Open Access

Open Access

REVIEW

Significant Advancements in UAV Technology for Reliable Oil and Gas Pipeline Monitoring

1 Department of Electrical and Electronics Engineering, Universiti Teknologi PETRONAS, Seri Iskandar, Perak, 32610, Malaysia

2 Interdisciplinary Research Centre for Aviation and Space Exploration (IRC-ASE), King Fahd University of Petroleum and Minerals (KFUPM), Dhahran, 31261, Saudi Arabia

3 Department of Computer Engineering, University of Ilorin, Ilorin, 240003, Nigeria

* Corresponding Author: Ghulam E Mustafa Abro. Email:

Computer Modeling in Engineering & Sciences 2025, 142(2), 1155-1197. https://doi.org/10.32604/cmes.2025.058598

Received 16 September 2024; Accepted 25 November 2024; Issue published 27 January 2025

Abstract

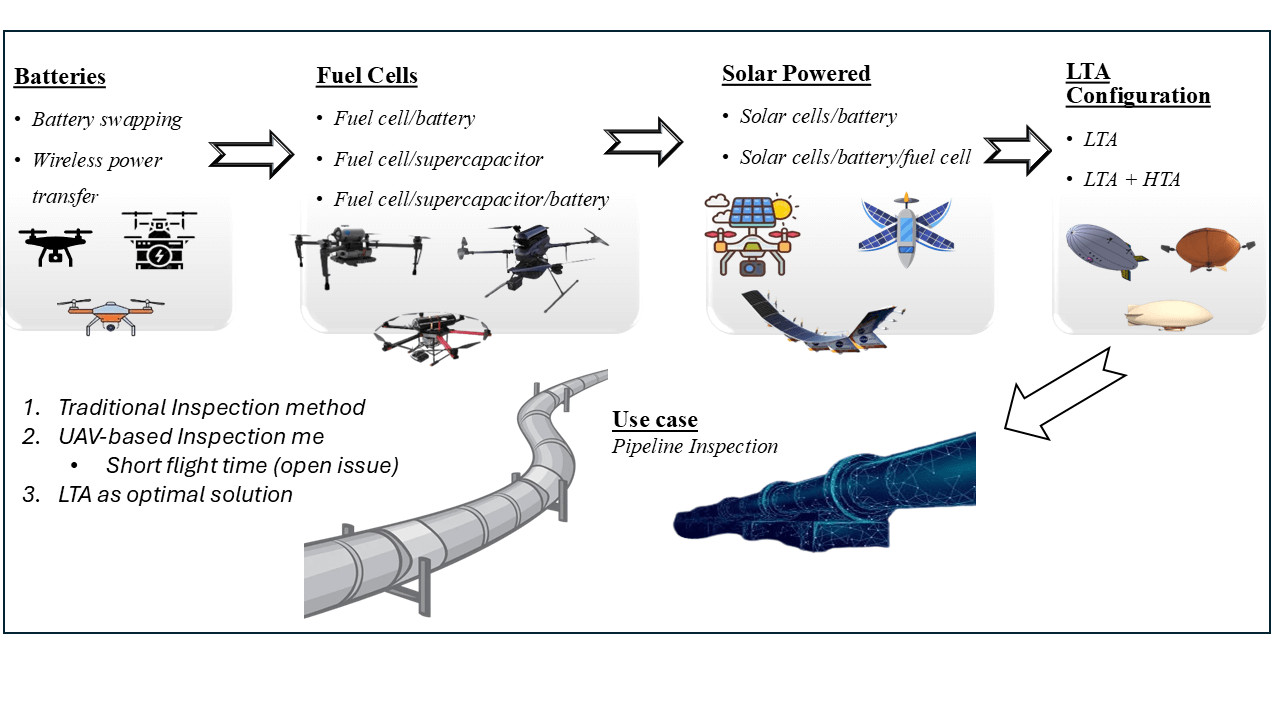

Unmanned aerial vehicles (UAVs) technology is rapidly advancing, offering innovative solutions for various industries, including the critical task of oil and gas pipeline surveillance. However, the limited flight time of conventional UAVs presents a significant challenge to comprehensive and continuous monitoring, which is crucial for maintaining the integrity of pipeline infrastructure. This review paper evaluates methods for extending UAV flight endurance, focusing on their potential application in pipeline inspection. Through an extensive literature review, this study identifies the latest advancements in UAV technology, evaluates their effectiveness, and highlights the existing gaps in achieving prolonged flight operations. Advanced techniques, including artificial intelligence (AI), machine learning (ML), and deep learning (DL), are reviewed for their roles in pipeline monitoring. Notably, DL algorithms like You Only Look Once (YOLO) are explored for autonomous flight in UAV-based inspections, real-time defect detection, such as cracks, corrosion, and leaks, enhancing reliability and accuracy. A vital aspect of this research is the proposed deployment of a hybrid drone design combining lighter-than-air (LTA) and heavier-than-air (HTA) principles, achieving a balance of endurance and maneuverability. LTA vehicles utilize buoyancy to reduce energy consumption, thereby extending flight durations. The paper details the methodology for designing LTA vehicles, presenting an analysis of design parameters that align with the requirements for effective pipeline surveillance. The ongoing work is currently at Technology Readiness Level (TRL) 4, where key components have been validated in laboratory conditions, with fabrication and flight testing planned for the next phase. Initial design analysis indicates that LTA configurations could offer significant advantages in flight endurance compared to traditional UAV designs. These findings lay the groundwork for future fabrication and testing phases, which will be critical in validating and assessing the proposed approach’s real-world applicability. By outlining the technical complexities and proposing specialized techniques tailored for pipeline monitoring, this paper provides a foundational framework for advancing UAV capabilities in the oil and gas sector. Researchers and industry practitioners can use this roadmap to further develop UAV-enabled surveillance solutions, aiming to improve the reliability, efficiency, and safety of pipeline monitoring.Graphic Abstract

Keywords

The rapid advancement of unmanned aerial vehicles (UAV) technology has significantly impacted various industries, with the oil and gas (O&G) industry being a notable beneficiary. UAVs, also known as drones, have transformed traditional inspection, surveillance, and monitoring methods, offering a more efficient and cost-effective approach [1,2]. In particular, drones have been increasingly employed to monitor O&G pipelines [3,4], a critical infrastructure that demands regular inspection to prevent leaks, environmental damage, and costly repairs. The industry’s pipelines, which often extend across remote, inaccessible areas, present considerable challenges for maintenance. Traditional inspection methods, such as foot patrols, are time-consuming, labor-intensive, and pose safety risks to personnel [5]. Furthermore, these methods often lack the real-time data collection and precision necessary to detect potential issues, such as corrosion and structural defects.

In addition to O&G pipelines, the industry faces a growing challenge with orphaned wells, wells that have been abandoned by defunct companies and left without proper capping or maintenance [6]. These wells pose significant environmental risks, as they often leak methane and other harmful greenhouse gases, contributing to climate change [7]. According to recent studies, there are hundreds of thousands of orphaned wells worldwide, with many located in remote or hard-to-reach areas, further complicating efforts to monitor and remediate them [8,9]. Given the environmental urgency, there is a critical need for cost-effective, scalable, and precise methods of detecting and assessing orphaned wells. Furthermore, the O&G industry continues to face challenges in managing the environmental and operational complexities of unconventional oil and gas reservoirs, which often involve complex gas transfer mechanisms and geomechanical factors. These complexities necessitate more advanced models and monitoring techniques to optimize production and maintain safety standards. Recent studies [10,11], have provided valuable insights into the gas transfer mechanisms and geomechanics that influence reservoir performance. By improving our understanding of these mechanisms, such models contribute to the development of more precise monitoring techniques, which can be complemented by UAV-based surveillance systems for real-time inspection of infrastructure like pipelines.

UAVs offer a versatile solution to these challenges. UAVs can be equipped with various cameras and sensors, such as magnetometers and methane detectors, among others, to capture different types of data, including visual, thermal, and multispectral imagery across large, remote areas [8,12,13]. This capability makes them indispensable for monitoring the environmental impact of orphaned wells and inspecting pipelines for leaks, structural integrity, and environmental conditions [14]. Moreover, UAVs can be deployed in challenging environments, such as offshore platforms or mountainous regions, where traditional inspection methods may be impractical or dangerous.

Despite these advantages, conventional UAVs face significant limitations, particularly flight endurance. Most UAVs can operate for only 15 to 20 min [15], restricting their effectiveness for long-range pipeline monitoring missions. Recent advancements have aimed to address this limitation by developing fixed-wing drones that offer longer flight times compared to their multi-rotor counterparts, but they require runways for takeoff and landing, limiting their operational flexibility [16]. Vertical TakeOff and Landing (VTOL) drones have emerged as a hybrid solution, combining the endurance of fixed-wing drones with the flexibility of multi-rotor designs. These drones can take off and land vertically, like helicopters, while achieving the extended flight durations of fixed-wing aircraft [17]. Yet, these advancements have not fully solved the endurance issue, prompting further exploration of alternative power sources and hybrid propulsion systems.

Various hybrid propulsion approaches have been explored, such as battery-swapping [18], solar power energy harvesting [19], fuel cell and Li-Po battery hybrid propulsion systems [20], supercapacitor-based hybrid electric propulsion system (HEPS) [21], and gasoline engines and electric motors hybrid propulsion system [22,23]. Wang et al. [24] evaluated the use of fuel and batteries as a power source for drones. The fuel cell was used during the cruise flight mode, the battery was used for takeoff and landing, and the battery was also set for other emergency flight modes. Another study by Chu et al. tested a 2-m wingspan UAV that is controlled remotely and uses a mix of solar and battery power. They show that the solar power system on the aircraft saves 22.5% of the battery capacity. While these approaches show promise, they often come with increased costs, larger sizes, and more complex maintenance procedures.

Additionally, lighter-than-air (LTA) technology has been proposed as a potential solution for extending UAV flight times [15,19]. LTA technology, commonly used in airships [25], relies on the buoyancy of lighter-than-air gases, such as helium, to provide lift [26]. Integrating LTA elements into UAVs can reduce the energy required for sustained flight, allowing the UAV to remain airborne for longer periods [27]. This approach extends flight time and enhances the UAV’s ability to hover and perform precise maneuvers, which are essential for detailed pipeline inspections. Burri et al. [28] demonstrated that a 2.7 m diameter spherical drone that uses helium gas and four propellers can move and rotate freely in any direction and axis. However, it is limited to being used indoors only.

Rae et al. [29] described a 15-m-long, teardrop-shaped blimp designed to optimize helium gas volume for lift while minimizing drag. Unlike traditional airships, this aircraft has no propellers, relying on a unique propulsion method. By filling and emptying an internal “lung” with air, the blimp can alternate between being lighter and heavier than the surrounding air, propelling itself forward. However, these designs are still primarily limited to indoor environments and have yet to be fully tested in outdoor, real-world conditions, especially in the O&G sector.

The motivation for this study arises from the critical need to overcome the endurance limitations of UAVs in oil and gas pipeline monitoring. While many recent studies have addressed incremental improvements in UAV technology, such as hybrid propulsion and VTOL designs, none have fully resolved the challenges of long-range, autonomous pipeline inspection. Furthermore, most studies fail to address the specific environmental and operational conditions of remote pipeline monitoring, such as adverse weather or the need for real-time, autonomous inspection capabilities. In response to these gaps, this study provides a comprehensive review of current advancements in drone technology for pipeline monitoring, critically examining the latest advances in hybrid propulsion systems and LTA integration.

The novelty of this work lies in its approach to incorporating LTA principles into UAVs specifically designed for long-endurance pipeline monitoring, a domain where existing drone designs have not fully addressed the challenges posed by remote, large-scale operations. Furthermore, by advocating for the use of autonomous flight control systems powered by machine learning and computer vision, this study offers new insights into how UAVs can perform fully autonomous inspections, reducing the need for human intervention and enhancing overall inspection accuracy. The key contributions of this work are outlined as follows:

• This review critically examines techniques for extending drone flight duration, with a particular focus on those utilizing hybrid power systems. It also identifies recent developments, challenges, and research gaps in the search for improving drone flight performance.

• It encourages researchers to explore integrating LTA design principles into drone architecture, proposing this as an improved approach to enhance flight efficiency.

• Additionally, it highlights the importance of autonomous flight control for pipeline inspection, advocating for the use of computer vision and machine learning-based methodologies to achieve this goal.

• The paper provides ongoing work as proof of concept for the proposed solution through design optimization, specifically by reducing the weight of hybrid drones.

The remainder of this paper is structured as follows. The paper examines the background of several drone types for longer flight times, pipeline surveillance, and algorithms in Section 2. Section 3 discusses the findings from the reviewed literature and proposes an optimal solution. The design methodology is described in Section 4. Section 5 presents and discusses the preliminary results from the ongoing work and future directions. Section 6 concludes the research. Fig. 1 shows the comprehensive organization of the paper, with five main categories.

Figure 1: Organizational block diagram

This section provides a comprehensive overview of drone technology, its various configurations, and its application to pipeline inspection. We delve into specific use cases and techniques employed for pipeline inspection, including advanced algorithms. The primary focus is identifying current limitations and challenges hindering drone efficiency in this domain. Drones have grown in popularity due to their unparalleled versatility and the transformative impact of cutting-edge technologies, especially artificial intelligence (AI) advancements [30,31]. These innovations have significantly expanded drones’ potential applications, enabling more sophisticated autonomous operations and enhancing their effectiveness across various industries, including transportation [32,33], urban planning [34,35], powerline maintenance [36], healthcare [37], and, crucially, pipeline monitoring [3,4]. However, the demand for extended flight times in specific applications, such as pipeline inspection, often conflicts with weight and design complexity constraints [38].

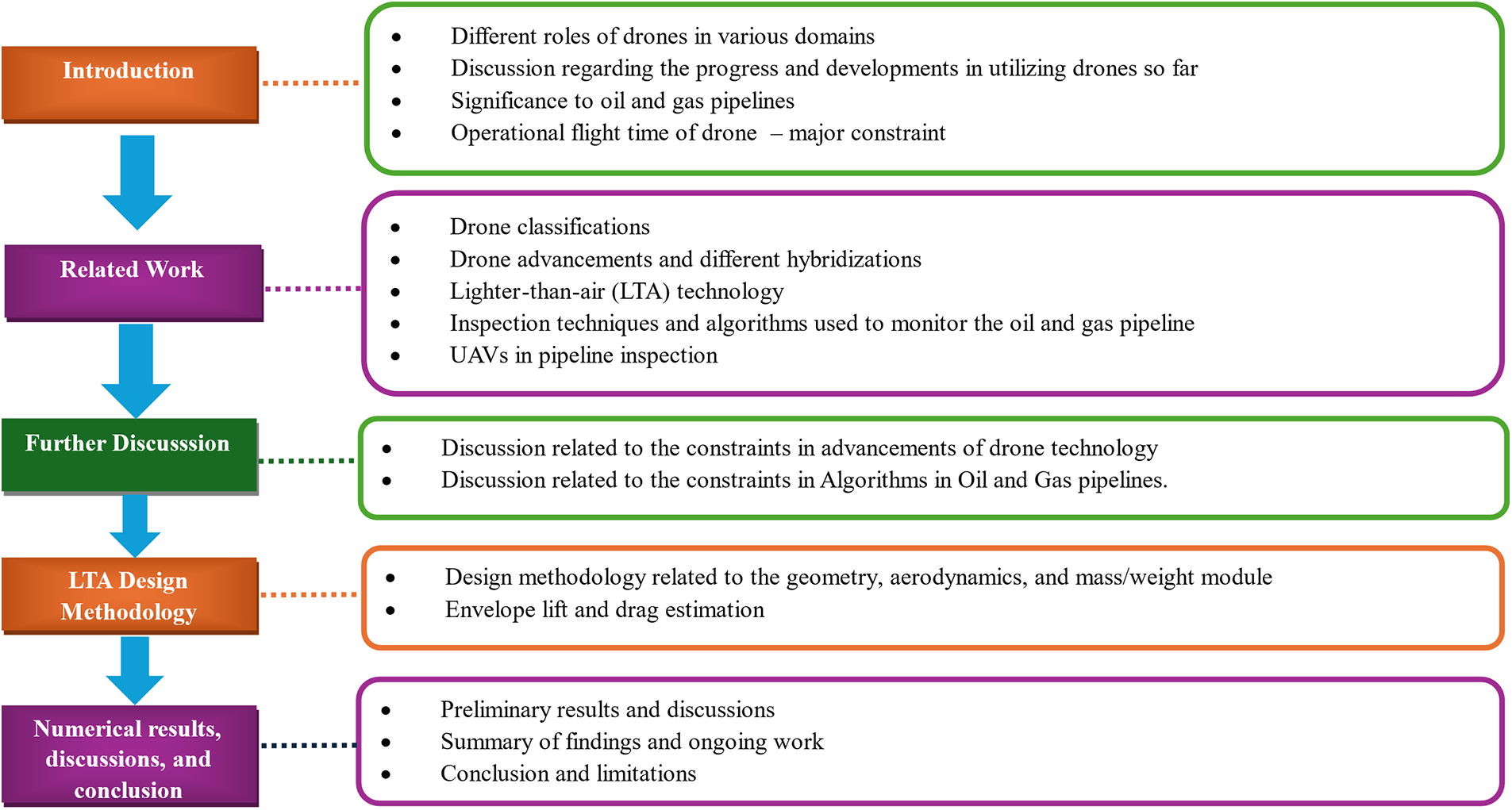

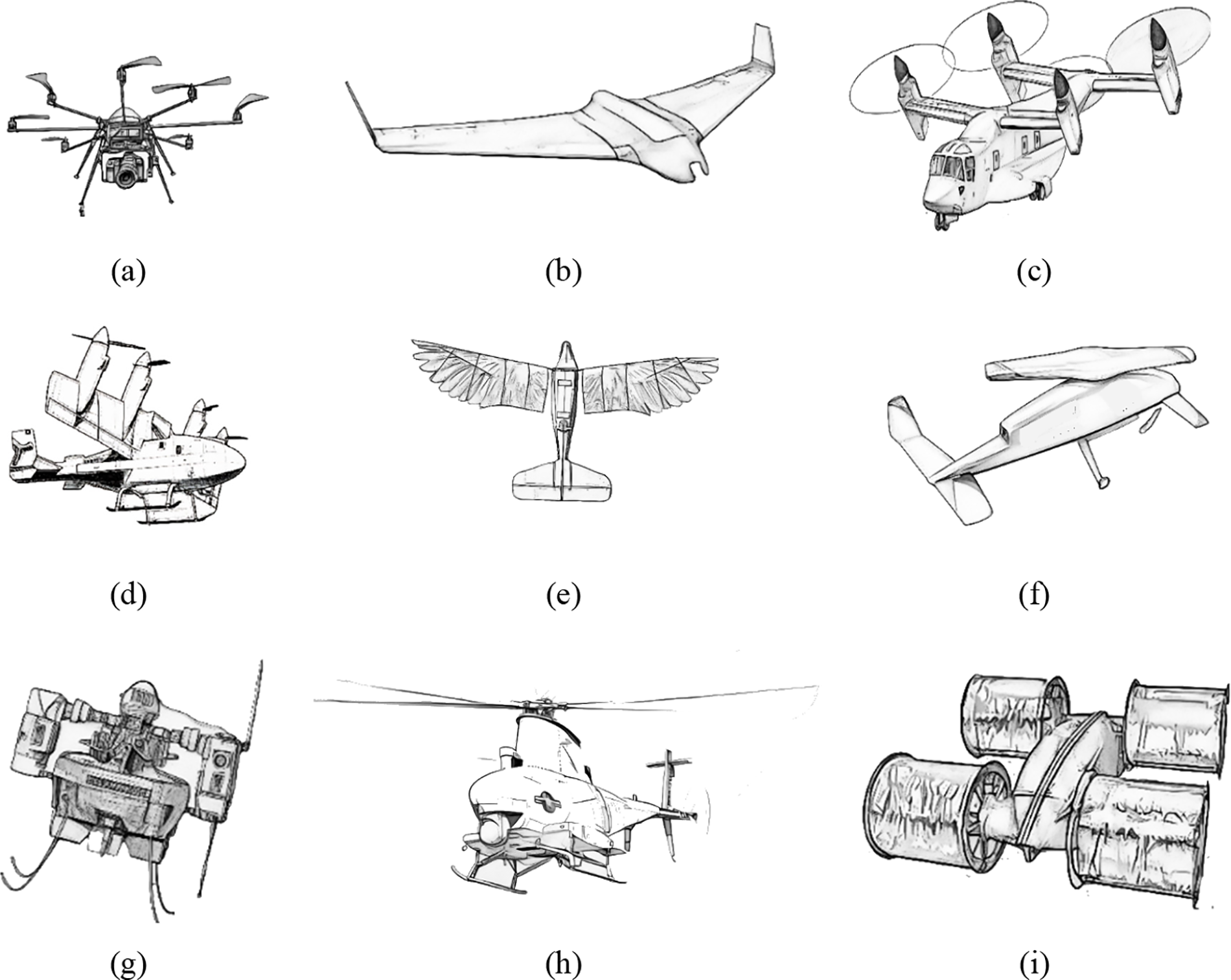

Existing literature classifies drones into various categories, including size, form factor, flight endurance, operational range, propulsion system, flight control system, payload capacity, landing mechanism, airframe, and weight [16,17,39,40]. Fig. 2 illustrates classifications of drones based on landing mechanism, airframe, and weight.

Figure 2: Classifications of drones

A notable classification is based on the landing mechanism, which includes VTOL, Horizontal TakeOff and Landing (HTOL), and Short TakeOff and Landing (STOL). VTOL drones are characterized by their ability to take off, hover, and land vertically without the need for a runway. This category includes multi-rotor drones, such as twin-copters, tri-copters, quadcopters, penta-copters, hexacopters, octocopters, deca-copters, and dodeca-copters, defined by the number of rotors or propellers they have. These rotors generate their lifting forces. These drones excel in stationary tasks like inspections and monitoring due to their ability to hover over a target for prolonged periods and their agility in maneuvering at specific points. However, they have lower cruise speeds compared to HTOL drones.

HTOL drones, similar to conventional aircraft, require a runway for takeoff and landing. They have faster cruise speeds but lack the maneuverability of VTOL drones. Fixed-wing drones typically fall into this category. Hybrid configurations such as tiltrotor and tilt-wing drones have been developed to compromise between the capabilities of HTOL and VTOL. Tilt-rotor drones demonstrate proficiency in hovering while tilt-wing drones are optimized for cruise efficiency [16,40]. STOL drones, characterized by a lifting body fuselage and rotating wing pair along the pitch axis, are designed to take off and land within short distances, making them suitable for areas with limited runway length. This mechanism differs from fixed or tilt-wing and rotor systems [41]. Free-wing tilt-body drones utilize this mechanism [42]. For a comprehensive classification of drones based on other criteria, readers are referred to [16,17].

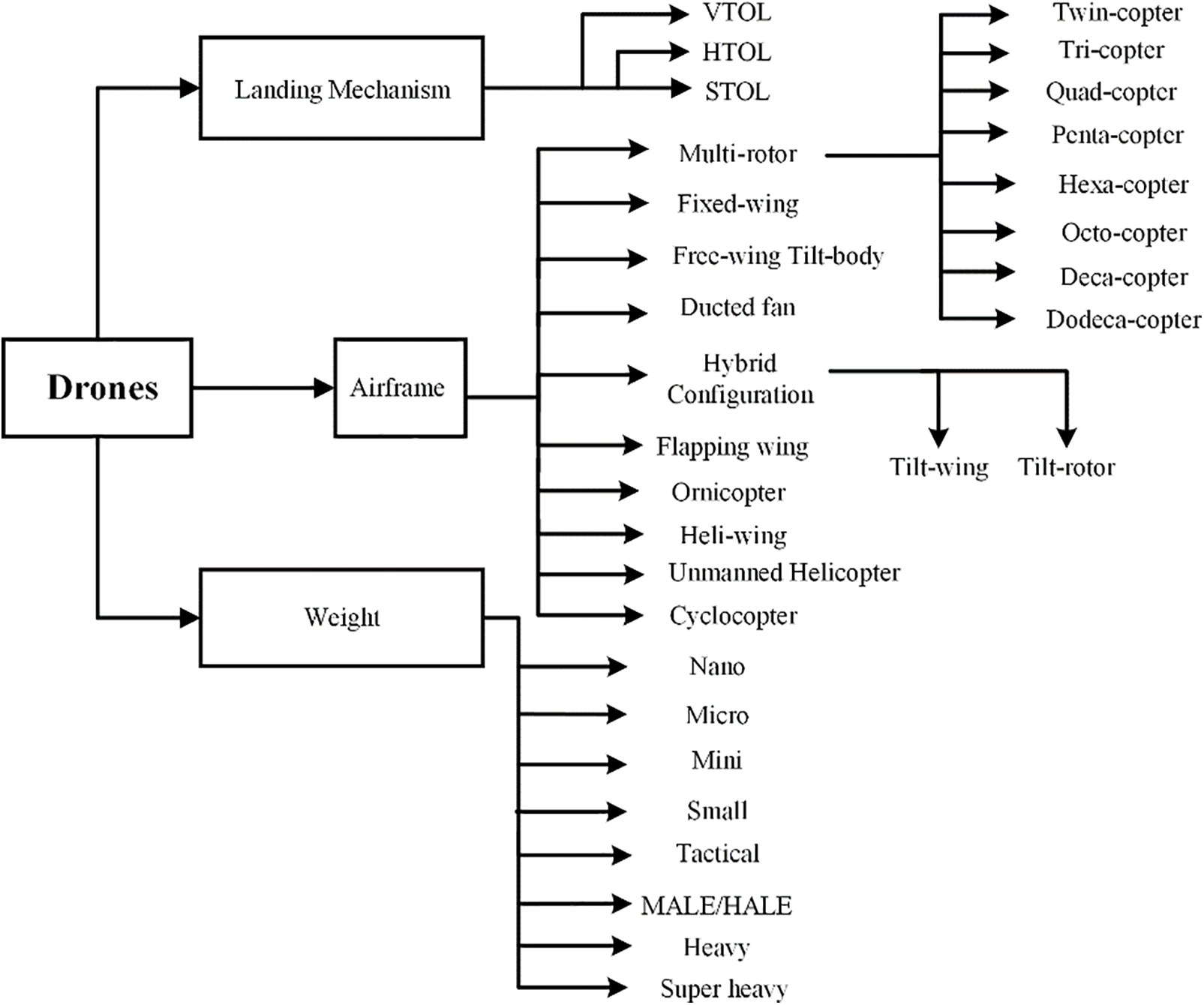

Another notable configuration is the ducted fan design based on drones’ airframes, where the fans acting as thrusters are encased within a duct. This configuration, which uses a VTOL mechanism, can include multiple fans, similar to multi-rotor drones. The duct’s primary function is to protect the fans from external elements. Flapping wing drones represent a smaller and more compact airframe category. These drones mimic the flight patterns of birds by opening and closing their wings, a method that allows for intricate aerial maneuvers. Heli-wing drones are another innovative design that enables vertical takeoff, hovering, and landing through a rotating wing that serves as the blade. This flexible configuration allows them to operate vertically, like helicopters, and horizontally, like fixed-wing drones. The ornithopter configuration combines the flapping wing design with that of a helicopter while eliminating the need for a tail rotor [43]. Lastly, the cyclocopter utilizes cycloidal rotors to produce lift and thrust. This distinctive approach to rotorcraft design offers potential advantages in aerodynamic efficiency and control [44]. Different classifications of UAVs are presented in Fig. 3.

Figure 3: Classification of UAV types, (a) multi-rotor, (b) fixed-wing, (c) tilt-rotor, (d) tilt-wing, (e) flapping wing, (f) heli-wing, (g) ducted fan, (h) unmanned helicopter, (i) cyclocopter

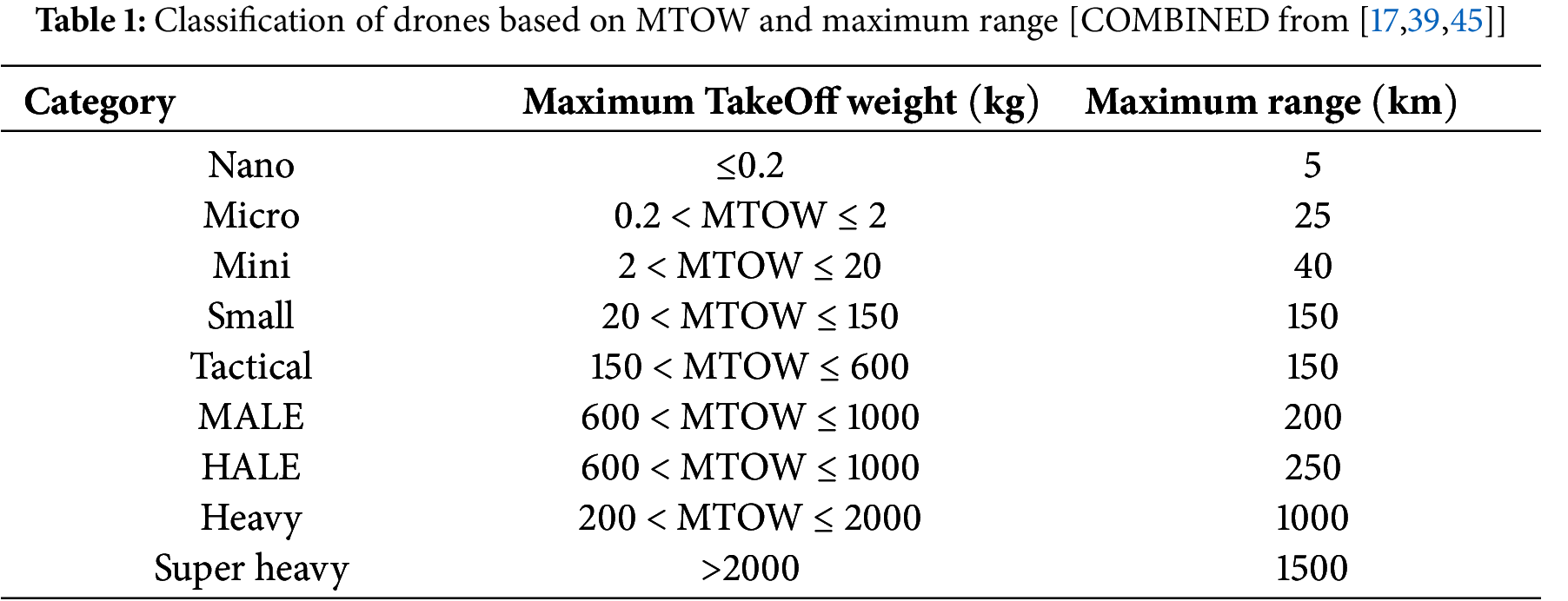

Classifying drones based on Maximum TakeOff Weight (MTOW) and the maximum distance they can cover, Brooke-Holland [39] classified drones with a Maximum TakeOff Weight (MTOW) of

Singhal et al. [45] specified MTOW between

The short operational flight time is a significant challenge for different multitudes of drones. Nano, micro, and mini drones use up their battery in around 20 to 30 min [18,45], and this challenge limits the application of drones in oil and gas monitoring that demands longer flight duration. To enhance the reliability of drones for oil and gas monitoring, researchers have explored various power sources and propulsion control methods, such as battery swapping [18], solar power energy harvesting [19], fuel cell [20], supercapacitor [21], gasoline engines and electric motors propulsion systems [22,23]. However, these approaches have drawbacks such as higher cost, size, and weight of the drones and more complex maintenance and safety procedures. Thus, a comprehensive study of the different power sources and their effects on the endurance of drones for oil and gas pipeline monitoring is needed. The following subsections will focus on the advancements in hybrid drones that utilize a combination of power sources, with particular attention to the efforts made to extend their operational flight times.

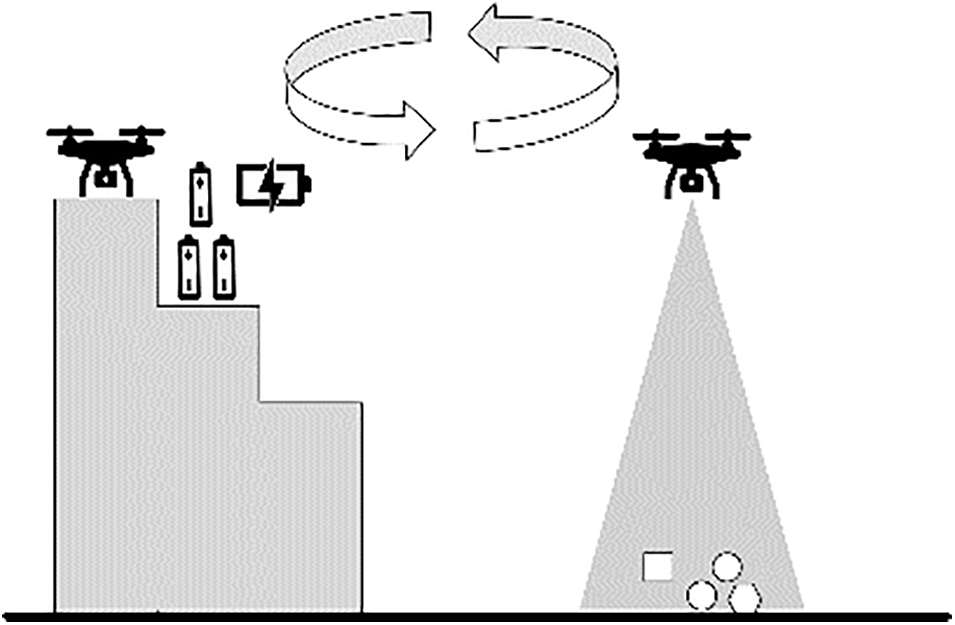

Efforts to extend drone operational time have led to exploring various strategies, including in-mission battery swapping and recharging. This method necessitates the establishment of ground-based stations where batteries can be either recharged or replaced during missions, as reported in these studies [46–48]. However, this approach introduces significant interruptions to the mission, as the drone must land and remain grounded until the batteries are fully recharged or swapped. Fig. 4 illustrates the battery swapping method.

Figure 4: Battery swapping method

A novel approach to mitigate this issue is presented in [18], where a primary quadrotor is supported by a secondary drone, referred to as a “flying battery.” This secondary drone carries additional batteries and docks with the main quadrotor to provide supplementary power. During these operations, the primary drone hovers in place while alternating between its primary and secondary power sources. Although innovative, this method presents challenges, including the need for multiple drones to function as flying batteries and the energy expenditure associated with the docking and undocking processes, ultimately diminishing overall operational efficiency.

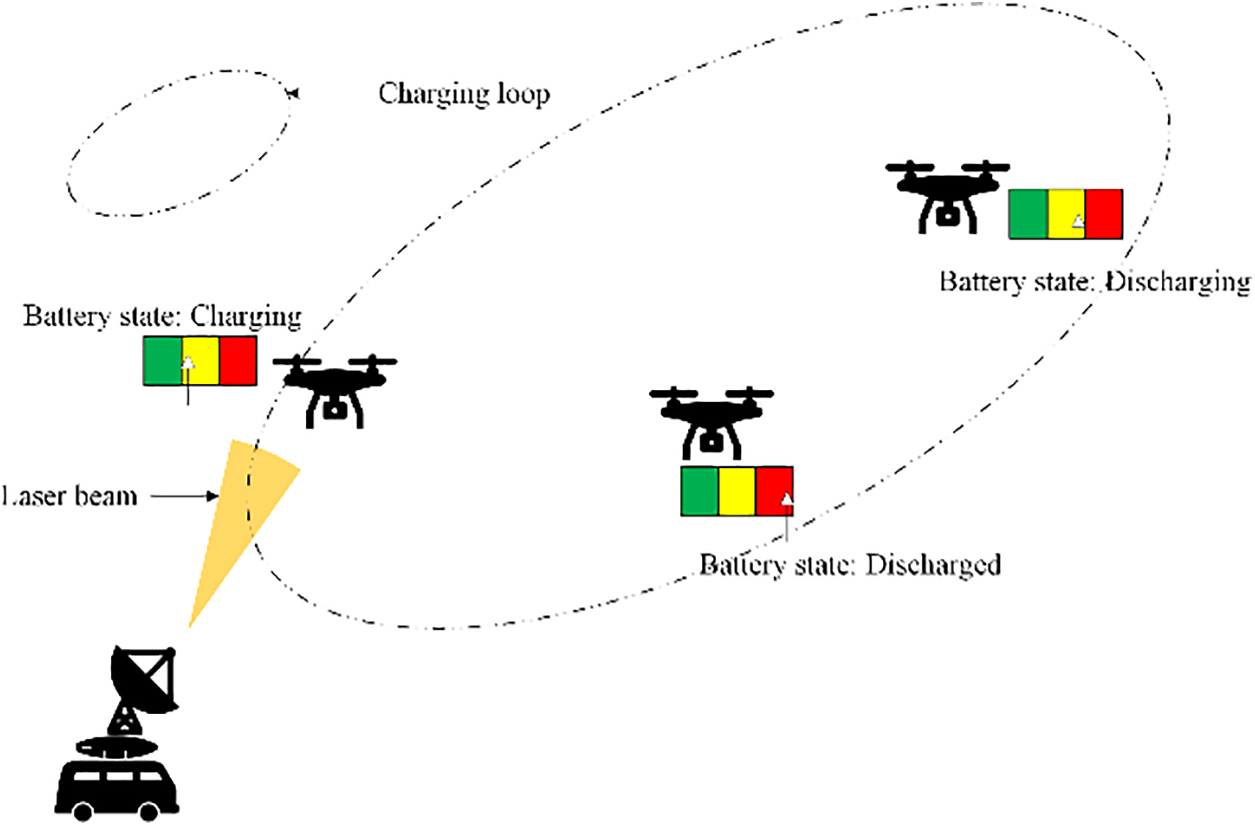

To address the problem of mission interruptions during power source transitions, wireless power transfer has been proposed as an alternative solution by researchers [49–52]. In this approach, demonstrated by Ouyang et al. [53], drones are equipped with photovoltaic (PV) panels that receive high-power transmissions from specialized ground-based laser sources. When the drone’s battery depletes, it connects to the nearest laser source to recharge. However, this system imposes significant limitations on the drone’s operational range and altitude, as it must maintain a direct line of sight with the laser source to ensure a stable connection. Fig. 5 illustrates the fundamental concept of the wireless power transfer process.

Figure 5: Procedure illustrating drone charging through laser beams

Fuel cells have emerged as a promising alternative for extending drone flight time, as highlighted by these studies [54–56]. These studies emphasize that fuel cells offer a higher energy density compared to traditional lithium-ion (Li-Po) batteries. For instance, Mi et al. [57] reported that Li-Po batteries typically provide an energy density of 130–200

Among the various types of fuel cells, Pan et al. [60] identified hydrogen fuel cells as the most efficient for drone applications. However, as noted by Kendall [61], the storage of hydrogen presents significant challenges due to the need for high-pressure and low-temperature conditions. To address these challenges, different hydrogen storage methods have been proposed, including compressed hydrogen gas [62], liquid hydrogen [63], and chemical hydrogen generation [58,64,65]. A comparative analysis conducted by Swider-Lyons et al. [66] revealed that, despite their potential, fuel cells are both costly and complex to manufacture and operate, noting that the storage processes are heavy and time-consuming. The studies by these authors [20,67] suggest that the operational delays and limitations associated with using fuel cells for drones have led to exploring power hybridization as a viable solution. This approach integrates fuel cells with traditional batteries, creating a hybrid power system that leverages the strengths of both energy sources while mitigating their weaknesses, as demonstrated by these studies [68–70].

Wang et al. [24] evaluated the use of both energy sources by feeding into a drone a fuel cell that could generate 162.7 W of electrical power. The fuel cell was used during the cruise flight mode, the battery was used for takeoff and landing, and the battery was also set for other emergency flight modes. Bayrak et al. [67] also proposed a similar method, but in their case study, the authors used two batteries, Li-ion and Ni-MH, because of their high energy density and combined them with a fuel cell with a switch. The switch decides which power source should be used for operation. Boukoberine et al. [71] addressed the drawback of poor response during takeoff and climbing when using fuel cells in drones by combining them with supercapacitors. They employed a direct current (DC)/DC boost converter to connect the fuel cell to the DC bus, controlling the power distribution through simulation. Their findings suggest a synergistic effect, with the fuel cell providing low-frequency components and the supercapacitor supplying high-frequency components. However, they also noted that this approach increases system complexity and weight, necessitating additional components like converters and controllers for practical drone applications.

Similarly, Fu et al. [72] proposed a hierarchical energy management strategy (EMS) for hybrid electric vehicles equipped with fuel cells, batteries, and supercapacitors. Their EMS utilizes a low-pass filter to optimize power distribution from the fuel cell and reduce hydrogen consumption. In this system, the supercapacitor manages peak power demands and recovers braking energy while the battery enhances fuel economy. The effectiveness of this EMS was validated through both simulation and experimental methods. However, they acknowledged that the complexity of this system might limit its practical application in drones. According to Xu et al. [73], while supercapacitors offer benefits for auxiliary power in UAVs, their use as a secondary power source in conjunction with fuel cells is hindered by their dynamic output voltage. Unlike batteries, which provide a relatively constant voltage during discharge, supercapacitors exhibit substantial voltage variations directly linked to their remaining energy.

These studies [74,75] proposed a tri-hybrid system incorporating batteries and supercapacitors alongside the fuel cell to compensate for the fuel cell’s output fluctuations. A study by Kaya et al. [76] investigates a triple-hybrid system for UAVs, combining a fuel cell, a Li-ion battery, and a supercapacitor. The researchers employed an electronic control unit to manage the energy flow and optimize system performance under different flight conditions. In this configuration, the fuel cell serves as the primary energy source, the Li-ion battery provides auxiliary power, and the supercapacitor handles sudden power demands, acting as a buffer for high-power transients. The authors of [77] presented an energy management strategy for a similar triple-hybrid system using a finite state machine method for power distribution. This method considers each energy device’s power capabilities and state of charge. Their results demonstrate that the proposed method ensures sufficient power delivery while potentially extending the fuel cell’s life cycle. Fig. 6 illustrates a UAV powered by a fuel cell.

Figure 6: Fuel cell-powered UAV

Due to these challenges, researchers, as highlighted in their works [78–80] have turned their attention to solar power as an alternative means to increase drone endurance, especially for high-altitude missions. Goh et al. [80] demonstrated that solar-powered drones, which rely solely on solar panels without any battery or energy storage device, could perform VTOL and hover operations. However, they pointed out that this design is highly sensitive to weather conditions because solar cells require a large surface area to be effective. Chu et al. [81] further investigated a hybrid solar-battery system in a 2-m wingspan UAV, showing that incorporating solar power could save 22.5% of the battery capacity during flight. Despite challenges with voltage, current, and power variations in drone solar modules, these researchers suggest that solar power offers a simpler and potentially more efficient alternative to fuel cells, particularly by reducing the need for heavy and complex energy storage systems. Lin et al. [82] moderated the challenges with voltage, current, and power variations in drone solar modules using additional batteries. However, the peak power demand wasn’t met.

Gao et al. [83] investigated the use of gravitational potential and rechargeable batteries for energy storage in solar-powered drones, finding that these methods offer the potential for extending flight times but are limited by their energy density and integration complexity. Shiau et al. [84] introduced a solar power management system for hybrid solar/battery setups, incorporating maximum power point tracking (MPPT), battery management, and power conversion. Their system effectively optimized energy extraction and battery charging, enhancing overall power efficiency for onboard systems. However, the study did not address the integration challenges with other power sources.

Gang et al. [85] designed a hybrid power system combining fuel cells, batteries, and solar arrays mounted on each wing. They implemented a solid-state relay-based power switching method to alternate between fuel cell and solar power, accommodating load variations during flight. While this approach improved power management, it introduced additional system complexity and weight. Lee et al. [86] developed a 200 W UAV powered by a combination of solar cells, a fuel cell, and batteries. Their active power management system (PMS) maintained operational boundaries and battery state-of-charge across various flight conditions, improving overall power management. However, the study did not explore the effects of power source variability on long-term reliability.

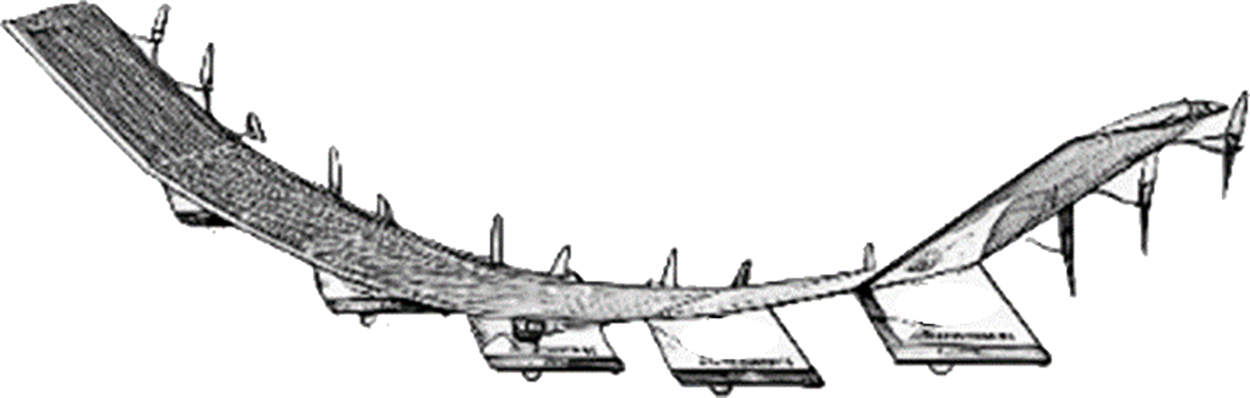

Lee et al. [87] examined a passive hybrid propulsion system integrating fuel cells, batteries, and solar cells. This design eliminated the need for DC-DC converters but required all power sources to operate at the same voltage level, which constrained the battery’s role in regulating solar power and ultimately reduced solar conversion efficiency. Shiau et al. [84] emphasized the critical role of MPPT controllers in maximizing solar energy utilization. Their findings showed that MPPT controllers significantly improve the efficiency of solar power generation by dynamically adjusting the solar array’s operating voltage to ensure peak power output despite varying environmental conditions and system voltage. However, the study did not address the integration challenges of MPPT with other power sources in hybrid systems. Fig. 7 illustrates a solar-powered drone. Table 2 provides a detailed comparison of various power sources used to enhance UAV endurance, outlining their benefits and limitations.

Figure 7: Solar-powered drone

2.3 Lighter-than-Air (LTA) Technology

Recent studies such as [15,19,96–98] have explored using LTA configurations, such as those found in airships and blimps, to reduce drone weight and extend flight time by integrating these designs with heavier-than-air (HTA) configurations, typically employed in drones, for added stability. Researchers such as [25,26] have proposed that airships or blimps, utilizing buoyant forces generated by LTA gases like hydrogen or helium, can reduce overall drone weight and improve aerodynamic efficiency. Chollet [99] reported helium gas as the ideal choice LTA due to its inherent properties. It offers a significant lift with minimal weight, a critical factor for maximizing flight time and payload capacity.

The potential benefits of helium-filled drones have been highlighted, with Song et al. [27] suggesting that LTA designs offer lower power consumption and increased operational flight time. To validate these claims, Macias et al. [100] developed a hybrid drone incorporating helium gas. Their findings, based on classical control theory, demonstrated a substantial increase in flight time, reaching 46 min. However, the design exhibited aerodynamic instability and wobbling.

Yamada et al. [101] proposed a blade-free drone that employs a helium balloon and 24 micro blowers for propulsion. This design enables vertical takeoff and landing, allowing the drone to remain airborne for weeks. However, the drone’s ability to move or operate in windy or indoor environments with air conditioning is limited due to its susceptibility to wind. Another design, demonstrated by Burri et al. [28], involves a 2.7-m diameter spherical drone that uses helium gas and four propellers, allowing for free movement and rotation in any direction. Despite its maneuverability, this drone is also constrained to indoor use.

Song et al. [27] designed a torus-shaped drone filled with helium gas to extend flight time, with a control unit centrally located within the envelope to manage translational and rotational motions. This design achieves a flight time of one hour, but its aerodynamics, particularly the shape of the balloon, make it highly vulnerable to wind interference, thus limiting its application to indoor environments. Sharma et al. [102] introduced a drone featuring a helium-filled balloon equipped with a rotor fault detection algorithm that can identify rotor malfunctions within 5.5 s, ensuring a safe landing. However, due to its shape, the drone’s design results in high aerodynamic drag.

Rae et al. [29] described a 15-m-long blimp with a teardrop shape designed to optimize helium gas volume for lift while minimizing drag. This blimp, lacking propellers, propels itself by alternating between being lighter-than-air and heavier-than-air, achieved by filling and emptying an internal “lung” with air to adjust its weight relative to the surrounding air. Although innovative, this design was tested exclusively indoors. Similarly, Tao et al. [103] developed an indoor miniature autonomous blimp capable of safe interaction with humans and a two-hour flight time. However, its limited payload capacity of 12 g and potential instability from wind or human touch pose significant drawbacks. Song et al. [104] introduced a buoyancy-aided UAV design with a symmetric torus blimp equipped with multiple tiltable actuators. This design, like many others in the field, was tested in indoor environments, where it demonstrated stable flight. However, its application remains limited to indoor use due to the aerodynamic constraints imposed by the design, particularly its susceptibility to external wind forces. Fig. 8 shows some examples of LTA drones.

Figure 8: Examples of LTA drones

Many of these studies highlight the limitations of current LTA drone designs, particularly their unsuitability for outdoor use due to aerodynamic instability and vulnerability to wind. Consequently, there is a clear need for more efficient designs that can overcome these challenges and be utilized in a wider range of environments. Table 3 summarizes recent studies’ key findings and limitations, providing a comprehensive overview of the current state of LTA designs for improved flight endurance.

2.4 Pipeline Inspection and Monitoring Techniques

In recent studies, the need for regular inspection and monitoring of pipelines has been emphasized due to the potential development of defects such as cracks, joint failures, and corrosion, which can result from extreme weather conditions, including temperature fluctuations, pressure, and humidity [105]. These defects, as highlighted by Shukla et al. [106] pose significant risks, including the potential for oil and gas leaks that could lead to environmental disasters and substantial revenue losses.

According to Shukla et al., visual inspection has traditionally been the primary method for detecting pipeline defects, relying heavily on human operators who use their eyes or cameras to identify and assess issues such as leaks by analyzing color, texture, and patterns in images or video data [5]. However, this method is not without its drawbacks. It requires specialized training and expertise, is time-consuming, carries risks, and is prone to human error, making it a costly approach. Despite these challenges, it was once the most commonly used inspection method.

To address these limitations, various alternative methods have been proposed. One approach involves using in-pipe robots [107–109], which can navigate the inside of pipelines to detect issues such as corrosion, metal loss, and cracks. These robots are equipped with sonar leakage detectors, HD cameras, LED lights, and magnetic and ultrasonic sensors to identify potential problems. As demonstrated by Shukla et al. [106], the robots are inserted into the pipeline through an entry point and are remotely controlled from a command center, transmitting data back for analysis. However, the internal nature of this inspection method can disrupt normal pipeline operations, leading to a preference for external inspection methods.

In response to this challenge, Tavakoli et al. [110] developed a novel pole-climbing robot with a V-shaped gripper to enhance safety and stability. Their robot was designed to navigate the complexities of 3D tubular structures, including bends and T-junctions. However, the authors acknowledged potential limitations in handling complex geometries, varying pipeline diameters, and obstacles. A system for detecting gas pipeline leaks using sensor fusion and model-based fault detection was proposed by [111]. This system utilizes a generalized state-space model of the pipeline, adaptable to various measurement and boundary conditions. It employs the Extended Kalman Filter and Fisher fusion techniques to estimate leak size and position from noisy pressure data along the pipeline.

Drones have also been explored for external inspection operations [112,113]. According to a survey by Cyberhawk, a North Sea E&P company, drone-based inspections can reduce costs by half and are twenty times faster than conventional methods [114]. Also, as reported by Aljuaid et al. [115], the use of drones for monitoring offers a promising alternative for the oil and gas industry, providing incredible speed, cost-efficiency, and safety with minimal human intervention. This technology’s flexibility allows for the integration of various sensors, addressing limitations in traditional inspection methods. However, as noted in [109,116,117], current drone-based pipeline inspections often rely on manual control, requiring a skilled engineer to manage drone flight, camera operation, and sensor data analysis, while another engineer monitors the live video feed for inspection purposes. This approach, though effective, is time-consuming, costly, and prone to human error, emphasizing the need for advancements in autonomous drone-based inspection systems to fully harness the potential of this technology for oil and gas monitoring.

Alharam et al. [3] describe an autonomous pipeline inspection system that utilizes a drone equipped with a thermal camera and parallel processing capabilities to achieve real-time performance. The system also features a gas detector to identify leaks and cracks in pipelines. Similarly, Shukla et al. [5] developed a method for autonomous tracking and inspection of pipelines, which operates in two stages: vision-based pipeline identification and navigation control. Their approach employs a proportional-integral-derivative (PID) controller with heuristic tuning to synchronize the drone’s position with the pipeline structure. Usamentiaga et al. [117] introduced a semi-autonomous pipeline inspection method using a drone fitted with an infrared camera. The drone follows a pre-programmed flight path aligned with the pipeline’s route, enabling it to inspect pipelines at night and detect temperature variations over time.

In addition, a hybrid manipulator system was proposed by Cacace et al. [118], combining both aerial and ground movement for pipeline inspection tasks. This system operates in fully autonomous and remote-controlled modes, with capabilities to navigate like a land vehicle for pipeline inspections. It includes flight, navigation, and stabilization components, allowing it to perform inspection tasks in complex environments. However, the system still encounters reliability and accuracy challenges in dynamic and uncertain conditions. A recent study proposed a visual-based UAV system for tracking and inspecting industrial pipes [119]. The system effectively utilized depth sensor data for pipe tracking and defect detection. While the study demonstrated promising results in controlled environments, further research is required to enhance system robustness and accuracy in real-world scenarios. Table 4 provides an organized overview of the different technologies, their features, benefits, and limitations, as reported in recent studies.

In comparison to traditional inspection and monitoring methods such as visual inspection, in-pipe, and pole-climbing robots, drone-based inspections have proven more cost-effective and reliable for pipeline monitoring. Visual inspections, while once common, are prone to human error, require specialized training, and are time-consuming, leading to higher operational costs. In-pipe and pole-climbing robots, although equipped with advanced sensors, often disrupt pipeline operations and face limitations when navigating complex geometries. UAV technology, on the other hand, offers faster inspection times, reduced costs, and increased safety with minimal human intervention. UAVs can be fitted with various sensors, including thermal cameras and gas detectors, enabling them to detect leaks, corrosion, and temperature variations without halting pipeline operations. Furthermore, UAVs are adaptable to different environments and can perform inspections autonomously, reducing human error and improving data accuracy. With advancements in autonomous navigation and sensor integration, drones are becoming the most promising solution for the oil and gas industry, offering significant advantages in terms of scalability, efficiency, and cost savings over other inspection methods.

2.5 Pipeline Inspection Algorithms

In recent studies, drones have demonstrated significant potential for performing faster, cheaper, and safer inspections than traditional methods. However, fully harnessing the capabilities of drones requires the development of robust algorithms. These algorithms are essential for various aspects of drone-based inspections, including image processing for anomaly detection [120,121], path planning for autonomous navigation [122,123], and real-time data analysis for informed decision-making [124]. This subsection reviews the current state-of-the-art algorithms in these areas and their potential to enhance the efficiency and accuracy of oil and gas pipeline monitoring.

For pipeline monitoring, especially in leak detection, advancements in image processing algorithms are proving transformative. The recent progress in AI, particularly in machine learning (ML) and deep learning (DL) algorithms, is ushering in a new era of autonomous pipeline monitoring. These algorithms are increasingly being applied to analyze data collected by drones and other sensors, enabling automated anomaly detection and proactive maintenance. This ultimately contributes to safer and more efficient pipeline operations [100,104,105]. Specifically, these algorithms can be trained to recognize particular features in pipeline imagery, such as vegetation encroachment, discoloration, or surface anomalies, potentially facilitating the early detection of leaks and minimizing environmental impact [100].

Alharam et al. [3] present an AI-based unmanned system designed for the inspection of oil and gas pipelines, which aims to enhance efficiency by automating the inspection process and delivering real-time alerts for leakages with a delay of less than 100 ms. The study compares several ML algorithms for detecting leaks, including Decision Tree, Support Vector Machine, and Random Forest. However, the research is limited by its reliance on a single dataset focused on methane gas leakage, indicating a need for the inclusion of multiple datasets and the potential integration of image processing techniques for more robust inspection validation.

Similarly, Al-Battbootti et al. [125] explore using UAV to capture images for subsequent analysis by ML models to detect and locate oil pollution. Their framework, incorporating object detection techniques and neural networks, was divided into training and operational models. While demonstrating promise, the model’s reliance on hypothetical oil spill scenarios limited its generalizability. Real-world conditions, characterized by diverse oil types, spill sizes, and environmental factors, could potentially impact the model’s accuracy and effectiveness.

Sonkar et al. [126] investigate the detection of natural gas leaks using UAVs equipped with ML algorithms, specifically the reduced support vector machine (RSVM) and artificial neural network (ANN), applied to methane detection data. The study acknowledges limitations, including the dependency of RSVM’s performance on the kernel function and the necessity for higher-quality data to improve algorithm performance. Furthermore, the current UAV system lacks the required endurance for extended inspection tasks.

Iwaszenko et al. [127] present a study on the use of UAVs equipped with laser-based methane sensors for detecting natural gas leaks in pipeline networks. The UAV’s capability to identify increased methane concentrations was tested on both artificial and real gas leaks, with ML methods employed to analyze the spatially correlated data. However, the study highlights challenges such as the difficulty in distinguishing real leaks from background methane levels, particularly at higher altitudes, and the potential impact of UAV propellers on methane dispersion at lower altitudes.

In recent advancements, DL algorithms have significantly enhanced pipeline inspection and monitoring through UAVs. Unlike traditional ML approaches, DL leverages complex neural networks to process and analyze vast amounts of data with improved accuracy and efficiency [128–130]. These algorithms, particularly convolutional neural networks (CNNs), have demonstrated their capability to perform intricate image analysis tasks, which are crucial for detecting anomalies in pipeline infrastructure.

Recent studies highlight the transformative impact of DL on pipeline inspection. For instance, Jiao et al. [131] integrated DL and the Otsu algorithm into a UAV system for oil spill detection. Experimental results demonstrated the system’s effectiveness in identifying oil spills at a lower cost compared to satellite-based methods. To enhance model accuracy, the researchers recommended compiling a larger dataset of oil spill images. Additionally, incorporating infrared cameras into the UAV system was suggested for improved nighttime detection capabilities. A comprehensive review by [109] highlighted the potential of unmanned systems, including UAVs, for oil and gas infrastructure inspections. The study emphasized the impact of UAVs, particularly when coupled with advanced algorithms like visual simultaneous localization and DL.

Similarly, Altabey et al. [132] introduced a CNN-based crack contour network method to enhance the efficiency and accuracy of identifying pipeline surface cracks through image processing. This method was evaluated using metrics such as accuracy rate, recall rate, and F-score, and the metrics indicated its potential for high-precision crack detection. However, the study also noted challenges, such as a high false detection rate, which may limit the direct application of this algorithm in fully automated pipeline inspection systems. Obaid et al. [133] present a DL approach for detecting oil pipeline leakages using aerial images captured by a drone. The aerial images were analyzed using the DexiNed algorithm to identify contours indicative of oil spills. The “CIELAB” color space is utilized to detect black-colored contours, which are potential oil spills. Limitations include the system’s dependency on weather conditions and the precision of images varying with the time of day and terrain.

A notable DL approach employed in pipeline inspection is the use of You Only Look Once (YOLO) algorithms [134]. YOLO is a real-time object detection system that has been integrated into UAV-based pipeline monitoring systems. According to [135], YOLO’s architecture allows for efficient and accurate detection of objects within images by processing them in a single pass. This capability is particularly beneficial for real-time applications where rapid detection and response are essential. YOLO models have been successfully implemented in various pipeline inspection tasks, demonstrating the ability to identify and classify pipeline defects and anomalies in real time.

This development aligns with recent work that leverages advanced deep neural networks and computer vision models for anomaly detection in oil and gas infrastructure, demonstrating the potential for fully automated drone systems to surpass traditional, human-reliant methods in both speed and accuracy [120]. A similar study by da Silva et al. [136] used a drone with image processing techniques and a YOLO algorithm for navigating complex unburied pipeline networks within the O&G industry. YOLO was utilized to accurately detect pipelines, while additional image processing techniques, such as Canny edge detection and the Hough Transform, were applied to establish a reference line along the pipeline. However, the study highlights further fine-tuning of the trained model to achieve better performance. Table 5 provides a detailed overview of the studies, highlighting the detection method, technology, tools, and algorithm used.

2.6 UAVs in Pipeline Inspection

Benyeogor et al. [137] developed a UAV equipped with gas leakage detectors, relying on Multiwii software for 3D motion control. Their solution demonstrates the potential for UAV-based pipeline monitoring. However, the study fails to address endurance limitations, which is critical for extended surveillance missions. Additionally, it lacks a detailed analysis of the sensors’ accuracy, which is vital for reliable leak detection. Furthermore, environmental factors such as weather conditions, which significantly influence UAV performance, are overlooked.

Prasetya et al. [138] explored the use of fixed-wing drones for aerial surveillance of pipeline right-of-ways, focusing on the risks posed by expanding residential and industrial activities. While this research highlights the relevance of aerial surveillance, it similarly neglects the drones’ endurance limitations. Moreover, the paper omits key discussions on data processing and analysis methods, both essential for ensuring the reliability and comprehensiveness of monitoring results.

Ondráček et al. [139] proposed a mathematical model to optimize UAV movement for pipeline monitoring, focusing on potential damage and timely surveillance. Though it addresses the importance of efficient UAV operations, the model overlooks real-world variables such as weather conditions, which could significantly impair performance. Additionally, its reliance on fixed parameters rather than adaptive ones limits its scalability and applicability in dynamic pipeline environments.

Xiaoqian et al. [140] presented a control mechanism for UAV-based pipeline visual tracking, focusing on navigation using a PID controller. The study emphasizes precision in navigation but suffers from limitations related to fluctuating terrain, adverse weather, and maintaining accurate tracking. This system’s performance depends on height accuracy and UAV model stability, factors that are difficult to ensure in unpredictable environments.

Akande et al. [141] proposed a real-time autonomous UAV system that detects leaks in buried and surface pipelines. While this system shows potential for responsive, real-time monitoring, its flight duration of only 15 min severely limits its effectiveness. The study does not address critical factors such as energy efficiency or battery sustainability, raising concerns about its practicality for large or remote pipeline networks.

Zhai et al. [120] presented a cloud-enabled UAV system for oil and gas field surveillance, integrating thermal imaging and deep learning for anomaly detection. While the system shows promise in terms of automation and real-time analysis, it faces similar challenges to the other studies: insufficient attention to endurance and weather adaptability. The system’s reliance on fixed weather-dependent flight paths further limits its flexibility in real-world scenarios.

Despite these advancements in UAV-based pipeline monitoring, the reviewed studies reveal several inadequacies. Majorly the limited endurance of current UAV systems restricts their capability for long-term, large-scale pipeline surveillance; the need for UAVs capable of carrying advanced sensor payloads and operating autonomously over vast distances is evident. Additionally, most studies neglect crucial factors like weather conditions and scalability, which are critical for reliable and sustained pipeline monitoring in diverse environments.

The pursuit of enhancing drone operational time has prompted the exploration of diverse strategies, ranging from in-mission battery swapping and recharging to integrating fuel cells and hybrid power systems. These methods represent significant advancements in drone technology, yet each comes with its technical challenges that impact the overall mission efficiency and operational feasibility. The conventional approach of in-mission battery swapping and recharging involves establishing ground-based stations where drones can land to either recharge or replace their batteries. While this method is straightforward, it introduces notable interruptions to the mission, as the drone must cease its operations during the battery replacement or charging process. The time required for these procedures can lead to significant mission downtime, which is especially problematic in long-duration surveillance or inspection tasks where continuous operation is critical. An innovative approach to mitigate the downtime associated with battery swaps is the “flying battery” concept, wherein a secondary drone equipped with additional batteries docks with the primary drone in mid-air to provide supplementary power. This method allows the primary drone to hover in place while transitioning between power sources. However, the implementation of such a system presents considerable challenges. The requirement for multiple drones functioning as flying batteries adds complexity to the operation and increases energy consumption due to the docking and undocking processes. Consequently, while the concept is promising, the overall operational efficiency may be compromised, particularly in missions requiring extended flight times.

Wireless power transfer has emerged as another potential solution, leveraging high-power laser transmissions to recharge drones equipped with PV panels. This method eliminates the need for the drone to land, theoretically enabling continuous operation. However, the reliance on a direct line-of-sight with the ground-based laser source imposes significant limitations on the drone’s operational range and altitude. The need for precise alignment with the laser source further complicates the system’s integration into dynamic flight environments, where maintaining a stable connection may prove challenging. Moreover, environmental factors, such as weather conditions, can significantly impact the effectiveness of this power transfer method, making it less reliable for consistent, long-duration missions.

Fuel cells have gained attention for their potential to extend drone flight times, owing to their higher energy density compared to traditional Li-Po batteries. Fuel cells, particularly hydrogen fuel cells, offer energy densities ranging from

Recent developments in tri-hybrid power systems, which integrate fuel cells, batteries, and supercapacitors, offer a promising solution to the limitations of single or dual power systems. These systems employ advanced EMS to optimize power distribution, ensuring that each power source operates within its optimal range. For example, supercapacitors can manage peak power demands and recover braking energy, while batteries provide auxiliary power, and fuel cells serve as the primary energy source. However, the increased system complexity, weight, and the need for precise control mechanisms to manage power flow among the different sources present significant challenges to implementing tri-hybrid systems in drones.

Solar power offers an environmentally friendly option for extending drone flight times, particularly in high-altitude missions where sunlight is abundant. By integrating solar panels with battery systems, drones can reduce reliance on stored energy, theoretically allowing longer flight durations. However, the effectiveness of solar power is highly dependent on environmental conditions, and the large surface areas required to capture sufficient solar energy impose design constraints. Additionally, voltage and power output fluctuations caused by varying sunlight intensity necessitate using MPPT controllers to optimize energy usage. Although solar power systems are relatively simple and less complex than fuel cells, their dependency on weather conditions and low energy density limits their utility in certain environments. Hybrid solar battery systems have been explored to mitigate these limitations, but challenges remain in achieving consistent performance across various weather conditions.

LTA configurations, such as airships and blimps, offer a unique approach to extending drone flight time by leveraging buoyant gases like helium or hydrogen to reduce the energy required for lift. These designs enable significantly longer flight durations compared to traditional drone configurations, making them ideal for long-term surveillance or inspection tasks. LTA designs are particularly suited for applications like pipeline inspection, where extended flight times are critical. However, LTA designs face challenges, particularly in outdoor environments where aerodynamic instability and susceptibility to wind forces can lead to unreliable performance. The optimized shapes for buoyancy often increase aerodynamic drag, further complicating their use in windy conditions. Despite these limitations, the potential of LTA configurations to enhance flight endurance and reduce power consumption remains significant. Advances in materials, aerodynamics, and hybrid LTA-HTA designs could mitigate some of these drawbacks, positioning LTA drones as a vital element in the future of aerial technology, offering a unique balance of endurance and energy efficiency.

The deployment environments of oil and gas pipelines introduce additional challenges that UAV systems must address. These pipelines often stretch across vast and rugged terrains spanning deserts, forests, arctic regions, and offshore platforms, each presenting unique obstacles. In desert regions, extreme heat and frequent sandstorms increase pipeline wear, necessitating early detection of corrosion or damage. Arctic environments bring the risk of freezing pipelines and harsh weather conditions that obscure traditional monitoring methods. Offshore platforms face the threat of saltwater corrosion and violent ocean conditions, making continuous monitoring vital to ensuring the safety and integrity of both the pipelines and the surrounding ecosystem.

UAVs have emerged as a powerful tool for external pipeline inspections, offering advantages in speed, cost-efficiency, and safety while minimizing human involvement. However, current UAV-based inspections still rely heavily on manual operations, which are time-consuming and prone to human error. To fully harness the potential of UAV technology in pipeline monitoring, there is a growing need for the integration of autonomous systems.

The integration of AI, ML, and DL into UAV-based inspections offers transformative possibilities. AI-driven systems can automate the detection of anomalies, such as identifying leaks and surface defects, through real-time analysis of drone-captured imagery. DL models, particularly those based on YOLO algorithms, have proven effective in real-time object detection and anomaly classification. By enabling drones to detect and classify defects autonomously, these technologies allow for more proactive and efficient maintenance processes.

However, significant challenges remain in enhancing drone endurance, reliability, and performance in dynamic environments. AI and ML models must be trained on robust datasets to ensure consistent accuracy across diverse scenarios, and ongoing refinement of these models is critical. As research progresses, fully autonomous systems capable of real-time decision-making and data analysis will play a key role in overcoming these obstacles, ultimately enhancing the safety and reliability of pipeline monitoring systems. Integrating advanced technologies like AI promises to revolutionize UAV-based surveillance, providing more efficient, accurate, and cost-effective solutions than traditional methods.

Given the limitations of conventional methods for extending drone flight time, such as fuel cell, solar power, and battery optimization, LTA technology emerges as a promising alternative, offering unique endurance and energy efficiency advantages. This section outlines the design methodology for LTA systems, focusing on critical aspects such as geometry, aerodynamics, and mass distribution. The design process begins with the geometry module, where the envelope shape and volume are determined. This is followed by an analysis of the aerodynamics module, which assesses the impact of the envelope’s shape on drag and stability. Finally, the mass/weight module evaluates the distribution and minimization of weight to optimize performance.

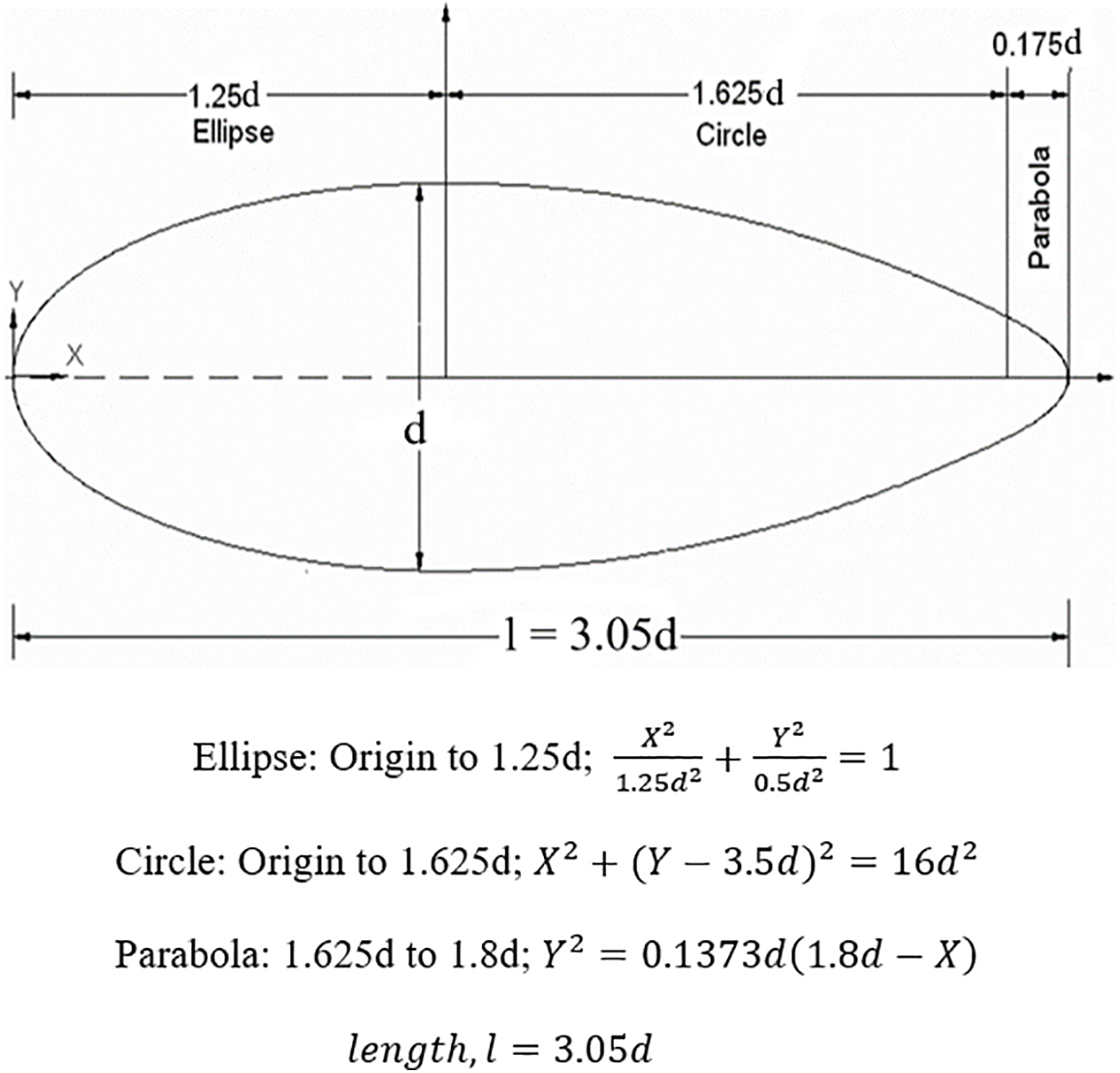

A review of LTA design literature highlights the importance of envelope shape in determining the performance of LTA aircraft. Several shapes, including GNVR, named after G. N. V. Rao of the Indian Institute of Science [142], ZHIYUAN-1 [143], Wang et al. [144], and the National Physics Laboratory (NPL) [145,146], have been identified as baseline airship models due to their low drag characteristics. The envelope profile significantly affects self-weight, drag, and lift generation. Although spheroids provide the highest lift per unit surface area, they are not aerodynamically optimal. The GNVR shape, which combines an ellipse, circle, and parabola, stands out for delivering the highest net lift per unit length among standard profiles, especially in small LTA applications [147]. This shape was chosen for the design methodology due to its low drag coefficient and practical design features. The geometric concept of this profile, parameterized by its maximum diameter

Figure 9: Schematic of the GNVR shape with geometry defined based on its maximum diameter

The envelope’s volume is a crucial parameter, and it is a function of the individual volumes of the ellipse, circle, and parabola. These shapes are not straightforward to model using basic geometric formulas, especially when combined into a single continuous envelope. Traditional volume calculation methods, such as approximating simple geometric volumes such as spheres and cylinders, may not capture the subtle variations and intricate profile of the GNVR shape. By using the volume of revolution approach denoted by Wilson et al. [150], we can precisely define the volume by revolving a curve around an axis. This method accounts for the nuances of each shape, resulting in a more accurate representation of the envelope’s volume. The volume of revolution is expressed as

where

Likewise, revolving the circular segment along its axis gives the volume of the circle,

The volume of the parabola is given as shown in Eq. (4).

Since the envelope’s shape is an approximate combination of these geometric shapes, the envelope volume,

Another important parameter is the surface area,

where

The envelope’s surface area,

Another crucial design consideration for LTA’s envelope design is the interplay between fineness and thickness ratios. The fineness ratio,

Conversely, the thickness ratio,

Accurate estimation of the envelope’s weight is crucial for LTA aircraft design. The envelope weight is determined by the weight of the envelope fabric, along with additional material for overlapping joints and reinforcement patches [146]. The fabric’s weight is influenced by the envelope’s surface area and the material’s specific density. To minimize the envelope’s impact on overall weight, a material with a high strength-to-weight ratio is essential. Low helium permeability is also required to prevent gas loss and maintain a stable lift. The envelope material must also exhibit high resistance to environmental factors to ensure durability. The total envelope weight,

where

This module concentrates on the aerodynamic forces influencing LTA aircraft, specifically buoyant lift and drag force. Accurate drag estimation is crucial as it directly impacts the aircraft’s performance, power requirements, and dynamic behavior. Consequently, this module develops functions to calculate these forces, correlating them with the aircraft’s geometric characteristics.

The total lift experienced by an LTA aircraft consists of the buoyant lift from the envelope and dynamic lift. Dynamic lift encompasses contributions from the aerodynamically shaped lifting body, tail lift including fins and control surfaces, and propulsive lift. The total lift,

The buoyancy force,

According to [146], at standard sea level and over an altitude range of

where

For the estimation of drag in a LTA envelope, Cheeseman [152] derived an equation for the volumetric drag coefficient based on experimental data. This equation incorporates the fineness ratio,

The friction coefficient,

By combining Eqs. (15) and (16),

The total drag,

The reference area

Weight estimation is conducted using analytical methods and established UAV design principles, incorporating material properties, component specifications, and design parameters. A detailed weight breakdown of the LTA’s key components is provided to optimize flight performance, payload capacity, and overall efficiency. The total weight

The weight of the envelope system is denoted as

The weight of the propulsion system

where

The payload system houses various sensors and equipment for mission-specific purposes. This study assumes a representative payload of 500 g, including cameras for navigation and data acquisition of the oil and gas pipeline. The structural weight,

Finally, the weight of other components

where

5 Numerical Results and Discussions

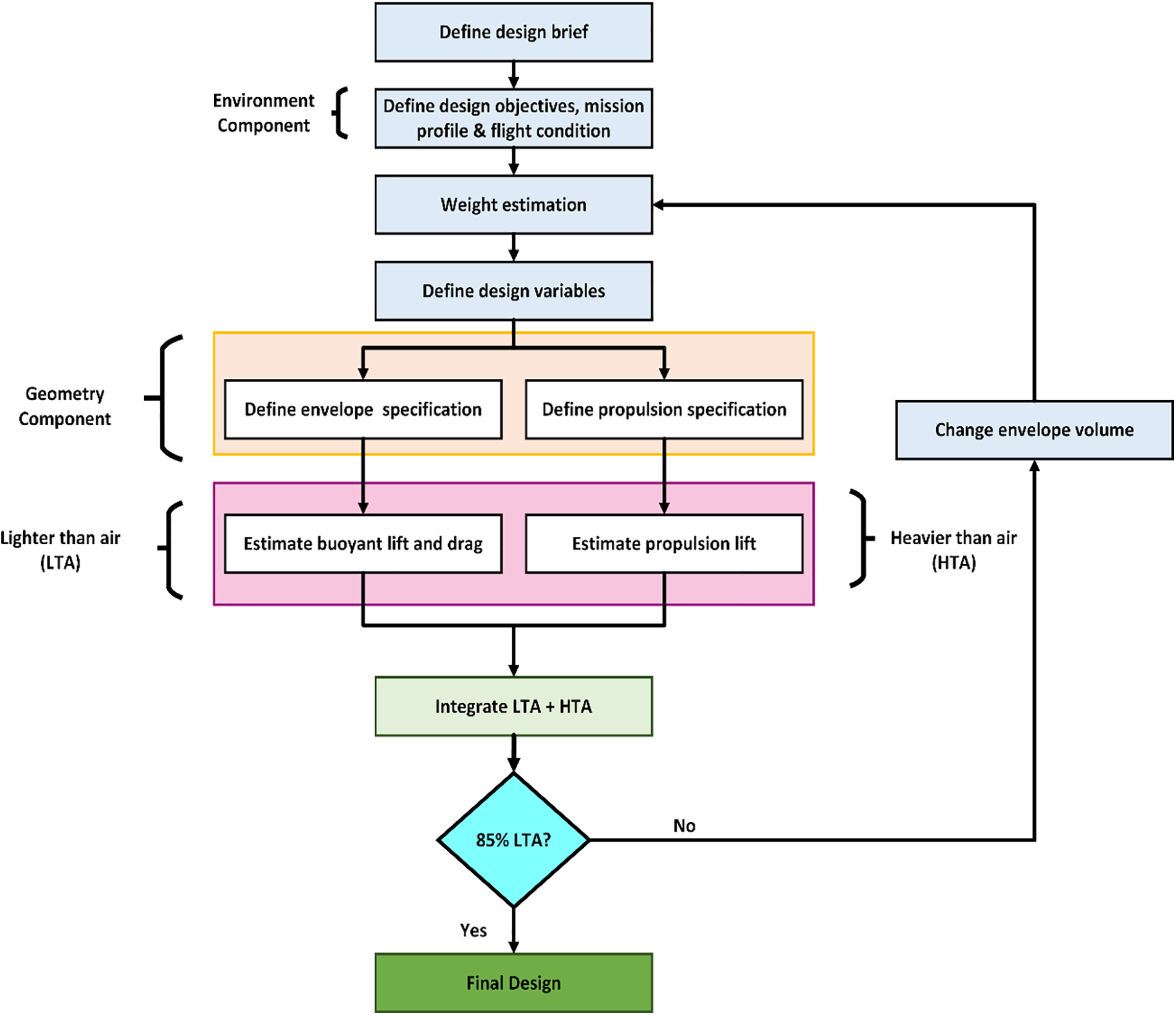

This section presents a hybrid drone design concept that integrates LTA and HTA configurations, demonstrating the feasibility and advantages of combining these two technologies. The proposed hybrid drone leverages the strengths of both LTA and HTA systems to achieve enhanced flight performance and operational efficiency. The core innovation lies in using LTA elements to provide 85% of the required lift through buoyant force, significantly reducing power consumption and extending the drone’s flight duration. The remaining 15% of the lift is supplied by HTA components, which enhance the drone’s maneuverability, speed, and control which is crucial for agile tasks like pipeline inspection. Fig. 10 illustrates the design algorithm of our hybrid drone.

Figure 10: The design algorithm

5.1 Optimization Objectives and Strategy

The design was systematically optimized to address three critical objectives: maximizing lift-to-weight ratio, enhancing flight endurance, and minimizing drag to improve overall energy efficiency. By focusing on weight reduction and strategic lift enhancement, we optimized both the material composition and structural components of the hybrid design.

5.1.1 Material Selection and Structural Optimization

In developing the hybrid drone’s envelope, polyurethane with a thickness of 0.1

5.1.2 Lift-to-Weight Ratio and Design Efficiency

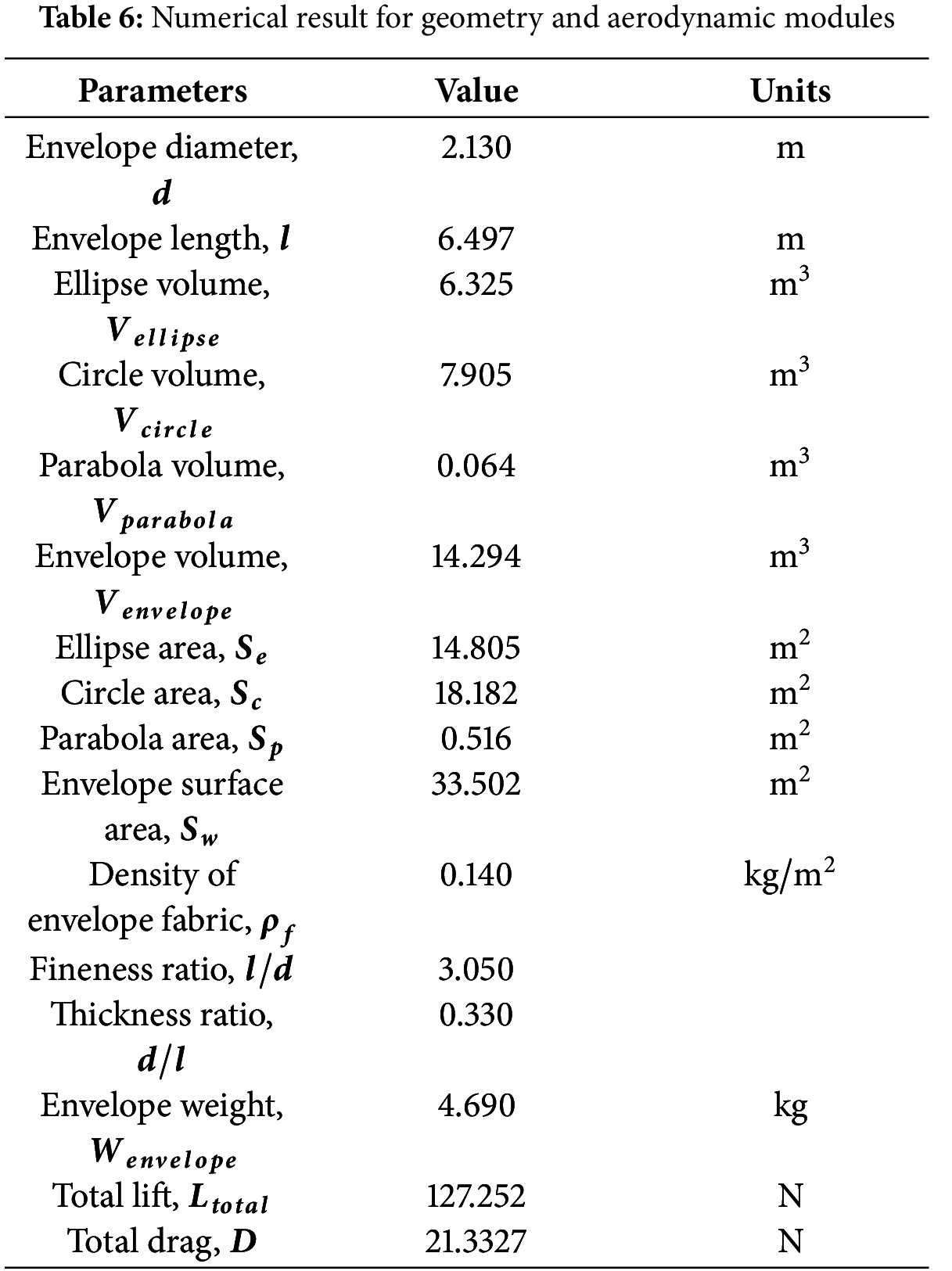

Our primary goal was to achieve 85% lift from the LTA elements, ensuring that only 15% of lift relies on HTA components, thereby reducing reliance on active power. To maintain this distribution, we refined the design using iterative simulations in CATIA and validated these with numerical calculations using the design approach from Section 4. The derived numerical results align closely with the data obtained from our design simulations in CATIA, as reported in Table 6. The analysis of the hybrid design confirms a balanced distribution of lift and drag forces, promoting stable flight while maintaining the flexibility needed for maneuverability. The resulting lift of approximately 127

5.1.3 Aerodynamic Shape Optimization

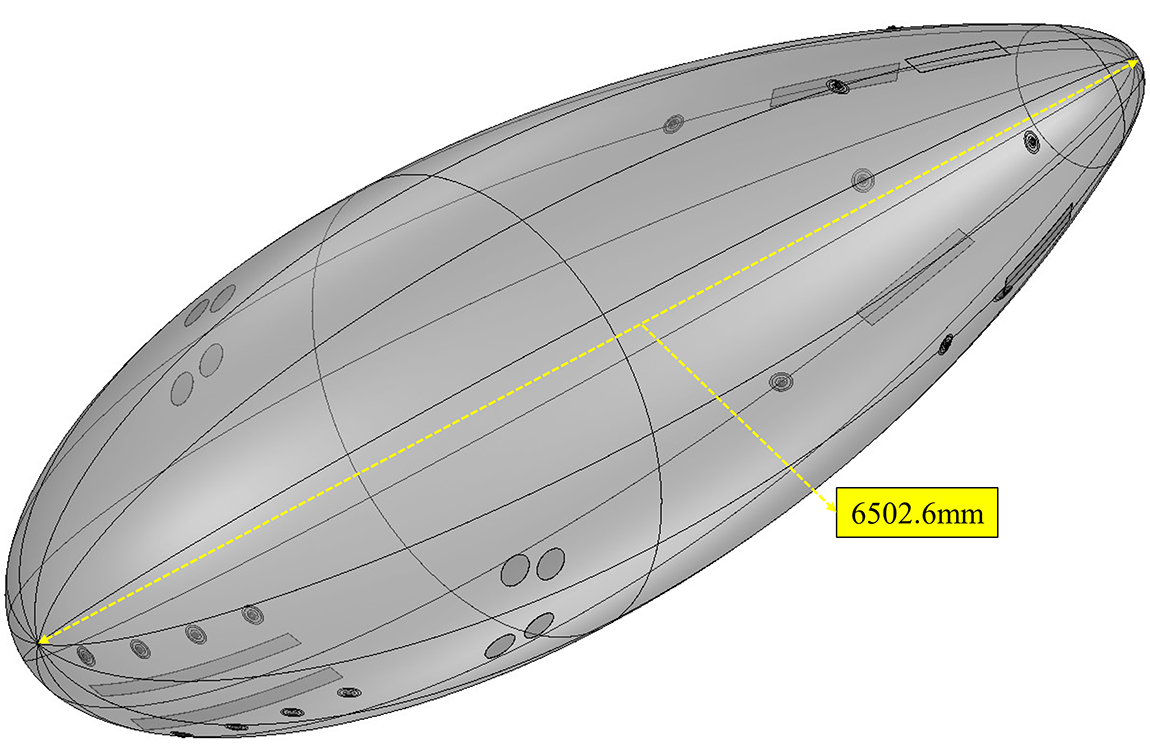

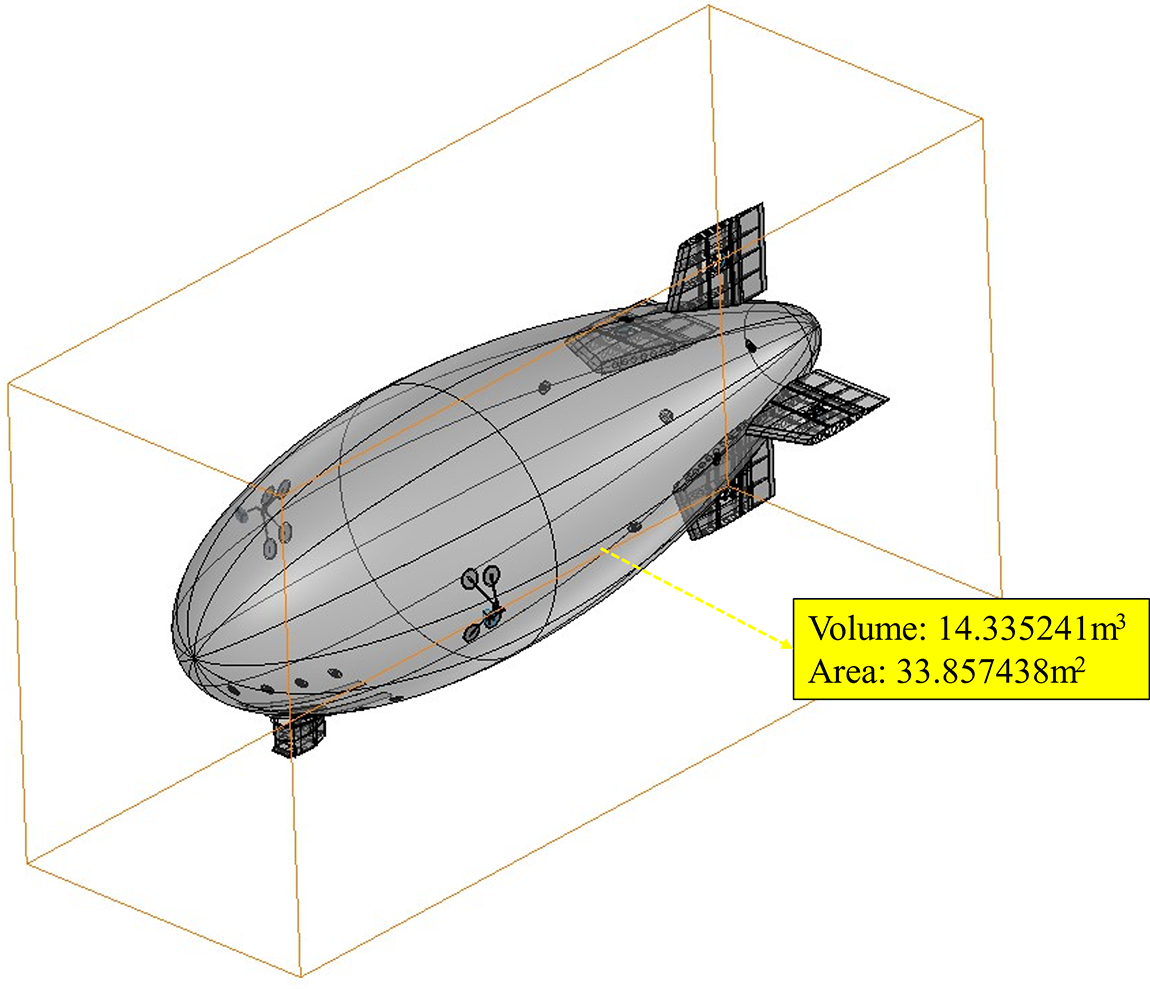

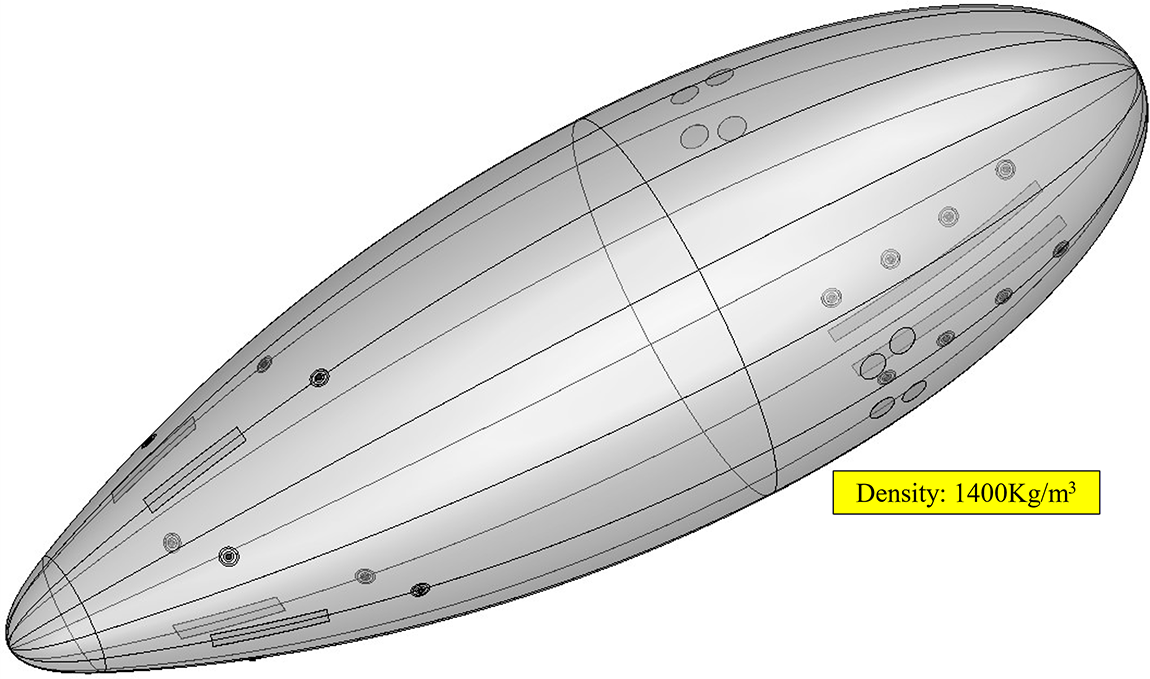

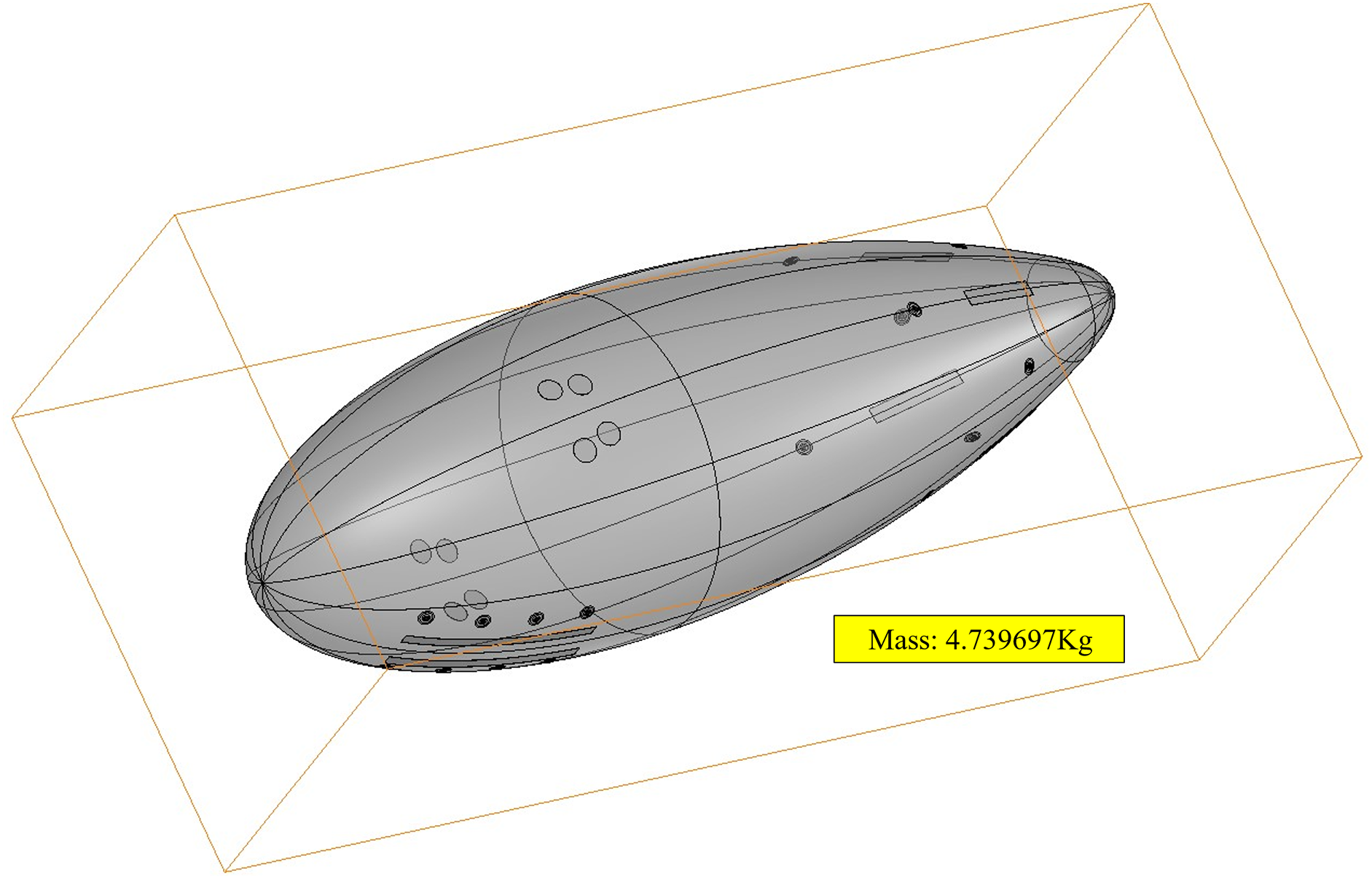

The GNVR-shaped envelope, characterized by its combination of elliptical, circular, and parabolic sections, was optimized for aerodynamic performance. This shape minimizes drag and maximizes lift, aligning with our design objective to maintain efficient flight dynamics. Figs. 11–14 present CATIA simulation results that align closely with the values in Table 6, confirming the envelope’s effectiveness in optimizing aerodynamic performance.

Figure 11: Simulation results from CATIA showing the envelope length

Figure 12: Simulation results from CATIA showing the envelope volume and surface area

Figure 13: Simulation results from CATIA showing the density of the envelope fabric

Figure 14: Simulation results from CATIA showing the mass of the envelope

5.1.4 Propulsion System and Weight Distribution

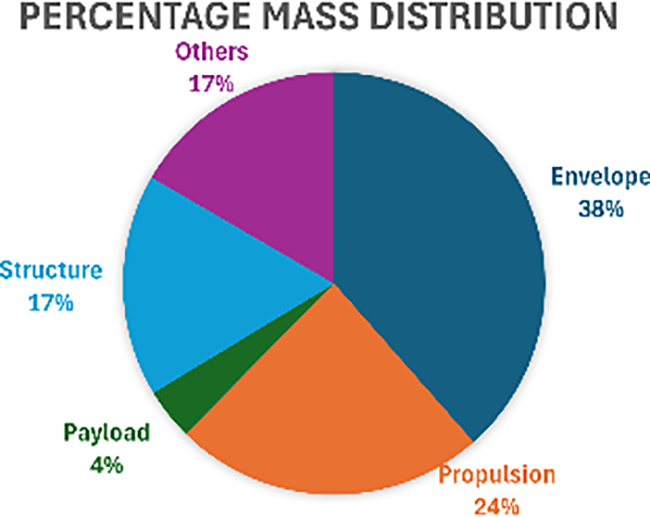

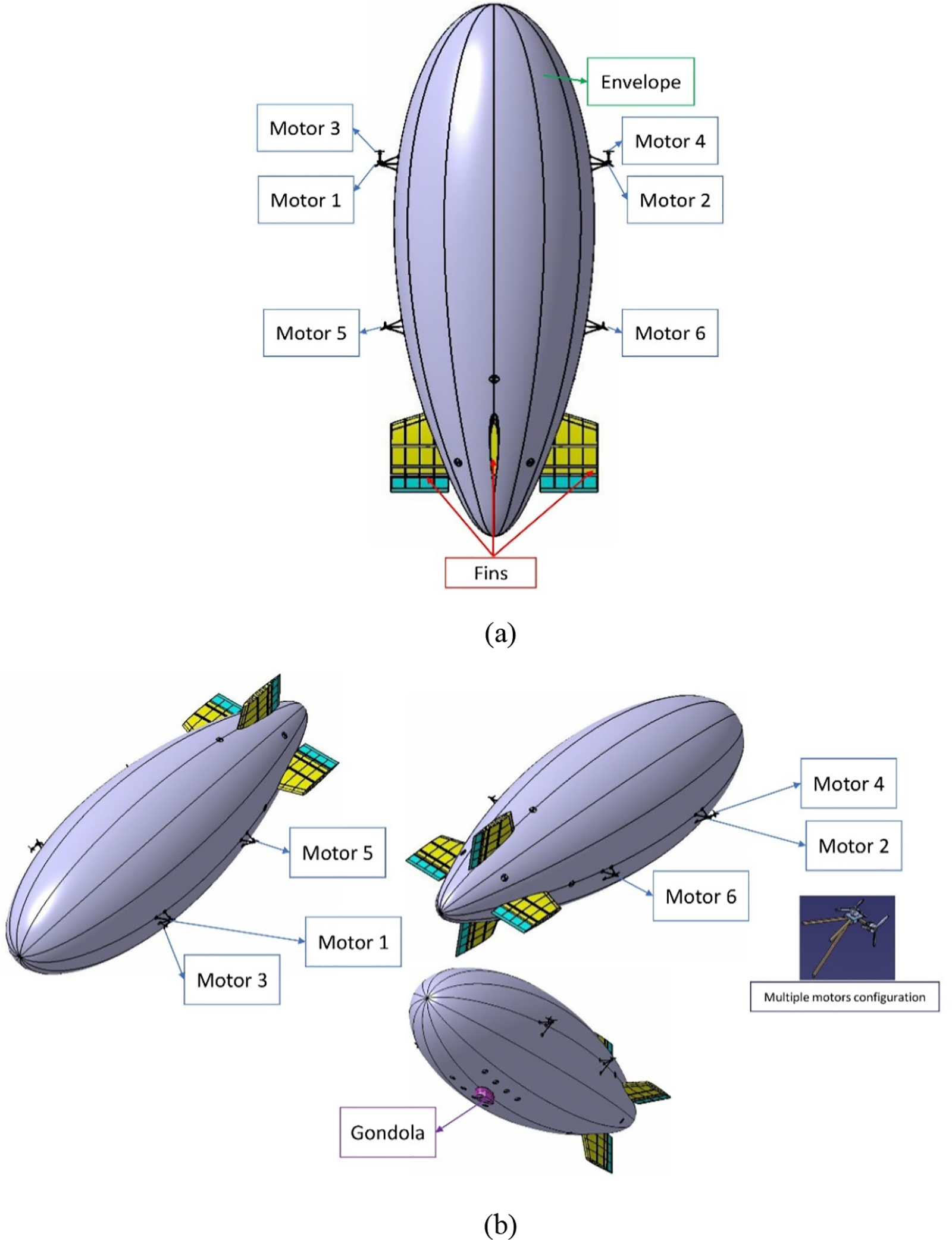

The weight distribution was configured to support agile maneuverability while maintaining flight stability. Table 7 outlines the weight distribution of the hybrid drone, which is visually represented in Fig. 15. The envelope system, constituting the largest percentage of the total weight (approximately 38%), aligns with existing studies [156], validating the design approach. The hybrid drone, shown in Fig. 16, utilizes six brushless DC motors for controlled propulsion. Four motors (Motors 1, 2, 5 and 6) are vertically aligned for lift during takeoff, landing, and hovering, while the remaining two motors (Motors 3 and 4) are horizontally aligned to provide forward thrust. This dual configuration optimizes energy use, enabling precise control in various flight modes and improving flight endurance by tailoring power delivery to different stages of the flight.

Figure 15: The mass distribution of the hybrid drone

Figure 16: The hybrid drone (a) top view (b) other views

The motor mounts are attached to lightweight balsa wood rods, minimizing the overall weight of the mounting structure. This setup connects horizontally positioned motors with vertical mounts, further conserving energy by optimizing thrust allocation. The gondola, designed to maximize weight efficiency, houses critical components like the battery, camera, and autopilot system. For stability, each motor leg is secured using Velcro pads and three individually adjustable strings, allowing structural adaptability and avoiding material strain from envelope shifts over time.

The proposed hybrid drone in this study has been conceptualized to ensure high reliability and operational safety, particularly in conditions where human intervention is limited. Key safety features of the LTA design include the use of helium as the lifting gas, which eliminates the risk of fire or explosion during flight. Additionally, the airship’s envelope is designed to last at least three years without needing replacement, ensuring long-term operational durability. The maximum takeoff weight, including the mission payload, is kept below

The proposed hybrid drone enhances reliability by minimizing the risk of mission failure due to power loss. It operates using a combination of electric power for propulsion and a buoyant gas for lift, with ground-based charging capabilities to ensure that no in-flight charging complications occur. This dual configuration emphasizes energy efficiency and operational reliability, offering advantages over traditional UAVs that rely solely on fuel or batteries for extended missions. In the event of a motor failure, the drone’s buoyant, balloon-like design enables it to remain afloat in the air, preventing unnecessary crashes and reducing the risk of damage to people or property. Additionally, the drone’s low energy consumption and extended flight endurance help reduce the carbon footprint of pipeline monitoring operations. This eco-friendly approach is particularly beneficial in environmentally sensitive areas, such as offshore platforms and protected wilderness regions.

The proposed hybrid drone solution in this study is tailored for pipeline monitoring in environments that pose challenges to conventional UAVs. For example, in Arctic environments, where traditional UAVs may struggle due to freezing conditions, the hybrid drone’s buoyancy-driven flight and optimized thermal-resistant material ensure continued operation. In desert regions, the vehicle’s ability to fly at a lower altitude and hover over specific waypoints enables it to capture high-resolution data even in high-temperature conditions that could compromise sensor accuracy. Additionally, the hybrid drone’s modular payload system allows it to be adapted for various pipeline inspection needs, including leak detection, structural integrity assessments, and environmental monitoring. This flexibility ensures the drone can be deployed across multiple regions with different geological and operational requirements, making it a versatile solution for comprehensive pipeline monitoring.

Upon full implementation, we intend to validate the effectiveness of our proposed approach through real-flight operations within an oil and gas pipeline test area spanning

This review presents a hybrid drone design that combines LTA and HTA technologies to enhance flight performance. By utilizing LTA for 85% lift and HTA for 15% stability, the design achieves a balance of endurance and maneuverability for complex tasks. The analysis and numerical results demonstrate the hybrid configuration’s viability and benefits, such as lower power use and improved efficiency in pipeline monitoring. The LTA methodology discussed here is a crucial resource for establishing baseline specifications in the conceptual design of LTA drones. The ongoing work focuses on fabricating the hybrid drone’s design by following the design parameters noted in this paper. Once finalized, this drone will autonomously inspect pipelines, providing an efficient solution for oil and gas surveillance and maintenance. Its low-power navigation capabilities will significantly enhance monitoring efficiency over extensive pipelines.

The integration of LTA drone configurations with DL algorithms such as YOLO marks notable progress in UAV pipeline inspection. This synergy overcomes traditional inspection challenges and paves the way for more autonomous and dependable monitoring systems. As research advances, these technologies are poised to become fundamental in modern pipeline management, ensuring infrastructure integrity and safety. Future publications will present results from flight tests and performance metrics, contributing to the evolution of drone technology in autonomous pipeline inspection. This initiative aspires to establish a standard for hybrid drones in industrial use, showcasing the advantages of merging LTA and HTA principles within a singular aerial platform.

Despite the significant advancements presented, the hybrid drone design combining LTA and HTA configurations also faces limitations, particularly in handling high-wind conditions and balancing power consumption across extended missions. The computational demand of integrating advanced DL algorithms for real-time detection adds further challenges, especially in remote deployments with limited maintenance infrastructure. Addressing these limitations will enhance the model’s robustness and reliability in varied operational environments.

Acknowledgment: The authors gratefully acknowledge the support of the Electrical and Electronic Engineering Department of Universiti Teknologi PETRONAS, Malaysia, the Yayasan Universiti Teknologi PETRONAS grant, and the technical support provided by the Interdisciplinary Research Centre for Aviation and Space Exploration (IRC-ASE) at King Fahd University of Petroleum and Minerals (KFUPM), Saudi Arabia.

Funding Statement: This research is supported by the Yayasan Universiti Teknologi PETRONAS (YUTP) under Cost Center 015LC0-485.

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Ibrahim Akinjobi Aromoye, Hai Hiung Lo; data collection: Ibrahim Akinjobi Aromoye, Hai Hiung Lo; analysis and interpretation of results: Ibrahim Akinjobi Aromoye, Hai Hiung Lo, Patrick Sebastian, Ghulam E Mustafa Abro; draft manuscript preparation: Ibrahim Akinjobi Aromoye, Ghulam E Mustafa Abro, Shehu Lukman Ayinla. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: All the research literature and data utilized in this paper comprise publicly accessible scholarly articles, conference proceedings, books, and reports. The references and citations are included in this manuscript’s reference list and can be accessed through online databases, academic libraries, or by contacting the respective publishers.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Jiao Z, Zhang Y, Xin J, Mu L, Yi Y, Liu H, et al. A deep learning based forest fire detection approach using UAV and YOLOv3. In: 2019 1st International Conference on Industrial Artificial Intelligence (IAI); 2019; Shenyang, China. p. 1–5. doi:10.1109/ICIAI.2019.8850815. [Google Scholar] [CrossRef]

2. Savkin AV, Huang H. Asymptotically optimal deployment of drones for surveillance and monitoring. Sensors. 2019;19(9):2068. doi:10.3390/s19092068. [Google Scholar] [PubMed] [CrossRef]

3. Alharam A, Almansoori E, Elmadeny W, Alnoiami H. Real time AI-based pipeline inspection using drone for oil and gas industries in Bahrain. In: 2020 International Conference on Innovation and Intelligence for Informatics, Computing and Technologies (3ICT); 2020; Sakheer, Bahrain. p. 1–5. [Google Scholar]

4. Marathe S. Leveraging drone based imaging technology for pipeline and RoU monitoring survey. In: SPE Symposium: Asia Pacific Health, Safety, Security, Environment and Social Responsibility; 2019; Kuala Lumpur, Malaysia. doi:10.2118/195427-ms. [Google Scholar] [CrossRef]

5. Shukla A, Xiaoqian H, Karki H. Autonomous tracking and navigation controller for an unmanned aerial vehicle based on visual data for inspection of oil and gas pipelines. In: 2016 16th International Conference on Control, Automation and Systems (ICCAS); 2016; Gyeongju, Republic of Korea. p. 194–200. doi:10.1109/ICCAS.2016.7832320. [Google Scholar] [CrossRef]

6. Boutot J, Peltz AS, McVay R, Kang M. Documented orphaned oil and gas wells across the United States. Environ Sci Technol. 2022;56(20):14228–36. doi:10.1021/acs.est.2c03268. [Google Scholar] [PubMed] [CrossRef]

7. Merrill MD, Grove CA, Gianoutsos NJ, Freeman PA. Analysis of the United States documented unplugged orphaned oil and gas well dataset. US Geolog Surv. 2023:2771–9448. doi:10.3133/dr1167. [Google Scholar] [CrossRef]

8. Saneiyan S, Mansourian D. Locating undocumented orphaned oil and gas wells with smartphones. J Appl Geophy. 2023;219(1):105224. doi:10.1016/j.jappgeo.2023.105224. [Google Scholar] [CrossRef]

9. Williams JP, Regehr A, Kang M. Methane emissions from abandoned oil and gas wells in Canada and the United States. Environ Sci Technol. 2021;55(1):563–70. doi:10.1021/acs.est.0c04265. [Google Scholar] [PubMed] [CrossRef]

10. Micheal M, Xu W, Jin J, Yu H, Liu J, Jiang W, et al. A multi-scale quadruple-continuum model for production evaluation of shale gas reservoirs considering complex gas transfer mechanisms and geomechanics. J Pet Sci Eng. 2022;213(4):110419. doi:10.1016/j.petrol.2022.110419. [Google Scholar] [CrossRef]

11. Li W, Liu J, Zeng J, Leong Y-K, Elsworth D, Tian J, et al. A fully coupled multidomain and multiphysics model for evaluation of shale gas extraction. Fuel. 2020;278:118214. [Google Scholar]

12. Asadzadeh S, de Oliveira WJ, de Souza Filho CR. UAV-based remote sensing for the petroleum industry and environmental monitoring: state-of-the-art and perspectives. J Pet Sci Eng. 2022;208:109633. [Google Scholar]