Open Access

Open Access

ARTICLE

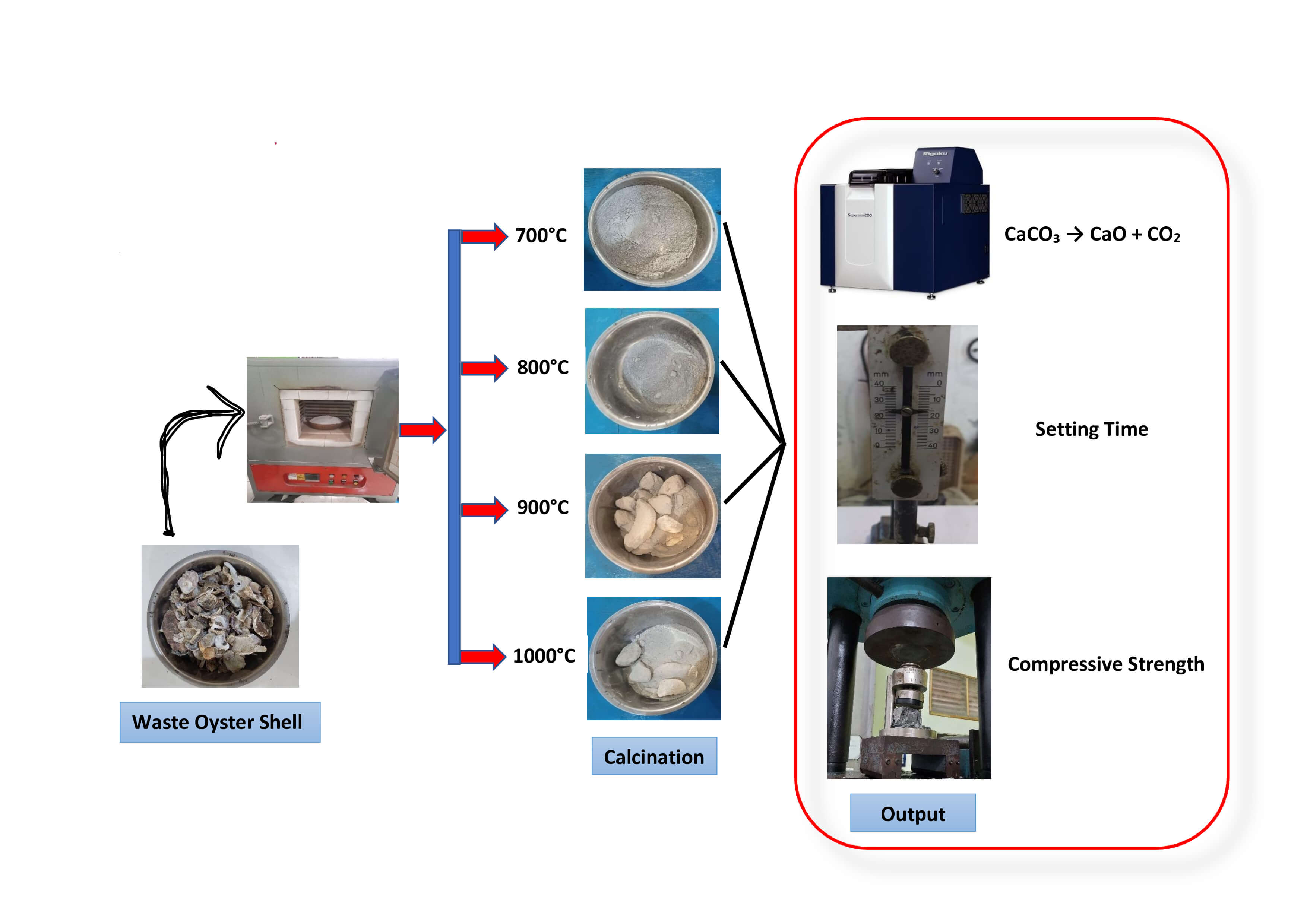

Calcination Analysis of CaCO3 from Waste Oyster Shells for Partial Cement Replacement

1 Doctoral Program, School of Engineering, Post Graduate Program, Universitas Syiah Kuala, Banda Aceh, 23111, Indonesia

2 Department of Civil Engineering, Faculty of Engineering, Universitas Iskandar Muda, Banda Aceh, 23234, Indonesia

3 Department of Civil Engineering, Universitas Syiah Kuala, Banda Aceh, 23111, Indonesia

4 Center for Environmental and Natural Resources Research, Universitas Syiah Kuala, Banda Aceh, 23111, Indonesia

* Corresponding Author: Muttaqin Hasan. Email:

Structural Durability & Health Monitoring 2025, 19(5), 1089-1109. https://doi.org/10.32604/sdhm.2025.066887

Received 19 April 2025; Accepted 12 June 2025; Issue published 05 September 2025

Abstract

Aceh in Indonesia is rich in marine resources and abundant fishery products such as oyster. Traditionally, fishermen only harvest oysters and discard the shells, which can cause pollution and environmental contamination. Waste Oyster Shells (WOS) contain a high percentage of calcium carbonate (CaCO3) that experiences thermal decomposition at high temperature, following the reaction CaCO3 → CaO + CO2 (ΔT = 825°C). At temperature > 900°C, dead-burned lime is formed, which severely influences CaO reactivity. However, the optimum temperature for producing high CaO content is still uncertain. Therefore, this study aimed to determine the optimum calcination temperature to produce high CaO content, assess initial setting time of WOS paste, and identify the best compressive strength of paste. For the experiment, WOS was used as a partial cement replacement (with a size of 0.075 mm) in paste at a proportion of 5% and calcined at temperature of 700°C, 800°C, 900°C, and 1000°C. The specimens used were an ebonite ring (dimensions: 70 mm bottom diameter, 60 mm top diameter, and 40 mm height) and a cube (dimensions: 5 cm × 5 cm × 5 cm). The experiment was conducted following the ASTM (American Society for Testing and Materials) standards and optimum compressive strength values were analyzed using ANOVA (Analysis of Variance) and Response Surface Methodology (RSM) through the Design Expert software. The results showed that WOS calcined at 1000°C increased CaO content by approximately 57.40%. Furthermore, the initial setting time test of 5% WOS paste at 1000°C showed a more uniform binding performance compared to conventional cement paste, with an initial setting time of 75 min and a penetration depth of 15 mm. In line with the analysis, optimum compressive strength of 71.028 MPa with a desirability value of 0.986 was achieved at 5% cement replacement and calcination temperature of 786.44°C.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools