Open Access

Open Access

REVIEW

A Comprehensive Review on Bridging the Research Gap in AI-Driven Material Simulation for FRP Composites

1 Department of Mechanical Engineering, Faculty of Mechanical and Electrical Engineering, Petroleum-Gas University of Ploiesti, 39 Bucharest Avenue, Ploiesti, 100680, Romania

2 Department of Automatic Control, Computers, and Electronics, Faculty of Mechanical and Electrical Engineering, Petroleum-Gas University of Ploiesti, 39 Bucharest Avenue, Ploiesti, 100680, Romania

3 Department of Business Administration, Faculty of Economic Sciences, Petroleum-Gas University of Ploiesti, 39 Bucharest Avenue, Ploiesti, 100680, Romania

* Corresponding Author: Maria Tănase. Email:

(This article belongs to the Special Issue: AI and Optimization in Material and Structural Engineering: Emerging Trends and Applications)

Computer Modeling in Engineering & Sciences 2025, 144(1), 147-199. https://doi.org/10.32604/cmes.2025.066276

Received 03 April 2025; Accepted 26 June 2025; Issue published 31 July 2025

Abstract

Fiber-reinforced polymer (FRP) composites are renowned for their high mechanical strength, durability, and lightweight properties, making them integral to civil engineering, aerospace, and automotive manufacturing. Traditionally, the simulation and optimization of FRP materials have relied on finite element (FE) methods, which, while effective, often fall short in capturing the intricate behaviors of these composites under diverse conditions. Concrete examples in this regard involve modeling interfacial cracks, delaminations, or environmental effects that involve nonlinear phenomena. These degradation mechanisms exceed the capacity of classical FE models, as they are not detailed to the required level of detail. This aspect increases the time and computational resources required, leading to a need for optimization regarding fiber reinforcement configurations or multiple scenario load analysis. Thus, FE methods are inefficient compared to AI-based approaches that generalize material behavior based on extensive datasets. The advent of artificial intelligence (AI) has introduced advanced tools capable of enhancing the analysis and design of FRP materials. This review examines the current landscape of AI applications in FRP composite simulations, highlighting existing research gaps. Through a comprehensive bibliometric analysis, the study underscores the limited number of investigations focused on leveraging AI for FRP optimization. Furthermore, it synthesizes findings related to AI-driven simulation techniques, the mechanical properties of FRP composites, and strategies for predicting and improving their durability. This review comprehensively explores the potential of AI to overcome these limitations by synthesizing over 170 scientific works published between 2015 and 2025. Key findings highlight that supervised learning methods—especially neural networks, support vector machines, and gradient boosting models—achieve prediction accuracies above 90% for mechanical properties and defect classification. However, bibliometric analysis reveals that there are limited studies that address AI-driven optimization or standardized datasets for FRP applications. This review identifies eight core classification domains and eight regression domains where AI excels, including defect detection, bond strength prediction, and fiber orientation optimization.Graphic Abstract

Keywords

Fiber-reinforced polymer (FRP) composites have gained recognition due to their properties, including lightweight, corrosion resistance, and long-term durability. These advantages have led to the exploration of FRP materials concerning their use in various applications. In the current technological context, efforts are being made to replace traditional analysis methods based on physical models and classical numerical simulations with modern artificial intelligence (AI) models. To identify the possibility of such predictions, the specialized literature offers several studies examining these approaches. This paper analyzes the volume of contributions from the specialized literature to determine the AI sector where detailed inspections regarding the simulation and optimization process of FRP materials are lacking.

This paper’s main objective is to conduct a systematic and analytical review of the use of AI models in the simulation, prediction, and optimization of FRP materials. The paper identifies suitable AI tools for analyzing and designing these materials. Subsequently, the gaps in specialized research are highlighted, allowing for the outline of future research directions that could improve the field. To achieve this objective, the paper analyzes both biometric and thematic aspects of scientific studies published between 2015 and 2025. It proposes a critical synthesis of the main applications of AI in three areas:

1. Prediction of the mechanical properties of FRP materials.

2. Structural monitoring and defect detection.

3. Modeling the degradation and durability of materials in aggressive environmental conditions.

The study highlights the need to develop standardized datasets, inspect additional machine learning (ML) models, and integrate them into engineering workflows. By incorporating innovative technologies that have not been sufficiently examined in the literature, the paper contributes to accelerating research in FRP materials.

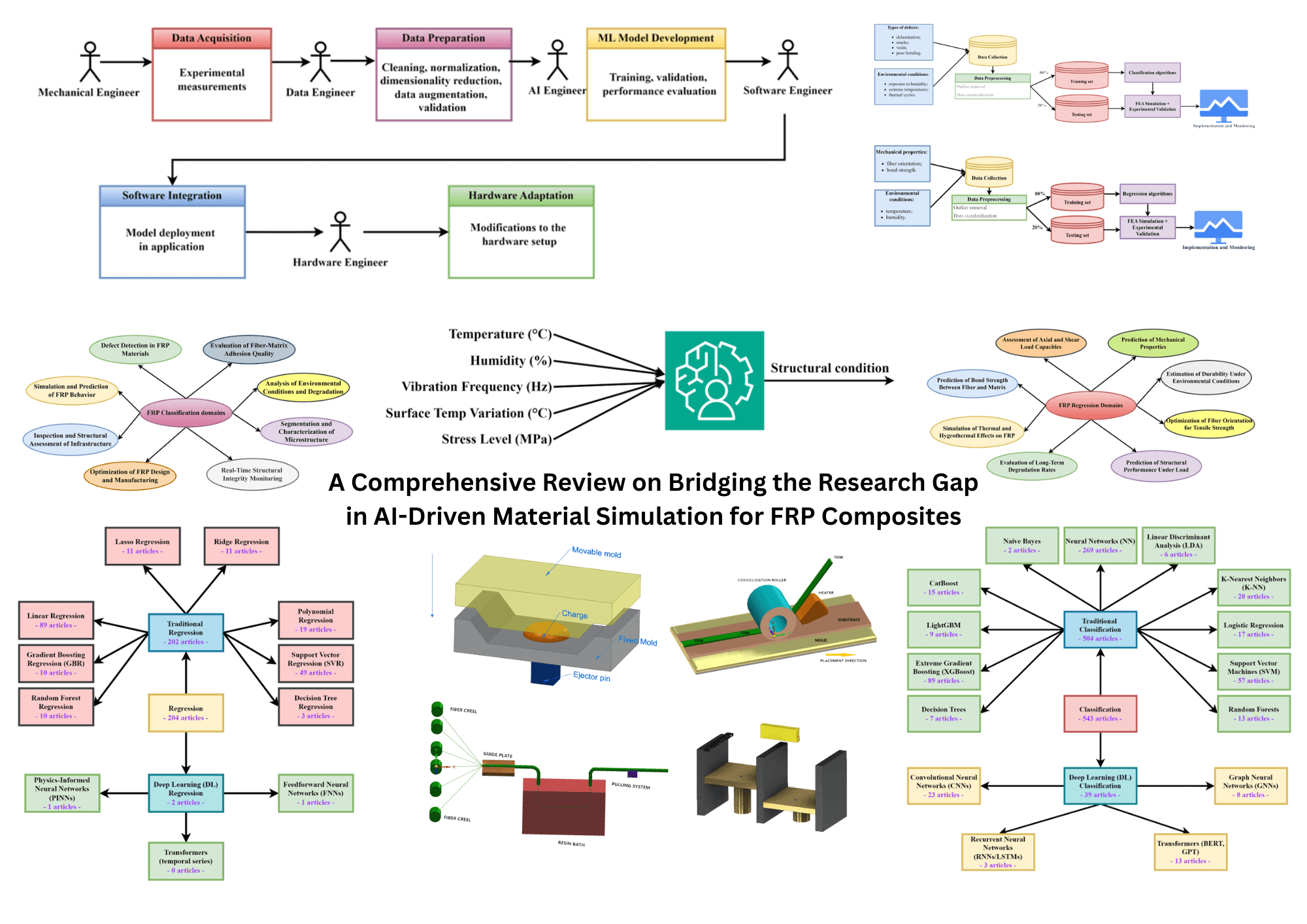

To achieve the general objective, the research utilizes a methodology based on three main components, summarized in Fig. 1, which include:

Figure 1: Flowchart for synthesizing the research development methodology

1. Identification in the Web of Science (WOS) database using the set of key terms defined by the authors of this research: “FRP,” “composites,” “machine learning,” “mechanical properties,” “durability,” and “simulation.” The studies from this search address various ML methods in predicting and optimizing the behavior of FRP materials. After this search, inclusion and exclusion criteria are applied to eliminate works that do not meet the time requirements, specifically the analysis period of 2015–2025.

2. The bibliometric and thematic analysis was conducted using the VOSViewer 1.6.20 software. This software aimed to identify research trends, institutional and geographical distribution, and the co-occurrence of key terms. In this way, the studies were thematically classified based on the types of applications of the FRP-AI combination.

3. The critical evaluation of the works identified in the specialized literature was based on the specific performances of the models, the interpretability achieved by the authors of this paper, and the integration with traditional simulation methods.

This method identified gaps in current research that should be addressed in future studies. Based on these observations, the authors have outlined future research directions to enable specialists in AI and mechanical fields to generate a substantial volume of contributions in the specialized literature, thereby aiding technological advancement in the field.

2 FRP Properties and Applications

FRP composites are increasingly utilized in civil engineering and construction as sustainable alternatives to conventional materials, such as steel. These advanced materials are favored for their exceptional strength-to-weight ratio, significantly reducing structural loads while maintaining performance [1]. Their application is particularly advantageous in environments exposed to aggressive chemical or physical agents (e.g., marine or industrial settings). FRP composites consist of polymer matrices reinforced with fibers (e.g., carbon, glass, or aramid), enabling the tailoring of mechanical properties to meet specific functional or environmental demands [2].

The widespread adoption of FRP composites in structural systems stems from their superior corrosion resistance, which eliminates the need for frequent maintenance and extends the infrastructure’s service life. The high corrosion resistance of FRPs is the main factor for their integration into structural systems. Other factors make them versatile, such as low weight, high specific stiffness, and the ability to be customized by varying the orientation of the fibers or the polymer matrix. FRP materials can be vulnerable to environmental effects such as water absorption and moisture expansion. These factors affect the durability and long-term mechanical behavior. For example, the paper [3] states that Glass Fiber Reinforced Polymer (GFRP) materials absorb up to 2% of their weight in water after prolonged immersion. This behavior represents a drawback for these materials, so applications with severe exposure to moisture or aggressive chemical agents require additional protection strategies. A directive in this regard would be to cover with waterproof layers or use epoxy resins with increased resistance to aggressive environments. A prime example is concrete-filled FRP tubular columns, which demonstrate enhanced resistance to chemical degradation and mechanical wear [4]. Their durability makes them ideal for critical infrastructure projects, such as bridge decks [5], seismic retrofits, and building strengthening systems [6]. The synergistic effect of combining glass and carbon fibers in FRP composites yields improved ductility and flexural strength, outperforming traditional single-material solutions [7]. Superior ductility in structural applications allows the material to absorb energy and deform without sudden failure. In this way, safety measures are ensured in the event of extreme loads, such as earthquakes, floods, or high winds. Increased resistance to bending allows FRP elements to withstand variable and unevenly distributed loads. Such situations occur every day in the case of bridges and slabs, especially in infrastructure components. Combining these properties allows for using FRP materials in applications where brittle failure or premature cracking can have serious consequences. Further optimization of mechanical properties can be achieved through strategic fiber orientation, enabling designers to address complex loading scenarios [8].

Beyond conventional applications, FRP composites are now integral to innovative engineering solutions, including seismic retrofitting, structural rehabilitation, and energy dissipation systems under dynamic loads (e.g., earthquakes or wind) [2] FRP composites’ versatility, durability, and low lifecycle costs position them as transformative materials for addressing 21st-century infrastructure challenges [6].

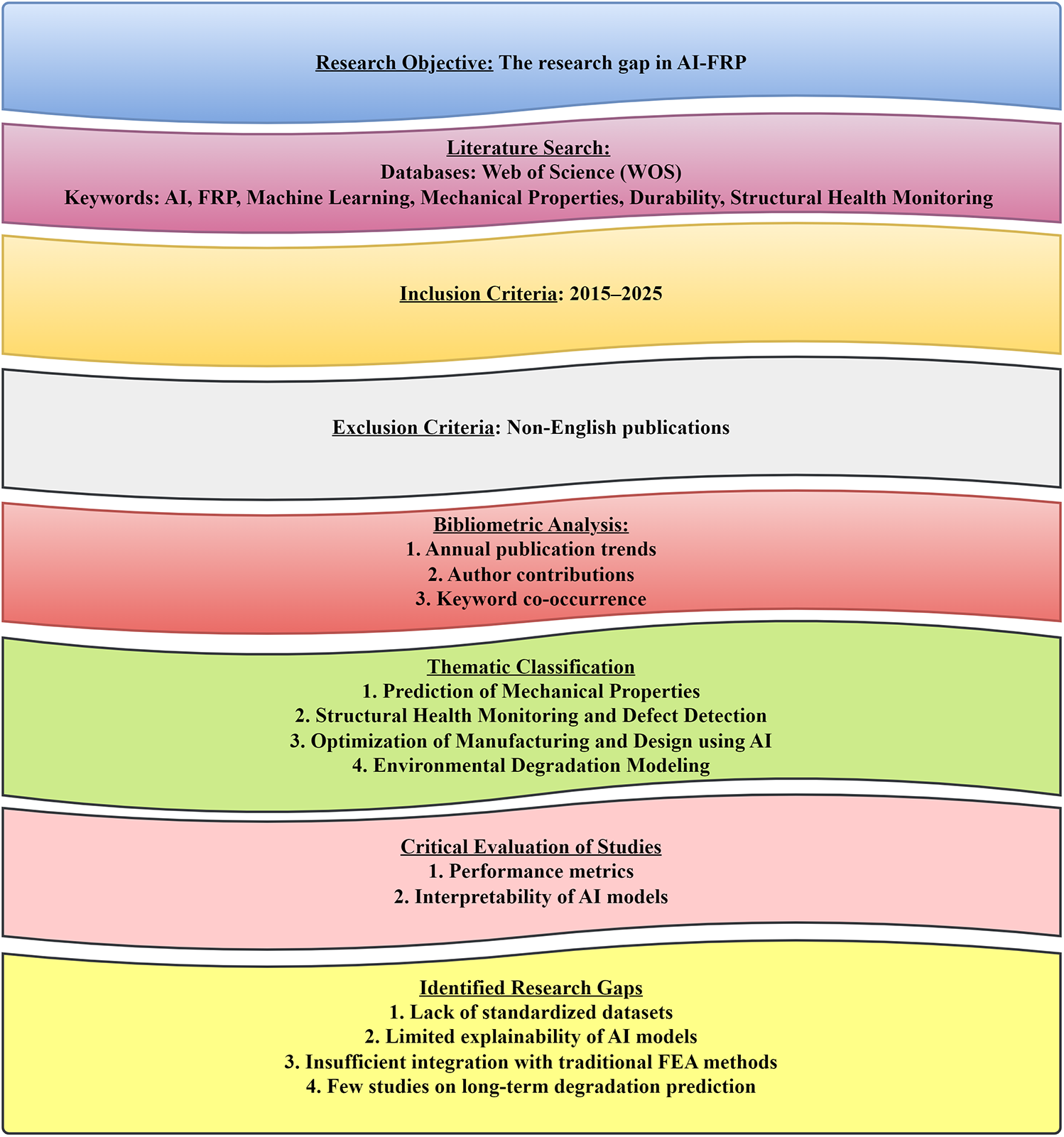

The market share of FRP applications is shown in Fig. 2.

Figure 2: The market share distribution of FRP across various applications [9]

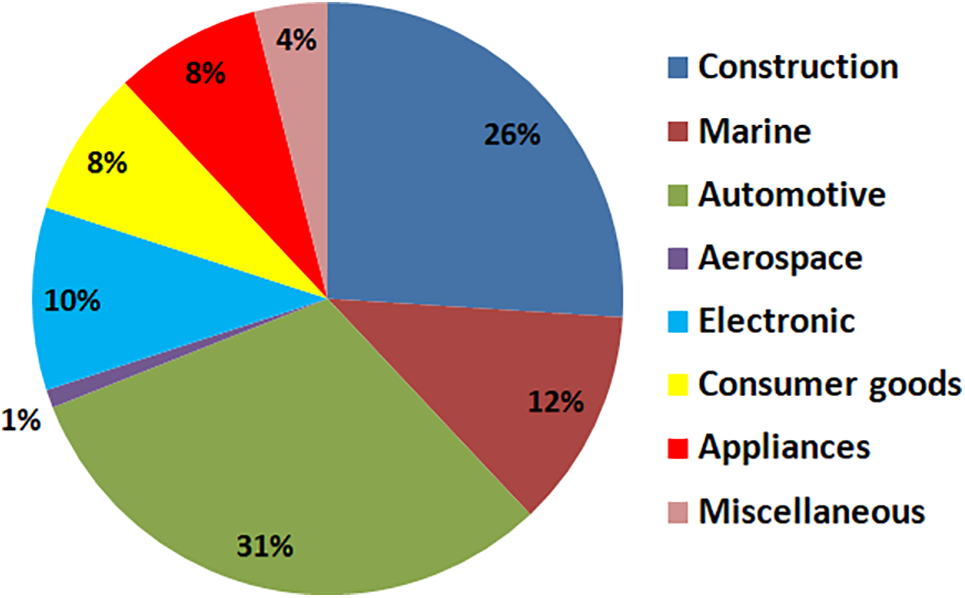

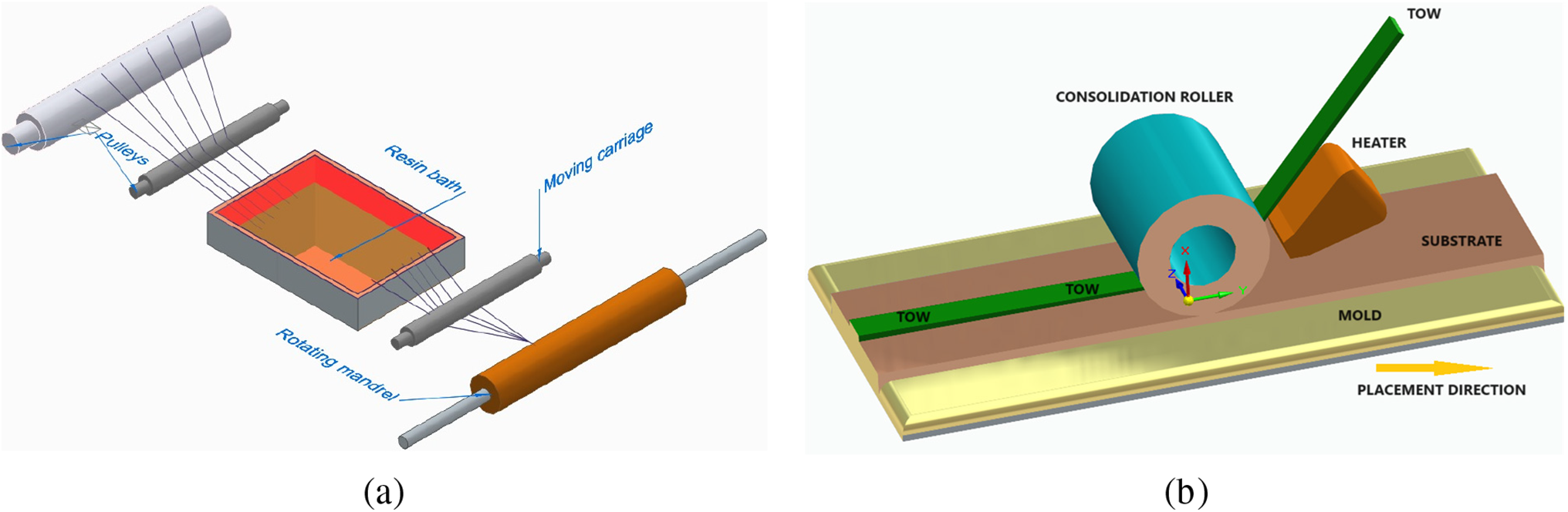

Figs. 3–6 present the main technologies used for composite manufacturing.

Figure 3: Main conventional manufacturing technologies of FRP based on matched die molding: (a) Hand lay-up; (b) Spray lay-up; (c) Pultrusion [9]

Figure 4: Main conventional manufacturing technologies of FRP based on contact molding: (a) Injection molding; (b) Compression molding; (c) Resin transfer molding; (d) Vacuum-assisted resin transfer molding [9]

Figure 5: Main automated manufacturing technologies of FRP: (a) Filament winding; (b) Automated fiber placement [9]

Figure 6: Main advanced manufacturing technologies of FRP: (a) Electrospinning; (b) Additive manufacturing [9]

Conventional FRP manufacturing methods, such as lay-up and filament winding, offer design flexibility but rely heavily on manual labor, resulting in variability and limited scalability. Automated techniques such as automated fiber placement and tape lay-up enhance efficiency and consistency, making them ideal for precision applications. Advanced methods, such as electrospinning and additive manufacturing, further enable high customization and control. Electrospinning produces ultrafine fibers, while additive manufacturing allows for complex, material-diverse FRP structures, representing significant advancements in composite fabrication [9].

FRP is used in structural engineering due to the unique properties mentioned earlier. These materials are used in construction engineering, aeronautics, civil infrastructure, and naval engineering [10] due to their durability against environmental degradation [11]. The lightweight characteristics of FRP make them suitable for bridge construction [12] and as reinforcement for concrete [13]. This approach is an alternative to traditional steel reinforcement in reinforced concrete [14], which is prone to corrosion in aggressive environments [15]. Corrosion resistance is a key characteristic of FRP composites, including GFRP. The consequence of utilizing these properties is reduced maintenance throughout the entire lifespan of the structure [16]. The use of hybrid systems that integrate steel and FRP enables engineers to enhance the performance of traditional materials by leveraging the complementary properties [17].

A key application of FRP is in retrofitting existing structures using FRP laminates [18] to strengthen degraded elements without altering the structural configuration [19]. In this way, the lifespan and load-bearing capacity of existing infrastructures are improved. For example, the inherent properties of FRP applied to pedestrian walkways allow for implementation through flexible architectural solutions in design [20]. Advances in additive manufacturing technologies for FRP composites have enabled the fabrication of complex structural configurations that were previously challenging to achieve [11].

Scientific works confirm the durability of FRP materials, mentioning the long-term performance of GFRP under outdoor exposure conditions [21]. Future practices in construction engineering will include design standards that integrate FRP technologies [15].

3 AI Tools for FRP Applications

Integrating AI in the development and simulation of FRP materials involves techniques that process large volumes of data. AI methodologies have enabled an evolution in material quality through the application of classification and regression techniques [22]. Researchers have developed new materials using machine learning (ML) algorithms, which have enabled them to identify complex relationships within datasets characterizing the composition and properties of these materials [23]. Predictive modeling of the performance of materials subjected to different conditions is carried out using ML algorithms to improve various engineering processes [24].

The study [25] uses Principal Component Analysis (PCA) to generate assemblies of sand particles with varied shapes. It demonstrates the possibility of preserving the particles’ morphological characteristics. The paper [26] employs the same technique for simulations related to the discrete element method, specifically regarding packing density and the angle of repose. Both studies analyze the influence of particle shape on mechanical behavior, a phenomenon also observed in the case of FRPs.

AI-driven simulations facilitate the analysis of interactions between the matrix and fibers in FRP composites. The paper [27] demonstrates that simulating thermal and hydrothermal aging processes anticipates material defects. This finding allows for the optimization of design. Advanced computational techniques applied in molecular dynamics simulations have allowed researchers to identify FRP behaviors under aggressive environmental conditions [28]. This way, characteristics that could not have been easily extracted from real-world applications were identified. Integrating AI systems into these simulations predicts new characteristics of these materials that would require very long timescales in the absence of these systems [29]. From these aspects, it can be deduced that these AI systems minimize the time materials could develop unforeseen behaviors.

Integrating AI applications alongside modern technologies, such as Digital Twins, virtualizes physical systems for real-time data analysis, enabling the generation of predictions that can replicate real-world performance [28]. This concept applies in environments such as warehouses or factories that use FRP [30]. Additionally, robotic systems incorporating AI components improve the handling processes of these materials [31]. The role of AI in modeling and assessing degradation processes in FRP materials contributes to the durability of composite structures under various loading conditions, including static, dynamic, and cyclic loads [32]. A concrete example is the analysis of interfacial stress in FRP systems, which requires ensuring longevity. A concrete example of integrating AI technologies in interfacial stress analysis can be found in the study [30]. This paper uses an artificial neural network (ANN) to evaluate the mechanical behavior of damaged reinforced concrete beams consolidated with FRP plates. The research uses an AI model trained on experimental data regarding the stress distribution at the interface between FRP and concrete under different loading conditions. The classical differential equations of the interface were combined with the AI model to achieve superior predictions compared to the classical variant. The predictions target the stress state without requiring complex FEM simulations from a computational standpoint. This approach demonstrates that the integration of AI supports the analysis of critical mechanical phenomena specific to delamination or loss of adhesion, having a direct long-term contribution to monitoring structural durability. Moreover, the method proposed in the paper [30] reduces reliance on destructive testing, contributing to identifying vulnerable areas. It is observed from this approach that materials science is closely linked to AI technologies in terms of guaranteeing material quality. The discovery of materials depends on the completeness of the datasets used in the model training stage [29]. Validation methodologies, error reduction, and the elimination of redundant data, along with testing, ensure the optimal design of FRP materials [33]. These steps are part of the workflow for designing FRP materials using AI technologies. The integration of these steps enables the identification of optimal fiber reinforcement configurations, thereby reducing experimental testing costs and facilitating the acceleration of new material development. Aspects related to workflow and costs are addressed in detail in a dedicated section of this article. Theoretical modeling and experimental validation, facilitated by AI techniques, ensure the continuous development of FRP and other composite materials [34].

Modern AI techniques also facilitate the predictive modeling of FRP materials. Traditional models use Finite Element Analysis (FEA) to estimate the axial capacity of reinforced concrete structures. They encounter difficulties in modeling the nonlinear behavior of elements degraded by corrosion due to the complexity of the calculations. A much easier modeling of nonlinear behavior justifies the transition to AI techniques. The ease of this approach comes especially when working with data from destructive tests or complex numerical simulations. These statements are supported by studies such as [35,36], which have demonstrated that ML algorithms support the estimation of the axial capacity of FRP-reinforced columns. Therefore, although classical methods can analyze FRP properties, integrating AI methods into the existing workflow achieves a faster analysis, marking a step towards predictive and customized structural engineering. An example is assessing the axial capacity of structures rehabilitated with FRP. The paper [37] emphasizes that the lack of empirical models to predict the axial capacity of columns affected by corrosion necessitates the development of predictive systems in this field. The orientation of the fibers determines the mechanical anisotropy of the composite. Therefore, the way the material behaves can be analyzed by the longitudinal alignment of the fibers, which ensures tensile strength. Chaotic or transverse orientation reduces the rigidity and durability of the structure. On the other hand, environmental conditions affect both the polymer matrix and the interface between the fibers and the matrix, causing phenomena such as thermal degradation of the resin, water absorption, hygroscopic expansion, reduced interfacial adhesion, and localized corrosion in defect areas. For this reason, predictions regarding the strength and durability of FRP materials in applications can be made using ML models. For this reason, the authors of this review study recommend ML algorithms for modeling these problems. In practice, it is suggested that fiber orientation and environmental conditions be analyzed to predict the strength of FRP materials. The suggestion to analyze factors using this method does not exclude the use of AI techniques; on the contrary, it supports them, demonstrating that AI is a superior alternative in terms of efficiency, provided that variables reflecting the physical reality of the material are integrated. Thus, our idea is consistent with using ML as a tool that generates superior results compared to classical techniques, provided that parameters from the process are included that contribute to establishing results aimed at the material and the environment in which the process is modeled. The influence of fiber orientation on structural properties can be analyzed using AI techniques when tests related to turbulent currents are combined with AI tools. The fiber alignment is visualized in this way, influencing the material’s performance [38]. Integrating advanced state methods with AI models allows engineers to simulate FRP composites faithfully in design workflows.

Optimization procedures in this field can be integrated under AI-assisted conditions. The paper [39] employs objective functions to minimize weight and maximize structural integrity, subject to specific constraints, in aerospace and automotive applications. This type of application demonstrates that using hybrid optimization algorithms constrains frequency constraints with the help of ML models [40]. FEA, used to simulate FRP composites’ behavior, is enhanced with AI tools. The paper [41] improves FEA in analyzing loading conditions for FRP repairs of submarine pipelines. Through simulations, AI replaces physical tests that are costly financially and in terms of actual effort. Nonlinear analysis with physical elements for debonding processes of reinforced concrete beams with FRP systems is also conducted using AI tools [32]. Combining FEA technologies with AI improves the analysis process by conducting simulations at the structural integrity level.

The lifespan of these composites reflects the durability of FRP materials. AI-based simulations improve this process. The paper [42] highlights the importance of incorporating environmental factors, such as humidity and temperature, into modeling FRP materials. This holistic approach enables the evaluation of long-term performance behavior under variable environmental conditions.

4 ML Analysis in the Context of the FRP Applications

AI encompasses multiple components that can be used in different fields. In a field, various AI components can be used simultaneously. The most well-known AI components are those for natural language processing (NLP) due to modern tools that allow interaction between computers and humans, computer vision (CV), which enables computing systems to interpret content from images and videos, expert systems that allow the imitation of human decision-making processes, as well as ML, which targets the problem-solving sector through classification or approximation. It is important to note that the most widely used components, such as NLP and CV, employ machine learning (ML) algorithms. The modeling and prediction of the mechanical properties of FRP are carried out with the help of the ML component. The reasons why this is the most suitable component are justified by the following arguments:

• The mechanical behavior of FRP materials is influenced by several factors (type of fibers, matrix, fiber orientation, material density, mechanical loading conditions, temperature, etc.). These many factors translate mathematical formalism into complex non-linear relationships between variables. Solving such a mathematical system by humans is impossible, which is why AI components are necessary. The components that can handle such situations are those of ML;

• ML models approximate complex mathematical formulas with predictive models that can anticipate material behavior based on a series of variables represented by the material parameters. For example, ML models can associate material parameters (such as fiber type, thickness, fiber orientation angle, etc.) with mechanical response (for example, tensile strength, compressive strength, torsional resistance, etc.);

• ML components use analyses on large volumes of data to identify certain common behaviors called patterns. This statement leads to the idea that as more process data is collected about the behavior of FRP materials under different operating conditions, ML models can continuously improve the accuracy of the simulations performed;

• Some ML algorithms can optimize the manufacturing process of FRP materials. This can be achieved by using models that predict the impact of various methods (such as manufacturing temperature) on the mechanical properties of the composites.

ML is a tool currently used for analyzing data associated with FRP due to its ability to work with large volumes of data. This ability facilitates the design of materials and optimizes the performance characteristics of composites. According to the paper [43], ML models have been successfully used to predict the performance of polymer membranes in pervaporation separation processes. The predictive component accelerates the screening of potential materials, which reduces the development time for new FRP applications. The paper [44] investigates the structure-property relationships of high-energy-density polymer composites. This highlights the role of ML in data analysis, which accelerates the discovery and characterization of new materials. The integration of ML in characterizing the microstructural properties of FRP was studied in the paper [45], serving as an example of quantitative analysis of microstructures in solid oxide fuel cells. This integration of ML not only enhances the understanding of composite behavior but also optimizes predictions regarding their performance based on microstructural factors. The anisotropic behavior analysis of FRP explores the unique mechanical behavior of FRP influenced by fiber orientation, also through ML methods [46].

ML dimensionality reduction techniques have proven useful in analyzing complex datasets associated with FRP. The paper [47] illustrates the usefulness of methods such as PCA in enhancing the interpretability of multidimensional data resulting from experiments with composite materials. Such techniques allow for the refinement of models that predict performance metrics related to FRP’s processing and mechanical properties, as discussed in the paper [48], which analyzes advancements in the unconventional processing of FRP.

The importance of unsupervised ML methods is increasingly recognized in evaluating the reliability of composite systems. For example, the paper [49] applies unsupervised learning techniques to evaluate the reliability and performance of power systems incorporating composite materials. Classification and clustering capabilities provide valuable insights into latent patterns, improving the’ accuracy of predictions regarding FRP components’ lifespan and durability.

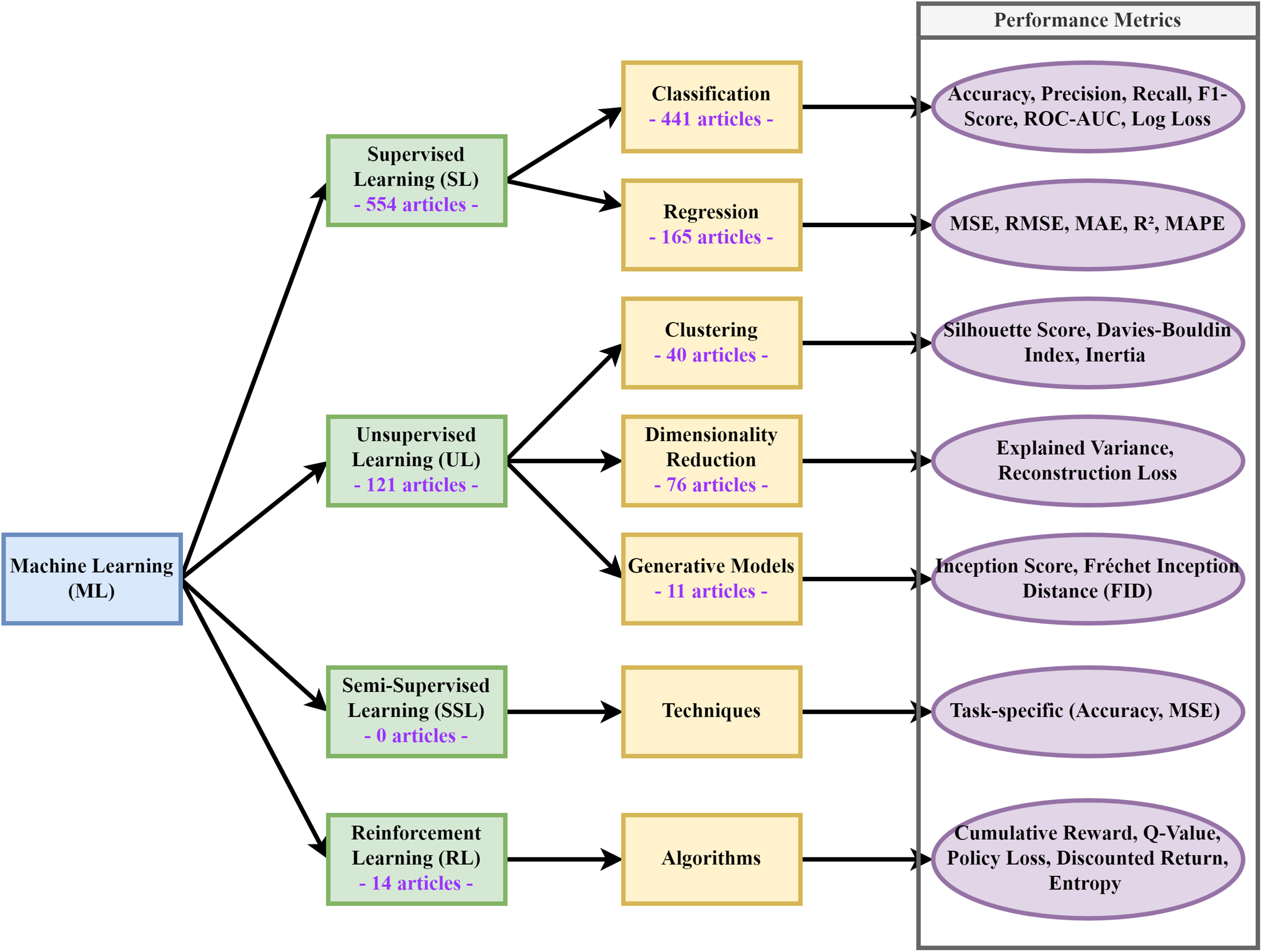

Fig. 7 presents the hierarchical structure of the ML concept. The authors categorize this concept into four main categories based on FRP-related results from the WOS. Thus, ML is classified into Supervised Learning (SL), Unsupervised Learning (UL), Semi-Supervised Learning (SSL), and Reinforcement Learning (RL). Fig. 7 also presents the evaluation metrics of ML models for each category. These metrics assess algorithm performance and serve as tools for model comparison. Most scientific papers address the issue of selecting the best-performing model for different scenarios. These metrics facilitate the identification of the optimal model for a given problem type.

Figure 7: Distribution of ML techniques based on the number of published articles and performance metrics

The diagram in Fig. 7 also includes the number of articles identified on the WOS platform. Through this approach, the authors aim to identify the most extensively studied ML direction in the literature between 2015 and 2025. Supervised Learning includes 554 articles in WOS and is subdivided into classification and regression. Classification (441 articles) is the most commonly employed technique, followed by regression (165). This suggests that most ML applications focus on predicting discrete categories or continuous values. The large number of existing articles on classification is explained by the ability of this ML component to identify the category in which a composite material fits based on its characteristics. Regression (165 articles) is explored for its predictive capability regarding numerical values associated with the mechanical properties of FRP materials. The most common applications involve predicting tensile or compressive strength, estimating the lifespan of FRP materials based on usage conditions, or simulating mechanical behavior to assess how an FRP material will respond to different types of loads (static or dynamic loading, extreme temperatures, etc.).

UL is identified in 121 articles in WOS. This relatively low number suggests that problems based on unlabeled data are either less common or more challenging to address successfully within the FRP domain. The results identified for SSL (no article) and RL (14 articles) indicate that these ML components are more difficult to apply in the FRP field.

Both classification and regression algorithms in ML use different methods to model the problems they must solve.

4.1 Classification Algorithms for FRP Applications

Regarding classification algorithms, they are studied in the literature in both traditional variants and through deep learning (DL) algorithms. In Fig. 8, the classification algorithms identified in WOS for FRP modeling are presented:

Figure 8: Distribution of research articles on ML classification algorithms for FRP analysis

• Neural Networks (NNs) are identified in 269 articles. Neural networks are the most used in modeling and simulating FRP properties. These allow for the non-linear analysis of the material composition and its mechanical behavior. Additionally, NNs are used to simulate numerical experiments without the need for costly tests;

• Extreme Gradient Boosting (XGBoost) has been used in 89 articles and is one of the most widely used algorithms in ML. The large number of articles (89) indicates that it is compatible with the issue of predicting the behavior of FRP materials. This is used to estimate residual stresses in FRP structures. It is also used in optimizing their design;

• Support Vector Machines (SVMs) are employed in 57 articles. They are frequently used to classify structural defects of FRP and predict the optimal type of matrix and fiber based on the application. The large number of articles confirms the repeated research that mentions this algorithm in solving classification problems (e.g., identifying the level of damage in an FRP laminate);

• Convolutional Neural Networks (CNNs) are applied in 23 articles for the analysis of microscopy images of FRP materials. Thus, they are helpful in the detection of microcracks and porosities;

• K-Nearest Neighbors (K-NNs) algorithm is cited in 20 articles in WOS. This is used in FRP analysis for defect classification based on the similarity between structures;

• Logistic Regression, identified in 17 articles, determines the probabilities of defects occurring in FRP materials. However, as a linear model, it provides poor results because it cannot model the nonlinear relationships between processing parameters and the mechanical properties of FRP;

• Random Forests (RFs) (13 articles) are used for the classification of FRP microstructures and in predicting mechanical behavior based on material composition;

• LightGBM (9 articles) and CatBoost (15 articles) are rarely used. In the literature, these algorithms have applications in predicting the degradation time of FRP composites;

• Decision Trees (DTs) (7 articles) demonstrate the limitation in the FRP issue, being poorly applicable to the complex mechanical properties of FRP;

• Recurrent Neural Networks (RNNs or Long Short-Term Memory (LSTM)—3 articles) and Transformers (13 articles) are rarely used in the analysis of experimental data series and the prediction of internal stresses in composite materials;

• Naive Bayes (2 articles), Linear Discriminant Analysis (LDA) with 6 articles, and Graph Neural Networks (GNNs) with no article are rarely used in FRP because they are more suitable for statistical data and cannot model the structural complexity of composite materials.

NN are employed in fiber-reinforced composites (FRC) because they can predict mechanical properties, optimize manufacturing processes, and improve material analysis. Numerous studies have applied NN to model and predict the static strength properties of carbon fiber reinforced composites, highlighting the utility of AI in composite material research. For example, the paper [50] presents an ANN model to accurately predict the static strength properties of carbon fiber reinforced composites, demonstrating the potential of ML in materials science.

The utility of NN extends to other aspects of FRP as well. The prediction of properties and structural analysis are frequently studied applications using NN. The paper [51] presents the role of ANN in discovering unknown constitutive laws, accelerating multiscale modeling, and detecting defects in composite materials. These characteristics reinforce the position of NNs as tools for optimizing the properties of composite materials, as they can model complex relationships that traditional methods cannot identify. In addition, advancements in specific types of NN, such as CNNs and GNNs, have extended their applicability in predicting the mechanical properties of composites. The paper [50] discussed using ANN to predict elastic properties, such as Young’s modulus and Poisson’s ratio, based on computational data generation. Additionally, the papers [52,53] have explored how GNNs can represent the structures of crystalline materials to predict target behaviors, providing valuable insights for the improved modeling of composite structures.

AI applications also include the improvement of composite manufacturing processes that employ NN. For example, studies [54,55] on carbon fiber reinforced polymer (CFRP) milling have shown that ANN models can predict surface roughness and delamination factors, optimizing operational parameters during processing. These applications demonstrate how NNs bridge the gap between theoretical predictions of properties and the practical requirements of manufacturing. The role of NN in understanding the behavior of composites also extends to real-time monitoring and predictive maintenance. Techniques such as using backpropagation algorithms combined with particle swarm optimization have been applied to identify defects in composite structures through material health monitoring [56]. The integration of NN in the study and application of fiber-reinforced composites has allowed the evolution towards an intelligent materials science. Their ability to model complex interactions and predict mechanical properties optimizes material processing and quality control [57].

Recent studies have demonstrated the applicability of SVM in predicting the mechanical properties and functional characteristics of various composite materials. For example, the paper [58] illustrates the capability of SVM, in combination with supervised learning techniques such as linear discriminant analysis and RFs, to generate predictive models for the petrochemical sector. This versatility indicates the possibility of using SVM to analyze FRP’s mechanical and thermal responses. MLL techniques, including SVM, have been used to examine the integrity of FRP bonds under hygrothermal conditions. The paper [59] emphasizes the importance of understanding these interactions for the durability of FRP-concrete bonds, highlighting the role of computational modeling, where SVM can analyze the factors influencing bond performance. Additionally, the paper [44] details the application of ML approaches, including SVM, in designing polymer composites with high energy density and optimizing their properties based on experimental data. In addition, the integration of ML with experimental data demonstrates that SVM can improve the accuracy of predictions in identifying material compositions and behaviors under various conditions. Innovations in high-efficiency stochastic simulations for material degradation reveal how ML frameworks, including SVM, are designed to predict energy storage performance in polymer composites [60]. These capabilities enable the optimization of material properties in civil engineering applications, where FRP is frequently used for structural reinforcement and durability enhancement [61]. In the context of FRP applications in civil engineering, SVM has demonstrated potential in optimizing predictive modeling for hybrid composites, which use multiple types of fibers in a matrix. The study [62] illustrates how ML techniques, including SVM, can facilitate understanding of the mechanical properties of these complex materials. As research continues to explore the capabilities of SVM in the field of FRP, combining these methodologies with rigorous material testing leads to advancements in the design and implementation of composite structures.

XGBoost has been recognized for its superior predictive capabilities compared to traditional methods [63]. Researchers have employed interpretation techniques, such as SHapley Additive exPlanations (SHAP), to elucidate how various input features impact output predictions, thereby enhancing the understanding of the model’s decision-making process [35]. This aspect allows engineering applications to understand the factors contributing to a prediction and make informed design and material selection choices for reinforced structures [64].

4.2 Classification Process for FRP Applied on a Proposed Example

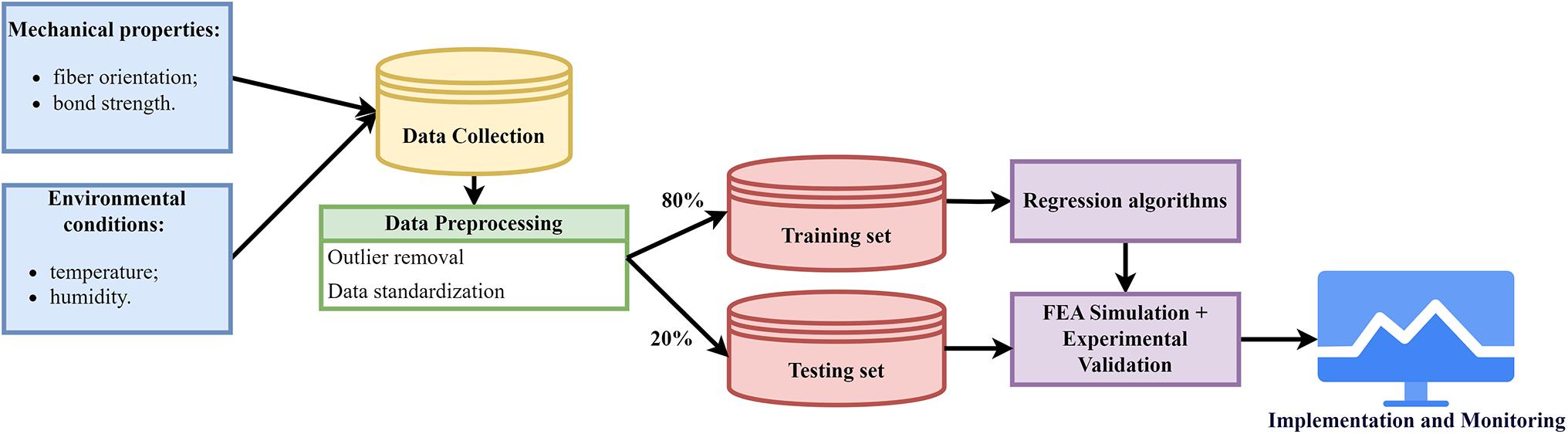

Fig. 9 illustrates the schematic flow for classification in FRP composite simulation and optimization. The flow is exemplified for defect detection using common defects such as delamination, cracks, voids, and poor bonding. These are critical issues that can compromise the structural integrity of FRP components. Fig. 9 outlines a structured ML classification process from data collection to implementation and monitoring. The presented example emphasizes the role of classification algorithms in identifying and categorizing defects within FRP materials.

Figure 9: Schematic flow for classification in FRP composite simulation and optimization

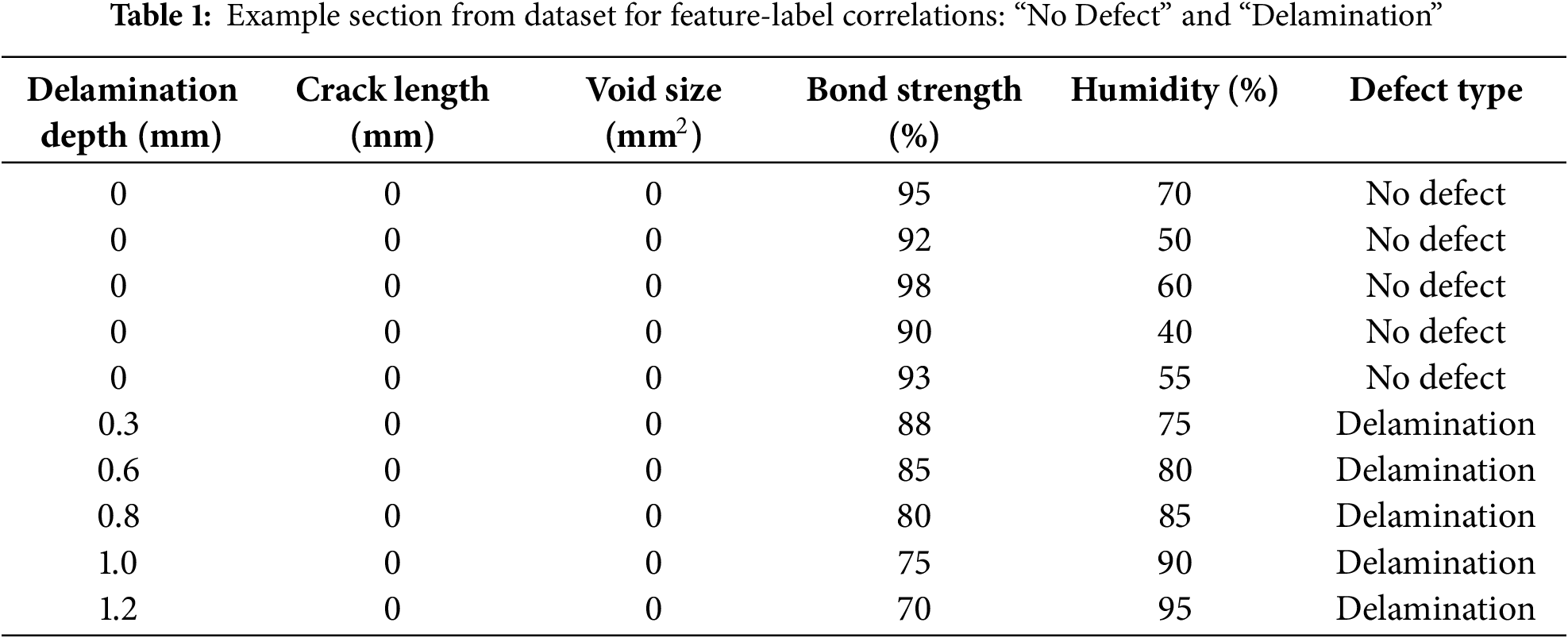

The Data Collection builds a database that contains correlations between elements with different types of defects and values associated with environmental conditions, as well as values for elements without defects and environmental parameters. Building the dataset with feature-label correspondences enables the training of a correct classification model. Fig. 9 highlights exposure to humidity, extreme temperatures, and thermal cycles as key factors influencing material behavior. Elements that contribute to training the model are called features, and the categories associated with these elements are called labels. Table 1 presents an example of correlations between features and labels. The dataset must contain tens of thousands of such configurations so that the model can predict correctly. The authors want to emphasize that the dataset’s volume must be substantial, which presents a primary challenge for AI models. Building the dataset is complicated because it requires acquiring real data that is known with certainty to correlate with the output correctly. Otherwise, the model will learn to recognize incorrectly.

In the data preprocessing stage, the data is standardized. At this stage, engineers clean and normalize the collected data to ensure its quality and compatibility with ML algorithms. Eliminate data points that are significantly different from other observations, as they may skew the results. Since the data can come from various sources, it must be standardized to a uniform format. In the first five records from Table 1, all features, such as delamination depth, crack length, void size, bond strength, and humidity, are within normal ranges, indicating healthy FRP components with no defects. In the last five examples, the delamination depth varies from 0.3 to 1.2 mm, indicating different levels of layer separation. Other features like crack length and void size remain at zero, suggesting that delamination is the primary defect. The bond strength and humidity levels also show some variation but are generally lower than the “No Defect” cases, reflecting the impact of delamination on the material’s integrity.

The training and testing stages are based on the quality of the data in the dataset. The preprocessed data are split into training and testing sets to develop and validate the classification models. Fig. 9 indicates an 80/20 split, where 80% of the data is used for training the model, and 20% is reserved for testing its performance. These values can vary; they are chosen for illustration purposes. There are situations when the ratio is 70/30 or 75/25, depending on the metrics obtained from testing. Assuming the dataset contains 1000 data points, 800 would be used for training and 200 for testing.

In the training phase, multiple classification algorithms are evaluated. Based on the evaluation metrics of the ML type, the algorithm that best models the problem is chosen.

FEA Simulation and Experimental Validation integrate the classification results with FEA simulations and experimental data to validate the model’s predictions. FEA simulates the effects of classified defects on the structural performance of FRP components. For instance, simulating how a 0.5 mm delamination affects the tensile strength of a FRP beam is an example of this stage. Experimental validation compares the simulation results with real-world test data to ensure the accuracy of the simulation. In this step, the engineer conducts tensile tests on FRP samples with known defects and compares the results with FEA predictions.

Finally, the algorithm is implemented into the optimized design and continuously monitors the structure’s performance to detect new defects. In this stage, the model is fed parameters such as delamination depth, crack length, void size, bond strength, and humidity, and it automatically generates the label for the defect type. This is possible because the model identifies similar situations within the large volume of data and assigns the label based on previous experiences from the dataset.

4.3 Regression Algorithms for FRP Applications

In FRP analysis, regression algorithms predict mechanical behavior, optimize material properties, and simulate the material’s response to different loading conditions. The results obtained for the regression algorithms demonstrate the research trends of each method regarding the FRP issue.

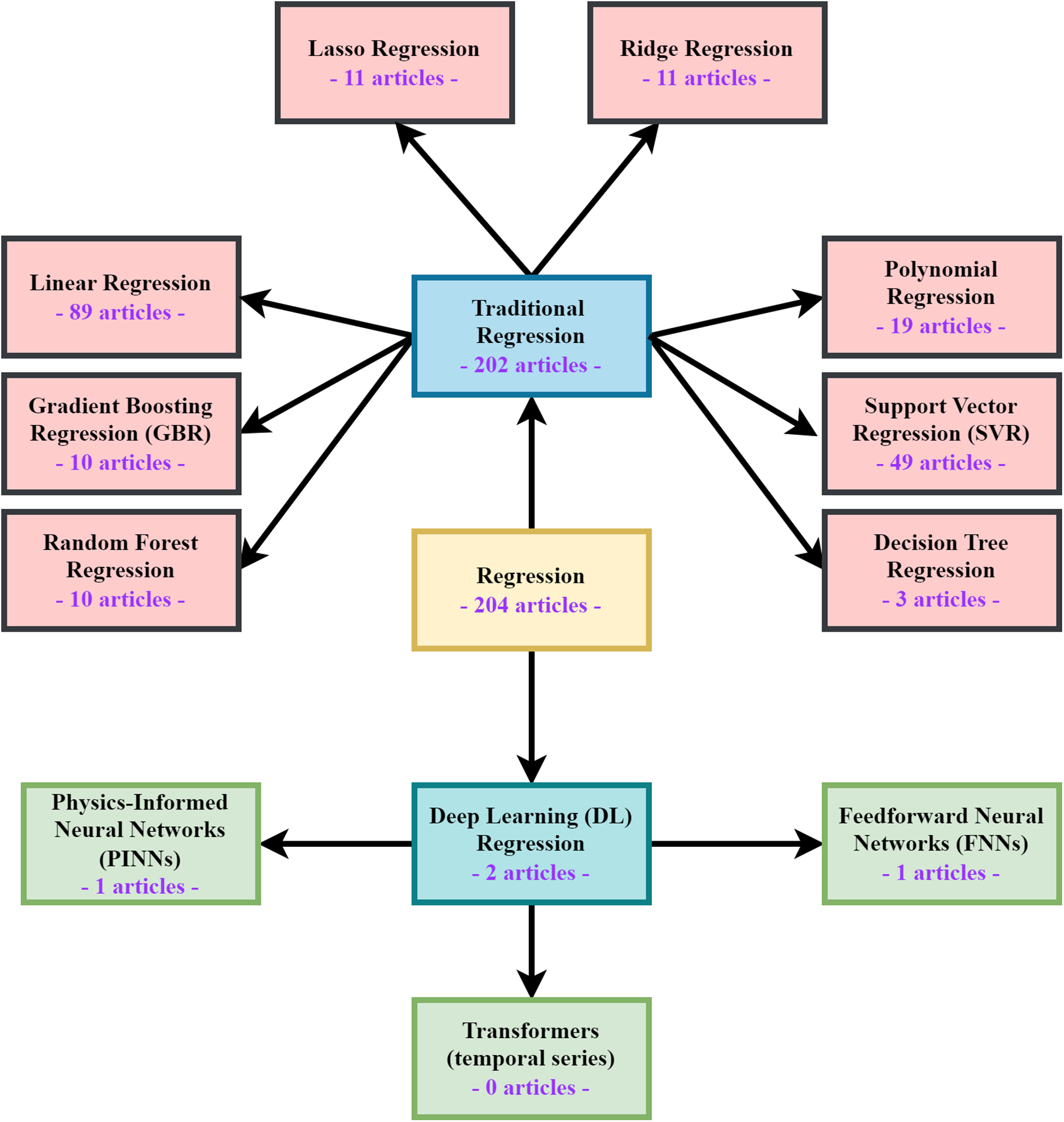

Fig. 10 presents the WOS results for each algorithm specific to regression models, whose values are analyzed as follows:

Figure 10: Distribution of research articles on ML regression algorithms for FRP analysis

• Linear regression methods (89 articles) and polynomial regression methods (19 articles) are used to establish correlations between manufacturing parameters (e.g., fiber percentage, resin type) and mechanical properties (e.g., tensile strength, modulus of elasticity). These algorithms are also used to simulate the complex behavior of FRP based on the nonlinear relationships between variables.

• The Lasso and Ridge Regression methods (11 and 10 articles, respectively) select specific features for FRP analysis, identifying those parameters that contribute little to FRP behavior. This reduction allows for the simplification of the analyzed model;

• Gradient Boosting Regression (GBR) is used in 10 articles, and Random Forest Regression (RFR) is also employed in 10 articles are used for the nonlinear prediction of the mechanical performance of FRP;

• Decision Tree Regression (DTR) (3 articles), Feedforward Neural Networks (FNNs) (1 article), and Transformers (Time Series—no article) are not explored in the literature for the FRP issue because they are not suitable for modeling such a problem as they tend to overfit the data, or require a much larger volume of data, or due to the lack of sequential datasets;

• Physics-informed neural Networks (PINNs) are used in one article, combining the laws of physics with machine learning. This relatively new technology has not yet been explored for the FRP issue.

Linear regression identifies FRP behavior in civil engineering and materials science. Decent studies have demonstrated linear regression’s ability to evaluate the performance associated with FRP-reinforced concrete systems. The paper [65] examines linear regression analysis of the bond strength of FRP bars in various types of concrete. This paper uses a dataset of 1010 samples. Similarly, the paper [66] studies the distortion of FRP reinforcements. Also, from the civil engineering category, the paper [67] studies the prediction of the resistance to bending of reinforced concrete beams with FRP. The paper emphasizes that the methodologies are applicable when the scenarios differ. ML models are used to improve the properties of FRP composites through applications that simulate different associated scenarios. The paper [68] achieved an R2 value of 85% in estimating the bond strength between the FRP laminate and concrete. The paper [69] highlights the advantage of using linear regression as a study element for predictions associated with FRP. This tool is simple, provides interpretable results, and can be used in various applications.

Support vector regression (SVR) predicts the mechanical behavior of FRP concrete components. This method is superior to the limitations of traditional empirical equations. SVR allows nonlinear relationships between input parameters and the resulting resistance measurements. The paper [70] proposed a hybrid approach that integrates SVR with a Bayesian optimization algorithm (BOA) to improve the predictive capability of shear strength in FRP-reinforced concrete beams without stirrups. Similarly, the paper [71] illustrated the effectiveness of SVR in predicting the joint strength of reinforced concrete elements. The versatility of SVR is also demonstrated in studies that predict bond and joint strength in these materials. Other evidence regarding SVR performance comes from studies focused on predicting shear capacity. For example, the SVR method was used to determine the bond strength at the concrete-FRP interface [72]. The paper [37] investigated the load-bearing capacity of glass-FRP columns by applying the SVR method to a wide range of structural assessments and conditions. In the paper [73], it was observed that SVR-based models exhibited shorter prediction times and reduced errors when applied to estimates of bond strength at the FRP-concrete interface.

4.4 Regression Process for FRP Applied on a Proposed Example

For regression, the flow is similar to that for classification. The fundamental difference between the two stems from the dataset, where the label is a numerical value. Fig. 11 shows that initially, experimental and numerical data regarding the mechanical properties and structural behavior of FRP materials are collected. The dataset may include mechanical properties such as tensile strength (MPa), elastic modulus (GPa), delamination resistance (N/mm2), environmental conditions such as temperature (°C), humidity (%), exposure to marine salts (ppm), or structural performance metrics like axial load capacity (kN) or shear behavior (MPa).

Figure 11: Schematic flow for regression in FRP composite simulation and optimization

The data is cleaned and normalized in the next stage to eliminate errors and redundancies. For example, data points with extreme values are removed (e.g., a tensile strength of 500 MPa if the normal range is 100–300 MPa).

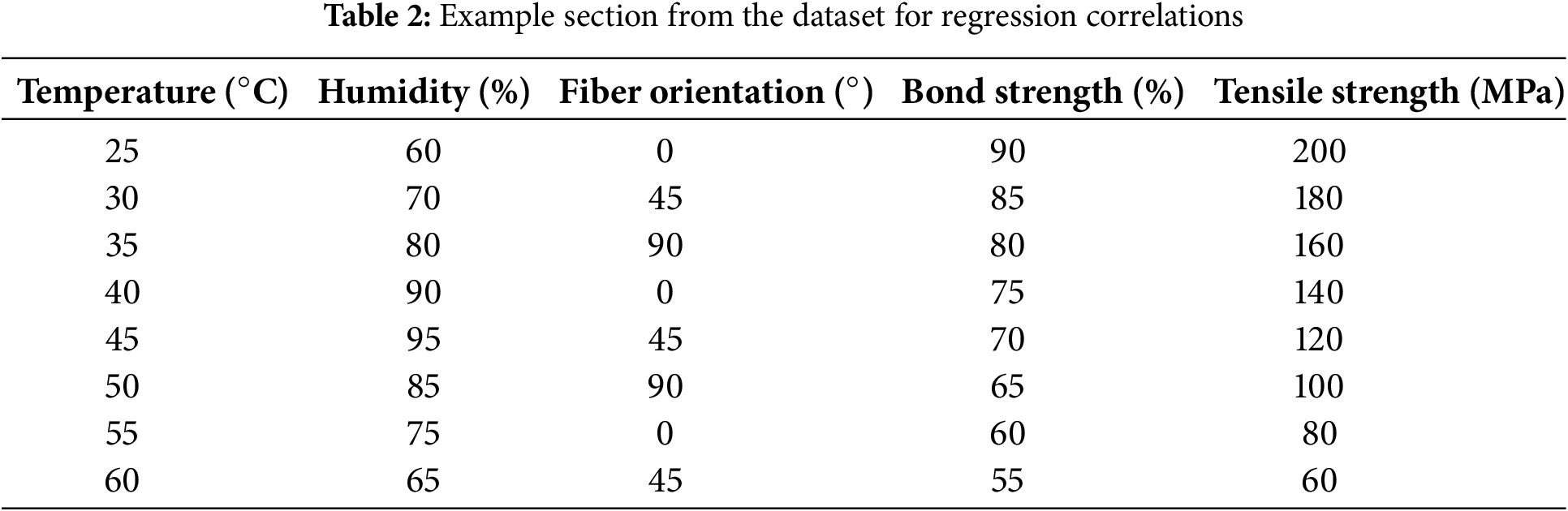

The dataset must be constructed to contain correspondences between inputs and outputs. Table 2 presents an example of such correspondences between Temperature (°C), Humidity (%), Fiber Orientation (degrees), Bond Strength (MPa), and Tensile Strength (MPa). Essentially, the model aims to predict Tensile Strength (MPa) values when temperature, humidity, fiber orientation, and bond strength are known.

The preprocessed data is split into training and testing sets at a ratio determined by the engineer, and subsequently, the model is trained using regression algorithms. The algorithm with the best performance is evaluated using specific metrics.

In the FEA Simulation and Experimental Validation stage, the effect of fiber orientation on tensile strength is simulated. The simulated results are then compared with experimental tests. The purpose of these tests is to evaluate the accuracy of the model’s predictions. The regression results are used to optimize FRP design. For example, fiber orientation can be optimized to maximize tensile strength.

Table 2 presents an example of correlations for training a model that determines the tensile strength of FRP material. The input variables used to train the regression model are:

• Temperature (°C) is the temperature to which the material is exposed;

• Humidity (%) represents the humidity level;

• Fiber orientation (°) is the material’s fiber orientation (in degrees);

• Bond strength (%) is the fiber-matrix adhesion strength.

Each row shows how certain combinations of features influence tensile strength. For example, at 25°C, 60% humidity, 0° fiber orientation, and 90% bond strength, the tensile strength is 200 MPa. At 50°C, 85% humidity, 90° fiber orientation, and 65% bond strength, the tensile strength decreases to 100 MPa.

4.5 Performance Algorithms for FRP Applications

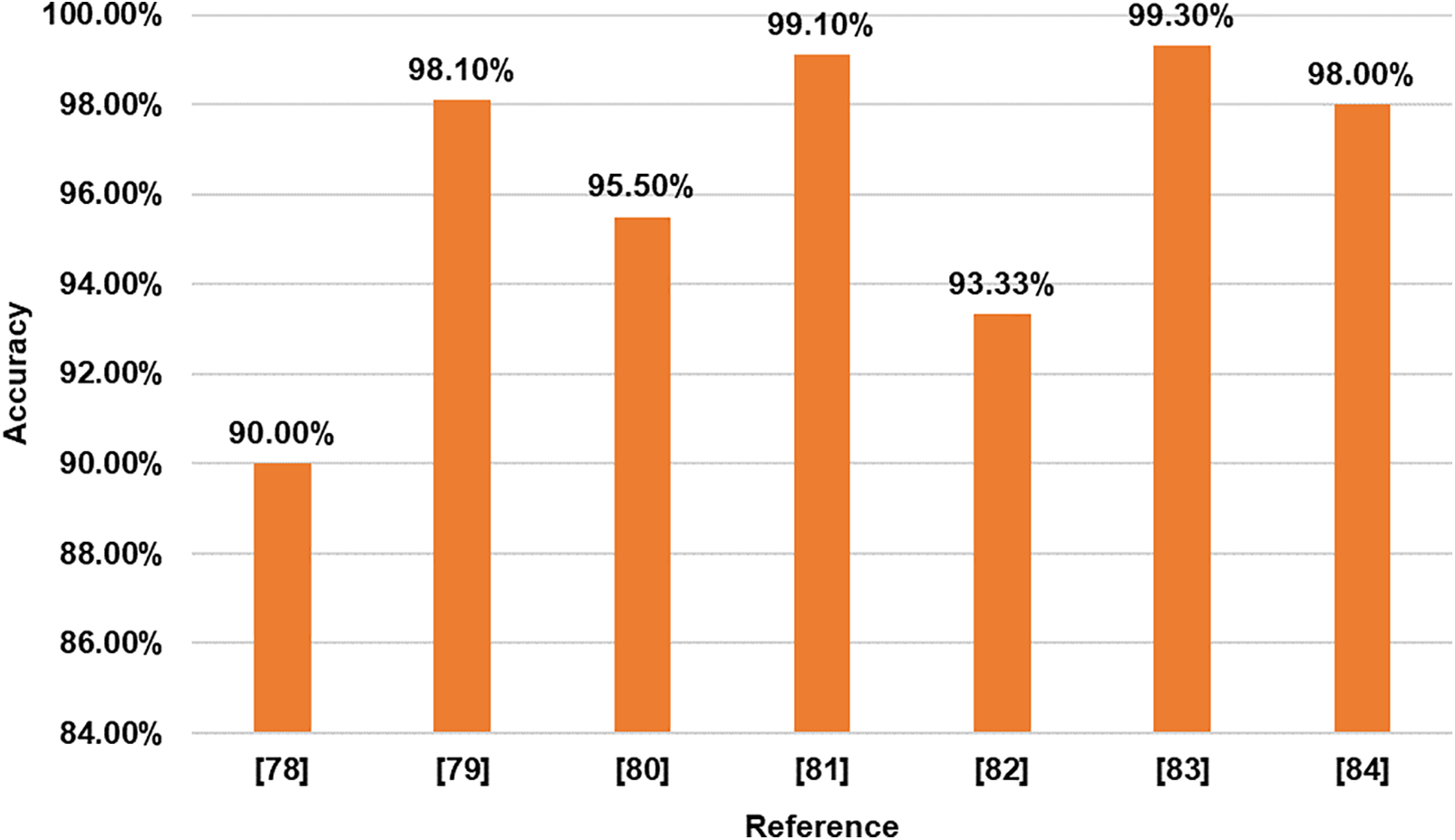

The application of ML in the simulation and analysis of FRP has progressed to accurately model and predict the performance characteristics of FRP in various structural applications. An example in this regard is structural applications at the concrete level. The paper [74] demonstrates the use of multilayer perceptron networks and radial basis function networks to estimate the compressive strength of FRP-confined columns. The results presented in the paper indicate that these NN models outperform traditional regression models. The paper [75] estimates the punching shear capacity of FRP-reinforced concrete slabs. Another paper [76] examines the bond strength between the FRP interface and concrete under various environmental conditions. Their results showed that NN based on improved meta-learning offers superior predictive performance compared to standard models. In the paper [77], an ANN-based framework was developed to predict the bond strength between FRP and concrete. The paper [73] evaluates the bond strength in surface-mounted FRP-concrete systems. Together, these studies signal a paradigm shift in identifying and quantifying material properties through AI technologies. These results underscore the importance of ML in composite materials engineering. The literature identifies two FRP applications in the ML field: structural health monitoring (SHM), and damage assessment. Fig. 12 summarizes the accuracy of the ML models analyzed in the literature. The accuracy values presented in Fig. 12 indicate the outstanding performance of the ML models in the context of SHM when applied to FRP materials. These results underscore the importance of ML algorithms in SHM.

Figure 12: Comparative analysis of ML model accuracy for SHM in FRP applications [78–84]

The results in Fig. 13 show accuracy values of 92% and 97.75% for the ML models in predicting the structural behavior of FRP-reinforced elements. These values confirm that ML models are well-suited for these applications.

Figure 13: Accuracy of ML models in predicting FRP-damage assessment [85–92]

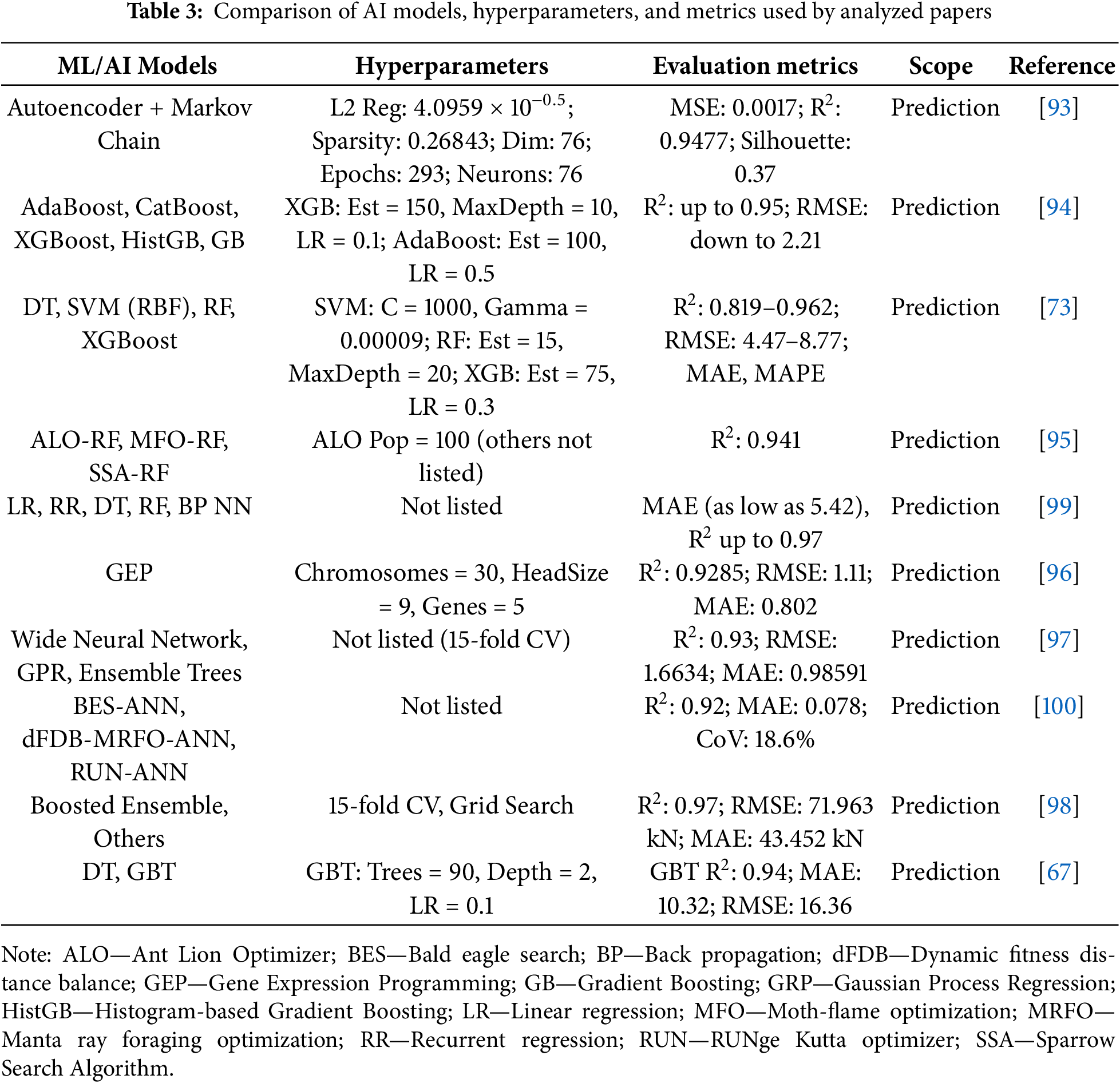

Works in the specialized literature demonstrate the superiority of ML models in predicting the mechanical behavior of FRP composite materials. The paper [93] presents a Markov chain autoencoder, which achieved an R2 of 94.77% and a mean squared error (MSE) of 0.0017. The paper [94] tests the XGBoost and AdaBoost algorithms and concludes that the XGBoost model achieved the best predictions regarding adhesion strength, with an R2 of 95% and a root mean square error (RMSE) of 2.21. The research [73] compares the SVM, RF, and XGBoost algorithms, yielding outstanding results for the RF model, which achieved R2 values of 81.9% and 96.2%, respectively. RMSE had a value of 4.47. The paper [95] employs a hybrid approach that integrates an RF component for estimating bond strength. In this case, the model achieved an R2 of 94.1%, whereas the research [96] obtained an R2 of 92.85%. The papers [97,98] use Boosted Enable models, achieving R2 between 93% and 97%, while the paper [67] uses the Gradient Boosted Trees (GBTs) model with an R2 of 94% and mean absolute error (MAE) of 10.32. The comparative results are summarized in Table 3.

Table 3 shows that the evaluation metrics of the models have exceptional results, demonstrating their practical usability; however, the number of these articles is limited, as will be shown in the bibliometric analysis section.

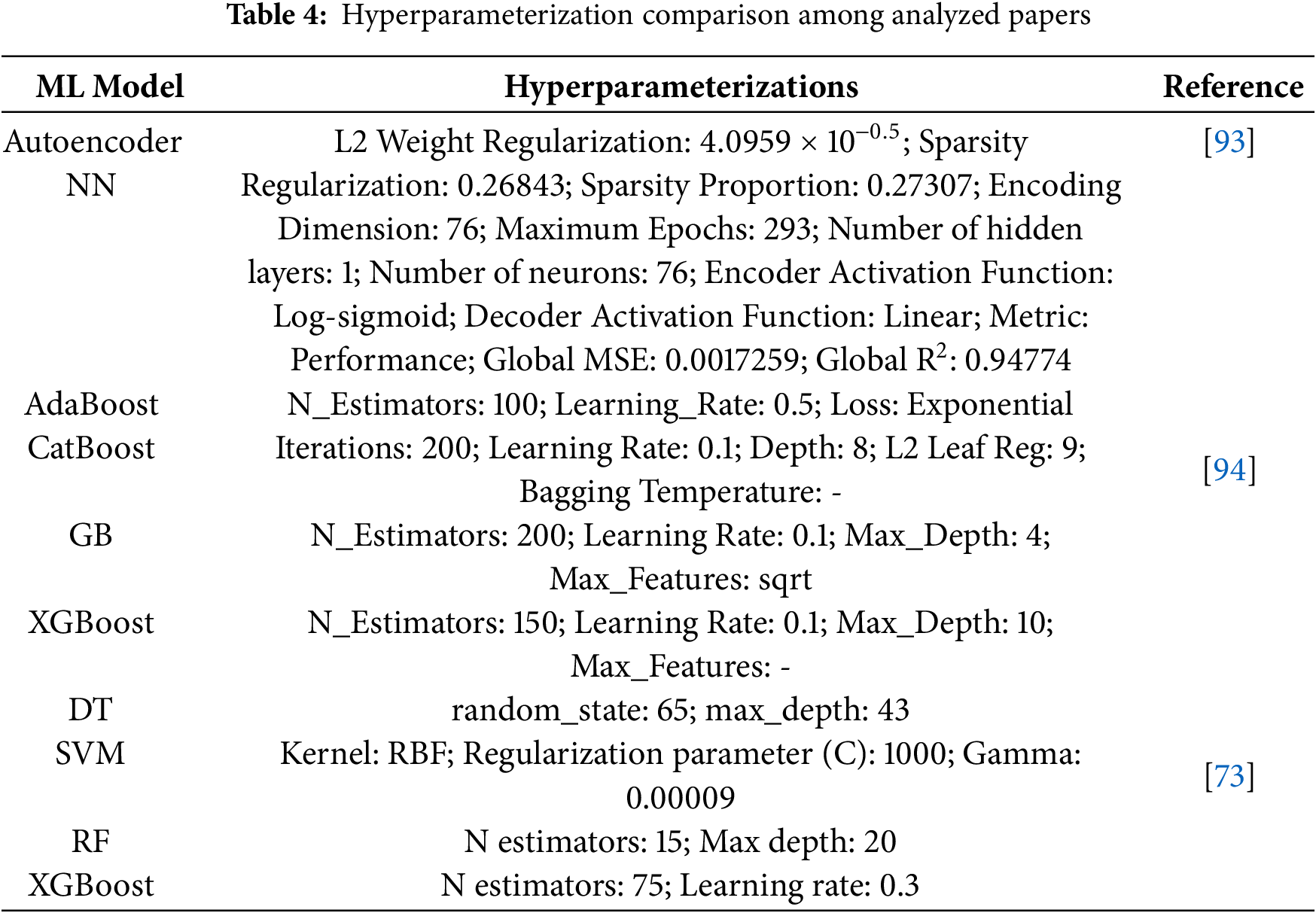

The comparison in terms of hyperparameterization or dataset among the specialized works is winding, as each model is characterized differently. Table 4 summarizes the hyperparameterizations from the papers [73,93,94].

Table 4 outlines that the hyperparameters differ depending on the model. Thus, in the paper [93], the autoencoder uses L2 and sparsity regularization to prevent overfitting. In the research [94], the AdaBoost model is hyperparameterized with 100 estimators, a learning rate of 0.5, and an exponential loss function. The other models, CatBoost, Gradient Boosting, and XGBoost, were configured with different estimators and learning rates, with Gradient Boosting limiting the depth to 4 to reduce the risk of overfitting. In the case of the paper [73], DT, SVM, RF, and XGBoost are adjusted to achieve the highest possible accuracy, obtaining a kernel with a regularization parameter value set to 100 for SVM.

5 Classification and Regression in FRP Composite Simulation and Optimization

Integrating ML techniques into the optimization process of obtaining FRP composites enables enhancement of their structural capacities [101]. Classification models improve the prediction of material behavior in damage detection. The analysis of current ML applications highlights the use of classification algorithms to predict the behavior of FRP composites. For example, the paper [102] uses ML in optimizing processes for various composite materials. These methods estimate the mechanical properties of composites. The research [103] proposes a multiscale approach that employs ML techniques in finite element modeling to predict the nonlinear behaviors of short fiber composites.

Identifying damage in FRP composites ensures the structural integrity of the materials. This is an essential requirement in the aerospace and automotive industries. The implementation of non-destructive evaluation methods alongside ML algorithms assists in the process of monitoring damage detection capabilities. The paper [104] demonstrates the claims above by evaluating the degradation state of composites based on their microstructure, similar to the paper [105], which classifies damages using Lamb wave signals processed with ML-based defect classification algorithms. These approaches support the idea that classification algorithms are widely used in the quality monitoring of FRP composites.

The optimization process also employs ML classification techniques, as supported by the papers [106,107]. Structural parameters are systematically varied to identify an ideal combination, facilitating the optimization of design parameters for composite structures [106]. The study presented in the research [107] utilizes FE methods and classification algorithms to enhance the understanding of material degradation through a cooperative approach. These technological advancements accelerate the process by optimizing the mechanical properties of composites. ML analyzes complex microstructures to anticipate material behavior. To achieve this objective, historical data is utilized to improve the accuracy of predictions [108]. The origin of this approach stems from the use of ANN for modeling composite materials. For this purpose, dedicated tools such as MPpredictor are employed. It predicts material properties based on their composition. This objective aligns with the Materials Genome Initiative to accelerate material discovery [109]. These initiatives allow researchers to expedite developments in materials science by reducing the time and costs associated with traditional experimental methods. The correlation between processing conditions and the resulting mechanical properties is modeled using ML algorithms for complex optimization strategies [110]. The paper [111] illustrates the improvement of composite synthesis using material preparation methods enhanced by AI approaches.

The use of SVM is employed to evaluate the structural health of polymer composites in hybrid systems. Thus, the degree of damage in carbon FRP is identified through acoustic emission techniques [112]. This applicability demonstrates the predictive modeling of real-time maintenance monitoring for complex composite structures. The optimization process compares traditional methods with ML approaches to facilitate the understanding of the influence of compositional adjustments on mechanical properties [113]. ML-specific regression algorithms predict mechanical behaviors based on factors influencing the process. The paper [114] mentions that regression models are successfully applied to predict the mechanical properties of magnesium matrix composites. These models accelerate research processes regarding property optimization in the discovery and design of materials. The paper [115] discusses the variability of mechanical properties in composites. The study uses regression algorithms to analyze tensile and compressive data for design decisions.

Hybrid composites are studied using ANN alongside regression techniques to predict the mechanical properties of Al2219/B4C-Gr composites. The paper [116] analyzes wettability in aluminum matrix composites. This applicability exemplifies the multifunctional nature of regression in various types of composites. The optimization of the mechanical properties of composites through regression methods is studied in conjunction with other statistical methods to identify new insights into the mechanical characteristics of reinforced composites. Regarding the optimization of composites using natural fibers, regression models highlight the synergistic relationship between mechanical properties [117].

The regression algorithm is correlated with application requirements, and the paper [118] proposes a material design that is correlated with mechanical properties. The study defines the sequences of layering and fiber orientation to improve performance under mechanical loads. The integration of classification and regression algorithms represents a transformative factor for the mechanical properties of FRP composites. The diversity of studies highlights the importance of these interdisciplinary approaches in the optimization process of FRP composites. In this way, the importance of AI tools in materials science is emphasized.

5.1 Classification Domains in FRP Composite

Synthesizing the presented information, eight FRP domains that utilize ML classification are identified, as shown in Fig. 14. The purpose of defect detection in FRP materials is to determine the possibility of specific defects using environmental characteristics or material properties. Evaluating the quality of fiber-matrix adhesion aims to identify areas with weak bonds between the fiber and matrix, thereby preventing structural defects such as delamination. Analyzing environmental conditions and degradation aims to identify the long-term effects of external factors (such as humidity, extreme temperatures, and thermal cycles) on the integrity of FRP materials and anticipate potential defects.

Figure 14: Key Areas of ML classification in FRP analysis and optimization

Segmentation and characterization of microstructures aim to classify the distribution of fibers, voids, or other structural anomalies within the FRP material, thereby evaluating its performance. Real-time structural integrity monitoring aims to identify changes in the material’s condition through periodic visual data analysis and generate alerts in the event of critical defects.

Optimizing the design and manufacturing of FRP involves classifying the performance of different fiber and matrix configurations to maximize mechanical strength and material durability. Inspecting and assessing the structural integrity of infrastructure consists of classifying the condition of FRP-reinforced elements (e.g., bridges, buildings) to plan maintenance and repair activities. Simulating and predicting the behavior of FRP aims to classify the effects of various loading scenarios and environmental conditions on the structural performance of FRP materials, thereby supporting engineering decisions.

These domains summarize the previous discussions regarding the applications of ML classification in the context of FRP.

5.2 Regression Domains in FRP Composite

Synthesizing the presented information, eight key domains of FRP applications utilizing ML regression are identified, as illustrated in Fig. 15. Predicting mechanical properties aims to estimate characteristics such as tensile strength, elastic modulus, and delamination resistance based on material composition and environmental conditions.

Figure 15: Key Areas of ML regression in FRP analysis and optimization

Estimating durability under environmental conditions involves forecasting how factors such as humidity, temperature, and exposure to marine salts affect the long-term performance and lifespan of FRP materials. The optimization of fiber orientation for tensile strength involves predicting the ideal alignment of fibers within the matrix to maximize mechanical performance and ensure structural efficiency under various loading scenarios. Predicting structural performance under load evaluates how FRP components behave under axial, shear, or combined stresses, enabling engineers to design safer and more reliable structures. The evaluation of long-term degradation rates aims to assess how FRP materials deteriorate over time due to continuous exposure to environmental stressors, providing insights into maintenance schedules and lifecycle management. The thermal and hygrothermal effects simulation on FRP predicts how temperature fluctuations and moisture absorption impact the material’s integrity and performance, ensuring robustness in diverse operating environments. The prediction of bond strength between fiber and matrix focuses on estimating the adhesion quality between the reinforcing fibers and the polymer matrix, which is crucial for preventing defects such as delamination. Finally, assessing axial and shear load capacities aims to determine the maximum loads that FRP structures can withstand, ensuring compliance with safety standards and optimizing material usage.

These sections collectively underscore the role of ML in advancing FRP composite applications. Classification and regression domains provide a comprehensive framework for addressing discrete and continuous challenges in material performance and structural optimization.

6 AI in Predicting and Improving FRP Durability

FRP materials are essential in civil engineering due to their high strength-to-weight ratio [119]. These materials are preferred for their corrosion resistance and durability, justified by the extended lifespan of concrete structures in harsh environmental conditions [120]. The prediction of FRP durability is based on ML classification algorithms. Studies have shown that predicting the resistance related to the structural behavior of reinforced concrete systems can be achieved through ANN methods. In the paper [76], such a network evaluates the bond strength affected by hygrothermal and salt attack conditions. In this way, the implications of AI tools in addressing the durability issues of FRP composites are demonstrated. The shear behavior of concrete beams is studied using the ANN model in the paper [121]. This approach presents a method for integrating AI tools to predict the performance of FRP composites under environmental stressors [77]. ML techniques model the inherent nonlinear relationships in the bond strength between concrete and FRP [36]. Hybrid approaches that combine ANN with genetic algorithms (GAs) improve the accuracy of predictions regarding the overall structural capacities of FRP-reinforced concrete (FRP-RC) elements [122].

Although these advancements in AI tools are remarkable, numerous studies are attempting to integrate them for the analysis of moisture absorption and environmental degradation. The paper [123] examines non-destructive testing (NDT) methods for evaluating damage in FRP-reinforced concrete. Exposure to seawater can compromise the integrity of the material, necessitating an in-depth investigation of NDT techniques [124]. Prolonged exposure to environmental conditions that lead to material degradation (e.g., delamination) generates structural problems if the material is not properly monitored [125]. To capture this durability information, alkaline-activated materials and other composites were exposed to diverse marine conditions [126]. In this way, predictive models aim to enhance the durability of FRP [127]. The durability of fiber-reinforced polymer materials used in concrete structures is investigated using ML tools.

The prediction of bond strength and other durability-related characteristics is examined in the paper [76] using NN. An improvement of the RF model is reported in the paper [77] by enhancing the potential of hybrid methodologies that combine traditional models with AI techniques. Regression algorithms combined with GAs predict the bond strength of FRP-concrete interfaces [36]. These approaches leverage material performance through predictions; for example, the paper [121] studies the shear behavior of FRP-reinforced concrete beams. This approach enables durability improvements through structural evaluation predictions.

The paper examines the longevity of FRP materials under different environmental conditions [128]. Research has demonstrated the superiority of ANN over traditional regression methods in addressing the degradation of mechanical performance in FRP-reinforced concrete. In this context, AI tools enable the understanding of how environmental factors (e.g., humidity and temperature) impact durability [129]. Investigations into moisture-induced degradation correlate the prediction of the longevity of FRP-concrete interfaces with AI under various conditioning methods [130].

In structural engineering, the detection of defects and damage classification in FRP materials is studied using AI techniques. Traditional NDT methods are used for defect detection. At the same time, advanced techniques such as infrared tomography, ultrasonic testing, and ground-penetrating radar are employed to identify bond defects, voids, and delamination issues in FRP-reinforced concrete elements [131,132]. For example, infrared (IR) tomography is used to detect defects in carbon fiber polymer composites. IR thermography with heating pulses assesses the integrity of FRP systems by visually depicting temperature variations resulting from defects [133]. These techniques assess the quality of the bond and defects using AI tools. The research [132] analyzes the ultrasonic transmission coefficient for defect detection in FRP structures. Laser ultrasonic scanning automatically detects delamination, highlighting the capabilities of NDT methodologies in structural health monitoring [134]. Deep Modular Networks algorithms improve prediction accuracy by analyzing segments of historical data from FRP-reinforced structures [135,136]. These algorithms address structural behavior through the impact of installation defects in FRP applications [137]. Examples of such defects include improper bonding or air bubbles.

ML models predict shear strength and axial capacities with superior accuracy compared to traditional methods [36]. These methodologies correlate identified defects with stress concentrations and failure risks [121]. The ability of ML algorithms to continuously learn from new data enables the refinement of predictions, thereby stimulating the continuous evolution of FRP applications [135].

The failure mechanisms vary depending on the nature of the FRP material, the type of load, and the environmental conditions to which it is subjected. The rupture of concrete beams due to exposure to high temperatures causes the rupture of FRP bars. The study of these characteristics is summarized in the thermal degradation examined in the paper [138]. The Mode I cracking toughness of adhesives used in FRP applications is studied in the paper [139]. This addresses the interaction between the adhesive and the substrate (concrete) in determining the failure mode in composite structures. The fragility of FRP under thermal stress or adhesive failure falls under the purview of ML tools.

Fiber delamination is a problem specific to different types of composites. In most cases, this arises from energy dissipation characteristics. Delamination occurs due to the mismatch between material phases, resulting in cracks that propagate in the direction of least resistance [140]. The works [141,142] have identified matrix cracking and fiber fractures by studying FRP design modalities. The acoustic emission technique is a non-destructive method for monitoring these situations, enabling timely maintenance interventions and rehabilitation [143].

Sudden shear cracks appear in bending zones [144]. This issue highlights the complexity of load distribution in FRP composites. Their interaction with concrete elements complicates ML predictions [145]. Identifying weak bonds at the interface improves the durability of FRP systems [3].

Researchers have identified that failure in FRP composites manifests as a combination of fiber fracture, resin cracking, and interfacial delamination under environmental factors [146]. This discovery necessitates predictive analyses for evaluating structural integrity.

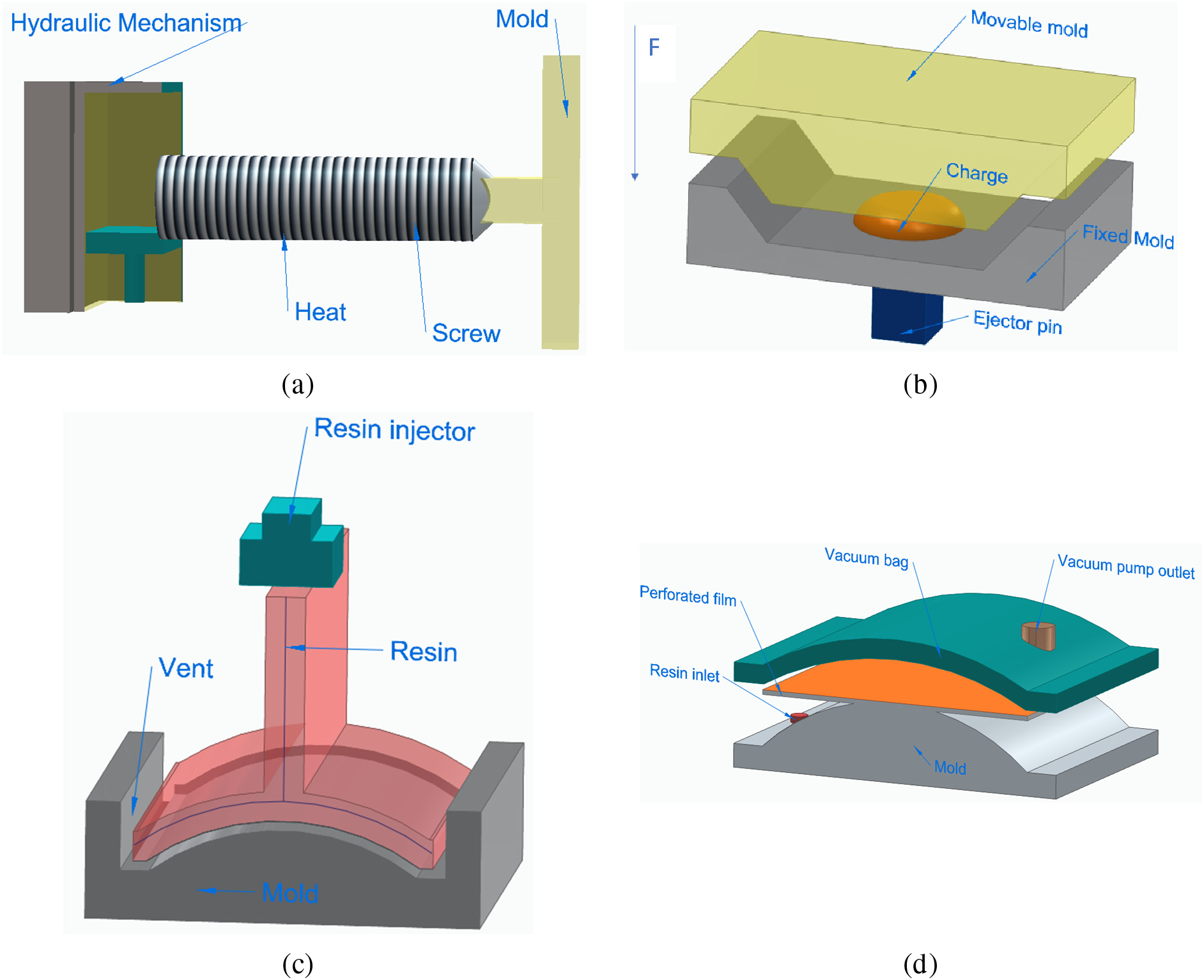

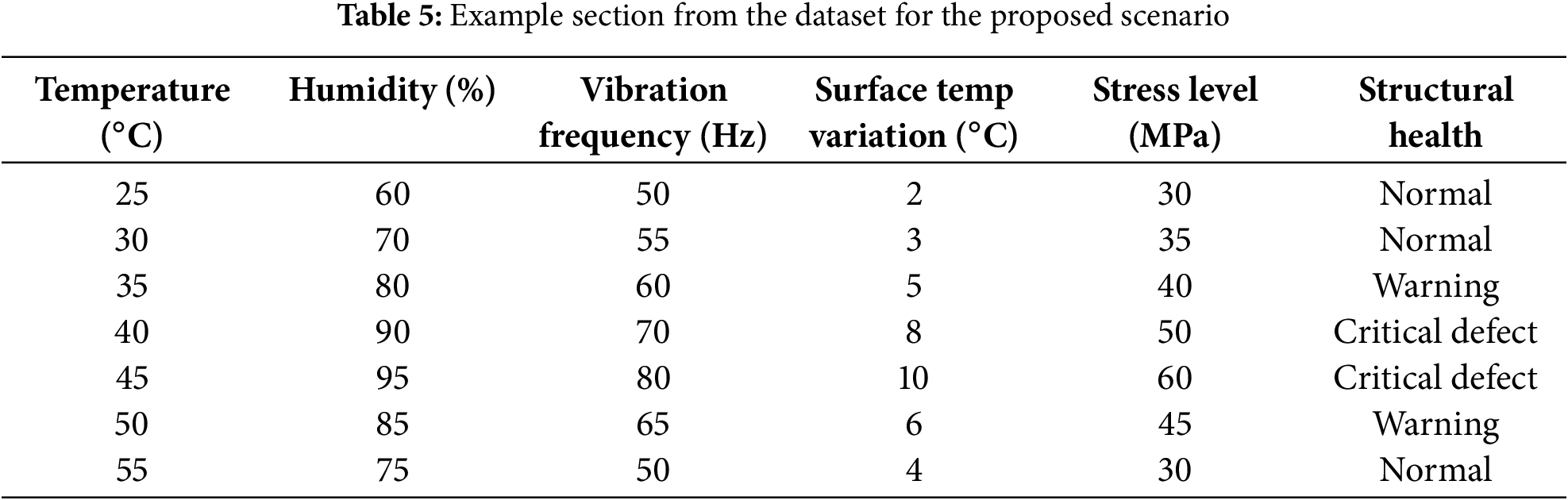

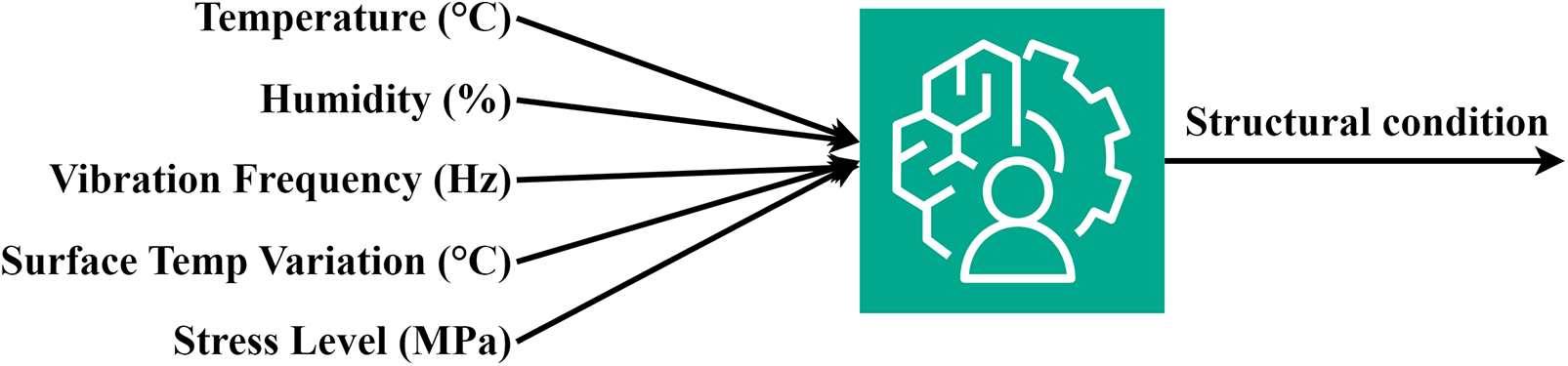

The following will illustrate the use of ML algorithms in the durability of FRP elements. Monitoring the structural health of FRP elements using ML algorithms requires a dataset that contains data collected from sensors embedded within the FRP structure. For exemplification, the scenario of a bridge reinforced with FRP materials is considered. It is equipped with real-time sensors that monitor environmental conditions and structural integrity. The objective is to integrate AI tools to detect structural conditions (such as delamination, cracks, or voids) and generate alerts when anomalies are identified. Table 5 proposes an example of a dataset constructed with synthetic data, where the features are presented in Fig. 16 and explained as follows:

Figure 16: AI model input features for structural health assessment in FRP elements

• Temperature (°C) is the ambient temperature measured in the structure’s area;

• Humidity (%) represents the humidity level in the surrounding environment;

• Vibration frequency (Hz) is the frequency of structural vibrations, which may indicate mechanical stress or deterioration;

• Surface temp variation (°C) is the variation of surface temperature (measured through IR thermography), which can highlight areas with defects (e.g., delamination);

• Stress level (MPa) represents the mechanical stress level applied to the structure.

The output labels represent the state of the structure:

• Normal: The structure is in good condition, with no signs of deterioration;

• Warning: There are indications of deterioration (e.g., increased vibrations or significant surface temperature variations);

• Critical defect: A critical defect is detected, requiring immediate intervention.

The data is used to train a classification ML model (e.g., RF, ANN, or SVM) to classify the structural state based on input features. Subsequently, the values can be integrated into FEA simulations to validate the effect of environmental conditions and other factors on the structure. Additionally, the model can be integrated into an IoT system to analyze real-time data and generate alerts.

In the following, a concrete monitoring scenario will be presented. The sensors installed on the FRP-reinforced bridge collect the following data:

• Temperature = 40°C

• Humidity = 90%

• Vibration Frequency = 70 Hz

• Surface Temperature Variation = 8°C

• Stress Level = 50 MPa

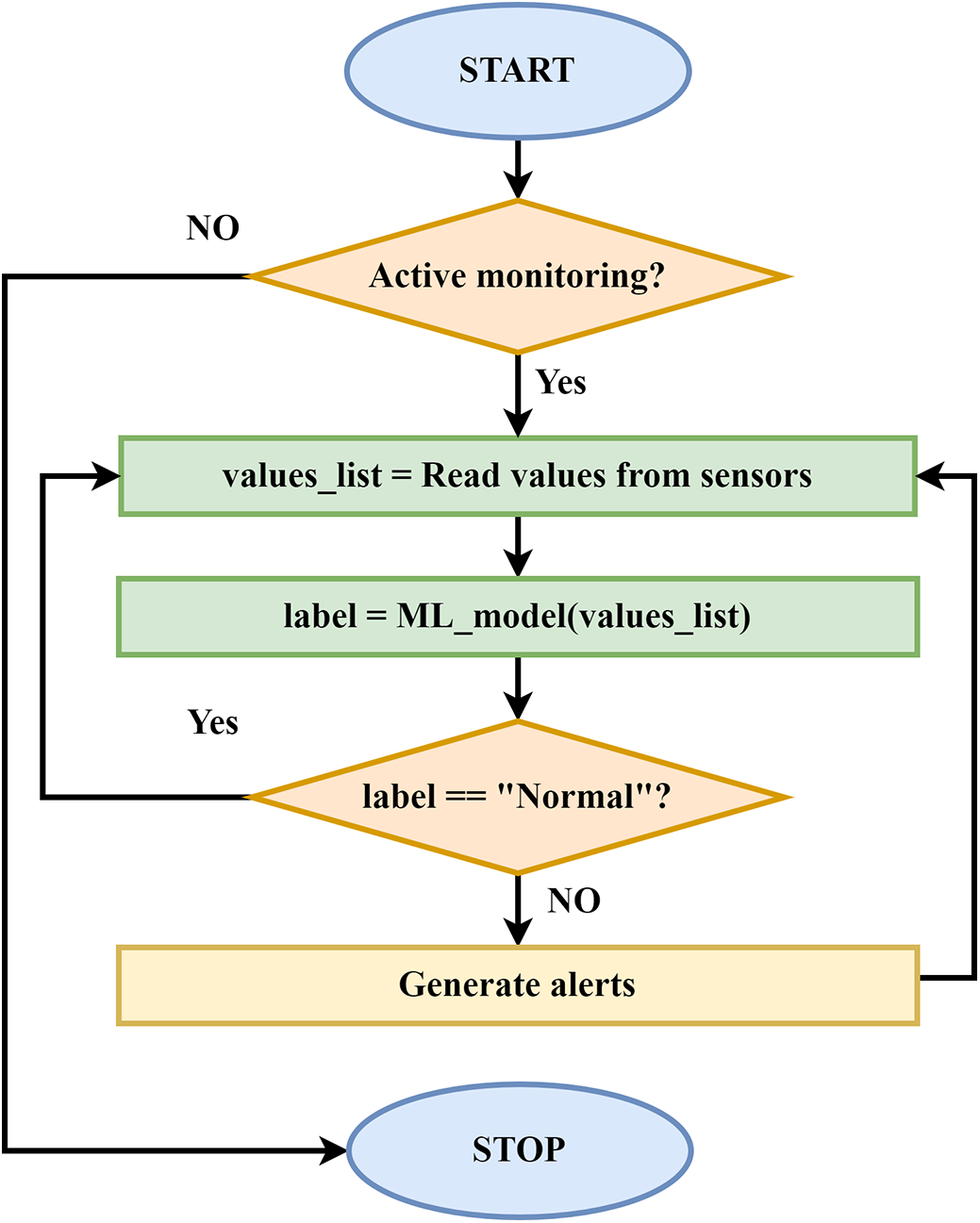

The AI model analyzes this data and classifies the structural state as a Critical Defect, triggering an alert for inspection and intervention. Fig. 17 illustrates the schematic flow of the proposed AI-driven structural health monitoring system designed for FRP elements. It outlines a step-by-step process that integrates real-time data collection, ML analysis, and alert generation to ensure the safety of FRP structures.

Figure 17: Schematic flow of AI-driven structural health monitoring for FRP elements

The process begins with the initiation of the monitoring system. The system reads real-time data from embedded sensors, collecting values such as temperature, humidity, vibration frequency, surface temperature variation, and stress level. The collected sensor data is fed into a pre-trained ML model. The model processes this data and assigns a label indicating the current state of the structure. If the label is “Normal”, the process changes to the active monitoring check. The system generates alerts if the label is not “Normal” (indicating a warning or critical defect). When anomalies or defects are detected, the system generates alerts to notify maintenance personnel of inspection and intervention.

7 AI in Predicting and Improving FRP Mechanical Properties

The integration of AI and ML in the field of composite materials has gained significant attention in recent years. These advanced computational techniques have been applied to predict, optimize, and analyze the mechanical properties of composites, reducing the need for extensive experimental testing. AI models, including NNs, regression algorithms, and DL approaches, have been used to evaluate parameters such as tensile strength, fatigue life, fracture toughness, and stress-strain behavior. Furthermore, AI-driven methodologies enable the rapid assessment of new composite formulations, facilitating the design of high-performance materials with tailored mechanical properties.

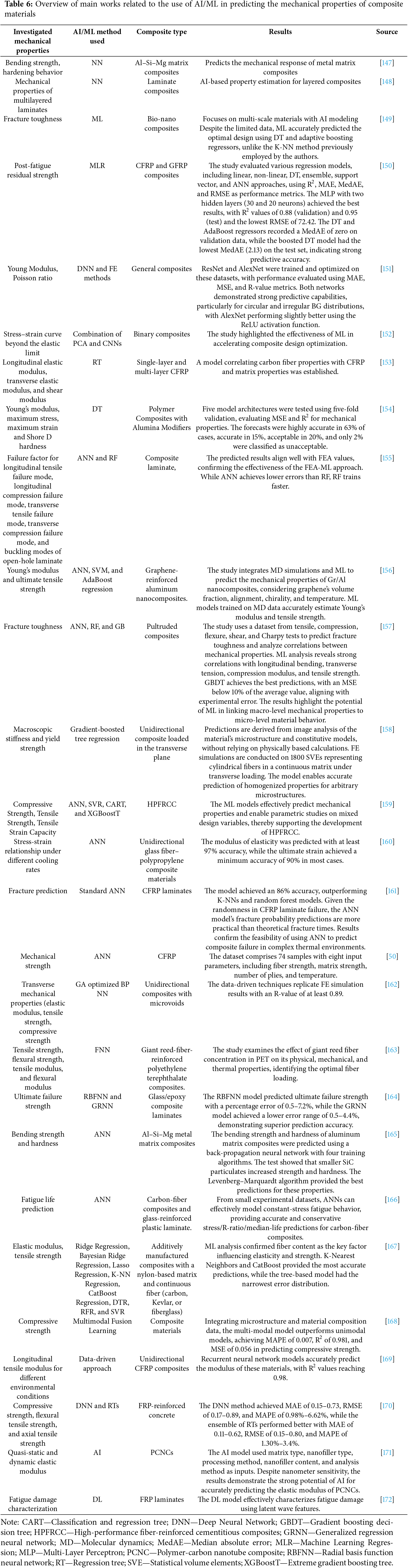

Table 6 provides an overview of key studies that investigate the mechanical properties of various composite materials using AI and ML techniques.

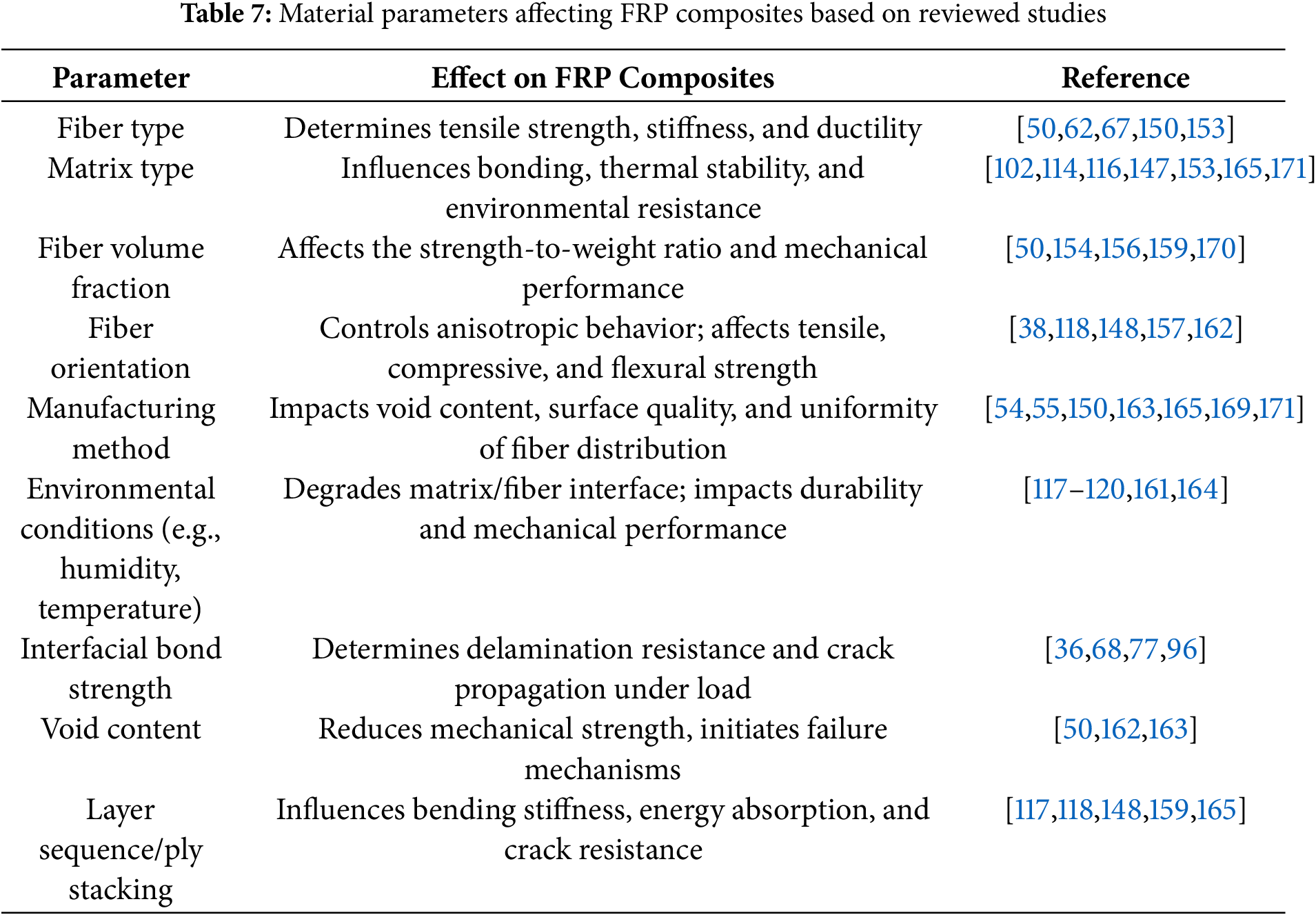

To provide a clearer understanding of the factors influencing the behavior and performance of fiber-reinforced polymer (FRP) composites, Table 7 presents the most frequently studied material parameters in recent literature. These include fiber type, matrix composition, fiber orientation, environmental conditions, and interfacial bond strength. Each parameter plays a significant role in shaping the mechanical properties, durability, and overall structural performance of FRP composites.

8 Bibliometric Analysis Regarding the Implementation of AI Tools to Predict Durability and Mechanical Properties of FRP

To analyze the research landscape on AI-driven predictions for the durability and mechanical properties of FRP composites, bibliometric analysis methods were employed using the WOS database and VOSviewer software.

The WOS database was selected as the primary data source due to its extensive collection of high-impact scientific publications across multiple disciplines. Relevant studies were identified using specific AI-related keywords, such as FRP composites, durability assessment, and mechanical property prediction. The extracted data included publication trends, citation records, author contributions, and research collaboration networks.

VOSviewer, a powerful bibliometric visualization tool, was used to analyze and map the relationships between key terms, research clusters, and influential authors.

To extract relevant studies, the following Boolean search query was applied: (“FRP” OR “composite materials”) AND (“durability” OR “mechanical properties”) AND “machine learning”.

This query was designed to ensure a comprehensive dataset, capturing studies focused on AI, particularly machine learning, in predicting FRP durability and mechanical performance. The search included research on both FRP and broader composite materials, specifically filtering for publications discussing mechanical properties, durability, and machine learning-based modeling techniques.

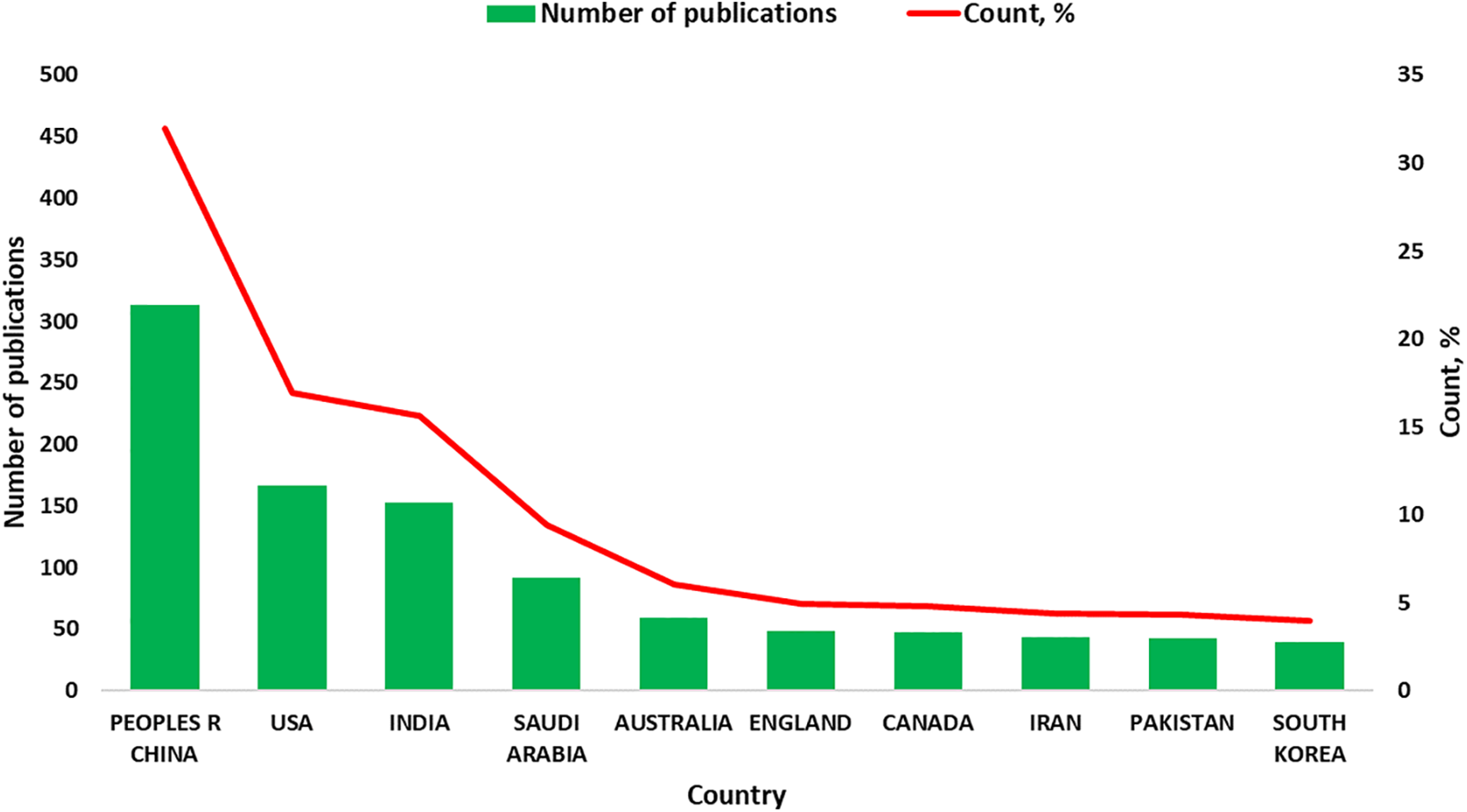

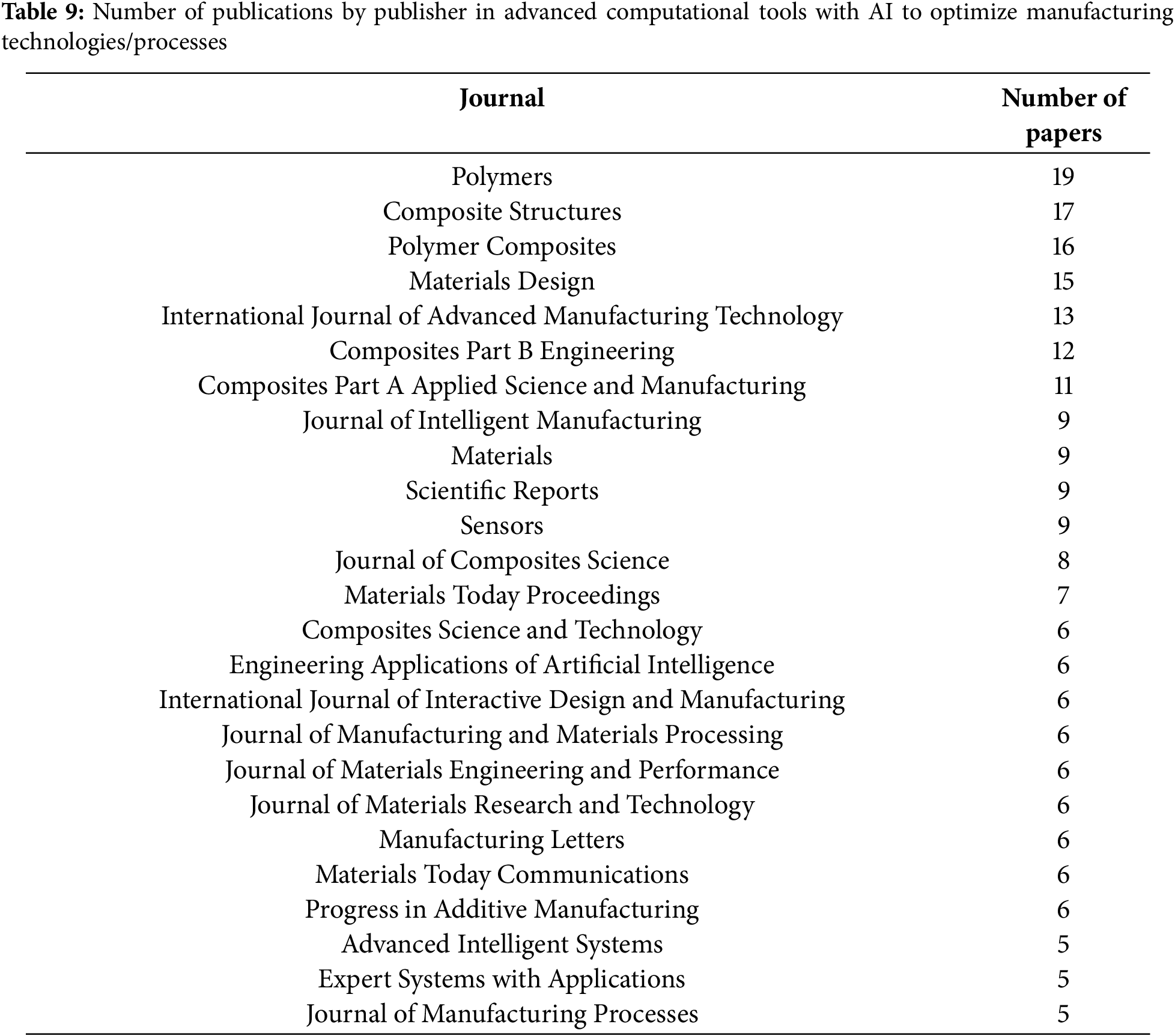

Applying this query within the WOS database yielded 974 relevant studies, all published in English (from 2015 to 2024). These results reflect the growing research interest in using AI methodologies, particularly machine learning, to evaluate and predict the durability and mechanical behavior of FRP composites.