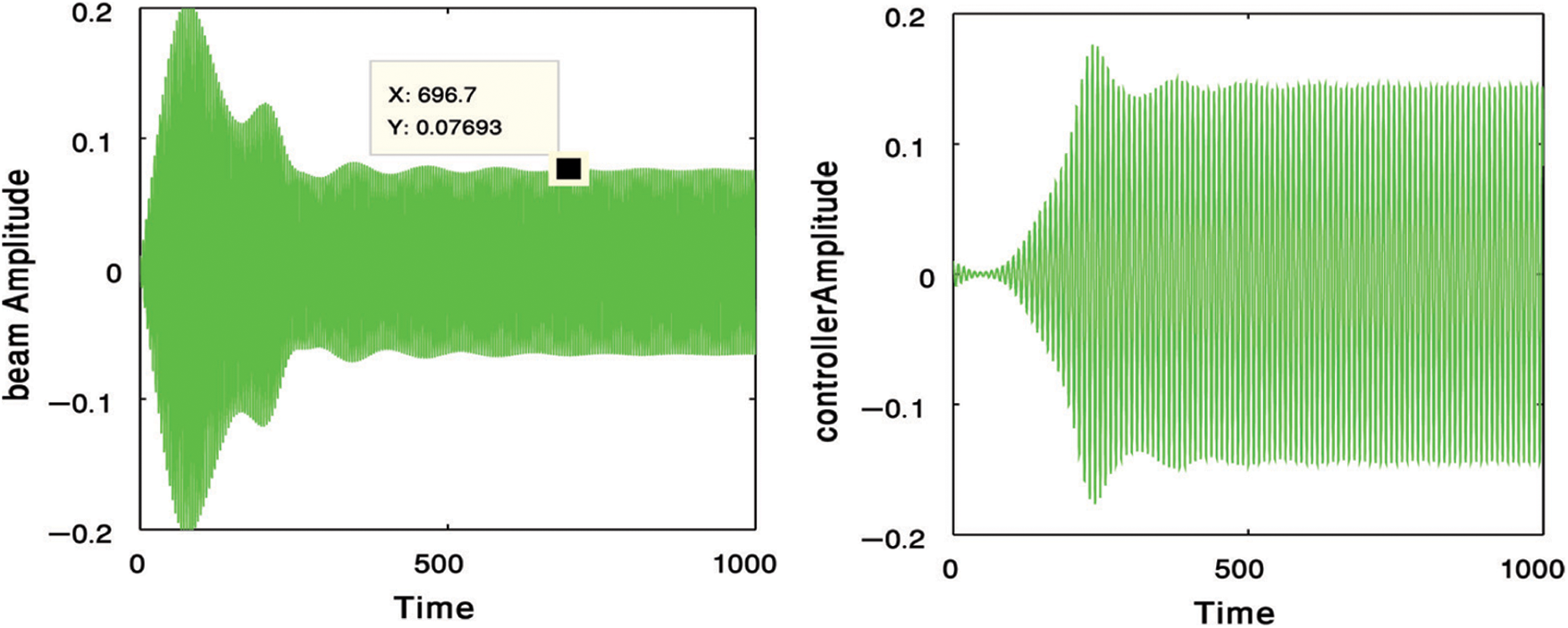

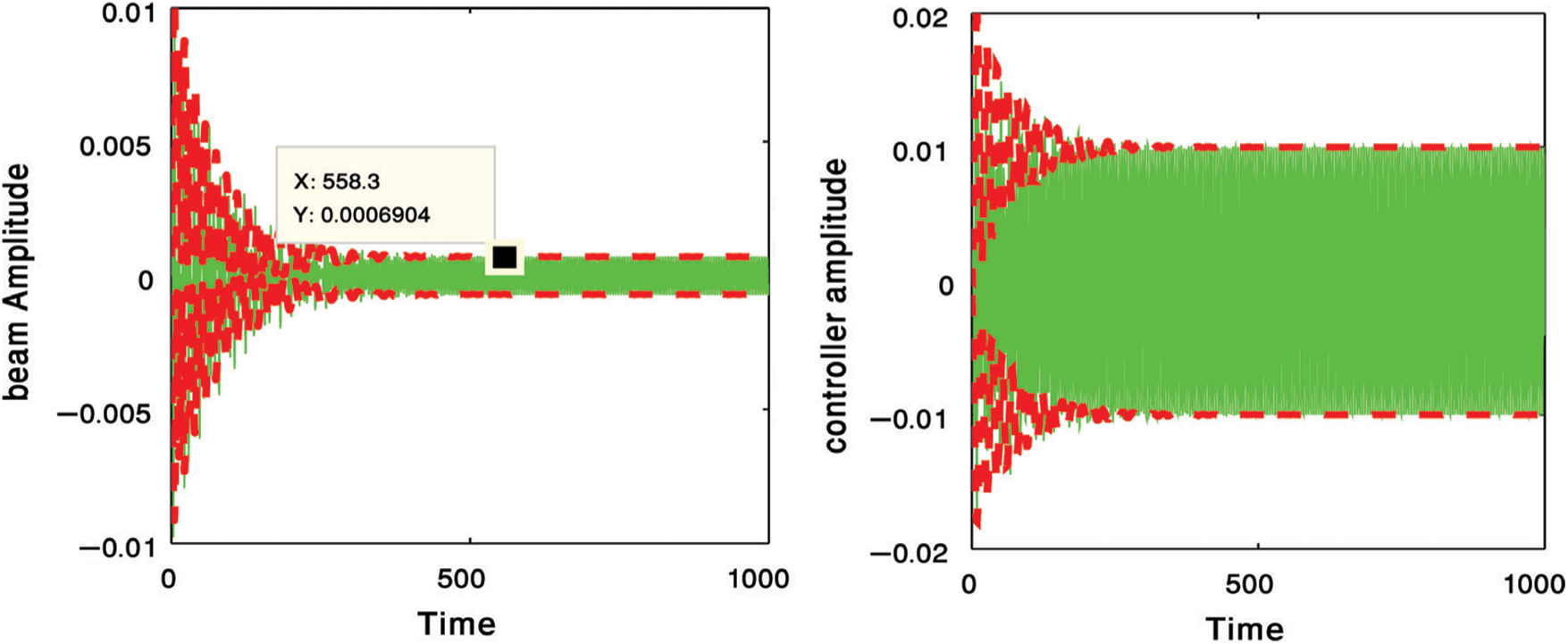

At this study, we compare between four different types of controllers for suppressing the vibration of a cantilever beam. Fig. 2 presents the uncontrolled cantilever beam before using any type of controllers at the primary resonance case. In Fig. 3, we used two types of controllers to decrease the vibration of the system. The first type, is a negative cubic velocity feedback control which decreasing the vibration of the system to reach 0.13, so, the effectiveness of the control (Ea = amplitude of uncontrolled system/amplitude of controlled system) equal one as shown in Fig. 3a. The second type, is a negative linear velocity feedback control which decreasing the vibration of the system to reach 0.007, so, the effectiveness of the control Ea = 21 as shown in Fig. 3b. Fig. 4 illustrates the effectiveness of the non-linear saturation controller (NSC) on the cantilever beam. From this figure, we concluded that, the NSC controller minimized the vibration to reach 0.07 which means that Ea = 2. The positive position feedback controller (PPF) is the best type of controllers for suppressing the vibrations of the cantilever beam where it reduced the vibrations to 0.0006 and Ea = 250 as shown in Fig. 5. The solid lines elucidated the numerical solution of the main system before and after using the PPF controller while, dash lines elucidated the amplitude adjustments

Figure 2: Uncontrolled system at primary resonance case

Figure 3: Negative cubic and linear velocity feedback for reducing the amplitude of the cantilever beam

Figure 4: NSC controller for reducing the amplitude of the main system

Figure 5: PPF controller for reducing the amplitude of the main system

According to the results that we obtained from Fig. 5, Which shows that the most appropriate controller is the PPF controller so we will study the main system after activating the PPF control. To get the approximate solution up to the first approximation, we applied the method of multiple scales [25,26] as the following:

where, the fast scale is

Inserting Eqs. (4) and (5) in Eqs. (2) and (3) such that:

Equating the coefficients of the same power of

Solving the homogenous differential Eqs. (10) and (11) to get the following:

Denote that A and B, are complex functions in

The complex conjugate parts collected in the term CC. For getting the particular solutions of Eqs. (16) and (17), we will remove the secular terms such that:

where

i) Primary resonance:

ii) Internal resonance:

iii) Simultaneous resonance: One-to-one internal and primary resonance.

In this section, the selected one is simultaneous resonance (

Including Eq. (20) into Eqs. (16) and (17) for compiling the solvability conditions as:

Exchanging A and B by the polar form as:

where

where,

where,

For steady-state solution, we maybe find the fixed point of the Eqs. (28)–(31) by putting

From the preceding system, the trigonometric functions can be written as:

Squaring then adding both sides of Eqs. (36) and (37) and Eqs. (38) and (39) to obtain the following two equations:

3.2 Equilibrium Solution of a Fixed Point

While in movement to evolve the steady state solution’s stability, start with the following procedures:

where,

In the appendix, we defined the coefficients

where

which, are the roots of the following polynomial:

where

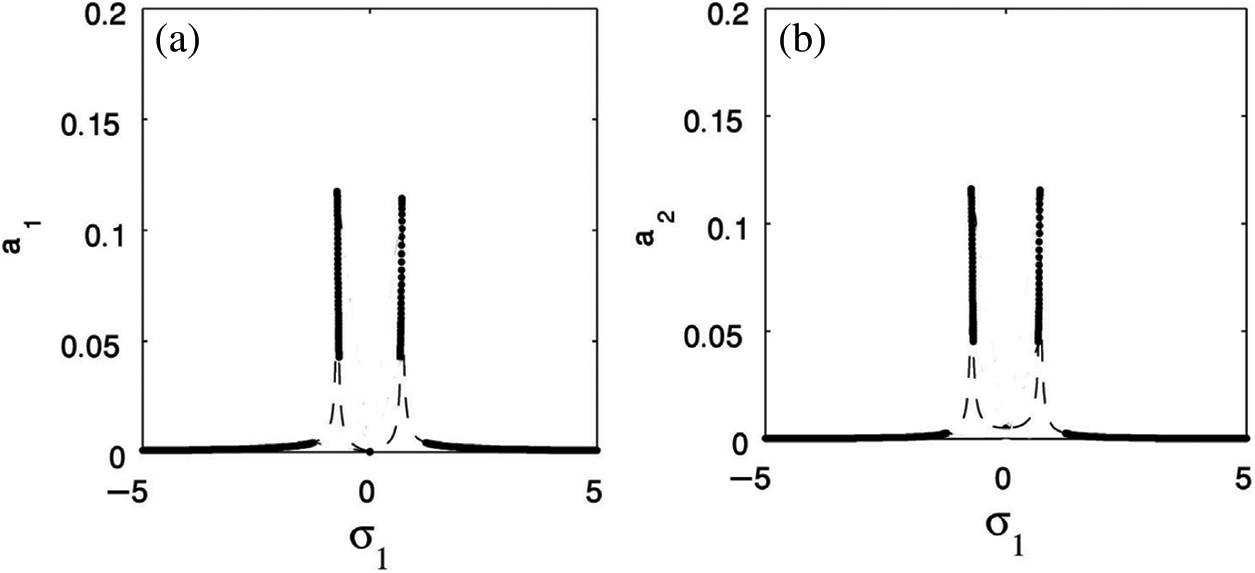

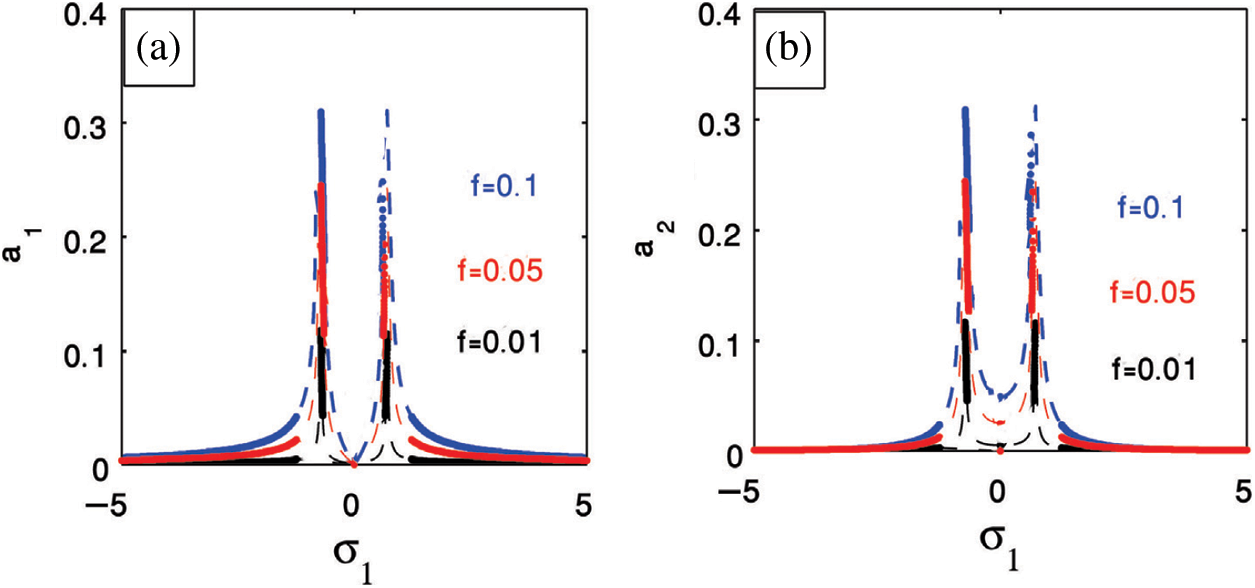

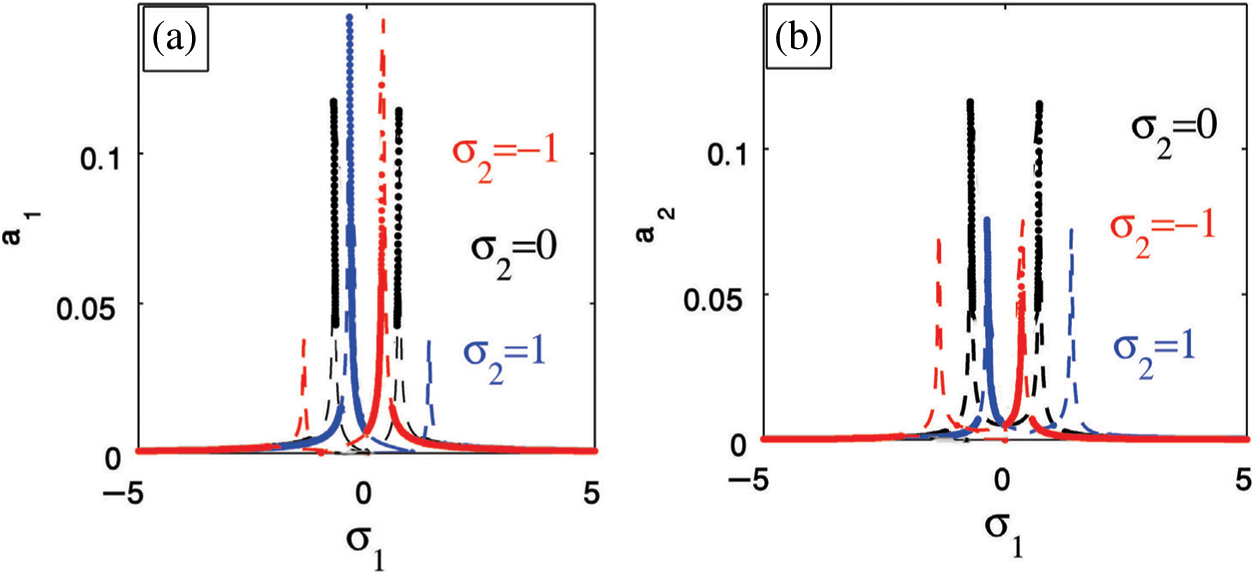

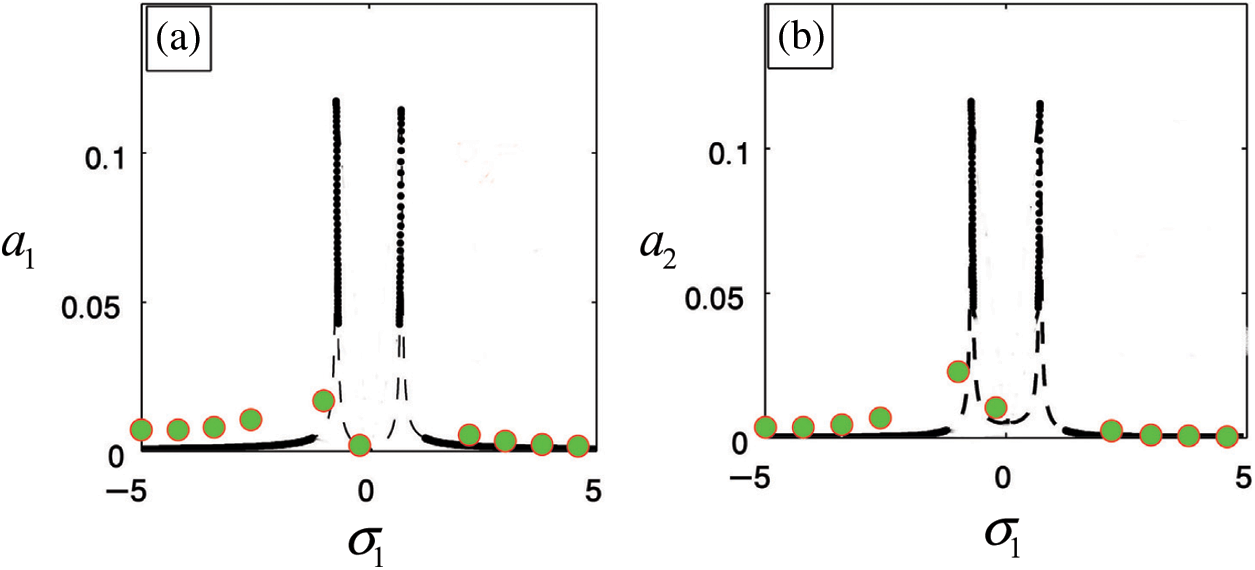

Eqs. (40) and (41) solved numerically to obtain the graphical solution for the amplitudes of both cantilever beam and the PPF controller via the detuning parameter

Figure 6: The response curves (a) The cantilever beam (b) The PPF controller

Figure 7: External force efficacy on (a) The cantilever beam (b) The PPF controller

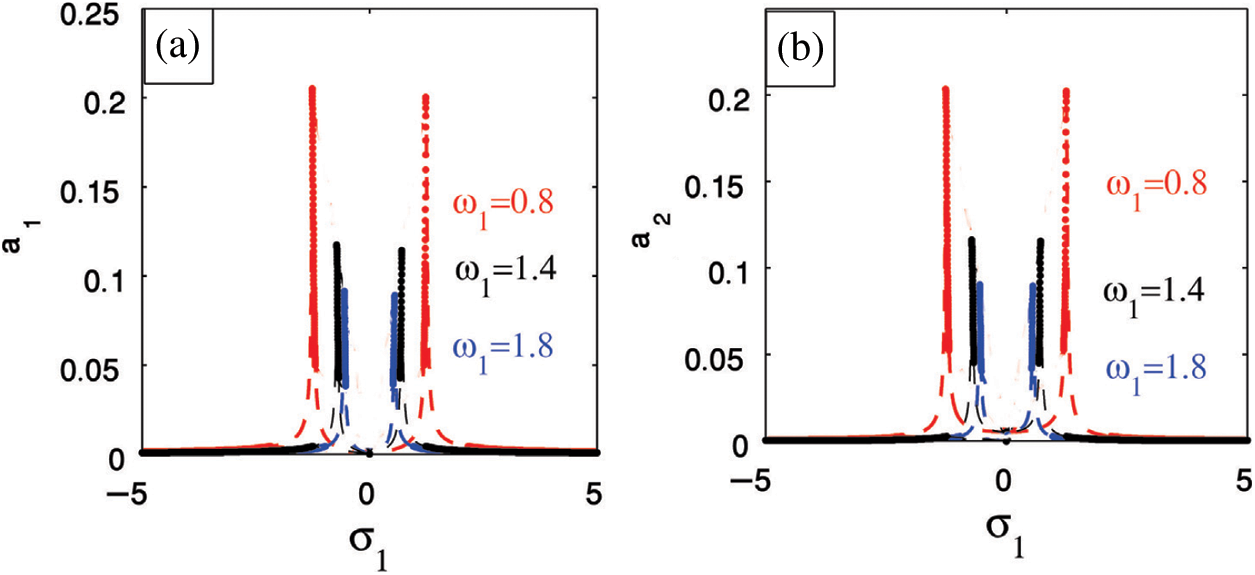

For small values of natural frequency for

Figure 8: Natural frequency efficacy on (a) The cantilever beam (b) The PPF controller

Figure 9: Control signal

Figure 10: Feedback signal

Figure 11: Detuning parameter

Figure 12: Comparison between the FRC solution and RK-4 solution

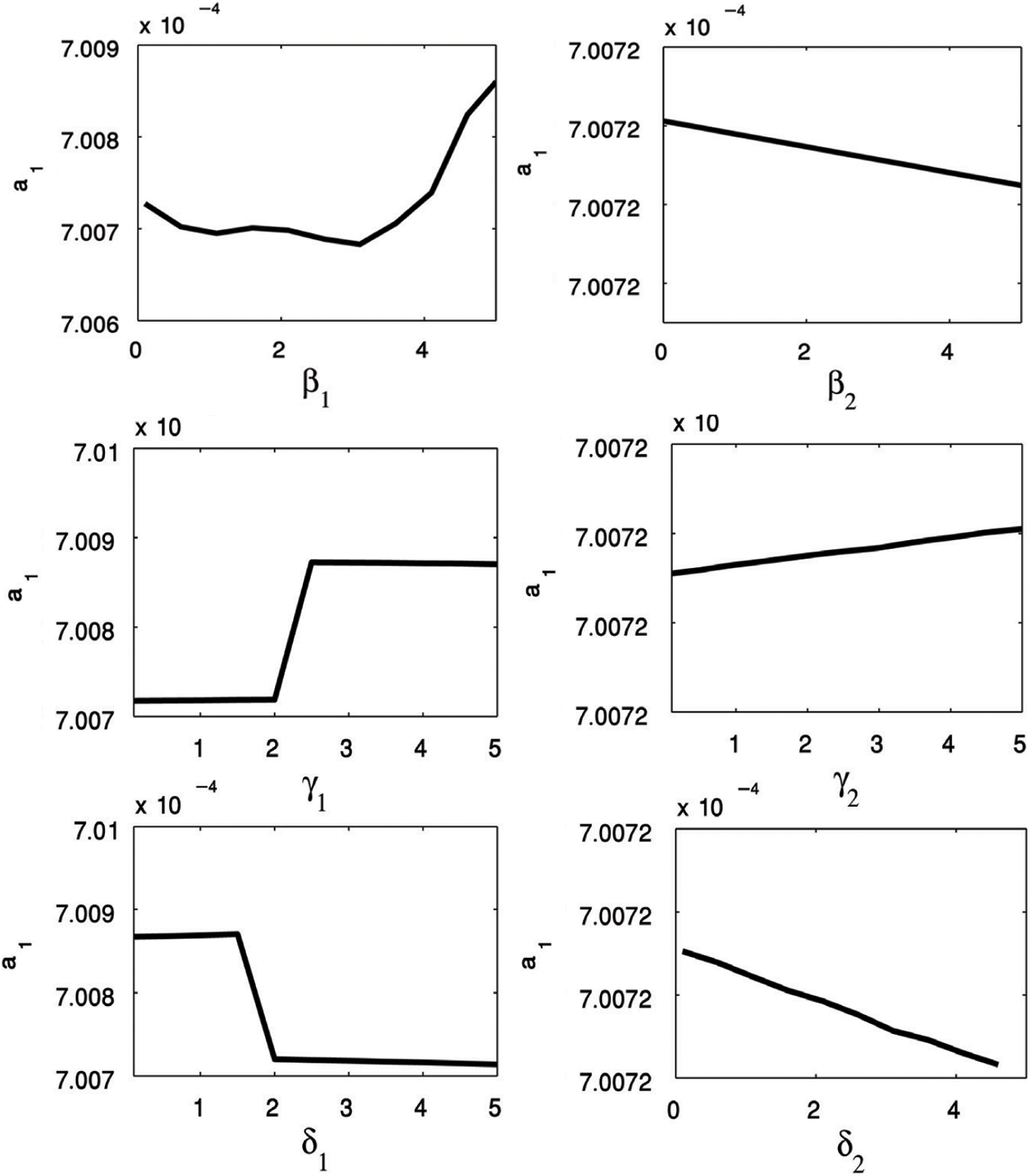

4.1 Influence of the Nonlinear Parameters

In the presence of the PPF controller, we studied the effectiveness of increases of all nonlinear parameters on the main system. The amplitude of the main system change either in decreasing or in increasing but this effect is very small so it do not appear clearly. For the nonlinear parameters

Figure 13: The influence of the nonlinear parameters on the main system amplitude

In this paper, we used four different types of active controllers for suppression the vibrations of the cantilever beam excited by an external force. Those four types are the linear velocity feedback control, the cubic velocity feedback control, the non-linear saturation controller (NSC) and the positive position feedback (PPF) controller. The best active control type for suppression the vibrations of the cantilever beam at the primary resonance case is the positive position feedback controller PPF as the following reasons:

i) Its effectiveness Ea equal 250 which more than the effectiveness of any type of controllers used to control the vibrating cantilever beam in this study.

ii) It is a suitable for small natural frequencies as the bandwidth of the vibration reduction increases.

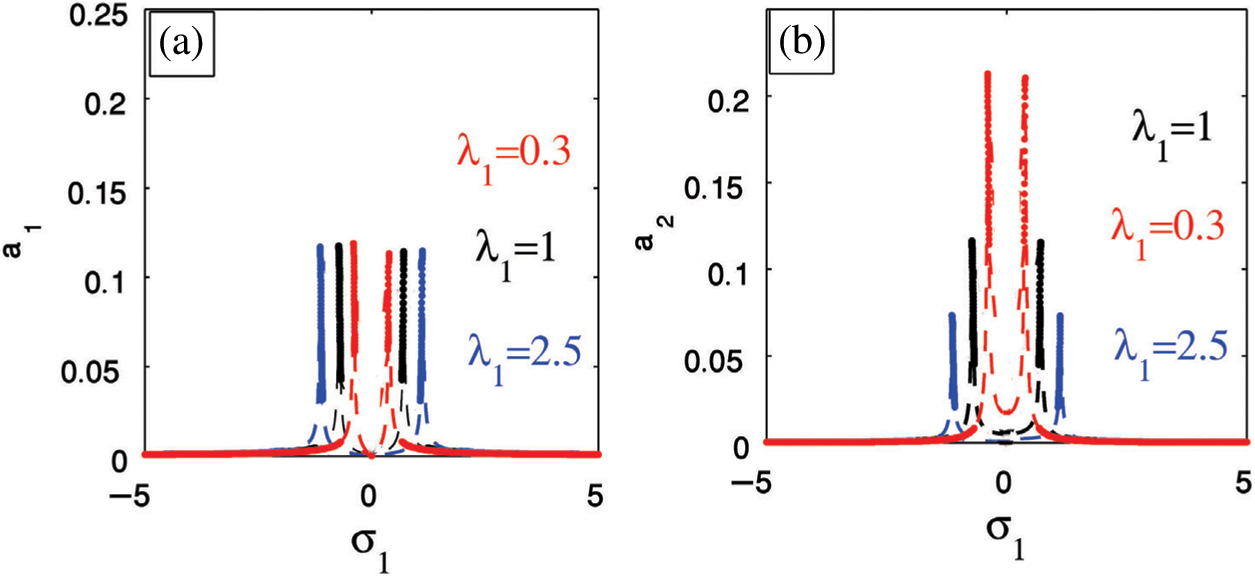

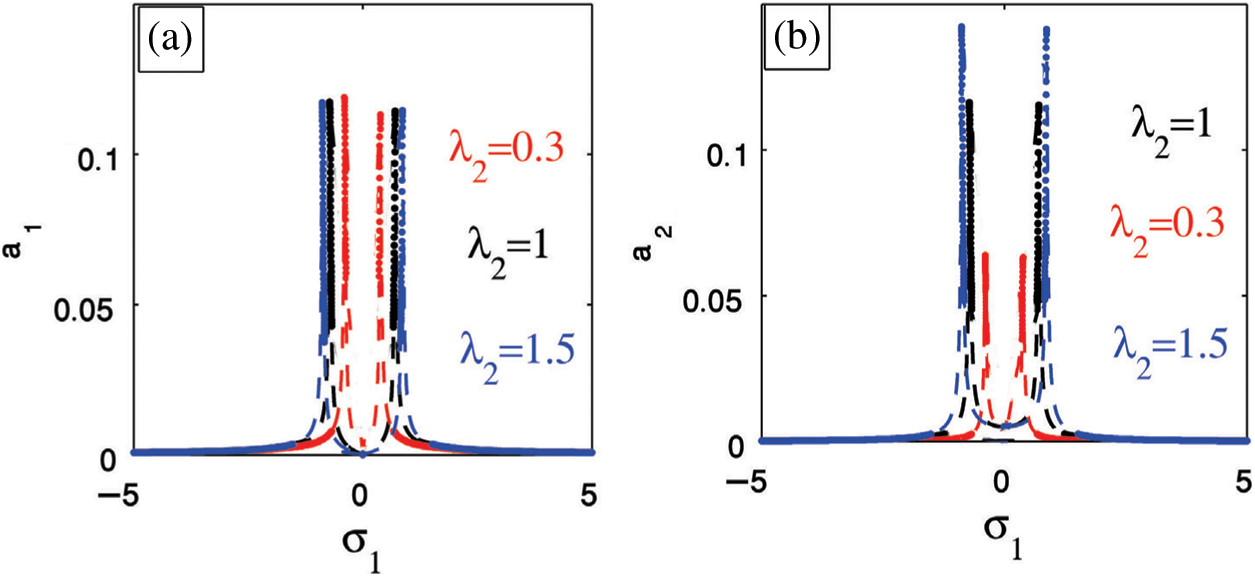

Farther more, the steady state amplitude is monotonic increasing function on the external excitation force. The bandwidth of the vibration reduction increases for increasing values of the control signal

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

1. Onur Ekici, H., Boyaci, H. (2007). Effects of non-ideal boundary conditions on vibrations of microbeams. Journal of Vibration and Control, 13, 1369–1378. DOI 10.1177/1077546307077453. [Google Scholar] [CrossRef]

2. Kuang, J. H., Chen, C. J. (2004). Dynamic characteristics of shaped micro-actuators solved using the differential quadrature method. Journal of Micromechanics and Microengineering, 14, 647–655. DOI 10.1088/0960-1317/14/4/028. [Google Scholar] [CrossRef]

3. Abdel-Rahman, E. M., Younis, M. I., Nayfeh, A. H. (2002). Characterization of the mechanical behavior of an electrically actuated microbeam. Journal of Micromechanics and Microengineering, 12(6), 759–766. DOI 10.1088/0960-1317/12/6/306. [Google Scholar] [CrossRef]

4. Younis, M. I., Nayfeh, A. H. (2003). A study of the nonlinear response of a resonant microbeam to an electric actuation. Nonlinear Dynamics, 31(1), 91–117. DOI 10.1023/A:1022103118330. [Google Scholar] [CrossRef]

5. Amer, Y. A., EL-Sayed, A. T., EL-Salam, M. A. (2018). Non-linear saturation controller to reduce the vibrations of vertical conveyor subjected to external excitation. Asian Research Journal of Mathematics, 11(2), 1–26. DOI 10.9734/ARJOM/2018/44590. [Google Scholar] [CrossRef]

6. Eftekhari, M., Ziaei-Rad, S., Mahzoon, M. (2013). Vibration suppression of a symmetrically cantilever composite beam using internal resonance under chordwise base excitation. International Journal of Non-Linear Mechanics, 48, 86–100. DOI 10.1016/j.ijnonlinmec.2012.06.011. [Google Scholar] [CrossRef]

7. Nayfeh, A. H., Younis, M. I. (2005). Dynamics of MEMS resonators under superharmonic and subharmonic excitations. Journal of Micromechanics and Microengineering, 15(10), 1840–1847. DOI 10.1088/0960-1317/15/10/008. [Google Scholar] [CrossRef]

8. Amer, Y. A., El-Sayed, A. T., El-Bahrawy, F. T. (2015). Torsional vibration reduction for rolling mill’s main drive system via negative velocity feedback under parametric excitation. Journal of Mechanical Science and Technology, 29(4), 1581–1589. DOI 10.1007/s12206-015-0330-8. [Google Scholar] [CrossRef]

9. Amer, Y. A., El-Sayed, A. T., Kotb, A. A. (2016). Nonlinear vibration and of the Duffing oscillator to parametric excitation with time delay feedback. Nonlinear Dynamics, 85(4), 2497–2505. DOI 10.1007/s11071-016-2840-z. [Google Scholar] [CrossRef]

10. Yaman, M. (2009). Direct and parametric excitation of a nonlinear cantilever beam of varying orientation with time-delay state feedback. Journal of Sound and Vibration, 324(3–5), 892–902. DOI 10.1016/j.jsv.2009.02.010. [Google Scholar] [CrossRef]

11. Alhazza, K. A., Majeed, M. A. (2012). Free vibrations control of a cantilever beam using combined time delay feedback. Journal of Vibration and Control, 18(5), 609–621. DOI 10.1177/1077546311405700. [Google Scholar] [CrossRef]

12. Cai, G. P., Yang, S. X. (2006). A discrete optimal control method for a flexible cantilever beam with time delay. Journal of Vibration and Control, 12(5), 509–526. DOI 10.1177/1077546306064268. [Google Scholar] [CrossRef]

13. Mirafzal, S. H., Khorasani, A. M., Ghasemi, A. H. (2016). Optimizing time delay feedback for active vibration control of a cantilever beam using a genetic algorithm. Journal of Vibration and Control, 22(19), 4047–4061. DOI 10.1177/1077546315569863. [Google Scholar] [CrossRef]

14. Amer, Y. A., El-Sayed, A. T., Abd El-Salam, M. N. (2020). Position and velocity time delay for suppression vibrations of a hybrid Rayleigh-Van der Pol-Duffing oscillator. Sound & Vibration, 54(3), 149–161. DOI 10.32604/sv.2020.08469. [Google Scholar] [CrossRef]

15. Abdelhafez, H., Nassar, M. (2016). Effects of time delay on an active vibration control of a forced and self-excited nonlinear beam. Nonlinear Dynamics, 86(1), 137–151. DOI 10.1007/s11071-016-2877-z. [Google Scholar] [CrossRef]

16. Liu, C. X., Yan, Y., Wang, W. Q. (2019). Primary and secondary resonance analyses of a cantilever beam carrying an intermediate lumped mass with time-delay feedback. Nonlinear Dynamics, 97(2), 1175–1195. DOI 10.1007/s11071-019-05039-w. [Google Scholar] [CrossRef]

17. El-Ganaini, W. A., Saeed, N. A., Eissa, M. (2013). Positive position feedback (PPF) controller for suppression of nonlinear system vibration. Nonlinear Dynamics, 72(3), 517–537. DOI 10.1007/s11071-012-0731-5. [Google Scholar] [CrossRef]

18. El-Sayed, A. T., Bauomy, H. S. (2016). Nonlinear analysis of vertical conveyor with positive position feedback (PPF) controllers. Nonlinear Dynamics, 83(1–2), 919–939. DOI 10.1007/s11071-015-2377-6. [Google Scholar] [CrossRef]

19. Ferrari, G., Amabili, M. (2015). Active vibration control of a sandwich plate by non-collocated positive position feedback. Journal of Sound and Vibration, 342, 44–56. DOI 10.1016/j.jsv.2014.12.019. [Google Scholar] [CrossRef]

20. Niu, W., Li, B., Xin, T., Wang, W. (2018). Vibration active control of structure with parameter perturbation using fractional order positive position feedback controller. Journal of Sound and Vibration, 430, 101–114. DOI 10.1016/j.jsv.2018.05.038. [Google Scholar] [CrossRef]

21. Omidi, E., Mahmoodi, S. N. (2015). Sensitivity analysis of the nonlinear integral positive position feedback and integral resonant controllers on vibration suppression of nonlinear oscillatory systems. Communications in Nonlinear Science and Numerical Simulation, 22(1–3), 149–166. DOI 10.1016/j.cnsns.2014.10.011. [Google Scholar] [CrossRef]

22. EL-Sayed, A. T., Bauomy, H. S. (2018). Outcome of special vibration controller techniques linked to a cracked beam. Applied Mathematical Modelling, 63, 266–287. DOI 10.1016/j.apm.2018.06.045. [Google Scholar] [CrossRef]

23. Jun, L. (2010). Positive position feedback control for high-amplitude vibration of a flexible beam to a principal resonance excitation. Shock and Vibration, 17(2), 187–203. DOI 10.1155/2010/286736. [Google Scholar] [CrossRef]

24. Omidi, E., Mahmoodi, S. N. (2015). Multimode modified positive position feedback to control a collocated structure. Journal of Dynamic Systems, Measurement, and Control, 137(5), 1–7. DOI 10.1115/1.4029030. [Google Scholar] [CrossRef]

25. Nayfeh, A. H., Mook, D. T. (1979). Nonlinear oscillations. New York: Wiley. [Google Scholar]

26. Marinca, V., Herisanu, N. (2012). Nonlinear dynamical systems in engineering: Some approximate approaches. USA: Springer Science & Business Media. [Google Scholar]

Appendix

| This work is licensed under a Creative Commons Attribution 4.0 International License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. |