Open Access

Open Access

REVIEW

Digital Twins and Cyber-Physical Systems: A New Frontier in Computer Modeling

1 Department of Computer Science and Engineering, SRM University AP, Amaravati, 522240, India

2 School of Computer Science and Engineering, VIT-AP University, Amaravathi, 522240, India

3 Robotics and Internet-of-Things Laboratory, Prince Sultan University, Riyadh, 12435, Saudi Arabia

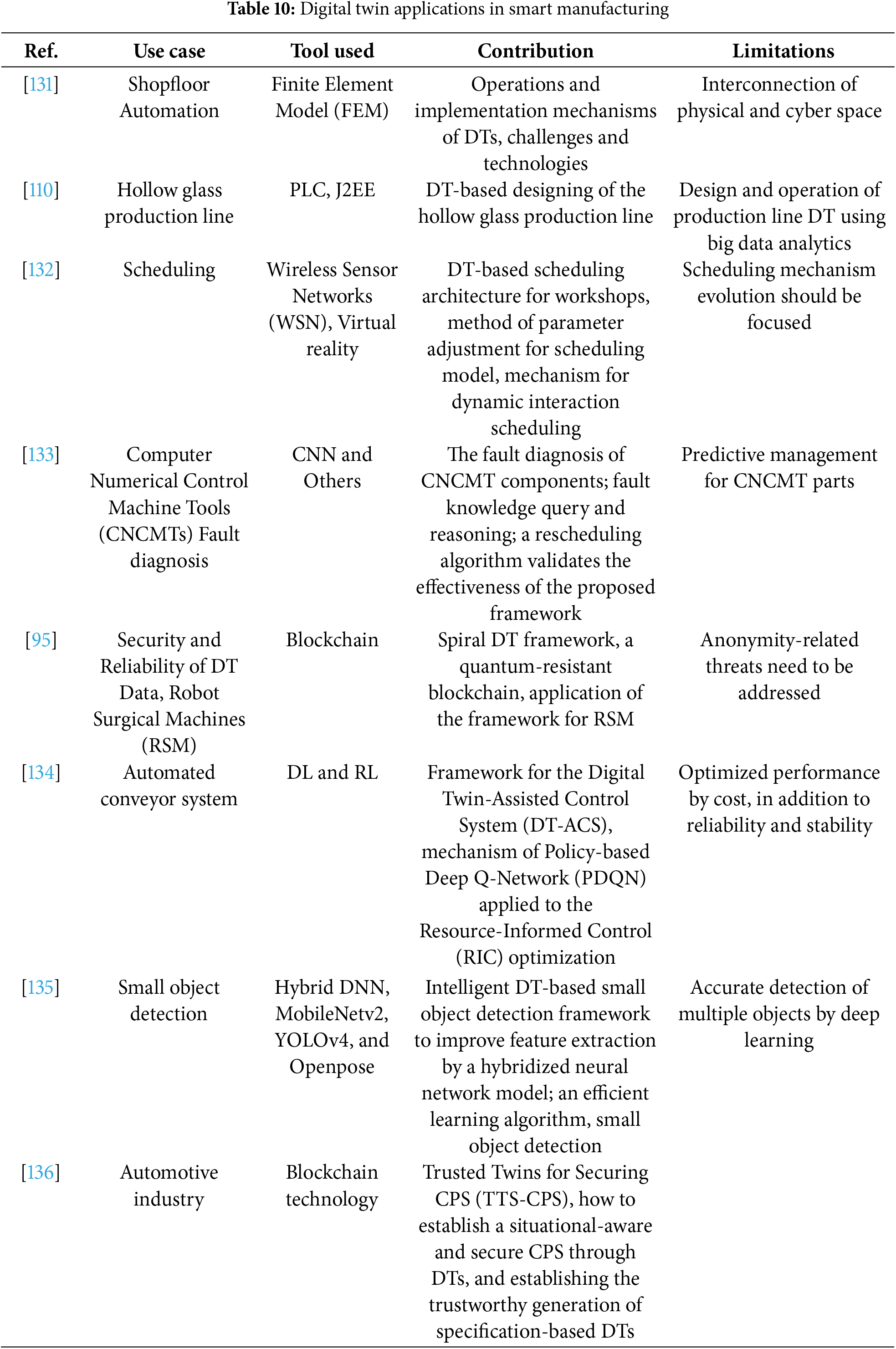

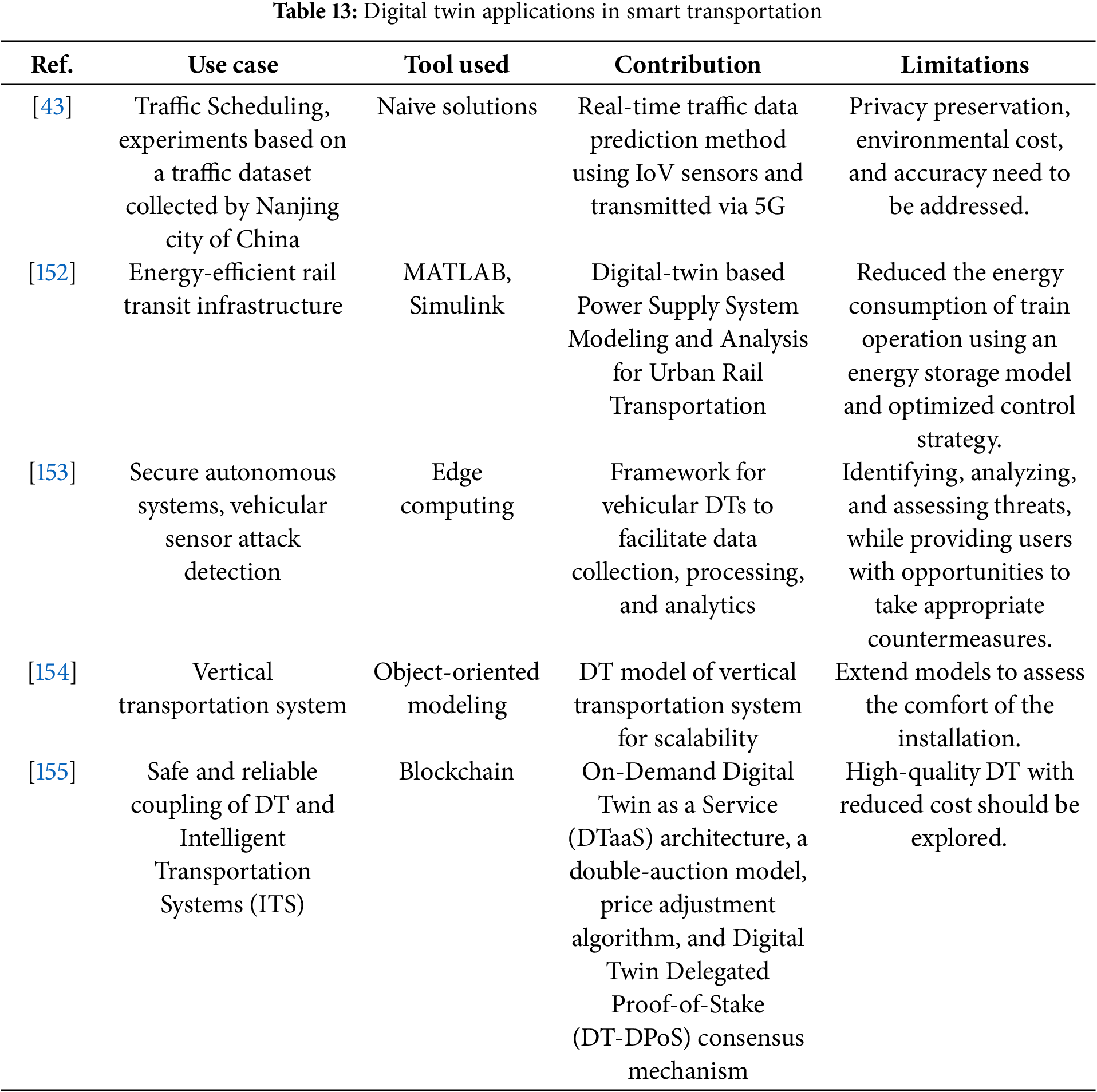

4 Department of Math and Computer Science, Brandon University, Brandon, MB R7A6A9, Canada

5 Research Centre for Interneural Computing, China Medical University, Taichung, 40402, Taiwan

* Corresponding Author: S Gopikrishnan. Email:

(This article belongs to the Special Issue: Data-Driven and Physics-Informed Machine Learning for Digital Twin, Surrogate Modeling, and Model Discovery, with An Emphasis on Industrial Applications)

Computer Modeling in Engineering & Sciences 2025, 143(1), 51-113. https://doi.org/10.32604/cmes.2025.057788

Received 27 August 2024; Accepted 20 December 2024; Issue published 11 April 2025

Abstract

Cyber-Physical Systems (CPS) represent an integration of computational and physical elements, revolutionizing industries by enabling real-time monitoring, control, and optimization. A complementary technology, Digital Twin (DT), acts as a virtual replica of physical assets or processes, facilitating better decision making through simulations and predictive analytics. CPS and DT underpin the evolution of Industry 4.0 by bridging the physical and digital domains. This survey explores their synergy, highlighting how DT enriches CPS with dynamic modeling, real-time data integration, and advanced simulation capabilities. The layered architecture of DTs within CPS is examined, showcasing the enabling technologies and tools vital for seamless integration. The study addresses key challenges in CPS modeling, such as concurrency and communication, and underscores the importance of DT in overcoming these obstacles. Applications in various sectors are analyzed, including smart manufacturing, healthcare, and urban planning, emphasizing the transformative potential of CPS-DT integration. In addition, the review identifies gaps in existing methodologies and proposes future research directions to develop comprehensive, scalable, and secure CPS-DT systems. By synthesizing insights from the current literature and presenting a taxonomy of CPS and DT, this survey serves as a foundational reference for academics and practitioners. The findings stress the need for unified frameworks that align CPS and DT with emerging technologies, fostering innovation and efficiency in the digital transformation era.Keywords

Cyber-Physical Systems (CPS) integrate computational, networking and physical components to seamlessly interact with the real world through sensor data collection and control loops [1]. Communication modules will hand over the measured data to the controller, which is software. Controllers make decisions and perform actions based on data collected via feedback loops [2,3]. CPS is a complex and multidimensional system that fills the gap between the virtual and physical worlds. Computation, communication and control in CPS, referred to as the “3C,” enable legitimate sensing, feedback of information, and control in addition to various services. Feedback loops, along with significant connectivity, provide a close intertwining of physical and computer processes [4]. The authors in [5] proposed a CPS framework consisting of the design of the connection, conversion, cyber, recognition, and configuration layers (5C CPS) to meet the objective of durable, smart, and self-adaptable robots.

A Digital Twin (DT) is a virtual replica of a physical object or process, allowing real-time monitoring, simulation, and optimization by mirroring the state and behavior of the physical counterpart. DT creates computerized representations of real physical processes to mimic and provide feedback on their real-world nature [6]. A DT is a dynamic mapping strategy that breaks down the limits in the product life cycle and gives an object a digital imprint [7]. As a result, DTs help firms predict and detect physical problems earlier and more precisely, as well as improve manufacturing processes and deliver superior goods [8]. DTs are dynamic models of physical systems built to address the specific needs of various stakeholders such as engineers, operators, and decision-makers. Multiple models of the same entity may exist to cater to different interests. A system must meet several requirements to be classified as a CPS. Increasing the efficiency and flexibility of different application processes requires greater autonomy and faster decision-making. CPS must be in sync with the outside environment to transmit information and trigger actions [9].

CPS and DT are key enablers of Industry 4.0. In the context of CPS, a DT serves as the digital reflection of the physical components within the system, receiving data continuously from sensors and actuators embedded in the physical environment. The Digital Twin mirrors the behavior, state, and performance of the physical system, allowing real-time monitoring, simulation, and predictive analysis. This integration allows for optimized control and decision-making within the CPS, providing a testing ground for various scenarios without interrupting the actual physical processes. By facilitating advanced modeling and analysis, DT enhances the functionality of CPS, making it a crucial tool for industries adopting smart, autonomous, and interconnected systems as part of Industry 4.0. In CPS, bidirectional communication channels are present between the physical and cyber realms. The addition of the Internet of Things (IoT) in the physical world will connect different types of sensors, actuators, and control devices to the equipment for actual data propagation, processing, responses, and service [10]. As CPS’s core technology, DT gives a straightforward and practical methodology to put CPS’s functions into action. The virtual copy of a real process (or system) reflects its geometry, actual state, and behavior. It also allows you to model and control performance in real-time in the best possible way.

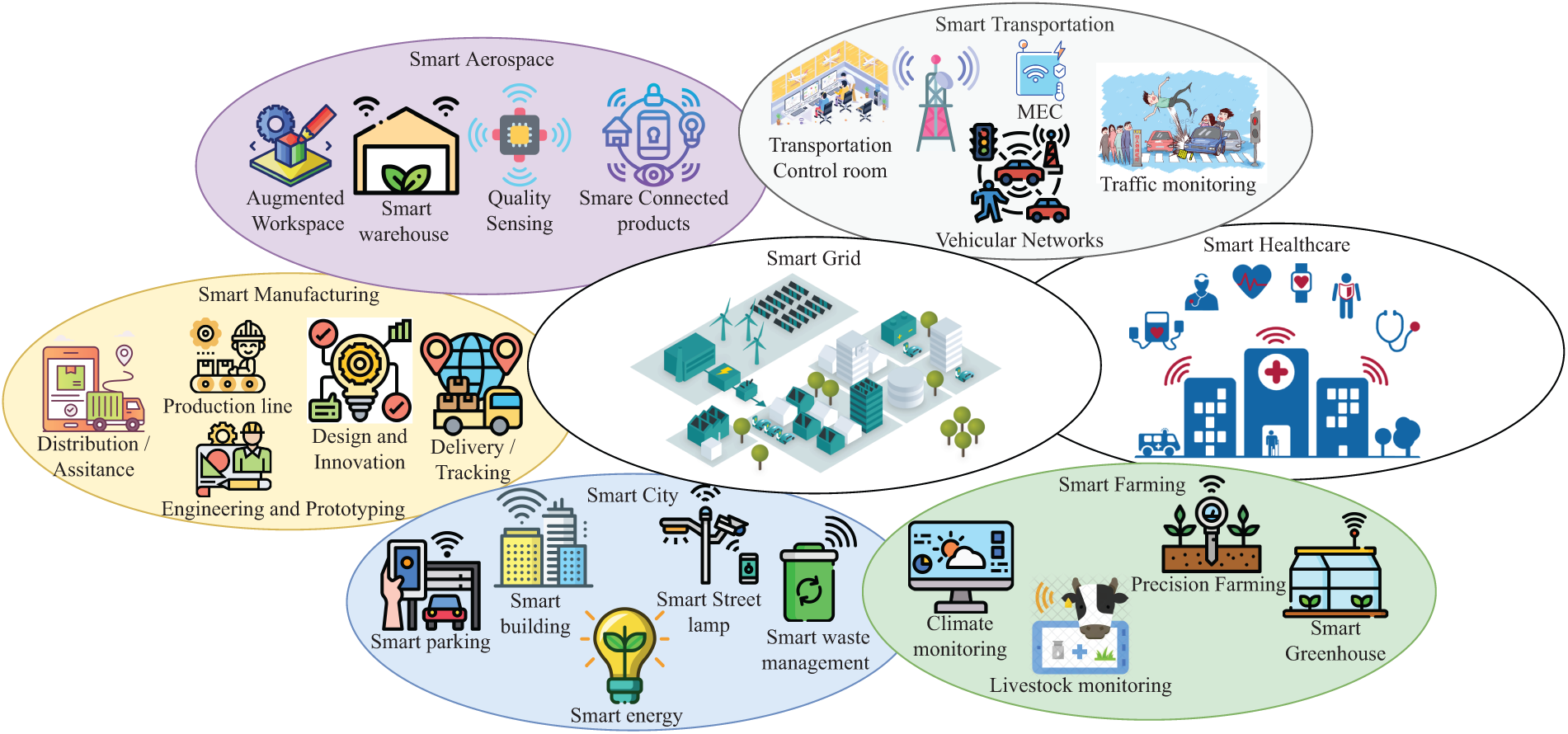

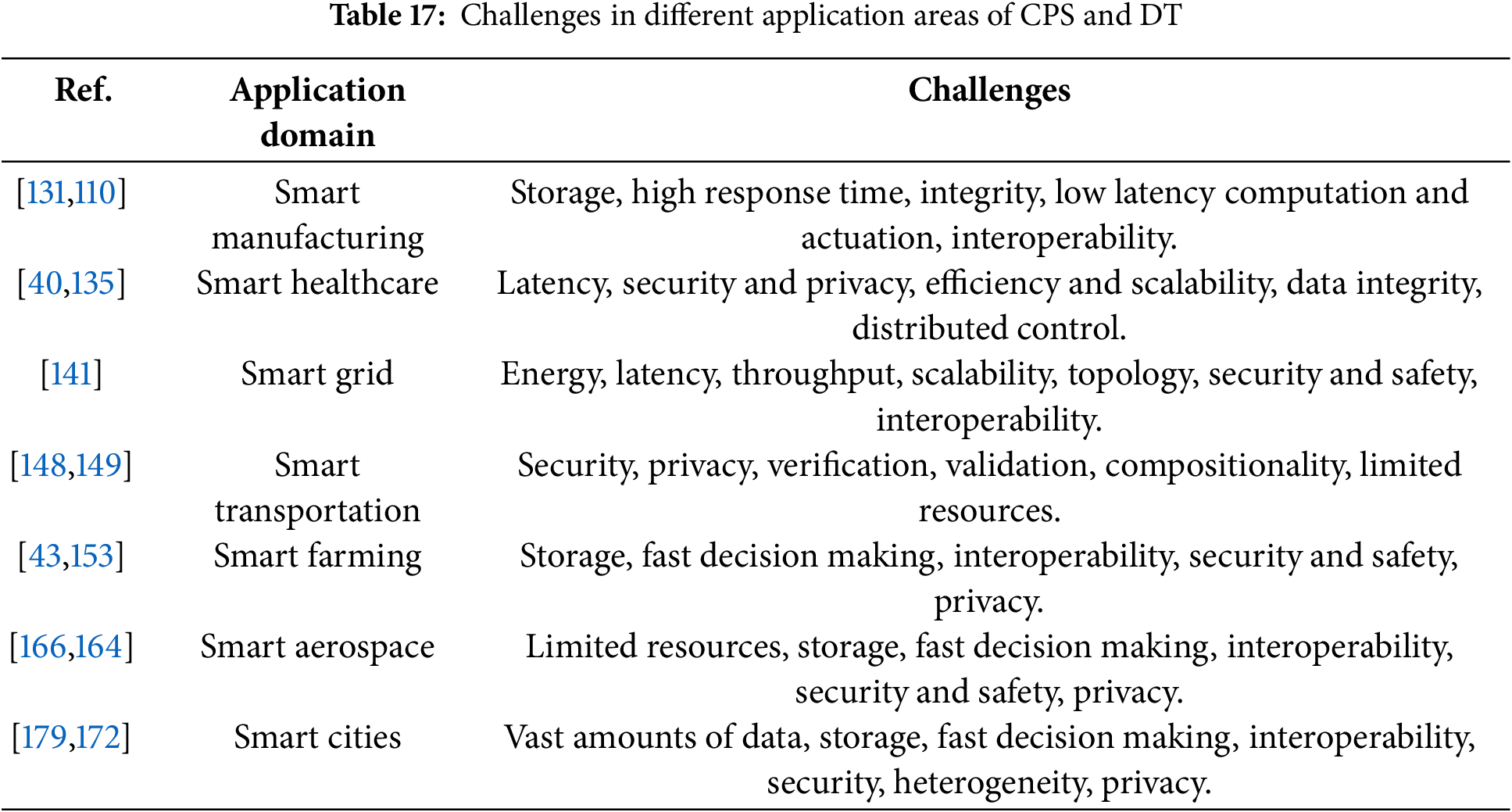

This research reviewed different communication protocols suitable for the physical and cyber parts of CPS, where we discussed the suitability of each protocol for different levels of CPS applications. The basic characteristics needed for CPS were mentioned by studying some modeling techniques available for CPS and also identified the challenges in modeling CPS. Eventually, according to existing research, DT is the preferred combination for modeling CPS, so the other technologies needed to develop CPS with DT were discussed. The features of DT and its main components were explored to emphasize the importance of DT in CPS. The layered architecture of DT was provided, and the enabling technologies to identify the tools required to develop DT for CPS were also presented. Various innovative applications in the combination of CPS and DT, such as in smart manufacturing, smart grids, smart healthcare, smart transportation, smart aerospace, and smart city, were examined, and the challenges of modeling were identified in all these application areas. The final aim of this research was to identify the modeling challenges of CPS, how DT is useful for developing CPS applications, and the required tools for DT were described with future research direction such as the need for a unique CPS modeling architecture.

Studying DTs and CPS together is essential because they are interconnected and complementary concepts. Understanding the relationship between DTs and CPS provides a more holistic view of how they can collectively enhance various aspects of technology, engineering, and decision-making. Here are some reasons why studying them together is beneficial.

Synergistic Benefits: DTs offer advanced modeling, simulation, and data-driven capabilities, while CPS incorporate physical components and the real-world context. By studying them together, we can leverage the strengths of each concept to achieve synergistic benefits, leading to more effective and efficient solutions in various industries.

Seamless Integration: DTs and CPS often work together in practical applications. For example, a DT of a manufacturing process can be integrated into the CPS of a smart factory to monitor and control the physical production line in real-time. Understanding how these components interact is crucial to a successful implementation.

Problem Solving:Many real-world challenges require a multidisciplinary approach that combines insights from both DTs and CPS. By studying them together, researchers and engineers can develop innovative solutions that bridge the gap between virtual and physical realms.

Performance Optimization: Integrating DTs with CPS allows continuous monitoring and optimization of physical systems. The insights gained from DTs can be used to fine-tune CPS operations, leading to improved efficiency, reduced downtime, and better resource utilization.

Risk Management: Understanding the interplay between DTs and CPS can help identify potential risks and vulnerabilities. For example, security threats targeting the DT might have severe implications on the physical system. By studying both aspects, organizations can implement comprehensive risk management strategies.

Education and Training: Students and professionals in relevant fields benefit from studying DT and CPS together, as it equips them with a wider set of skills and prepares them to tackle complex real-world problems.

Future Innovations: Emerging technologies often involve the integration of DTs and CPS. By studying them together, researchers and innovators can explore new possibilities and push the boundaries of technological advancements.

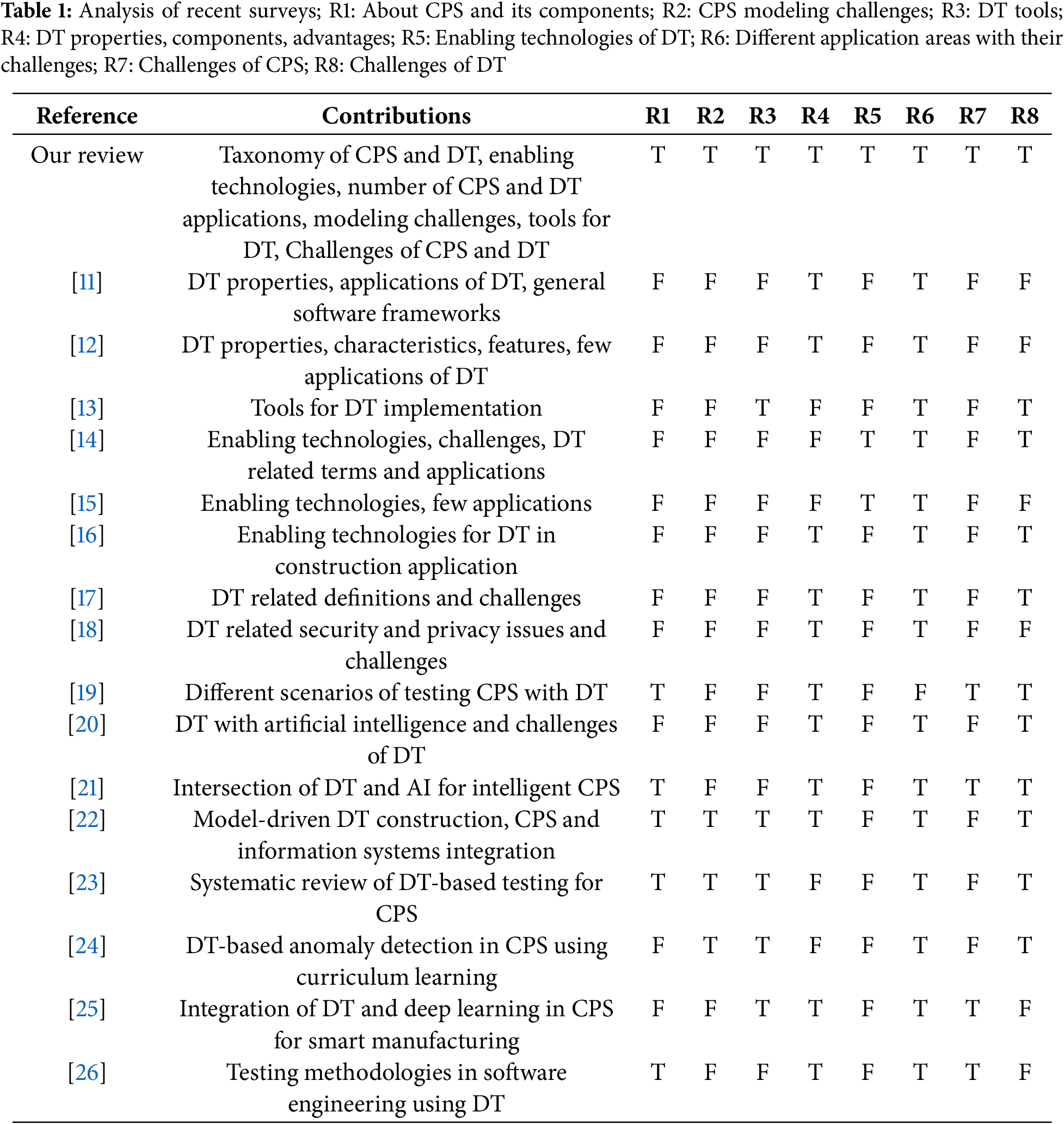

DTs and CPS together allow us to unlock their full potential, understand their interdependencies, and create more sophisticated and practical solutions for a wide range of industries and applications. Foster a comprehensive approach to problem-solving, innovation, and decision-making in the digital transformation era. In the context of recent research, CPS and DT have become highly prominent subjects, resulting in a proliferation of surveys. Table 1 presents a comprehensive analysis of previous surveys related to CPS and DT, comparing their contributions with the present survey, as illustrated in the table. Notably, this survey stands out in several aspects: it primarily focuses on implementing CPS with DT, presents the required prerequisites, offers a comprehensive taxonomy of CPS and DT, includes papers from early works to the most recent ones, examines diverse application areas of CPS and DT, and addresses the challenges associated with both CPS and DT. These distinctive characteristics distinguish this survey from others and contribute to its uniqueness and relevance in the field.

This study examined various concepts related to CPS and DT using which we can build a DT for different CPS applications. Section 2 presents the methodology adopted for conducting the review, including the search strategy, quality assessment rules, and research questions. Section 3 provides the background by defining CPS and DT, classifying their types, and reviewing recent literature to position the current survey. Section 4 elaborates on the architecture, characteristics, and modeling challenges of CPS, focusing on communication protocols, system heterogeneity, and concurrency issues. Section 5 introduces Digital Twins in depth, discussing their relationship with CPS, layered architecture, enabling technologies, components, and a roadmap for CPS-DT integration. Section 6 highlights the role of supporting technologies such as IoT, big data, machine learning, cloud computing, and blockchain in enhancing CPS and DT functionalities. Section 7 explores a wide range of application domains, including smart manufacturing, healthcare, urban infrastructure, transportation, and energy systems, emphasizing the practical utility of CPS-DT fusion. Section 8 outlines the key challenges and open issues in modeling and deploying CPS and DT, while also suggesting future research directions toward building secure, scalable, and interoperable digital frameworks. Finally, the conclusion summarizes the insights derived from the survey and reinforces the significance of CPS and DT in enabling next-generation intelligent systems.

The main objective of this review article is to explore the existing and proposed approaches to CPS and DT, including their components, characteristics, applications, and challenges. Initially, a thorough understanding of the concepts of CPS is established, which includes its components, features, and the prevalent modelling challenges. Subsequently, the relevant concepts related to DTs, such as components, properties, advantages, and various tools, are extensively investigated. The roles of different technologies in both CPS and DT are also emphasized.

This paper focuses primarily on heterogeneous CPS, encompassing both anthropogenic systems, such as industrial automation and smart grids, and natural systems, such as environmental monitoring and smart water networks. Therefore, the research methodology delves into the combined applications of CPS and DT through the analysis of multiple case studies. Each application area is thoroughly examined and the associated challenges are documented. Finally, the review presents challenges in both the CPS and DT domains, paving the way for future research directions. To achieve the study goal, a comprehensive approach is followed, which includes four distinct stages: formulation of a search strategy, selection of relevant research studies, quality assessment of the chosen studies, and in-depth analysis of case studies. Through this systematic review, the article seeks to provide a holistic view of the advancements and potential of CPS and DT, identifying areas where further research is warranted. By synthesising existing knowledge and exploring case studies, the objective of the review is to contribute to the advancement of CPS and DT technologies and their applications in diverse domains.

One of the essential aspects of a review paper is accurately defining the research topic and subsequently identifying the most relevant papers related to this topic. In the process of seeking the necessary research papers, the primary library resources employed are Science Direct, IEEE Xplore, ACM Digital Library, and Google Scholar. A thorough and extensive search was conducted, covering articles ranging from the earliest to the most recent, to identify any relevant literature regarding CPS, DT, and their combined applications. The terms encompassing terms such as “Cyber physical systems”, “CPS”, “DTs”, “DT”, “applications of CPS and DT”, “IoT in CPS and DT”, “ML in CPS and DT”, “Big data in CPS and DT”, “blockchain technology in DT implementation for CPS”, as well as domain-specific phrases like “smart manufacturing”, “smart transportation”, “smart farming”, “smart aerospace”, “smart healthcare”, “smart grid”, and “smart city”. Initially we considered 848 paper excluding conference papers and non scopus indexed papers from this list of papers, the selection process involved reviewing case studies and research articles from the earliest to the most recent publications relevant to CPS and DT. A rigorous quality assessment process was applied using seven quality assessment rules to ensure that only the most relevant and high-quality 157 papers were included in the final analysis.

The objective of this review paper is to focus on the implementation of CPS with DT. To ensure the selection of appropriate research papers for this study, certain inclusion and exclusion criteria have been applied. This review covers case studies spanning from the first to the most recent publications, with a particular emphasis on recent research papers. However, case studies that are not relevant to the topic or do not utilise machine learning models or deep learning models in the context of cloud security and case studies that are not written in the English language have not been considered.

In this review article, every research paper is subjected to inclusion and analysis, ensuring its quality and ability to address the key questions of the review. The selection process adheres to seven quality assessment rules specified within the review. Each paper is evaluated against these criteria and if it meets the prescribed threshold, it is included in the review; otherwise, it is excluded. The quality assessment rules applied in this review are presented as follows:

• QA1: Is the research question addressed by the research topic?

• QA2: Is it apparent in the paper what the study’s objectives are?

• QA3: Is the implementation issue in the research paper well defined?

• QA4: Does the collected data satisfy the following characteristics (up-to-date, comprehensive, sufficient, etc.)?

• QA5: Is the proposed ML/DL model used to solve the addressed security issue?

• QA6: In which year is the paper published?

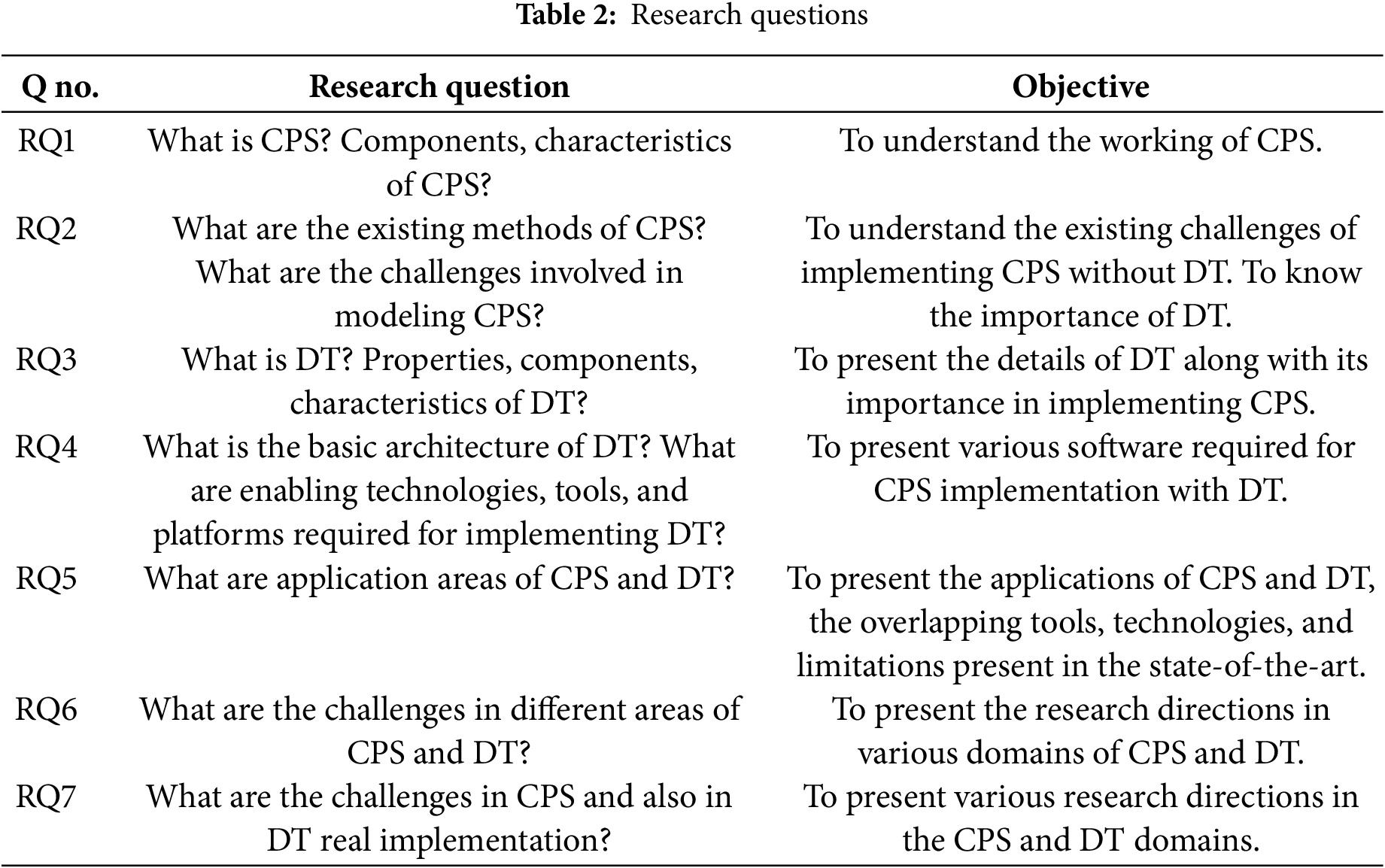

The primary focus of the paper is on the integration of CPS and DT, exploring how DT can enhance the design, operation, and modelling of CPS in various application domains. The paper provides a comprehensive survey on CPS, the role of DT in the implementation of CPS, and the challenges associated with their integration, particularly in smart applications such as smart manufacturing, healthcare, transportation, and urban infrastructure. The study also investigates enabling technologies, tools, and methodologies for modelling CPS through DT and offers insights into future research directions. Based on this, the research questions that are tried to answer in this paper are presented in Table 2.

CPS and DTs are central to Industry 4.0, enabling the integration of physical and cyber domains for real-time interaction, monitoring, and optimisation [5,7]. CPS combines physical components with computational algorithms and networking [1,2], while digital twins enhance these systems by creating virtual replicas that reflect the real-time states of physical entities [6,7]. This section defines key concepts, distinguishes between types of digital twins, clarifies the focus of this review, and positions it within the context of existing literature.

3.1 Definitions of Key Concepts

A Cyber-Physical System (CPS) is defined as a multidisciplinary system that integrates computational algorithms, network communication, and physical processes. CPS operates through real-time feedback loops, facilitating autonomous sensing, decision making, and control in various domains, including smart manufacturing, energy grids, healthcare and transportation [3,4]. The core characteristics of CPS are summarised by the “3C” framework: Computation, communication, and control, ensuring that physical components interact seamlessly with software-based systems to execute intelligent tasks [1,34].

A Digital Twin (DT) is defined as a virtual model of a physical asset, process, or system, dynamically updated with real-time data from its physical counterpart [7,14]. Not only does it mirror the current state of the physical entity, but it also enables simulations and predictive analytics [12,20]. Digital twins offer insights for improved decision making, maintenance, and optimisation. They are typically categorised into two types:

• Runtime Digital Twins operate concurrently with physical systems, allowing real-time monitoring, optimisation, and predictive maintenance [11,35]. By continuously receiving sensor data, these DTs provide immediate feedback, allowing adjustments and proactive interventions. Common applications include smart factories, autonomous vehicle control, and real-time energy management [8,16].

• Production-Stage Digital Twins, on the other hand, focus on the design, development, and testing phases [12,24]. They provide virtual simulations before physical deployment, facilitating design refinements, error detection, and resource optimisation. These DTs are especially valuable in manufacturing, aerospace, and infrastructure projects, where early virtual testing reduces cost and development time [36,37].

3.2 Overview of Recent Reviews on DT in CPS

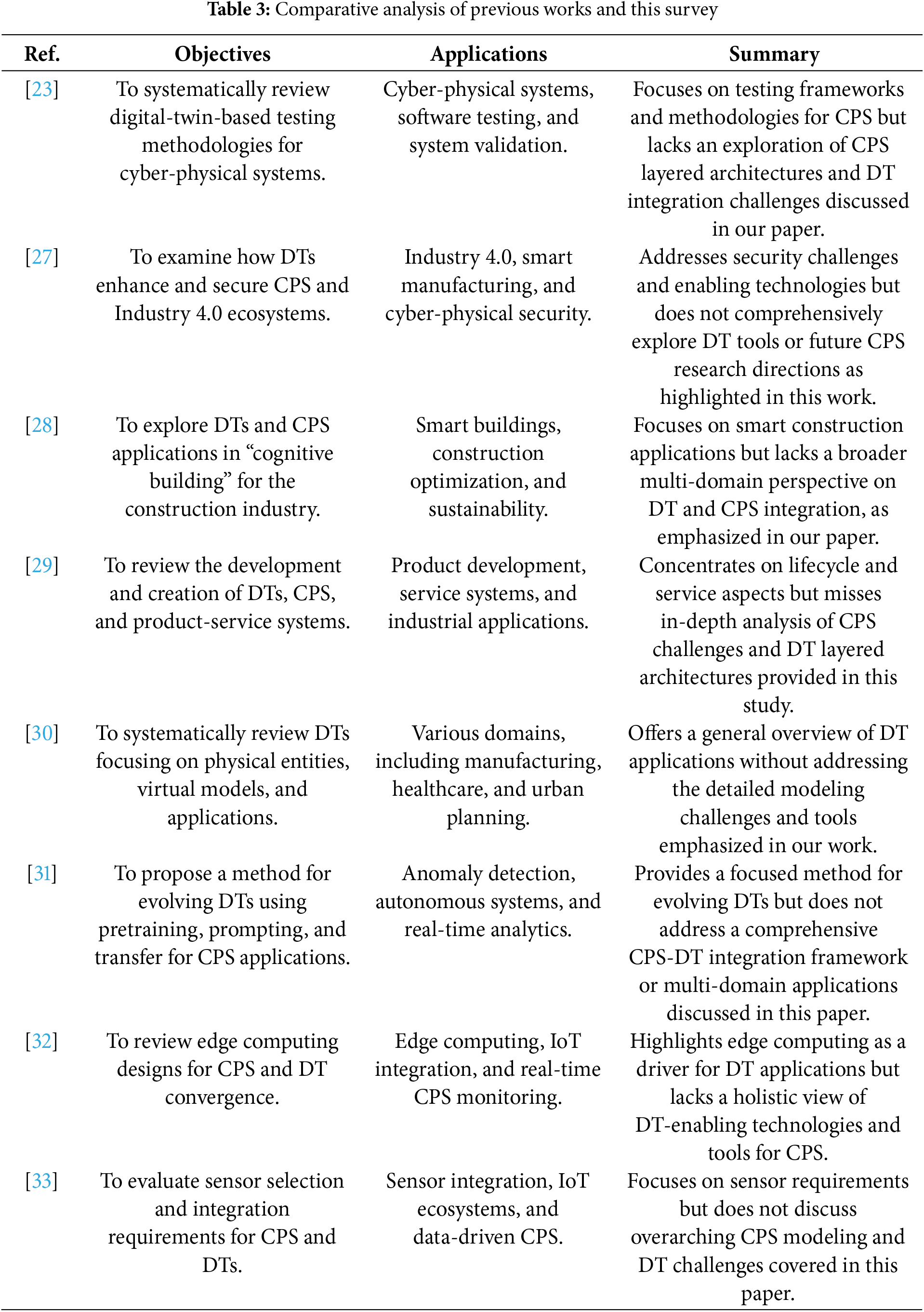

The use of DTs within CPS has been widely explored in recent literature, with numerous reviews examining their applications, enabling technologies, challenges, and potential impact in diverse domains [24,26]. The summary of the existing reviews with CPS DT implementations has been presented in Table 3. To provide context for the current study, this section offers a brief overview of key reviews highlighting the evolution of digital twin integration within CPS.

Recent reviews have focused on specific aspects of DTs, such as their roles in smart manufacturing, healthcare, energy systems, and transportation networks. For example, reviews on smart manufacturing emphasise the capabilities of runtime digital twins for real-time process monitoring, predictive maintenance, and supply chain optimisation [13,38]. These studies explore the use of IoT, AI, and big data analytics to enable seamless integration and operation of DTs within CPS environments, emphasising challenges such as interoperability, communication latency, and security risks [16,39].

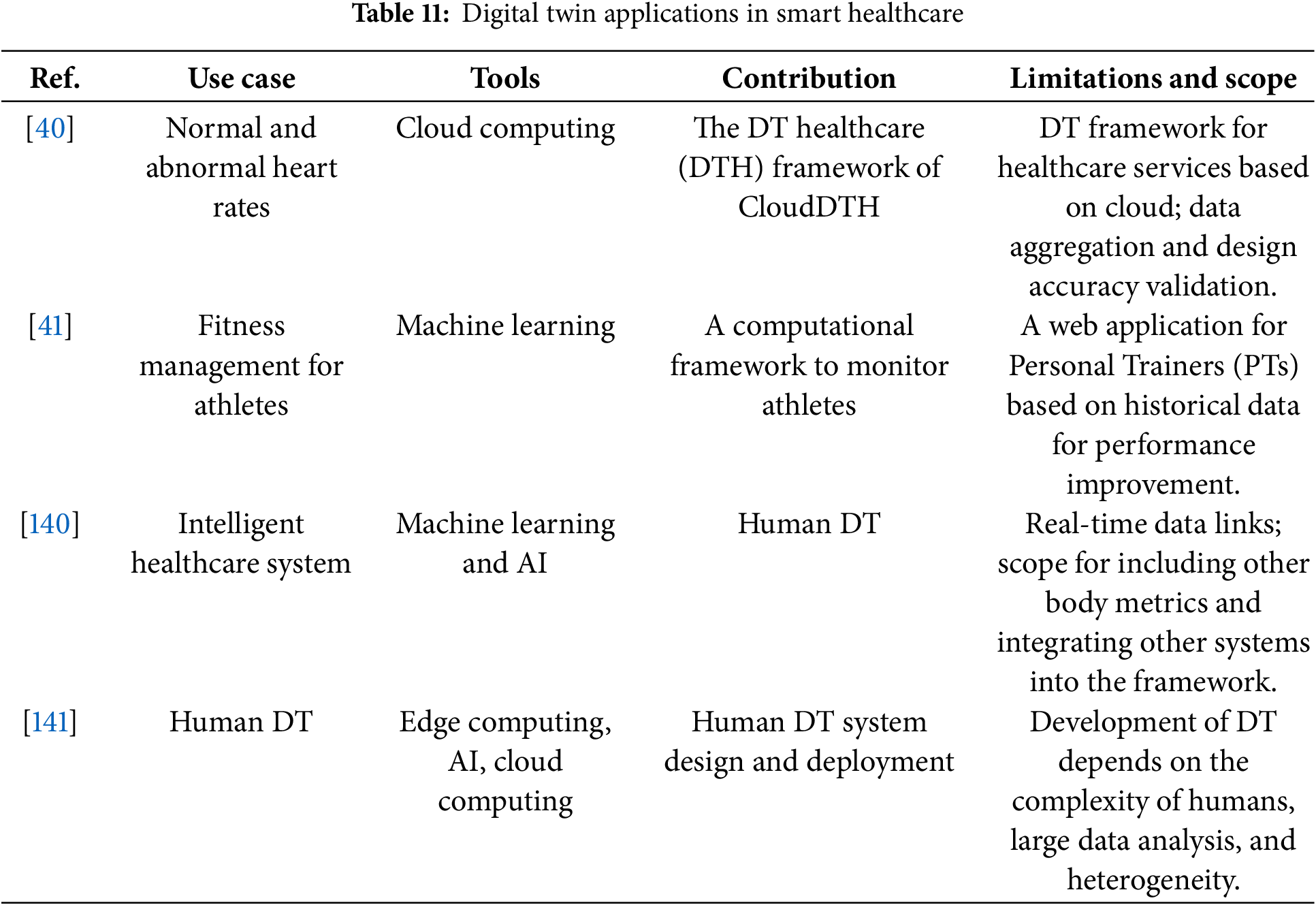

In healthcare systems, reviews detail how digital twins aid patient monitoring, predictive diagnostics, and personalised medicine [40,41]. These studies emphasise the role of digital twins in real-time patient data analysis, simulation of treatment outcomes, and optimisation of healthcare workflows. Enabling technologies such as AI, cloud computing, and advanced sensors are frequently discussed, along with challenges related to data privacy, accuracy, and scalability [42,43].

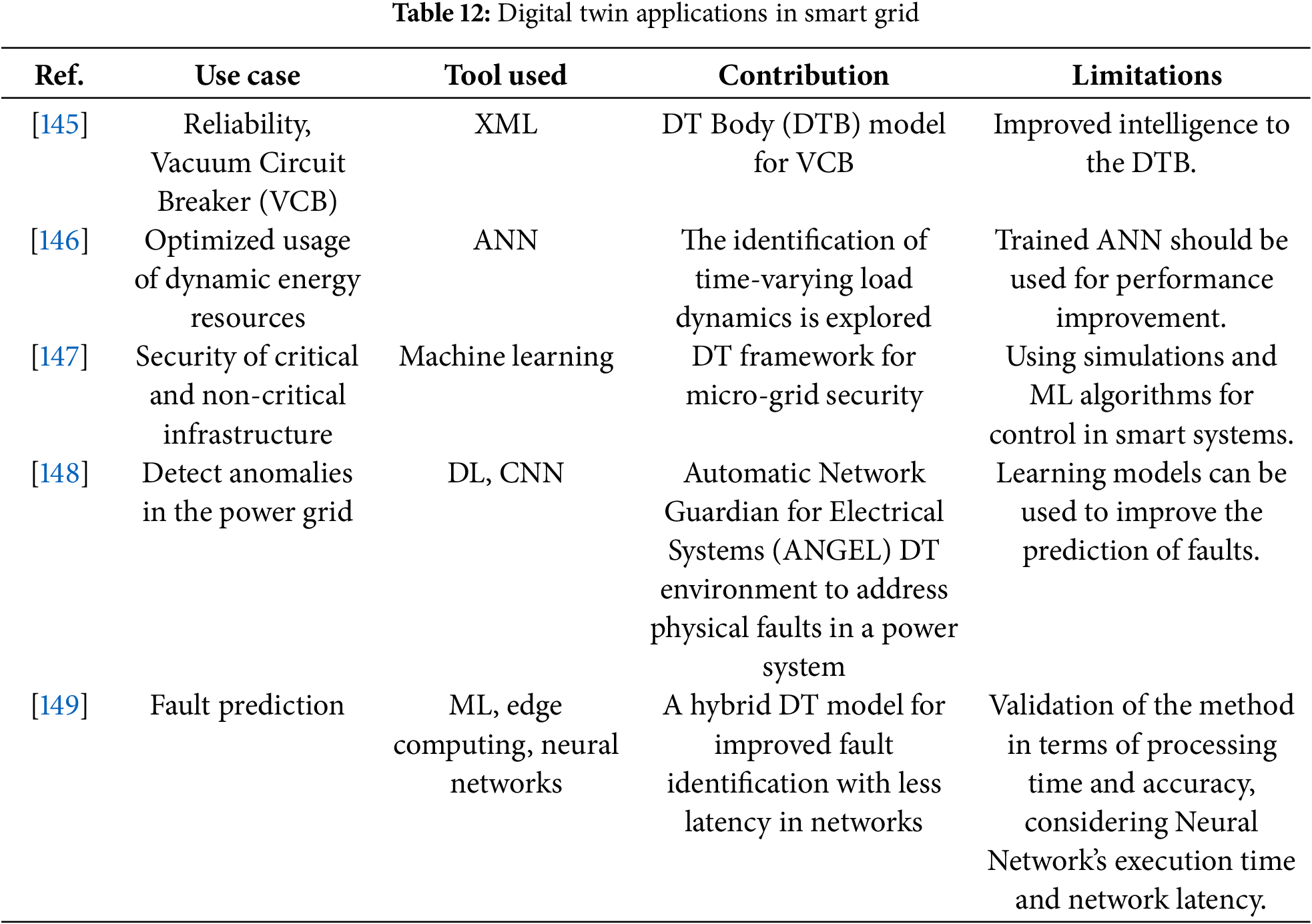

Reviews on energy systems discuss how digital twins contribute to managing smart grids, optimising energy flows, and ensuring grid reliability through real-time data analytics [44,45]. These studies highlight the potential of digital twins in the production and execution stages for grid stability, energy forecasting, and resource management, while identifying barriers such as data integration, system heterogeneity, and cybersecurity vulnerabilities [23,46].

In addition, there are reviews that take a broader perspective, analysing the enabling technologies of digital twins in CPS [9,11]. These reviews provide insights into how technologies such as blockchain, machine learning, edge computing, and IoT networks are used to develop robust digital twin frameworks [25,47]. They identify the challenges of ensuring interoperability between different components of the CPS, maintaining secure communication channels, and addressing scalability requirements [48,49].

Despite the extensive coverage of digital twins in CPS, existing reviews often focus on DT in the execution or production stage, rarely offering an integrated perspective in both stages [20,39]. The present review addresses this gap by providing a comprehensive analysis that consolidates the findings of these diverse reviews, integrating the roles, applications, challenges, and enabling technologies of digital twins in the execution and production stage in CPS [19,24]. In doing so, this study not only synthesises recent insights, but also identifies areas where further research is needed, setting a foundation for future work in this field.

3.3 Contextualizing This Review within Existing Literature

This review explicitly addresses both types of digital twins runtime and production stage in the context of CPS. The aim is to provide a comprehensive analysis that integrates the roles, applications, challenges, and enabling technologies of each type within CPS environments [13,24]. While runtime digital twins focus on real-time operation, control, and predictive maintenance, production-stage digital twins emphasise design optimisation, virtual testing, and predeployment improvements [12,23]. By covering both categories, this review captures the entire lifecycle of digital twins within CPS, from initial design stages to ongoing real-time operation, offering a holistic view that encompasses diverse applications, techniques, and results [2,36]. The detailed comparison of this review with the existing review is presented in Table 3.

Recent literature has explored digital twins in CPS from various angles, including specific applications, technological frameworks, or challenges [9,14]. For example, some reviews emphasise runtime DTs, focussing on their impact on predictive maintenance, real-time control, and supply chain optimisation, particularly in smart manufacturing and transportation [13]. Other reviews concentrate on production-stage DTs, detailing their role in design simulations, process optimisation, and virtual testing in fields such as aerospace and infrastructure development [24,36]. Furthermore, several studies address enabling technologies such as IoT, AI, and blockchain that facilitate the deployment of DT in CPS, highlighting challenges related to data integration, interoperability, and cybersecurity [47,49].

However, most existing reviews focus on digital twins in the execution or production stage, rarely addressing the complete lifecycle of DT integration within CPS [19,24]. This review distinguishes itself by bridging the gap, offering a consolidated perspective that examines the implementation and implications of digital twins in the runtime and production stage across various CPS applications [12,36]. Not only does it synthesise current research, but it also identifies gaps, emerging trends, and directions for future work. By integrating findings across different phases and types of digital twins, this review aims to provide a comprehensive understanding of DTs’ contributions to CPS, addressing current limitations and setting a foundation for further exploration.

4 Cyber Physical System Architecture

The CPS system in Fig. 1 is a general architecture. Four actions take place in a typical CPS system. Sensor gadgets gather specific data from the monitored and controlled physical environment. Subsequently, these data are sent through specialised sinks and gateways, which may perform data cleaning, prediction, and aggregation as intermediate functions [50]. Data duplication can be removed by using these functions. Certain techniques may be applied to other forms of data (e.g., mean value, maximum value, minimum value, etc.). This minimises the quantity of data transported from the local environment to the rest of the system, saving bandwidth, transmission energy, and computation.

Figure 1: Cyber physical systems architecture

The data is then sent across the network to designated servers for storage, additional processing, and analysis. The Internet is usually the network used for data transfer [51]. Other types of proprietary networks controlled by businesses, which can provide better security and privacy, can also be used. Such considerations are relevant, if not critical, for particular firms that handle sensitive and secret data. Cloud computing enables the use of storage and other services, providing increased resources and flexibility.

Users and control workers can easily access the processed results and analyse them on a variety of platforms, including PCs, tablets, and mobile devices. Furthermore, the combination of user input and sensor data analysed using specific control algorithms resulted in system control commands [52]. These control commands are then executed by actuators in the physical environment, which carry out various regulatory and control functions. The localised sensors can then monitor for changes in the physical system and send the data to the database, where a server will repeat the control and feedback cycles. Fig. 2 shows a simplified representation of the different stages of a CPS. As stated previously, detection and detection, storage and analysis, deciding and acting are different phases to affect specific physical parameters and transmit the resulting data to perform the specified closed-loop process [34].

Figure 2: Phases of CPS

4.1 Communication and Computation in CPS

CPS’s computational and physical parts are gently connected. The physical entities are then monitored and controlled by the computing entities. Heterogeneous communication networks connect entities that frequently involve many computational platforms. This is a basic characteristic and a requirement for cyber-physical entities [42]. Due to their low power consumption, wireless sensors and actuators can be placed in a large number and in a range of random physical locations to measure a specific physical phenomenon. This enables more precise monitoring and control of physical processes, something that wired systems make difficult or impossible. As a result, wireless technology is extremely beneficial for CPS, and wireless sensor networks, in particular, can be regarded as an essential component for communication and control [53].

Due to the extensive use of digital systems, a variety of protocols have been developed for wired communication. The transmission control protocol/Internet protocol stacks and the user datagram protocol stacks are used in house and organizational applications, whereas the Fieldbus protocols are used in industrial applications. CAN, OPC UA, Modbus, CANopen, PROFINET, Foundation Fieldbus, INTERBUS, HART, and others [54,55] are some of the communication protocols used in industrial environments between field equipment, controllers, and software. Compared to wired alternatives, cost savings from cable replacement, changeable network topology, extensibility, and fewer operational efforts are just a few of the evident advantages [56].

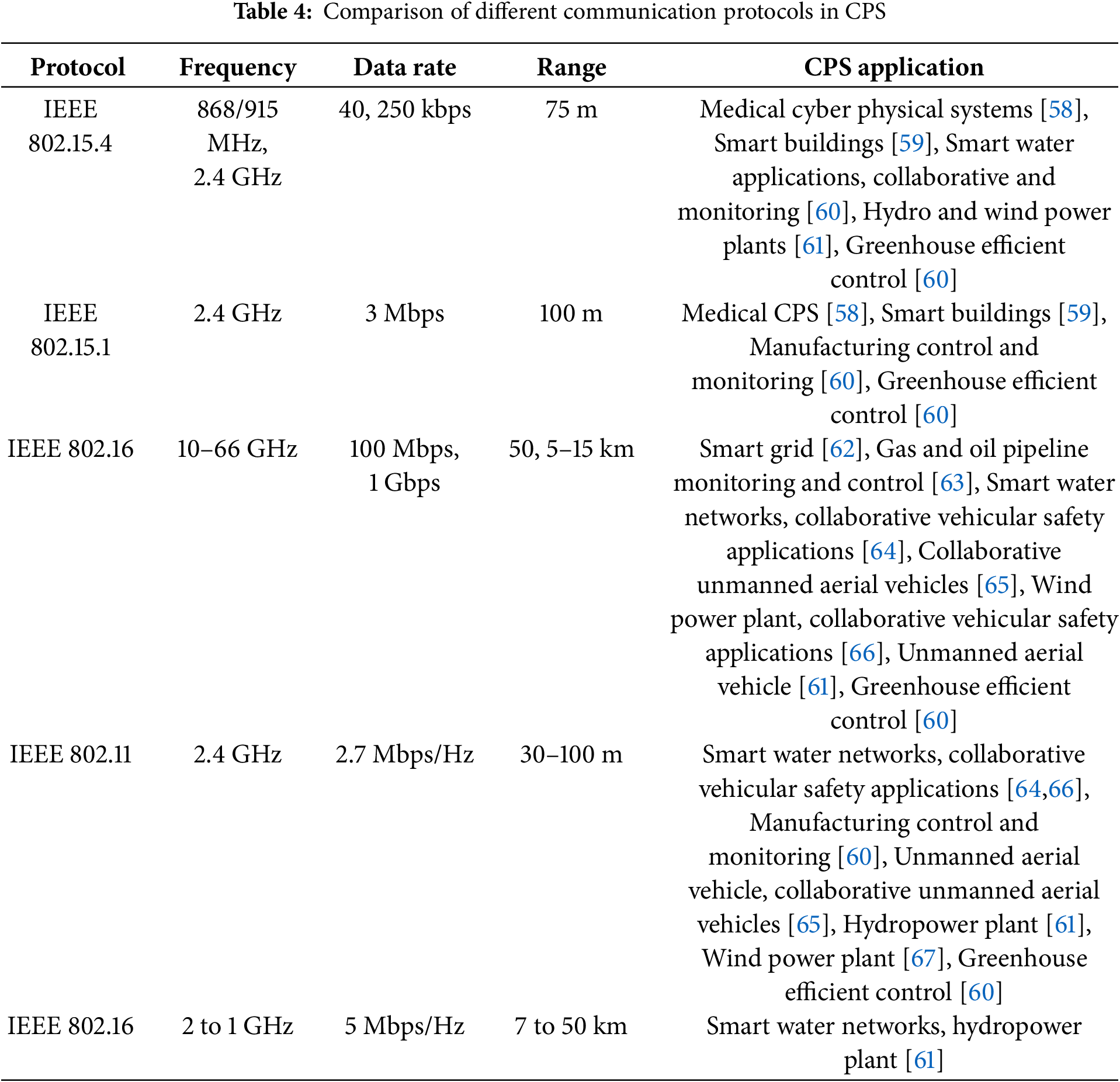

Wireless communication, on the other hand, comes with a slew of obstacles that people should overcome. In most situations, wireless sensors and wireless actuators in different application domains are restricted in terms of energy efficiency, information exchange, and energy supplies, so issues such as transmission consistency, data shipping, and efficiency must be considered from the design step. The important factor affecting the choice of communication protocols in any application is the power consumption of the nodes, which must be maintained as low as possible [57]. The CPS-supported network protocols along their primary features, including the parameters of the physical and data connection layer, the data speeds, and the transmission range, are listed in Table 4.

The network features and necessities of CPS are determined by various factors, such as the need for bandwidth, tolerance for delays, level of power consumption, demand for reliability, security concerns, diversity of network links (wired, wireless, or both), and mobility traits unique to each application. CPS can be categorised into four main types according to their size and geographic coverage.

Device CPSs embedded within a particular device or body operate within a limited or personal geographic space using protocols from the body area network (BAN) and personal area network (PAN) categories, such as IEEE 802.15.4 (Zigbee) and 802.15.1 (Bluetooth). These protocols are generally associated with lower bandwidth, low energy consumption, and short-range communication. Localised CPSs are located within a relatively small geographic region that covers an area of several hundred metres, such as a house, a building, a warehouse, or a manufacturing facility. These CPS applications require longer-range communication protocols from the local area network (LAN) category, such as IEEE 802.11 (WiFi). These protocols are also suitable for mobile CPS applications. However, efficient and robust routing protocols must be designed for mobile CPS systems due to the highly variable and dynamic environment.

Extensive CPS situated across a large to very large geographic region, spanning from a small city to the entire world. Mobile CPS comprises mobile nodes that establish a flexible structure. Wireless communication links enable nodes to communicate with each other using a multi-hop mechanism. As nodes move in and out of each other’s range, these links are formed and broken continuously. Communication protocols of the wide area network (WAN) category, such as IEEE 802.16 (WiMAX), cellular, and satellite, are required for extensive CPS. These protocols offer provisions to support both synchronous and asynchronous data connections. Real-time CPS applications have specific requirements for security and bandwidth. However, implementing security features often requires additional processing, which can result in increased delays and energy. Therefore, these factors should be carefully considered before implementing security features. Additionally, bandwidth requirements within the same type of application can vary from low to medium to high, depending on the type of data being generated.

The delay tolerance varies between different CPS applications. Although some applications require a low end-to-end delay, others can tolerate higher delays. For example, applications that focus on data collection and monitoring can tolerate higher delays, since the data is processed later. Examples of such applications include medical CPS that records patient data for later analysis and Unmanned Aireal Vehicles (UAVs) that take images for later processing. Power consumption is another crucial requirement for CPS applications. CPS also places great importance on reliability, ensuring that the systems operate consistently and predictably. Another critical characteristic of CPS is mobility, as nodes may be moving or the system itself may be deployed in a mobile environment.

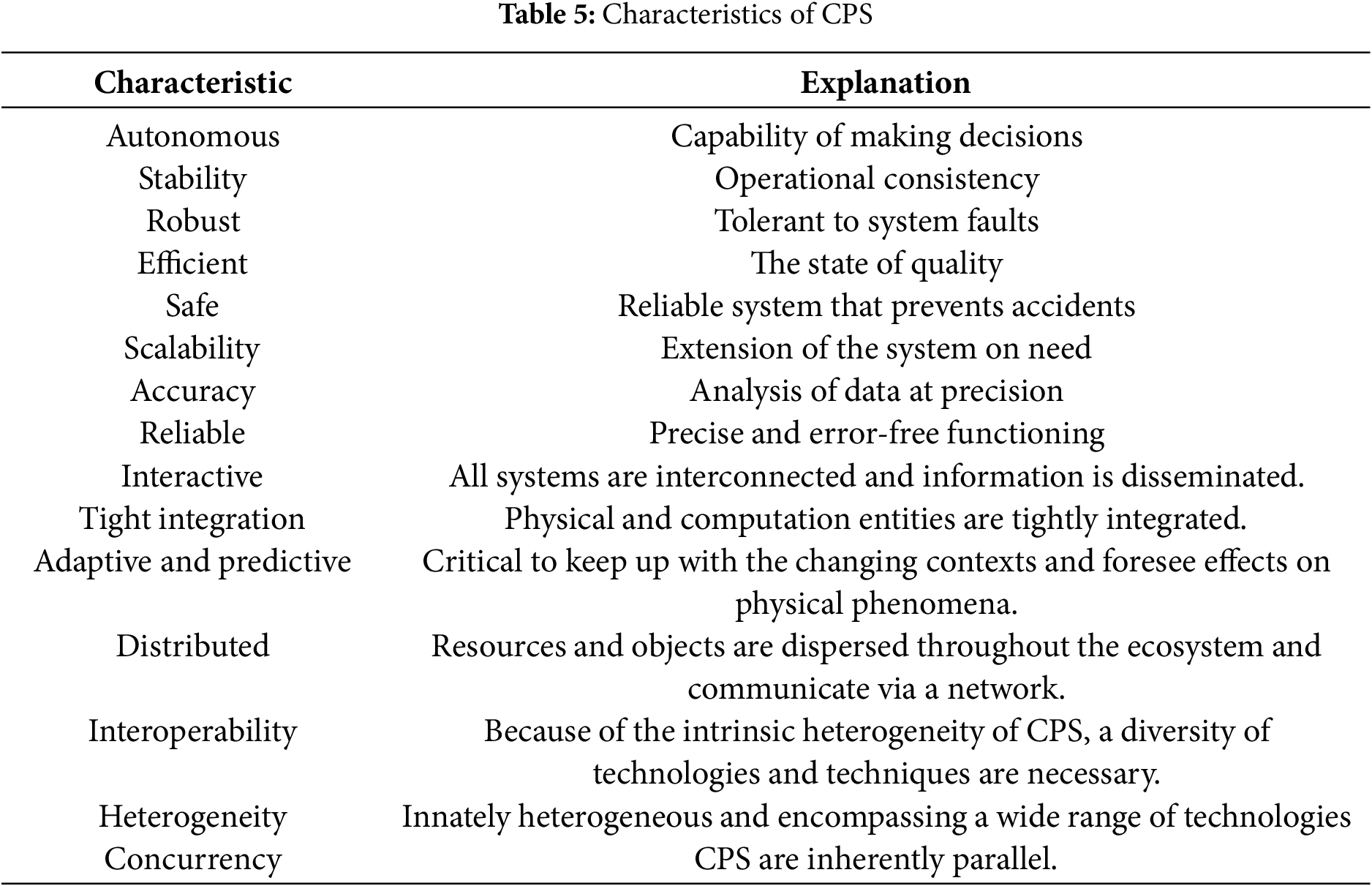

CPS has some characteristics that make it usable in different smart applications. To increase the efficiency and flexibility of manufacturing processes and also in other domains, considerable autonomy and quick choice procedures are required. CPS and the outside environment must always be in sync in order to transmit facts and trigger actions [42]. Table 5 presents the characteristics of the CPS.

Complexity/heterogeneity encapsulation: The components used to construct a CPS can have different properties, such as different processing speeds, power requirements, communication protocols and sensing capabilities. These differences in inherent properties can impact the overall performance and behaviour of the CPS. Therefore, designing a CPS requires careful consideration of the properties of each component and how they interact with each other in the system.

Interoperability: For a system to be interoperable, its components must be able to interact with each other effectively. This is particularly important for CPSs, where the ability to communicate in an understandable way is crucial to ensure an adaptive response. Standardisation is essential to achieve interoperability, as it establishes a common language or protocol that enables components from different CPSs to communicate seamlessly. Interoperability and understanding of shared knowledge are crucial in various CPS systems

Communication and connectivity: To acquire information from the physical domain and obtain feedback from the cyber environment in real time, CPSs include the communication or, analogously, the connectivity feature. With IoT, any object can be linked to the internet, enabling bidirectional connections between or between production systems; this facilitates the availability of fresh data across operations and encourages the use of horizontal applications with decentralised decision making. CPSs use the IoT’s infrastructure to exchange and analyse data, then use that information to direct the deployment of physical resources and the subsequent management of physical operations.

Networking capability/scalability: Many authors have provided descriptions of network capacity: With the goal of adding intelligence across different fields, CPSs should be made up of clusters of processing and physical components in wired or wireless networks via various sensors and actuators. Internet is commonly used to link these disciplines, allowing dynamic network participation.

Modularity: If a CPS has modularity, it can be easily modified and reconfigured to meet the ever-evolving demands of the market. As a result, the freedom afforded by modularity gives the system increased adaptability. To this end, modularity is a key feature of CPSs.

Similarity of autonomy and self-capabilities: Autonomy refers to the ability of CPSs to acquire knowledge and modify their behaviour without external intervention. Complex adaptive systems are autonomous, dynamic, and incredibly complicated. In order for the components to recover from localised changes, to disturbances and recover from localised changes. The autonomy of CPSs enhances their inherent potential.

Decentralization: The term “distribution,” which can also mean “decentralisation,” is commonly used to describe the method through which CPSs make and implement decisions. Parts of a distributed system exist on different computers connected by a network and work together to achieve a common objective by exchanging data and coordinating their efforts.

Integration: For CPSs, integration is a crucial and difficult challenge. Integrated CPSs are the natural result of the merging of computational and physical processes. As a design issue (including physical systems, software, and platform engineering), CPS integration will speed up the creation of new process networks across production assets.

Virtualization: Simply put, virtualization is the process of establishing a digital representation of the real physical environment and maintaining a connection to it over time. This includes the capacity to correlate sensor data to digital representations of factories and simulations. CPSs allow remote monitoring and analysis of physical processes, simulation of behaviour, and, in some cases, communication from the virtual environment to the field.

Real-time capability: When it comes to equipment, quality, and raw materials, CPSs with real-time capabilities can acquire, analyse, and quickly deliver real-time data. In order to meet the operational and safety demands of the system, CPSs rely on this feature, which allows them to notice any changes in the physical mechanisms and respond immediately. It follows that real-time capability may also involve taking concrete measures to forestall breakdowns.

Computational capability: The cyber components of CPSs should be able to carry out a significant chunk of the computation and control work previously undertaken by humans, with the added benefit of today’s enhanced capacity for data sharing and interoperability.

Intelligence/smartness: CPSs are expected to have intelligence, sometimes known as smartness, because of their ability to be recognised, perceive the world around them, engage in social interaction and make independent judgments. In order to impart intelligence to a physical component, CPSs equip it with the means of computation and communication. This sort of knowledge is shared among physical, communication and computational components of CPS.

Cooperation and collaboration: Despite the fact that collaboration is typically viewed as a more powerful notion due to the sharing of resources and the pursuit of common goals, the terms (cooperation and collaboration) are frequently interchanged. Cooperation refers to a distributed system’s ability to dynamically determine which of its independent subsystems will carry out a task in order to maximise performance such as reaction time.

Dynamic reconfigurability, adaptability: The ability to quickly adapt to changing market conditions and disruptions is what the term “dynamic reconfigurability” means. Specifically, CPSs can change over time by dynamically reconfiguring their structures, features, behaviours, and boundaries. To the same extent, flexibility refers to the capacity of CPSs for rapid reorganisation/reconfiguration in response to unexpected circumstances and novel objectives.

4.3 Challenges in Modeling CPS

A crucial design need for CPS is the capacity of computer elements, physical components, and communication technology to work together to deliver the desired functionality. The primary difficulties in designing and testing CPS are concurrency and asynchronous communication [68]. Furthermore, in CPS, software with time limitations is widespread, such as activities that must be executed on a regular basis, deadline requirements, or latency restrictions. Traditional control systems use discrete-time or continuous signaling, in which the controller continuously or periodically observes and acts on the physical subsystem (e.g., industrial plant). Unlike these systems, signaling in a typical CPS architecture is mediated by software and networks.

In CPS, time-triggered or event-triggered methods are often used to transfer information between physical and cyber components [69]. Physical subsystems function on a time continuum, whereas cyber subsystems are made up of discrete, sequential actions. An industrial CPS control system, for example, collects system status measurements from sensors and samples them periodically on a time-triggered basis, whereas the interaction between a man and a system often operates on a demand-interference basis when certain events occur [70]. For CPS, integrating engineering abstractions for continuous dynamics (such as differential calculus) with computer science abstractions is a major challenge (such as algorithms) [71].

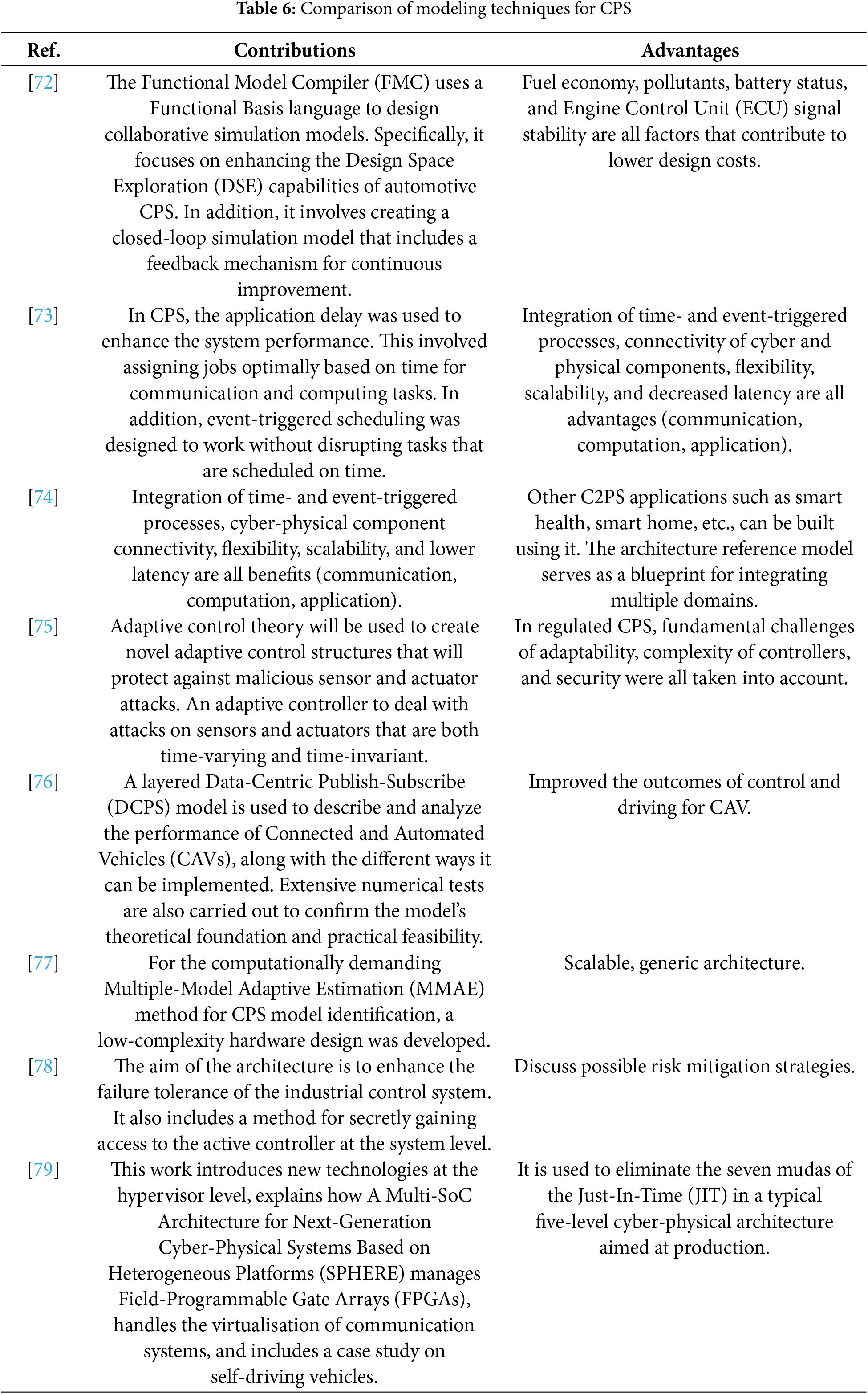

The inability to fully model interactions between various components and between the physical and cyber aspects is a major impediment to the efficient implementation of CPSs. It is difficult to explain the connections between these cyber and physical worlds precisely. Due to the required qualities, designing a CPS presents distinct challenges. As a result, a substantial gap has been discovered: there are no generalised approaches to CPS design. However, a few traits of the CPS modelling technique have been outlined, and various CPS structural concepts are being developed. The known approaches for modelling CPS are listed in Table 6.

In CPS, physical dynamics and computer operations are inherently diverse. Machine motion control and chemical and biological processes, for example, could all be part of the physical domain. In the cyber world, networking technologies, programming languages, software models, and concurrency methodologies are all possible.

As a result, the goal is to build engineering processes and tools to aid in large-scale design techniques so that the underlying systems must be studied and better understood [80]. Self-configuring, self-adjusting, and self-optimizing production environments will lead to increased agility. The authors [81] proposed a cyber-physical system of systems. This variation helps to manage CPS and makes the design process easier. The most common practical production issues are the unpredictability of the quality of the machine, the unpredictability of the prices of the machine, and the unpredictability of the machining efficiency [82]. Although process equipment is chosen with care in terms of process design, some unknown aspects are present in the real process, including damage to equipment, overlap with various processes, etc. As a result of these challenges, the processing route is usually unable to run smoothly. In addition, procedures are slowed [83] in CPS applications.

The authors argue in [84] that today’s computer processing and networking abstract concepts are insufficient for CPS modeling because of the inability to adequately render the passage of time and parallelism of a physical process, and they suggest research directions for improved computational and networked abstractions for CPS. The work in [85] illustrates the limitations of CPS modeling, as well as an evaluation of recent developments using an insightful description of a fuel management platform in an aircraft. CPS can be found in almost every industry area and operates according to the Industry 4.0 paradigm. Computation, networking, and physical processes incorporate numerous types of system with the goal of managing a physical process. To accomplish CPS, cloud and machine intelligence will increasingly combine with physical systems and processes with the help of wireless communication.

DTs, which mainly consist of real-time data collection, data mapping, and data-based anticipation technologies, will help products achieve physical and virtual space convergence [86]. From the literature on CPS modeling techniques, challenges in CPS modeling, and combined applications of CPS and DT, it can be observed that DT is useful in implementing critical safety systems, i.e., CPS. So, the concepts required for implementing CPS through DT are provided in the following sections.

5 Introduction to Digital Twins

The cyber components of the CPS driven by data promote new and inventive design methods to build, operate, and manage our smart systems in the future and the DT is an example of this. “A realistic digital depiction of assets, processes, or systems in a built or natural environment” [87] is what a DT is. DT can reflect any sort of physical, social and/or economic conditions and processes [88]. DT implementation can be done in a variety of ways. While some [89] classify DTs as prototypes, instances, aggregates, and environments, others classify them as status, operational, and simulation twins. IoT, CAD (Computer-Aided Design) models, networked sensors, artificial intelligence, data analytics, and algorithms in machine learning, as well as cognition, can be included in DTs.

Regardless of the types of CPS, the technologies involved in implementation or the systems they attempt to imitate in a digitized form, DTs facilitate a way of gathering and combining data for the enhancement, development, operation and management of physical things. Networked twins, for example, can analyze and optimize outbound energy as well as material usage through smart IoT. Alternatively, DTs can track infrastructure usage, efficiency, safety, and other metrics, as well as promote more environmentally friendly practices [87]. CPS includes software, communication protocols, and physical and embedded systems, which are recognized as a fundamental driver of digital transformation [90]. Sensors collect data from the physical environment and send it to compute units of DT. These data are analyzed by DT computing units, which subsequently notify physical systems of their findings and, in some situations, transmit controls to make the necessary adjustments to the physical environment of the system properties [91].

The Product Life cycle Management (PLM) class was an initiative of the DT. The PLM is a management of a product’s entire lifecycle, from inception to disposal. DT has rapidly expanded its application beyond PLM to additional yields such as aerospace, oil and gas, medical, and so on, because of its distinctive advantages in terms of expansibility, reproducibility, and openness. Although there is a considerable review on DTs for smart manufacturing, there is not much to say about smart cities, and they are mostly about technological decisions, with only a handful for infrastructure. CPS is built on the foundation of the DT.

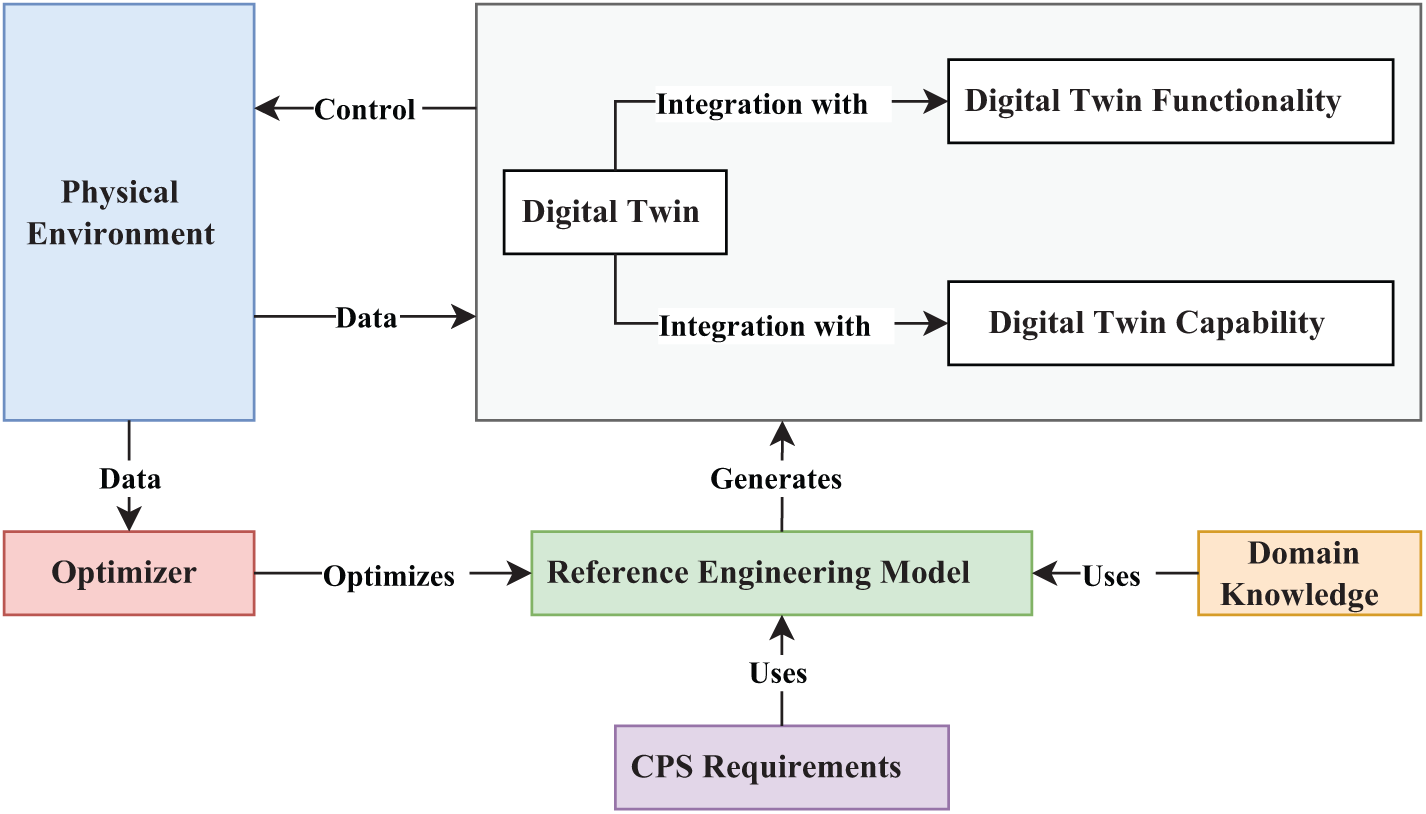

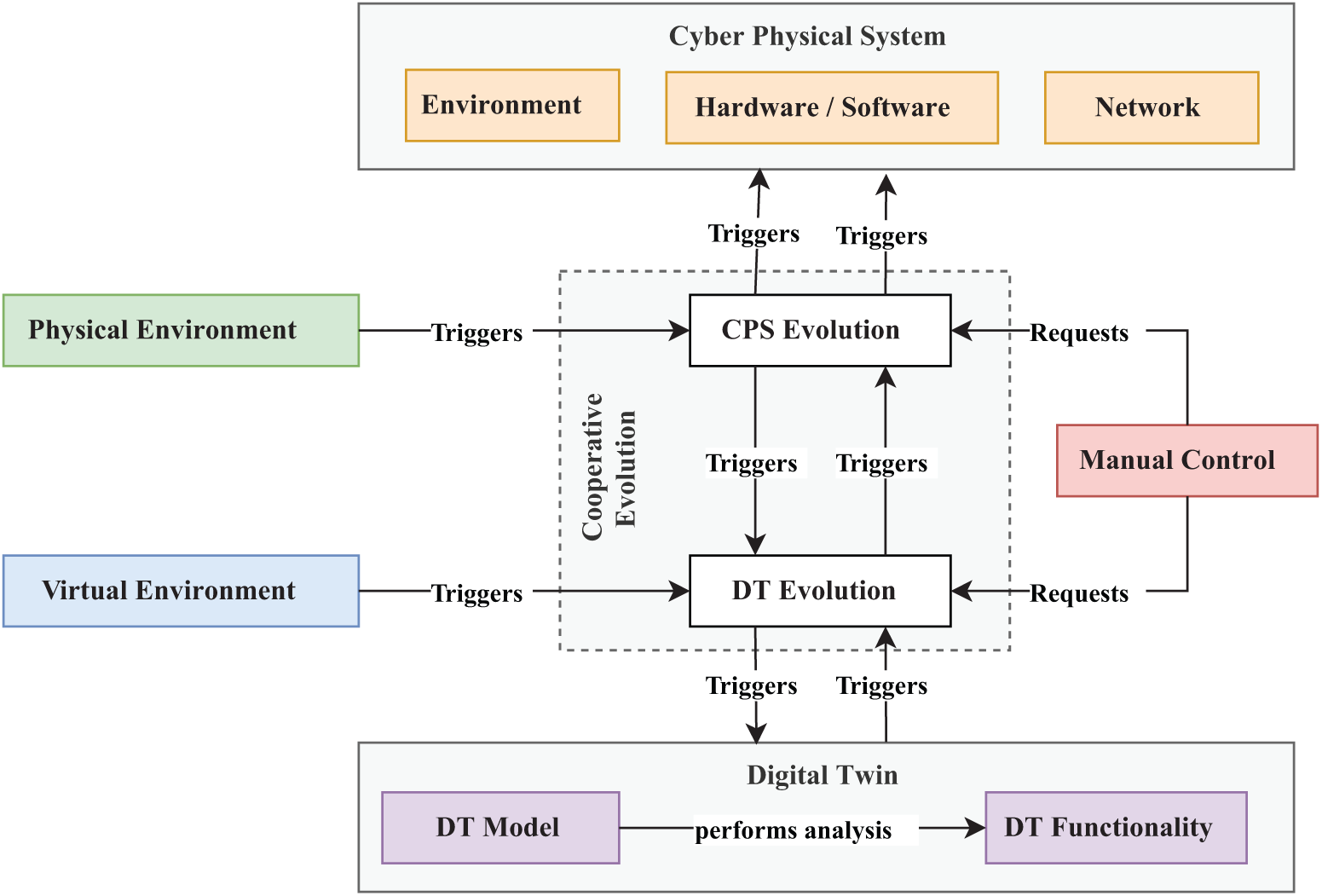

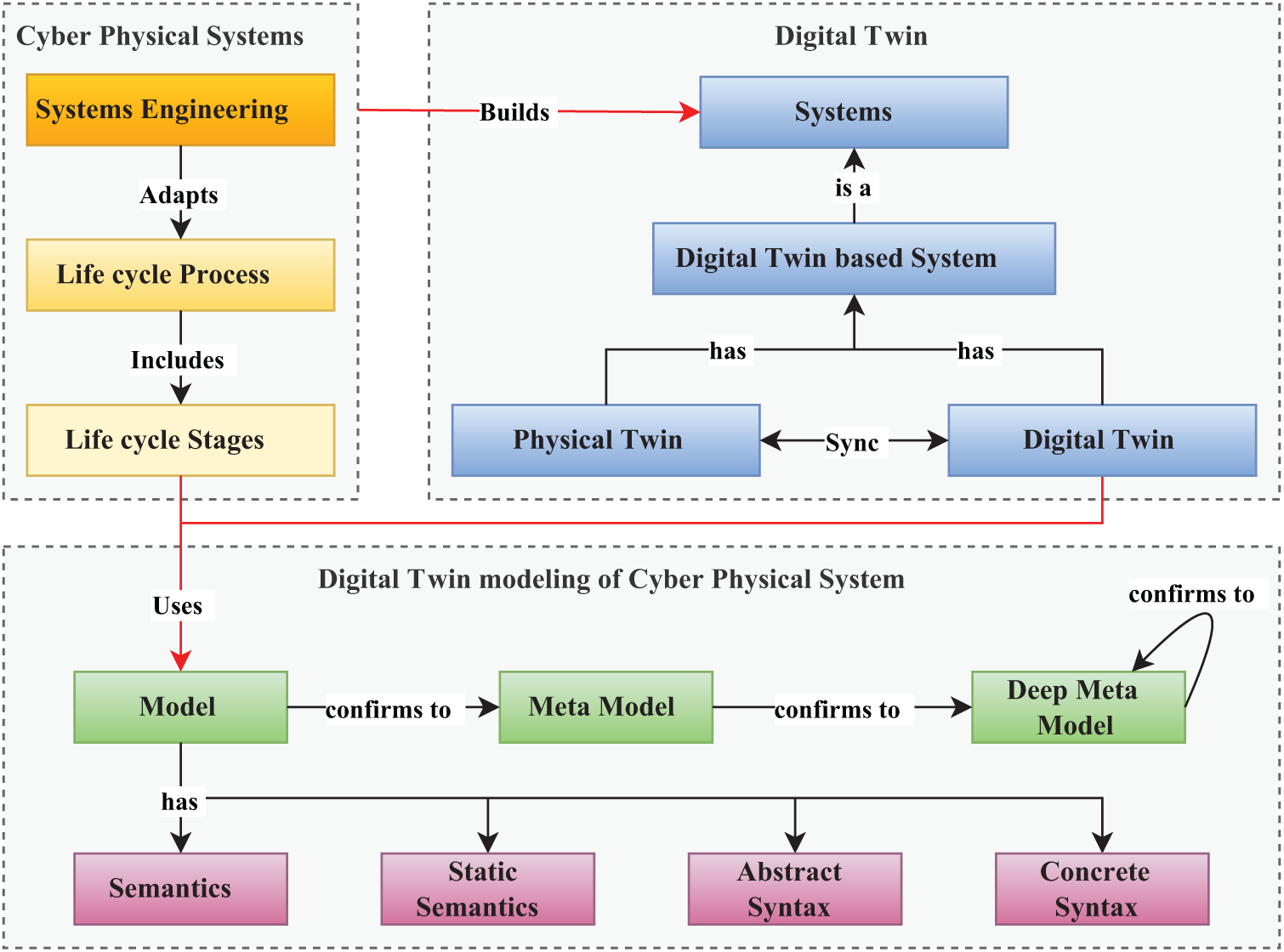

5.1 Relationship between CPS and DT

While CPS integrates the physical and cyber components for real-time monitoring and control of physical systems, DT serves as the virtual counterpart of CPS by providing a digital replica of physical assets or processes. The role of CPS is to collect real-time data from physical environments, which are then fed into the DT to model, simulate, and optimize performance. DTs, in turn, enhance CPS by enabling advanced analysis, simulation, and decision-making capabilities. In essence, DT augments the CPS by providing a comprehensive platform for real-time feedback, control, and performance optimization. The relationship between CPS and DT is depicted in Fig. 3, emphasizing the flow of real-time data from CPS into the DT for simulation and optimization, with feedback enhancing control and decision-making. The left section of the diagram represents CPS, capturing real-time data from physical systems through sensors and actuators. This data flows into the DT, depicted on the right, where it is used for simulation, optimization, and predictive insights. The bi-directional arrows highlight the feedback loop where CPS influences DT and vice versa, showcasing their complementary roles.

Figure 3: The visual illustration of the interplay between CPS and DT

In different applications, CPS and DT play complementary yet distinct roles: CPS Responsibilities: The primary responsibility of CPS is real-time monitoring and control of the physical system in real time. CPS ensures that physical assets operate within the desired parameters by collecting sensor data, making decisions based on control algorithms, and sending commands to actuators. DT Responsibilities: DTs are responsible for simulating, analyzing, and predicting the behavior of the physical system in real-time. They improve the CPS by providing insights that allow predictive maintenance, optimisation, and risk assessment without disrupting the actual system.

Use cases: In a smart manufacturing setup, the CPS ensures that the machinery operates correctly by monitoring performance metrics and controlling the production line. Meanwhile, DT provides predictive analytics and simulations that help optimise the production process, identify potential failures, and reduce downtime. In smart cities, CPS manages the real-time operation of infrastructure (e.g., traffic lights, energy grids), while DT simulates city-wide operations to improve resource allocation and optimise urban planning.

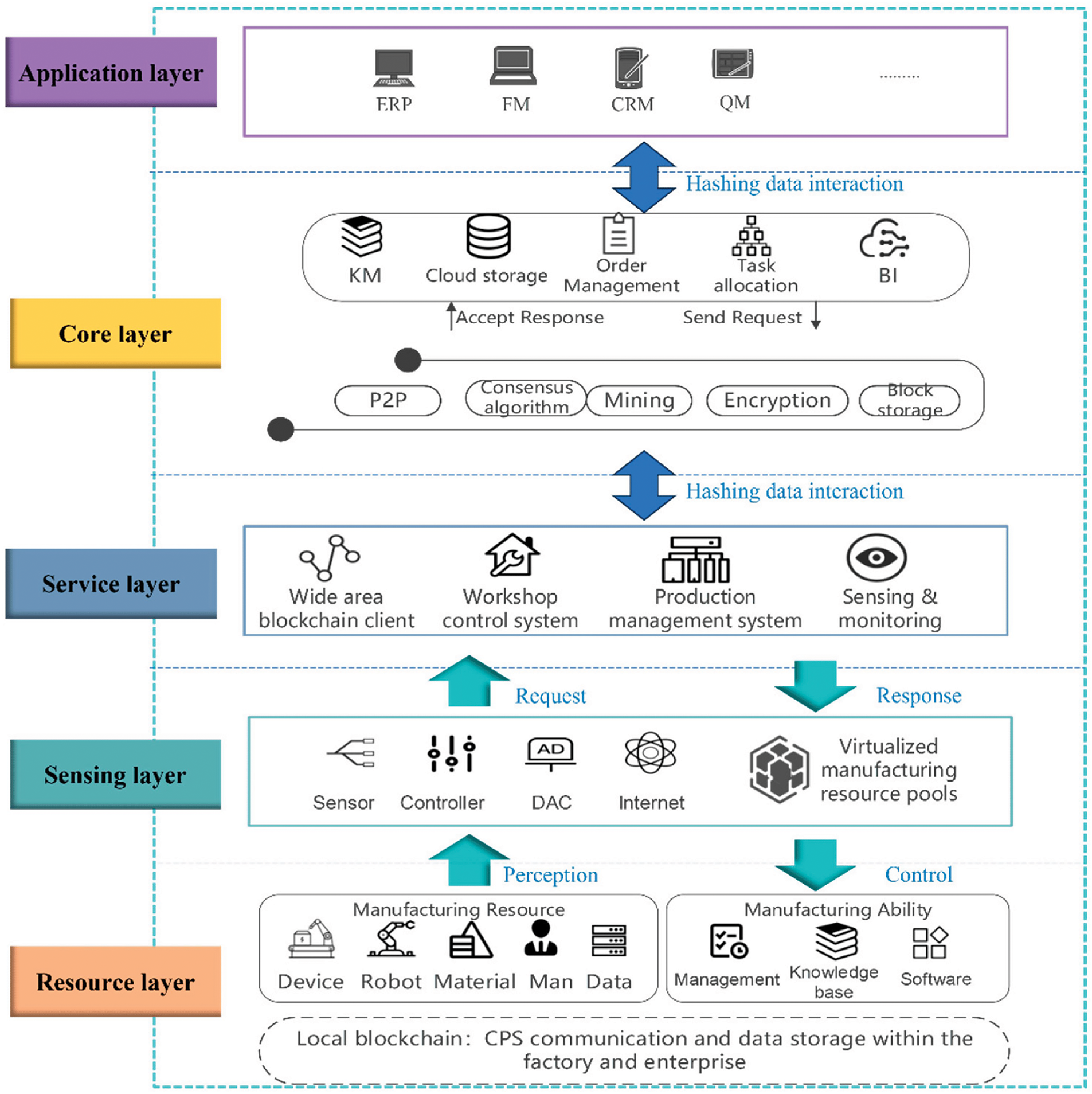

5.2 Layered Architecture of CPS and DTs

The modern CPS are often complex, multi-level distributed systems, structured as federated and coalition systems, which require distributed modeling approaches rather than viewing the DT as a monolithic software module. There are a number of DT architectures based on different applications. The authors in [92] proposed a unified architecture for a DT to increase processing efficiency, reduce manual intervention, and reduce investment. This allowed a combination of models and simulations at various levels. Another research in [93] identified design-derived security needs for DT-based data sharing and control and also showed that coordinating design met the expected synchronization requirement given the high-level design and other security components of the architecture. The authors [94] presented the modular architecture for the implementation of DT based on open source tools to control the process and easy tools for 3D representation. The authors [95] presented a new blockchain variant, twin chain, which proposes quantum-resilient and instant transaction confirmation. A twin chain deployment architecture for the construction of a robotic surgical machine was also presented.

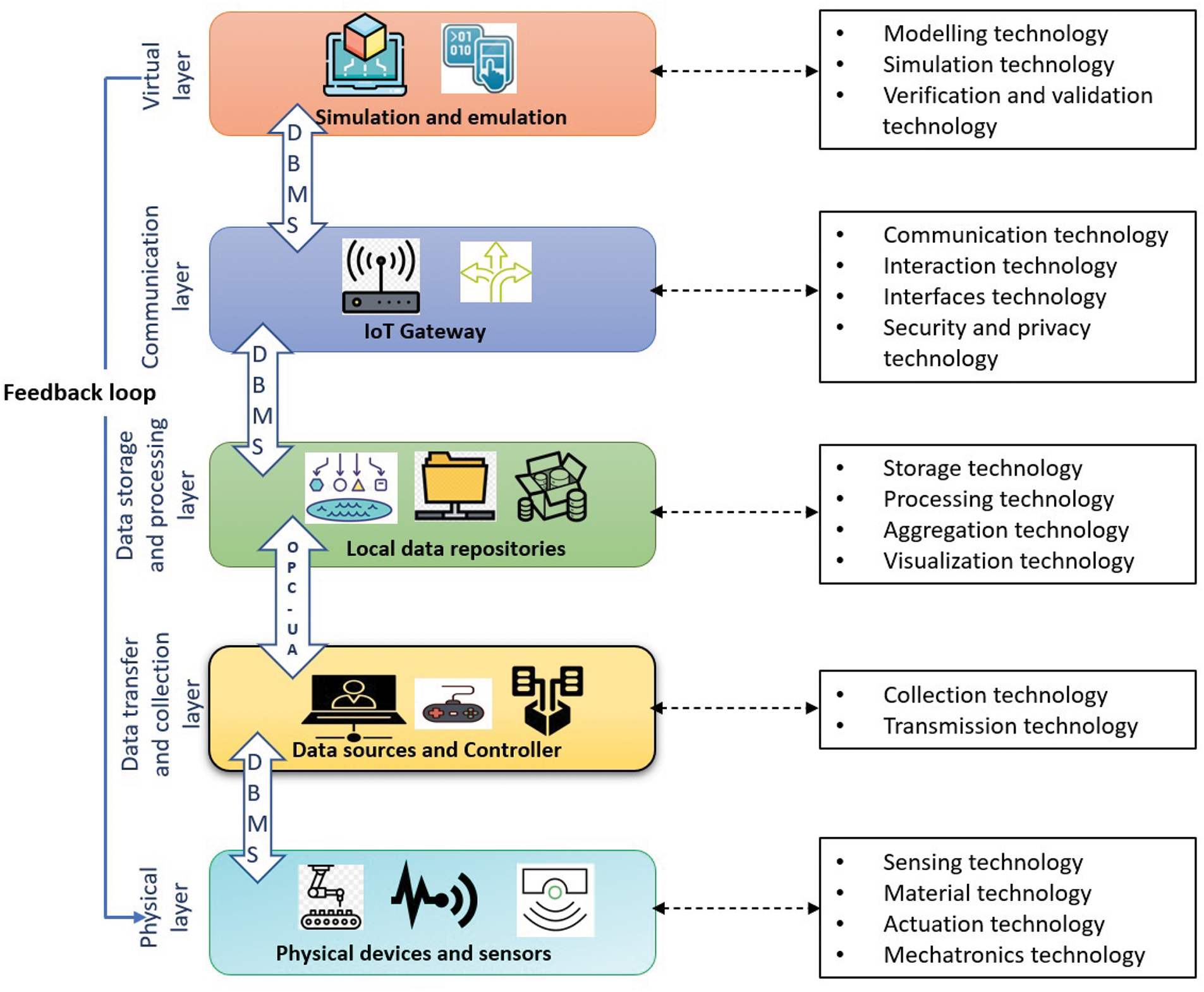

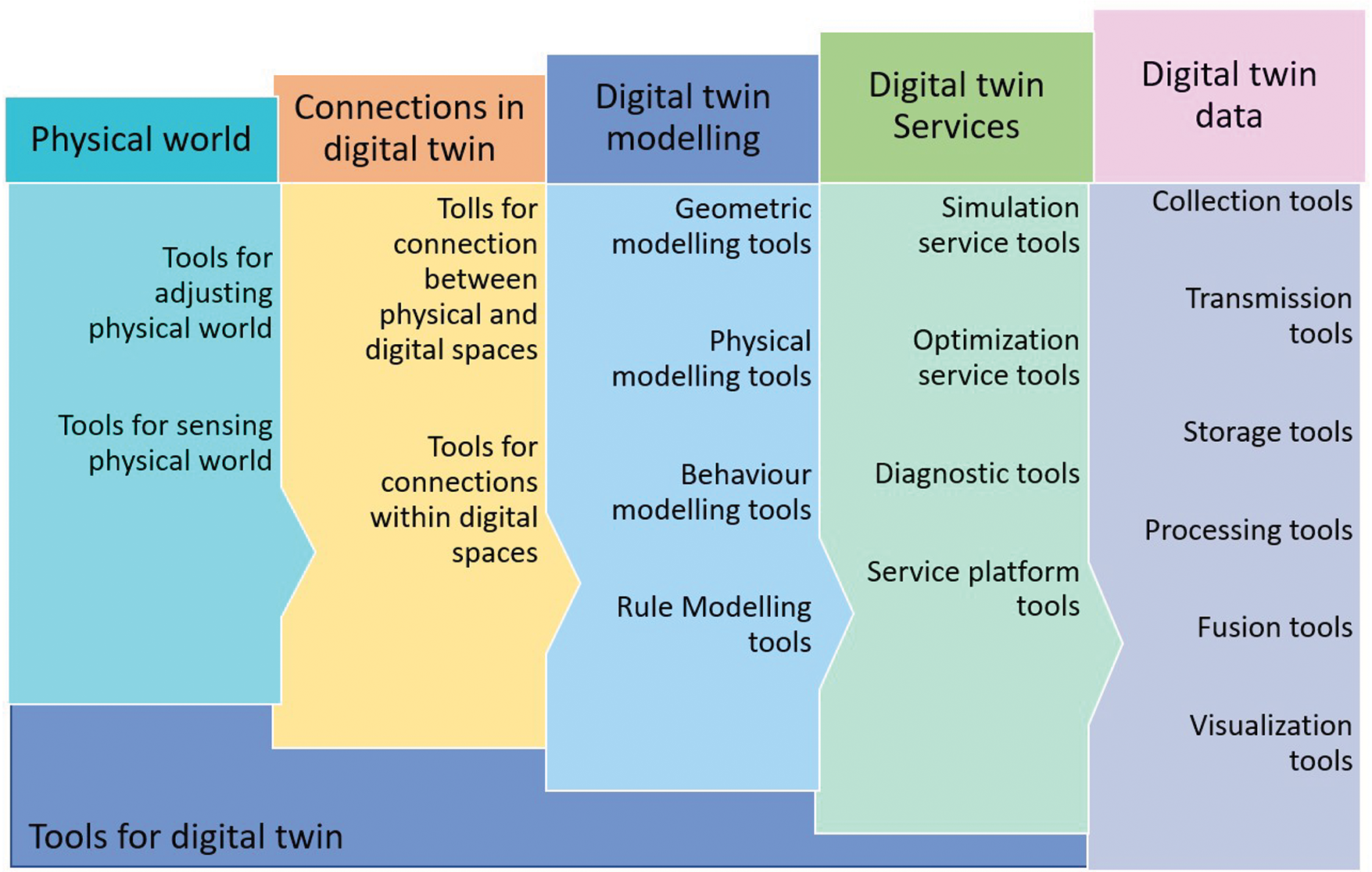

In this review, we emphasize the interplay between CPS and DTs in the integration of physical and digital layers. CPS, as a bridge between the cyber and physical worlds, utilizes sensors, actuators, and real-time feedback to directly control physical systems. Given the distributed nature of CPS, the Digital Twin must comprise a system of interconnected models that represent both physical and software entities. These models allow for the layered, dynamic interaction of components, providing a more accurate and flexible simulation environment. Digital Twins, in contrast, provide a virtual representation of these physical components, offering advanced modeling, simulation, and predictive capabilities based on real-time data. Fig. 4 depicts the architecture and enabling technologies across each layer that are essential to integrate physical devices with their virtual counterparts in the cyber-physical domain. While data transfer, processing, collection, computation, and communication occur within the virtual environment, the architecture also utilizes various physical devices, sensors, and data capture systems in the real world. Layers 1 and 2 of the architecture represent the physical aspect, where Layer 1 consists of actuators, sensors, and other hardware, and Layer 2 defines the data sources for a given physical object.

Figure 4: Layered architecture of DT with enabling technologies

While CPS is concerned with immediate interaction with the physical world, DTs rely on these inputs to maintain an accurate, real-time virtual replica of the physical system. The physical layer within the DT architecture serves an essential role in connecting DTs to real-world data, enabling synchronization between the digital twin and its physical counterpart. This layer ensures that the DT’s simulations, predictions, and optimizations reflect the current state of the physical system. Thus, CPS and DTs, though distinct, work synergistically, with CPS handling real-time physical control and DTs enhancing system performance through virtual modeling and predictive analytics. DT requires a deep understanding of the physical domain, which encompasses disciplines such as dynamics, thermodynamics, material science, structural mechanics, electromagnetism, hydro mechatronics, acoustics, and control theory. Using advanced sensing, measurement, and knowledge-based technologies, physical entities and processes are mapped to virtual environments, enhancing the realism and accuracy of the models. Throughout its operation, DT generates large amounts of data, contributing to the continuous improvement of the digital representation.

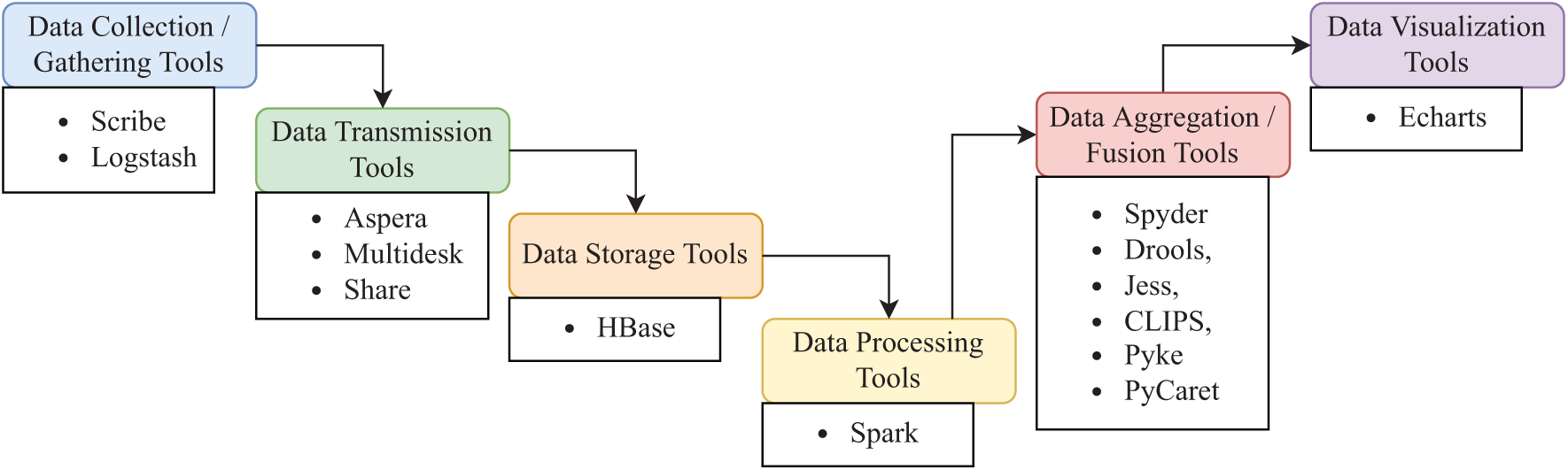

Data analysis and aggregation technologies are required to extract usable information from raw data. Data gathering, transmission, storage, processing, aggregation, and display are all part of the process. Advanced data analytics and fusion technologies are required to extract meaningful information from raw data sets. The controller values are transferred from Layer 2 to a local data vault in Layer 3, which is the interaction between the higher architectural levels and the physical entity. The most important component for efficient data sharing between the layers is Open Platform Communication-Unified Architecture (OPC-UA). The OPC-UA is a communication protocol that ensures seamless machine-to-machine interaction in industrial automation. Layer 4 uses Internet of Things (IoT) tools to transform raw data into meaningful insights. By applying various transformations to the data collected in Layer 3, this layer makes it more useful for subsequent architectural layers.

Connecting Layers 3 and 5, Layer 4 transforms Layer 2 data into suitable information for Layer 5. Again, OPC-UA is crucial to the flow of information in this scenario. The cognitive layer, that is, Layer 5, located at the top of the design, stores the physical replicas’ past data and allows for continuous monitoring of the machine’s health. This layer allows users to interact with a digital version of the physical twin, improving their ability to make decisions, enhance existing procedures, and anticipate future results. Several types of modeling techniques are required for the virtual model. Physical assets and processes must be monitored in real time using visualization technology. An accurate virtual model directly influences the performance of the DT. Therefore, verification, affirmation, and certification technologies and optimization techniques must be used to validate and optimize the models. To further speed up quality defect detection, simulations and retrospective technologies might be used. Model evolution technology is required to keep up with the ever-changing real world.

The architecture of Digital Twins allows for the inclusion of multiple models that cater to different stakeholders, each focusing on specific aspects such as operational efficiency, life cycle management, or safety. These models are built with varying perspectives to ensure that all stakeholder requirements are met effectively. As explained, DT consist of multiple layers, each performing a specific role in linking the physical and cyber domains. These layers include physical devices, data collection, and processing technologies. Each key component of the DT belongs to a specific layer:

• Physical Layer (Layer 1): This layer consists of physical devices such as sensors and actuators that collect real-world data from the physical system.

• Data Source Layer (Layer 2): The collected data from the physical layer flows through this layer, which aggregates the information and prepares it for further processing.

• Communication and Data Processing Layer (Layer 3): Here, data from the physical systems is transferred and managed using technologies like OPC-UA. This layer acts as the interface between the physical and digital environments.

• IoT and Analytics Layer (Layer 4): In this layer, data from sensors is processed into meaningful insights using advanced analytics and IoT tools. This allows for real-time decision-making based on the physical system’s state.

• Cognitive Layer (Layer 5): At the top of the architecture, this layer stores historical data and provides predictive analysis and simulation capabilities, allowing for performance optimization and future predictions.

By mapping these components to specific layers, it becomes clear how DT’s physical and virtual components interact, ultimately enabling real-time synchronization, performance optimization, and control of physical systems. In addition to physical components, software entities also serve as observed and controlled objects within the DT, allowing for a more comprehensive management of CPS across different operational levels. Depending on the stakeholder’s role, a single entity within the Digital Twin might be modeled in multiple ways, addressing distinct requirements like real-time performance monitoring for operators or long-term predictive maintenance for engineers.

5.4 Road-Map for Building CPS with Digital Twins

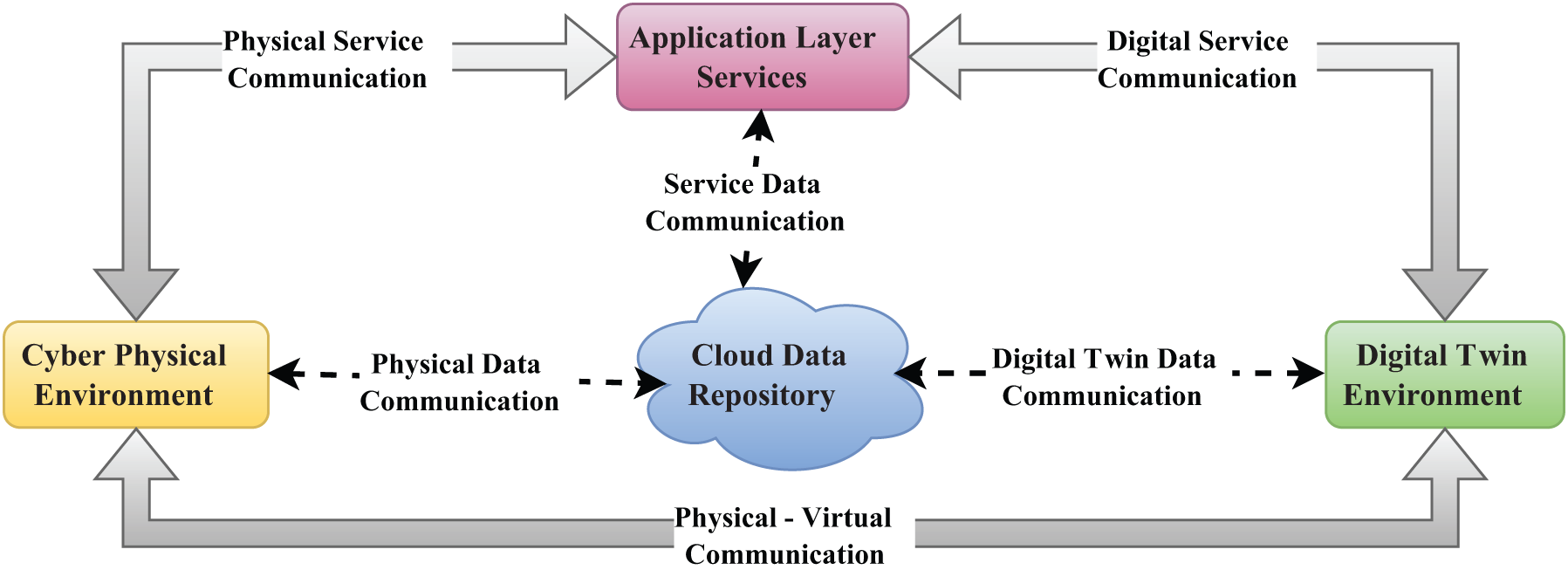

Building a Cyber-Physical System (CPS) with integrated Digital Twins (DTs) requires a structured roadmap encompassing key steps that ensure seamless interaction between the physical and digital domains. The process begins with the deployment of sensors and actuators in the physical environment, forming the foundation for real-time data collection. This data, essential for creating a DT, enables accurate simulation of the physical environment. The collected data is then transmitted to the computational layer of the CPS, where it is processed and relayed to the DT. This ensures that the DT maintains a real-time representation of the physical system. A detailed digital model of the physical system is developed, capturing its geometry, state, and behavioral characteristics, thus creating a high-fidelity digital replica. To enable seamless integration, real-time synchronization and feedback loops are established between the CPS and DT. This ensures that changes in the physical system are reflected in the DT, allowing for timely and accurate responses. Finally, the DT supports dynamic decision-making by simulating various scenarios, predicting future behaviors, and optimizing the performance of the physical system.

The visual representation in Fig. 5 illustrates the layered architecture of this integration. It highlights the application layer hosting services and the digital twin environment, interconnected with the physical environment via communication pathways. These pathways enable the bidirectional flow of data, connecting the physical, virtual, and service domains. The cloud data repository ensures centralized data management, supporting the synchronization and analysis required for effective CPS and DT integration. This depiction emphasizes the importance of a well-coordinated infrastructure, integrating physical systems, digital twins, and service communications to achieve robust system optimization and real-time adaptability.

Figure 5: Overview for building CPS with digital twins

5.5 Essential Components of Digital Twin

DT has a number of components. Some of them are used for the administration, and the remaining ones are useful for its creation. From the literature [96–98], the components of DT creation are outlined as.

Identifier Each physical product requires a worldwide identification in order to be linked to its digital representations. In this context, RFID (radio frequency identification) and the EPC (electronic product code), etc., are used to create an identity for each physical process, no matter where it is or how long it has existed.

Information management: Throughout the product life cycle, the beginning, middle, and end stages produce and evolve product data and information. The number of saved data may increase to huge proportions during these three phases, providing a data management challenge for storing required data. Reference [99] proposed a data collection technique, whereas in [100] concentrated on DT to realise and organise data. The End-of-Life (EoL) of DTs in information management refers to the phase or process when a DT is retired, decommissioned, or taken out of active use. Like physical products, DTs also have a life cycle, and there comes a point when they are no longer needed or relevant for ongoing operations or analysis.

During the life cycle of a DT, it serves various purposes, such as monitoring, analyzing, and optimizing the performance of a physical asset or system. However, as the physical asset or system it represents undergoes changes or reaches the end of its useful life, the DT may also become outdated or unnecessary. The End-of-Life (EoL) of DTs involves proper management and handling of the digital representation to ensure data security, privacy, and responsible disposal. Some key aspects related to the End-of-Life of DTs in information management may include:

• Data Retention and Archiving: Depending on the organization’s policies and regulations, data from DTs might need to be retained or archived for a certain period even after the DT itself is retired. This could be for historical reference, compliance reasons, or future analysis.

• Data Deletion and Privacy: As with any data management process, the EoL of DTs requires careful consideration of data privacy and protection. Personal or sensitive information collected and used by the DT should be properly deleted or anonymized, ensuring that privacy is maintained.

• Knowledge Capture: Before retiring a DT, it is essential to capture any valuable insights, lessons learned, or knowledge gained during its life cycle. This information can be used to improve future DT implementations or to inform decision-making for similar assets or systems.

• Communication and Reporting: Stakeholders and relevant parties should be informed of the DT’s retirement to avoid confusion or unintended usage of outdated information. Proper reporting and communication channels are necessary to ensure everyone is aware of the DT’s EoL.

• Integration with Legacy Systems: In some cases, the DT’s data and information might need to be integrated or migrated into legacy systems or other data repositories for long-term storage or analysis.

• Continuous Improvement: Organizations should use insights from the DT’s performance and its EoL process to continuously improve their DT implementations and information management practices.

It is important to note that the EoL of DTs can vary depending on the specific use case, industry, and organization. Proper planning and policies must be in place to ensure a smooth and responsible EoL process for DTs to maximize their value while minimizing potential risks.

Digital twin models: During the product life cycle, several product models are created, which include system, functional, 3-D geometric, multi-physic, production, and consumption prototypes. These are incompatible, causing a major problem; as a result, a means of integrating all of these prototypes is necessary. Accurate product information feedback is required between the physical product and its digital version [101]. Establishing a DT, according to [102], requires the collaboration of an information model with greater data processing and business interactions. AutomationML, according to [103], should be used to create DT.

Data analysis: It is obtained from massive volumes of data collected throughout the life cycle of a product, with real-time limits in some cases [104]. When applying approaches to estimate changing product behavior in the future, maintenance, and usage data are critical. Reference [35] published a study to analyze huge data and DT.

Human-computer interface: It is obvious that retrieving and displaying essential data to the appropriate user is a challenge. Throughout its existence, the DT offers information to a wide range of users and stakeholders. As a result, the DT’s human-machine interface (HMI) should be well-designed. Using augmented reality technology, Schroeder et al. [105] begin his work in this manner. Rasheed et al. [98] saw interface modeling as a crucial enabler for new DT technologies in a variety of industries.

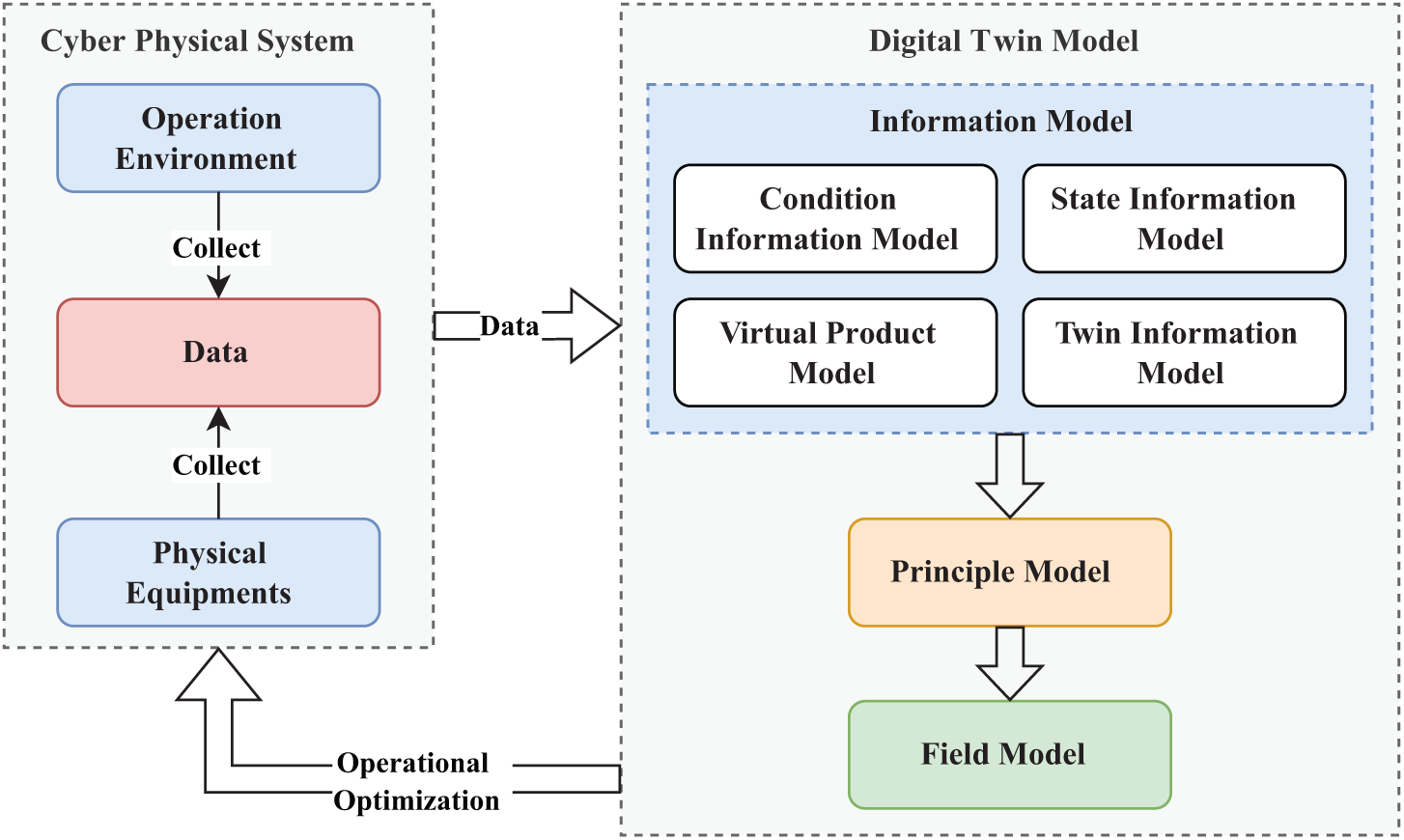

Architecture: The architecture of Digital Twins (DTs) for Cyber-Physical Systems (CPS) emphasizes the seamless integration of physical and virtual components through a well-defined data flow and communication framework. DTs store their information across various databases, necessitating mechanisms for remote data access at any location and time. Sensors deployed in the physical system collect data, which is transmitted via communication protocols to centralized databases, forming the backbone for CPS-DT integration. Villalonga et al. [106] introduced an architecture model for CPS, which delineates the roles of basic and advanced computation modes while leveraging cloud platforms for DT operations. This model is critical for differentiating layers of data processing and computational complexity. Similarly, Borodulin et al. [107] highlight a hierarchical organization of data across private and shared databases, ensuring efficient and secure information management.

Fig. 6 visualizes the CPS-DT architecture, emphasizing the layered structure where the operational environment integrates with the virtual twin environment through robust communication pathways. The data acquisition layer includes physical equipment capturing condition and state information, which feeds into the twin’s information model. This model incorporates detailed representations such as the virtual product model, principle model, and field model, enabling precise operational optimization. The cloud data repository acts as a central hub for data storage and computational resources, facilitating real-time synchronization between CPS and DT. This synchronization supports advanced services like predictive analytics and dynamic decision-making, ensuring continuous improvement in system performance and reliability.

Figure 6: Essential components of CPS with digital twins

Simulation: Most researchers, such as [108], address the necessity of employing the DT for simulation. Several authors have employed the DT simulation to control the quality. In [109], the DT imitated the shop-floor layout in order to improve production. A model of a hollow glass production line was built by [110]. The replication phase of a DT refers to the process of creating and establishing a virtual representation of a physical object, system, process, or entity in the digital world. During this phase, a DT is “replicated” based on the real-world counterpart, incorporating various data sources, sensors, and models to simulate and mirror the behavior, characteristics, and properties of the physical asset or system.

The replication phase is a crucial step in developing a DT, as it lays the foundation for the virtual representation that will be used for monitoring, analysis, simulation, and decision making. The process typically involves the following steps:

• Data Acquisition: Relevant data is collected from the physical object or system through sensors, IoT devices, or other data sources. This data can include parameters such as temperature, pressure, vibration, location, and more.

• Data Integration: The acquired data is integrated into the DT model to create a holistic and comprehensive representation of the physical asset.

• Model Creation: Mathematical models, simulations, and algorithms are developed to replicate the behavior and performance of the physical asset accurately. These models are based on the collected data and can simulate various real-world scenarios.

• Real-Time Update: The DT is continuously updated with real-time data from the physical counterpart, ensuring that the virtual representation stays synchronized with the actual asset’s current state.

• Validation and Calibration: The DT is validated and calibrated to ensure its accuracy and reliability. This involves comparing the virtual model’s behavior with the real-world data to verify its correctness.

• Connectivity: The DT is connected to the relevant systems and databases to enable seamless data exchange and integration with other processes and technologies.

Once the replication phase is complete, the DT becomes an active representation of the physical asset, capable of offering valuable insights, predictive capabilities, and decision support for various applications, such as predictive maintenance, performance optimization, and real-time monitoring.

In the literature, DT implementations and examples have shown a variety of technological functionalities, i.e., DT features (DTFs) which includes the functionalities of DT that facilitate simulation, monitoring, and optimization. Despite the fact that many implementations have DTFs, publications that expressly mention DTFs are hard to come across. Some of the DT feature lists are mentioned here from [38,111–114] to highlight the state of the literature.

1. Product identity, product lifespan, product information, product configuration, and product models are the significant themes for the DT of a product in the aerospace sector, according to [111].

2. According to [112], the DT concept faces challenges in the areas of “intelligent perception and connection, virtual modeling, running simulation and verification, DT data construction and management, DT-driven operation technology, smart production, and precision service.”

3. According to [113], the most significant aspects of constructing a DT are identification, product models, human-computer interface data management, and communication.

4. DTs have seven qualities, according to [38]: “unique identity, sensors and actuators, AI, communication, representation, trust, and privacy and security.”

5. Data link, analysis, identification, security, coupling, user interface, simulation model, artificial intelligence, and computation are some of the distinctive elements that can exist in a single product’s DT, according to literature [114].

5.6 Characteristics of Digital Twin

DTs exhibit several defining characteristics that make them valuable in the monitoring and management of physical assets and systems. One of the core characteristics is the integration of real-time data. Using IoT sensors and other data acquisition technologies, DTs continuously gather and update data from their physical counterparts. This ensures that the virtual model remains synchronized with the current state of the physical object, allowing for real-time monitoring and control. By continuously reflecting the actual conditions, DTs enable decision makers to make timely interventions when needed. Another important characteristic is the ability to simulate and predict system behaviors. Using data gathered from the physical object, DTs can simulate various operational scenarios and predict future behaviors, providing a significant advantage in anticipating potential failures or problems. This predictive capability improves system optimization and enables more efficient maintenance schedules. Simulation also allows industries to test different operational strategies without impacting the physical object, ensuring a cost-effective and risk-free way to improve performance.

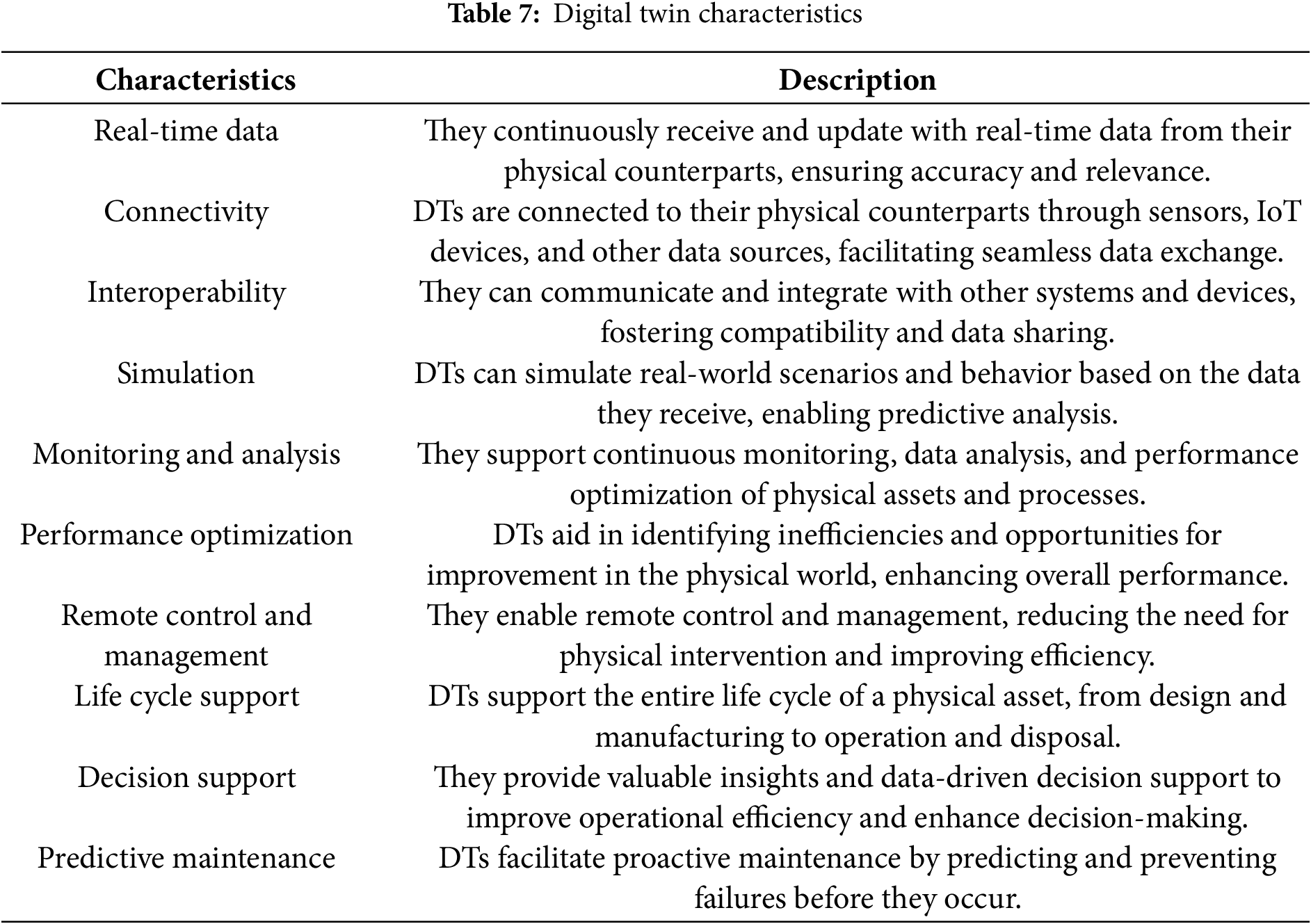

DTs are also characterized by their scalability and interoperability. Whether a single component or a complex system is modeled, DTs can adapt to varying levels of complexity across industries. They promote collaboration by integrating with various systems and platforms, allowing for seamless data sharing and analysis. This interoperability enables cross-functional teams to collaborate more effectively, making DTs an essential tool for optimizing operations and improving communication within organizations. The compilation of DT characteristics is illustrated in Table 7.

5.7 Properties of Digital Twins

DTs possess several foundational properties that enable them to replicate, monitor, and optimize physical systems effectively. Hence, properties are essential for creating effective and efficient DT systems in various applications and industries according to [11,12]. One of the primary properties of DTs is representation and contextualization. A DT serves as an accurate digital representation of its physical counterpart (PO) within a specific environment or operational context. The DT captures the essential characteristics and behaviors of the PO, allowing for feature simplification while maintaining functional accuracy. Contextualization ensures that the DT is adaptable to various industries, such as manufacturing, healthcare, and urban infrastructure, enabling it to represent a wide range of scenarios effectively.

Another key property is reflection and synchronization. A DT must continuously reflect the real-time status of the physical object it represents. This is achieved through constant synchronization with IoT sensors and other data sources. As changes occur in the physical object, they are mirrored immediately in the DT, allowing real-time monitoring and analysis. This capability makes the DT indispensable for decision-making processes that rely on up-to-date system information. The predictive capabilities of DTs are also crucial. Using both real-time and historical data, DTs can forecast future behaviors of physical systems, allowing for proactive risk management and performance optimization. This predictive functionality is vital for anticipating potential failures and optimizing maintenance schedules, particularly in high-stakes industries such as aerospace, manufacturing, and healthcare.

Another essential property of DTs is their persistence and availability. A DT remains available even when the physical object it represents is offline or has been decommissioned. This allows stakeholders to access historical performance data for analysis and decision-making. DTs also retain historical data over time, providing a comprehensive view of the system’s life cycle that can be used to inform long-term strategies and future system enhancements. Finally, DTs offer augmented functionality that extends the capabilities of physical objects. DTs provide additional services, such as advanced analytics, predictive maintenance, and data visualization, that help optimize system performance and improve decision-making. This augmented functionality transforms DTs into intelligent systems capable of not only monitoring but also optimizing and predicting future outcomes. These properties of Digital Twins representation and contextualization, reflection and synchronization, predictive capabilities, persistence and availability, and augmented functionality are critical for their effective deployment and operation. These properties enable DTs to go beyond simple replication and serve as powerful tools to optimize physical systems across a wide array of industries and applications.

6 Building Blocks of Digital Twins

The building blocks of DTs consist of several essential components that interact to create a comprehensive digital representation of physical systems. These include:

• Physical Assets: These are the real-world devices, machines, or systems that are replicated digitally within a CPS. The physical assets interact with the digital twin environment through sensors and other data sources.

• Digital Twin Environment: This is the digital counterpart of the physical assets, where their digital representations are created and managed. It serves as a platform for simulations, monitoring, and performance analysis.

• Data Sources: Data is collected from the physical assets through sensors, IoT devices, and other mechanisms. These data sources provide either real-time or historical data that are fed into the digital twin environment for continuous updates.

• Digital Twin Modeling: The process of creating a digital representation of the physical assets and their behavior is known as digital twin modeling. This involves simulating the behavior and predicting the performance of the physical assets based on the data collected from the sensors.

• Digital Twin Services: These services include data analytics, predictive maintenance, and optimization functionalities. Digital twin services enable enhanced performance, real-time monitoring, control, and decision-making processes.

• Physical and Logical Objects: The digital twin contains both the Physical Object (PO), which refers to the real-world entity, and the Logical Object (LO), which is the digital representation of the physical object. The LO reflects the properties and behavior of the PO in the digital world.

• Foundational Properties: These are the core attributes that define a digital twin. Foundational properties include the ability to monitor, control, optimize, and simulate the physical object, ensuring the digital twin accurately represents the physical counterpart.

• Architectural Model: The architectural model outlines how the components of a digital twin interact, including data acquisition, processing, storage, and visualization. This model provides a structure for implementing digital twins across different industries and applications.

These components collectively empower Digital Twins to accurately mimic, oversee, and enhance the functioning of physical systems, delivering crucial insights for maintenance, decision-making, and operational efficiency.

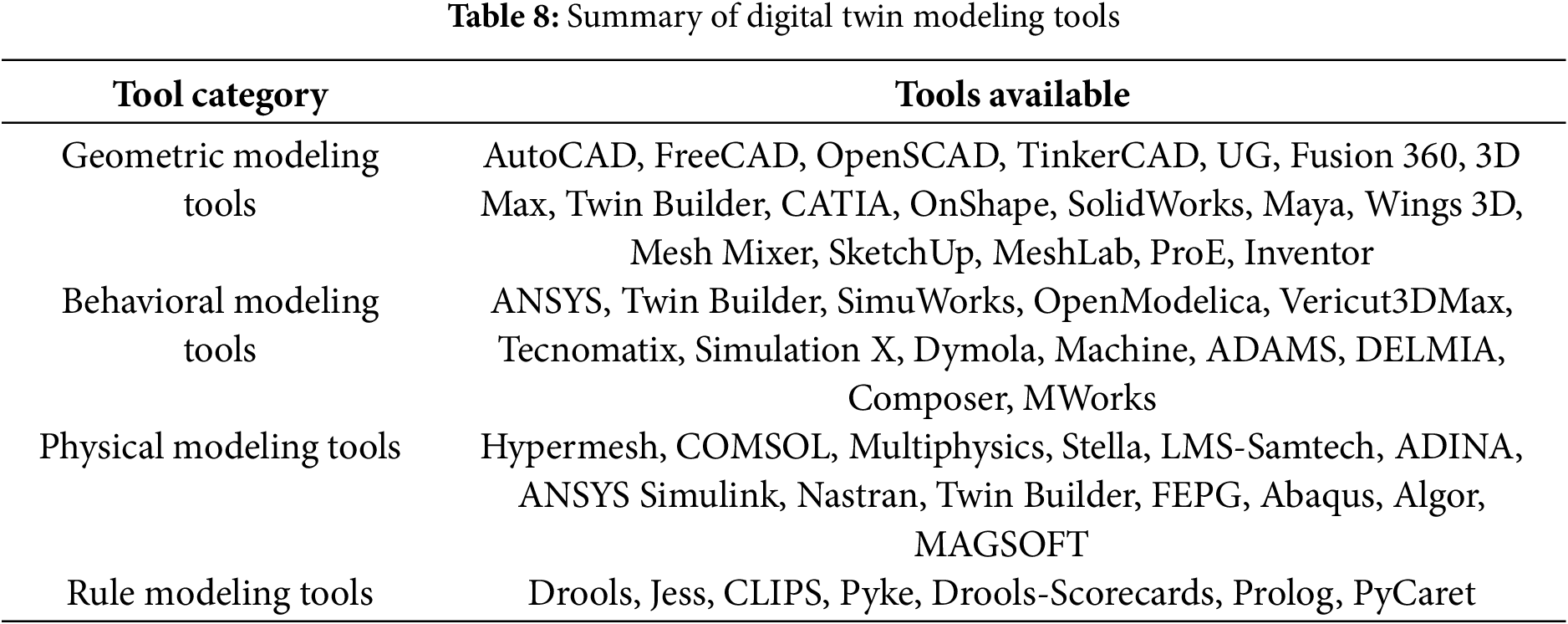

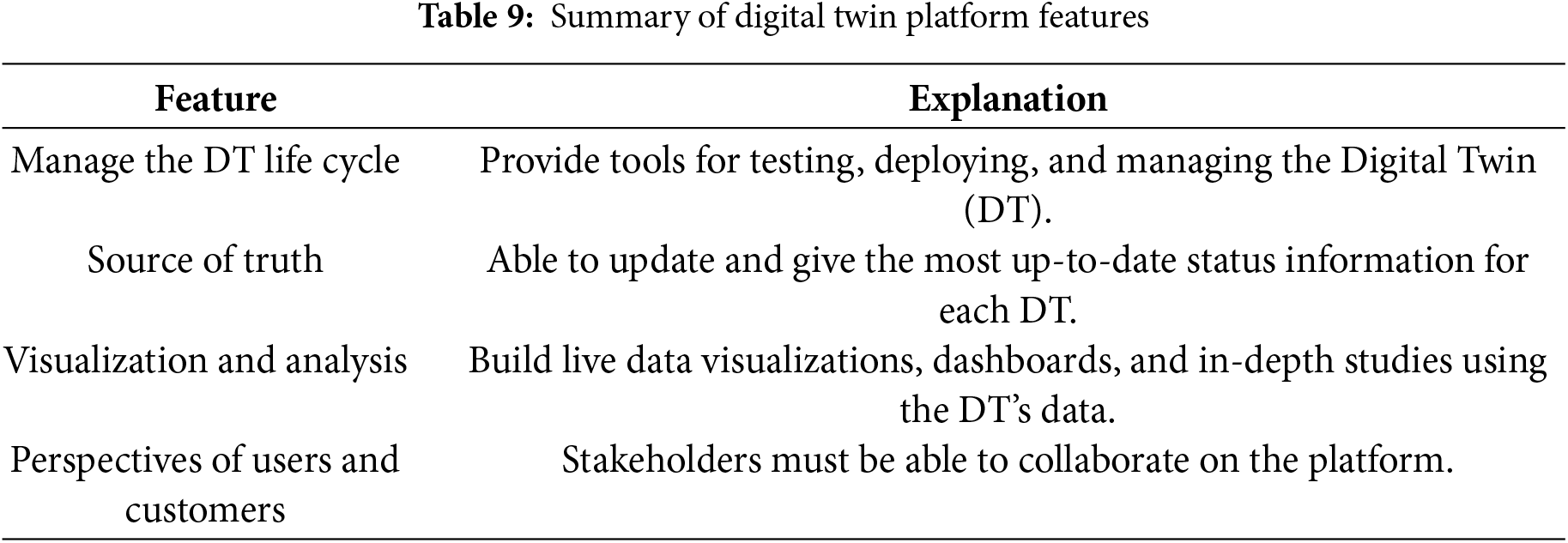

6.1 Digital Twin Data Management Tools