Open Access

Open Access

ARTICLE

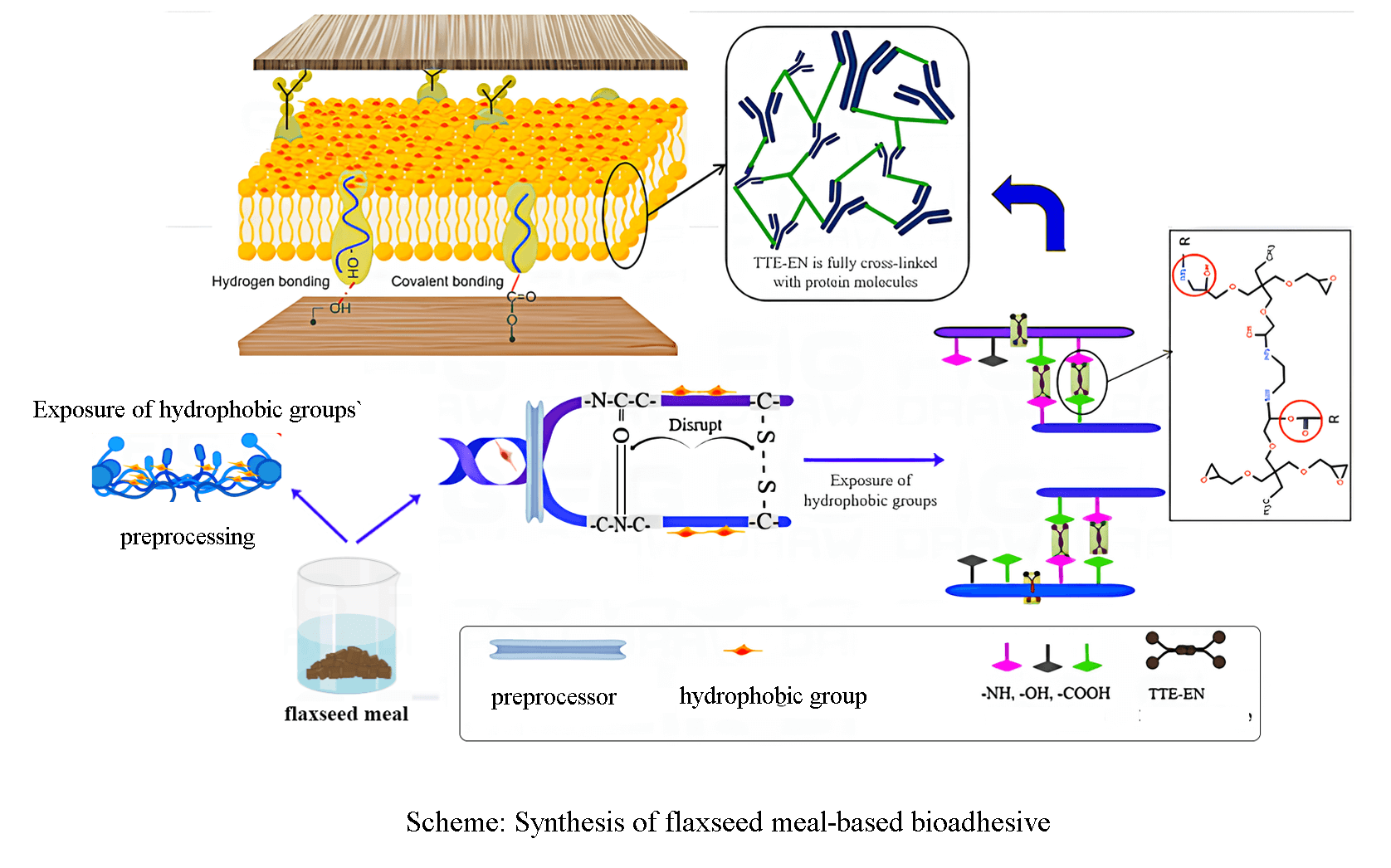

Preparation of Flaxseed Meal Protein Renewable Bioadhesive by Using Small Proportions of Trimethylolpropane Trigglycidyl Ether and Ethylenediamine

1 Key Laboratory of Bio-Based Materials and Energy Ministry of Education, South China Agricultural University, Guangzhou, 510642, China

2 Guangxi Key Laboratory of Chemistry and Engineering of Forest Products, Guangxi Collaborative Innovation Center for Chemistry and Engineering of Forest Products, Guangxi University for Nationalities, Nanning, 530006, China

* Corresponding Author: Xianfeng Hou. Email:

Journal of Renewable Materials 2025, 13(2), 297-310. https://doi.org/10.32604/jrm.2024.049534

Received 10 January 2024; Accepted 17 May 2024; Issue published 20 February 2025

Abstract

The main raw material utilized in wood adhesives comes from petrochemical extractives. However, due to the excessive dependence on petrochemical resources and the adverse impact on the ecosystem and human well-being, there is an increasing trend to develop byproduct protein-based adhesives in the current global food safety context. In this research, flaxseed meal was subjected to pretreatment, and trimethylolpropane triglycidyl ether (TTE) and ethylenediamine (EN) were utilized as crosslinkers to establish a more compact adhesive layer and to prevent water intrusion. The pretreatment decreased the FM/UB viscosity by 60% compared to FM. The combination of CD analysis indicated that the Urea-NaOH pretreatment effectively stretched the flaxseed meal protein. According to Fourier transform infrared (FTIR) spectroscopy, X-ray diffraction (XRD), and differential scanning calorimetry (DSC) were used to analyze the resulting adhesive’s reaction mechanism and thermal response. Furthermore, the physical properties of the adhesive were characterized using wet shear strength testing and SEM observation. Remarkably, the dry bond strength increased from 0.72 to 2.12 MPa, representing a 194.4% increase. The wet bonding strength of the adhesive was improved from 0.22 to 1.21 MPa, representing a 550% increase compared to the original flaxseed protein-based adhesive, which far exceeded the minimum requirement for plywood of Type II (≥0.7 MPa, by GB/T 9846-2015). This study demonstrated an eco-friendly and sustainable method for the development of protein adhesives as viable substitutes for petrochemical resins.Graphic Abstract

Keywords

Supplementary Material

Supplementary Material FileCite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools