Open Access

Open Access

ARTICLE

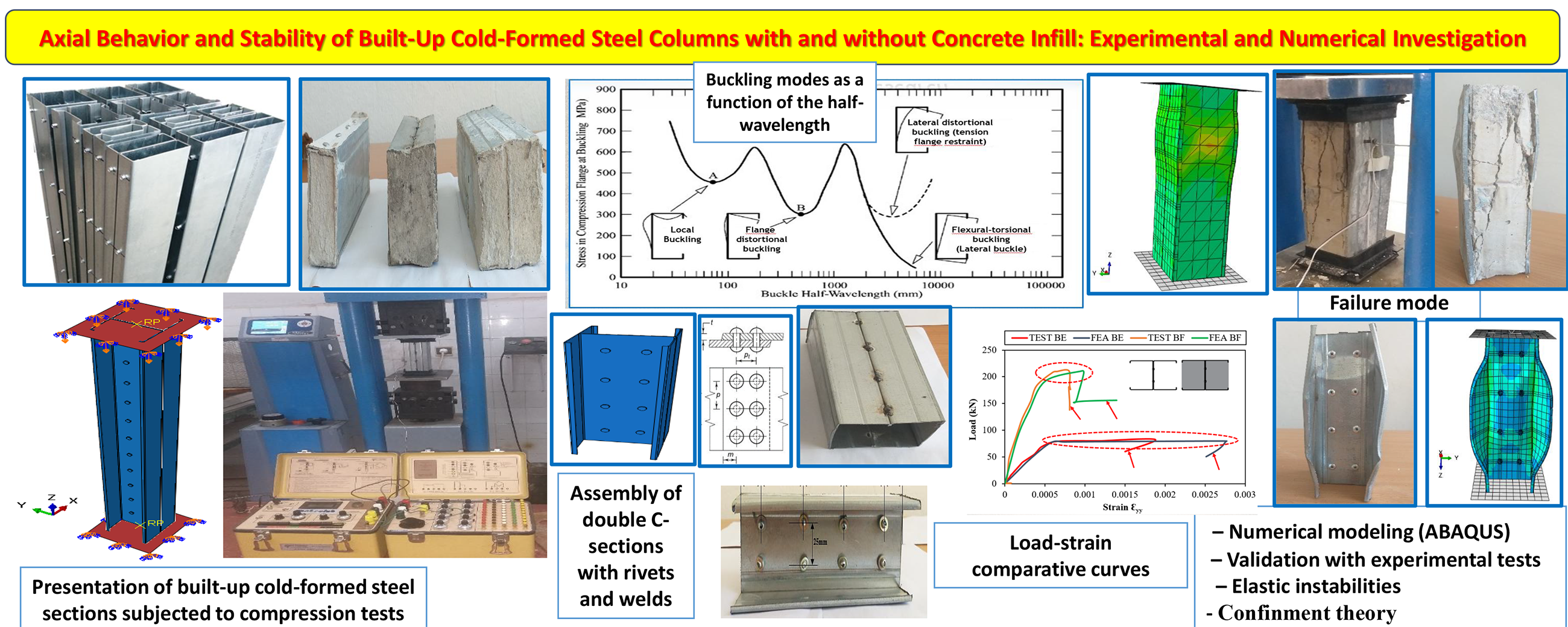

Axial Behavior and Stability of Built-Up Cold-Formed Steel Columns with and without Concrete Infill: Experimental and Numerical Investigation

1 Civil Engineering Laboratory (LGC), Faculty of Technology, Department of Civil Engineering, Badji Mokhtar-Annaba University, P.O. Box 12, Annaba, 23000, Algeria

2 Materials Geomaterials and Environment Laboratory (LMGE), Faculty of Technology, Department of Civil Engineering, Badji Mokhtar-Annaba University, P.O. Box 12, Annaba, 23000, Algeria

3 Department of Civil Engineering, Faculty of Engineering and Technology, Jamia Millia Islamia (Central University), New Delhi, 110025, India

4 Faculty of Sciences and Technology, Department of Civil Engineering, Chadli Bendjedid-El Tarf University, P.O. Box 73, El Tarf, 36000, Algeria

5 Civil Engineering Department, Istanbul Gelisim University, Avcilar, 34310, Turkey

6 Research Institute of Clean Growth and Future Mobility, Coventry University, Priory Street, Coventry, CV1 5FB, UK

* Corresponding Authors: Mohammed Benzerara. Email: ; S. M. Anas. Email:

(This article belongs to the Special Issue: Frontiers in Computational Modeling and Simulation of Concrete)

Computer Modeling in Engineering & Sciences 2025, 145(1), 457-481. https://doi.org/10.32604/cmes.2025.071600

Received 08 August 2025; Accepted 23 September 2025; Issue published 30 October 2025

Abstract

In recent years, cold-formed steel (CFS) built-up sections have gained a lot of attention in construction. This is mainly because of their structural efficiency and the design advantages they offer. They provide better load-bearing strength and show greater resistance to elastic instability. This study looks at both experimental and numerical analysis of built-up CFS columns. The columns were formed by joining two C-sections in different ways: back-to-back, face-to-face, and box arrangements. Each type was tested with different slenderness ratios. For the experiments, the back-to-back and box sections were connected using two rows of rivets. The face-to-face sections, on the other hand, were joined by welding. In order to improve axial strength and overall stability, all column samples were filled with ordinary concrete, conforming to class C25/30. The numerical modeling was done in ABAQUS to study the mechanical behavior of the columns. This helped in understanding how different joining methods affect their axial compression performance. Analytical checks were also carried out using Eurocode 3 for hollow sections and Eurocode 4 for concrete-filled sections. The role of concrete confinement was examined as well, following American Concrete Institute (ACI) guidelines, for both face-to-face and box-shaped columns. The numerical results matched closely with the experimental findings, with variations of less than 5%. The study identified key failure modes such as local buckling and distortional buckling. It highlighted how section shape, type of connection, and concrete infill all play a major role in improving the strength of built-up CFS columns.Graphic Abstract

Keywords

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools