Open Access

Open Access

ARTICLE

Enhancing Sound Absorption in Micro-Perforated Panel and Porous Material Composite in Low Frequencies: A Numerical Study Using FEM

Department of Occupational Health Engineering, School of Public Health, Tehran University of Medical Sciences, Tehran, Iran

* Corresponding Author: Mohammad Javad SheikhMozafari. Email: Array

Sound & Vibration 2024, 58, 81-100. https://doi.org/10.32604/sv.2024.048897

Received 21 December 2023; Accepted 11 January 2024; Issue published 27 February 2024

Abstract

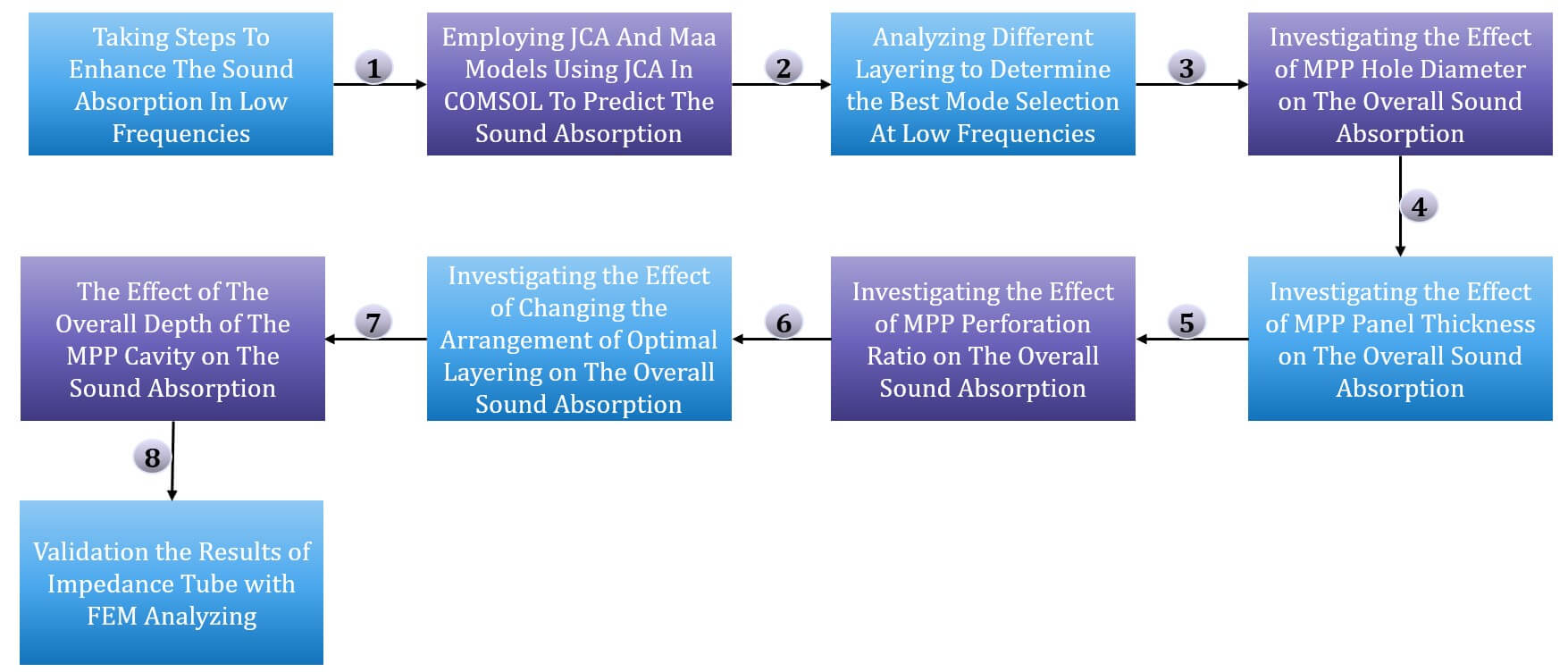

Mitigating low-frequency noise poses a significant challenge for acoustic engineers, due to their long wavelength, with conventional porous sound absorbers showing limitations in attenuating such noise. An effective strategy involves combining porous materials with micro-perforated plates (MPP) to address this issue. Given the significant impact of structural variables like panel thickness, hole diameter, and air gap on the acoustic characteristics of MPP, achieving the optimal condition demands numerous sample iterations. The impedance tube’s considerable expense for sound absorption measurement and the substantial cost involved in fabricating each sample using a 3D printer underscore the advantage of utilizing simulation methods to attain the optimal state. This study focuses on optimizing low-frequency enhancement by investigating key parameters. Using the Finite Element Numerical Method (FEM) in COMSOL software, a composite panel was constructed comprising date palm fiber layers, an intervening air layer, and MPP. The study explored the arrangement of these layers and the impact of parameters like hole diameter, plate thickness, and perforation ratio on acoustic behavior. The selected optimal parameter at each stage was consistently maintained for subsequent steps. Results revealed that layer arrangement significantly influenced acoustic characteristics. Placing the MPP layer before the porous material yielded superior low-frequency performance. Optimizing low-frequency behavior involved reducing hole diameter and perforation ratio while increasing plate thickness. Elevating the porous material’s thickness relative to the air layer behind the MPP enhanced absorption peak and resonance frequency. In conclusion, halving the porous layer’s thickness while incorporating an air layer and single MPP proved more effective than using a thick porous material. This approach not only reduces costs and space requirements but also enhances low-frequency performance. The study highlights the precision of numerical methods like FEM, reducing the need for resource-intensive direct methods and associated laboratory expenses.Graphic Abstract

Keywords

Cite This Article

Copyright © 2024 The Author(s). Published by Tech Science Press.

Copyright © 2024 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools