Open Access

Open Access

ARTICLE

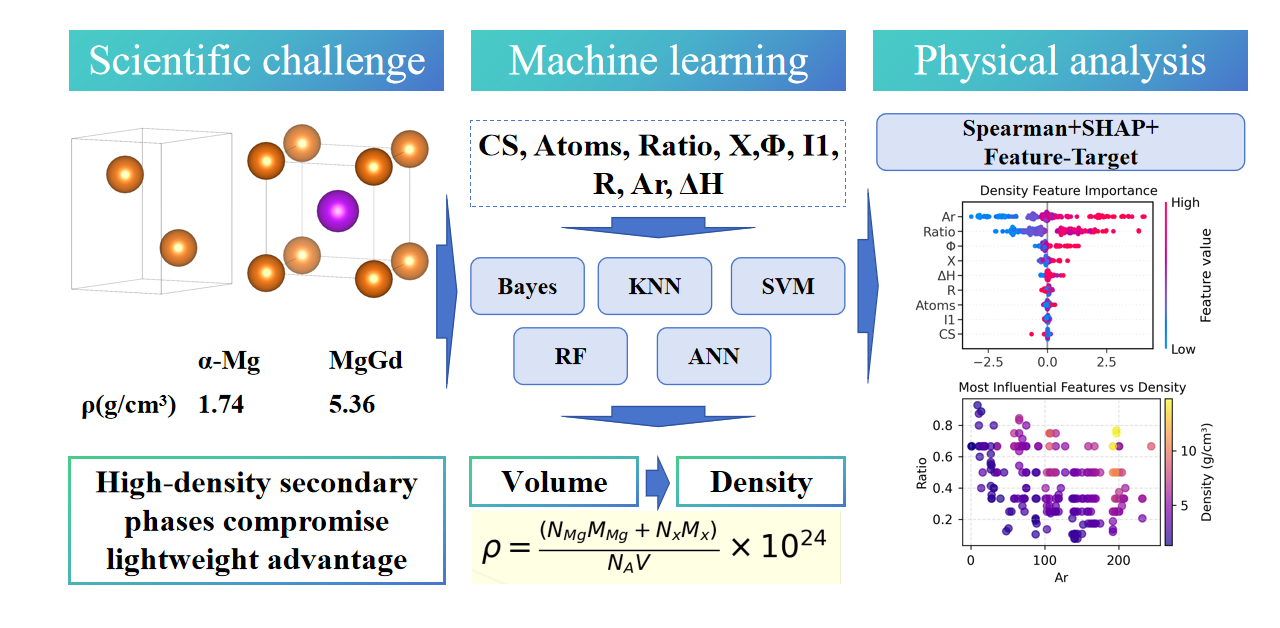

Machine Learning Prediction of Density for Binary Mg-Containing Phases

1 Lanxi Magnesium Materials Research Institute, Lanxi, 321100, China

2 School of Metallurgy and Power Engineering, Chongqing University of Science and Technology, Chongqing, 401331, China

3 College of Materials Science and Engineering, Chongqing University of Technology, Chongqing, 400054, China

4 National Engineering Research Center for Magnesium Alloys, Chongqing University, Chongqing, 400044, China

* Corresponding Authors: Xiaoxi Mi. Email: ; Shibo Zhou. Email:

(This article belongs to the Special Issue: Machine Learning-Assisted Light Alloy Design)

Computers, Materials & Continua 2025, 85(3), 4571-4586. https://doi.org/10.32604/cmc.2025.070649

Received 21 July 2025; Accepted 12 September 2025; Issue published 23 October 2025

Abstract

Magnesium (Mg) alloys face a critical challenge in balancing performance optimization and unintended density increases caused by high-density secondary phases. To address this, machine learning was employed to predict the density and volume of Mg-containing binary phases, aiming to guide lightweight alloy design. Using 211 experimentally observed data points, five machine learning (ML) algorithms—Random Forest (RF), Support Vector Machine (SVM), Artificial Neural Network (ANN), K-Nearest Neighbors (KNN), and Bayesian Ridge (Bayes)—were trained and tested. Quantitative results showed that RF achieved exceptional performance in volume prediction, with a testing coefficient of determination (R²) exceeding 0.96 and a mean absolute error (MAE) of 41.0 Å3, while SVM outperformed others in density prediction with a testing R2 of 0.885 and MAE of 0.421 g/cm3. Feature importance analysis revealed that atomic count is the primary determinant of phase volume, whereas density prediction depends on the synergistic interaction of relative atomic mass and stoichiometric ratio, as further validated by SHapley Additive exPlanations (SHAP) analysis. This work establishes a physics-informed predictive model that accelerates the development of lightweight Mg alloys by mitigating high-density secondary phases, and can be extended to other alloy systems.Graphic Abstract

Keywords

Supplementary Material

Supplementary Material FileCite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools