Open Access

Open Access

ARTICLE

Low-Carbon Economic Dispatch Strategy for Integrated Energy Systems under Uncertainty Counting CCS-P2G and Concentrating Solar Power Stations

1 Institute of Economics and Technology, State Grid Gansu Electric Power Corporation, Lanzhou, 730050, China

2 College of Electrical and Information Engineering, Lanzhou University of Technology, Lanzhou, 730050, China

* Corresponding Author: Jie Lin. Email:

(This article belongs to the Special Issue: Solar and Thermal Energy Systems)

Energy Engineering 2025, 122(4), 1531-1560. https://doi.org/10.32604/ee.2025.060795

Received 10 November 2024; Accepted 17 February 2025; Issue published 31 March 2025

Abstract

In the background of the low-carbon transformation of the energy structure, the problem of operational uncertainty caused by the high proportion of renewable energy sources and diverse loads in the integrated energy systems (IES) is becoming increasingly obvious. In this case, to promote the low-carbon operation of IES and renewable energy consumption, and to improve the IES anti-interference ability, this paper proposes an IES scheduling strategy that considers CCS-P2G and concentrating solar power (CSP) station. Firstly, CSP station, gas hydrogen doping mode and variable hydrogen doping ratio mode are applied to IES, and combined with CCS-P2G coupling model, the IES low-carbon economic dispatch model is established. Secondly, the stepped carbon trading mechanism is applied, and the sensitivity analysis of IES carbon trading is carried out. Finally, an IES optimal scheduling strategy based on fuzzy opportunity constraints and an IES risk assessment strategy based on CVaR theory are established. The simulation shows that the gas-hydrogen doping model proposed in this paper reduces the operating cost and carbon emission of IES by 1.32% and 7.17%, and improves the carbon benefit by 5.73%; variable hydrogen doping ratio model reduces the operating cost and carbon emission of IES by 3.75% and 1.70%, respectively; CSP stations reduce 19.64% and 38.52% of the operating costs of IES and 1.03% and 1.80% of the carbon emissions of IES respectively compared to equal-capacity photovoltaic and wind turbines; the baseline price of carbon trading of IES and its rate of change jointly affect the carbon emissions of IES; evaluating the anti-interference capability of IES through trapezoidal fuzzy number and weighting coefficients, enabling IES to guarantee operation at the lowest cost.Keywords

An integrated energy system (IES) is characterized by the internal integration of multiple energy sources, primarily gas flow and electric current. This system is further augmented by energy storage and conversion equipment, facilitating the realization of multi-energy complementary coexistence, synergistic optimization, and gradient utilization [1]. Given the intricate nature of IES architecture and the heterogeneity of load profiles, an integrated energy system leveraging distributed renewable energy as its core component can meet the demands of diverse load types, thereby enhancing the low-carbon efficiency of IES and the rate of renewable energy consumption [2,3].

Integrated Energy Systems (IESs) pursue decarbonized operation via two key technical routes: indirect and direct emission reduction [4]. In the area of indirect emission cuts, the combined heat and power (CHP) unit, a central power-generating element in IES, shows a distinct heat-power linkage, causing significant carbon discharges. To address this, ramping up the use of renewable energy along with incorporating energy storage systems is vital. These strategies facilitate a well-planned shift in energy consumption timing, ultimately trimming the IES’s indirect carbon footprint [4,5].

For direct emission reduction, carbon sink measures and market trading policies present feasible solutions. Carbon capture and storage (CCS) systems have been proven to perform large-scale, efficient carbon capture [6]. Power-to-gas (P2G) technologies, which tap into leftover renewable energy, offer a promising means to boost renewable energy utilization and lower emissions [7]. Multiple research efforts have explored the carbon reduction benefits of CCS and P2G. For instance, reference [8] designed an all-around coordinated optimization model for P2G-carbon capture power plants. Since gas-fired units are major carbon emitters, treating their CO₂-laden flue gas properly is indispensable. Reference [9] illustrated how CO₂ captured from gas-fired co-generation plants can be sent to electric-to-gas conversion gear for gas synthesis and then recycled back, cutting carbon emissions, gas purchases, and wasted wind power simultaneously. Reference [10] merged CCS with waste incineration power plant flue gas treatment for load adjustment, relying on the integration of CCS and P2G to ease the impacts of renewable energy fluctuations. Moreover, scholars in reference [11] paired P2G with CCS and extended this pairing to complex, multi-energy-source IES. By contrast, reference works [12,13] separated CO₂ capture and utilization processes by connecting P2G and CCS via carbon storage devices. References [14,15] set up CCS setups with liquid storage equipment, which disentangle carbon absorption and regeneration, providing broader output regulation scope and more peaking flexibility. To tackle the high energy costs of carbon capture, reference [16] put forward a flexible capture operation mode to modulate the capture degree of carbon capture equipment, deferring the associated energy expenses over time. However, within the CCS-P2G coupled system, the electro-hydrogen conversion process, other hydrogen application methods, and methanation inefficiencies are often overlooked, and the combination with the carbon trading low-carbon mechanism has yet to be considered.

As shown in reference [17], an optimal CHP model scheduling method based on CCS-P2G was established, solving carbon source and emission issues for CHP unit output. Reference [18] built an integrated wind-PV-hydrogen power system, facilitating renewable energy use and reliable H2 supply in IES. The CCS-P2G coupling model turned carbon trading costs positive, promoting carbon sinks, cutting IES costs, and increasing trading revenues. The Carbon Emission Trading (CET) mechanism [19,20] supports furthering renewable energy consumption and IES low-carbon potential. Some literature, like reference [21], has explored CET’s benefits in IES operations via a cross-regional optimal dispatch model integrating CET and Green Certificate Trading. Reference [22] built an IES dispatch model using the stepped CET mechanism and multi-energy response, showing 6.7% carbon and 9.21% cost reductions. Yet, existing literature has limitations. It separately considers IES equipment’s carbon reduction potential and the trading market, ignoring combined low-carbon tech-policy benefits. Also, the CCS-P2G model overlooks the power-to-hydrogen stage and other hydrogen utilization paths. To fix this, this paper will propose a two-stage P2G model and use gas doping to enhance hydrogen use, applying the stepped CET mechanism for IES decarbonization research.

Concentrating solar power (CSP) is a new solar power generation mode, that integrates photothermal conversion, thermal storage, and synchronous power generation. In integrated energy system research, many scholars focus on CSP. Reference [22] pioneered in clarifying its basic features, laying the foundation for later work. For power system optimal scheduling, reference [23] built a two-stage stochastic model for power systems with CSP, aiming to cut operating costs, highlighting CSP’s value in high-proportion new energy grids. References [24,25] studied photovoltaic power plants in Gansu, Qinghai, etc., evaluating their power generation and flexibility benefits. In grid scheduling, reference [26] proposed coordinating photovoltaic, wind, and thermal power. Electric heating devices convert unused wind power to heat, store it in the photovoltaic plant’s thermal storage, and reuse it, enhancing the plant’s value. References [27–29] adjusted photovoltaic output and paired it with thermal storage operations to suppress wind-solar-storage power fluctuations and promote joint frequency regulation, bringing economic and capacity benefits. To ensure power system stability, reference [30] developed a wind-solar-photothermal combined power generation system model, making grid-connected power match the dispatch curve, and strengthening operation reliability. Reference [31] exploited the complementary regulation characteristics of thermal and photovoltaic power to build a coordinated dispatch model, reducing abandoned new energy and dispatch costs.

Presently, the main analytical methods for uncertainty optimization are the fuzzy chance constraint, robust optimization, and multi-scenario stochastic optimization [32]. Many studies use these to analyze system source-load uncertainties. In reference [33], fuzzy chance constraints handle wind power and load uncertainties, while optimization hierarchy analysis addresses multi-objective functions in a Regional Integrated Energy System (RIES) with pumped storage, wind, hydro, and thermal power units. The model boosts the RIES’s integrated performance. Another study focuses on a multi-timescale cross-provincial grid scheduling strategy for PV-load uncertainties. A VAR model forecasts PV output [34]; multi-scenario stochastic optimization analyzes day-ahead PV uncertainty; a trapezoidal fuzzy number equivalence model examines intraday uncertainties. This strategy cut’s intraday fuzzy chance constraint complexity raises PV cross-provincial consumption via pumped storage and optimizes PV output and load differences between provinces. In reference [35], the multi-energy virtual power plant model, considering carbon capture and storage, uses fuzzy numbers to study wind and load uncertainties’ impact on carbon capture. The model reduces system carbon emissions. Reference [36] looks at a MEH energy scheduling scheme with carbon emissions in mind, generating multiple scenarios via the probability density function to assess renewable energy output uncertainties. Reference [37] explores a day-ahead optimal scheduling model with multi-scenario analysis, using improved K-means clustering for scenario generation and reduction to shorten computation time. Reference [38] studies an MMG two-tier scheduling strategy for wind-scenic cooperative energy storage, establishing power balance constraints with uncertain parameters and introducing slack power constraints to cut power supply-demand deviation. Finally, reference [39] examines a coupled electricity-carbon MMG cooperative game optimization scheduling model with multiple uncertainties, applying the opportunity constraint method to wind power output uncertainty and robust optimization to tariff uncertainty.

In summary, although research on low-carbon operation of IES has made some progress, existing studies have neglected the stability problem of renewable energy generation. In IES containing a high proportion of renewable energy, the disturbance problems caused by the fluctuation and randomness of renewable energy generation cannot be ignored. To promote the low-carbon operation of IES and improve the disturbance-resistant capability of IES, this paper proposes a low-carbon economic dispatch study of IES under uncertainty taking into account CCS-P2G and CSP station, with the following steps: (1) a low-carbon dispatch model of IES based on CCS-P2G, CSP station and gas hydrogen doping unit is established, and the effectiveness of the gas hydrogen doping and variable hydrogen doping ratio modes are analyzed; (2) the ladder-type carbon trading mechanism into IES, and conducted sensitivity analysis of the carbon trading benchmark price of IES and its growth rate; (3) used trapezoidal fuzzy numbers to relax the IES power balance constraints and transform them into clear equivalence classes, and established the IES optimal scheduling strategy based on the fuzzy opportunity constraints; (4) used weight coefficients as the risk assessment indexes, and established the IES risk assessment based on the CVaR strategy. Finally, the simulation example shows that the proposed strategy effectively reduces the operation cost and carbon emission of IES, the carbon trading base price of IES and its growth rate jointly decide the carbon emission of IES, and the anti-disturbance ability of IES is evaluated by the trapezoidal fuzzy number and CVaR.

2 IES Model with CCS-P2G, Gas-Fired Hydrogen-Doped Units and CSP

The IES in this paper consist of a thermal unit (TU), gas turbine (GT), gas boiler (GB), P2G, CSP power plant, wind turbine (WT), CCS and electric energy storage, and the load consists of electric and thermal loads. The structure of IES in this paper is shown in Fig. 1:

Figure 1: IES structure diagram

2.1 Mechanisms and Models for Coupled CCS-P2G Operation

2.1.1 Mechanisms and Models of CCS Operation

The introduction of a flue gas diverter system and liquid storage vessel in CCS forms an integrated and flexible operation mode of CCS [40], which improves the flexibility of its operation in conjunction with P2G. Gas boilers, gas turbines, and thermal power units all generate CO2 during operation, and in the CCS-P2G coupled operation mode proposed in this paper, the CCS collects the captured CO2 and transports it to the methane reactor (MR) for methanation, which reduces the cost and carbon emission of purchasing CO2 from external sources by the IES and avoids the leakage of CO2 during the transportation to the CCS or CCUS. It also avoids the leakage of CO2 during transportation to CCS or CCUS, which may cause environmental pollution [41]. Fig. 2 shows the energy flow diagram of the coupled CCS-P2G operation mode:

Figure 2: Energy flow diagram of CCS-P2G coupled gas hydrogen doping system

The actual capture energy consumption of CCS in the time

where

The CCS contains a flue gas splitter system that increases CCS operational flexibility and reduces energy consumption by actively venting CO2 into the atmosphere as required by the IES:

where

The decoupling of the CO2 absorption and regeneration processes is realized by installing a liquid storage vessel between the absorption and regeneration towers and transferring the CCS energy consumption by adjusting the liquid storage volume of the vessel. The CCS energy consumption is reduced when the liquid-rich unit has more liquid storage and the liquid-poor unit has less liquid storage and vice versa, which is modelled as follows:

where

In this paper, we use the form of the volumetric amount of solution instead of a CO2 amount, if a unit volume of enriched liquid absorbs 20 times the volume of CO2:

where

The regenerated CO2 is transported to the MR or sequestered, and some is discharged to the atmosphere:

where

2.1.2 Mechanisms and Models for the Two-phase Operation of the P2G

The P2G operation process is divided into two stages: P2H and hydrogen to gas (H2G). In the first stage, the electrolytic (EL) electrolyzes water, realizing the conversion of “electricity-hydrogen energy”; in the second stage, the EL delivers the hydrogen energy to MR, GT, and GB, respectively. Fig. 3 shows the process diagram of the two stages of P2G:

Figure 3: Two-stage operational process of P2G

The MR is mechanized to produce CH4, which can be supplied directly to the gas load or delivered to the CHP or GB to produce electricity/thermal energy. The raw materials consumed by the GT and GB consist of the hydrogen generated by the P2G and natural gas, as well as the gas purchased from an external gas grid. This P2G two-stage model also reduces carbon emissions and improves the efficiency of P2G operation by operating GT and GB with gas-doped hydrogen compared to the conventional P2G model.

The P2G model is as follows:

where

where

P2G generates CH4 by a volume equal to the volume of CO2 consumed:

P2G generates CH4 volume

where

2.2 Operational Modelling of Hydrogen Doping in Gas Turbines and Gas Boilers

2.2.1 Hydrogen-Doped Gas Turbine Model

The standard hydrogen-doped gas turbine can maintain safe operation in the range of 0%~30% hydrogen-doping ratio, beyond which the standard hydrogen-doped gas turbine needs to be improved, which increases the investment cost [43]. Therefore, in this paper, the gas turbine with a hydrogen doping ratio of 10%~20% is selected and modelled as follows:

where

2.2.2 Modeling of Hydrogen-Doped Gas Boilers

GB can also be doped with a certain amount of H2 operation is modeled as follows:

where

The CSP station is divided into a concentrating solar collector link, thermal energy storage link and power generation link. The solar field (SF) of the CSP station absorbs solar energy into the collector, and produces high-pressure steam through the heat exchanger to the turbine generator (TG) for power generation, and the remaining thermal energy is stored in the TES, which can be transferred to the TG for power generation or directly supplied to the thermal load when the light intensity is weak or no light is available. The remaining thermal energy is stored in the TES, which can be transferred to the TG for power generation or directly supplied to the thermal load when the solar irradiance is weak. The CSP station will produce light and thermal energy loss during operation, and the degree of loss is related to the material of the TES and the external environment, etc. The CSP station can also be used as a solar energy storage system.

2.3.1 Concentration of Solar and Thermal Collection Links

where

The thermal power

where

The following constraints need to be met for the thermal storage segment of a CSP station:

where

TES stored thermal can be used for direct heat loads or for TG generation:

where

The output electric power

where

2.4 Electrically Heated Models

where

The CSP station thermal storage system model is shown in Eqs. (13)–(15), and the electrical storage station (ESS) model is as follows:

where

3 Stepped Carbon Trading Mechanism

The carbon trading mechanism renders carbon emissions tradable in the market, enabling parties to trade for emission control. Carbon emission quotas are assigned to IES emitters. If actual emissions exceed the allocated amount, extra quotas must be bought from the market; surplus ones can be sold for income. The stepped carbon trading mechanism consists mainly of the quota, actual emission, and stepped trading models.

3.1 IES Emission Right Quota Model

This paper adopts the baseline method as the indicator of the gratuitous quota model for allocation, this paper IES carbon emission sources are GB, GT and external power purchase, and it is considered that the external power purchase comes from thermal power unit generation. In this paper, IES carbon credits are modeled as:

where

3.2 IES Actual Carbon Emission Model

In this paper, the actual carbon emissions from the IES are the amount of generated CO2 minus the amount of CO2 utilized by P2G and the amount of CO2 sequestered. The amount of CO2

The actual amount of CO2 generated by the IES

where

3.3 IES Ladder-Type Carbon Trading Mechanism Model

By solving for the IES carbon allocation

To impose further limitations on IES carbon emissions, this paper employs a stepped carbon trading model. In contrast to the conventional carbon trading pricing model, this model employs distinct carbon trading prices across various carbon emission intervals. The magnitude of the carbon trading price within a specific interval is directly proportional to the quantity of carbon emission rights allocated. The specific structure of the stepped carbon trading model is outlined as follows:

where

4 IES Optimized Scheduling Model

4.1 IES Low Carbon Economics Scheduling Model

The goal of the IES low carbon economics scheduling in this paper is to minimize the IES operating costs

where

where

4.2 IES Optimal Scheduling Model Based on Fuzzy Chance Constraints

The notion of opportunity constraints has the capacity to articulate the confidence level of the system. Moreover, the decision scheme can incorporate risk and cost in an uncertain environment. However, it is imperative to acknowledge that the reasonable measurement function exerts a direct influence on the expression of the confidence level. Consequently, the selection of this function must be endowed with a clear physical meaning and practical value. Conventional chance-constrained planning is exclusively for stochastic environments; however, the absence of the row-medium law signifies that wind power also possesses considerable ambiguity [44–46].

Decision-making processes based on fuzzy sets permit adjustments within a specific fuzzy range. Confronted with the inherent uncertainty associated with wind power, decisions pertaining to grid scheduling and energy storage allocation can be made without being constrained by predetermined thresholds. In circumstances where extreme weather events, characterized by their rarity but severe consequences, are difficult to predict with accuracy, the employment of fuzzy decision rules facilitates a swift response, thereby mitigating the potential for complete cessation of energy supply. This approach deviates from conventional deterministic or random strategies by employing a more adaptable and agile decision-making process.

Compared with complex probabilistic statistical analysis, fuzzy set operations rely on the affiliation function and the rules are relatively simple. In the context of large-scale wind power integration into the power system, the fuzzy set method has been shown to have a low computational demand and to facilitate rapid decision-making, thereby assisting dispatchers and maintenance personnel in responding in a timely manner and enhancing system control efficiency. In this section, we propose a methodology that utilizes fuzzy opportunity constraints to relax IES power balance constraints, and trapezoidal fuzzy numbers to convert these constraints into clear equivalence classes. The utilization of fuzzy chance constraints stipulates that the feasibility of the decision outcome satisfying the constraints is not less than the specified confidence level. In the absence of light, the thermal storage system of the CSP plant can maintain stable power generation for an extended period, thereby mitigating the impact of weather uncertainty [47]. This section focuses exclusively on wind power output and load, both of which are subject to uncertainty.

4.2.1 Trapezoidal Fuzzy Numbers

This chapter uses trapezoidal fuzzy numbers for fuzzy planning, which is modeled as follows [34]:

where

Trapezoidal fuzzy number characterization using quaternions:

where

4.2.2 Clear Equivalence Class Modeling

Since the trapezoidal fuzzy array characterized by the quaternion cannot be solved linearly, the transformation method of the reference [34] is used to separate the fuzzy variables from the decision variables and to prove that there is a linear relationship between the two, as described in the reference [34].

Set the confidence level to

Therefore, the clear equivalence model for wind power and load in this paper is:

where

4.3 IES Risk Assessment Model Based on Conditional Value-at-Risk Theory

In this paper, the IES presents a high proportion of renewable energy characteristics. However, due to the volatility and stochasticity of renewable energy output, there is a risk in optimizing dispatch based on forecast data. To enhance the IES’s capacity to manage uncertainties, a risk assessment model is developed in this section. This model is based on conditional value-at-risk (CVaR) theory.

VaR cost

where

Discretization of Eq. (35):

where

Modeling CVaR-based IES risk assessment:

where

In this article, the weight coefficients are set using a subjective method. In practical applications, the weight coefficients represent the degree of aversion to risks in the project. Since the judgment criteria for risks vary in actual systems and are difficult to quantify through objective methods, the setting method we adopt can also intuitively reflect the effectiveness of this risk assessment system. In this paper, we ignore the effect of solar variations on the output of CSP plants [29], only the effect of uncertainty factors on WT output is considered.

4.4.1 Power Balance Constraints

The IES is internally coupled with electrical, thermal, gas, and hydrogen energy and is constrained to maintain a balance of load and equipment supply:

where

1) WT and CSP plant output constraints:

where

2) Gas turbine and gas boiler output and climb constraints:

where

where

3) Electrically heated restraints:

where

4) Thermal unit constraints:

where

5) Carbon capture constraints:

CCS operation cannot exceed the maximum operating power

The CCS reservoir vessel is required to meet the following constraints:

where

The CCS storage vessel has the same storage capacity at the beginning and end of a dispatch cycle:

6) P2G constraints:

7) Remaining constraints:

The CSP plant thermal storage system cannot operate at full capacity 24 h:

where

The IES low-carbon optimal dispatch model in this paper, considering CCS-P2G and concentrating solar power plants under the stepped carbon trading system, is a mixed-integer nonlinear one. We use the segmental linearization method to turn it into a mixed-integer linear model, then solve it with the CPLEX commercial solver. The specific linearization process is detailed in Appendix A.

5.1 Parameters of the Algorithm

The internal structure of IES in this paper is shown in Fig. 1, containing 1 WT, 1 CSP station, 1 GB, 1 GT, 1 P2G, 1 CCS, 1 EH, 1 TU, and 1 ESS. The carbon trading in the IES has a base price of 200 yuan per ton, an interval of 50 tons, and a growth rate of 25%. The price of natural gas is set at 3.2 yuan per cubic meter, while the price of coal for the thermal power unit is 500 yuan per ton. the mass of CH in 1 m is 0.715 kg; the mass of CO in 1 m is 1.95 kg; the mass of H unit coal price is 500 yuan/t; 1 m3 of CH4 mass of 0.715 kg; 1 m3 of CO2 mass of 1.95 kg; 1 m3 of H2 mass of 0.09 kg;

5.2 IES Power Balance Analysis

As Fig. 4 shows, IES power goes mainly to electric loads, heating, ESS charging, CCS, and P2H. At night, when the wind is strong, the WT and gas turbine power the IES, and the ESS stores spare wind power. After 6:00, as solar intensity rises, the CSP plant starts generating, peaking from 11:00 to 13:00. This peak load time makes thermal units emit more carbon. So, the CCS captures carbon, and the ESS discharges to add power. Between 18:00 and 21:00, the IES mainly powers the CSP’s thermal storage, cutting thermal unit output. During dispatch, the CSP plant provides stable power at peaks and low-solar times, keeping the IES stable. High thermal output triggers CCS to capture carbon for the IES cycle. The ESS quickly stores/discharges to shift electric power. IES thermal energy goes to loads and the CSP’s thermal storage. At night’s peak, the storage releases heat; in the morning, it stores heat, using its fast heat shift to exploit the CSP’s flexibility. The CO2 balance is in Fig. A2a, and the CCS power balance in Fig. A2b.

Figure 4: IES power balance

5.3 Analysis of Gas Hydrogen Doping Models

5.3.1 Analysis of the Effectiveness of the Gas Hydrogen Doping Model

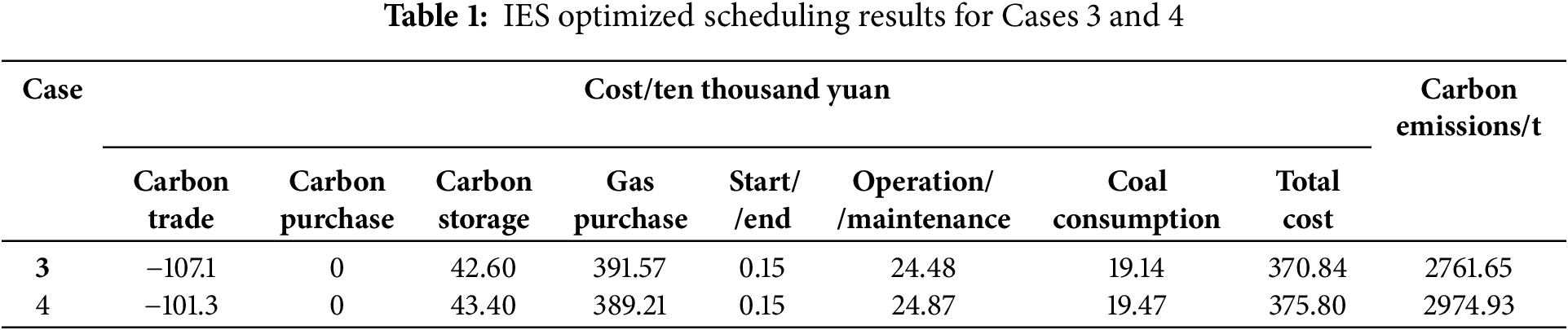

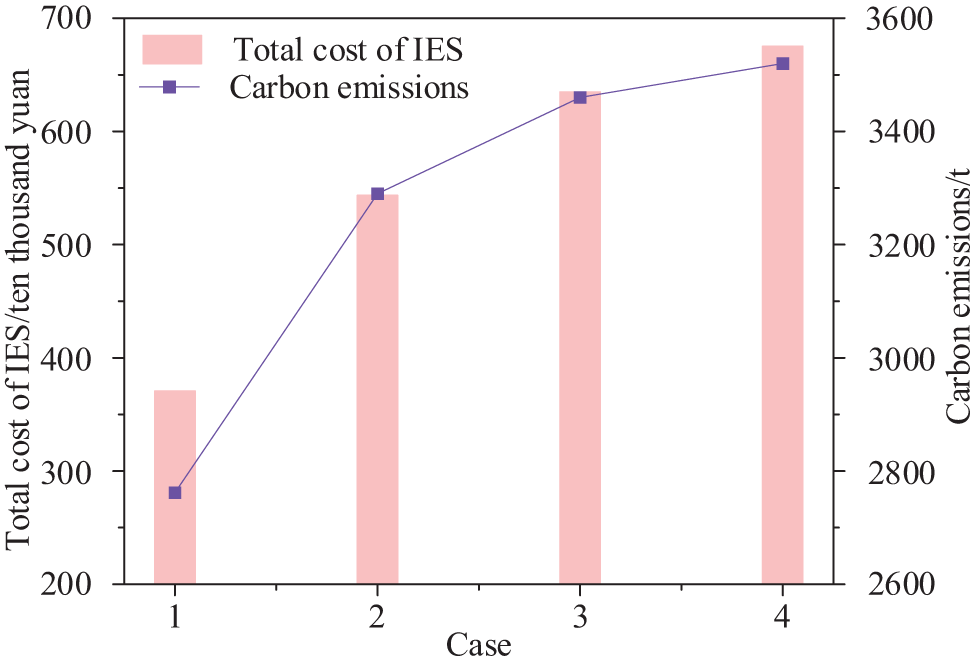

To verify the effectiveness of the gas-hydrogen doping mode proposed in this paper, based on Case 3 (i.e., the scheme proposed in this paper), Case 4 without hydrogen doping mode is set for comparative analysis. Table 1 shows the IES optimization scheduling results for Cases 3 and 4:

As shown in Table 1, compared to Case 4, Case 3 sees a 49,600-yuan reduction in IES operation cost. The gas purchase cost climbs by 23,600 yuan, while the coal consumption cost rises by just 3300 yuan. Operating in the hydrogen doping mode requires copious amounts of H2. Thus, to meet the demand, the electric load drives higher power output for H2 production, escalating overall power consumption. The IES chooses the lower-emission hydrogen-doped gas unit over the thermal unit, which hikes gas purchase costs but leaves coal costs nearly static. Between Case 3 and Case 4, carbon emissions declined by 213.28 t. Even though the hydrogen-doped gas turbine’s output in the IES increases, its per-unit electricity CO2 emission is lower. Thanks to the strong thermoelectric coupling and fixed thermal load, the hydrogen-doped gas turbine’s thermal output rises, the gas boiler’s thermal output drops, and the gas boiler emits less CO2 per unit of power.

5.3.2 Analysis of Hydrogen Doping Ratio Effectiveness

To further investigate the hydrogen doping ratio benefits, in this section, the hydrogen doping ratios were varied by changing the hydrogen doping ratio for gas turbines (HDR-GT) and gas boilers (HDR-GB) by setting the hydrogen doping ratios to 2%, 6%, 10%, 12%, and 16%, respectively. The hydrogen doping ratios were set to 2%, 6%, 10%, 12% and 16%, respectively. The relationship between CO2 emission and the total cost of IES for gas turbines and gas boilers with different hydrogen doping ratios is shown in Fig. 5.

Figure 5: Relationship between the total cost of IES and CO2 emission for different hydrogen doping ratios

As shown in Fig. 5a, when HDR-GT is fixed at 20% and HDR-GB at 16% and 2%, the IES’s total operating cost drops by 1%. With fixed HDR-GT, a rising HDR-GB leads to a decreasing cost of IES. When HDR-GB is fixed, increasing HDR-GT also reduces the IES cost, which levels off upon reaching 20%. In Fig. 5b, IES carbon emissions decline with growing HDR-GT, stabilizing at 18% or above. At HDR-GT of 15% and up, differences in emissions under various HDR-GB values shrink. Overall, the gas hydrogen doping mode cuts IES operation costs and emissions, enabling low-carbon operation. Properly setting HDR-GT and HDR-GB ratios can control these factors effectively.

5.3.3 Analysis of the Effectiveness of Variable Hydrogen Doping Ratios

Due to the electric-hydrogen strong coupling of EL (analogous to the gas turbine electric-thermal coupling), EL is forced to electrolyze H2 to satisfy the demand of H2 in the hydrogen doping mode, which generates a waste of electric energy. In this section, a comparative analysis of varying hydrogen doping ratios and fixed hydrogen doping ratios is used, and Case 5 is set as the variable hydrogen doping ratio mode. The hydrogen doping ratios of the gas turbine and gas boiler are shown in Fig. 6a, and the relationship between the unit’s hydrogen consumption power and net electric load in the two hydrogen doping modes is shown in Fig. 6b, and the results of IES optimal scheduling for Cases 3 and 5 are shown in Table 2.

Figure 6: Relationship between IES hydrogen consumption power and net electrical load in two hydrogen doping modes

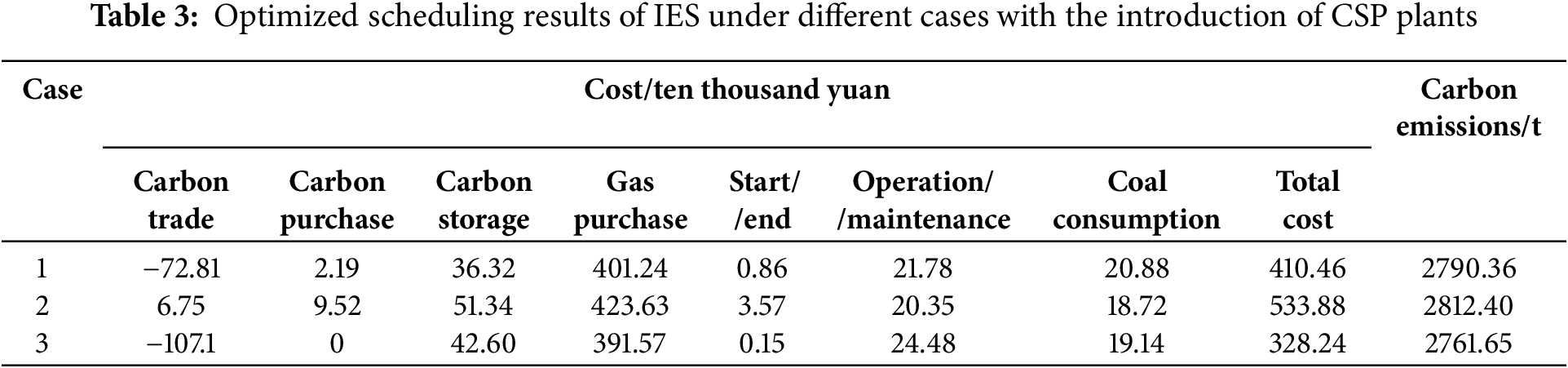

As illustrated in Fig. 6, the hydrogen power consumption in the variable doping ratio mode is equivalent to or lower than the hydrogen power consumption in the fixed doping ratio mode. Furthermore, the hydrogen power consumption in the variable doping ratio mode exhibits a substantial decrease during the peak net electricity load period. As demonstrated in Table 3, in comparison with Case 3, Case 5 results in a reduction of the purchased gas cost by 7.15 ten thousand yuan. Despite an increase in carbon trading costs of 4.61 ten thousand yuan, the total cost is reduced by 3.75 ten thousand yuan, accompanied by a decrease in carbon emissions of 46.94 t. In summary, the IES modifies the power output of the gas turbine and the gas boiler by decreasing the amount of hydrogen doping, thereby reducing both the total cost and the carbon emission.

5.4 Analysis of the Effectiveness of CSP Plants

To verify the effectiveness of this paper’s IES introducing CSP plant, based on Case 3 in Section 4.2, this section sets three cases for comparative analysis: (1) using equal capacity PV units to replace the CSP plant to participate in the IES operation; (2) using the gas turbine with the same upper output limit and climbing power to replace the CSP plant to participate in the IES operation; and (3) the cases proposed in this paper. The results of IES optimal scheduling for the three cases are shown in Table 3.

As Table 3 shows, Case 3’s total cost drops by 19.64% compared to Case 1 and 38.52% against Case 2, proving the CSP plant’s good economic impact on IES optimal operation. Comparing Case 3 with Case 2, the carbon trading cost falls by 113.85 × 104 yuan, but the gas purchase cost rises by 32.06 × 104 yuan. Since the gas turbine, replacing the CSP plant, has a “thermal to set electricity” constraint, during electricity-heat load mismatches, it must increase output, hiking gas and carbon trading costs. Case 1, Case 3 uses PV units instead of CSP plants. Without sunlight, PV units need external gas and coal, raising gas turbine and thermal unit outputs. Case 3’s O&M cost is 12.40% higher than Case 1’s because CSP plant O&M involves thermal storage and power generation, so its unit power O&M cost is greater.

5.5 Sensitivity Analysis of Carbon Trading Mechanisms

In the Integrated Energy System (IES), the differences in stepped carbon trading parameters directly and significantly affect IES dispatching results. The carbon trading base price is a key parameter for in-depth study. In this research’s scheduling model, the amount of carbon emission allowances is much higher than the system’s actual emissions. As Fig. 7 shows, when the carbon trading base price is below 90 RMB, the system’s carbon emissions steadily decrease as the base price rises. This is because a higher base price strongly motivates the system to cut carbon emissions, enabling it to get more tradeable allowances and gain extra economic benefits. However, when the base price exceeds 90 RMB, the system’s carbon emissions stabilize, with few further fluctuations.

Figure 7: Sensitivity of carbon trading mechanisms to carbon trading base prices

Secondly, we consider the sensitivity of the carbon trading mechanism to the growth rate of the carbon trading price. With a baseline carbon trading base price of 90 yuan, as shown in Fig. 8, when the growth rate of the carbon trading price is in the range of [0, 0.2), carbon emissions show a downward trend. This is because a higher growth rate provides stronger incentives for the system to cut emissions, prompting a change in the unit output pattern and thus reducing carbon emissions. Fewer emissions mean the system can supply more carbon allowances, boosting revenue and cutting total costs. However, when the carbon trading price growth rate exceeds 0.2, the system’s ability to affect each unit’s output is nearly zero, and carbon emissions remain unchanged.

Figure 8: Sensitivity of carbon trading mechanisms to the magnitude of carbon trading price increases

It’s also remarkable that the total cost of the IES declines even as the carbon trading price goes up. To show how the carbon base price and its growth rate jointly affect the system’s carbon emissions, look at Fig. 9. Generally, a lower carbon base price along with a smaller increment in the carbon price correlates with higher overall carbon emissions in the system. Specifically, when the carbon trading base price is between 40 yuan and 120 yuan, the system displays different levels of sensitivity to various increases in the carbon trading price. However, once the carbon trading base price exceeds 120 yuan, changes in the carbon trading price no longer have an impact on the system’s carbon emissions.

Figure 9: Carbon emissions under varying carbon trading base prices and increments in carbon trading prices

5.6 Analysis of Fuzzy Affiliation Parameters

The selection of fuzzy affiliation parameters will have an impact on the optimal operation of IES. To study the impact of wind power output and load uncertainty on the total cost and carbon emission of IES, based on Case 3, set the confidence level as 0.98, and select different fuzzy affiliation parameter schemes shown in Table 4 for comparative validation, in which fuzzy degree 1 is the deterministic case, and get the relationship curves of the total cost and carbon emission of IES under the different fuzzy affiliation parameter shown in Fig. 7.

As can be seen in Fig. 10, with the same confidence level, the total IES cost, and carbon emissions increase as the level of ambiguity increases. Cases 2, 3, and 4 increase the total IES cost by 46.58%, 71.21%, and 82.10%, and the carbon emission by 19.13%, 25.29%, and 27.46%, respectively, compared to Case 1. The reason is that as the degree of ambiguity increases, the uncertainty of IES source load increases and faces higher operational risks, IES chooses to increase the purchased gas cost and gas unit output to cope with the risks, and the carbon emissions increase accordingly. Among them, the growth rate of carbon emissions is gradually smaller than the growth rate of the total cost of IES, because, under the CET mechanism, the price of carbon emission rights increases more and more, the cost of purchasing carbon emission allowances gradually increases, and IES chooses to purchase gas to cope with the risk of uncertainty.

Figure 10: Relationship between the total cost of IES and carbon emissions under different fuzzy affiliation parameters

5.7 Analysis of Weighting Factors

The CVaR weighting coefficients reflect the decision maker’s level of risk aversion caused by the uncertainty faced by the IES. To study the impact caused by the weighting coefficients on the optimal operation of IES, the CVaR confidence level is set to 0.98 based on Case 3 in Section 4.2, and the relationship curves between the total cost of IES and CVaR under different weighting coefficients are obtained as shown in Fig. 11:

Figure 11: Relationship curves of IES total cost and CVaR with different weighting coefficients

As shown in Fig. 11, the total IES cost and CVaR are 369.12 ten thousand yuan and 455.3 ten thousand yuan at

In this paper, in the background of IES containing a high proportion of renewable energy, CSP station is introduced in IES as renewable energy generation and storage, and the uncertainty analysis of renewable energy generation and load is carried out; gas hydrogen doping model is introduced on the basis of CCS-P2G coupled model, and carbon trading sensitivity analysis is carried out in combination with the stepped carbon trading mechanism, and the comparative study in different cases is conducted to get the following conclusions:

1. The coupled CCS-P2G model with gas hydrogen doping unit reduces 1.32% operating cost and 7.17% carbon emission of IES and improves 5.73% carbon benefit.

2. The variable hydrogen doping ratio model of EL reduces 3.75% operating cost and 1.70% carbon emission of IES and realizes the decoupling of EL electric-hydrogen strong coupling.

3. CSP station involved in IES optimized operation reduced IES operating costs by 19.64% and 38.52%, and IES carbon emissions by 1.03% and 1.80%, respectively, compared with equivalent capacity PV and wind turbines.

4. Sensitivity analysis of the carbon trading base price and its growth rate is carried out. When the base price is lower than 90 yuan, the carbon emission of IES decreases as the price rises, and when the base price is higher than 90 yuan, the carbon emission of IES tends to stabilize. When the price growth rate is in the interval of [0, 0.2], the carbon emission of IES decreases; when the price growth rate is in the interval of

5. The carbon trading base price and its growth rate together affect the IES carbon emissions. The lower the base price is, the lower the price growth rate is, and the higher the IES carbon emissions are; when the base price is in the range of [40, 120], the IES shows different sensitivities to the price growth rate; when the base price is more than $120, the price growth rate has no impact on the IES carbon emissions.

6. The sum of changes in the fuzzy affiliation parameter

7. The confidence level is fixed at 0.98 and the weighting coefficient

This study has limitations in IES scheduling optimization. Currently, it relies only on forecast data, ignoring complex real-time power system conditions and intraday scheduling. In the future, adding an intraday rolling optimization scheduling link will enable the plan to adapt to real-time data, meeting IES optimization needs across time scales and following power system dynamics.

Acknowledgement: This research was supported by the State Grid Gansu Electric Power Company Science and Technology Program and the National Natural Science Foundation of China.

Funding Statement: State Grid Gansu Electric Power Company Science and Technology Program (Grant No. W24FZ2730008). National Natural Science Foundation of China (Grant No. 51767017).

Author Contributions: The authors confirm contribution to the paper as follows: Zhihui Feng: Funding acquisition, Resources; Jun Zhang: Data curation; Jun Lu: Project administration; Zhongdan Zhang: Data curation, Investigation; Wangwang Bai: Conceptualization; Long Ma: Formal analysis; Resources; Haonan Lu: Software, Visualization, Original draft; Jie Lin: Supervision, Writing—review and editing. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Ethics Approval: This study is theoretical in nature and does not involve human or animal experimentation or the collection of personal data, and therefore does not require the approval of an ethics committee.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

Nomenclature

| The actual capture energy consumption at time t | |

| The operational energy consumption at time t | |

| The stationary energy consumption at time t | |

| The energy consumption corresponding to each unit mass of CO₂ captured with CCS | |

| The mass of CO2 captured by the CCS regeneration tower at time t | |

| The total amount of CO2 emitted by the IES at time t | |

| The amount of CO2 absorbed by the CCS at time t | |

| The volume of CO₂ released from the CCS into the atmosphere via the flue gas splitter system at time t | |

| The volume of liquid stored in the liquid-rich and liquid-poor vessels over time | |

| The volume of liquid inflows to and outflows from the liquid-rich vessel over time | |

| The volume of liquid inflow and outflow in the liquid-poor vessel at time t | |

| The CO2 gaseous density | |

| The amount of CO2 produced by CCS at time t | |

| The amount of CO2 sequestered at time t | |

| The P2H conversion efficiency | |

| The hydrogen-consuming power and gas-producing power of the Membrane Reactor (MR) at time t | |

| The MR conversion efficiency | |

| The GT power and thermal generation efficiencies | |

| The volumetric power conversion factor of CH4 | |

| The mass power conversion factor of H2 | |

| The GT gas and hydrogen consumption at time t | |

| The density of H2 | |

| The intensity of carbon credits per unit of electricity output of GT | |

| The electricity-thermal conversion factor of GT | |

| The intensity of carbon credits per unit of thermal power output | |

| The intensity of carbon credits per unit of electricity output of thermal power units | |

| The base price of carbon trading | |

| The length of the carbon-emitting interval | |

| The increase in the price of carbon trading | |

| The operation and maintenance (O&M) costs factors at time t of WT, EH, P2G, CCS, GB, and ESS | |

| The O&M cost coefficients for CSP power generation and storage-exchange thermal | |

| The O&M cost coefficients for GT power generation and thermal generation | |

| The intensity of carbon credits per unit of electricity output of GT | |

| The electricity-thermal conversion factor of GT | |

| The heating efficiency of GB | |

| The gas consumption and hydrogen consumption of GB at the time | |

| The photothermal conversion rate of the SF | |

| The thermal loss rate of the SF | |

| The electrical-to-thermal conversion rate | |

| The ESS charging and discharging efficiencies | |

| The ESS self-damage rate | |

| The ESS charging and discharging status bits | |

| The heating efficiency of GB | |

| The gas consumption and hydrogen consumption of GB at time t |

Appendix A

Eq. (31) contains the square term, for which the segmented linearization method is used in the following procedure:

Step 1: Take

Step 2: Add

Step 3: Replace the nonlinear expression with Eq. (A2):

For Eq. (25), linearization is performed using steps 2 and 3.

Appendix B

Figure A1: IES Forecasts for electric thermal load, wind power and DNI

Figure A2: CO2 power diagram for IES

References

1. Zhang W, Xu Y. Distributed optimal control for multiple microgrids in a distribution network. IEEE Trans Smart Grid. 2019;10(4):3765–79. doi:10.1109/TSG.2018.2834921. [Google Scholar] [CrossRef]

2. Zhang SX, Wang DY, Yang HZ, Song Y, Yuan K, Du W. Key technologies and challenges of low-carbon integrated energy system planning for carbon emission peak and carbon neutrality. Autom Electr Power Syst. 2022;46(8):189–207 (In Chinese). [Google Scholar]

3. Fu X, Zhang X, Qiao Z, Li G. Estimating the failure probability in an integrated energy system considering correlations among failure patterns. Energy. 2019;178(2):656–66. doi:10.1016/j.energy.2019.04.176. [Google Scholar] [CrossRef]

4. Zhang G, Wang W, Chen Z, Li R, Niu Y. Modeling and optimal dispatch of a carbon-cycle integrated energy system for low-carbon and economic operation. Energy. 2022;240:122795. doi:10.1016/j.energy.2021.122795. [Google Scholar] [CrossRef]

5. Chen YB, Zhang N, Li JQ, Fang Z, Wu SC, Mei SW, et al. Review and prospect of zero carbon park research. Proc CSEE. 2024;44(14) (In Chinese). doi:10.13334/j.0258-8013.pcsee.231293. [Google Scholar] [CrossRef]

6. Wang R, Wen X, Wang X, Fu Y, Zhang Y. Low carbon optimal operation of integrated energy system based on carbon capture technology, LCA carbon emissions and ladder-type carbon trading. Appl Energy. 2022;311(7):118664. doi:10.1016/j.apenergy.2022.118664. [Google Scholar] [CrossRef]

7. Zhu H, Yu T, Chen Z, Wu Y, Li Z, Wu W. Distributed optimal dispatching of interconnected electricity-gas-heating system. IEEE Access. 2020;8:93309–21. doi:10.1109/ACCESS.2020.2994771. [Google Scholar] [CrossRef]

8. Zhou RJ, Xiao JW, Tang XF, Zheng QG, Lv J, Cao JB. Coordinated optimization of carbon utilization between power-to-gas renewable energy accommodation and carbon capture power plant. Electr Power Autom Equip. 2018;38(7):61–7 (In Chinese). doi:10.16081/j.issn.1006-6047.2018.07.008. [Google Scholar] [CrossRef]

9. Zhou RJ, Deng ZA, Xu J, Zhu JS, Wang YZ. Optimized operation using carbon recycling for benefit of virtual power plant with carbon capture and gas thermal power. Electr Power. 2020;53(9):166–71 (In Chinese). doi:10.11930/j.issn.1004-9649.201908007. [Google Scholar] [CrossRef]

10. Sun HJ, Liu Y, Peng CH, Meng JH. Optimization scheduling of virtual power plant with carbon capture and waste incineration considering power-to-gas coordination. Power Syst Technol. 2021;45(9):3534–45 (In Chinese). doi:10.13335/j.1000-3673.pst.2020.1720. [Google Scholar] [CrossRef]

11. Zhang XP, Zhang YZ. Multi-objective optimization model for park-level electricity-heat-gas integrated energy system considering P2G and CCS. Electr Power Constr. 2020;41(12):92–101 (In Chinese). doi:10.12204/j.issn.1000-7229.2020.12.009. [Google Scholar] [CrossRef]

12. Chen BD, Lin KD, Zhang YJ, Chen ZX, Wang J, Su JY. Optimal dispatching of integrated electricity and natural gas energy systems considering the coordination of carbon capture system and power-to-gas. South Power Syst Technol. 2019;13(11):9–17 (In Chinese). doi:10.13648/j.cnki.issn1674-0629.2019.11.002. [Google Scholar] [CrossRef]

13. Tian F, Jia YB, Ren HQ, Bai Y, Huang T. “Source-load” low-carbon economic dispatch of integrated energy system considering carbon capture system. Power Syst Technol. 2020;44(9):3346–55 (In Chinese). doi:10.13335/j.1000-3673.pst.2020.0728. [Google Scholar] [CrossRef]

14. Peng Y, Lou SH, Wu YW, Wang Y, Zhou KP. Low-carbon economic dispatch of power system with wind power considering solvent-storaged carbon capture power plant. Trans China Electrotech Soc. 2021;36(21):4508–16 (In Chinese). doi:10.19595/j.cnki.1000-6753.tces.201249. [Google Scholar] [CrossRef]

15. Zhou RJ, Sun H, Tang XF, Zhang WJ, Yu H. Low-carbon economic dispatch based on virtual power plant made up of carbon capture unit and wind power under double carbon constraint. Proc CSEE. 2018;38(6):1675–83,1904 (In Chinese). doi:10.13334/j.0258-8013.pcsee.170541. [Google Scholar] [CrossRef]

16. Chen HP, Chen JD, Zhang Z, Wang CL, Wang JQ, Han H, et al. Low-carbon economic dispatching of power system considering capture energy consumption of carbon capture power plants with flexible operation mode. Electr Power Autom Equip. 2021;41(9):133–9 (In Chinese). doi:10.16081/j.epae.202109040. [Google Scholar] [CrossRef]

17. Ma Y, Wang H, Hong F, Yang J, Chen Z, Cui H, et al. Modeling and optimization of combined heat and power with power-to-gas and carbon capture system in integrated energy system. Energy. 2021;236(5):121392. doi:10.1016/j.energy.2021.121392. [Google Scholar] [CrossRef]

18. Wang S, Wang S, Zhao Q, Dong S, Li H. Optimal dispatch of integrated energy station considering carbon capture and hydrogen demand. Energy. 2023;269(1):126981. doi:10.1016/j.energy.2023.126981. [Google Scholar] [CrossRef]

19. Jin J, Wen Q, Cheng S, Qiu Y, Zhang X, Guo X. Optimization of carbon emission reduction paths in the low-carbon power dispatching process. Renew Energy. 2022;188(12):425–36. doi:10.1016/j.renene.2022.02.054. [Google Scholar] [CrossRef]

20. Sun Q, Wang X, Liu Z, Mirsaeidi S, He J, Pei W. Multi-agent energy management optimization for integrated energy systems under the energy and carbon co-trading market. Appl Energy. 2022;324(5):119646. doi:10.1016/j.apenergy.2022.119646. [Google Scholar] [CrossRef]

21. Liu D, Luo Z, Qin J, Wang H, Wang G, Li Z, et al. Low-carbon dispatch of multi-district integrated energy systems considering carbon emission trading and green certificate trading. Renew Energy. 2023;218:119312. doi:10.1016/j.renene.2023.119312. [Google Scholar] [CrossRef]

22. Yang M, Liu Y. Research on multi-energy collaborative operation optimization of integrated energy system considering carbon trading and demand response. Energy. 2023;283:129117. doi:10.1016/j.energy.2023.129117. [Google Scholar] [CrossRef]

23. Aseri TK, Sharma C, Kandpal TC. A techno-economic appraisal of parabolic trough collector and central tower receiver based solar thermal power plants in India: effect of nominal capacity and hours of thermal energy storage. J Energy Storage. 2022;48:103976. doi:10.1016/j.est.2022.103976. [Google Scholar] [CrossRef]

24. Praveen RP, Chandra Mouli KVV. Performance enhancement of parabolic trough collector solar thermal power plants with thermal energy storage capability. Ain Shams Eng J. 2022;13(5):101716. doi:10.1016/j.asej.2022.101716. [Google Scholar] [CrossRef]

25. Wei S, Liang X, Mohsin T, Wu X, Li Y. A simplified dynamic model of integrated parabolic trough concentrating solar power plants: modeling and validation. Appl Therm Eng. 2020; 169:114982. doi:10.1016/j.applthermaleng.2020.114982. [Google Scholar] [CrossRef]

26. Cui Y, Yu S, Wang X, Fu G, Wang M. Optimal configuration of heat storage capacity considering the balance between system peak shaving demand and concentrating solar power plant revenue. Proc of the CSEE. 2023; 43(228745–56. [Google Scholar]

27. Wang Y, Lou S, Wu Y, Wang S. Co-allocation of solar field and thermal energy storage for CSP plants in wind-integrated power system. IET Renew Power Gener. 2018; 12(14):1668–74. doi:10.1049/iet-rpg.2018.5224. [Google Scholar] [CrossRef]

28. Du E, Zhang N, Hodge BM, Wang Q, Kang C, Kroposki B, et al. The role of concentrating solar power toward high renewable energy penetrated power systems. IEEE Trans Power Syst. 2018;33(6):6630–41. doi:10.1109/TPWRS.2018.2834461. [Google Scholar] [CrossRef]

29. Chen R, Sun H, Guo Q, Li Z, Deng T, Wu W, et al. Reducing generation uncertainty by integrating CSP with wind power: an adaptive robust optimization-based analysis. IEEE Trans Sustain Energy. 2015;6(2):583–94. doi:10.1109/TSTE.2015.2396971. [Google Scholar] [CrossRef]

30. Du E, Zhang N, Hodge BM, Kang C, Kroposki B, Xia Q. Economic justification of concentrating solar power in high renewable energy penetrated power systems. Appl Energy. 2018;222(2):649–61. doi:10.1016/j.apenergy.2018.03.161. [Google Scholar] [CrossRef]

31. Jorgenson J, Denholm P, Mehos M. Estimating the value of utility-scale solar technologies in California under a 40% renewable portfolio standard. Golden CO: National Renewable Energy Laboratory; 2014. [Google Scholar]

32. Guevara E, Babonneau F, Homem-de-Mello T, Moret S. A machine learning and distributionally robust optimization framework for strategic energy planning under uncertainty. Appl Energy. 2020;271(2):115005. doi:10.1016/j.apenergy.2020.115005. [Google Scholar] [CrossRef]

33. Chen Y, Chen C, Ma J, Qiu W, Liu S, Lin Z, et al. Multi-objective optimization strategy of multi-sources power system operation based on fuzzy chance constraint programming and improved analytic hierarchy process. Energy Rep. 2021;7(5):268–74. doi:10.1016/j.egyr.2021.01.070. [Google Scholar] [CrossRef]

34. Li GQ, Li XT, Bian J, Li ZH. Two level scheduling strategy for inter-provincial DC power grid considering the uncertainty of PV-load prediction. Proc CSEE. 2021;41(14):4763–76 (In Chinese). doi:10.13334/j.0258-8013.pcsee.200763. [Google Scholar] [CrossRef]

35. Chen JM, Xu Q, Li Y, Yu XW, Chen WC. Optimal dispatch of electricity-natural gas interconnection system considering source-load uncertainty and virtual power plant with carbon capture. Acta Energiae Solaris Sin. 2023;44(10):9–18 (In Chinese). doi:10.19912/j.0254-0096.tynxb.2022-0840. [Google Scholar] [CrossRef]

36. Salehi J, Namvar A, Gazijahani FS. Scenario-based Co-Optimization of neighboring multi carrier smart buildings under demand response exchange. J Clean Prod. 2019;235(4):1483–98. doi:10.1016/j.jclepro.2019.07.068. [Google Scholar] [CrossRef]

37. Yao JM, Zhao SQ, Wei ZY, Zhang H. Day-ahead dispatch and its fast solution method of power system based on scenario analysis. Electr Power Autom Equip. 2022;42(9):102–10 (In Chinese). doi:10.16081/j.epae.202204022. [Google Scholar] [CrossRef]

38. Lü HP, Xiwang A, Meng LP. Two-stage stochastic optimal scheduling of microgrid considering uncertainty of source-load forecasting. Electr Power Autom Equip. 2022;42(9):70–8 (In Chinese). [Google Scholar]

39. Zhang M, Wang JH, Chang X, Yang CY, Li R, Sun CW, et al. Multi-objective robust planning method for heat-electricity coupled micro energy system considering uncertainty of renewable energy. Electric Power China. 2021;54(4):119–129, 140 (In Chinese). [Google Scholar]

40. Lei D, Zhang Z, Wang Z, Zhang L, Liao W. Long-term, multi-stage low-carbon planning model of electricity-gas-heat integrated energy system considering ladder-type carbon trading mechanism and CCS. Energy. 2023;280(9):128113. doi:10.1016/j.energy.2023.128113. [Google Scholar] [CrossRef]

41. Chen M, Lu H, Chang X, Liao H. An optimization on an integrated energy system of combined heat and power, carbon capture system and power to gas by considering flexible load. Energy. 2023;273(4):127203. doi:10.1016/j.energy.2023.127203. [Google Scholar] [CrossRef]

42. He L, Lu Z, Zhang J, Geng L, Zhao H, Li X. Low-carbon economic dispatch for electricity and natural gas systems considering carbon capture systems and power-to-gas. Appl Energy. 2018;224(4):357–70. doi:10.1016/j.apenergy.2018.04.119. [Google Scholar] [CrossRef]

43. Yun Y, Zhang D, Yang S, Li Y, Yan J. Low-carbon optimal dispatch of integrated energy system considering the operation of oxy-fuel combustion coupled with power-to-gas and hydrogen-doped gas equipment. Energy. 2023;283(6):129127. doi:10.1016/j.energy.2023.129127. [Google Scholar] [CrossRef]

44. Liang RH, Liao JH. A fuzzy-optimization approach for generation scheduling with wind and solar energy systems. IEEE Trans Power Syst. 2007;22(4):1665–74. doi:10.1109/TPWRS.2007.907527. [Google Scholar] [CrossRef]

45. Chen HY, Chen JF, Duan XZ. Fuzzy modeling and optimization algorithm on dynamic economic dispatch in wind power integrated system. Autom Electr Power Syst. 2006;30(2):22–6 (In Chinese). [Google Scholar]

46. Sun CY. Research on the unit commitment problem with large-scale wind power based on credibility theory. Beijing, China: North China Electric Power University; 2011. [Google Scholar]

47. Zhang DH, Yuan YY, Wang XJ, He JH, Dong HY. Economic dispatch of integrated electricity-heat-gas energy system considering generalized energy storage and concentrating solar power plant. Autom Electr Power Syst. 2021;45(19):33–42 (In Chinese). doi:10.7500/AEPS20210220002. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools