Open Access

Open Access

ARTICLE

Enhancing Evaporative Cooler Efficiency through Magnetized Water and Heat Exchanger Optimization

1 Department of Mechanical Engineering, Faculty of Engineering, Kufa University, Najaf, 54002, Iraq

2 Refrigeration & Air-Conditioning Technical Engineering Department, College of Technical Engineering, The Islamic University, Najaf, 54002, Iraq

3 Najaf Technical Institute, Al-Furat Al-Awsat Technical University, Najaf, 31100, Iraq

4 Najaf Technical College, Al-Furat Al-Awsat Technical University, Najaf, 31100, Iraq

5 Centre for Sustainable Cooling, School of Chemical Engineering, University of Birmingham, Edgbaston, Birmingham, B15 2TT, UK

6 College of Engineering, University of Warith Al-Anbiyaa, Karbala, 56001, Iraq

* Corresponding Author: Hameed B. Mahood. Email:

(This article belongs to the Special Issue: Solar and Thermal Energy Systems)

Energy Engineering 2025, 122(4), 1359-1372. https://doi.org/10.32604/ee.2025.060613

Received 06 November 2024; Accepted 16 January 2025; Issue published 31 March 2025

Abstract

This research presents a new method to boost the efficiency of evaporative coolers by integrating magnetized water and a heat exchanger. Magnetized water, known for its high evaporation rate and reduced surface tension, offers a promising way to enhance air cooler performance. Additionally, the advanced heat exchanger both improves air cooling capacity and controls humidity levels. Aloni 100 L, a locally manufactured evaporative cooling system, and tap water were used in experiments. Tap water was magnetized using recycled magnets extracted from computer hard drives. Twenty-six magnets meticulously arranged within rectangular grooves, each with a minimum strength of 0.5 to 1 T, were used to magnetize tap water. Our experiments show a significant rise in cooling efficiency, with magnetized water increasing from 70.62% to 91.43%. In a similar vein, adding the heat exchanger leads to a significant improvement, raising the cooling efficiency from 69.44% to 93.96%. Furthermore, the combined use of magnetized water and a heat exchanger results in exceptional performance, increasing cooling efficiencies by 29.5% and 35.3% compared to using only magnetized water or only a heat exchanger, respectively. This study also explores the largely untapped potential of magnetized water, providing valuable insights into its effects on water properties and its broader applications in various fields. These findings represent a significant advancement in air cooling technology and pave the way for more energy-efficient and sustainable solutions.Keywords

In the 21st century, tropical nations have seen a significant rise in air conditioning usage, bringing much-needed relief to billions of people and acting as a key driver for human prosperity. appliances currently account for nearly 20% of global electricity use by buildings, and this proportion is expected to grow substantially by 2050. The building sector represents 30% of global final energy consumption and causes 26% of global energy sector carbon dioxide (CO2) emissions. As global temperatures rise and socio-demographic changes continue, residential air conditioning (AC) usage is projected to increase significantly, potentially doubling global residential cooling electricity consumption to between 1590 and 2377 terawatt-hours per year by mid-century. This surge in electricity use is estimated to result in additional 590 to 1365 million tons of carbon dioxide equivalent (MtCO2e) emissions annually, which will have a direct impact on climate change [1].

The Earth’s magnetic field has been a constant element of the environment throughout the evolution of life. Nowadays, artificial magnetic fields can be found in electronic devices, power grids, and electric vehicles. Water becomes magnetized (MW) when it flows through a magnetic field. This process changes many properties of the water, such as surface tension, electrical conductivity, pH, and viscosity [2]. This technology can help mitigate the impacts of climate change on plant productivity and address soil and water contamination [3,4]. Comparing regular water to magnetized water shows significant differences in surface tension and evaporation rates, favouring magnetized water. Hence, air cooling systems can be enhanced by utilizing magnetized water [4].

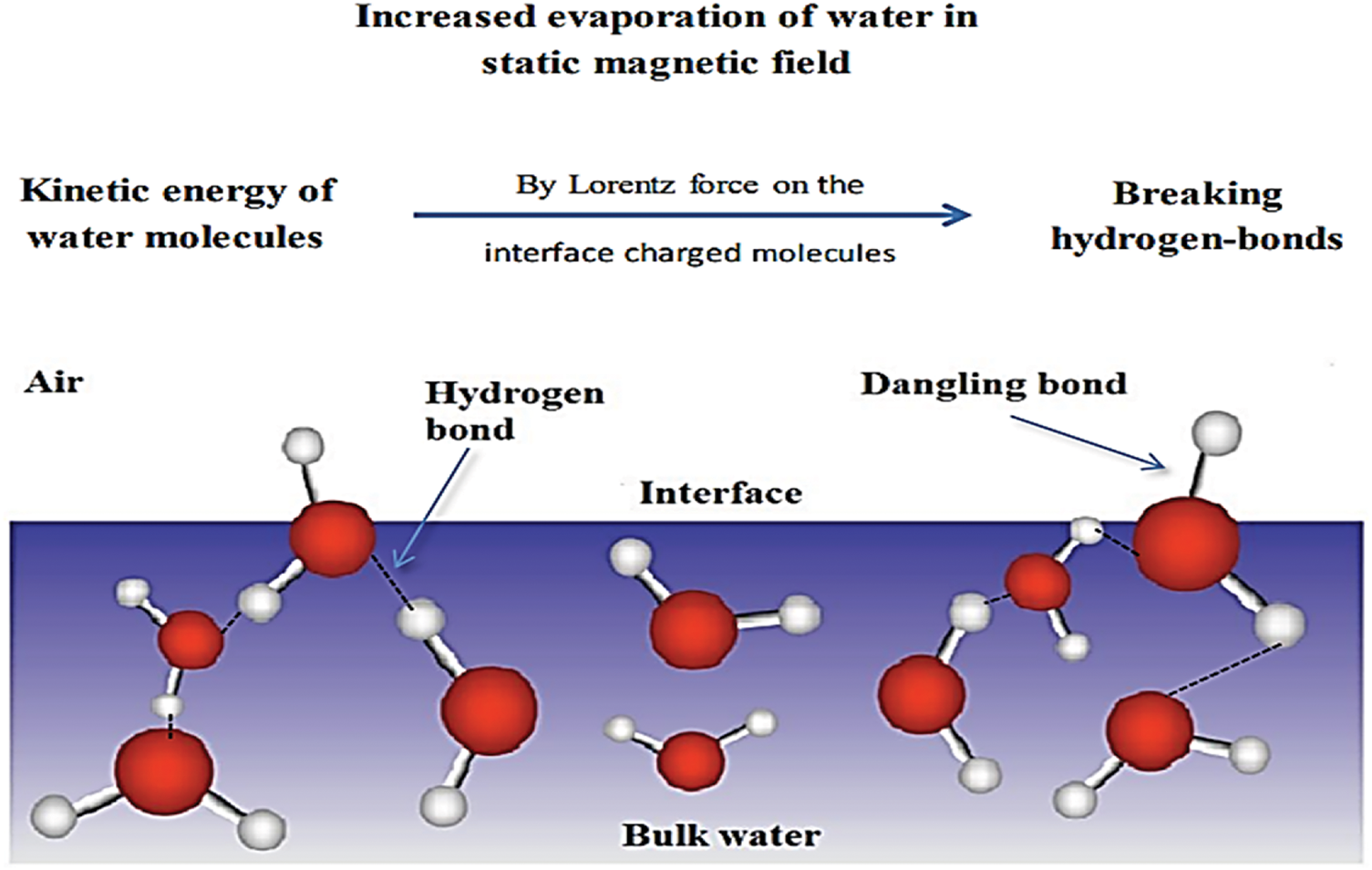

Experiments have shown that magnetized water has a faster evaporation rate compared to regular water [5]. This phenomenon occurs due to the influence of the magnetic field on the hydrogen bonds in the water, which makes them weaker and thus accelerates the evaporation process [6]. These effects are defined and analyzed in terms of the kinetic energy of water molecules and the Lorentz force acting on these moving charged molecules at the interface, which weakens or breaks hydrogen bonds [7]. Fig. 1 shows hydrogen bonding in the water-air interface structure.

Figure 1: Structure of the water-air interface showing hydrogen bonds with dangling bonds in the air above the interface. Large and small spheres represent oxygen and hydrogen atoms, respectively [7]

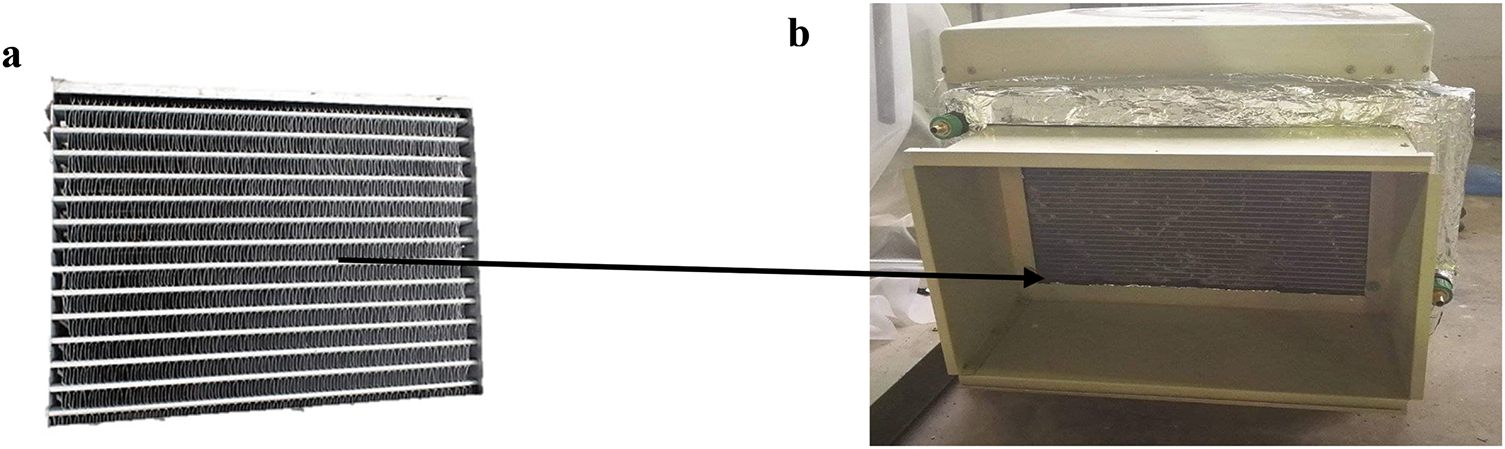

Magnetized water (MW) and magnetic nanofluids (MNFs) are distinct but related concepts. Magnetized water (MW) can be obtained by subjecting the water to a magnetic field, causing changes in its hydrogen bonding structure and, consequently, in its physicochemical properties [8]. Conversely, magnetic nanofluids (MNFs) are composed of magnetic nanoparticles dispersed in a base fluid, enabling adjustable heat transfer and flow properties by varying particle size, concentration, and type [9]. MNFs excel in heat transfer applications, especially in automotive and industrial cooling systems where magnetically driven thermal performance improvements are key [10]. Furthermore, MNFs have demonstrated high thermal conductivity enhancements under certain conditions, including the presence of external magnetic fields that align nanoparticles and promote more efficient heat dissipation [11]. Ultimately, the main distinction between MW and MNFs lies in their magnetic mechanisms: MW depends on structural changes of water molecules, whereas MNFs rely on the magnetic response of suspended nanoparticles. This difference is critical when selecting which fluid to use for specific applications, whether in environmental, biomedical, or engineering scenarios. Key distinctions between magnetic nanofluids and magnetized water are shown in Table 1.

Many researchers investigated the relationship between magnetic fields and water, and the reported results showed substantial enhancements in water’s physical and chemical properties when exposed to magnetic effects [12,13]. For instance, Mghaiouini et al. conducted a thorough analysis of its optical characteristics and their changes. These changes in optical properties are attributed to the changes in hydrogen bonds and the reformation of water clusters at the molecular level caused by the magnetic field [14]. Another study was conducted by Sronsri et al., where they investigated the effect of magnetic fields on water under static and dynamic magnetization processes. They detected changes in the distribution of electrons, polarization, and dipole moment of magnetized water. Moreover, they observed appreciable differences in the heat capacity and an increase in the solubility of salts. The duration of exposure to magnetic flux and its intensity are the main factors affecting water properties [15]. Youkai et al., along with other studies, investigated the effects of magnetic fields on tap water, reporting an increase in the evaporation rate, a reduction in specific heat, and a lower boiling point [5,16,17]. On the other hand, Ammar et al. found that exposing water to a high-intensity magnetic field for a short time reduces the possibility of calcium carbonate formation with monoethylene glycol within capillary coils [17]. In dry and semi-dry regions, evaporative cooling systems have been proven effective, with high efficiency and low cost. However, their performance is limited by low water evaporation rates and challenges in controlling humidity [18].

This work proposes combining magnetized water with a heat exchanger in an evaporative cooling system. Although the aforementioned studies suggested different methods, to the best of our knowledge, utilizing both magnetized water and a heat exchanger together has not been studied before. This work includes a further parametric investigation to enhance the performance of the evaporative cooling system. The results of this study offer potential benefits in many applications, including improving air-cooling efficiency and saving energy

2.1 Evaporative Cooler and Heat Exchanger

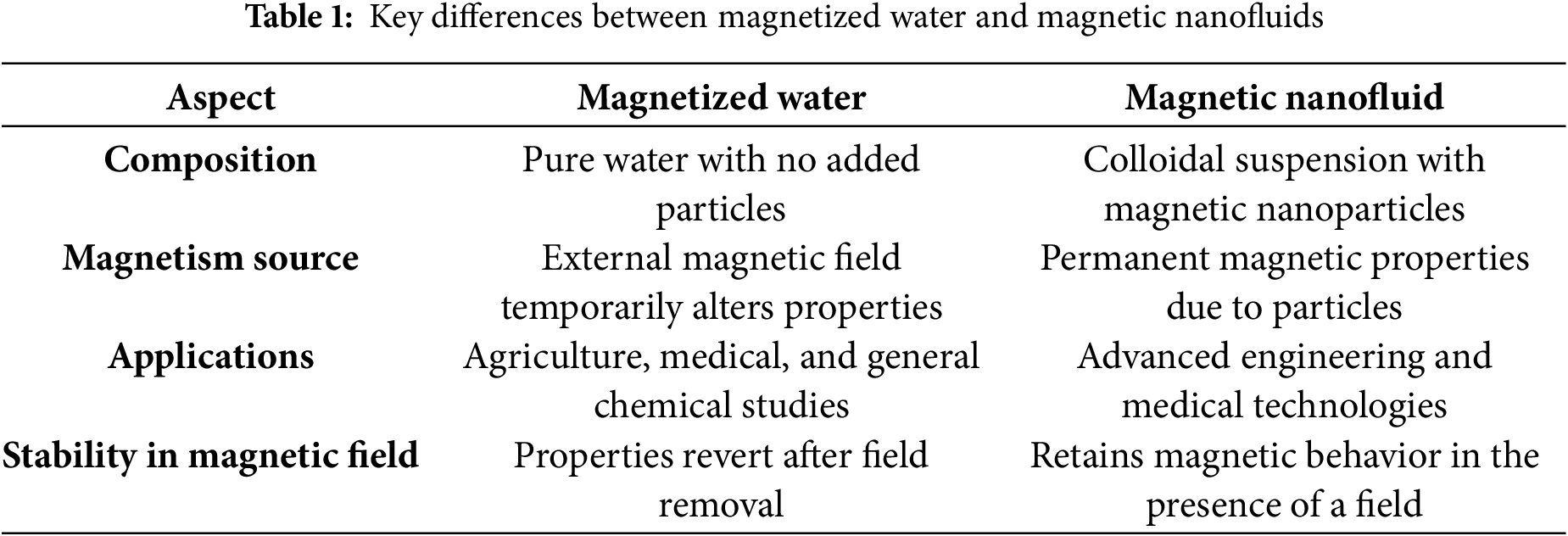

Aloni 100 L is a locally manufactured evaporative cooling system that implements the concept of reducing the air temperature through water evaporation using thermal energy [19]. The required energy is available by nature, making the energy system efficient. Fig. 2 illustrates the equipment.

Figure 2: Visualisation of the “Aloni 100 L” Locally-manufactured evaporative cooling system. (a) Detailed overview of the cooler. (b) Basic structure and principal components [19]

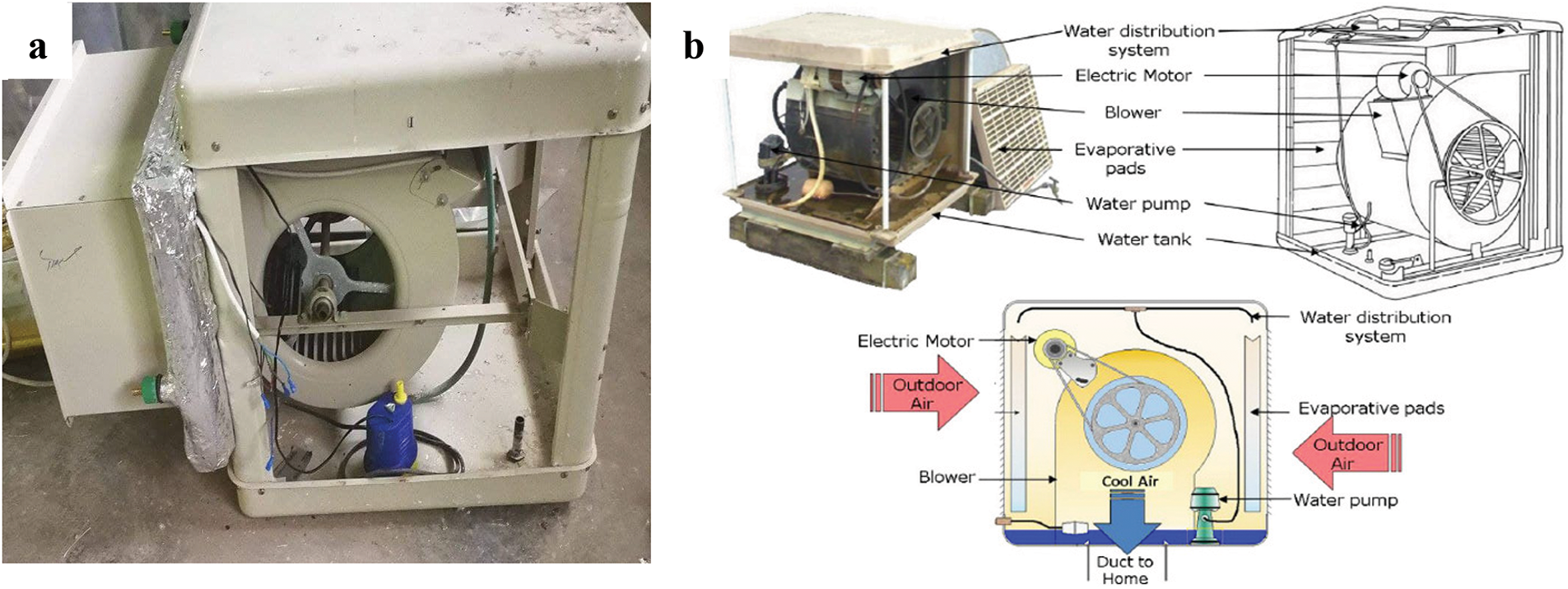

Fig. 3 delineates an “LT type” aluminium plate-fin heat exchanger, a product of Japanese engineering. This exchanger is characterised by its square shape, which has dimensions of 0.5 by 0.5 m. Aluminum, known for its superior thermal conductivity, corrosion resistance, and optimal strength-to-weight ratio, is the primary material utilized in constructing this exchanger. Functionally, it is an essential device for thermal management systems, enabling efficient thermal energy transfer between two fluids. The “LT type” designation refers to its specialized design and material properties. Its strategic placement at the outlet duct of an evaporative cooler suggests a design intention to maximize thermal exchange efficiency and assist in humidity control within the system [20,21].

Figure 3: Evaporative cooling system heat exchanger setup (a) “LT type” aluminum plate fin heat exchanger (b) Heat exchanger positioned directly in front of the evaporative cooler outlet duct

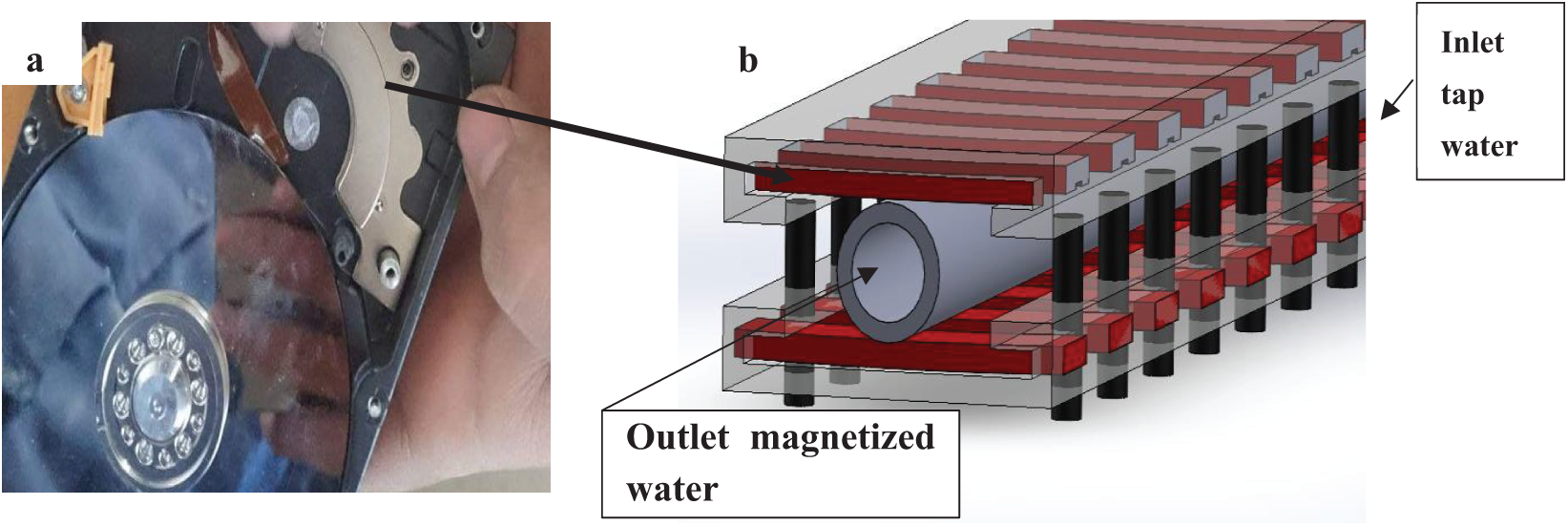

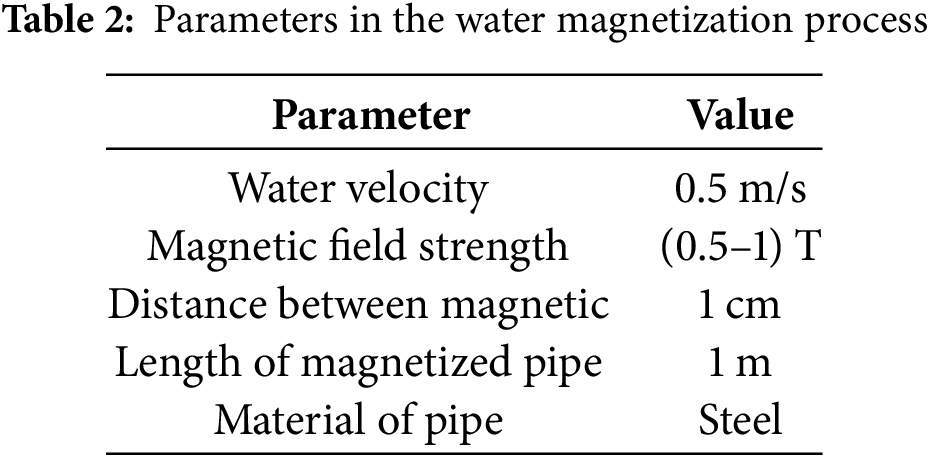

This study employed tap water sourced from the local water supply. Magnetization of tap water was achieved using recycled magnets extracted from computer hard drives, as illustrated in Fig. 4a. The alterations induced by the magnetic field (MF) are contingent on the magnetizing conditions. Two pivotal factors, magnetic field strength (MFS) and water velocity, were taken into account (see Table 2). A magnetizing apparatus was designed to produce magnetized water (MW), comprising 26 magnets, each with a minimum strength of (0.5–1) T. These magnets were meticulously arranged within rectangular grooves, as depicted in Fig. 4b.

Figure 4: Magnetized water system configuration (a) Computer hard drive magnets for water magnetization. (b) Detailed arrangement of 26 magnets (0.5–1) T each within rectangular channels

A 200 mm air duct is equated with an anemometer (PRODIT model 6772, Italy) with a range of (1.5 to 34.5) m/s and an accuracy of ±1.0% of reading ±1 digit. The pressure drop across the duct was measured using a micro-manometer and correlated with fan power measurements. This correlation was based on Eq. (1), which represents the air fan power (Fpower) in a system where both air velocity and pressure are measured [15,22]:

where:

• is the volumetric flow rate, representing the volume of air passing through a section of the duct per unit time.

• FTP is the thrust power, which is the power associated with the force exerted by the moving air.

• ρa is the air density, which is the mass of air per unit volume.

• uA is the velocity of air times the cross-sectional area of the duct through which the air is flowing.

The airflow within the circuit was adjusted by manipulating the AC power through a variac transformer connected to the axial fan. The corresponding fan power was easily read directly from the watt meter.

2.4 Temperature and Relative Humidity Measurement

The experiment utilized LAE ELECTRONIC-HT2W (Italy) relative humidity (RH) sensors, known for their rapid and reliable measurements across the full range of 0%–100% relative humidity. These sensors integrate a LAE Hygrometry AC-1 thin-film capacitive humidity sensor, ensuring precise detection of atmospheric moisture content. The sensors operate with an accuracy of ±5% RH, ensuring reliable data for various environmental conditions. Their robust design and 4-wire configuration enhance measurement stability and reduce signal interference. The sensors were powered using a 12 V DC, 0.2 W power supply, ensuring consistent operation throughout the experimental runs [23].

In this experiment, the RH sensors produce an output signal in milliamps (mA), which is incompatible with the humidity meter, as it requires a voltage signal. To address this, a high-accuracy LAE ELECTRONIC-LT12 humidity and temperature meter (Italy) was employed. This device effectively converted the milliampere output of the RH sensors into a voltage signal compatible with the recording system. The LT12 device also measures temperature with an accuracy of ±0.2°C across a range of −40°C to +60°C, ensuring reliable monitoring of environmental and system temperatures [24].

Integrating these high-precision instruments was critical for ensuring accurate and reproducible measurements in the experiment. These sensors and meters enhanced the collected data’s overall reliability and ensured compatibility with the experimental setup, facilitating seamless data acquisition for both humidity and temperature parameters.

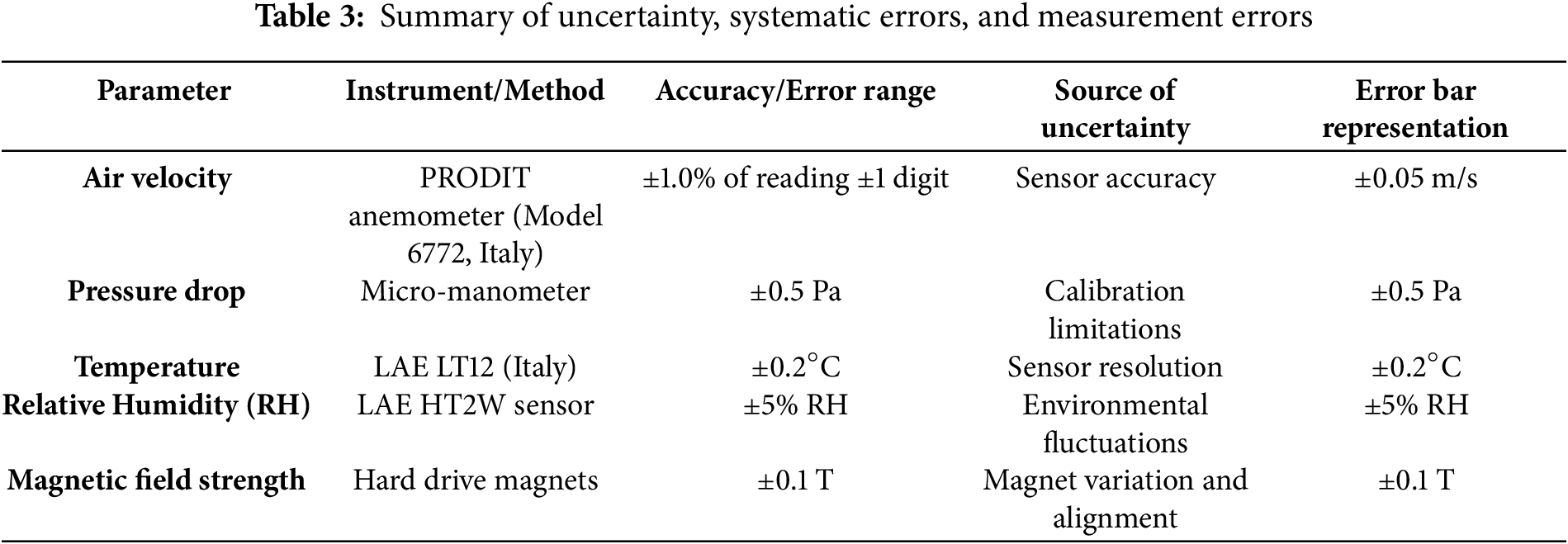

2.5 Uncertainty and Error Analysis

To address concerns regarding the reliability of the results, the experiment was repeated five times under identical conditions to ensure consistency and reproducibility [25]. Each run involved measuring air velocity, temperature, and relative humidity at key points in the system. Standard deviation and error bars for the obtained data were calculated to quantify experimental uncertainties [26]. The primary sources of error include systematic errors, measurement errors, and random variations. Table 3 presents a breakdown of these sources.

The standard deviation () and standard error of the mean (SEM) were calculated for the repeated measurements to determine the error bars [27,28]:

where (equal to 5) is the number of repeated trials and is the standard deviation. The results are presented with error bars for key parameters (temperature, RH, and air velocity) to account for uncertainties.

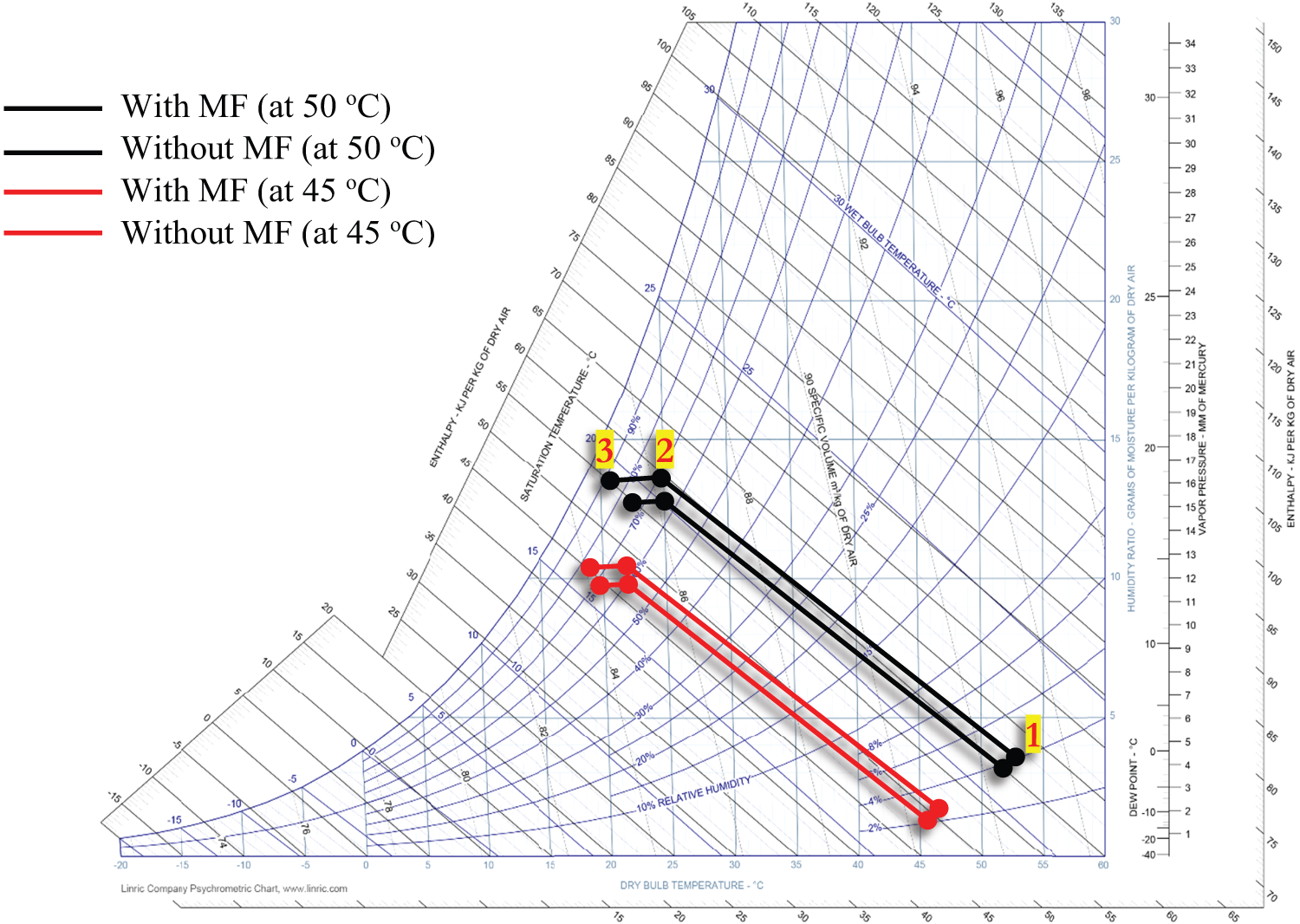

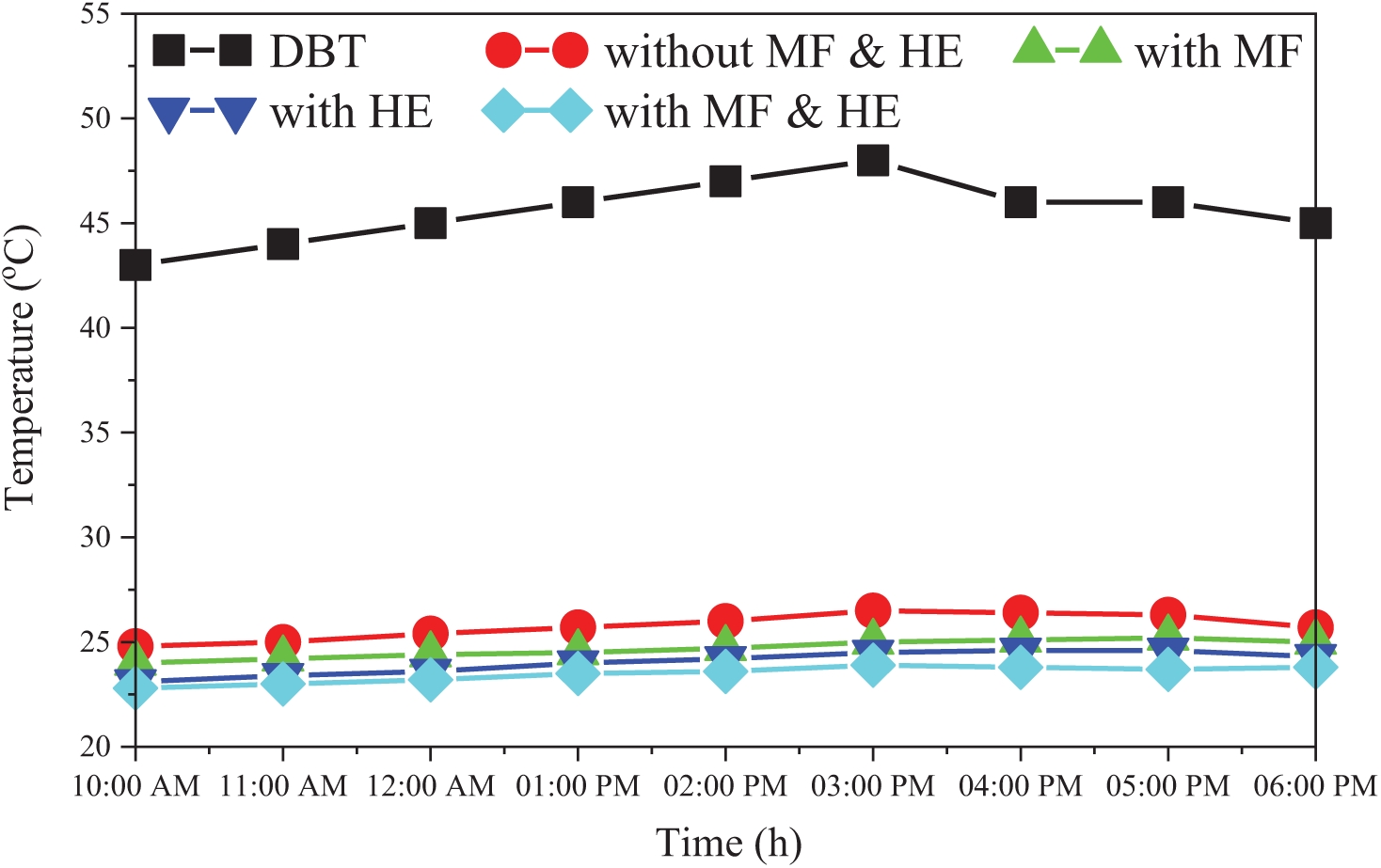

Many characteristics, such as relative humidity RH, air velocity, and dry bulb temperature DBT, need to be investigated in the course of studying the thermal performance of evaporative cooling using magnetized water. To investigate the performance of residential air coolers, the performed experimental tests were comparable in four distinct modelled situations (conventional, equipped with magnetized water, with heat exchanger evaporative cooling systems, and a combination of magnetized water and heat exchanger). To model real environmental conditions, a wide range of dry-bulb temperatures (DBT) and relative humidity (RH) levels were selected; however, only a few representative values are shown on the psychrometric chart, with RH set to 10%. The DBTs were chosen around 45°C and 50°C, reflecting Iraq’s summer weather, where temperatures start at 45°C and can reach up to 55°C. Fig. 5 illustrates the energy differences in the evaporative cooling system (ECS) under conditions with a magnetic field applied to the water and using a heat exchanger. The solid line represents the cooling process with magnetically treated water, showing a reduction in the air’s thermal energy as DBT decreases. Additionally, a noticeable increase in air moisture content was observed as the air passed through the cooling pads.

Figure 5: Energy differences in ECS in cases provided with both MF and HE

As air moves over the pads in the ECS, they act as a humidifier. On the other hand, the lower DBT led to a precooling process for the air to pass over the witted pads. Such was presented by the inclined line (1–2), which is an adiabatic process. The air departs the pads colder and more humid. As depicted by inclined lines (2–3), due to the air moving across the heat exchanger, it undergoes latent and sensible heat transfer processes, represented as cooling and dehumidification processes.

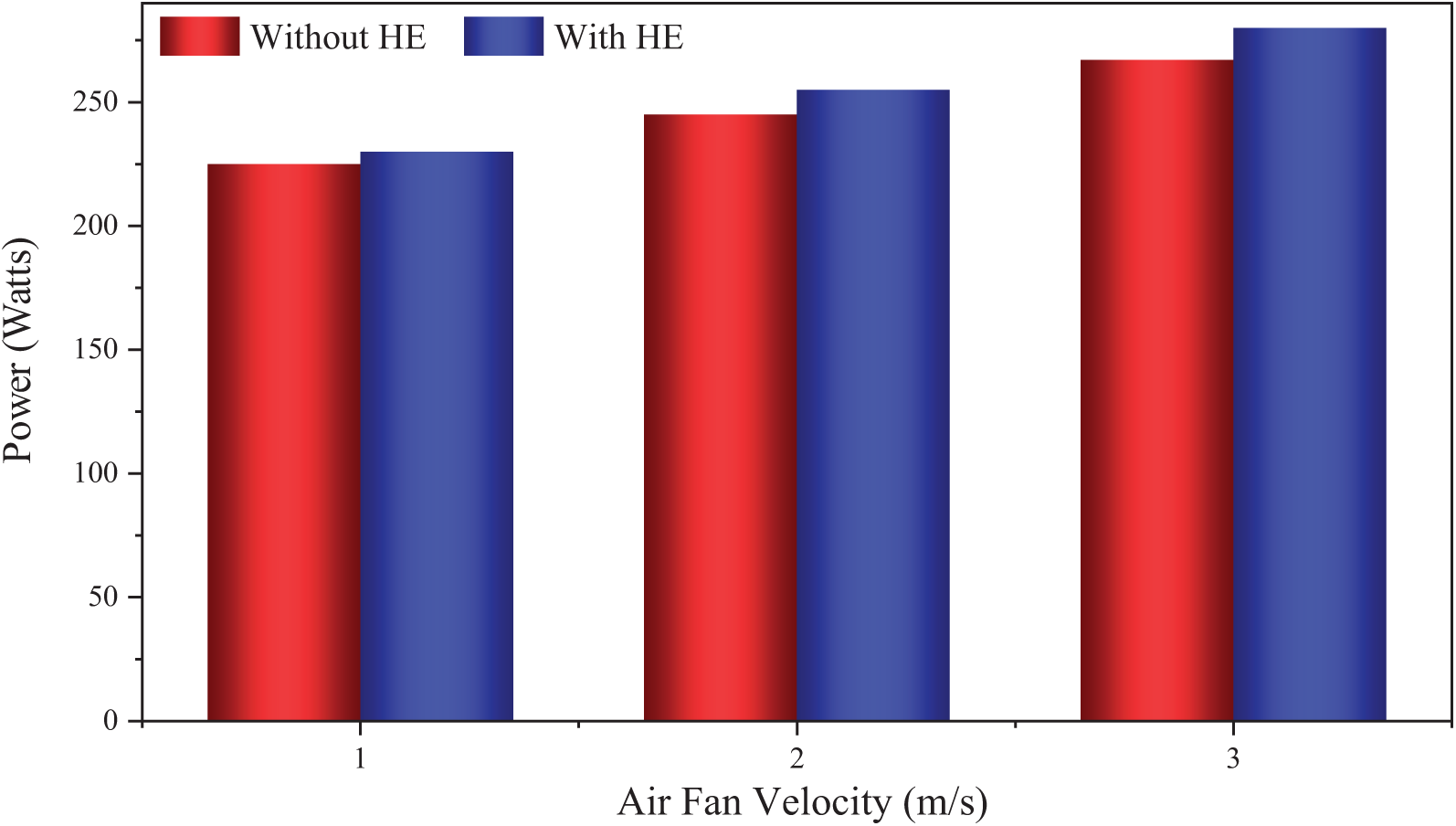

According to scientific evidence, the quantity of heat transmission is proportionally related to air velocity. As a result, it was seen that with the low, medium, and high velocities of air (i.e., 1, 2, 3 m/s), air velocity substantially impacts the ECS’s effectiveness and energy savings. Also, one can observe the decrease in pressure drops at a low velocity of air, which leads to an increase in the efficiency of the evaporative cooling process. This is attributed to the use of the formula (1/2V2)) [13], which is represented mathematically in Fig. 6. So, the velocity of air (1 m/s) led to the highest efficiency of the system. Also, the pressure dropping makes the fan use more energy.

Figure 6: Variation of power consumed with air fan velocity

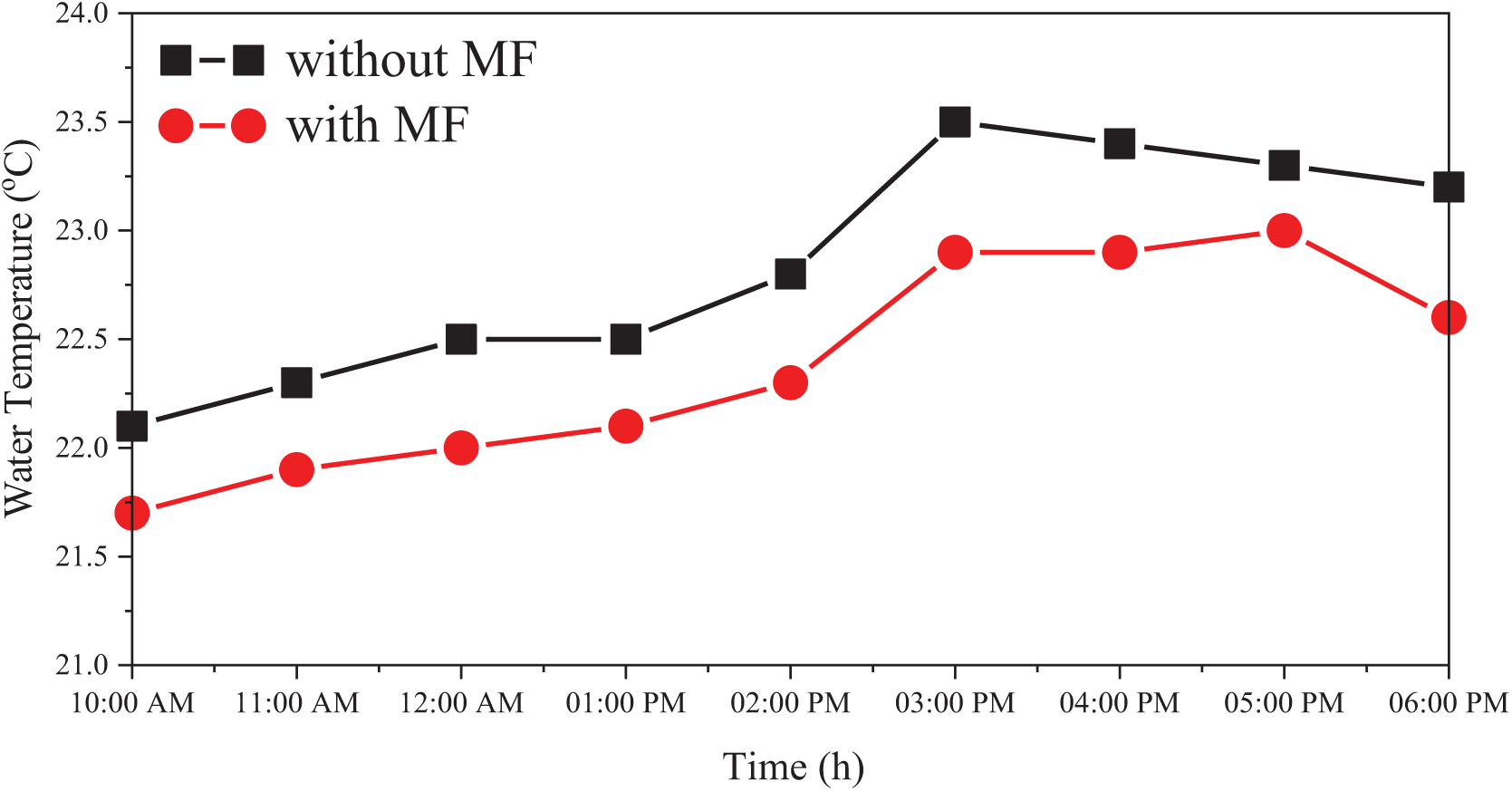

Fig. 7 compares the cooling system and water temperature degrees when using magnetized and regular water during July 2023. When the evaporative cooler operates, the water in the basin drops after a period of operation. For example, in July, the measured temperature of the water in the coolant basin was 35°C. After an hour of operation, the temperature dropped to 22.2°C due to the evaporation process during air passage for the conventional air cooler.

Figure 7: Variation of water temperature during the time of experiment with and without MF

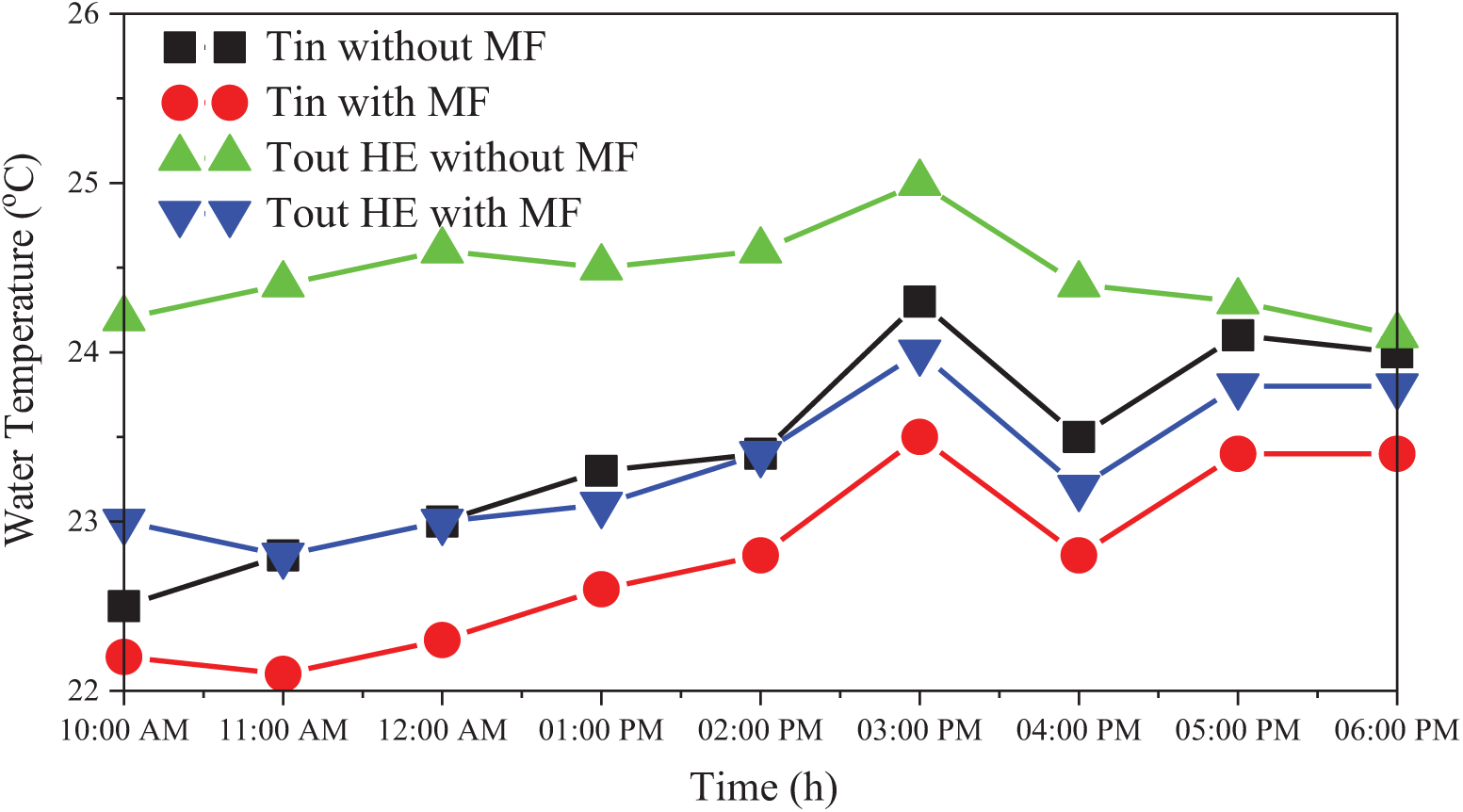

However, when using the magnetized water, the water basin temperature dropped to 21.6°C after an hour of operation. Also, when using the magnetized water during the full operation, the temperature of the water was reduced more than before compared to the previous situation, which is because magnetized water reduced the surface tension of water, then the rate of evaporation increased, which in turn led to lowering the basin water temperature. As the operation continues, basin water temperature naturally drops further due to the presence of evaporation due to air passing and magnetic energy. Moreover, Fig. 8 illustrates that the heat exchanger’s inlet and outlet water temperature was reduced when the magnetized water was used specifically in dry weather (Rh = 10%). For instance, the magnetized and non-magnetized inlet water temperatures of the heat exchanger were 22.5°C and 24°C, respectively, and the magnetized and non-magnetized outlet water temperatures of the heat exchanger were 22°C and 23.6°C, respectively.

Figure 8: Variation of water temperature during the experiment for different cases

Also, the evaporative cooler outlet air temperature using the heat exchanger and the magnetized water decreased compared to the previous air temperature throughout July. The reason behind that is the evaporative cooler inlet air temperature is higher than the basin water temperature with the existence of the heat exchanger. Thus, the air temperature is lower from 43°C to 24.8°C in July. While using the magnetized water only, the air temperature is lower from 43°C to 23.3°C in July. As a result, by adding the two features (the magnetized water and the heat exchanger) to the evaporative cooler, the air temperature is lowered from 43°C to 22.8°C. As described in Fig. 9.

Figure 9: Variation of water temperature during the time of the experiment

In other words, the heat exchanger’s existence leads to a decrease in the basin water temperature and the inlet and outlet air and water temperatures of the heat exchange. Similarly, the use of magnetized water reduces the air and water temperatures of the evaporative cooler parts.

In addition, the experimental results represent the effect of adding a heat exchanger and magnetized water to the evaporative cooler on the relative humidity of the outlet air of the evaporative cooler through July. The outlet air of the evaporative cooler had a high relative humidity percentage of around 50%–60% when using normal and magnetized water, without using the heat exchanger, while the circumstance relative humidity percentage was 30%–40%. After integrating the heat exchange, the relative humidity of the outlet air of the evaporative cooler was minimized to approximately 40%–45% when using magnetized and non-magnetized water, respectively. It can be noticed that the heat exchange played a vital role in decreasing the relative humidity due to the relative condensation that was created on the heat exchange and helped to remove a small part of the humidity. Also, the results described that using the magnetized water and the heat exchanger in the evaporative cooler was very efficient for controlling the humidity of the air to be an adequate percentage, especially for South Iraq cities that have highly humid weather, especially during summer.

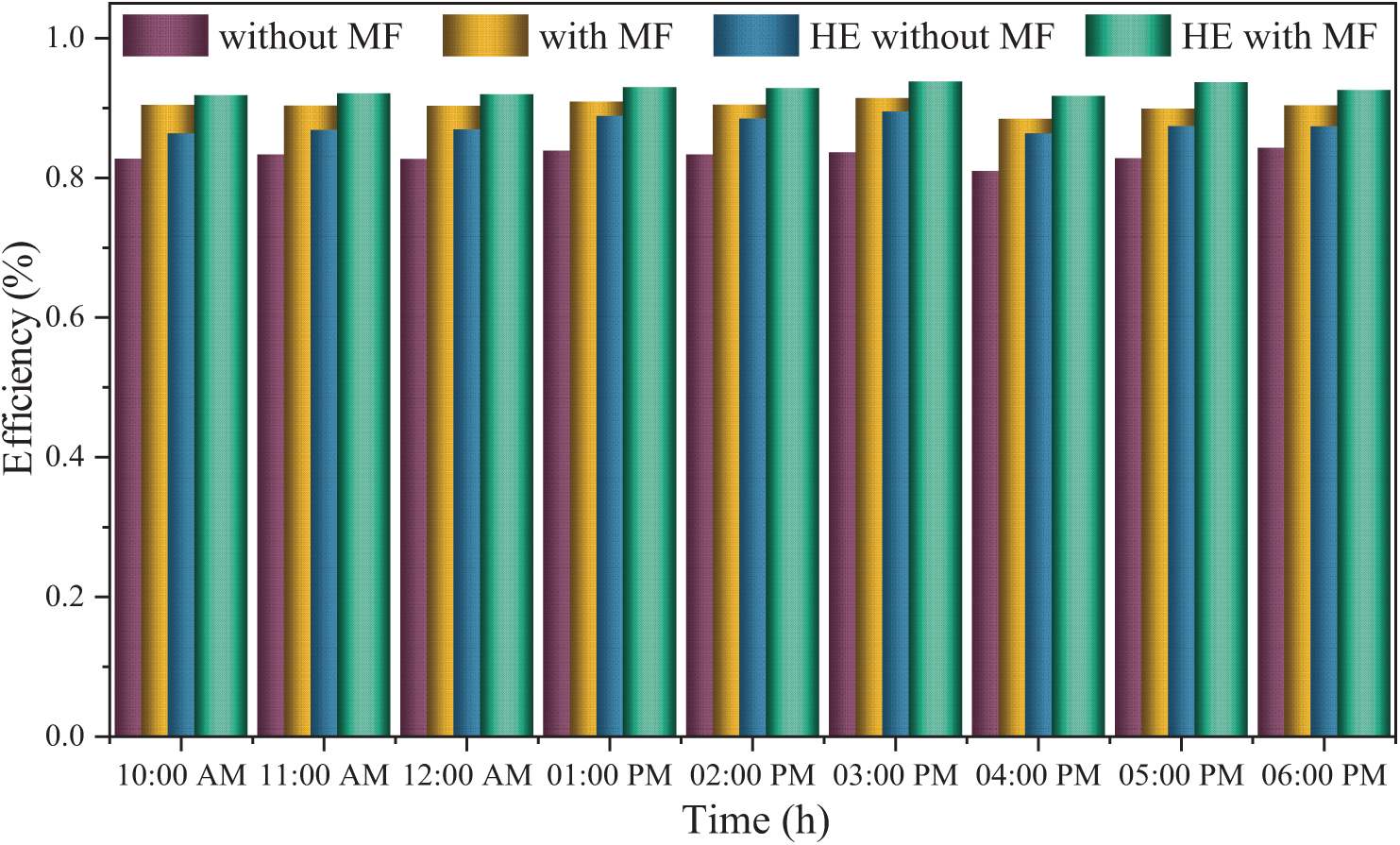

Fig. 10 illustrates the cooling efficiency of the evaporative cooler when utilizing both a heat exchanger and magnetized water. The heat exchanger increased the average cooling efficiency from 69.44% to 93.96% during July. This improvement is attributed to the enhanced heat transfer capabilities of the exchanger, which facilitates better temperature regulation and improves the system’s overall cooling performance. Similarly, the use of magnetized water enhanced the average cooling efficiency from 70.62% to 91.43%. Magnetized water has been shown to promote more rapid evaporation, which results in faster cooling by reducing the heat absorbed by the water, thereby improving the system’s efficiency.

Figure 10: Efficiencies during the time of experiment for all four cases

Furthermore, a slight increment in cooling efficiency was observed when both the heat exchanger and magnetized water were used together, reaching 91.44% and 93.97%, respectively. This synergistic effect is due to the combined impact of both methods in reducing the outlet air temperature of the evaporative cooler. As a result, there is a higher temperature difference between the ambient weather temperature and the cooler’s outlet air temperature, which directly contributes to the increased cooling efficiency. Combining these two methods optimizes the heat exchange process and enhances the overall performance of the evaporative cooling system.

The influence of using magnetized water and fined heat exchanger on the thermal performance of evaporative air cooler were investigated in this manuscript. Four case studies were carried out during the experiments (i.e., conventional air cooler, with MF, with HE, and with both MF and HE air cooler). It was concluded the following:

1. Applying the magnetic field reduced the surface tension of water, and the rate of evaporation increased, which in turn led to a lower basin water temperature.

2. Using magnetized water reduces the air and water temperatures of the evaporative cooler parts.

3. The heat exchange played a vital role in decreasing the relative humidity due to the relative condensation that was created on the heat exchange, which helped to remove a small part of the humidity.

4. The use of a heat exchanger decreases the basin water temperature and the inlet and outlet air and water temperatures of the heat exchange.

5. Using both the magnetized water and the heat exchanger in the evaporative cooler was very efficient for controlling the air humidity to an adequate percentage, especially for highly humid weather regions.

6. The heat exchanger increased the average cooling efficiency during July from 69.44% to 93.96%, while the magnetized water enhanced the average cooling efficiency from 70.62% to 91.43%.

7. Utilizing the heat exchangesr and magnetized water together in the evaporative cooler led to higher efficiencies, reaching 91.44% and 93.97%, due to the reduction in the outlet air temperature of the evaporative cooler.

Acknowledgement: None.

Funding Statement: No funds have been used to develop this manuscript.

Author Contributions: Mohammed J. Alshukri: Conceptualization, methodology data curation and investigation; Amjed Al-Khateeb: Resources, data curation, and writing the first draft; Ahmed Mohsin ALsayah: Writing draft, resources, and project administration; Adel A. Eidan: writing—review and editing, and supervision; Hameed B. Mahood: Resources, writing—review and editing. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The data will be available on request.

Ethics Approval: I am writing to confirm that the manuscript titled “Enhancing Evaporative Cooler Efficiency through Magnetized Water and Heat Exchanger Optimization”, submitted for consideration in Energy Engineering, adheres to all ethical guidelines required for publication. I assure you that the manuscript does not involve any form of misconduct, including plagiarism, data fabrication, or unethical research practices. Furthermore, the authors have adhered to the journal’s submission policies, and all listed contributors have agreed to the content of the manuscript and its submission for publication. I have read the manuscript, and I hereby affirm that the content of this manuscript or a major portion has not been published in a refereed journal, and it is not being submitted fully or partially for publication elsewhere.

Conflicts of Interest: The authors whose names are listed immediately below certify that they have no affiliations with or involvement in any organization or entity with any financial interest (such as honoraria; educational grants; participation in speakers’ bureaus; membership, employment, consultancies, stock ownership, or other equity interest; and expert testimony or patent-licensing arrangements), or non-financial interest (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or materials discussed in this manuscript: Mohammed J. Alshukri: University of Kufa, Iraq; Amjed Al-Khateeb: Najaf Technical Institute, Iraq; Ahmed Mohsin ALsayah: The Islamic University, Najaf, Iraq; Adel A. Eidan: Al-Furat Al-Awsat Technical University (ATU), Iraq; Hameed B. Mahood: University of Birmingham, UK.

Nomenclature

| AC | Alternating Current |

| DBT | Dry-Bulb Temperature (°C) |

| ECS | Evaporative Cooling System |

| Fpower | Air fan power in the cooling system (W) |

| FTP | Thrust Power, associated with the force exerted by moving air (W) |

| HE | Heat Exchanger |

| LT | Low Temperature (in the context of heat exchanger design) |

| MFS | Magnetic Field Strength (T, teslas) |

| MW | Magnetized Water |

| RH | Relative Humidity (%) |

| TWh | Terawatt hours (a sunit of energy) |

| Volumetric flow rate of air (m³/s) | |

| ρa | Air density (kg/m³) |

| uA | Velocity of air times cross-sectional area of duct (m/s) |

References

1. Falchetta G, De Cian E, Pavanello F, Wing IS. Inequalities in global residential cooling energy use to 2050. Nat Commun. 2024;15:7874. doi:10.1038/s41467-024-52028-8. [Google Scholar] [PubMed] [CrossRef]

2. Shalatonin V, Pollack GH. Effect of unipolar magnetic fields on UV absorption and evaporation of water. Chem Phys Impact. 2022;4:100077. doi:10.1016/j.chphi.2022.100077. [Google Scholar] [CrossRef]

3. Esmaeilnezhad E, Choi HJ, Schaffie M, Gholizadeh M, Ranjbar M. Characteristics and applications of magnetized water as a green technology. J Clean Prod. 2017;161:908–21. doi:10.1016/j.jclepro.2017.05.166. [Google Scholar] [CrossRef]

4. Dobránszki J. From mystery to reality: magnetized water to tackle the challenges of climate change and for cleaner agricultural production. J Clean Prod. 2023;425:139077. doi:10.1016/j.jclepro.2023.139077. [Google Scholar] [CrossRef]

5. Guo YZ, Yin DC, Cao HL, Shi JY, Zhang CY, Liu YM, et al. Evaporation rate of water as a function of a magnetic field and field gradient. Int J Mol Sci. 2012;13(12):16916–28. doi:10.3390/ijms131216916. [Google Scholar] [PubMed] [CrossRef]

6. Dueñas JA, Weiland C, García-Selfa I, Ruíz-Rodríguez FJ. Magnetic influence on water evaporation rate: an empirical triadic model. J Magn Magn Mater. 2021;539:168377. doi:10.1016/j.jmmm.2021.168377. [Google Scholar] [CrossRef]

7. Seyfi A, Afzalzadeh R, Hajnorouzi A. Increase in water evaporation rate with increase in static magnetic field perpendicular to water-air interface. Chem Eng Process Process Intensif. 2017;120:195–200. doi:10.1016/j.cep.2017.06.009. [Google Scholar] [CrossRef]

8. Singh R, Gupta A, Paul AR, Paul B, Saha SC. Improving heat transfer in parabolic trough solar collectors by magnetic nanofluids. Energy Eng. 2024;121(4):835–48. doi:10.32604/ee.2024.046849. [Google Scholar] [CrossRef]

9. Halawa T, Tanious AS. Investigation of the optimum design of magnetic field arrangement to enhance heat transfer performance of Fe3O4-water magnetic nanofluid. Int J Therm Sci. 2023;184:108014. doi:10.1016/j.ijthermalsci.2022.108014. [Google Scholar] [CrossRef]

10. Niknejadi M, Afrand M, Karimipour A, Shahsavar A, Meghdadi Isfahani AH. Experimental investigation of the hydrothermal aspects of water-Fe3O4 nanofluid inside a twisted tube. J Therm Anal Calorim. 2021;143(1):801–10. doi:10.1007/s10973-020-09271-0. [Google Scholar] [CrossRef]

11. Pang XF. The experimental evidences of the magnetism of water by magnetic-field treatment. IEEE Trans Appl Supercond. 2014;24(5):4402806. doi:10.1109/TASC.2014.2340455. [Google Scholar] [CrossRef]

12. Kapilan N, Isloor AM, Karinka S. A comprehensive review on evaporative cooling systems. Results Eng. 2023;18:101059. doi:10.1016/j.rineng.2023.101059. [Google Scholar] [CrossRef]

13. Chibowski E, Szcześ A. Magnetic water treatment—a review of the latest approaches. Chemosphere. 2018;203:54–67. doi:10.1016/j.chemosphere.2018.03.160. [Google Scholar] [PubMed] [CrossRef]

14. Mghaiouini R, Benzbiria N, Belghiti ME, Belghiti HE, Monkade M, El bouari A. Optical properties of water under the action of the electromagnetic field in the infrared spectrum. Mater Today Proc. 2020;30:1046–51. doi:10.1016/j.matpr.2020.04.518. [Google Scholar] [CrossRef]

15. Sronsri C, U-Yen K, Sittipol W. Analyses of vibrational spectroscopy, thermal property and salt solubility of magnetized water. J Mol Liq. 2021;323:114613. doi:10.1016/j.molliq.2020.114613. [Google Scholar] [CrossRef]

16. Wang Y, Wei H, Li Z. Effect of magnetic field on the physical properties of water. Results Phys. 2018;8:262–7. doi:10.1016/j.rinp.2017.12.022. [Google Scholar] [CrossRef]

17. Helal AA, Soames A, Iglauer S, Gubner R, Barifcani A. The influence of magnetic fields on calcium carbonate scale formation within monoethylene glycol solutions at regeneration conditions. J Pet Sci Eng. 2019;173:158–69. doi:10.1016/j.petrol.2018.09.100. [Google Scholar] [CrossRef]

18. Ganesha A, Kumar S, Kumar N, Girish H, Harsha AK, Sekhar MV. Performance evaluation of an indirect-direct evaporative cooler using aluminum oxide-based nanofluid. J Therm Anal Calorim. 2023;148(23):13543–57. doi:10.1007/s10973-023-12652-w. [Google Scholar] [CrossRef]

19. Mohsin Alsayah A, Faraj JJ, Eidan AA. A review of recent studies of both heat pipe and evaporative cooling in passive heat recovery. Open Eng. 2024;14(1):1–18. doi:10.1515/eng-2024-0012. [Google Scholar] [CrossRef]

20. Alshukri MJ, Hamad RF, Eidan AA, Al-Manea A. Convective heat transfer analysis in turbulent nanofluid flow through a rectangular channel with staggered obstacles: a numerical simulation. Int J Thermofluids. 2024;23:100753. doi:10.1016/j.ijft.2024.100753. [Google Scholar] [CrossRef]

21. Hamad RF, Alshukri MJ, Eidan AA, Alsabery AI. Numerical investigation of heat transfer augmentation of solar air heater with attached and detached trapezoidal ribs. Energy Rep. 2023;10:123–34. doi:10.1016/j.egyr.2023.06.031. [Google Scholar] [CrossRef]

22. Abed MH, Al-Asadi HA, Oleiwi A, Ali Kadhim S, Al-Yasiri M, Alsayah AM, et al. Improving building energy efficiency through ventilated hollow core slab systems. Case Stud Therm Eng. 2024;60:104793. doi:10.1016/j.csite.2024.104793. [Google Scholar] [CrossRef]

23. AL-Bonsrulah HAZ, Danook SH, Alshukri MJ, Ahmed AM, Raja V, Veeman D, et al. CFD modeling of a horizontal wind turbine by utilizing solar nozzle for power production. Int J Low Carbon Technol. 2023;18:31–7. doi:10.1093/ijlct/ctac127. [Google Scholar] [CrossRef]

24. Alsabery AI, Alshukri MJ, Jabbar NA, Eidan AA, Hashim I. Entropy generation and mixed convection of a nanofluid in a 3D wave tank with rotating inner cylinder. Energies. 2023;16(1):244. doi:10.3390/en16010244. [Google Scholar] [CrossRef]

25. Ali Kadhim S, Hammoodi KA, Alshukri MJ, Omle I, Hussein KKA, Khalaf AF, et al. Enhancing the melting rate of RT42 paraffin wax in a square cell with varied copper fin lengths and orientations: a numerical simulation. Int J Thermofluids. 2024;24:100877. doi:10.1016/j.ijft.2024.100877. [Google Scholar] [CrossRef]

26. AL-Bonsrulah HAZ, Alshukri MJ, Alsabery AI, Hashim I. Numerical and theoretical study of performance and mechanical behavior of PEM-FC using innovative channel geometrical configurations. Appl Sci. 2021;11(12):5597. doi:10.3390/app11125597. [Google Scholar] [CrossRef]

27. Ali SH, Eidan AA, Sahlani AA, Alshukri MJ, Ahmad AQ. The effect of vibration pulses on the thermal performance of evacuated tube heat pipe solar collector. J Mech Eng Res Dev. 2020;43(4):340–7. [Google Scholar]

28. Hammoodi KA, Abdulghafor IA, Kadhim SA, Elsheikh A, Nayyaf DR, Alsayah AM, et al. Effect of air layer on PCMs melting process inside a spherical container: a numerical investigation. Results Eng. 2024;24:103088. doi:10.1016/j.rineng.2024.103088. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools