Open Access

Open Access

ARTICLE

Synergistic Effect of Silicone Macromolecular Charring Agent and Ammonium Polyphosphate on Improving Flame Retardancy and Mechanical Properties of Ethylene-Butyl Acrylate Copolymer Composites

1 College of Materials Science and Engineering, Qingdao University of Science and Technology, Qingdao, 266042, China

2 National Engineering Research Center of Flame Retardant Materials, School of Materials Science & Engineering, Beijing Institute of Technology, Beijing, 100081, China

* Corresponding Authors: Chuncheng Hao. Email: ; Xin Wen. Email:

Journal of Polymer Materials 2025, 42(2), 517-530. https://doi.org/10.32604/jpm.2025.065320

Received 10 March 2025; Accepted 27 May 2025; Issue published 14 July 2025

Abstract

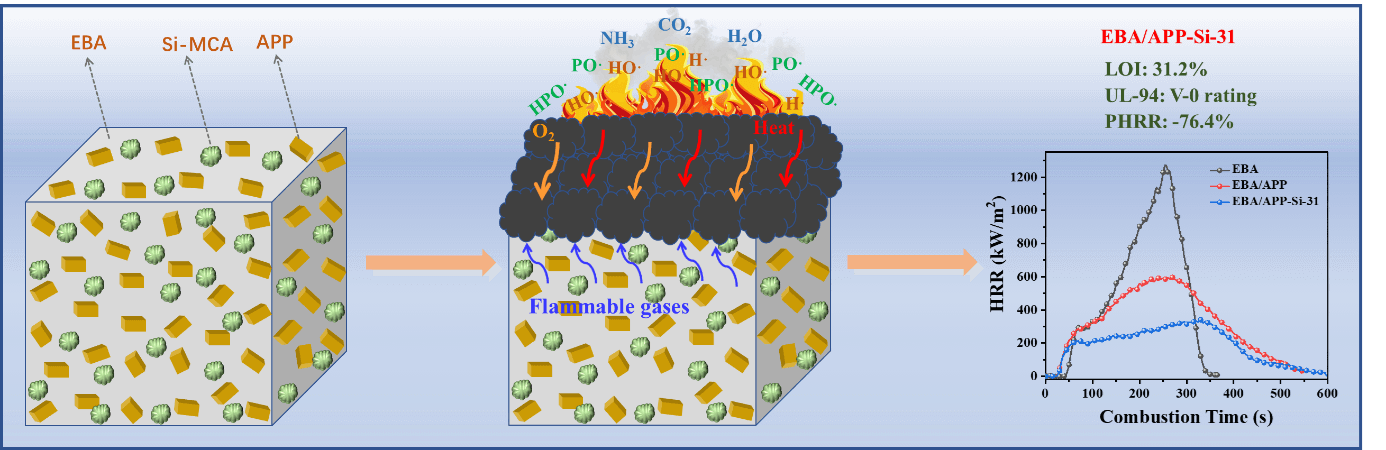

Power cables are important pieces of equipment for energy transmission, but achieving a good balance between flame retardancy and mechanical properties of cable sheaths remains a challenge. In this work, a novel intumescent flame retardant (IFR) system containing silicone-containing macromolecular charring agent (Si-MCA) and ammonium polyphosphate (APP) was designed to synergistically improve the flame retardancy and mechanical properties of ethylene-butyl acrylate copolymer (EBA) composites. The optimal mass ratio of APP/Si-MCA was 3/1 in EBA composites (EBA/APP-Si-31), corresponding to the best flame retardancy with 31.2% of limited oxygen index (LOI), V-0 rating in UL-94 vertical burning test, and 76.4% reduction on the peak of heat release rate (PHRR) in cone calorimeter test. The enhancement mechanism was attributed to the synergistic effect of APP/Si-MCA during combustion, including the radical-trapping effect, the dilution effect of non-flammable gases, and the barrier effect of the intumescent char layer. Meanwhile, the tensile results indicated that EBA/APP-Si-31 also exhibited good mechanical properties with the addition of maleic anhydride-grafted polyethylene (PE-g-MA) as the compatibilizer. Thus, the APP/Si-MCA combination is an effective IFRs system for preparing high-performance EBA composites, and it will promote their applications as cable sheath materials.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools