Open Access

Open Access

ARTICLE

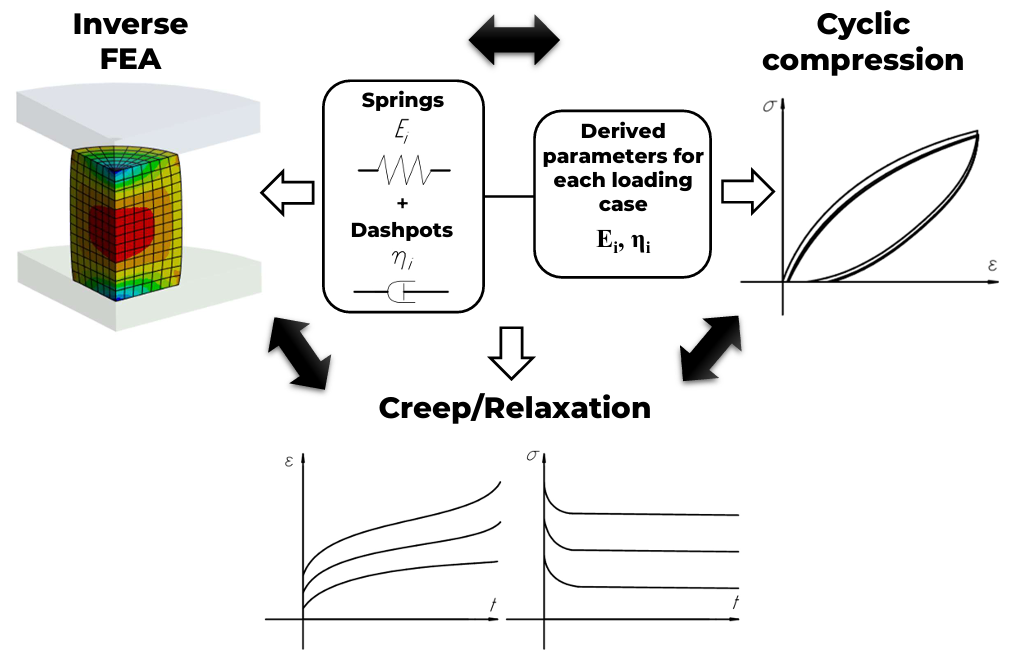

A Hybrid Experimental-Numerical Framework for Identifying Viscoelastic Parameters of 3D-Printed Polyurethane Samples: Cyclic Tests, Creep/Relaxation and Inverse Finite Element Analysis

1 National Research Centre “Kurchatov Institute”, Moscow, 123182, Russia

2 Moscow Center for Advanced Studies, Moscow, 101000, Russia

3 Applied Mechanics Department, Bauman Moscow State Technical University, Moscow, 105005, Russia

* Corresponding Author: Arthur Krupnin. Email:

(This article belongs to the Special Issue: Perspective Materials for Science and Industrial: Modeling and Simulation)

Computers, Materials & Continua 2026, 86(3), 18 https://doi.org/10.32604/cmc.2025.073161

Received 11 September 2025; Accepted 04 November 2025; Issue published 12 January 2026

Abstract

This study presents and verifies a hybrid methodology for reliable determination of parameters in structural rheological models (Zener, Burgers, and Maxwell) describing the viscoelastic behavior of polyurethane specimens manufactured using extrusion-based 3D printing. Through comprehensive testing, including cyclic compression at strain rates ranging from 0.12 to 120 mm/min (0%–15% strain) and creep/relaxation experiments (10%–30% strain), the lumped parameters were independently determined using both analytical and numerical solutions of the models’ differential equations, followed by cross-verification in additional experiments. Numerical solutions for creep and relaxation problems were obtained using finite element analysis, with the three-parameter Mooney-Rivlin model and Prony series employed to simulate elastic and viscous stress components, respectively. Energy dissipation per cycle was quantified during cyclic compression tests. The results demonstrate that all three models adequately describe material behavior within the 0%–15% strain range across various strain rates. Comparative analysis revealed the Burgers model’s superior performance in characterizing creep and stress relaxation at low strain levels. While Zener and Burgers model parameters from uniaxial compression showed limited applicability for energy dissipation calculations, the generalized Maxwell model effectively captured viscoelastic properties across different strain rates. Notably, parameters derived from creep tests provided a more universal assessment of dissipative properties due to optimization based on characteristic curve regions. Both parameter sets described polyurethane’s elastic-hysteretic behavior with approximately 20% error, proving significantly more accurate than the linear strain-time dependence hypothesis. Finite element analysis (FEA) complemented numerical modeling by demonstrating that while the generalized Maxwell model effectively describes initial rapid stress-strain changes, FEA provides superior characterization of steady-state processes. This computational approach yields more physically representative results compared to simplified analytical solutions, despite certain limitations in transient analysis.Graphic Abstract

Keywords

Supplementary Material

Supplementary Material FileCite This Article

Copyright © 2026 The Author(s). Published by Tech Science Press.

Copyright © 2026 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools