Open Access

Open Access

ARTICLE

Influence of Fracturing Fluid Properties on the Frictional Coefficient of Shale Rock and Hydraulic Fracture Length

1 Changqing Downhole Liquid Laboratory, Chuanqing Drilling Engineering Co., Ltd., CNPC, Xi’an, 710016, China

2 State Key Laboratory of Petroleum Resources and Engineering, China University of Petroleum (Beijing), Beijing, 102249, China

* Corresponding Author: Wei Yan. Email:

Energy Engineering 2025, 122(5), 1823-1837. https://doi.org/10.32604/ee.2025.062199

Received 12 December 2024; Accepted 10 March 2025; Issue published 25 April 2025

Abstract

This study investigated the micro-sliding frictional behavior of shale in fracturing fluids under varying operational conditions using Chang 7 shale oil reservoir core samples. Through systematic micro-sliding friction experiments, the characteristics and governing mechanisms of shale friction were elucidated. Complementary analyses were conducted to characterize the mineral composition, petrophysical properties, and micromorphology of the shale samples, providing insights into the relationship between microscopic structure and frictional response. In this paper, the characteristics and variation law of shale micro-sliding friction under different types of graphite materials as additives in LGF-80 (Low-damage Guar Fluid) oil flooding recoverable fracturing fluid system were mainly studied. In addition, the finite element numerical simulation experiment of hydraulic fracturing was adopted to study the influence of the friction coefficient of natural fracture surfaces on fracture propagation and formation of the fracture network. The geometric complexity of fracture networks was systematically quantified under varying frictional coefficients of natural fracture surfaces through multi-parametric characterization and morphometric analysis. The research results show that graphite micro-particles reduce friction and drag. Based on this, this paper proposes a new idea of graphite micro-particles as an additive in the LGF-80 oil flooding recoverable fracturing fluid system to reduce friction on the fracture surface.Keywords

Shale reservoirs represent a critical class of unconventional hydrocarbon systems, serving as globally significant sources of tight oil and shale gas resources [1,2]. Hydraulic fracturing, especially volume Fracturing, is one of the important technologies in shale oil production and has been studied deeply by scholars and experts [3]. Volume fracturing is a critical mechanism in unconventional reservoir stimulation, wherein hydraulic fractures interact dynamically with pre-existing natural fractures. This process triggers shear slippage along natural fracture surfaces due to induced stress perturbations, while simultaneously promoting fracture propagation aligned with the natural fracture orientations. The synergistic effects of these mechanisms facilitate the development of interconnected fracture networks characterized by multi-scale branching and cross-cutting fracture geometries, ultimately enhancing reservoir contact area and hydrocarbon drainage efficiency [4–6]. In essence, the shear slip phenomenon of natural fractures in shale oil reservoirs is the process of sliding friction during hydraulic fracturing, Friction resistance, roughness and waviness of sliding friction surface, mineral composition of friction rock sample, sliding displacement distance, the pore structure of sliding friction, temperature, positive pressure and liquid properties of sliding friction surface all affect the sliding friction characteristics of rock [7–10].

Numerous studies have investigated the influence of different factors on the frictional sliding of shale. Significant progress has been made in the study of the multiscale influences on the frictional properties of rocks, focusing on three key dimensions: mineral fraction, surface morphology, and fluid environment. Regarding mineralogical controls, Clay minerals have a significant effect on the coefficient of friction of rock. In response to this factor, Morrow et al. [11] have measured the frictional sliding behavior of pure montmorillonite, mixed montmorillonite/illite and pure illite as a function of effective pressure, Additionally, Tembe et al. [12] conducted a series of triaxial compression tests, They found that, in all cases, frictional strengths of mixtures fall between the end members of pure quartz (strongest) and clay (weakest), the overall trend was a decrease in strength with increasing clay content. Zhang [13] conducted micro friction experiments on various types of granite, basalt, sandstone, and limestone, mainly studying the influence of rock composition on the sliding friction characteristics of rocks. Ramana [14] also studied the influence of clay minerals in fault gouge on rock friction coefficient. Hang et al. [15] studied the influence of mineral composition on the tribomechanical properties of rock from macroscopic and microscopic perspectives, and established the relationship between them. It provides a theoretical basis for revealing the mechanism of cross-scale friction mechanics.

In the field of surface morphology, scholars have conducted extensive research. By developing a set of experimental devices for rock microfriction slip, Barton et al. [16] has established a mechanical model of rock microfriction properties based on the existing model from a microscopic point of view. Through integrated theoretical analysis and experimental investigations, Wang et al. [17] systematically characterized the shear behavior of rock discontinuities, culminating in the development of the JRC-JCS empirical model. Xia [18] studied the separation method of waviness and roughness of rock surfaces.

In terms of sliding friction surface liquid properties, Zhu et al. [19] and Zheng [20] established the coupled model of seepage damage in fractured rock mass, Zhao [21] developed the multi-field coupling theory of seepage damage fracture, which laid a mechanical foundation for understanding the evolution of friction behavior under fluid pressure. In terms of experimental research, Qi et al. [22] systematically revealed the chemical mechanismof the regulation of drag reducer components on rock friction, and Horn et al. [23] studied the frictional properties of various rock components in different fluid environments. Moore et al. [24] further investigated the variation characteristics of sliding friction of various silicate minerals under different water content on this basis. Liu et al. [25] analyzed the mechanical and frictional properties of shale under soaking conditions, and their experimental results showed that the shale friction coefficient decreased with increasing soaking time, and the shale friction coefficient decreased significantly within 6 h of soaking and then tended to be stable. Zhang et al. [26] and Xiao et al. [27] studied the friction characteristics of shale in contact with dry quartz sand and alumina respectively. Current research on shale micro-sliding frictional behavior remains limited, particularly regarding the influence of particulate-laden media (e.g., quartz particles) at fracture interfaces. Existing studies predominantly focus on quartz-dominated systems, leaving critical gaps in understanding multiphase particle effects, interfacial chemo-mechanical coupling, and scale-dependent friction mechanisms under realistic reservoir conditions.

This paper will combine the above research results, through sliding friction tests on shale specimens, investigates the micro-sliding friction behavior of shale in fracturing fluid systems containing graphite additives, with focused examination of LGF-80 oil displacement can be the recovery of the fracturing fluid system in different conditions (base environment, drag reduction agent proportion, and graphite material type) under the micro sliding friction characteristics and change the law of shale to the complex medium environment for the future study, especially under the condition of different types of particles shale micro sliding friction feature provides new thought.

2.1 Experimental Materials and Setup

The experimental material is mainly composed of shale friction samples with mineral components and formulations of fluid with three types of graphite materials (60–80 mesh graphite ball, 80–100 mesh graphite ball, and 100 mesh graphite sheet).

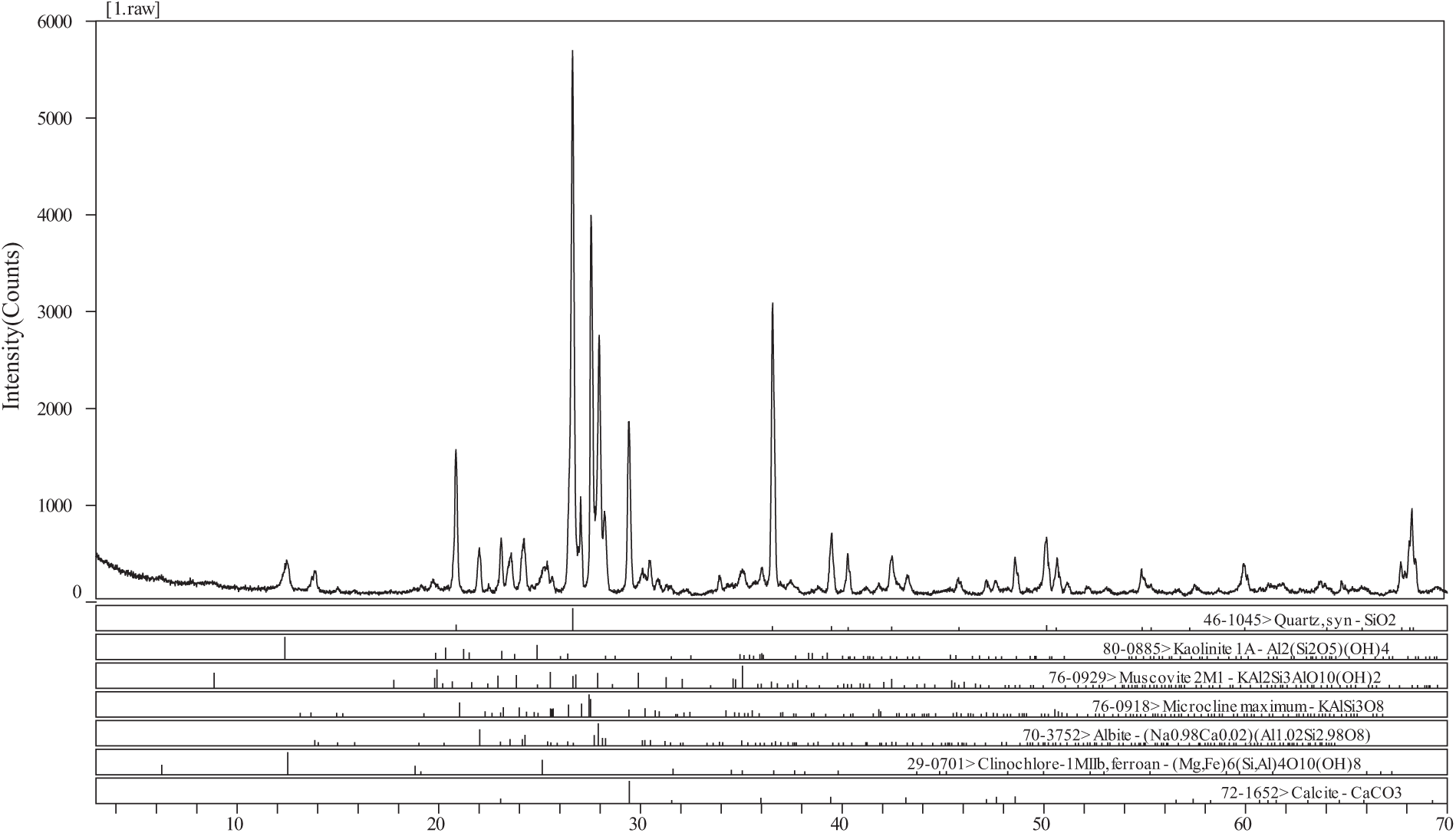

This experimental study used an X-ray polycrystalline diffractometer to identify and analyze common phases. X-rays have specific diffraction directions and intensities for powder solids with different conformations and crystal forms, known as characteristic diffraction spectra, which can effectively determine the phases present in the material. Crush the shale sample with a hammer and collect the powder for X-ray Diffraction (XRD) testing. Compare the X-ray diffraction pattern (position, number, and relative peak intensity) of the shale sample with the standard diffraction pattern of the known phase in the card library to qualitatively analyze the phase composition of the shale sample, as shown in Fig. 1.

Figure 1: X-ray diffractometer

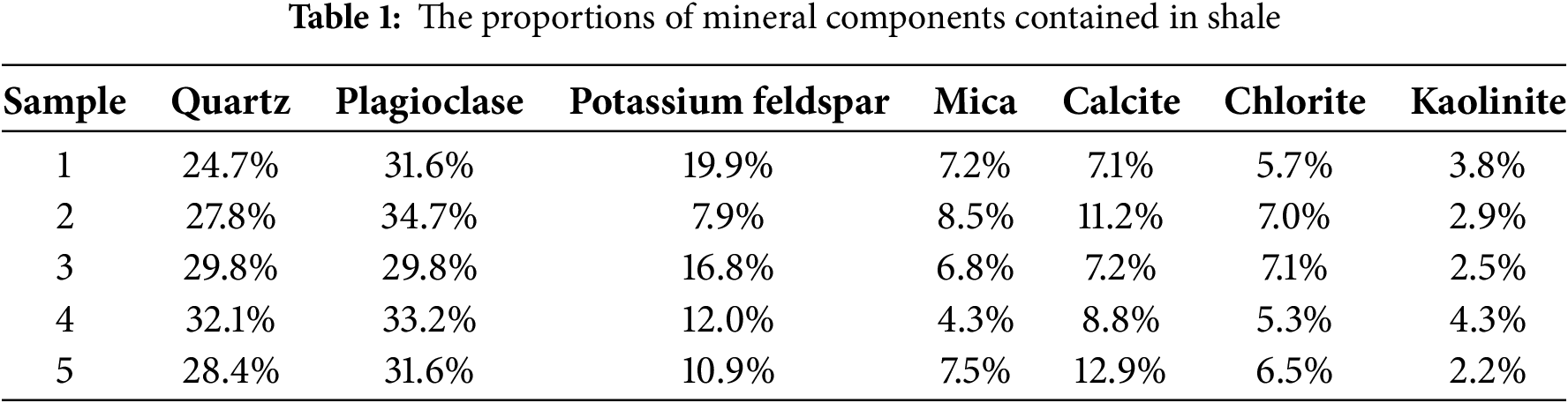

The types and proportions of clay, quartz, and feldspar components of the shale sample are shown in Fig. 2 and Table 1. A comprehensive analysis of the experimental results shows that the shale of the target reservoir contains a large proportion of hard grain minerals, about 81.10%. The proportion of clay minerals is small, about 18.90%.

Figure 2: Types of mineral components contained in shale

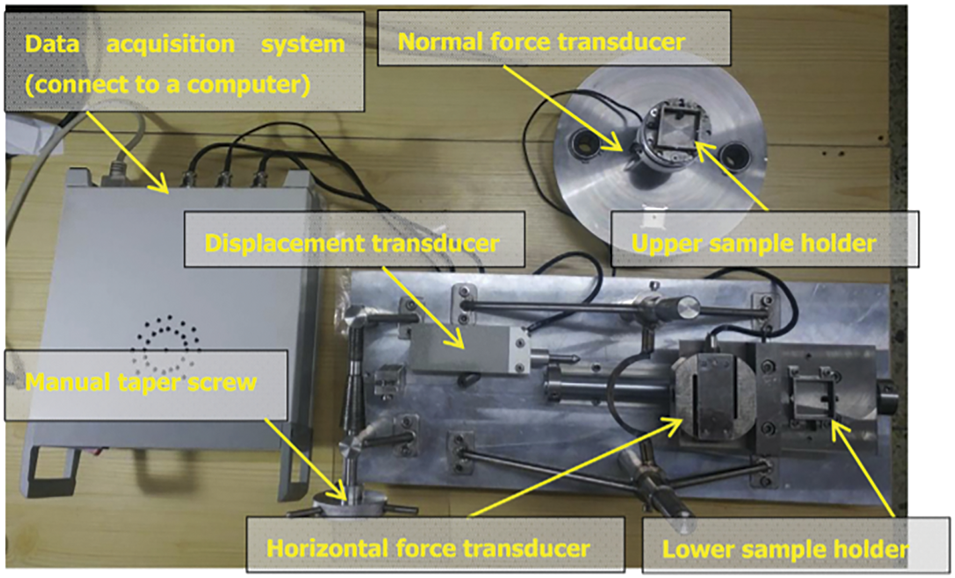

The base fluids selected for this fluid system are clean water and salt water (simulated formation water). The fluid environments are shown in Table 2, and the simulated formation water concentration is configured as follows. The fluid formulations are 0.6% XYZC-6 and 0.6% XYTJ-3. The saltwater contains 2.0% KCl, 5.5% NaCl, 0.45% MgCl2, and 0.55% CaCl2, and then diluted by 10%. The additives include a drag reducer (XYJZ-1), graphite ball, and 100 mesh graphite sheet. And the proportion of drag reducer is 0.5%, 1.0%, and 1.5%.

In addition, 60–80 mesh graphite balls can be aggregated into visible particles in the liquid used for friction experiments. 80–100 mesh graphite balls and 100 mesh graphite sheets can be well dissolved in the liquid and form suspension. Considering the large size of 60–80 mesh graphite balls, it is easy to float on the liquid surface due to the influence of liquid surface tension. In the liquid stirring process, the graphite balls floating on the liquid surface then gather together, resulting in visible particles.

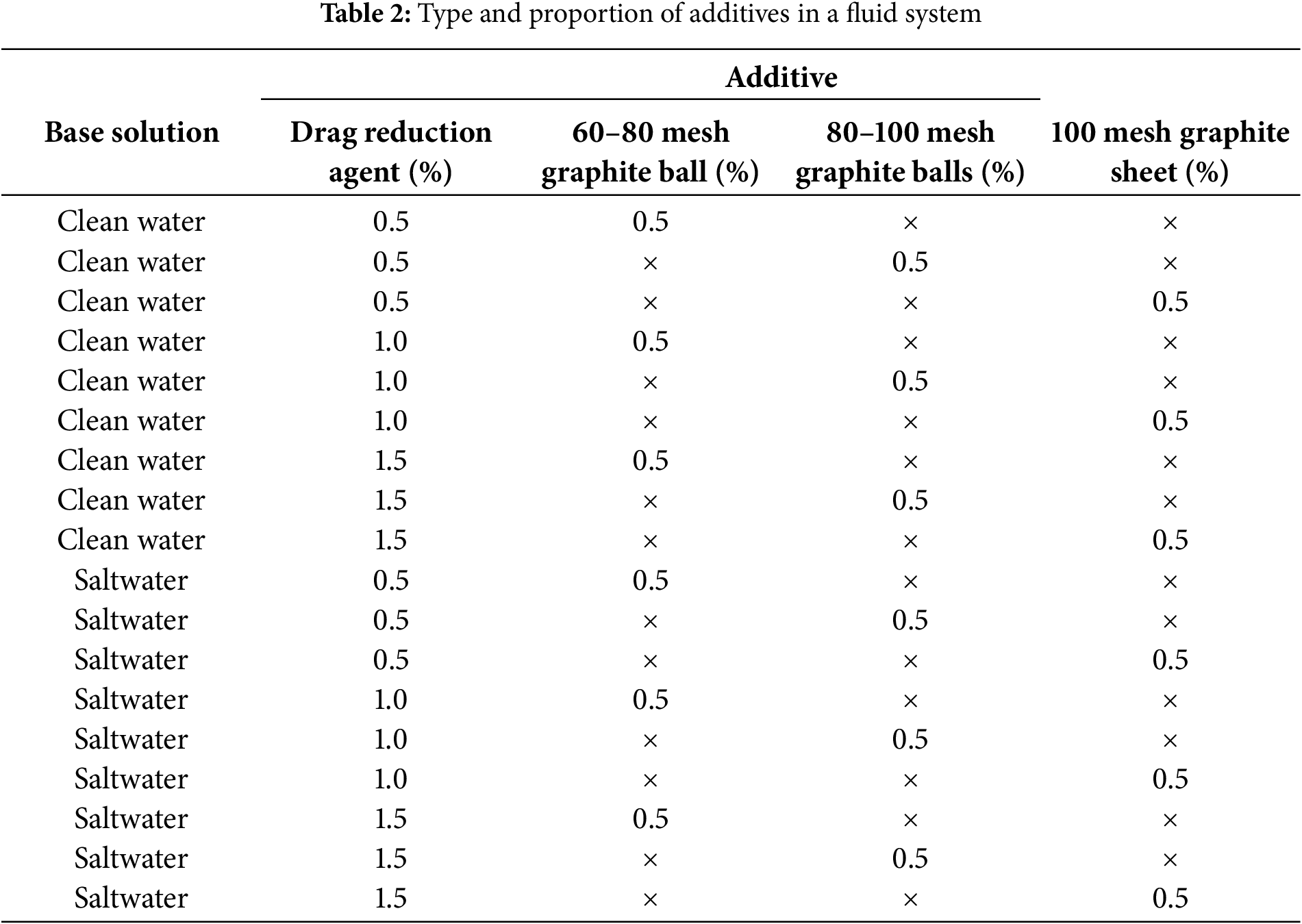

To obtain high precision test results (horizontal force and normal force of 1 N, horizontal displacement of 2.0 μm), by referring to Tember’s experimental investigation into the impact of clay minerals on the rock friction coefficient, a capable of measuring rock friction characteristics has been engineered, with its schematic representation provided in Fig. 3 (Tembe et al., 2010). The device consists of a manual taper screw, flexible steel rope, horizontal force transducer, normal force transducer, upper and lower sample slots, leveling mechanism, liquid pool, displacement transducer, data acquisition, isolation platform, and computer. Place the samples separately in the upper and lower sample holder, and the drag force was applied by a manual taper screw, and the drag force, displacement, and normal pressure (force) were measured using a data acquisition system, that was connected to a computer, and recorded automatically.

Figure 3: New developed rock friction tester system

2.2 Experimental Process and Result Analysis

Cut the rock sample into a 2 × 2 × 3 cm cuboid. Use the wire-cutting method to split the two blocks of 2 × 2 × 1.5 cm along the center of the rock long axis, and then use the new rock friction tester system to test the friction coefficient changes of each sample in different environments.

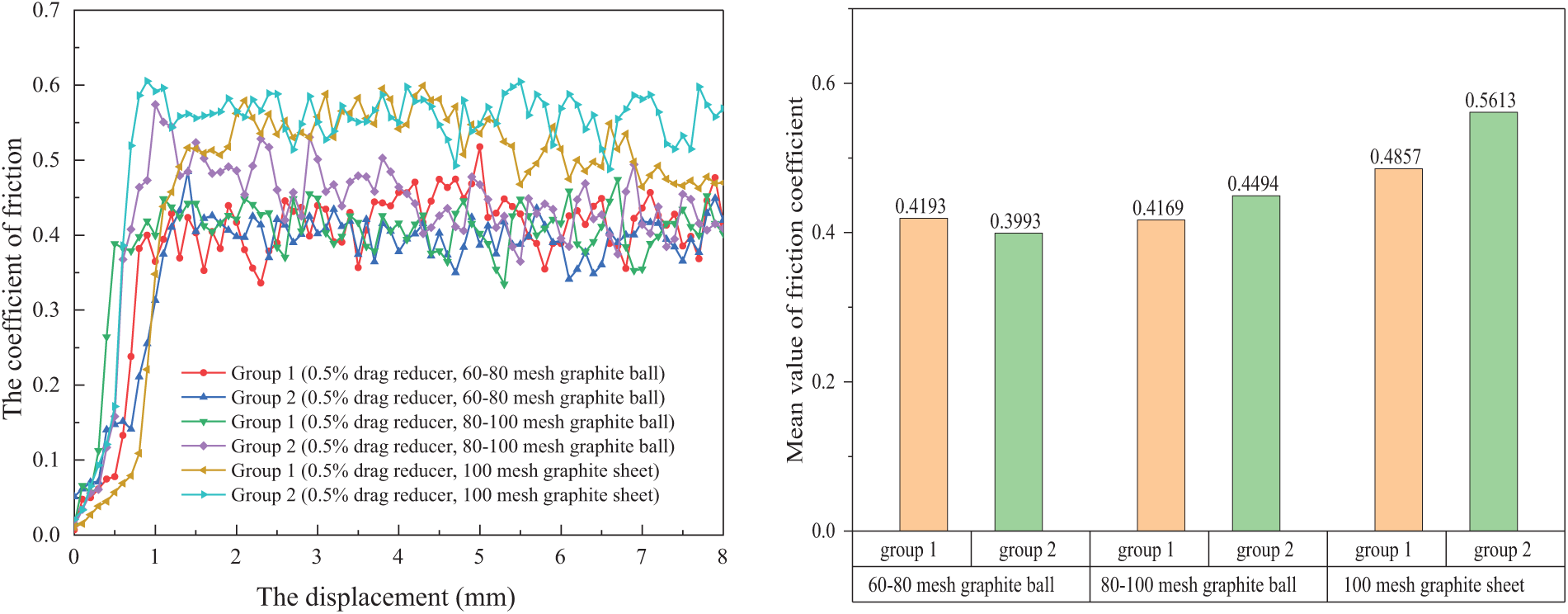

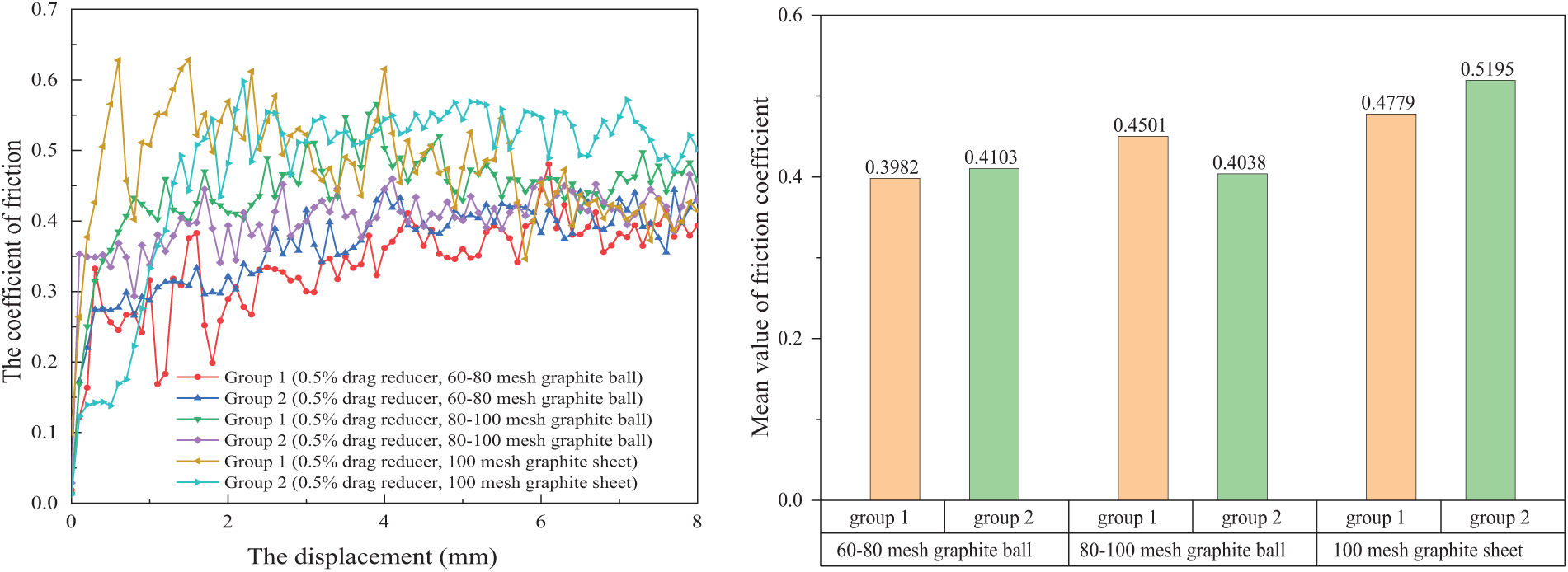

2.2.1 Effect of Different Graphite Additives on Friction Coefficient of Shale When the Ratio of Drag Reducer in Clear-Water Based Liquid Is 0.5%

When the proportion of drag reducer is 0.5% and graphite material is 60–80 mesh graphite ball, 80–100 mesh graphite ball, and 100 mesh graphite sheet, the micro-friction experimental results of the shale rock sample are shown in Fig. 4. To reduce the error, two groups of experiments were conducted on different graphite materials. The effect of 100 mesh graphite on reducing the friction coefficient in the shale fracture surface is not ideal, and the average friction coefficient of the shale sample is 0.5235. The effect of the two kinds of graphite balls on reducing the friction coefficient of the shale fracture surface is similar, and the average friction coefficient of 60~80 mesh graphite balls is 0.4093. The average friction coefficient is 0.4482 when the graphite sphere is 80~100 mesh.

Figure 4: Microfraction test results of six groups of shale samples under these conditions

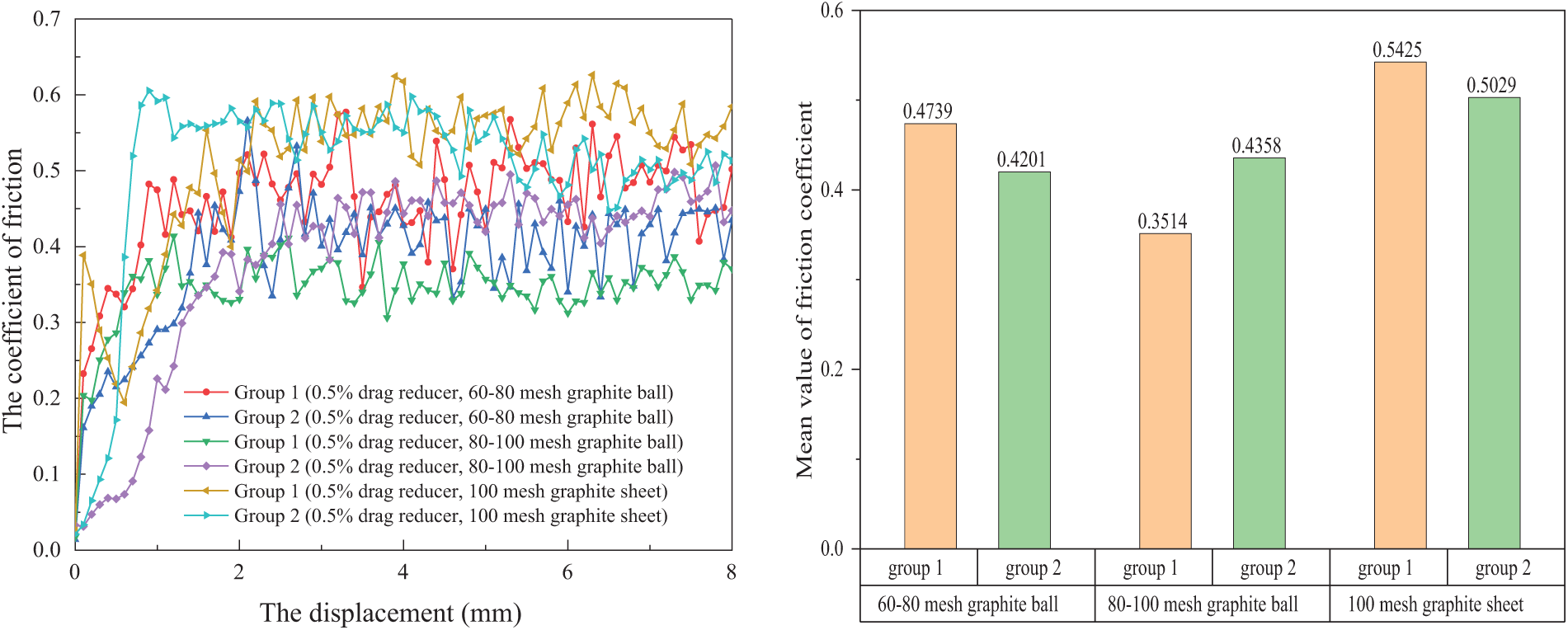

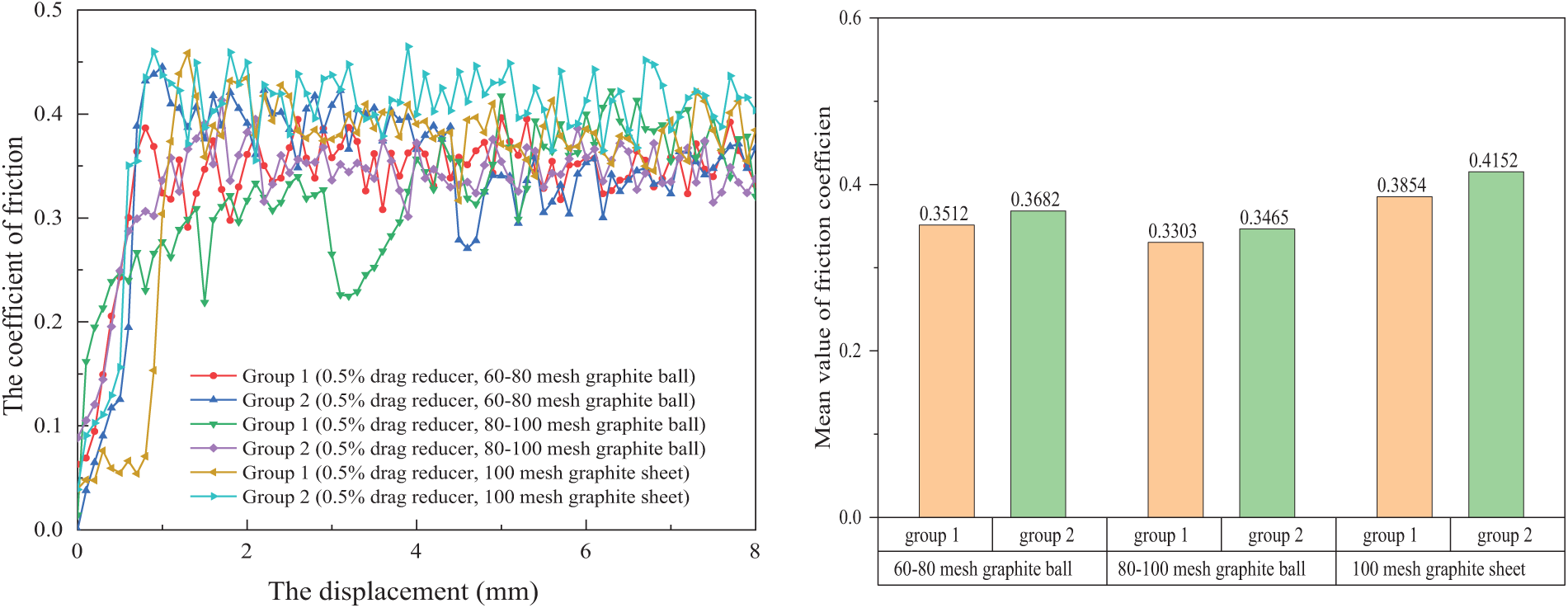

2.2.2 Effect of Different Graphite Additives on Friction Coefficient of Shale When the Ratio of Drag Reducer in Clear-Water-Based Liquid Is 1.0%

When the proportion of the drag reducer is 1.0% and the graphite material is 60–80 mesh graphite ball, 80–100 mesh graphite ball, and 100 mesh graphite sheet, respectively, the micro-friction experimental results of the shale sample are shown in Fig. 5. To reduce the error, two groups of experiments were conducted on different graphite materials, and a total of six groups of experimental results were obtained. The average friction coefficient of shale samples is 0.5227. The two kinds of graphite balls have similar effects on reducing the friction coefficient of shale samples. The average friction coefficient is 0.4470 under the condition of 60–80 mesh graphite balls. The average friction coefficient is 0.3936 under the condition of 80~100 mesh graphite spheres.

Figure 5: Microfraction test results of six groups of shale samples under these conditions

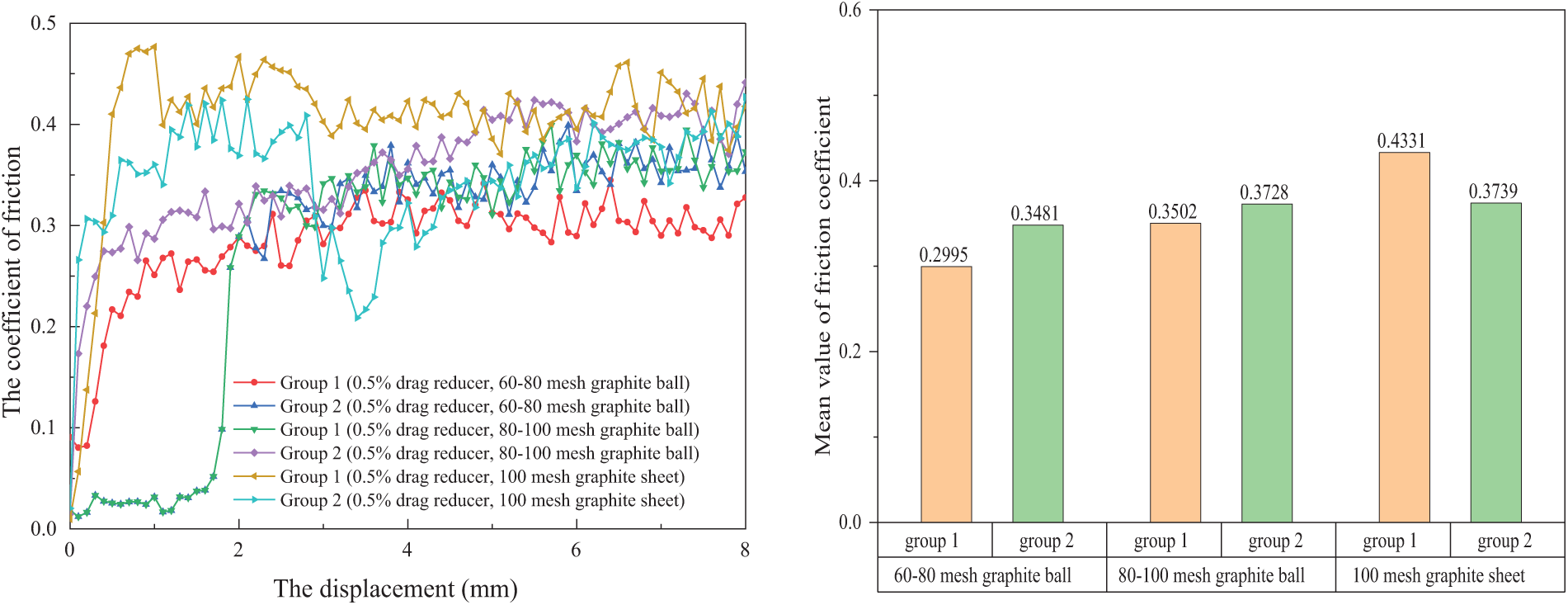

2.2.3 Effect of Different Graphite Additives on Friction Coefficient of Shale When the Ratio of Drag Reducer in Clear-Water-Based Liquid Is 1.5%

Under the condition that the proportion of the drag reducer is 1.5% and the graphite material is 60–80 mesh graphite ball, 80–100 mesh graphite ball, and 100 mesh graphite sheet, the micro-friction experimental results of the shale sample are shown in Fig. 6. To reduce the error, two groups of experiments were conducted on different graphite materials. The friction coefficient of shale samples decreases under different types of graphite materials. Among them, the effect of 100 mesh graphite pieces on reducing the friction coefficient of the fracture surface in shale samples is small, and the average friction coefficient of the shale samples is 0.4035. The effect of the two kinds of graphite balls on reducing the friction coefficient of the fracture surface of tight rock samples is similar. The average friction coefficient is 0.3238 when 60~80 mesh graphite balls are used as additives, and 0.3615 when 80~100 mesh graphite balls are used as additives.

Figure 6: Microfraction test results of six groups of shale samples under these conditions

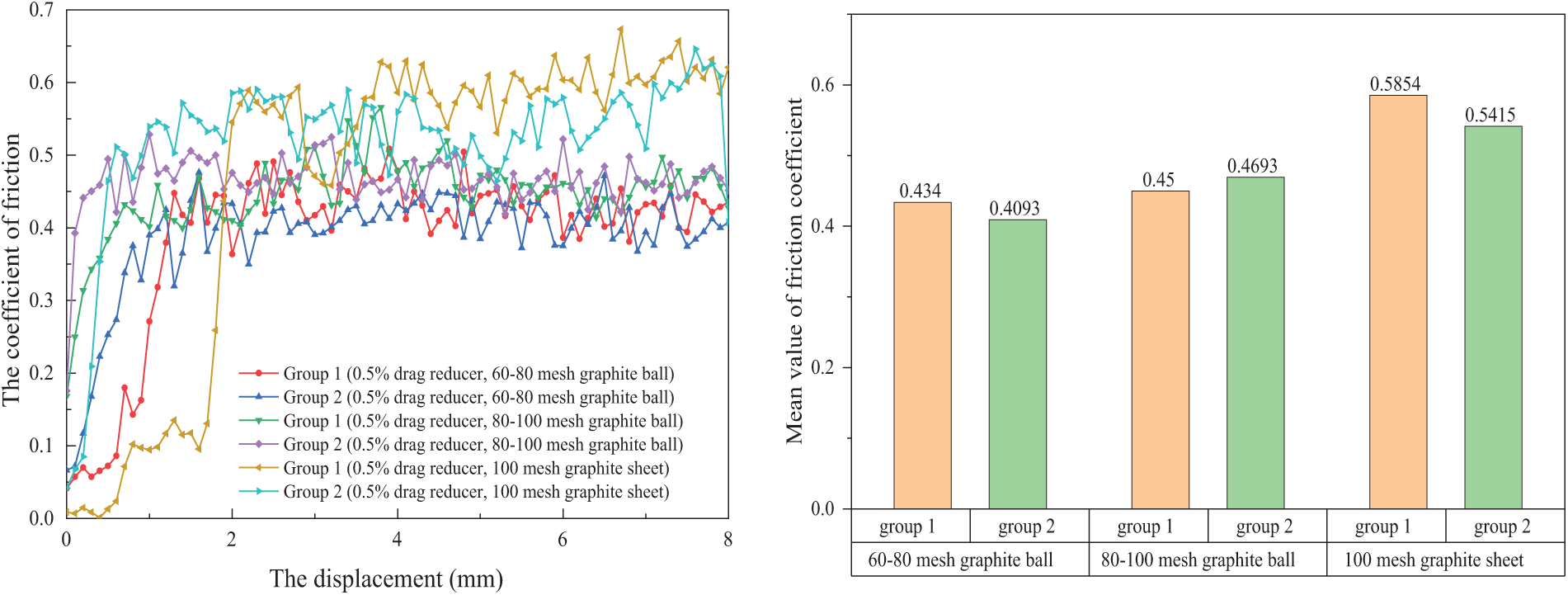

2.2.4 Effect of Different Graphite Additives on Friction Coefficient of Shale When the Ratio of Drag Reducer in Salt-Water-Based Liquid Is 0.5%

When the proportion of drag reducer is 0.5% and graphite material is 60–80 mesh graphite ball, 80–100 mesh graphite ball, and 100 mesh graphite sheet, the micro-friction experimental results of the shale sample are shown in Fig. 7. To reduce error, two groups of experiments were conducted on different graphite materials. The average friction coefficient of shale samples is 0.5653. The two kinds of graphite balls have similar effects on reducing the friction coefficient of shale samples. The average friction coefficient of shale samples is 0.4217 under the condition of 60–80 mesh graphite balls. The average friction coefficient is 0.4597 under the condition of 80–100 mesh graphite spheres.

Figure 7: Microfraction test results of six groups of shale samples under these conditions

2.2.5 Effect of Different Graphite Additives on Friction Coefficient of Shale When the Ratio of Drag Reducer in Salt-Water Based Liquid Is 1.0%

When the proportion of the drag reducer is 1.0% and the graphite material is 60–80 mesh graphite ball, 80–100 mesh graphite ball and 100 mesh graphite sheet, the micro-friction experimental results of the shale sample are shown in Fig. 8. In order to reduce the error, two groups of experiments were conducted on different graphite materials. The average friction coefficient of shale samples is 0.4987. The two kinds of graphite balls have a similar effect on reducing the friction coefficient of shale samples. The average friction coefficient of shale samples is 0.4043 when the graphite balls are 60–80 mesh. The average friction coefficient is 0.4270 for 80~100 mesh graphite spheres.

Figure 8: Microfraction test results of six groups of shale samples under these conditions

2.2.6 Effect of Different Graphite Additives on Friction Coefficient of Shale When the Ratio of Drag Reducer in Salt-Water-Based Liquid Is 1.5%

Under the condition that the proportion of the drag reducer is 1.5% and the graphite material is 60–80 mesh graphite ball, 80–100 mesh graphite ball, and 100 mesh graphite sheet, the micro-friction experimental results of the shale sample are shown in Fig. 9. To reduce the error, two groups of experiments were conducted on different graphite materials. The friction coefficient of shale samples decreases under different types of graphite materials, and the three graphite balls have similar effects on reducing the friction coefficient of the fracture surface in shale samples. The average friction coefficient is 0.3597 under the condition of 60–80 mesh graphite balls as additives, and 0.3384 under the condition of 80–100 mesh graphite balls as additives. The average friction coefficient is 0.4003 when a 100-mesh graphite sheet is used as an additive.

Figure 9: Microfraction test results of six groups of shale samples under these conditions

Through comprehensive analysis of friction test results of shale samples, the following conclusions can be drawn:

Different base fluid components (water and salt water) of the fluid used in the friction experiment have no significant influence on the friction coefficient of the shale sample. Under the condition of different base fluid components and the same other conditions, the friction coefficient of the shale sample has a small difference, the difference is about 0.05.

The drag reduction agent ratio on the shale-friction coefficient has a certain influence, in general, the other under the same conditions of drag reduction agent ratio is higher, the lower the shale friction coefficient, which when the drag reducer ratio increases from 0.5% to 1.0%, the shale sample to reduce friction coefficient is not obvious, but when the drag reduction agent increased to 1.5%, The friction coefficient of the shale sample decreases obviously.

The type of graphite material has a certain effect on the friction coefficient of shale samples. In general, the drag reduction effect of a graphite ball is better than that of a graphite sheet. There is no obvious difference between the drag reduction effect of 60–80 mesh graphite ball and 80–100 mesh graphite ball, and the drag reduction effect of 100 mesh graphite ball is poor.

3 Numerical Simulation Experiment Process and Result Analysis

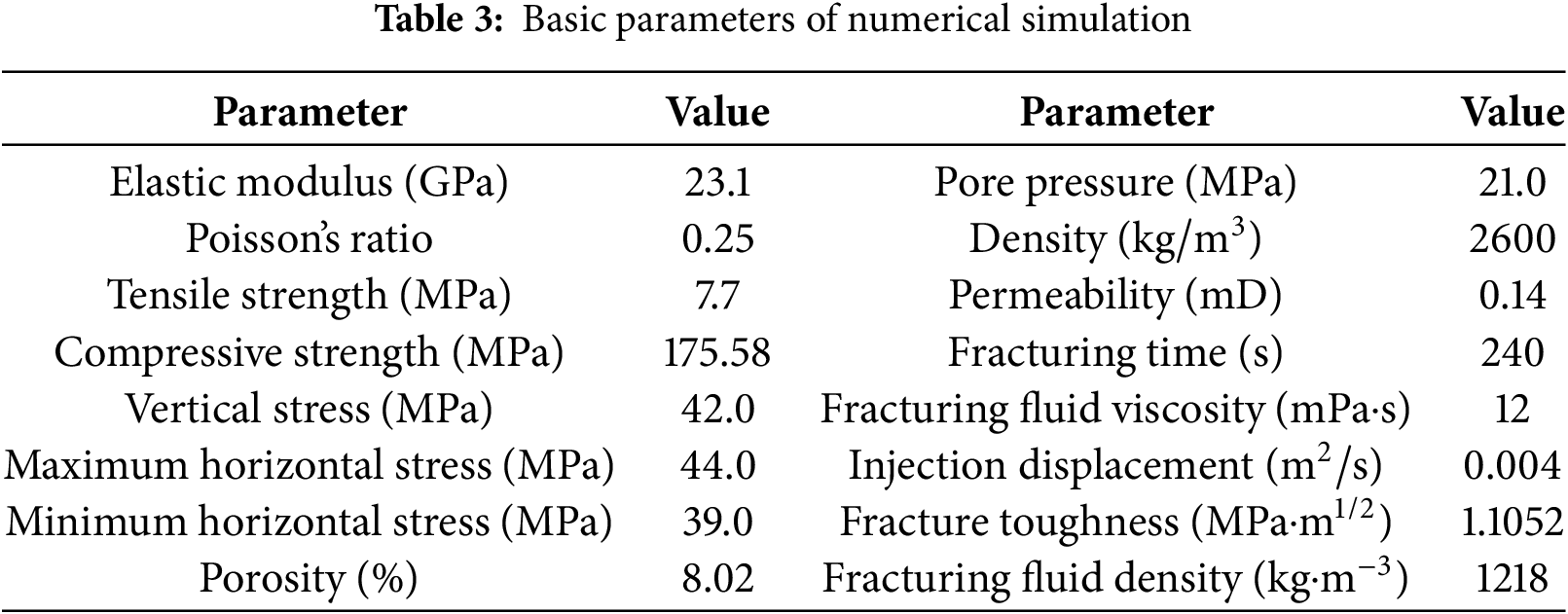

3.1 Numerical Simulation Test Flow

In the aforementioned experiment, we examined how fracturing fluid performance affects the friction coefficient under various conditions, including the base environment, drag-reducing agent ratio, and graphite material type. In this section, we will undertake numerical simulation experiments to investigate the impact of varying friction coefficients on the length of hydraulic fracturing fractures. The details of the poroelastic-fracture-propagation model refer to the mathematical model of Ouchi [28]. This model simultaneously solves the three governing equations for mechanics, porous flow, and fracture flow. The key input parameters for computational modeling were derived from field measurements conducted at the site, as documented in Table 3. Utilizing the cohesive zone modeling capabilities within ABAQUS finite element platform, a planar geological profile spanning 40 m in both horizontal and vertical dimensions was successfully established, with the geometric configuration illustrated in Fig. 10.

Figure 10: Schematic of the 2D stratigraphic model

In this model, the injection point is placed at the center, with 30 natural cracks of 6 m and 20 natural cracks of 4 m arranged symmetrically on either side of the injection point. A triangular meshing technique is used, resulting in a total of 3558 triangular elements and 5257 interface elements. The model is subject to boundary conditions of fixed displacement and impermeability.

3.2 Numerical Simulation Test Results Analysis

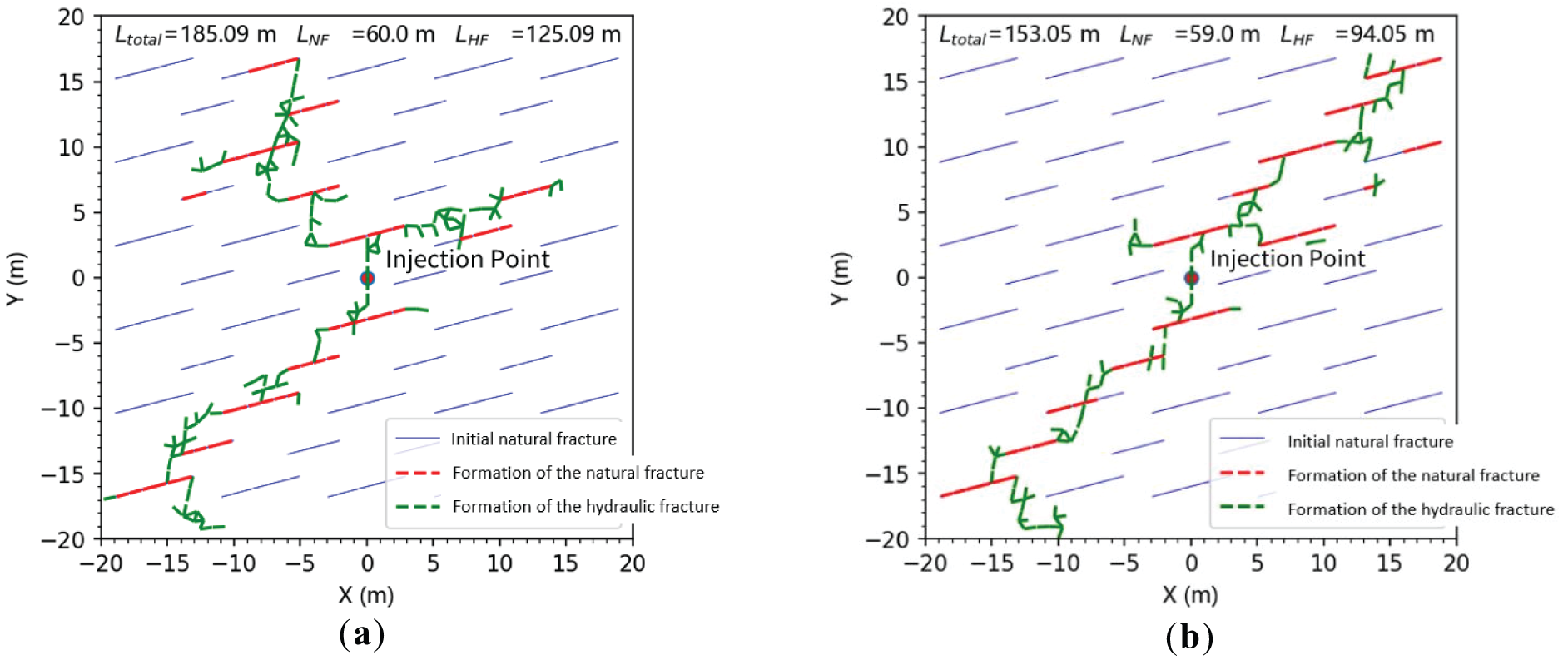

This numerical simulation study systematically investigates the influence of natural fracture interface friction variations (0.3, 0.35, 0.4, 0.45, 0.5, 0.6) on crack extension characteristics. The experimental results are shown in Fig. 11.

Figure 11: Crack propagation under different friction coefficients. (a)

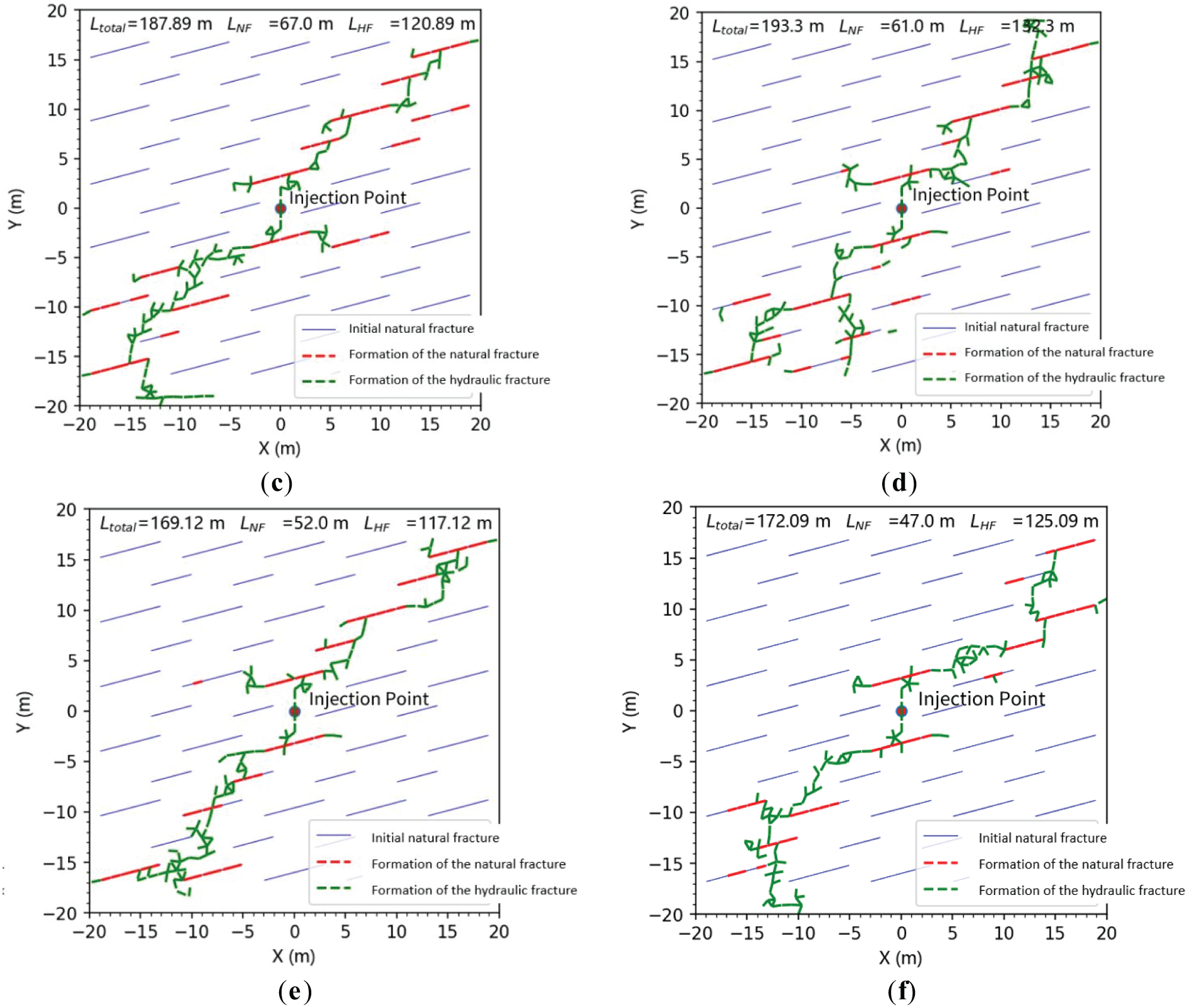

In Fig. 12, the fracture lengths of numerical simulation results under different friction coefficients of natural fracture surfaces are statistically analyzed. In general, with the increase of friction coefficients, the total fracture lengths first increase and then decrease, and when the friction coefficient of natural fracture surfaces is 0.45, the longest fracture lengths are 193.3 m. As the friction coefficient increases, the length of the natural fracture surface increases first and then decreases. When the coefficient is 0.4, the longest length of the natural fracture surface is 67 m. With the increase of coefficient, the length of hydraulic fracture is stable.

Figure 12: Fracture length under different natural fracture surface friction coefficients

The results of numerical simulation of fracture propagation under different friction coefficients can be summarized as follows:

When the friction coefficient is small, the total fracture length is long and the fracture network complexity is large; When the friction coefficient is larger, the total length of the fracture is shorter and the complexity of the fracture network is smaller. When the friction coefficient is 0.45, the natural fracture length is the longest.

In this paper, micro-friction experiments of shale under different liquid environments and numerical simulation experiments under different friction coefficients were carried out. Received target shale reservoir in different base fluid (water and saltwater) and drag reduction agent proportions (0.5%, 1.0% and 1.5%), and different graphite material types (60~80 mesh graphite ball, 80~100 mesh graphite and 100 mesh flake graphite) under the condition of friction coefficient change law and the target reservoir in the conditions of different natural fracture surface friction coefficient when working conditions on-site. According to the numerical simulation test results under different friction coefficients, when the friction coefficient of the natural fracture surface is in the range of 0.4~0.45, the complexity of the fracture network formed by the interaction between hydraulic fractures and natural fractures is the highest under the hydraulic fracturing operation and geomechanical conditions of the target reservoir.

Based on the above research and analysis, the main conclusions can be drawn as follows:

The results of shale micro-friction experiments under different liquid environments show that: (1) Different base fluid components (water and salt water) have no significant influence on the friction coefficient of shale samples; (2) When the proportion of drag reducer increases from 0.5% to 1.0%, the friction coefficient of the shale sample does not decrease significantly; when the proportion of drag reducer increases to 1.5%, the friction coefficient of the shale sample decreases significantly; (3) There is no obvious difference in drag reduction effect between 60–80 mesh graphite balls and 80–100 mesh graphite balls, and the drag reduction effect of 100 mesh graphite balls is poor; (4) The dissolution effect of 60–80 mesh graphite balls in the liquid used for the friction experiment is poor, and they tend to aggregate into visible particles and float on the upper surface of the liquid. 80–100 mesh graphite balls and 100 mesh graphite sheets can be well dissolved in the liquid and form suspension. Combined with the experimental results of shale micro-friction under different liquid environments and the numerical simulation results under different friction coefficients, it can be seen that in the LGF-80 oil displacement recoverable fracturing fluid system, when the graphite material additives are 60~80 mesh graphite balls or 80~100 mesh graphite balls and the proportion of drag reducer is 0.5%~1.0%, the friction coefficient of the target reservoir is in the range of 0.40~0.45.

Under this condition, the fracture network complexity formed by hydraulic fracturing of the target reservoir is also the highest. However, 60–80 mesh graphite balls are easy to float on the solution surface and aggregate into particles, while 80~100 mesh graphite balls are easy to form a suspension. Therefore, it is more suitable to select 80~100 mesh graphite ball as graphite material additive in the LGF-80 oil displacement recoverable fracturing fluid system.

Acknowledgement: The authors gratefully acknowledge the support from Chuanqing Drilling Engineering Co., Ltd. for this research.

Funding Statement: The authors received no specific funding for this study.

Author Contributions: The authors confirm contribution to the paper as follows: experimental design and program conceptualization: Yining Zhou, Chen Zhang; data collection: Jingru Zhang, Bowen Yun, Rui Tan, Wei Yan; experiment: Tao Wu, Yufeng Li, Jingru Zhang; numerical simulation: Yining Zhou, Chen Zhang, Wei Yan; analysis and interpretation of results: Yining Zhou, Yufeng Li, Tao Wu; draft manuscript preparation: Yining Zhou, Yufeng Li, Chen Zhang. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: The authors confirm that the data supporting the findings of this study are available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

References

1. Li QH, Li SX, Liu JK, Wen H. Rock mechanical properties of deep shale-gas reservior and their effects on reservoir stimulation. In: The 55th U.S. Rock Mechanics/Geomechanics Symposium; 2021 Jun 18–25; Virtual. [Google Scholar]

2. Zhang YQ, Xia Y, Fu SH, Zhang YZ. The experimental investigation of rock mechanical characteristics of coal measure shale reservoir. In: The 55th U.S. Rock Mechanics/Geomechanics Symposium; 2021 Jun 18–25; Virtual. [Google Scholar]

3. Fu YR. Development status and prospect of shale gas in China. Pet Geol Eng. 2013;27(6):19–22. doi:10.3969/j.issn.1673-8217.2013.06.006. [Google Scholar] [CrossRef]

4. Chen Z, Xue CJ, Jiang TX, Qin YM. Suggestions on the application of volumetric fracturing technology in shale gas wells in China. Nat Gas Ind. 2010;30(10):30–2. doi:10.3787/j.issn.1000-0976.2010.10.007. [Google Scholar] [CrossRef]

5. Ning WX, He B, Li FX, Xie LZ, Shi AP, He Q. Experiment on hydraulic fracture morphology of continental shale oil reservoir. Sci Technol Eng. 2021;21(18):7505–12. doi:10.3969/j.issn.1671-1815.2021.18.015. [Google Scholar] [CrossRef]

6. Wu Q, Xu Y, Wang X, Wang T, Zhang S. Volume fracturing technology of unconventional reservoirs: connotation, design optimization and implementation. Petrol Explor Dev. 2012;39(3):377–84. doi:10.1016/S1876-3804(12)60054-8. [Google Scholar] [CrossRef]

7. Yu J, Wang J, Li Y, El-Fayoumi A, Wu R, Liu X, et al. Permeability-friction relationships for propped fractures in shale. In: 56th U.S. Rock Mechanics/Geomechanics Symposium; 2022 Jun 26–29; Santa Fe, NM, USA. doi:10.56952/arma-2022-2242. [Google Scholar] [CrossRef]

8. An M, Zhang FS, Elsworth D. HPHT fault gouge friction experiments: implication for hydraulic fracturing induced seismicity in the Sichuan basin. In: The 55th U.S. Rock Mechanics/Geomechanics Symposium; 2021 Jun 18–25; Virtual. [Google Scholar]

9. Seyed Ghafouri SMH, Aboayanah KR, Abdelaziz A, Grasselli G. Numerical investigation of the influence of bedding plane thickness and friction on cracking pattern and mechanical behavior of shale under unconfined loading condition using the finite-discrete element method (FDEM). In: 56th U.S. Rock Mechanics/Geomechanics Symposium; 2022 Jun 26–29; Santa Fe, NM, USA. doi:10.56952/arma-2022-0310. [Google Scholar] [CrossRef]

10. Luo H, Shi X, Gou Q, Zhang D, Zhang F, Cui L. Friction-stability-permeability relationship of Longmaxi shale fractures from the southern Sichuan basin, southwest China. In: 56th U.S. Rock Mechanics/Geomechanics Symposium; 2022 Jun 26–29; Santa Fe, NM, USA. doi:10.56952/arma-2022-0202. [Google Scholar] [CrossRef]

11. Morrow C, Radney B, Byerlee J. Frictional strength and the effective pressure law of montmorillonite and lllite clays. Int Geophys. 1992;51(14):69–88. doi:10.1016/S0074-6142(08)62815-6. [Google Scholar] [CrossRef]

12. Tembe S, Lockner DA, Wong TF. Effect of clay content and mineralogy on frictional sliding behavior of simulated gouges: binary and ternary mixtures of quartz, illite, and montmorillonite. J Geophys Res. 2010;115(B3):2009JB006383. doi:10.1029/2009JB006383. [Google Scholar] [CrossRef]

13. Zhang L. Experimental study on frictional slip characteristics of fault rock in Longmenshan Fault zone under hydrothermal condition [dissertation]. Beijing, China: Institute of Geology, China Earthquake Administration; 2013. [Google Scholar]

14. Ramana YV, Gogte BS. Dependence of coefficient of sliding friction in rocks on lithology and mineral characteristics. Eng Geol. 1989;26(3):271–9. doi:10.1016/0013-7952(89)90014-8. [Google Scholar] [CrossRef]

15. Hang M, Lv MY, Wu YW, Liu D, Zhang H, He ZH. Study on the correlation between rock’s mineral compositions and macro-micro friction properties. Chin J Rock Mech Eng. 2025;44:1–11. [Google Scholar]

16. Barton N, Choubey V. The shear strength of rock joints in theory and practice. Rock Mech. 1977;10(1):1–54. doi:10.1007/BF01261801. [Google Scholar] [CrossRef]

17. Wang JB. Study on frictional sliding characteristics of fracture surface in shale reservoir [dissertation]. Beijing, China: China University of Petroleum; 2016. [Google Scholar]

18. Xia CC. Waviness characteristics and mechanical effects of rock discontinuity surface topography. J Tongji Univ. 1993;21(3):371–7. [Google Scholar]

19. Zhu ZD, Sun J. Coupling model of seepage field and damaging field of fractured rock mass and its application. J Yangtze River Sci Res Inst. 1999;16(5):22–7. doi:10.3969/j.issn.1001-5485.1999.05.006. [Google Scholar] [CrossRef]

20. Zheng SH. Study and application of coupling theory of seepage field-damage field in fractured rock mass [dissertation]. Wuhan, China: Institute of Rock and Soil Mechanics, Chinese Academy of Sciences; 2000. p. 56–74. doi:10.3321/j.issn:1000-6915.2001.03.038. [Google Scholar] [CrossRef]

21. Zhao YL. Seepage damage-fracture coupling theory and its application in fractured rock mass [dissertation]. Changsha, China: Central South University; 2009. [Google Scholar]

22. Qi Z, Huang T, Kalgaonkar R, AlGhunaimi F. A novel and cost-effective dry friction reducer based slickwater for unconventional reservoir stimulation. In: SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition; 2023 Oct 10–12; Jakarta, Indonesia. doi:10.2118/215263-ms. [Google Scholar] [CrossRef]

23. Horn HM, Deere DU. Frictional characteristics of minerals. Géotechnique. 1962;12(4):319–35. doi:10.1680/geot.1962.12.4.319. [Google Scholar] [CrossRef]

24. Moore DE, Lockner DA. Friction of the smectite clay montmorillonite. Seism Zone Subduction Thrust Faults. 2007;11:317–45. doi:10.7312/dixo13866-011. [Google Scholar] [CrossRef]

25. Liu PL, Li J, Lian W, Xi Y, Liu XB, Wang D. Experiments on mechanics and friction characteristics of shale under soaking conditions. Fault-Block Oil Gas Field. 2024;31(4):734–9. doi:10.6056/dkyqt202404022. [Google Scholar] [CrossRef]

26. Zhang H, Liu S, Xiao H. Sliding friction of shale rock on dry quartz sand particles. Friction. 2019;7(4):307–15. doi:10.1007/s40544-018-0213-y. [Google Scholar] [CrossRef]

27. Xiao H, Liu S, Wang D. Tribological properties of sliding shale rock-alumina contact in hydraulic fracturing. Tribol Lett. 2019;62(2):1–9. doi:10.1007/s11249-016-0667-x. [Google Scholar] [CrossRef]

28. Ouchi H, Katiyar A, Foster JT, Sharma MM. A peridynamics model for the propagation of hydraulic fractures in naturally fractured reservoirs. SPE J. 2017;22(4):1082–102. doi:10.2118/173361-PA. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools