Open Access

Open Access

PROCEEDINGS

Vat Photopolymerization 3D Printing of NiO-YSZ Anode for Solid Oxide Fuel Cells

Department of Mechanical and Energy Engineering, Southern University of Science and Technology, Shenzhen, 518055, China

* Corresponding Authors: Haijiang Wang. Email: ; Jiaming Bai.

The International Conference on Computational & Experimental Engineering and Sciences 2025, 33(4), 1-2. https://doi.org/10.32604/icces.2025.011073

Abstract

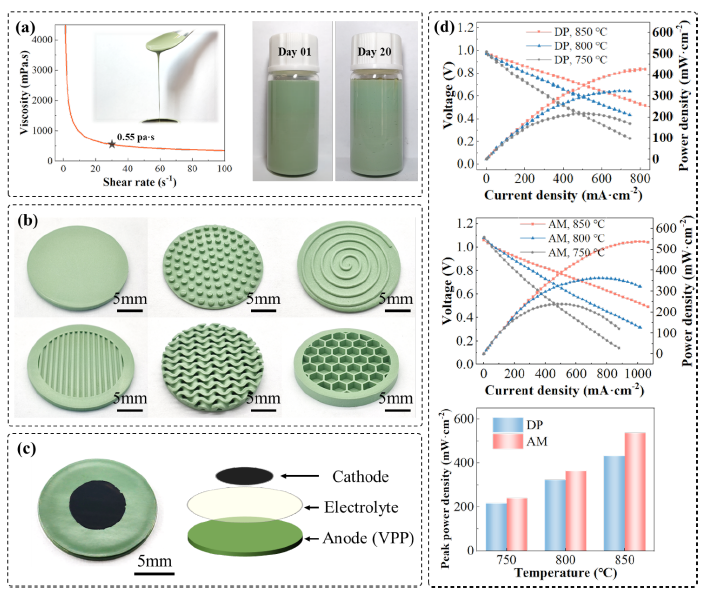

Solid oxide fuel cells (SOFCs) have attracted considerable attention for their high efficiency, environmental advantages, and versatility in fuel sources. Research has shown that optimizing the structure of SOFCs can lead to significant performance improvements. Additive manufacturing (AM) has emerged as a promising technology for geometrical optimization of SOFCs, owing to its capability to create complex and programmable structures. However, fabricating three-dimensional electrode structures with fine, highly resolved features remains a significant challenge. Herein, a vat photopolymerization (VPP) 3D printing process was developed for fabricating the Nickel Oxide-Yttria Stabilized Zirconia (NiO-YSZ) anode structure of SOFC. A photosensitive NiO-YSZ slurry with appropriate curing properties, low viscosity, and stability was prepared [Fig. 1 (a)]. Various NiO–YSZ anode-support structures with different geometric configurations were successfully printed using this slurry [Fig. 1 (b)]. The debinding process was further optimized based on thermo-gravimetric analysis to effectively prevent cracking and deformation of the green bodies. Microstructural analysis and pore size distribution assessment revealed a uniform and finely distributed pore structure in the anode. The fabricated anode-supported SOFC is shown in Fig. 1 (c). Remarkably, the cells featuring the VPP printed NiO-YSZ anode demonstrated notable performance with peak power densities of 239 mW·cm-2, 364 mW·cm-2, and 536 mW·cm-2 observed at temperatures of 750 °C, 800 °C, and 850 °C, respectively, which were comparable to the conventional fabrication techniques [Fig. 1 (d)]. This novel method opens avenues for enhancing the performance of SOFCs through the optimization of anode structure.

Figure: (a) Rheological properties of NiO-YSZ UV slurry. (b) Demonstration of various anode support structures fabricated by VPP. (c) NiO-YSZ anode-supported SOFC. (d) Comparison of the electrochemical performance between the 3D printed SOFC (AM sample) and the SOFC fabricated by the conventional dry pressing (DP) method.

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools