Open Access

Open Access

REVIEW

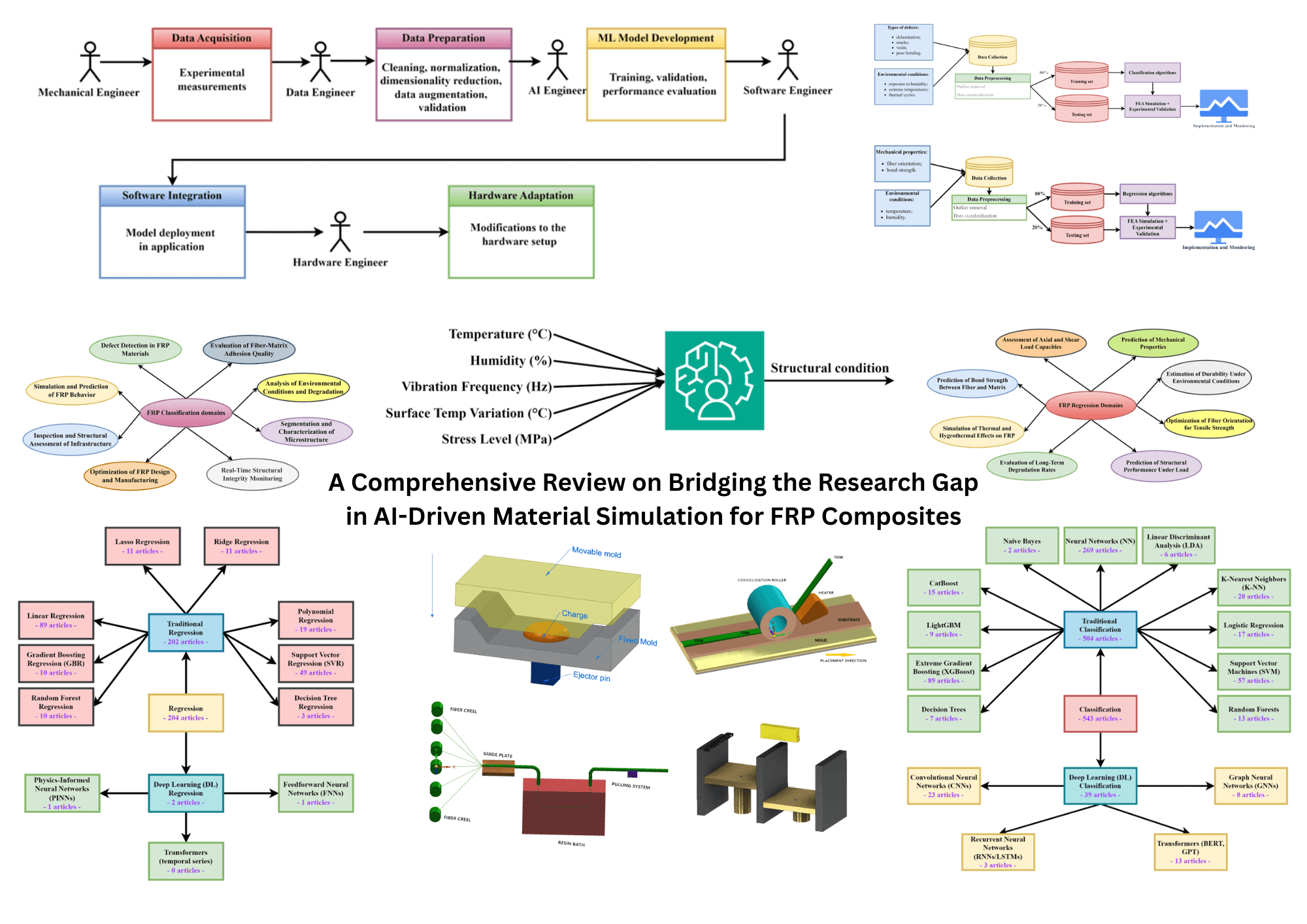

A Comprehensive Review on Bridging the Research Gap in AI-Driven Material Simulation for FRP Composites

1 Department of Mechanical Engineering, Faculty of Mechanical and Electrical Engineering, Petroleum-Gas University of Ploiesti, 39 Bucharest Avenue, Ploiesti, 100680, Romania

2 Department of Automatic Control, Computers, and Electronics, Faculty of Mechanical and Electrical Engineering, Petroleum-Gas University of Ploiesti, 39 Bucharest Avenue, Ploiesti, 100680, Romania

3 Department of Business Administration, Faculty of Economic Sciences, Petroleum-Gas University of Ploiesti, 39 Bucharest Avenue, Ploiesti, 100680, Romania

* Corresponding Author: Maria Tănase. Email:

(This article belongs to the Special Issue: AI and Optimization in Material and Structural Engineering: Emerging Trends and Applications)

Computer Modeling in Engineering & Sciences 2025, 144(1), 147-199. https://doi.org/10.32604/cmes.2025.066276

Received 03 April 2025; Accepted 26 June 2025; Issue published 31 July 2025

Abstract

Fiber-reinforced polymer (FRP) composites are renowned for their high mechanical strength, durability, and lightweight properties, making them integral to civil engineering, aerospace, and automotive manufacturing. Traditionally, the simulation and optimization of FRP materials have relied on finite element (FE) methods, which, while effective, often fall short in capturing the intricate behaviors of these composites under diverse conditions. Concrete examples in this regard involve modeling interfacial cracks, delaminations, or environmental effects that involve nonlinear phenomena. These degradation mechanisms exceed the capacity of classical FE models, as they are not detailed to the required level of detail. This aspect increases the time and computational resources required, leading to a need for optimization regarding fiber reinforcement configurations or multiple scenario load analysis. Thus, FE methods are inefficient compared to AI-based approaches that generalize material behavior based on extensive datasets. The advent of artificial intelligence (AI) has introduced advanced tools capable of enhancing the analysis and design of FRP materials. This review examines the current landscape of AI applications in FRP composite simulations, highlighting existing research gaps. Through a comprehensive bibliometric analysis, the study underscores the limited number of investigations focused on leveraging AI for FRP optimization. Furthermore, it synthesizes findings related to AI-driven simulation techniques, the mechanical properties of FRP composites, and strategies for predicting and improving their durability. This review comprehensively explores the potential of AI to overcome these limitations by synthesizing over 170 scientific works published between 2015 and 2025. Key findings highlight that supervised learning methods—especially neural networks, support vector machines, and gradient boosting models—achieve prediction accuracies above 90% for mechanical properties and defect classification. However, bibliometric analysis reveals that there are limited studies that address AI-driven optimization or standardized datasets for FRP applications. This review identifies eight core classification domains and eight regression domains where AI excels, including defect detection, bond strength prediction, and fiber orientation optimization.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools