Open Access

Open Access

REVIEW

Empowering Underground Utility Tunnel Operation and Maintenance with Data Intelligence: Risk Factors, Prospects, and Challenges

1 School of Civil Engineering, Chongqing Jiaotong University, Chongqing, 400074, China

2 School of Civil Engineering and Architecture, NingboTech University, Ningbo, 315100, China

3 Ningbo Urban Construction Design & Research Institute Co., Ltd., Ningbo, 315012, China

* Corresponding Author: Ping Wu. Email:

Structural Durability & Health Monitoring 2025, 19(3), 441-471. https://doi.org/10.32604/sdhm.2024.058864

Received 23 September 2024; Accepted 11 November 2024; Issue published 03 April 2025

Abstract

As an essential part of the urban infrastructure, underground utility tunnels have a long service life, complex structural performance evolution and dynamic changes both inside and outside the tunnel. These combined factors result in a wide variety of disaster risks during the operation and maintenance phase, which make risk management and control particularly challenging. This work first reviews three common representative disaster factors during the operation and maintenance period: settlement, earthquakes, and explosions. It summarizes the causes of disasters, key technologies, and research methods. Then, it delves into the research on the intelligent operation and maintenance architecture for utility tunnels. Additionally, it explores the data challenges, monitoring technologies, and management platform architectures faced during the operation and maintenance process. This work provides new research perspectives for the long-term, healthy, and sustainable development of utility tunnels, which serve as the underground arteries of cities.Keywords

Nomenclature

| AI | Artificial Intelligence |

| ML | Machine Learning |

| IOT | Internet of Things |

| ICTs | Information and Communication Technologies |

| BIM | Building Information Modelling |

| FEMs | Finite Element Models |

| O&M | Operation and Maintenance |

| GPS | Global Positioning System |

| InSAR | Interferometric Synthetic Aperture Radar |

An underground utility tunnel is a public infrastructure built beneath cities that integrates most lifeline systems, such as electricity, telecommunications, water supply and drainage, heating, and gas pipelines. Compared with the traditional method of direct burial for pipelines, utility tunnels offer significant comprehensive benefits. These tunnels enable efficient emergency repairs, maintenance, and upgrades of various pipelines in the tunnel, which effectively prevent the “street zipper” phenomenon (where roads are repeatedly dug up for repairs). As a result, utility tunnels represent a new type of municipal infrastructure that the government aims to promote extensively in the future.

According to data from the China Urban Construction Statistics Yearbook, by the end of 2022, the total length of underground utility tunnels in China had reached 7093.95 km, and 1638.46 additional kilometres were constructed that year. The fixed asset investment for these projects was approximately 30.756 billion yuan. In July of the same year, the “14th Five-Year National Urban Infrastructure Construction Plan” was issued, which called for the development of a new layout for urban underground spaces. This plan promotes the construction of utility tunnels based on functional needs and local conditions and solidifies systematic municipal infrastructure development. As a result, the geological conditions for utility tunnel construction have become more complex, and the challenges of construction and maintenance have increased.

Moreover, utility tunnels have long service lives; the complexity of structural performance evolution and dynamic changes in internal and external environments result in diverse risk factors during the operation and maintenance phases, which makes risk management more challenging. Common disaster factors for utility tunnels include structural settlement, explosions caused by pipeline leaks, and seismic responses, all of which can endanger nearby buildings and facilities.

Currently, experts systematically implement control measures from multiple perspectives, including material selection, structural design, construction techniques, and intelligent monitoring, to increase the safety and durability of utility tunnels. In terms of material selection, high-performance composite materials such as ultrahigh-performance concrete (UHPC) and engineered cementitious composites (ECCs) [1,2] are utilized because of their exceptional crack resistance and impermeability. The strength of these components can be further enhanced through reinforcement methods such as porous steel plates, thereby reducing the risk associated with settlement or crack propagation. In construction, ground treatment is crucial, particularly in soft soil areas. Foundation reinforcement techniques [3], such as piling and grouting, can significantly improve the load-bearing capacity and stability of foundations, preventing structural deformation. Advanced intelligent monitoring methods, in which stress and displacement sensors are installed at key points in the tunnel to enable real-time monitoring of stress and deformation data, are also employed. This continuous monitoring facilitates dynamic assessments of tunnel operational status. Additionally, predictive models constructed with machine learning based on sensor data enable rapid identification of structural health and potential risks, providing precise and efficient decision support for maintenance management.

Analyses of such factors typically rely on theoretical research, model testing, and numerical simulations, but each approach has limitations: traditional theoretical formulas cannot capture dynamic changes over time, and numerical simulations often involve large-scale models with numerous elements, which makes them time-consuming, resource-intensive, and difficult to converge.

Thus, there is an urgent need to explore new methods, such as combining machine learning, to quickly obtain mechanical state data during the monitoring of utility tunnel components and develop accurate real-time analyses for structural performance.

Fig. 1 illustrates the research framework of this work. First, it provides a comprehensive review of three common disaster factors during the operation and maintenance phase (settlement, earthquakes, and explosions), summarizes their causes, key technologies, and research methods, and offers recommendations. Next, it delves into the mechanisms of intelligent operation and maintenance for utility tunnels and analyses the data challenges, monitoring technologies, and management platform architecture, including research on digital twin-driven architectures. This work provides new theoretical foundations and research perspectives for researchers who seek to explore practical operation and maintenance strategies for urban underground utility tunnels.

Figure 1: Research on the operation and maintenance of utility tunnel systems

2 Analysis of the Factors that Affect the Operation and Maintenance of Integrated Utility Tunnels

The research focus during the construction phase of utility corridors primarily revolves around geotechnical body excavation [4], its interaction with the surrounding geological environment [5], the mechanical equipment [6,7] in the excavation process and their impact on mechanical behaviour simulation. While maintaining detailed research characteristics, the focus of utility tunnel studies has gradually shifted towards the operational phase. Compared with the construction stage, the operational phase of utility corridors is characterized by a longer service life, more complex structural performance evolution, and dynamic changes in both internal and external environments, which lead to a wider range of risk factors during operation and maintenance. Managing these operational risks has become more challenging. The risks during the operational phase mainly stem from the structure of the utility tunnel, pipeline leakage, and external environmental impacts. Fig. 2 shows a schematic of the multihazard analysis for utility tunnels, which highlights representative disaster-inducing factors such as uneven structural settlement, fire and explosion caused by pipelines, and seismic response. Fig. 2 also summarizes and reviews the existing research methods and technologies.

Figure 2: Multihazard analysis of integrated utility tunnel systems

During the long-term operation and maintenance of utility tunnels, significant internal and external changes occur due to various factors, such as different hydrogeological conditions, structural material properties, and surface loads, as shown in Fig. 3. These changes can disrupt the original stress equilibrium and structurally damage the components or walls of the utility tunnel. Additional stresses may develop in the superstructure, and increasing localized stress can result in uneven foundation conditions. This issue may cause settlement or cracking in the utility tunnel and even structural failure or collapse in severe cases, which can result in major safety incidents.

Figure 3: Integrated utility tunnel under the influence of multiple factors

Although considerable research has been conducted on the mechanical performance of underground structures, much of this work has focused on tunnels, subways, and underground stations. In the literature on utility tunnels, the main areas of study are seismic performance, impact of vehicle loads [8,9], and structural damage assessment [10,11]. However, there is limited research on the mechanical performance of utility tunnels under earth pressure. This performance is directly related to factors such as the depth of the soil cover, soil properties, and ground disturbances. The performance can manifest in forms such as horizontal displacement, vertical settlement, and ground tilting.

Current research on the settlement characteristics of underground structures can be divided into several methods: empirical formulas, theoretical analysis, model testing, numerical simulation, and machine learning. From a theoretical perspective, statistical and regression analysis based on monitoring data to establish ground settlement calculation models is a practical and effective approach. For example, based on soil disturbances caused by shield tunneling, Peck first proposed an empirical formula for lateral settlement, which did not account for soil consolidation, drainage, and creep. Many scholars have expanded on this work, and the formula is widely used to predict ground settlement in tunnel engineering [12].

Analytical methods are primarily based on consolidation theory and often incorporate viscoelastic–plastic models. For example, Liu [13] developed a coupled consolidation–creep model based on the Merchant rheological model and Terzaghi–Rendulic’s two-dimensional consolidation theory. This simplified method for tunnel settlement calculation accounts for factors such as surface loads, soil properties, structural self-weight, and train loads and reveals that long-term settlement in shield tunnels is related to the properties of the underlying soil layers.

The construction of utility tunnels in areas with special soil conditions presents significant challenges. In coastal regions, the foundation beneath utility tunnels often consists of soft soil, predominantly silty clay, which is characterized by high compressibility, high sensitivity, low permeability, and uneven thickness [14]. Soil replacement through filling is often not feasible. The varying foundation bearing capacity directly affects the mechanical performance of utility tunnels. In some cases, metro tunnels must be constructed below existing utility tunnels due to urban planning constraints. When the regional soil is unstable and the soil parameters significantly vary, the settlement of utility tunnels is more affected by the soil layers in which the tunnels are located [7].

International and domestic studies on the impact of nonuniform foundations on underground structures have focused mostly on buried pipelines and culverts [15]. Although utility tunnel structures are similar to buried pipelines, their structural stiffness, cross-sectional dimensions, and depth are significantly greater, and the interactions between the structure and the surrounding strata differ accordingly.

Theoretical research on the longitudinal deformation of underground structures has focused on the “beam–spring model” and equivalent continuum models [16]. In practical engineering, the longitudinal structure of utility tunnels consists of both monolithic cast-in-place sections and prefabricated segmented sections, which lead to varying longitudinal stiffness. Table 1 presents the current research on utility tunnel deformation, which typically combines multiple methods to account for more complex ground conditions and effectively reveals settlement patterns and their evolution mechanisms.

In recent years, the construction of utility tunnels has increased, and prefabricated buildings have been widely adopted because of their efficiency, which aligns well with the demands of utility tunnel projects. However, issues such as differential settlement at joints and frequent leakage are often observed, especially due to the variability in foundation bearing capacity and the decrease in the elastic modulus of soft soil layers [23].

Advances in artificial intelligence (AI) have led to the increasing application of machine learning (ML) algorithms in predicting tunnel-induced settlement, which account for multiple factors, such as environmental, construction, and time-related parameters [24,25]. Unlike traditional methods, ML does not require extensive geological parameter modelling or prior engineering experience. Instead, it utilizes computer simulations or learns from a given dataset to discover the coupling relationships of specified parameters. Pretrained models can quickly generate relevant data in real-world scenarios [26–28] and effectively capture the complex, dynamic, and nonlinear relationships hidden in monitoring data [29].

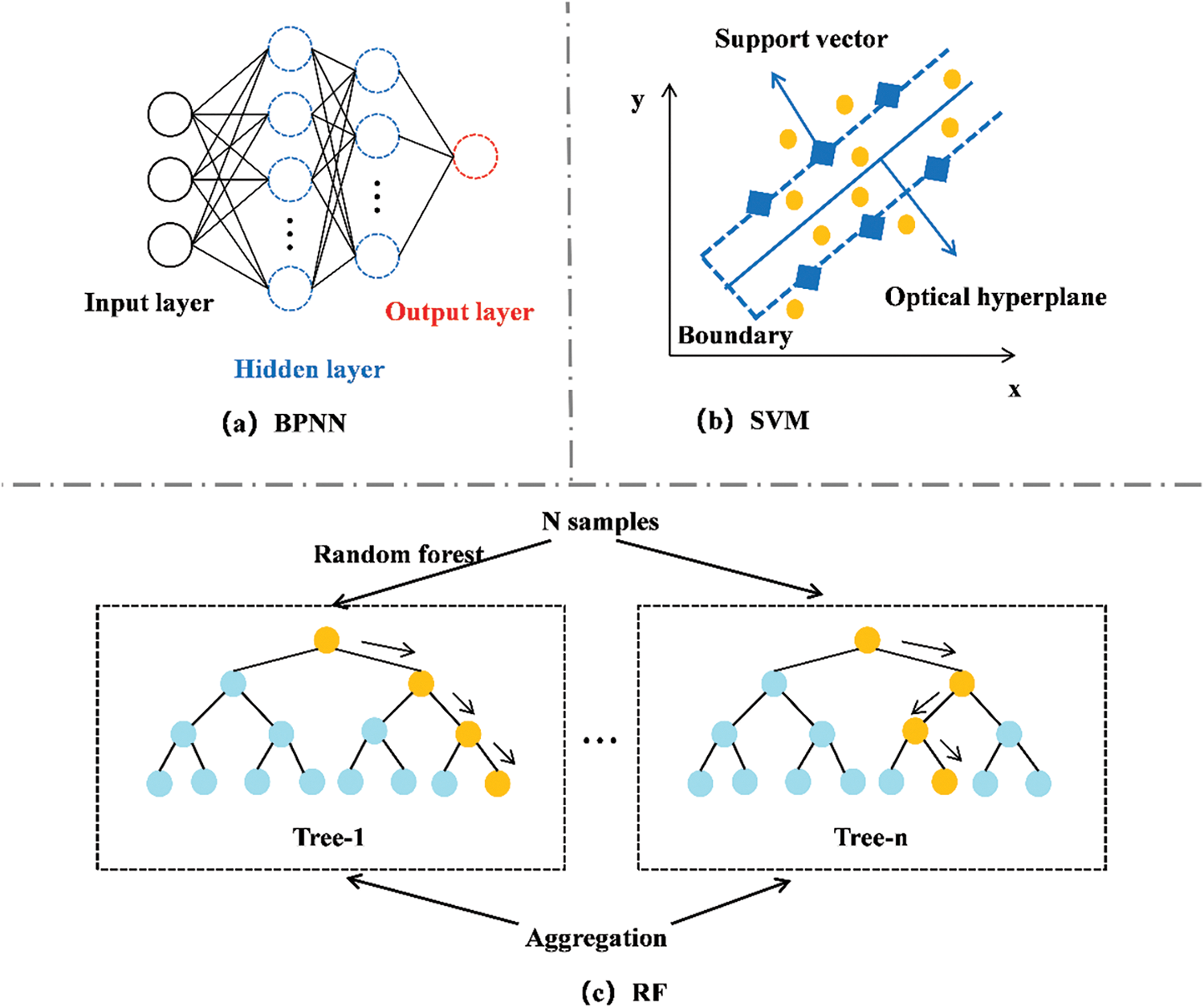

The performance of these models highly depends on the data quantity, quality, and preprocessing techniques. Researchers [30,31] have used various machine learning methods, such as backpropagation neural networks (BPNNs, Fig. 4a), support vector machines (SVMs, Fig. 4b), and random forest (RF, Fig. 4c), to predict the maximum ground surface settlement induced by tunnel boring. The results indicate that the RF model, which has acceptable time costs, excels in predicting large, concealed settlements, whereas SVMs are effective for preanalysis, where they balance the predictive accuracy and computational cost. However, BPNNs tend to have higher computational costs and lower accuracy. Table 2 provides a detailed overview of the application of AI methods in tunnel-induced ground settlement. Although AI applications in tunnel structures have yielded considerable achievements, there is an urgent need to expand research on performance analysis, especially for utility tunnels.

Figure 4: Schematic diagram of various machine learning methods: (a) backpropagation neural network (BPNN); (b) support vector machine (SVM); (c) random forest (RF)

Overall, theoretical research on the impact of nonuniform settlement on underground utility tunnels, particularly those with rectangular cross-sections, remains insufficient. Three-dimensional finite element models (FEMs) present significant challenges due to their large size, vast number of elements needed, and associated computational demands, including time consumption, resource intensity, and convergence difficulties. A key area of focus is how to efficiently determine the deformation and internal force distribution across various sections of utility tunnels under nonuniform settlement by integrating analytical solutions and machine learning techniques.

Currently, both domestic and international researchers have focused largely on the seismic performance of shield tunnels and other deeply buried structures. However, existing studies have shown that utility tunnels, as shallowly buried structures, are more susceptible to seismic damage. Their deformation is caused mainly by longitudinal nonuniform excitation from seismic waves, which leads to axial tension–compression and flexural deformation, and lateral ground motion, which induces lateral bending, rotation, side–way composite deformation, or warping deformation. Fig. 5 illustrates the typical failure modes of utility tunnels under seismic conditions. During seismic events, the lateral stiffness of utility tunnels is relatively high, and damage is often characterized by bending–shear failure. Cracks typically initiate at the haunch edges, and bending failure is observed at joints, particularly in the lower parts of the wall panels and areas near sections with varying cross-sections. Like other underground structures, utility tunnels are prone to damage areas with nonuniform soil conditions or significant cross-sectional changes, which lead to large-scale concrete spalling, through-cracks, misaligned or opened joints, and shear fractures caused by ground liquefaction or uplift [41]. Utility tunnels serve as critical urban infrastructures and house various municipal pipelines. When subjected to deformation during seismic events, acceleration-induced movements in the tunnel structure can easily trigger secondary disasters.

Figure 5: Classic failure modes of integrated utility tunnels under seismic effects

The key factors that affect seismic damage to utility tunnels include the constraint effect between the soil and tunnel structure, cross-sectional shape and cross-sectional dimensions. Research in this area typically utilizes four methods: prototype observation, theoretical analysis, model testing, and numerical simulation. In situ monitoring methods involve onsite inspections of underground structures to observe their operational conditions, acquire the dynamic characteristics of utility tunnels in real time during seismic events, and enable rapid earthquake reporting and response. Currently, strong-motion observation stations are deployed in free-field areas and across various building structures to monitor seismic activity. The structural type of strong-motion stations significantly impacts the recorded seismic motion under different site conditions and greatly varies with the natural vibration period and volume of the structure [42].

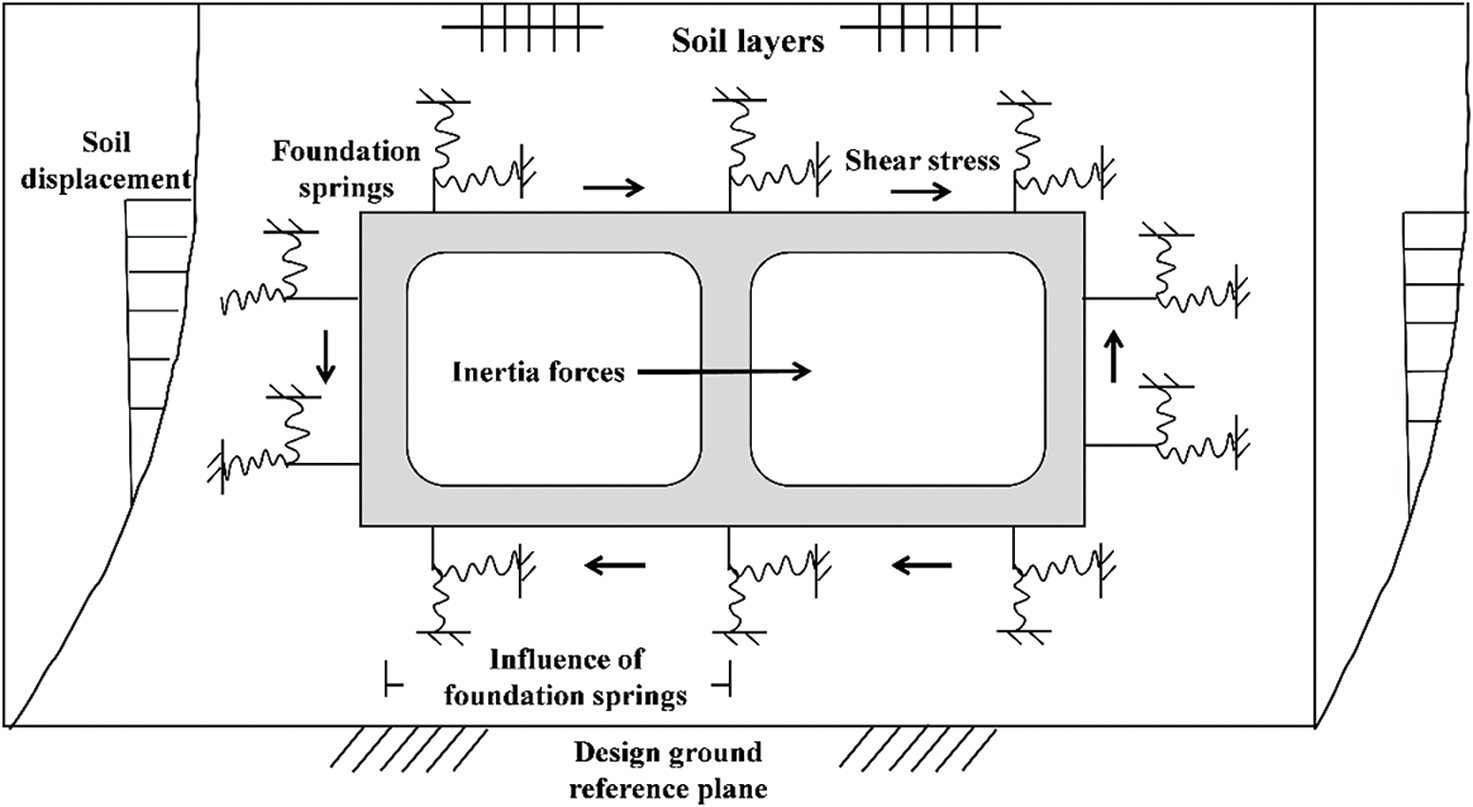

In simplified seismic design methods for underground structures, researchers commonly use the seismic coefficient method [43] (Fig. 6), free-field deformation method [44] (Fig. 7), response acceleration method [45] (Fig. 8), response acceleration method [46] (Fig. 9), and underground structure pushover method [47] (Fig. 10) for the seismic analysis of underground cross-sections. These methods provide convenient calculations and analyses, but they struggle to capture the variations in the dynamic properties of the soil and critical structural details such as tunnel joints. Additionally, they cannot accurately describe the nonlinear response of components that transition from continuous to discrete behaviour under strong seismic action [48].

Figure 6: Seismic coefficient method

Figure 7: Free-field deformation method

Figure 8: Response displacement method

Figure 9: Response acceleration method

Figure 10: Underground structure pushover method

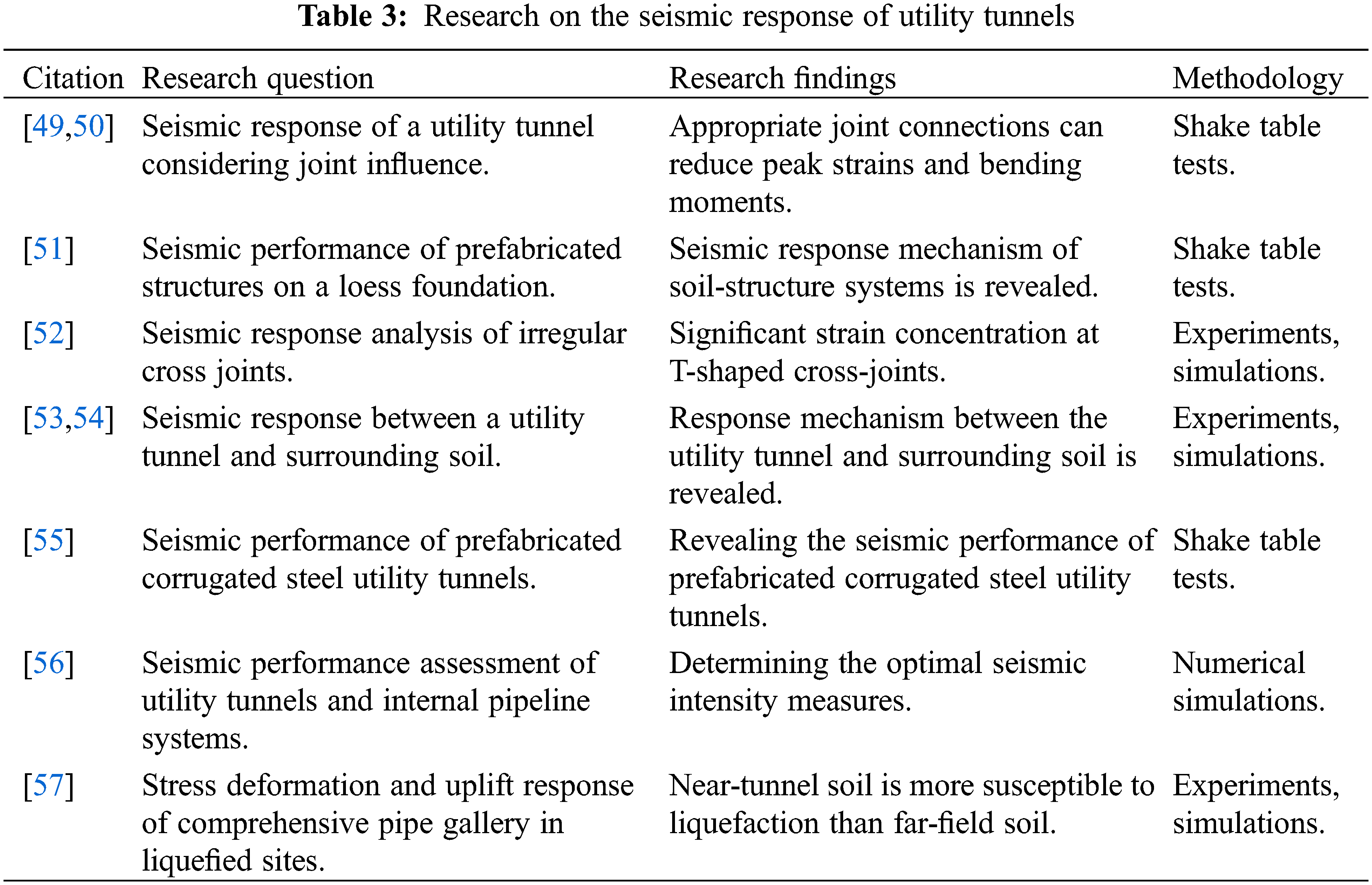

Table 3 presents research on the seismic response of utility tunnels. Utility tunnels are complex segmented, long-line structures. Although model testing is an effective approach to study the seismic damage response of utility tunnels, the fabrication and assembly of models require significant engineering effort. Furthermore, replicating the actual dynamic response of utility tunnels under seismic conditions is limited by the testing environment. However, with the advancement of various numerical simulation software, these limitations have been effectively mitigated. This progress has facilitated interdisciplinary research in areas such as joint structures, heterogeneous soil layers, soil–structure interactions, and seismic-induced soil failure in relation to utility tunnels.

With the rapid development of prefabricated utility tunnels, the trend is shifting towards multichamber designs, larger structural space scales, and more complex local node constructions, which pose greater demands. These tunnels must simulate the deformation and failure mechanisms of vulnerable areas at a microscopic scale while ensuring the balance and coordination of the stress–strain relationships of the macro- and micro-models to enable smooth energy transitions. For abnormally large cross-section tunnels situated in weak soil layers, full lightweight concrete prefabricated utility tunnels have demonstrated excellent seismic performance [58,59], and prefabricated seismic solutions [60] can constitute a viable strategy. In the longitudinal seismic analysis of multichamber prefabricated tunnels with asymmetrical cross-sections, the shell–spring model, which incorporates the effects of prestressed steel strands [61], compensates for the shortcomings of the traditional beam–spring model [62] in reflecting the shear characteristics and internal force distribution of the structure across the cross-section.

In conclusion, although there has been extensive research on seismic damage to utility tunnels, the rapid urbanization process presents new challenges. Utility tunnels are increasingly being constructed near existing buildings or bridge foundations. The seismic response of complex interaction systems that involve building cluster–soil–utility tunnel structures remains underexplored. Additionally, when finite element models of foundation soil are established, the assumption of homogeneous soil layers is often unrealistic. Existing longitudinal seismic analyses of underground utility tunnel structures, which are mostly based on beam–spring models, must be further refined to more accurately reflect real-world conditions. To adapt to complex and unfavourable site conditions, further research is necessary on the dynamic coupling mechanism of strong earthquakes and the catastrophic mechanism that affects long-line utility tunnel structures.

The construction of utility tunnels has provided a convenient new method for transporting gas and reducing environmental corrosion and damage to pipelines and cables. These tunnels can accommodate two or more types of urban engineering pipelines [63,64], which makes them important solutions for addressing various pipeline and facility layout issues. However, they also introduce new risks.

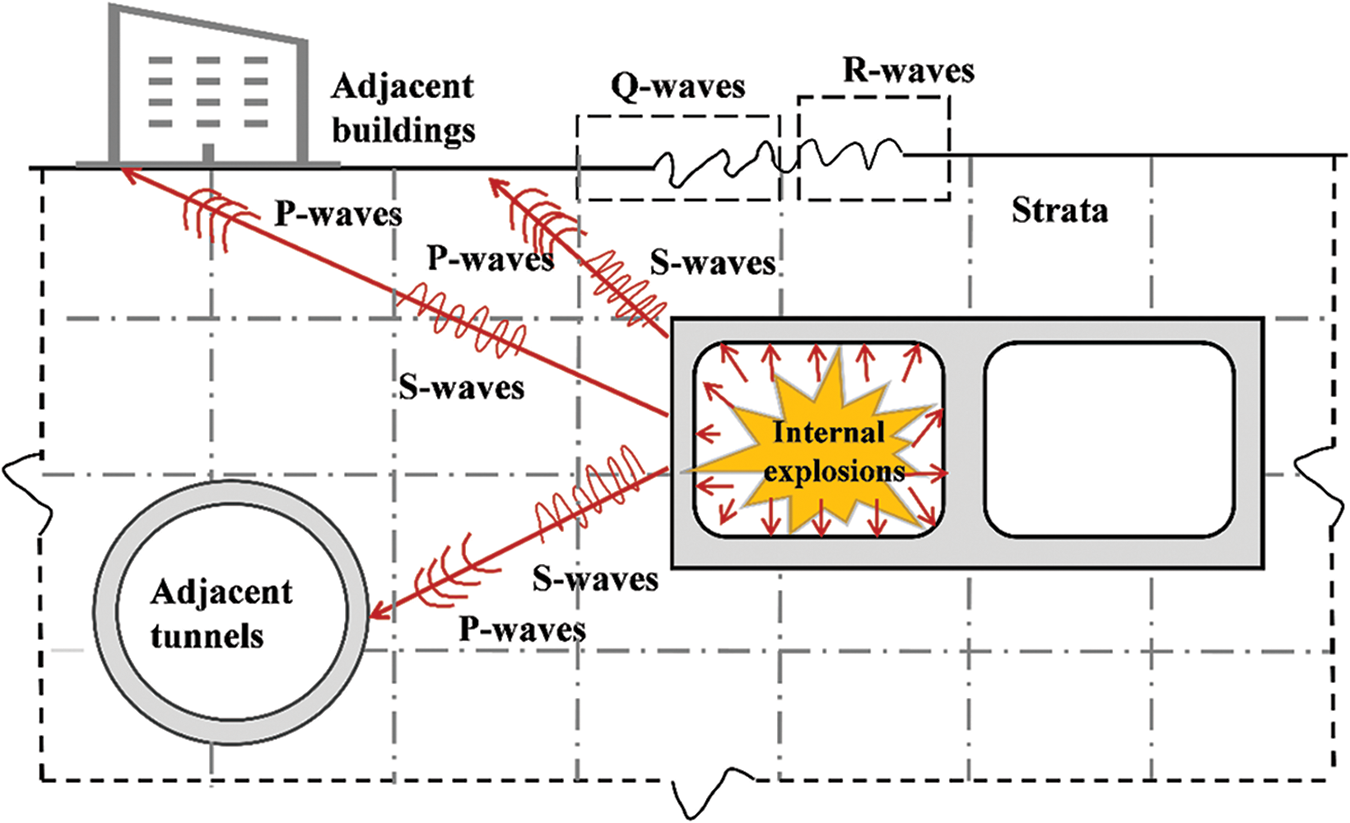

The natural gas compartments inside utility tunnels contain supporting infrastructure such as concrete brackets, fire extinguishing boxes, and metal wire frames, which make the analysis of flame characteristics more complex than that for traditional gas pipelines [65,66]. Additionally, the fire source is not fixed and can spread along internal cables, which can result in varied temperature distributions and smoke diffusion [67,68]. Current research on the blast resistance of utility tunnels focuses mainly on internal and external explosions, where internal explosions are typically caused by gas leaks. These gas leaks are due primarily to factors such as natural corrosion and stress-induced perforations in gas pipelines. This process involves strong dynamic changes, which include multiple complex chemical reactions. When gas leaks occur, smoke rapidly spreads along the tunnel compartments, accumulates, and forms explosive premixed gas. The resulting high-temperature, high-pressure shock waves can affect adjacent compartments in underground utility tunnels and nearby surface structures.

Fig. 11 illustrates the effects of internal explosions in utility tunnels. Stress waves generated by explosions propagate as compression waves (P-waves) and shear waves (S-waves), transmit to the surrounding tunnel structure, and can severely affect the ground layers and endanger neighbouring underground structures. Additionally, when explosive stress waves reach the surface, Love (Q) waves, Rayleigh (R) waves, and travelling body waves (P-waves and S-waves) can further impact the stability of nearby surface buildings.

Figure 11: Schematic diagram of explosions in utility tunnels

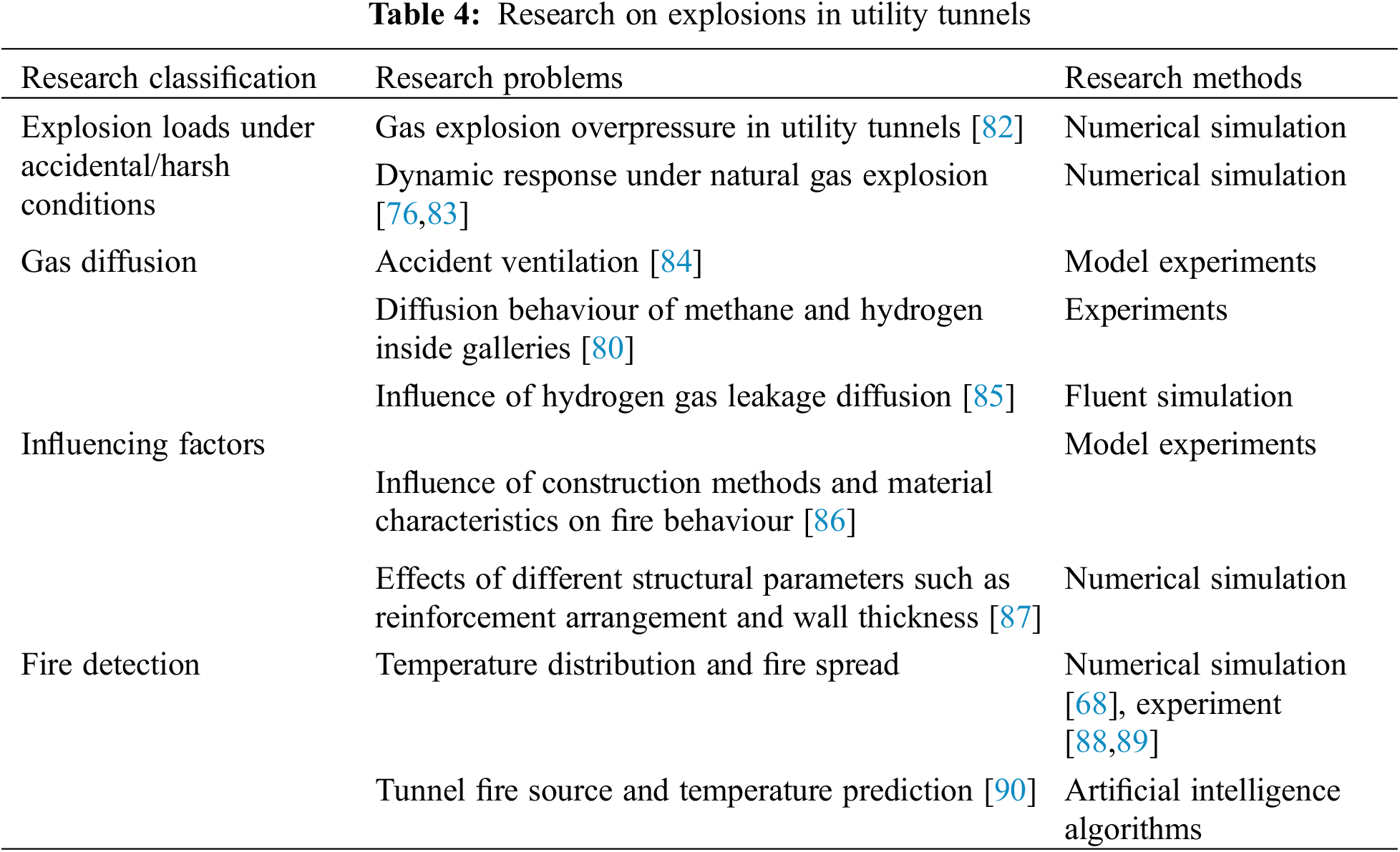

Table 4 summarizes the research on utility tunnel explosions, which can be divided into studies on the performance of utility tunnels under explosive loads, studies on gas diffusion, and studies on fire behaviour and detection. Gas diffusion theory [69] is well developed, where the Gaussian model [70] is widely applied in open environments. For gas diffusion in confined spaces [71], experimental or numerical simulations are more common. Experimental studies are typically conducted in shock tubes or narrow underground tunnels. The use of numerical software such as OpenFOAM [72], FLACS [73–75], LS-DYNA [76], and FLUENT [77] has effectively mitigated the high-risk and high-cost nature of explosion experiments, which enables the study of multicomponent hydrogen-containing gas leaks in confined spaces [78,79]. Hydrogen, as a new energy carrier, poses significant explosion risks and hydrogen embrittlement concerns. During transportation, the confined space of the gas compartment of a utility tunnel increases the explosion risk compared with aboveground or buried pipelines. Research [80], which is based on a three-dimensional numerical model, has examined the diffusion behaviour of methane and hydrogen in utility tunnels and revealed that hydrogen has a higher diffusion rate and a higher concentration than methane does. Moreover, the nonlinear characteristics of fire risk prediction in cases of leaks in a tunnel are significant, and algorithms such as artificial neural networks [81] can effectively improve the prediction accuracy.

Reducing the energy wave released during an explosion is the key factor in explosion suppression. For explosion mitigation techniques and methods, various chemical suppressants [91] are commonly used. Considering the one-time use of chemical suppressants, the use of reusable porous adsorption materials has emerged as a novel physical explosion suppression measure. Experimental studies [92] have investigated the flame propagation and dynamic pressure distribution under the suppression of porous media and have shown that this material has a certain explosion suppression effect when it is used as a utility tunnel lining. Considerable research has been conducted on explosion suppression, which involves various porous metal materials, such as metal foams [93], metal meshes [94], and steel wool [95]. These studies offer insights into the sidewall materials of utility tunnels and their effects on the propagation of explosion waves and flames.

In conclusion, although significant progress has been made in studying the explosion performance of utility tunnels based on their structural characteristics, research must be expanded on the overpressure and temperature change patterns during gas explosions. The reasons are the complex structure of gas compartments in underground utility tunnels and insufficient understanding of internal energy changes during deflagration. Furthermore, there are no clear design parameters for porous structures and no comprehensive evaluation standards for engineering applicability and explosion suppression effectiveness, so many issues have not been addressed.

3 Intelligent Operation and Maintenance Architecture

In the past, underground infrastructure operation and maintenance relied primarily on manual inspections with relevant standards and regulations to provide damage identification results and state assessment ratings. However, digitalization, automation, and intelligent systems have become inevitable in the transformation of traditional industries. Intelligent systems differ from automation by leveraging advanced technologies such as machine learning, deep learning, knowledge graphs, and computer vision. These systems emphasize adaptive learning and autonomous decision-making.

Smart utility tunnels support the development of new productive forces by integrating traditional utility tunnels with modern information and communication technologies (ICTs). Using technologies such as the Internet of Things (IoT), 5G, artificial intelligence (AI), and big data, various smart tunnel cloud platforms have emerged and fostered the intelligent and digital transformation of utility tunnel systems.

Fig. 12 illustrates the architecture of an intelligent utility tunnel operation and maintenance system. The system consists of a perception layer, a transmission layer, a data layer, a service layer, and an application layer. High-dimensional spatial structural data and damage characteristics are extracted via sensors installed on the tunnel body (such as displacement metres and gas alarm detectors) or mounted on drones (such as microcameras, laser scanners, and infrared thermal imagers). Data are transmitted via protocols such as HTTP or dedicated fibre optic networks. By integrating IoT technology and big data analysis, the system facilitates data recognition, organization, learning, and prediction. Finally, AR/VR/MR devices are used to present the data and enable real-time monitoring, model management, emergency management, etc. This approach establishes a comprehensive intelligent operation and maintenance system for utility tunnels.

Figure 12: Construction of intelligent operation and maintenance systems

The intelligent operation and maintenance (O&M) architecture must be designed on the basis of the specific purpose and characteristics of a utility tunnel. For example, in power tunnels, compared with traditional cable installations, more monitoring devices such as gas sensors and cable surface temperature sensors must be deployed. By researching system hardware and software architectures, system function design, and feature point tracking algorithms, functionalities such as inspection route planning, equipment location prompts, and gesture-based data recall for devices can be implemented to monitor the operational status of equipment and cables in real time.

The sensing layer encompasses various detection technologies. During utility tunnel O&M, problems such as leakage, segment misalignment, and segment deformation may occur. Traditional hazard monitoring techniques involve instruments such as strain gauges, load sensors, inclinometers, and accelerometers to measure strain, load, pressure, deformation, tilt, and vibration. However, these methods suffer from low monitoring efficiency, slow response times, and inaccurate measurement points [96]. New monitoring technologies with features such as fast data acquisition, wide monitoring coverage, and high precision, including 3D laser scanning monitoring technology (3D LSMT), optical fibre sensing technology (OFST), and photogrammetry, have emerged [97].

Table 5 categorizes various monitoring and sensing technologies, which integrate multiple methods that assist in evaluating decision-making tasks. These methods include the use of geodetic data from the Global Positioning System (GPS), Interferometric Synthetic Aperture Radar (InSAR), and strain sensors to invert the cumulative shallow surface strain in utility tunnels [98], multipoint fibre optic methane remote sensing technology based on pseudodifferential detection [99], and quantum gravity gradient sensors for underground tunnel detection [100].

Multisensor information fusion technology achieves the intelligence of the entire sensor system through multilevel and multidimensional complementary optimization of different sensors. These methods can be categorized into three levels: data layer fusion processing, feature layer fusion processing, and decision layer fusion processing [110]. The focus is on how to make advanced decisions based on application requirements, while the challenges lie in the technical barriers faced by the underlying algorithms. Ding et al. [111] proposed a data fusion method that uses rotation and strain gauge measurements to estimate the deformation of shield tunnel segments, which has been successfully deployed in practical projects. Zhang et al. [112] employed Dempster-Shafer (D-S) evidence theory to integrate multisensor data, achieving time-varying predictions and probability warnings for tunnel fault classification based on collaborative multisensor data fusion.

Currently, most inspection systems within underground cable tunnels utilize track-based and wheeled robots. While these systems provide advantages in terms of stability and safety, they also present drawbacks, including high costs and sensitivity to terrain variations. The introduction of simultaneous localization and mapping [113] (SLAM) technology, which is equipped with various sensor systems, such as vision, laser, and ultrasonic sensors, holds promise for achieving high-precision and robust localization and mapping capabilities across diverse complex scenarios.

3.2 Transmission and Data Layers

The network transmission layer provides a data transmission channel that supports data exchange and communication among various nodes in a utility tunnel. The arrangement of the sensor nodes determines the monitoring coverage of the utility tunnel. Both the reception and transmission of monitoring information consume energy. An effective solution to achieve low-power consumption in monitoring data transmission is wireless sensor network technology [114]. The transmission layer stores front-end embedded data, sensor device data, and back-end data in the database during operations and maintenance. Owing to the internal and external influences on the utility tunnel structure, monitoring data from various parts of the tunnel often exhibit multilayered changes, which reflect the underlying mechanical transformation characteristics. Extracting the information hidden behind the vast amount of data to empower utility tunnel management is challenging and requires robust data processing and analysis capabilities. Big data technology excels at handling and preprocessing large amounts of operational data, supports the training of machine learning models, and revitalizes utility tunnel management. This technology helps address previous challenges in accurately identifying structural damage due to incomplete data coverage and insensitivity to dynamic characteristics.

Supported by advanced sensing technologies, a wide range of data can be collected and recorded throughout the tunnel’s entire lifecycle, providing a foundation for deep learning models. High-quality datasets are crucial for ensuring effective model training. However, geospatial data, which are obtained primarily through geological exploration and geophysical methods (e.g., resistivity, seismic reflection, and gravity surveys), are inherently discrete. Additionally, the varied acquisition frequencies of sensors result in imbalances between geospatial and other monitoring data, impacting the construction and utilization of operational datasets. Table 6 outlines the data preprocessing methods used for tunnel monitoring and analysis, which support subsequent analyses and decision-making.

Recent advancements in computer vision [126], machine learning [127,128], and deep learning methods in the field of underground utility tunnel health monitoring and damage detection include improved backpropagation algorithms for crack detection on tunnel walls in complex environments [127], multi-instance learning-driven anomaly detection for personnel monitoring in video surveillance systems [129], anomaly detection in utility tunnels based on image processing and multi-instance learning [130], and intelligent control of tunnel temperature and humidity environments via an LSTM-RNN architecture [131].

Fig. 13 shows an example of the use of big data analysis techniques for performance prediction in utility tunnels. When constructing models, the highly nonlinear and high-dimensional nature of the data requires maximum fitting to achieve predetermined performance indicators. On the basis of the measured responses, regression neural networks are used for intelligent inversion to help researchers identify optimal parameters and understand soil properties, groundwater conditions, and seismic impacts. Then, the model predicts the monitoring data over a certain period; if the results exceed the warning threshold, the relevant units are promptly notified to take action.

Figure 13: Utility tunnel performance prediction driven by big data

Although the aforementioned technologies have various applications, the complexity of utility tunnel systems presents certain challenges. Issues such as the difficulty of training data collection, the need for high responsiveness in security scenarios, and limitations of hardware resources must be addressed. To optimize relevant algorithms and technologies, mitigating issues such as overfitting, large model sizes, and response delays is essential.

Integrating technologies such as data fusion and integration, intelligent monitoring and diagnostics, data mining and analysis, distributed computing and edge computing, and deep learning is crucial for overcoming the complexity and diversity of data in utility tunnels. By addressing these challenges, we can revitalize the comprehensive monitoring and precise management of utility tunnel operations. This approach will promote the safe and stable operation of these systems and provide robust support for the sustainable development of urban infrastructure.

3.3 Service and Application Layer

After a utility tunnel has been put into operation, the BIM model (building information modelling), which has accumulated data during the construction phase, can output a 3D model that includes the structural components and internal facilities. By aggregating BIM model data, utility tunnel operational data, and third-party data and utilizing big data techniques for filtering, analysis, and mining, relationships can be modelled to establish an interactive mechanism [132]. This process helps formulate intelligent control strategies, creates a knowledge base of trigger conditions and response measures [133] and ultimately builds a new framework for smart utility tunnels [134]. This approach can reduce the labour intensity of operations and maintenance personnel, decrease maintenance costs, and improve the emergency response to accidents and disasters.

BIM modelling focuses primarily on the design and management of the overall building project, but it does not attribute mechanical properties to structural components, which limits the breadth and depth of its application in operation and maintenance platforms. Moreover, numerical simulation software such as Abaqus, Ansys, Plaxis, and FLAC 3D emphasize the analysis of the mechanical behaviour and stress distribution of structures, decompose the structure into numerous small elements and predict its responses to different loads based on mechanical principles and mathematical models. However, developing refined models for complex structures via these methods is challenging and time-consuming.

Therefore, advancing the integration of BIM digital models with finite element models will facilitate the digital, refined, and substantive analysis of structures to increase the ability to interact and exchange information among systems. This integration enables a more comprehensive understanding of the design and mechanical performance of structures in the context of utility tunnels.

Fig. 14 illustrates the conversion principle between the BIM model and structural analysis model, where an intermediate file in the Industry Foundation Classes (IFC) format acts as the “bridge.” The parameters and attributes of the BIM model are extracted and subsequently converted into the language of mechanical models. There have been several applications, such as the development of BIM-ABAQUS data conversion interfaces [135] and the analysis of ground settlement via BIM-ANSYS-FLAC3D data conversion [136].

Figure 14: Principles of the BIM and structural analysis model conversion

In addition to the identification of structural damage and deformation, 3D reconstruction [137] can be used to describe the topological relationships and similarities of large-span structural components of utility tunnels via computer vision and deep learning. Information from various data sources, such as laser scanning, drone imagery, and satellite images, can be integrated for visualization, analysis, and simulation. However, obtaining high-quality point clouds is often challenging since they tend to have specific applicability and may not be transferable to other structures.

In summary, although simulation software can provide model conversion based on the IFC standard, differences in data file types imply that BIM applications often remain in a unidirectional transfer mode. The databases and corresponding plugins across platforms are not universally compatible, and there is no interoperability among multiple platforms. Therefore, a complete model conversion system is necessary to efficiently translate BIM models across different software platforms. Moreover, the efficiency and accuracy of intelligent agents in solving complex control equations must be improved.

In construction maintenance, technologies such as new surveying, identification sensing, collaborative computing, full-element representation, and simulation modelling have rapidly advanced, have been driven by the Fourth Industrial Revolution, and are converging into a collective force for digital twin applications. There is growing interest in the digital twin-driven management of underground 3D spatial information infrastructure and disaster response services, which has led to the proposal of a unified paradigm for multisource data fusion in urban disaster digital twins [138] This process has facilitated the development of digital twin-driven intelligent decision-making platforms [139] and enhanced capabilities in managing and responding to urban infrastructure needs such as utility tunnels.

Fig. 15 illustrates the construction of a digital twin. As a key technology for “virtual-physical integration” in operation and maintenance, digital twins and cyber-physical systems can be applied to utility tunnel systems. With the concept of a digital twin, dynamic virtual models of physical structures are created to replicate the attributes of real-world entities. These models capture sensory data related to environmental conditions and structural responses and feed this information back to the model layer in real time. Finally, based on intelligent algorithms, the system enables autonomous decision-making for tasks such as structural performance evaluation [140–142], disaster scenario simulations [143], and vulnerability analyses for disaster prevention [144].

Figure 15: Construction of a digital twin

With respect to research on technologies and intelligent systems for data monitoring in utility tunnels, experts and scholars have made innovative advancements in several areas. These advancements include the development of early warning systems based on various intelligent technologies [145], safety monitoring systems for utility tunnels via data fusion analysis [146], intelligent inspection robots [147,148], and smart surveillance devices [149]. These studies focused on planning, seismic design, structural design, and fire risk analysis and achieved a series of breakthroughs and outcomes. These innovations have provided multiple solutions for the safe operation and maintenance of smart utility tunnels.

The exploration of an integrated information management platform for utility tunnels is currently in a critical phase of development. Intelligent operation and maintenance platforms built on monitoring systems have reached a mature stage in systematically studying the monitoring of pipelines and equipment in utility tunnels and the operational environment. However, there is a significant lack of research regarding the analysis of real-time operational data, particularly in predicting the dynamic responses of the utility tunnel structure and its interaction with surrounding geological conditions. Fig. 16 outlines the construction and development framework for utility tunnels and highlights future trends towards “multi-pipeline shared chamber design,” “lightweight auxiliary systems,” “cross-sectional compact optimization,” and “functional integration optimization.” These advancements aim to enhance the service performance of utility tunnels by utilizing new materials and promoting the intelligence of auxiliary facilities. This approach is expected to address previous challenges, such as high operational costs, frequent accidents, data silos, and a low level of system intelligence. Ultimately, it will strengthen urban resilience and open new chapters in construction planning and operational management.

Figure 16: Utility tunnel construction and development

This work reviewed the existing research methods and technologies related to three representative disaster factors (settlement, fire and explosion, earthquakes) during the operation and maintenance phases of utility tunnels. It also clarified the current status of utility tunnel operation and maintenance frameworks and highlighted areas where their application is lacking. The following points are proposed for future research reference:

(1) As emerging infrastructures, utility tunnels have been widely studied in areas such as planning, seismic design, structural design, and fire risk analysis. However, with the trend towards multichamber designs, larger structural spaces, and increasingly complex local node configurations, future research can focus on the following directions:

Interaction response characteristics of systems that involve “surface buildings (clusters)—soil—tunnel structures (clusters)”.

The catastrophic mechanism for complex nodes, such as intersecting utility tunnels, considers the dynamic coupling effects between structures and surrounding environmental media.

A comprehensive evaluation of the engineering applicability of new materials for utility tunnels and their effectiveness in explosion suppression was performed.

(2) Based on the initial data model and relying on theoretical computational methods for underground structures, future research should aim to combine the structure with the surrounding soil layers and incorporate BIM information models and simulation software. The goal is to develop modelling methods that accurately reflect the actual conditions of utility tunnels, which include the development of collaborative and shared utility tunnel engineering coupling models, to form a complete model conversion system.

(3) Although innovations in digital inspection technologies, personnel tracking, and environmental monitoring within tunnels are important, a key focus should be on enhancing the ability for automatic monitoring and comprehensive sensing in utility tunnels. Effectively integrating long-term uncertain monitoring data and using intelligent algorithms to extract the underlying mechanical properties are essential. By combining this approach with whole-life-cycle safety management, researchers can predict structural parameters such as deformation and acceleration. The creation of an intelligent operation and maintenance system that organically integrates physical laws with data paradigms will be a critical area for developing new technologies to evaluate the safety of utility tunnel structures.

Acknowledgement: None.

Funding Statement: This work was financially supported by the Scientific Research Projects of the Education Department of Zhejiang Province (Grant No. Y202454744), the Ningbo Public Welfare Science and Technology Project (Grant Nos. 2023S007 and 2023S165), and the Key Research and Development Program of Zhejiang (Grant No. 2023C03183).

Author Contributions: The authors confirm the contributions to the paper as follows: Writing—original draft, investigation, data collection: Jie Zou; Conceptualization, methodology, investigation: Ping Wu; Resources: Jianwei Chen; Funding acquisition: Weijie Fan; Study conception and design, funding acquisition: Yidong Xu. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data and materials utilized in this study are available upon request from the corresponding author, Ping Wu, upon reasonable inquiry. For inquiries regarding the availability of specific data or materials, please contact Ping Wu at wuping@nit.zju.edu.cn.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Huang BT, Dai JG, Weng KF, Zhu JX, Shah SP. Flexural performance of UHPC-concrete–ECC composite member reinforced with perforated steel plates. J Struct Eng. 2021;147(6):04021065. doi:10.1061/(ASCE)ST.1943-541X.0003034. [Google Scholar] [CrossRef]

2. Huang B-T, Zhu J-X, Weng K-F, Huang J-Q, Dai J-G. Prefabricated UHPC-concrete-ECC underground utility tunnel reinforced by perforated steel plate: experimental and numerical investigations. Case Stud Constr Mater. 2022;16(11):e00856. doi:10.1016/j.cscm.2021.e00856. [Google Scholar] [CrossRef]

3. Qian H, Li J, Zong Z, Wu C, Pan Y. Behavior of precast segmental utility tunnel under ground surface Explosion: a numerical study. Tunnell Undergr Space Technol. 2021;115:104071. doi:10.1016/j.tust.2021.104071. [Google Scholar] [CrossRef]

4. Dai X, Xu G, Huo H, Cheng X, Yan X. Three-dimensional finite element analysis of impact of utility tunnel construction on overlying deep excavations. Chin J Geotech Eng. 2019;41(S1):21–4 (In Chinese). [Google Scholar]

5. Zhou J, Guo H, Koopialipoor M, Jahed Armaghani D, Tahir M. Investigating the effective parameters on the risk levels of rockburst phenomena by developing a hybrid heuristic algorithm. Eng Comput. 2021;37(3):1679–94. doi:10.1007/s00366-019-00908-9. [Google Scholar] [CrossRef]

6. Liu W, Wu B, Shi P, Xu X. Analysis on face stability of rectangular cross-sectional shield tunneling based on an improved two-dimensional rotational mechanism. Acta Geotech. 2021;16(11):3725–38. doi:10.1007/s11440-021-01219-4. [Google Scholar] [CrossRef]

7. Wei S, Zenglin H, Min Y, Ning L, Tianxiang T. Impact of subway shield tunnel construction on deformation of existing utility tunnel. Front Earth Sci. 2023;11:1104865. doi:10.3389/feart.2023.1104865. [Google Scholar] [CrossRef]

8. Jiang L, Xie Z, Huang Y. Prototype test study on dynamic stress of utility tunnel under traffic load. J Vibroeng. 2020;22(1):170–83. doi:10.21595/jve.2019.20483. [Google Scholar] [CrossRef]

9. Che H, Tong L, Liu S, Yang Q. Field investigation on the mechanical performance of corrugated steel utility tunnel (CSUT). J Constr Steel Res. 2021;183(1):106693. doi:10.1016/j.jcsr.2021.106693. [Google Scholar] [CrossRef]

10. Kong G, Wu D, Wei Y. Experimental and numerical investigations on the energy and structural performance of a full-scale energy utility tunnel. Tunnel Undergr Space Technol. 2023;139(3):105208. doi:10.1016/j.tust.2023.105208. [Google Scholar] [CrossRef]

11. Wang X, Ma Z, Zhang Y. Research on safety early warning standard of large-scale underground utility tunnel in ground fissure active period. Front Earth Sci. 2022;10:828477. doi:10.3389/feart.2022.828477. [Google Scholar] [CrossRef]

12. Zhou Z, Chen Y, Liu Z, Miao L. Theoretical prediction model for deformations caused by construction of new tunnels undercrossing existing tunnels based on the equivalent layered method. Comput Geotech. 2020;123(3):103565. doi:10.1016/j.compgeo.2020.103565. [Google Scholar] [CrossRef]

13. Liu J. Long-term settlement calculation of shield tunnel in section of deep soft ground in Nansha District, Guangzhou. Tunnel Constr. 2020;40:138–44. [Google Scholar]

14. Lin P, Chen X, Jiang M, Song X, Xu M, Huang S. Mapping shear strength and compressibility of soft soils with artificial neural networks. Eng Geol. 2022;300(5):106585. doi:10.1016/j.enggeo.2022.106585. [Google Scholar] [CrossRef]

15. Jia P, Zhao W, Khoshghalb A, Ni P, Jiang B, Chen Y, et al. A new model to predict ground surface settlement induced by jacked pipes with flanges. Tunnel Undergr Space Technol. 2020;98:103330. doi:10.1016/j.tust.2020.103330. [Google Scholar] [CrossRef]

16. Chuan H, Jing Z, Kun F. Research on structural analysis method of shield tunnels. China J Highw Transp. 2017;30(8):1–14 (In Chinese). [Google Scholar]

17. Deng B, Zheng X, Shen C, Fu Y. Study on dynamic response characteristics of shallow buried pipe gallery structure under vehicle vibration load. Soil Dyn Earthquake Eng. 2024;181(11):108597. doi:10.1016/j.soildyn.2024.108597. [Google Scholar] [CrossRef]

18. Tong L, Zhou H, Liu H, Ding X. Failure envelope of an underground rectangular pipe gallery in clay under pipe-soil interactions. Int J Geomech. 2023;23(1):04022261. doi:10.1061/(asce)gm.1943-5622.0002631. [Google Scholar] [CrossRef]

19. Zhao C, Lei M, Shi C, Cao H, Yang W, Deng E. Function mechanism and analytical method of a double layer pre-support system for tunnel underneath passing a large-scale underground pipe gallery in water-rich sandy strata: a case study. Tunnel Undergr Space Technol. 2021;115:104041. doi:10.1016/j.tust.2021.104041. [Google Scholar] [CrossRef]

20. Yang M, Li H, Li N, Yang S. Effect of subway excavation with different support pressures on existing utility tunnel in Xi’an loess. Adv Civ Eng. 2020;2020(1):1–14. doi:10.1155/2020/8818949. [Google Scholar] [CrossRef]

21. Sun W, Han F, Zhang Y, Zhang W, Zhang R, Su W. Experimental assessment of structural responses of tunnels under the groundwater level fluctuation. Tunnell Undergr Space Technol. 2023;137:105138. doi:10.1016/j.tust.2023.105138. [Google Scholar] [CrossRef]

22. Zhang Y, Duan L, Li Y, Gao M. Study on deformation characteristics of underground pipeline corridors and uneven settlement factors of foundations in sandy chalky soil layer. Front Earth Sci. 2024;11:1266559. doi:10.3389/feart.2023.1266559. [Google Scholar] [CrossRef]

23. Wang Z, Wang Y, Huang W, Shan H, Zhu L. Research on natural foundation bearing capacity and foundation pit settlement of prefabricated utility tunnel. Adv Civ Eng. 2022;2022(1):5361199. doi:10.1155/2022/5361199. [Google Scholar] [CrossRef]

24. Zhang K, Lyu H-M, Shen S-L, Zhou A, Yin Z-Y. Evolutionary hybrid neural network approach to predict shield tunneling-induced ground settlements. Tunnell Undergr Space Technol. 2020;106(2):103594. doi:10.1016/j.tust.2020.103594. [Google Scholar] [CrossRef]

25. Ye X-W, Jin T, Chen Y-M. Machine learning-based forecasting of soil settlement induced by shield tunneling construction. Tunnell Undergr Space Technol. 2022;124(2):104452. doi:10.1016/j.tust.2022.104452. [Google Scholar] [CrossRef]

26. Oh S, Ki H. Deep learning model for predicting hardness distribution in laser heat treatment of AISI H13 tool steel. Appl Therm Eng. 2019;153:583–95. doi:10.1016/j.applthermaleng.2019.01.050. [Google Scholar] [CrossRef]

27. Wang K, Shi X, Goh APX, Qian S. A machine learning based study on pedestrian movement dynamics under emergency evacuation. Fire Saf J. 2019;106:163–76. doi:10.1016/j.firesaf.2019.04.008. [Google Scholar] [CrossRef]

28. Kim J-S, Kim D-Y, Kim Y-T. Experiment on radial inflow turbines and performance prediction using deep neural network for the organic Rankine cycle. Appl Therm Eng. 2019;149(8):633–43. doi:10.1016/j.applthermaleng.2018.12.084. [Google Scholar] [CrossRef]

29. Zhang W, Zhang R, Wang W, Zhang F, Goh ATC. A multivariate adaptive regression splines model for determining horizontal wall deflection envelope for braced excavations in clays. Tunnell Undergr Space Technol. 2019;84(3):461–71. doi:10.1016/j.tust.2018.11.046. [Google Scholar] [CrossRef]

30. Tang L, Na S. Comparison of machine learning methods for ground settlement prediction with different tunneling datasets. J Rock Mech Geotech Eng. 2021;13(6):1274–89. doi:10.1016/j.jrmge.2021.08.006. [Google Scholar] [CrossRef]

31. Zhang P, Wu H-N, Chen R-P, Chan TH. Hybrid meta-heuristic and machine learning algorithms for tunneling-induced settlement prediction: a comparative study. Tunnell Undergr Space Technol. 2020;99(6):103383. doi:10.1016/j.tust.2020.103383. [Google Scholar] [CrossRef]

32. Huang C, Du H, Li L, Ni J, Sun Y. Application of tree-based methods in predicting the surface settlement arising from the tunnel excavation with large mix-shield. Soils Found. 2023;63(6):101379. doi:10.1016/j.sandf.2023.101379. [Google Scholar] [CrossRef]

33. Zhou X, Zhao C, Bian X. Prediction of maximum ground surface settlement induced by shield tunneling using XGBoost algorithm with golden-sine seagull optimization. Comput Geotech. 2023;154(4):105156. doi:10.1016/j.compgeo.2022.105156. [Google Scholar] [CrossRef]

34. Wen Z, Guo L, Meng S, Rong X, Shi Y. IoT-assisted feature learning for surface settlement prediction caused by shield tunnelling. Comput Commun. 2023;203(15):276–88. doi:10.1016/j.comcom.2023.03.007. [Google Scholar] [CrossRef]

35. Yin Q, Zhou Y, Rao J. An intelligent prediction method for surface settlement of shield tunnel construction based on CNN-BiLSTM-SA. KSCE J Civ Eng. 2024:100061. doi:10.1016/j.kscej.2024.100061. [Google Scholar] [CrossRef]

36. Kong F, Zhou X, Guo C, Lu D, Du X. Elastic analytical method with machine learning for predicting the stratum displacement field induced by shallow tunneling. Eng Anal Boundary Elem. 2024;159(1):201–12. doi:10.1016/j.enganabound.2023.11.028. [Google Scholar] [CrossRef]

37. Zhao D, Sun Z, He Y, Chen X, Liu R. Prediction of ground subsidence by shield tunneling using ensemble learning. Tunnell Undergr Space Technol. 2023;141:105343. doi:10.1016/j.tust.2023.105343. [Google Scholar] [CrossRef]

38. Hu D, Hu Y, Yi S, Liang X, Li Y, Yang X. Prediction method of surface settlement of rectangular pipe jacking tunnel based on improved PSO-BP neural network. Sci Rep. 2023;13(1):5512. doi:10.1038/s41598-023-32189-0. [Google Scholar] [PubMed] [CrossRef]

39. Kannangara KPM, Su L-J, Zhou W-H. Analysis of post-ground settlement induced during twin tunnelling in silty sand. Tunnell Undergr Space Technol. 2024;152(4):105949. doi:10.1016/j.tust.2024.105949. [Google Scholar] [CrossRef]

40. Liu Z, Fang Q, Shen Y, Ai Q, Wang H, Huang X, et al. Two-stage surrogate modeling strategy for predicting foundation pit excavation-induced strata and tunnel deformation. Tunnell Undergr Space Technol. 2024;151(6):105845. doi:10.1016/j.tust.2024.105845. [Google Scholar] [CrossRef]

41. Liang J, Chen H, Li D, Ba Z. Review of seismic analysis of underground utility tunnels. Tianjin Daxue Xuebao/J Tianjin Univ Sci Technol. 2024;57(2):209–22 (In Chinese). [Google Scholar]

42. Lee C-T, Cheng C-T, Liao C-W, Tsai Y-B. Site classification of Taiwan free-field strong-motion stations. Bull Seismol Soc Am. 2001;91(5):1283–97. doi:10.1785/0120000736. [Google Scholar] [CrossRef]

43. Yan Q, Ma T, Wu L, He C. Comparison research of some approximate analytical methods for seismic design of circular tunnel. J Southwest Jiaotong Univ. 2011;46(1):12–7 (In Chinese). [Google Scholar]

44. Hashash YM, Hook JJ, Schmidt B, John I, Yao C. Seismic design and analysis of underground structures. Tunnell Undergr Space Technol. 2001;16(4):247–93. doi:10.1016/S0886-7798(01)00051-7. [Google Scholar] [CrossRef]

45. GB50909 CC. Code for seismic design of urban rail transit structures. Beijing: China Planning Press; 2014. [Google Scholar]

46. Tateishi A. A study on seismic analysis methods in the cross section of underground structures using static finite element method. Struct Eng/Earthq Eng. 2005;22(1):41s–54s. doi:10.2208/jsceseee.22.41s. [Google Scholar] [CrossRef]

47. Liu J, Wang W, Dasgupta G. Pushover analysis of underground structures: method and application. Sci China Technol Sci. 2014;57(2):423–37. doi:10.1007/s11431-013-5430-z. [Google Scholar] [CrossRef]

48. Yu H, Yuan Y, Bobet A. Seismic analysis of long tunnels: a review of simplified and unified methods. Undergr Space. 2017;2(2):73–87. doi:10.1016/j.undsp.2017.05.003. [Google Scholar] [CrossRef]

49. Ding X, Feng L, Wang C, Chen Z, Han L. Shaking table tests of the seismic response of a utility tunnel with a joint connection. Soil Dyn Earthquake Eng. 2020;133(9):106133. doi:10.1016/j.soildyn.2020.106133. [Google Scholar] [CrossRef]

50. Han L, Liu H, Zhang W, Ding X, Chen Z, Feng L, et al. Seismic behaviors of utility tunnel-soil system: with and without joint connections. Undergr Space. 2022;7(5):798–811. doi:10.1016/j.undsp.2021.08.001. [Google Scholar] [CrossRef]

51. Duan X, Dong Q, Ye W. Experimental study on seismic performance of prefabricated utility tunnel. Adv Civ Eng. 2019;2019(1):1–14. doi:10.1155/2019/8968260. [Google Scholar] [CrossRef]

52. Liang J, Zhang J, Dong B, Xu A, Ba Z. Shaking table tests on the seismic performance of prefabricated T-shaped cross utility tunnel. Structures. 2023;58(4):105516. doi:10.1016/j.istruc.2023.105516. [Google Scholar] [CrossRef]

53. Jiang L, Chen J, Li J. Seismic response of underground utility tunnels: shaking table testing and FEM analysis. Earthquake Eng Eng Vibr. 2010;9(4):555–67. doi:10.1007/s11803-010-0037-x. [Google Scholar] [CrossRef]

54. Huang D, Zong Z, Tao X, Liu Q, Huang Z, Tang A-P,editors. Seismic response of utility tunnel in horizontal nonhomogeneous site based on improved discrete element method. Structures. 2023;57:105179. doi:10.1016/j.istruc.2023.105179. [Google Scholar] [CrossRef]

55. Yue F, Liu B, Zhu B, Jiang X, Chen S, Jaisee S, et al. Shaking table investigations on seismic performance of prefabricated corrugated steel utility tunnels. Tunnell Undergr Space Technol. 2020;105(9):103579. doi:10.1016/j.istruc.2023.105179. [Google Scholar] [CrossRef]

56. Li J, Zhong Z, Bi K, Hao H. Selection of optimal intensity measures for seismic performance evaluation of underground utility tunnel and internal pipeline system. Tunnell Undergr Space Technol. 2024;148(9):105780. doi:10.1016/j.tust.2024.105780. [Google Scholar] [CrossRef]

57. Yue F, Liu B, Zhu B, Jiang X, Chen L, Liao K. Shaking table test and numerical simulation on seismic performance of prefabricated corrugated steel utility tunnels on liquefiable ground. Soil Dyn Earthquake Eng. 2021;141:106527. doi:10.1016/j.soildyn.2020.106527. [Google Scholar] [CrossRef]

58. Zhong Z, Li G, Li J, Shen J, Zhao M, Du X. Experimental study on out-of-plane seismic performance of precast composite sidewalls of utility tunnel with grouting-sleeve joints. Undergr Space. 2024;16(9):1–17. doi:10.1016/j.undsp.2023.10.004. [Google Scholar] [CrossRef]

59. Zhao G, Zhu L, Wu S, Liu W, Duan S,editors. Experimental and numerical investigation on the cross-sectional mechanical behavior of prefabricated multi-cabin RC utility tunnels. Structures. 2022;42(1):466–79. doi:10.1016/j.istruc.2022.06.025. [Google Scholar] [CrossRef]

60. Wang Z, Chang L, Ma H, Zhu L, Cui G, Shan H, et al. Seismic isolation technology of shallow buried large section utility tunnel with soft soils in seismically vulnerable area. Front Earth Sci. 2024;12:1351978. doi:10.3389/feart.2024.1351978. [Google Scholar] [CrossRef]

61. Liang JW, Li DQ, Wang CX, Gan MY, Yan CQ. Shell-spring model for longitudinal seismic analysis of precast utility tunnels considering prestress. Earthq Eng Eng Dyn. 2021;41(4):13–22 (In Chinese). [Google Scholar]

62. Hai-tao Y, Yong Y. Review on seismic response analysis and test methods for long and large tunnels. China J Highw Transp. 2018;31(10):19–35 (In Chinese). [Google Scholar]

63. Luo Y, Alaghbandrad A, Genger T, Hammad A. History and recent development of multi-purpose utility tunnels. Tunnell Undergr Space Technol. 2020;103(1–2):103511. doi:10.1016/j.tust.2020.103511. [Google Scholar] [CrossRef]

64. Bai Y, Zhou R, Wu J. Hazard identification and analysis of urban utility tunnels in China. Tunnell Undergr Space Technol. 2020;106(2):103584. doi:10.1016/j.tust.2020.103584. [Google Scholar] [CrossRef]

65. Zhang B, Li Y, Liu H. Ignition behavior and the onset of quasi-detonation in methane-oxygen using different end wall reflectors. Aerosp Sci Technol. 2021;116(1):106873. doi:10.1016/j.ast.2021.106873. [Google Scholar] [CrossRef]

66. Zhang B, Li Y, Liu H. Analysis of the ignition induced by shock wave focusing equipped with conical and hemispherical reflectors. Combust Flame. 2022;236(10):111763. doi:10.1016/j.combustflame.2021.111763. [Google Scholar] [CrossRef]

67. An W, Tang Y, Liang K, Cai M, Wang T, Wang Z. Study on temperature distribution and CO diffusion induced by cable fire in L-shaped utility tunnel. Sustainable Cities Soc. 2020;62:102407. doi:10.1016/j.scs.2020.102407. [Google Scholar] [CrossRef]

68. Liang K, Hao X, An W, Tang Y, Cong Y. Study on cable fire spread and smoke temperature distribution in T-shaped utility tunnel. Case Stud Therm Eng. 2019;14(8):100433. doi:10.1016/j.csite.2019.100433. [Google Scholar] [CrossRef]

69. Montiel H, Vı́lchez JA, Casal J, Arnaldos J. Mathematical modelling of accidental gas releases. J Hazard Mater. 1998;59(2–3):211–33. doi:10.1016/S0304-3894(97)00149-0. [Google Scholar] [CrossRef]

70. Guo Y. Study on quantifiable visualization of blasting dust based on gaussian diffusion model. Tiedao Xuebao (J China Railw Soc). 2022;44(1):153–9 (In Chinese). [Google Scholar]

71. Apak MY, Ozen H, Calis M, Golgeli B, Ataoglu S. Applications of utility tunnels for natural gas pipelines. Tunnelli Undergr Space Technol. 2022;122(1):104243. doi:10.1016/j.tust.2021.104243. [Google Scholar] [CrossRef]

72. Gao K, Liu Z, Wu C, Li J, Liu K, Liu Y, et al. Effect of low gas concentration in underground return tunnels on characteristics of gas explosions. Process Saf Environ. 2021;152(36):679–91. doi:10.1016/j.psep.2021.06.045. [Google Scholar] [CrossRef]

73. Zhang S, Ma H, Huang X, Peng S. Numerical simulation on methane-hydrogen explosion in gas compartment in utility tunnel. Process Saf Environ. 2020;140:100–10. doi:10.1016/j.psep.2020.04.025. [Google Scholar] [CrossRef]

74. Li Z, Wu J, Liu M, Li Y, Ma Q. Numerical analysis of the characteristics of gas explosion process in natural gas compartment of utility tunnel using FLACS. Sustainability. 2019;12(1):153. doi:10.3390/su12010153. [Google Scholar] [CrossRef]

75. Xu Y, Huang Y, Li J, Ma G. A risk-based optimal pressure relief opening design for gas explosions in underground utility tunnels. Tunnell Undergr Space Technol. 2021;116(5):104091. doi:10.1016/j.tust.2021.104091. [Google Scholar] [CrossRef]

76. Wang S, Li Z, Fang Q, Yan H, Chen L. Performance of utility tunnels under gas explosion loads. Tunnell Undergr Space Technol. 2021;109(40):103762. doi:10.1016/j.tust.2020.103762. [Google Scholar] [CrossRef]

77. Wang X, Tan Y, Zhang T, Zhang J, Yu K. Diffusion process simulation and ventilation strategy for small-hole natural gas leakage in utility tunnels. Tunnell Undergr Space Technol. 2020;97:103276. doi:10.1016/j.tust.2019.103276. [Google Scholar] [CrossRef]

78. Ebrahimi-Moghadam A, Farzaneh-Gord M, Arabkoohsar A, Moghadam AJ. CFD analysis of natural gas emission from damaged pipelines: correlation development for leakage estimation. J Cleaner Prod. 2018;199:257–71. doi:10.1016/j.jclepro.2018.07.127. [Google Scholar] [CrossRef]

79. Bu F, Liu Y, Wang Z, Xu Z, Chen S, Hao G, et al. Analysis of natural gas leakage diffusion characteristics and prediction of invasion distance in utility tunnels. J Nat Gas Sci Eng. 2021;96(4):104270. doi:10.1016/j.jngse.2021.104270. [Google Scholar] [CrossRef]

80. Shao X, Yang S, Yuan Y, Jia H, Zheng L, Liang C. Study on the difference of dispersion behavior between hydrogen and methane in utility tunnel. Int J Hydrogen Energy. 2022;47(12):8130–44. doi:10.1016/j.ijhydene.2021.12.123. [Google Scholar] [CrossRef]

81. Zhang Z, Liu Z, Zhang H, Meng S, Shi J, Zhao J, et al. Spatial distribution and machine learning-based prediction model of natural gas explosion loads in a utility tunnel. Tunnell Undergr Space Technol. 2023;140(2):105272. doi:10.1016/j.tust.2023.105272. [Google Scholar] [CrossRef]

82. Cai P, Liu Z, Li P, Zhao Y, Li M, Li R, et al. Effects of fuel component, airflow field and obstacles on explosion characteristics of hydrogen/methane mixtures fuel. Energy. 2023;265(2):126302. doi:10.1016/j.energy.2022.126302. [Google Scholar] [CrossRef]

83. Xue Y, Chen G, Zhang Q, Xie M, Ma J. Simulation of the dynamic response of an urban utility tunnel under a natural gas explosion. Tunnell Undergr Space Technol. 2021;108:103713. doi:10.1016/j.tust.2020.103713. [Google Scholar] [CrossRef]

84. Li S, Liu X, Wang J, Zheng Y, Deng S. Experimental reduced-scale study on the resistance characteristics of the ventilation system of a utility tunnel under different pipeline layouts. Tunnell Undergr Space Technol. 2019;90(1):131–43. doi:10.1016/j.tust.2019.04.021. [Google Scholar] [CrossRef]

85. Zhang C, Li J, Zhang Y, Li L, Duan P, Wei J. Safety analysis of hydrogen-blended natural gas leakage in comprehensive pipe gallery. Xi’an Jiaotong Daxue Xuebao (J Xi’an Jiaotong Univ). 2024;58(2):22–30 (In Chinese). [Google Scholar]

86. Yang Y, Xiong Y, Li Y, Meng X, Wang P, Cai T. Temperature and structural responses of a single-section utility tunnel throughout fire exposure. Front Struct Civ Eng. 2022;16(10):1351–64. doi:10.1007/s11709-022-0857-6. [Google Scholar] [CrossRef]

87. Qian H, Zong Z, Wu C, Li J, Gan L. Numerical study on the behavior of utility tunnel subjected to ground surface explosion. Thin-Walled Struct. 2021;161(3):107422. doi:10.1016/j.tws.2020.107422. [Google Scholar] [CrossRef]

88. Kong X, Wang X, Cong H, Liu Y, Zhu J. Temperature profile and flame extension length of a ceiling impinging round jet fire in an inclined tunnel. Int J Therm Sci. 2019;137(3):526–33. doi:10.1016/j.ijthermalsci.2018.12.023. [Google Scholar] [CrossRef]

89. Liu H, Zhu G, Pan R, Yu M, Liang Z. Experimental investigation of fire temperature distribution and ceiling temperature prediction in closed utility tunnel. Case Stud Therm Eng. 2019;14(3):100493. doi:10.1016/j.csite.2019.100493. [Google Scholar] [CrossRef]

90. Sun B, Liu X, Xu Z, Xu D. Temperature data-driven fire source estimation algorithm of the underground pipe gallery. Int J Therm Sci. 2022;171(6):107247. doi:10.1016/j.ijthermalsci.2021.107247. [Google Scholar] [CrossRef]

91. Jiang B, Liu Z, Tang M, Yang K, Lv P, Lin B. Active suppression of premixed methane/air explosion propagation by non-premixed suppressant with nitrogen and ABC powder in a semi-confined duct. J Nat Gas Sci Eng. 2016;29(5):141–9. doi:10.1016/j.jngse.2016.01.004. [Google Scholar] [CrossRef]

92. Wu J, Zhao Y, Zhou R, Cai J, Bai Y, Pang L. Suppression effect of porous media on natural gas explosion in utility tunnels. Fire Saf J. 2022;128(5):103522. doi:10.1016/j.firesaf.2021.103522. [Google Scholar] [CrossRef]

93. Cao J, Wu J, Zhao Y, Cai J, Bai Y, Pang L. Suppression effects of energy-absorbing materials on natural gas explosion in utility tunnels. Energy. 2023;281:128262. doi:10.1016/j.energy.2023.128262. [Google Scholar] [CrossRef]

94. Feng X, Zhang H, Si F, Dou J, Li M, Wu L, et al. Suppression characteristics of multi-layer metal wire mesh on premixed methane-air flame propagation. Front Mater. 2023;10:1107133. doi:10.3389/fmats.2023.1107133. [Google Scholar] [CrossRef]

95. Bivol GY, Golovastov S, Golub V. Detonation suppression in hydrogen-air mixtures using porous coatings on the walls. Shock Waves. 2018;28(5):1011–8. doi:10.1007/s00193-018-0831-3. [Google Scholar] [CrossRef]

96. Iskander M. Geotechnical underground sensing and monitoring. Undergr Sens. 2018:141–202. doi:10.1016/B978-0-12-803139-1.00003-5. [Google Scholar] [CrossRef]

97. Liu C, Liu Y, Chen Y, Zhao C, Qiu J, Wu D, et al. A state-of-the-practice review of three-dimensional laser scanning technology for tunnel distress monitoring. J Perform Constr Facil. 2023;37(2):03123001. doi:10.1061/JPCFEV.CFENG-4205. [Google Scholar] [CrossRef]

98. hu Li S, Li C, Yao D, Wang CX. Using GPS and InSAR data to assess the cumulative damage of an underground utility tunnel. Arabian J Geosci. 2020;13(2):1–12. doi:10.1007/s12517-019-5035-3. [Google Scholar] [CrossRef]

99. Wang Z, Chang T, Zeng X, Wang H, Cheng L, Wu C, et al. Fiber optic multipoint remote methane sensing system based on pseudo differential detection. Opt Lasers Eng. 2019;114:50–9. doi:10.1016/j.optlaseng.2018.10.013. [Google Scholar] [CrossRef]

100. Stray B, Lamb A, Kaushik A, Vovrosh J, Rodgers A, Winch J, et al. Quantum sensing for gravity cartography. Nature. 2022;602(7898):590–4. doi:10.1038/s41586-021-04315-3. [Google Scholar] [PubMed] [CrossRef]

101. Yao Y, Yan M, Bao Y. Measurement of cable forces for automated monitoring of engineering structures using fiber optic sensors: a review. Autom Constr. 2021;126(1):103687. doi:10.1016/j.autcon.2021.103687. [Google Scholar] [CrossRef]

102. Han H, Shi B, Zhang C, Sang H, Huang X, Wei G. Application of ultra-weak FBG technology in real-time monitoring of landslide shear displacement. Acta Geotech. 2023;18(5):2585–601. doi:10.1007/s11440-022-01742-y. [Google Scholar] [CrossRef]

103. Maheshwari M, Yang Y, Upadrashta D, Huang ES, Goh KH. Fiber Bragg grating (FBG) based magnetic extensometer for ground settlement monitoring. Sens Actuators A. 2019;296:132–44. doi:10.1016/j.sna.2019.06.053. [Google Scholar] [CrossRef]

104. Li S, Sun Y, Casas JR, Chen X, Wang H, Zeng J, et al. Long-distance and continuous horizontal displacement sensor of deep excavation based on distributed optical fiber sensing. IEEE Sens J. 2023;23(20):24608–16. doi:10.1109/jsen.2023.3312947. [Google Scholar] [CrossRef]

105. Wijaya H, Rajeev P, Gad E. Distributed optical fibre sensor for infrastructure monitoring: field applications. Opt Fiber Technol. 2021;64(6):102577. doi:10.1016/j.yofte.2021.102577. [Google Scholar] [CrossRef]

106. Hu D, Li Y, Yang X, Liang X, Zhang K, Liang X. Experiment and application of NATM tunnel deformation monitoring based on 3D laser scanning. Struct Control Health Monit. 2023;2023(1):3341788. doi:10.1155/2023/3341788. [Google Scholar] [CrossRef]

107. Cacciari PP, Futai MM. Mapping and characterization of rock discontinuities in a tunnel using 3D terrestrial laser scanning. Bull Eng Geol Environ. 2016;75(1):223–37. doi:10.1007/s10064-015-0748-3. [Google Scholar] [CrossRef]

108. Li Y, Yang K, Zhang J, Hou Z, Wang S, Ding X. Research on time series InSAR monitoring method for multiple types of surface deformation in mining area. Nat Hazards. 2022;114(3):2479–508. doi:10.1007/s11069-022-05476-8. [Google Scholar] [CrossRef]

109. Liu H, Yue Y, Liu C, Spencer BF Jr, Cui J. Automatic recognition and localization of underground pipelines in GPR B-scans using a deep learning model. Tunnell Undergr Space Technol. 2023;134:104861. doi:10.1016/j.tust.2022.104861. [Google Scholar] [CrossRef]

110. Kashinath SA, Mostafa SA, Mustapha A, Mahdin H, Lim D, Mahmoud MA, et al. Review of data fusion methods for real-time and multi-sensor traffic flow analysis. IEEE Access. 2021;9:51258–76. doi:10.1109/ACCESS.2021.3069770. [Google Scholar] [CrossRef]

111. Ding N, Zhou Y, Li D, Zeng K. Real-time deformation monitoring of large diameter shield tunnel based on multi-sensor data fusion technique. Measurement. 2024;225(2):114061. doi:10.1016/j.measurement.2023.114061. [Google Scholar] [CrossRef]

112. Zhang L, Chao W, Liu Z, Cong Y, Wang Z. Crack propagation characteristics during progressive failure of circular tunnels and the early warning thereof based on multi-sensor data fusion. Geomech Geophys Geo-Energy Geo-Resour. 2022;8(5):172. doi:10.1007/s40948-022-00482-3. [Google Scholar] [CrossRef]

113. Lu D, Zhang Y, Gong Z, Wu T. A slam method based on multi-robot cooperation for pipeline environments underground. Sustainability. 2022;14(20):12995. doi:10.1007/s40948-022-00482-3. [Google Scholar] [CrossRef]

114. Borges LM, Velez FJ, Lebres AS. Survey on the characterization and classification of wireless sensor network applications. IEEE Commun Surv Tut. 2014;16(4):1860–90. doi:10.1109/COMST.2014.2320073. [Google Scholar] [CrossRef]

115. Pan Y, Wu M, Zhang L, Chen J. Time series clustering-enabled geological condition perception in tunnel boring machine excavation. Autom Constr. 2023;153(6):104954. doi:10.1016/j.autcon.2023.104954. [Google Scholar] [CrossRef]

116. Zhu H, Huang M, Zhang Q. TunGPR: enhancing data-driven maintenance for tunnel linings through synthetic datasets, deep learning and BIM. Tunnell Undergr Space Technol. 2024;145(1):105568. doi:10.1016/j.tust.2023.105568. [Google Scholar] [CrossRef]

117. Fu X, Wu M, Tiong RLK, Zhang L. Data-driven real-time advanced geological prediction in tunnel construction using a hybrid deep learning approach. Autom Constr. 2023;146(3):104672. doi:10.1016/j.autcon.2022.104672. [Google Scholar] [CrossRef]

118. Bo Y, Huang X, Pan Y, Feng Y, Deng P, Gao F, et al. Robust model for tunnel squeezing using Bayesian optimized classifiers with partially missing database. Undergr Space. 2023;10(3):91–117. doi:10.1016/j.undsp.2022.11.001. [Google Scholar] [CrossRef]

119. Chen C, Shi P, Zhou X, Wu B, Jia P. A novel hybrid model for missing deformation data imputation in shield tunneling monitoring data. Adv Eng Inf. 2023;56(1):101943. doi:10.1016/j.aei.2023.101943. [Google Scholar] [CrossRef]

120. Zhao N, Wei J, Long Z, Yang C, Bi J, Wan Z, et al. An integrated method for tunnel health monitoring data analysis and early warning: savitzky-golay smoothing and wavelet transform denoising processing. Sensors. 2023;23(17):7460. doi:10.3390/s23177460. [Google Scholar] [PubMed] [CrossRef]

121. Zhou P, Li K, Fu C, Xu X, Geng Z, Yang W, et al. Random noise attenuation in tunnel based on EMD-T-FSS. Geotech Geol Eng. 2023;41(1):27–42. doi:10.1007/s10706-022-02259-7. [Google Scholar] [CrossRef]

122. Nilot EA, Fang G, Li YE, Tan YZ, Cheng A. Real-time tunneling risk forecasting using vibrations from the working TBM. Tunnell Undergr Space Technol. 2023;139(3):105213. doi:10.1016/j.tust.2023.105213. [Google Scholar] [CrossRef]

123. Lee J, Lee Y, Park S, Hong C. Implementing a digital twin of an underground utility tunnel for geospatial feature extraction using a multimodal image sensor. Appl Sci. 2023;13(16):9137. doi:10.3390/app13169137. [Google Scholar] [CrossRef]