Open Access

Open Access

PROCEEDINGS

Heat Transfer Performance Improvement of Twisted Tubes with Different Starts by Combination of Dimples

1 Lanzhou Jiaotong University, Lanzhou, 730070, China

* Corresponding Author: Kewei Song. Email:

The International Conference on Computational & Experimental Engineering and Sciences 2023, 27(4), 1-3. https://doi.org/10.32604/icces.2023.8880

Abstract

With the rapid development of the economy and the increasing consumption of fossil energy, energysaving becomes imperative [1,2]. Improving the heat transfer efficiency of heat exchangers, which are widely applied in many fields, is important for energy utilization [3,4]. Twisted tube can produce secondary flow, increase turbulence and thin thermal boundary layer, and hence the enhancement of heat transfer [5-9]. However, the mixture of the fluid between the center of the twisted tube and the region around the tube is still not effectively improved. Thus, the heat transfer of the twisted tube can be further improved by combining with other technologies [10].In present work, the flow and heat transfer characteristics of twisted tubes with oval dimples and different starts under turbulent flow condition are numerically investigated. The dimples are arranged spiraling along the flow direction with constant dimple parameters.

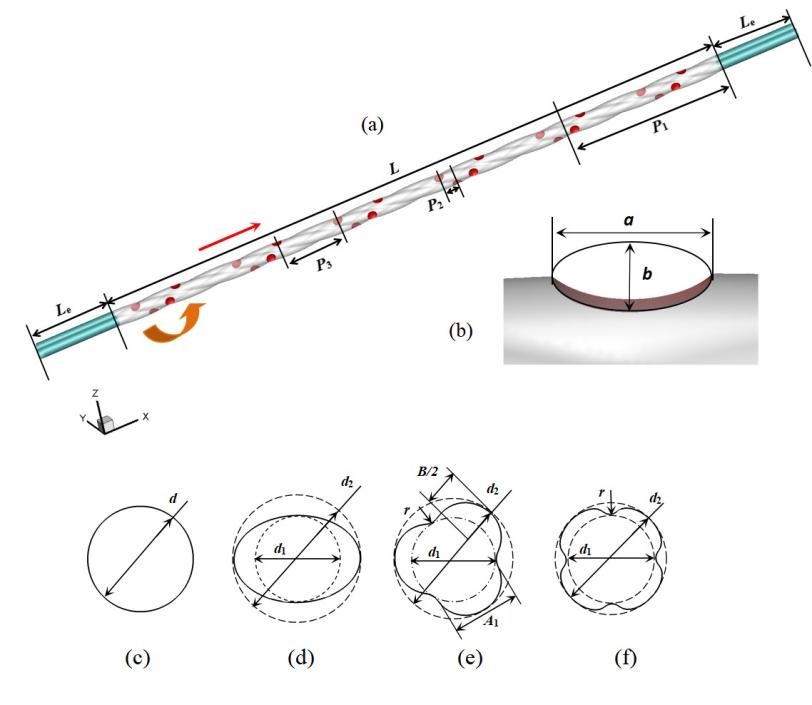

Figure 1: Tube configuration, (a) view of whole tube , (b) dimple configuration, (c) straight tube, (d) twostart twisted tube, (e) three-start twisted tube, (f) four-start twisted tube.

Fig. 1 presents the dimpled twisted tube with extended sections. The twist pitch of the tube is P1. Four dimples in each group are evenly distributed along the circumference with a distance of P2=17 mm along flow direction. And there are total of six groups of dimples. The distance P3 between two groups of dimple is 74.2 mm. The length of each extended section Le is 100 mm. The configurations of the straight, two-start, three-start and four-start tubes are shown in Fig.1(c), (d), (e) and (f), respectively. The wetted circumferences of different tubes are kept as consistent.

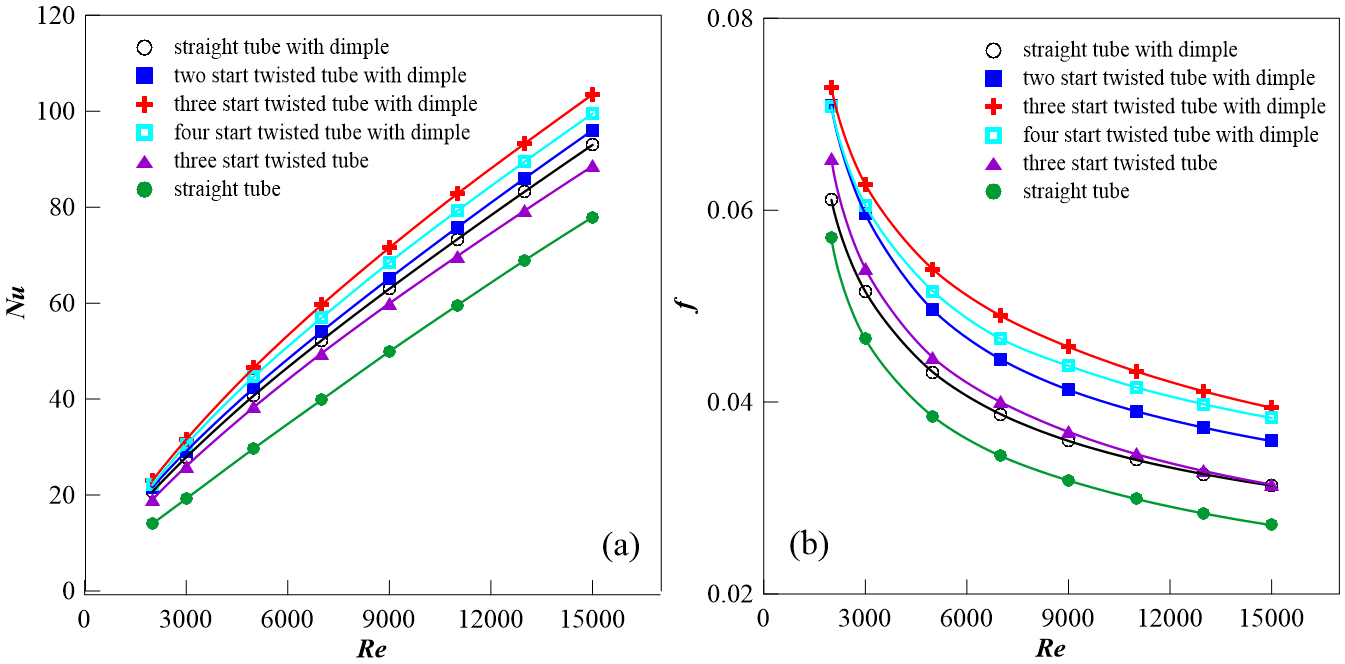

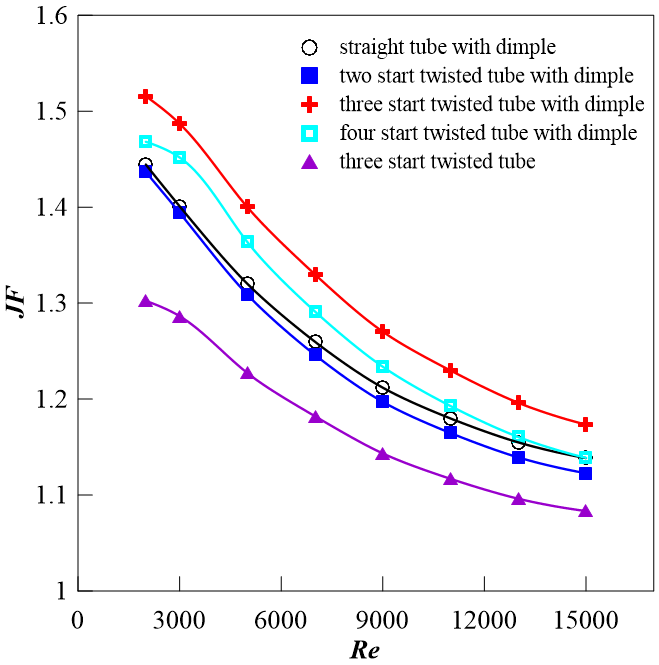

The distributions of Nu and f for different tubes are presented in Fig. 2. When Re ranges from 2000 to 15000, Nu of the three-start twisted tube with dimple increases by 32.8%-64.3% compared with that of the straight tube. Meanwhile, f of the three-start twisted tube with dimple increases by 27.4%-45% compared with that of the straight tube. The distribution of thermal performance factor JF is shown in Fig. 3. JF of the three-start twisted tube with dimple increases by 8.3%-16.3% compared with that of the three-start twisted tube.

Figure 2: Effects of tube shapes on the distributions of Nu and f

Figure 3: Effects of tube shapes on the distribution of JF.

The main conclusions are as follows

(1) The dimple can generate secondary flow, effectively thin the thermal boundary layer, redistribute the fluid inside the tube, and hence the heat transfer enhancement.straight tube. And Nu increases by 16.8%- 20.6% compared with the three-start twisted tube without dimples.

(2) The three-start twisted tube with dimples has the best heat transfer performance among the studied different tube shapes. When Re ranges from 2000 to 15000, the Nusselt number of the three-start twisted tube with dimples increases by 32.8% - 64.3% compared with the smooth straight tube. And Nu increases by 16.8%-20.6% compared with the three-start twisted tube without dimples.

(3)The friction factor of the three-start twisted tube with dimples increases by 27.4% - 45.0% compared with the smooth straight tube. And f increases by 11.3% - 25.5% compared with the three-start twisted tube without dimples.

(4)The thermal performance factor JF of the three-start twisted tube with dimple is also the largest about 1.51. JF of the three-start twisted tube with dimples increases by 8.3%-16.3% compared with the threestart twisted tube without dimples.

Keywords

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools