Open Access

Open Access

ARTICLE

Systematic Benchmarking of Topology Optimization Methods Using Both Binary and Relaxed Forms of the Zhou-Rozvany Problem

1 School of Engineering, Deakin University, Geelong, VIC 3216, Australia

2 Department of Mechanical Engineering, University of Alberta, Edmonton, AB T6G 1H9, Canada

* Corresponding Author: Kazem Ghabraie. Email:

(This article belongs to the Special Issue: Topology Optimization: Theory, Methods, and Engineering Applications)

Computer Modeling in Engineering & Sciences 2025, 143(3), 3233-3251. https://doi.org/10.32604/cmes.2025.065935

Received 25 March 2025; Accepted 30 May 2025; Issue published 30 June 2025

Abstract

Most material distribution-based topology optimization methods work on a relaxed form of the optimization problem and then push the solution toward the binary limits. However, when benchmarking these methods, researchers use known solutions to only a single form of benchmark problem. This paper proposes a comparison platform for systematic benchmarking of topology optimization methods using both binary and relaxed forms. A greyness measure is implemented to evaluate how far a solution is from the desired binary form. The well-known Zhou-Rozvany (ZR) problem is selected as the benchmarking problem here, making use of available global solutions for both its relaxed and binary forms. The recently developed non-penalization Smooth-edged Material Distribution for Optimizing Topology (SEMDOT), well-established Solid Isotropic Material with Penalization (SIMP), and continuation methods are studied on this platform. Interestingly, in most cases, the grayscale solutions obtained by SEMDOT demonstrate better performance in dealing with the ZR problem than SIMP. The reasons are investigated and attributed to the usage of two different regularization techniques, namely, the Heaviside smooth function in SEMDOT and the power-law penalty in SIMP. More importantly, a simple-to-use benchmarking graph is proposed for evaluating newly developed topology optimization methods.Keywords

Topology optimization, as a conceptual design tool, has been widely applied in the fields of aerospace, automotive manufacturing, and biomedical science [1–3]. Common element-based topology optimization methods typically determine the optimal material distribution by solving problems in either their binary or relaxed form. In the binary form of topology optimization, the material distribution within the design domain is represented by only two values, 0 and 1, indicating void and solid regions, respectively. Methods belonging to this category include the Evolutionary Structural Optimization (ESO) [4] and the Bidirectional Evolutionary Structural Optimization (BESO) [5,6]. In contrast, the relaxed form allows the material density in each element of the design domain to vary continuously between 0 and 1, which introduces intermediate values that must be pushed back to the binary limits using a regularization technique. The Solid Isotropic Material with Penalization (SIMP) method [7] is an example of this approach.

The importance of having standard benchmarks to evaluate the performance of different proposed methods has been recognized in topology optimization [8]. A number of problems, like the simply supported MBB (Messerschmitt-Bölkow-Blohm) beam, have been used as classic benchmarks to test topology optimization methods [9]. However, apart from few limited cases [10–12], the benchmark problems used have no exact solution. Very few computational and theoretical results on global optimization using deterministic methods are available for the topology optimization of continuum structures [13], and such results are even more scarce for multiphysics and multimaterial problems [14–16]. One of the problems with relatively few design variables for which global optimal solutions are known is the Zhou-Rozvany (ZR) problem [17].

The ZR problem is originally introduced to illustrate the limitations of the ESO method in solving topology optimization problems [18]. It involves optimizing a tie beam demonstrated in Fig. 1. The structure is supported by a fixed boundary condition on the left side and a roller support at the top. The material is modeled as linearly elastic and isotropic, with a Young’s modulus of 1.0 and a Poisson’s ratio of 0.3. The loading conditions consist of a horizontal force with an intensity of 2.0 and a vertical force with an intensity of 1.0. The design domain is discretized using 100 four-node quadrilateral elements.

Figure 1: Geometry and boundary conditions for the ZR problem

Using ESO on this problem results in Fig. 2 where the tie breaks and the optimization method fails to recover it and successfully solve the problem. Rozvany stated that the issue observed in ESO cannot be solved by using its bidirectional version, BESO [18].

Figure 2: The solution obtained by ESO for the ZR problem after removing 1 element

Due to the significance of the ZR problem in evaluating binary-based topology optimization methods, Several research works investigated the reasons why binary methods like ESO and BESO fail to solve the ZR problem and proposed different approaches to address this issue. Some of the suggested techniques include mesh refinement [19,20], using soft elements [21], and freezing elements [4]. Rozvany [22] critically reviewed and questioned most of these suggestions. Ghabraie [23] showed that using high-order sensitivity analysis can help binary-based methods like ESO solve the ZR problem but highlighted that ESO also suffers from its unidirectional approach to the solution. More recently, the ZR problem is solved by adding a connectivity constraint into the BESO method [24].

The ZR problem is suggested to be introduced into the standard repertoire of benchmark examples when assessing new topology optimization methods [17]. To facilitate this benchmarking, Stolpe and Bendsøe [17] provided the global optima for the binary formulation of the ZR problem across different volume constraints. However, most of the material distribution-based topology optimization methods convert the binary form to a continuous form before solving it and then push the solution back to binary limits. The binary form of the ZR problem cannot be used to benchmark these methods properly, because as emphasized by Sigmund et al. [25], the selected form of the problem can have a great impact on the final solution. To properly benchmark topology optimization methods that solve the relaxed form of the problem, it would be ideal to consider solutions to both relaxed and binary forms of the benchmark problem.

To establish the ZR problem as a comprehensive benchmark, this study utilizes both its global binary solution [17] and its relaxed (convex) global solution, obtained via the Variable Thickness Sheet (VTS) formulation [25]. This work implements a grayness measure (based on the proposed measure of discreteness in [26]) to systematically benchmark a selected list of topology optimization methods against both binary and relaxed global optima of the ZR problem. Selected topology optimization methods include SIMP with a penalty factor of 3.0, SIMP combined with a continuation method [27], and the recently developed non-penalization Smooth-edged Material Distribution for Optimizing Topology (SEMDOT) method [28,29]. It should be noted that SEMDOT involves two steps: 1) solving the relaxed form and pushing it to binary using the Heaviside smooth function resulting in greyscale solutions, and 2) finding the smooth boundary of the design using a bisection approach on grid point densities. While the results obtained after the first step of SEMDOT should be benchmarked against both relaxed and binary solutions, its final smooth results can be benchmarked against the binary solutions.

The rest of this paper is organized as follows: Section 2 summarizes the global solutions to the relaxed and binary forms of the ZR problem. Section 3 proposes an indicator to measure the relaxedness of solutions. Section 4 explains the topology optimization methods to be benchmarked. Section 5 benchmarks the SIMP, SIMP with continuation, and grayscale SEMDOT results, discussing their Pareto fronts. Section 7 evaluates the smooth structures from the SEMDOT method more accurately by remeshing approach, presenting the Pareto front for binary-form designs. Finally, conclusions are drawn in Section 8.

2 Global Solutions for Binary and Relaxed Forms of the ZR Problem

Binary and relaxed forms of the ZR problem can be formulated as:

where

For plane stress problems, the relaxed version of Eq. (1) is a convex VTS problem [7,25,30]. The VTS problem can be solved by using SIMP with a penalty factor of 1 (no penalization) and the solutions obtained will be global as the problem is convex. The global optima for the binary form are presented in [17]. These two sets of global optima are shown in Fig. 3.

Figure 3: Optimal Pareto fronts for both relaxed and binary forms of ZR problem [17]

As expected, the solutions of the relaxed form are always lower than those of the binary form. This is because the binary form is much more restrictive. Note that, unlike the relaxed form, the binary form cannot be solved at very low-volume fractions. Hence the Pareto fronts in Fig. 3 are presented for

Figure 4: Optimal designs at

3 Measuring the Relaxedness of a Solution

To assess the relaxedness of a solution, a grayness measure defined below is used in this study:

where N is the number of design variables in the design domain, commonly defined as 100 for the original ZR problem. The grayness value for a single element will be 0 if that element is either solid (

The VTS formulation represents a fully relaxed formulation in topology optimisation, making the problem fully convex and resulting in density fields that significantly deviate from binary designs. Therefore, the maximum grayness value, denoted by

As is clear from Table 1, as the target volume fraction increases, the

Monitoring

4 Topology Optimization Methods to Be Benchmarked

This section covers briefly introduces the methods that will be benchmarked here, namely SIMP and SEMDOT. Like other density-based approaches, both methods initially relax the optimization problem by using continuous design variables. These variables are then regularized to push the solution towards binary results in different ways.

4.1 SIMP Method and Continuation Method

The SIMP method [7,31] applies a power-law regularization technique to steer the element densities closer to binary solutions. In this approach, the Young’s modulus

where

The continuation approach [32] can be used to reduce the possibility of getting trapped in a local optima. This approach applies the regularization gradually, e.g., by starting from

The SEMDOT method defines the elemental volume fraction

where

Figure 5: Different types of elements in SEMDOT and their grid points

A linear material interpolation scheme is used for calculating the stiffness of the element

where

To push the design towards a binary solution, a smooth Heaviside regularization [33,34] is utilized in SEMDOT:

where

The densities of internal grid points are evaluated via a level set function

where the threshold value

5 Benchmarking SIMP and Grayscale Designs in SEMDOT

This section presents the benchmarking results for the considered methods. For the SIMP method, the 88 lines code [38] with

Table 2 presents the numerical results for different relaxed form methods. Topologies obtained by SEMDOT, and continuation methods are very similar, but SIMP provides different topologies. Additional holes are observed in SIMP solutions for volume fractions less than 0.8.

SEMDOT produces compliance values more comparable to those of the VTS method and better than the continuation method. On the other hand, the SIMP method with

5.1 Comparison at Similar Grayscale Values

To achieve a more equitable comparison, the upper limit of the penalty factor (

The SEMDOT results exhibit higher relaxedness, as the

The Pareto fronts corresponding to Table 3 are illustrated in Fig. 6. Notably, none of the methods generate solutions spanning the entire range between the two global solutions. SEMDOT achieves solutions within this range only for volume fractions below 0.65. On the other hand, for SIMP and continuation methods with

Figure 6: Comparing results of SIMP, continuation, and SEMDOT at similar

5.2 A Simple-to-Use Benchmarking Graph

Beyond basic comparisons, different sets of results can serve as a quick reference for benchmarking topology optimization methods, as shown in Fig. 7. The five-pointed star region is bounded by the two global solutions for the relaxed and binary forms of the ZR problem. The horizontal line region shows the results of the continuation method, with the final penalty values ranging from

Figure 7: Pareto fronts of the ZR problem with distinct regions for global optima, SIMP, and SIMP with continuation. Patterned fills are chosen for grayscale compatibility. Outlines are added to improve visual separation. The SEMDOT method is shown as a thick dashed black line [17]

The distinctions among various methods diminish at higher volume fractions because, as the volume fraction increases, the available design space decreases and becomes predominantly filled with material. This leads to a more continuous material distribution reducing the differences between methods in handling intermediate density elements and material layouts [39]. Another key observation is that for the ZR problem, achieving results within the green region becomes increasingly difficult at volume fractions above 0.7, as this region is very narrow.

Methods that generate results closer to the target five-pointed star region demonstrate better performance. When benchmarking a method, if the results fall outside the five-pointed star region but lie within the other two regions, it can be concluded that its performance is comparable to the well-established SIMP or continuation methods. However, results that deviate significantly from these regions may be questionable.

As an example, the black dashed line represents the results of SEMDOT in solving the ZR problem. For a target volume fraction below 0.7, the results fall within the five-pointed star (global) region. When the volume fraction exceeds 0.7, although the results are not contained within the global region, they mostly remain within the horizontal line (continuation) and vertical line (SIMP) regions. This indicates that the grayscale results produced by the SEMDOT method are reasonable and effective. A similar assessment can be applied to other developed topology optimization methods.

5.3 Impact of Filtering Radius

In topology optimization, filters are used to mitigate numerical issues like checkerboard patterns and mesh dependency [32]. The selection of filter radius significantly affects geometric features and structural performance of optimized results [26]. The value of filtering radius

For all the methods tested in this paper, a density filter in the same form as illustrated in [26] is employed. Fig. 8 depicts various methods’ responses to filter radius (

Figure 8: Impact of filtering radius on solutions obtained from different methods

Filter radius can significantly affect optimization outcomes as shown in Fig. 8. In particular, SIMP and continuation methods exhibit high sensitivity to variations in filtering radius. Increasing the filter radius leads to a substantial rise in compliance values especially at lower target volume fractions. Notably, the solutions from both methods converge, resulting in identical Pareto fronts for

6 Solutions Based on Different Mesh Discretizations

The ZR problem features a tie beam with a design domain initially discretized into 100 elements. However, the sensitivity of the proposed benchmarking platform and associated optimization methods to mesh discretization remains uncertain. To investigate this aspect, the ZR problem was analyzed under different mesh refinement levels. To mitigate the checkerboard issue, the filter radius

In Table 4,

7 Benchmarking the Smooth Designs in SEMDOT

The SEMDOT method uses a two-step process:

1. Solve the relaxed form of the problem and push it to a binary solution using a smooth Heaviside projection. The result is a grayscale solution on a fixed mesh.

2. Calculate grid point densities within elements using level-set values. Reported results are designs with partial elements along the boundary. This step is schematically shown in Fig. 9.

Figure 9: The transformation from grayscale results in smooth structures

It would be insightful to compare the performance of these smooth designs with the global solutions to the binary form of ZR reported by [17]. It should be noted, however, that objective function and sensitivity values calculated in SEMDOT are based on the grayscale structure. The values of the objective function for the smooth and grayscale structures are obviously different. To calculate more accurate compliance values for smooth designs of SEMDOT, one should properly re-mesh the design to capture the partial elements on the boundary [40].

7.1 Remeshing for More Accurate Calculation of Responses of SEMDOT Smooth Designs

Mesh regeneration significantly influences finite element (FE) calculations [41]. As noted by [42], a high-fidelity evaluation is important to accurately assess optimization performance, which remains a common challenge in many studies. To minimize interference, the mesh division process adopted here uses triangular (T3) finite elements for accurate modeling of intricate smooth boundaries while the rest of the design (solid regions) are modeled using the same quadrilateral (Q4) elements to the original mesh. This process is shown in Fig. 10. This remeshing approach allows more accurate calculation of compliance values for smooth designs while ensuring that only a limited number of elements are changed in the mesh.

Figure 10: A simple re-meshing approach to more accurately calculate the compliance of smooth structures

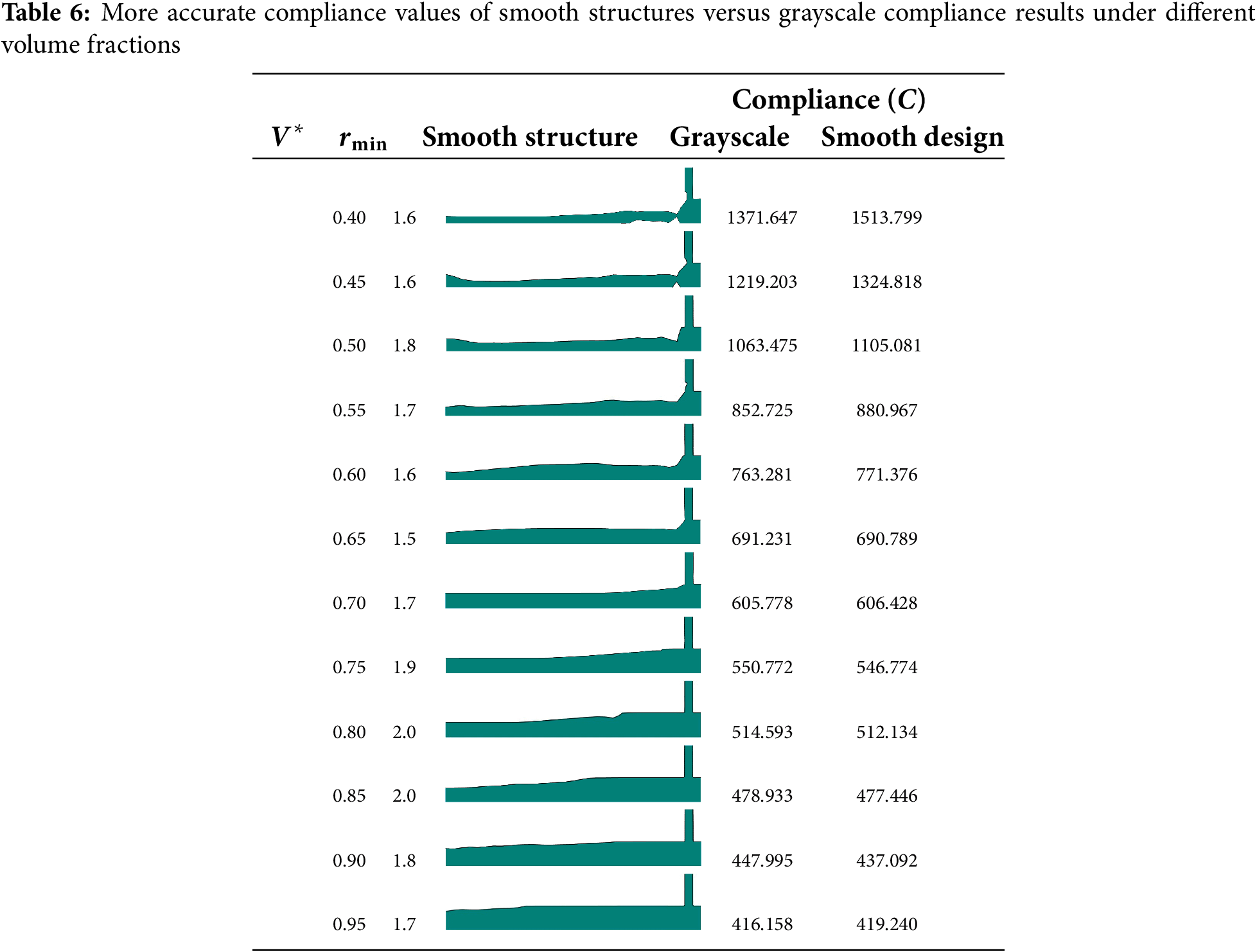

7.2 More Accurate Compliance Values of Smooth Designs in SEMDOT

Solving the ZR problem in its binary form is very challenging [17]. It is a common observation that one of the tie elements is removed and the solution is trapped in a highly inefficient local optimum [23,43]. This also applies to the SEMDOT method, where the material in tie elements can be insufficient to create a connected link when the grayscale solutions are converted to smooth designs. Looking at the relaxed form solutions in Table 2, it can be seen that, particularly for SEMDOT, the tie elements are becoming progressively softer as the volume fraction decreases. In this situation, using the filtering radius of

The break issue originates from the load distribution characteristics of the ZR problem. For the SIMP, VTS, and SEMDOT methods, it is particularly difficult to allocate sufficient material to slender rod, which are required to carry substantial loads primarily oriented in the horizontal direction. To better illustrate this limitation, a test was conducted by gradually increasing the vertical load intensity

Figure 11: The vertical tensile load of intensity

Table 5 presents the results of the three methods under varying vertical load intensities at a 40% target volume fraction. As the vertical load intensity

To address the above limitation and distribute more material for tie elements, numerical tests suggest that

Figure 12: Recalculated compliance values of SEMDOT smooth designs for filtering radii between 1.5 to 2.0

However, in Fig. 12, some data points are missing due to the breaking of the tie. It means that not all filter radii within the range of 1.5 to 2.0 produce smooth designs, cause deviations and oscillations in optimizing design variables through the method of moving asymptotes (MMA) optimizer can be difficult to control precisely. Alternatively, smooth structures may be enforced using a fixed filter radius of 1.0 by fixing the densities of elements along the slender rod. However, this approach falls outside the scope of the ZR problem.

Nevertheless, some well-performing structures can still be obtained according to the data from Fig. 12, Table 6 lists the best-performing smooth structures and their corresponding more accurate compliance values.

It should be noted that the compliance values of the smooth structures are comparable to those of grayscale structures for target volume fractions larger than 0.55. On the other hand, significant fluctuations appear at lower volume fractions, which can be attributed to two main factors: 1) increased geometric discrepancies between the grayscale and smooth structures due to the higher presence of grayscale elements, and 2) variations in the filter radius, which can negatively affect results, as illustrated in Fig. 8.

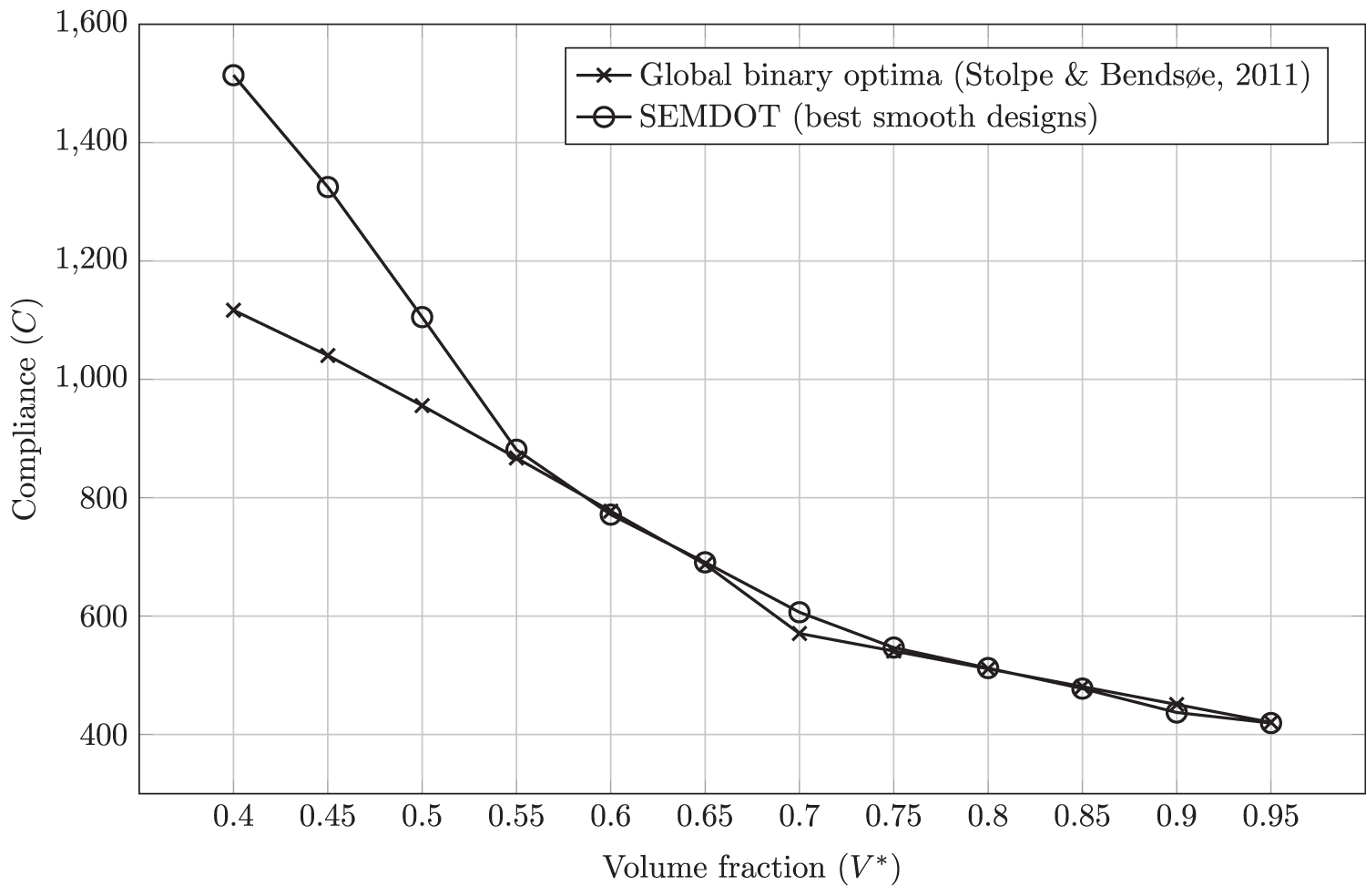

Hand-picking the best-performing smooth structures in SEMDOT, the resulting Pareto front is visualised in Fig. 13.

Figure 13: Pareto front of best-performing smooth SEMDOT results and the global binary optima [17]

Fig. 13 shows that when the best designs are selected, the more accurate compliance values for SEMDOT can closely approximate the global binary optima [17] for volume fractions higher than 0.55. At volume fractions of 0.6 and 0.9, SEMDOT results slightly surpass the global binary optima. This is due to the smooth boundary structures not being confined to the predefined mesh, allowing for more flexible shapes for boundary elements. At lower volume fractions, SEMDOT results deviate from global binary optima.

This study systematically benchmarks topology optimization methods using both the binary and relaxed forms of the ZR problem. Within this benchmarking framework, the SIMP method, SIMP with continuation, and the non-penalized SEMDOT method are compared. Through numerical tests, the main conclusions of this study are as follows:

1. At comparable grayness levels, SEMDOT produces more optimal solutions for the ZR problem compared to the SIMP and continuation methods, mainly due to the usage of smooth Heaviside function, whereas SIMP and continuation methods rely on power-law approach. Furthermore, when the volume fraction is below 0.8, the topologies generated by SIMP (

2. All methods are influenced by the filter radius and mesh discretization, with SIMP and continuation methods being the most sensitive to changes in these parameters. SEMDOT is less sensitive, with its numerical results remaining almost consistent across different mesh resolutions and often achieving the lowest compliance. Notably, for finer meshes, SEMDOT generates structures that are closer to binary solutions (indicated by lower g values) compared to the other methods.

3. Similar to other binary methods, the smooth designs produced by SEMDOT in the ZR problem can also become trapped in inefficient local optima due to tie breakage. Although adjusting the filter radius can partially mitigate this issue, it cannot be completely avoided across all volume fractions. A simple re-meshing approach used to assess the compliance of smooth designs more accurately shows that for volume fractions above 0.55, the best smooth design by SEMDOT performs comparably to the global binary optimum for the ZR problem.

Having a small number of finite elements, simple boundary conditions, and yet a challenging nature, the ZR problem serves as a convenient test case for different topology optimization methods. Apart from the above points, a key contribution of this study is the introduction of a simple-to-use benchmarking graph (Fig. 7) for the ZR problem. The proposed benchmarking graph can be used to quickly assess different topology optimization methods and benchmark them against global solutions and the well-established SIMP method.

However, this study primarily validates and benchmarks under the assumption of linear elasticity, while in practical structural design, material and geometric nonlinearities (such as plasticity and large deformations) often play a critical role. Future research could extend the linear elastic material model to more complex constitutive relations (e.g., von-Mises plasticity) and adopt Lagrangian formulations to introduce nonlinear stiffness matrices and large deformation effects in finite element solutions, thereby enhancing the overall applicability of benchmarked methods.

Acknowledgement: Jiye Zhou appreciates the financial support from the school: School of Engineering HDR.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: Conceptualization, Jiye Zhou, Yun-Fei Fu and Kazem Ghabraie; methodology, Jiye Zhou, Yun-Fei Fu and Kazem Ghabraie; software, Jiye Zhou; formal analysis, Jiye Zhou and Kazem Ghabraie; investigation, Jiye Zhou; writing—original draft preparation, Jiye Zhou; writing—review and editing, Jiye Zhou, Yun-Fei Fu and Kazem Ghabraie; visualization, Jiye Zhou and Kazem Ghabraie; supervision, Kazem Ghabraie. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data that support the findings of this study are available from the first author upon reasonable request.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Zhu J, Zhou H, Wang C, Zhou L, Yuan S, Zhang W. A review of topology optimization for additive manufacturing: status and challenges. Chin J Aeron. 2021;34(1):91–110. [Google Scholar]

2. Mallick PK. Materials, design and manufacturing for lightweight vehicles. Woodhead Publishing; 2020. [Google Scholar]

3. Wu J, Aage N, Westermann R, Sigmund O. Infill optimization for additive manufacturing-approaching bone-like porous structures. IEEE Trans Visual Comput Grap. 2017;24(2):1127–40. [Google Scholar]

4. Xie YM, Steven GP, Xie Y, Steven G. Basic evolutionary structural optimization. London, UK: Springer; 1997. [Google Scholar]

5. Yang XY, Xie YM, Steven GP, Querin OM. Bidirectional evolutionary method for stiffness optimization. AIAA J. 1999;37(11):1483–8. [Google Scholar]

6. Huang X, Xie Y. Convergent and mesh-independent solutions for the bi-directional evolutionary structural optimization method. Fin Elem Anal Des. 2007;43(14):1039–49. [Google Scholar]

7. Bendsøe MP. Optimal shape design as a material distribution problem. Struct Optim. 1989;1:193–202. [Google Scholar]

8. Sigmund O. On benchmarking and good scientific practise in topology optimization. Struct Multidiscipl Optim. 2022;65(11):315. [Google Scholar]

9. Bulman S, Sienz J, Hinton E. Comparisons between algorithms for structural topology optimization using a series of benchmark studies. Comput Struct. 2001;79(12):1203–18. [Google Scholar]

10. Rozvany G. Exact analytical solutions for some popular benchmark problems in topology optimization. Struct Optim. 1998;15:42–8. [Google Scholar]

11. Lewiński T, Rozvany G. Exact analytical solutions for some popular benchmark problems in topology optimization II: three-sided polygonal supports. Struct Multidis Optim. 2007;33(4):337–49. [Google Scholar]

12. Lewiński T, Rozvany G. Exact analytical solutions for some popular benchmark problems in topology optimization III: l-shaped domains. Struct Multidiscip Optim. 2008;35(2):165–74. [Google Scholar]

13. Stolpe M. On models and methods for global optimization of structural topology. Stockholm: Matematik; 2003. [Google Scholar]

14. Nguyen MN, Hoang VN, Lee D. Topology optimization framework for thermoelastic multiphase materials under vibration and stress constraints using extended solid isotropic material penalization. Compos Struct. 2024;344:118316. [Google Scholar]

15. Banh TT, Lieu QX, Kang J, Ju Y, Shin S, Lee D. A novel robust stress-based multimaterial topology optimization model for structural stability framework using refined adaptive continuation method. Eng Comput. 2024;40(2):677–713. [Google Scholar]

16. Nguyen MN, Hoang VN, Lee D. Multiscale topology optimization with stress, buckling and dynamic constraints using adaptive geometric components. Thin-Walled Struct. 2023;183:110405. [Google Scholar]

17. Stolpe M, Bendsøe MP. Global optima for the Zhou-Rozvany problem. Struct Multidis Optim. 2011;43:151–64. [Google Scholar]

18. Zhou M, Rozvany G. On the validity of ESO type methods in topology optimization. Struct Multidiscip Optim. 2001;21(1):80–3. [Google Scholar]

19. Edwards C, Kim H, Budd C. Investigation on the validity of topology optimisation methods. In: 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference; 2006 May 1–4; Newport, RI, USA. [Google Scholar]

20. Edwards C, Kim H, Budd C. An evaluative study on ESO and SIMP for optimising a cantilever tie—beam. Struct Multidis Optim. 2007;34:403–14. [Google Scholar]

21. Rozvany GI, Querin OM. Combining ESO with rigorous optimality criteria. Int J Veh Des. 2002;28(4):294–9. [Google Scholar]

22. Rozvany GI. A critical review of established methods of structural topology optimization. Struct Multidis Optim. 2009;37:217–37. [Google Scholar]

23. Ghabraie K. The ESO method revisited. Struct Multidis Optim. 2015;51:1211–22. [Google Scholar]

24. Munk DJ, Vio GA, Steven GP. A bi-directional evolutionary structural optimisation algorithm with an added connectivity constraint. Fin Elem Anal Des. 2017;131:25–42. [Google Scholar]

25. Sigmund O, Aage N, Andreassen E. On the (non-)optimality of Michell structures. Struct Multidis Optim. 2016;54:361–73. [Google Scholar]

26. Sigmund O. Morphology-based black and white filters for topology optimization. Struct Multidis Optim. 2007;33:401–24. [Google Scholar]

27. Tarek M, Ray T. Adaptive continuation solid isotropic material with penalization for volume constrained compliance minimization. Comput Methods Appl Mech Eng. 2020;363:112880. [Google Scholar]

28. Fu YF, Long K, Rolfe B. On non-penalization SEMDOT using discrete variable sensitivities. J Optim Theory Appl. 2023;198(2):644–77. [Google Scholar]

29. Fu YF, Long K, Zolfagharian A, Bodaghi M, Rolfe B. Topological design of cellular structures for maximum shear modulus using homogenization SEMDOT. Mater Today Proc. 2024;101:38–42. [Google Scholar]

30. Kandemir V, Dogan O, Yaman U. Topology optimization of 2.5 D parts using the SIMP method with a variable thickness approach. Procedia Manuf. 2018;17:29–36. [Google Scholar]

31. Rozvany GI, Zhou M, Birker T. Generalized shape optimization without homogenization. Struct Optim. 1992;4:250–2. [Google Scholar]

32. Sigmund O, Petersson J. Numerical instabilities in topology optimization: a survey on procedures dealing with checkerboards, mesh-dependencies and local minima. Struct Optim. 1998;16:68–75. [Google Scholar]

33. Kawamoto A, Matsumori T, Yamasaki S, Nomura T, Kondoh T, Nishiwaki S. Heaviside projection based topology optimization by a PDE-filtered scalar function. Struct Multidis Optim. 2011;44:19–24. [Google Scholar]

34. Wang F, Lazarov BS, Sigmund O. On projection methods, convergence and robust formulations in topology optimization. Struct Multidiscip Optim. 2011;43(6):767–84. [Google Scholar]

35. Fu YF, Rolfe B, Chiu LN, Wang Y, Huang X, Ghabraie K. SEMDOT: smooth-edged material distribution for optimizing topology algorithm. Adv Eng Softw. 2020;150:102921. [Google Scholar]

36. Fu YF, Rolfe B, Chiu LNS, Wang Y, Huang X, Ghabraie K. Smooth topological design of 3D continuum structures using elemental volume fractions. Comput Struct. 2020;231:106213. [Google Scholar]

37. Fu YF, Ghabraie K, Rolfe B, Wang Y, Chiu LN. Smooth design of 3D self-supporting topologies using additive manufacturing filter and SEMDOT. Appl Sci. 2020;11(1):238. [Google Scholar]

38. Andreassen E, Clausen A, Schevenels M, Lazarov BS, Sigmund O. Efficient topology optimization in MATLAB using 88 lines of code. Struct Multidiscip Optim. 2011;43:1–16. [Google Scholar]

39. Bendsoe MP, Sigmund O. Topology optimization: theory, methods, and applications. Berlin/Heidelberg, Germany: Springer Science & Business Media; 2013. [Google Scholar]

40. Zhou J, Wang Y, NS L, Ghabraie K. On suitability of a simplified sensitivity estimation for partial elements in topology optimisation. Eng Optim. 2025;1–23. doi:10.1080/0305215X.2025.2466825. [Google Scholar] [CrossRef]

41. Szabó B, Babuška I. Finite element analysis: method, verification and validation. Hoboken, NJ, USA: John Wiley & Sons Inc.; 2021. [Google Scholar]

42. Hua Y, Luo L, Le Corre S, Fan Y. Heat spreading effect on the optimal geometries of cooling structures in a manifold heat sink. Energy. 2024;308:132948. [Google Scholar]

43. Huang X, Xie YM. A further review of ESO type methods for topology optimization. Struct Multidisc Optim. 2010;41(5):671–83. [Google Scholar]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools