Open Access

Open Access

ARTICLE

The Influence of Water-Polymer Co-Flooding on the Development Effect of Oil Reservoirs

1 National Key Laboratory for Efficient Development of Offshore Oil and Gas, Beijing, 100028, China

2 CNOOC Research Institute Co., Ltd., Beijing, 100027, China

3 Research Institute of Petroleum Exploration and Development of Changqing Oilfield Company, CNPC, Xi’an, 710018, China

4 College of Petroleum Engineering, Yangtze University, Wuhan, 430100, China

* Corresponding Author: Yaguang Qu. Email:

(This article belongs to the Special Issue: Integrated Geology-Engineering Simulation and Optimizationfor Unconventional Oil and Gas Reservoirs)

Energy Engineering 2025, 122(6), 2337-2354. https://doi.org/10.32604/ee.2025.062530

Received 20 December 2024; Accepted 11 April 2025; Issue published 29 May 2025

Abstract

The J oilfield in the Bohai has a long development history and has undergone comprehensive adjustment measures, including water injection and polymer injection. Following these adjustments, the injection and production well network now features coexistence of both polymer injection wells and water injection wells, which has negatively impacted production dynamics. Firstly, based on the adjusted reservoir well network in the J oilfield, a representative water-polymer co-injection well network was established. Subsequently, a numerical simulation model of this typical reservoir unit was developed using reservoir numerical simulation methods to confirm the interference issues associated with water-polymer co-injection. Multiple reservoir numerical simulation models were designed to investigate various factors influencing water-polymer interference, resulting in graphical representations of each factor’s impact under different conditions. Finally, gray relational analysis was employed to rank the influence of these factors, yielding the following order of significance: polymer concentration, the ratio of drainage distance to well spacing, horizontal permeability variation, interlayer permeability variation, and intralayer permeability variation. This understanding provides robust guidance for future adjustments in the oilfield.Keywords

Water flooding continues to be one of the predominant techniques for oil field development, accounting for a significant portion of global oil production. However, as water flooding advances and reaches a high water-cut phase, daily fluid production escalates markedly, resulting in an increased water cut at the wellhead and a gradual reduction in the economic returns from water flooding [1–4]. This issue is particularly pronounced in offshore oil fields, where late-stage water flooding yields elevated daily fluid production while platform liquid processing capabilities are constrained. Without platform upgrades, total fluid output from the field necessitates regulation. Consequently, the efficacy of water flooding is inherently limited. To mitigate this, pilot tests of polymer flooding have been conducted in select reservoirs within the offshore Bohai oil fields of China, characterized by favorable physical properties and continuous sand body distributions. Early results from polymer flooding indicate substantial incremental oil recovery, establishing it as a critical supporting technology for the efficient development of Chinese offshore oil fields [5–9].

The integration of water flooding and polymer flooding can produce excellent outcomes for offshore reservoirs with desirable physical attributes and continuous sand body formations. The implementation of simultaneous water and polymer flooding technology effectively enhances oil recovery and production in offshore oil fields. In this approach, water flooding facilitates crude oil flow, while the addition of polymers improves the oil-water relative permeability differential, thereby boosting oil recovery efficiency. Experimental and field studies have demonstrated significant incremental production benefits from the simultaneous application of water and polymer flooding in the development of offshore oil fields [10,11]. Moreover, this methodology can reduce formation pressure and enhance reservoir fluid mobility, thereby augmenting the efficacy of water injection and oil extraction. By judiciously adjusting the injection parameters for water and polymers, superior channeling effects can be achieved, leading to an increase in the effective flow area of the reservoir and a reduction in lateral mixing between water and oil, ultimately improving oil recovery rates [12]. Tavakkoli et al. (2022) provided a thorough examination of the utilization of simultaneous water and polymer flooding technology to enhance the efficiency of offshore oil field development, detailing the mechanisms, influencing factors, and applicable scenarios [13]. Han et al. (2022) conducted a case study on the practical implementation of polymer flooding in contemporary offshore oil fields, investigating the feasibility and effectiveness of simultaneous water and polymer flooding technology in these environments. Their findings indicate that this technology can markedly enhance oil field recovery and production, suggesting promising application potential [14]. Khanifar et al. (2020) optimized the development strategy for simultaneous water and polymer flooding through reservoir numerical simulation utilizing commercial software CMG. By simulating various injection schemes and parameter combinations, they derived the optimal development plan for offshore oil fields in Malaysia [15]. Nonetheless, numerous challenges persist in addressing issues related to simultaneous water and polymer flooding in offshore oil fields.

In the initial development stage, the J oil field in Bohai employed a water flooding strategy using a counter nine-spot well pattern. Eight years after production commenced, the field transitioned to polymer flooding. After fifteen years of production, comprehensive infill adjustments were implemented, changing from the original counter nine-spot well pattern to a staggered line-drive well pattern. However, the dense positioning of polymer injection wells during these infill adjustments led to interference between water flooding and polymer flooding, resulting in suboptimal production outcomes [16–18]. Due to the complex nature of this issue, reservoir engineering research addressing it has been relatively limited. Moreover, the developmental approach for offshore oil fields differs significantly from that of onshore fields. Given the constrained operational lifespan of offshore platforms, China’s offshore oil fields adopt a high-speed and high-efficiency development model, which imposes specific requirements on oil production rates and platform liquid processing capabilities [19]. Furthermore, expanding the scale of polymer injection in the current field is not feasible, making it impractical to convert water injection wells to polymer injection wells to eliminate interference at this stage. Therefore, to enhance the development effectiveness of the J oil field, it is imperative to conduct in-depth analyses of the geological and developmental factors influencing the effectiveness of concurrent water flooding and polymer flooding [20–24].

Currently, there is no unified understanding of the impact of water-polymer interference on polymer flooding efficiency. Research in the SaBei Development Area of the Daqing Oilfield suggests that simultaneous water and polymer flooding (co-flooding) is feasible. Under the premise of maintaining pressure balance, co-flooding does not affect the efficiency of polymer flooding. This conclusion is based on the challenge of mobilizing low-permeability oil layers in the second category, where water flooding is implemented to achieve effective utilization. However, the research context and reservoir characteristics differ significantly from those of the J oilfield in Bohai.

Therefore, it is necessary to conduct in-depth studies on the interference issues of water-polymer co-flooding to provide technical support for the development plan adjustments in the later stages of polymer flooding in existing development blocks and other offshore oilfields. This study focuses on the reservoir, fluid, and polymer characteristics of the J oilfield. It employs reservoir engineering, dynamic analysis, and numerical simulation to investigate the mechanisms and influencing factors of water-polymer interference during polymer flooding. The results aim to provide technical support for the smooth implementation of polymer flooding schemes in Bohai and to ensure the effectiveness of oil production enhancement.

2 Water-Polymer Co-Flooding of Oil Reservoir Injection and Production Well Network

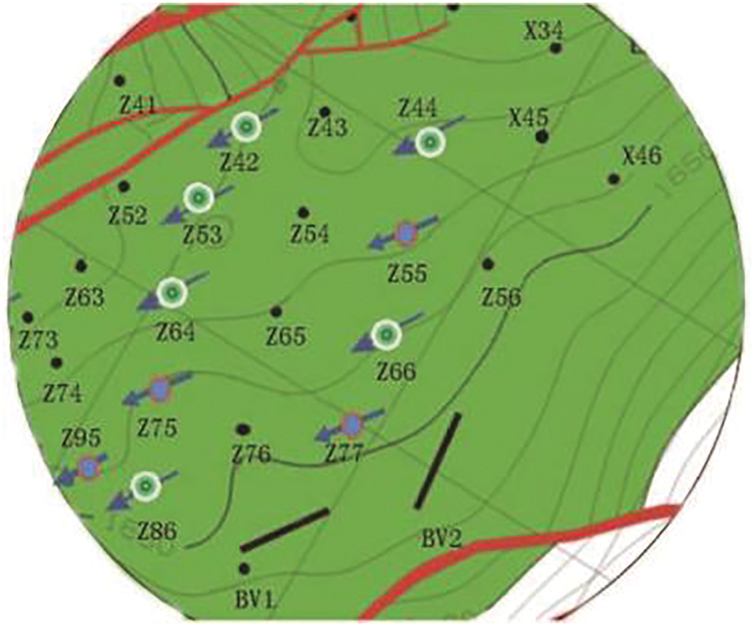

The J oil field reservoir is approximately 1700 m in depth, with an average porosity of about 26%, and an average permeability of about 1200 mD. The underground viscosity of crude oil is about 20 mPa·s. The injected water in the J oilfield and the formation water are fundamentally consistent. The total mineralization of the injected water is 7974.0 mg/L. The oil field is characterized by numerous oil-bearing layers longitudinally, with a significant disparity in permeability, severe heterogeneity, and prominent interlayer and intralayer conflicts. The oil field began production in 1999, transitioned to water injection in 2000, and gradually implemented the well group polymer injection scheme in 2007. This resulted in a noticeable characteristic of water reduction and oil increase, achieving a desirable effect in field application. The original well network of the J oil field was a reverse nine-point well network, with a basic well network consisting of eight water injection wells. These were sequentially transitioned to polymer injection around 2008. In 2016, the well network in this block was adjusted, and 12 additional water wells were drilled sequentially. The well network was adjusted from a reverse nine-point well layout to a row-based well network. However, the adjustment did not achieve the expected production development effect. The previously effective wells showed a significant decrease in fluid and oil production, demonstrating a noticeable phenomenon of polymer water interference. Therefore, it is necessary to conduct research on the issue of polymer water co-driving interference (Fig. 1).

Figure 1: J oilfield polymer injection well group

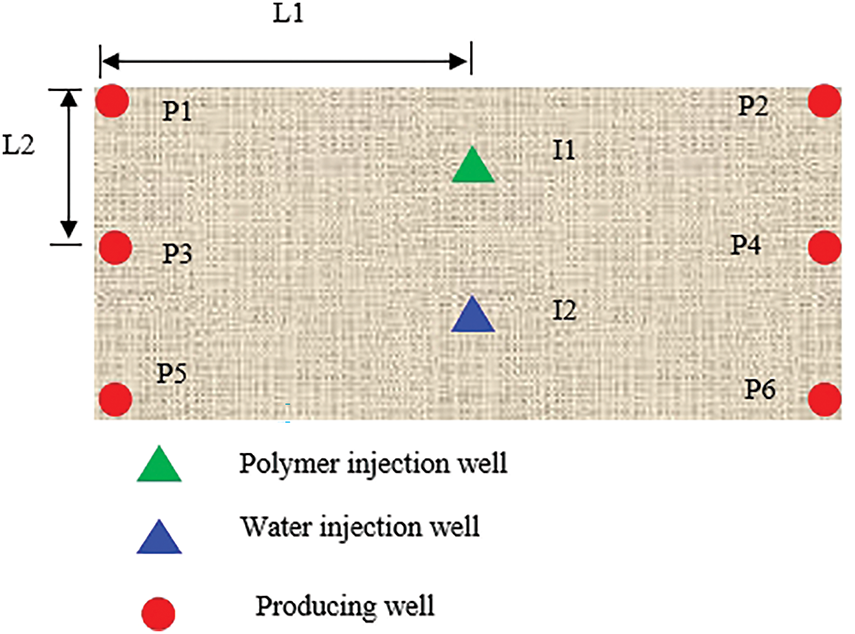

Based on the characteristics of the adjusted injection and production well network in the J oilfield, it can be concluded that the current well network primarily employs a staggered arrangement in a row format, with a ratio of row spacing to well spacing of 2. Consequently, to investigate the impact of water-polymer co-injection on reservoir development effectiveness, it is essential to establish a typical unit for the injection-production well network, as illustrated in Fig. 1. Within this reservoir unit, there are two rows of production wells and one row of injection wells; specifically, this includes one water injection well and one polymer injection well within the injection well row. The production well row comprises three oil wells, resulting in a total of six wells (Fig. 2). This established configuration characterizes a typical reservoir unit that demonstrates water-polymer interference within its plane.

Figure 2: Schematic diagram of injection-production well pattern with water convergence flooding

3 Dynamic Characteristics of the Reservoir under Water and Polymer Injection Interference

3.1 The Main Mechanism of Enhanced Oil Recovery by Polymer Flooding

Polymer flooding is a crucial tertiary oil recovery technology that primarily enhances waterflooding efficiency by injecting high-molecular-weight polymer solutions, thereby improving oil reservoir recovery. Its main mechanisms mainly include the following aspects.

3.1.1 Improving Mobility Ratio and Expanding Sweep Volume

During conventional water flooding, the viscosity of water is significantly lower than that of crude oil, which easily leads to the “fingering” phenomenon. This results in premature water breakthrough and low sweep efficiency.Polymer solutions significantly increase the viscosity of injected water while reducing aqueous phase mobility. Polymer molecules adsorbed on porous media surfaces or retained in pore throats decrease water phase permeability. The reduced mobility ratio promotes more uniform advancement of the displacement front, mitigates viscous fingering, and expands vertical and areal sweep efficiency.

3.1.2 Enhancing Viscoelasticity of Displacing Fluid

The viscoelastic properties of polymer solutions generate normal stresses during extensional deformation in pores. This viscoelastic behavior enables the fluid to detach or “pull” residual oil droplets adhering to rock surfaces, thereby improving microscopic displacement efficiency.

3.1.3 Improving Interface Characteristics

The use of polymers can alter the oil-water interfacial tension, making it easier for oil droplets to detach from the rock surface and enter the flowing phase. This effect of reducing interfacial tension aids in better oil flow.

3.1.4 Optimizing Injection Profile and Mitigating Heterogeneity

During water flooding, due to the heterogeneity of the reservoir (such as differences between high-permeability and low-permeability layers), water tends to preferentially enter the high-permeability layers, making it difficult to displace the crude oil in the low-permeability layers. Polymer solutions preferentially enter high-permeability zones, where adsorption or mechanical entrapment creates flow resistance. This resistance diverts subsequent displacing fluids to low-permeability layers, alleviating interlayer conflicts, enhancing utilization of low-permeability regions, and reducing ineffective circulation.

3.1.5 Extending the Effective Duration of Water Flooding

The high viscosity of polymer solutions delays the breakthrough time of the displacing phase, thereby prolonging the stable production period of oil wells. The technology combining polymer flooding with water flooding can effectively suppress the increase in water cut, slow down the rate of production decline, and extend the economic validity period of polymer injection projects.

The essence of polymer flooding lies in mobility control to expand sweep efficiency, combined with viscoelastic effects to improve microscopic displacement, thereby reducing residual oil saturation. Its effectiveness depends on optimal matching between reservoir conditions and polymer systems, making it one of the most cost-efficient enhanced oil recovery technologies. Conventional water flooding requires a large volume of injected water and is limited in terms of recovery efficiency, leading to high development costs. By combining polymer flooding with water flooding, higher recovery rates can be achieved with lower injection volumes, thereby reducing development costs. Reservoirs vary greatly in their physical properties, and a single displacement method is unlikely to be suitable for all types of reservoirs. The combination of polymer flooding and water flooding has strong adaptability and can be applied to a variety of complex conditions, including high-water-cut reservoirs, high-temperature and high-salinity reservoirs, and heterogeneous reservoirs.

3.2 Establishment of a Numerical Simulation Model for Water-Polymer Co-Injection

Numerical simulation of polymer flooding reservoirs is an important tool for the quantitative analysis and prediction of this process. It mainly includes the establishment of reservoir geological models and fluid property models, the construction of mathematical models, numerical discretization methods, and the analysis of simulation processes and results.

Based on the typical water-polymer flooding injection-production well pattern established in Fig. 1, a corresponding reservoir numerical simulation model has been developed. Using the Eclipse software’s polymer flooding module, a typical well group with two injection and six production wells was established to visually simulate and analyze the water-polymer interaction phenomena occurring during the polymer flooding process. Meanwhile, in the reservoir numerical simulation mechanistic model, parameters such as the oil layer thickness, average reservoir permeability, high-pressure physical properties of the reservoir fluids, well spacing and row spacing of the injection and production well pattern unit and the operating regimes of the oil and water wells are all consistent with those of J Oilfield.

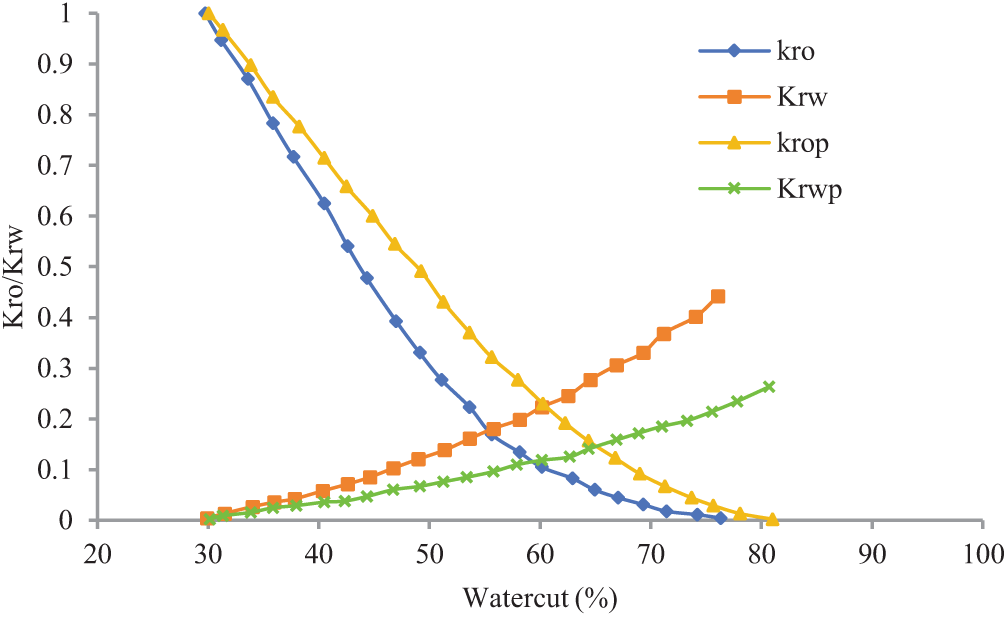

The relative permeability curves and PVT of crude oil used in the reservoir numerical model are derived from the J reservoir, with specific parameters illustrated in Fig. 3. The viscosity of crude oil is 45 mPa·s. The reservoir numerical model maintains consistency with the J reservoir in terms of reservoir thickness, depth, and reservoir properties. Additionally, the well spacing and row spacing in the reservoir units are aligned with the average well pattern parameters of the actual reservoir.

Figure 3: Relative permeability curve between the polymer flooding and water flooding

The reservoir’s three-dimensional geological model is divided into 91 grids in the X direction, 41 grids in the Y direction, and two grids in the Z direction, taking into account the interlayer heterogeneity characteristics of the reservoir. The grid spacing in the X, Y, and Z directions is uniformly set at 10 m, resulting in a reservoir cell dimension of 910 m × 410 m, with a thickness of the oil layer of 20 m. The spacing between injection and production well units is 450 m, while the distance between wells is 200 m. The reservoir model is longitudinally divided into two layers, with horizontal permeabilities of 665 mD and 1335 m, and porosities of 23% and 27%, respectively. The interlayer permeability is 0 mD to ensure no fluid exchange between the two layers.

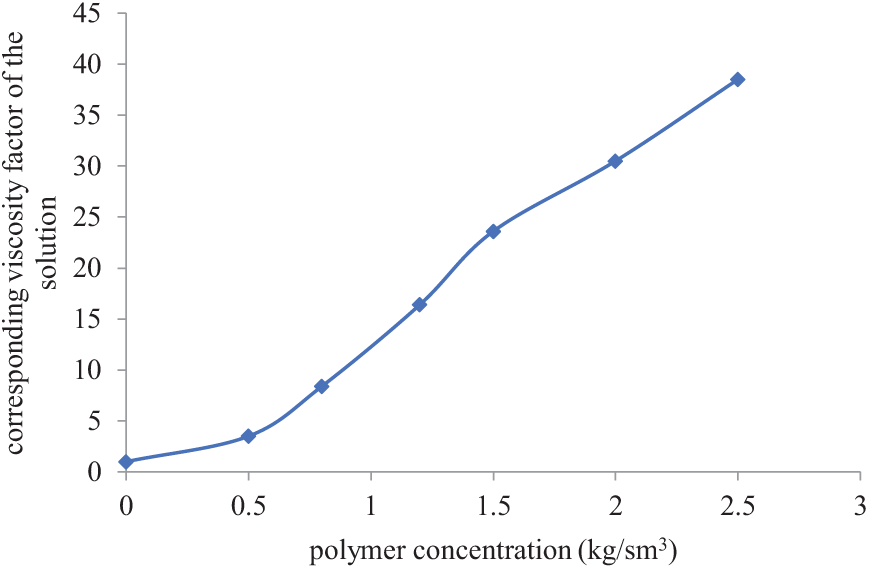

For the J oilfield, the injected polymer is a hydrophobic associative polymer, AP-P4, with an injection polymer concentration of 1200 mg/L. The polymer concentration used in the simulation is based on the field application. The residual resistance factor of the polymer solution is recorded as 2.2, and other characteristic parameters of the polymer are illustrated in Fig. 4. The properties of the injected water are consistent with those of the formation water in the J reservoir.

Figure 4: Polymer solution viscosity function

The mechanisms of polymer flooding include: the change in polymer solution viscosity with polymer concentration; the change in surfactant solution with surfactant concentration; the diffusion phenomena of chemical agent components in the formation flow; the adsorption of chemical agents in the formation changes with the concentration of chemical agent components; consideration of the inaccessible pore volume phenomenon of polymer solution; the permeability reduction phenomenon and residual resistance phenomenon during the polymer flooding process.

The operational regime of the injection wells is characterized by a fixed injection volume, while the production wells maintain a constant bottom-hole flowing pressure. Initially, both injection wells within the reservoir unit are designated as water injection wells; once the comprehensive water cut of the reservoir reaches 80%, one of the water injection wells is converted into a polymer injection well, with a total polymer injection volume of 0.4 PV, after which water is injected until the comprehensive water cut reaches 98%.

3.3 Research on the Mechanism of Water Aggregation-Induced Interference

Based on the established numerical simulation model of a two-layer heterogeneous reservoir, this study thoroughly investigates the cumulative and annual oil production, distribution of oil saturation, recovery factor, and water content variation within the reservoir unit under both water flooding and polymer flooding displacement methods. The primary objective is to comprehensively analyze the displacement and dynamic changes under conditions of water-polymer co-injection interference, shedding light on the complex interactions between these two displacement mechanisms.

The J oil field initially used water injection development. When the water cut of the oil reservoir reached 80%, polymer flooding adjustment was carried out. The cumulative polymer injection volume of the oil reservoir is 0.4 PV. Three simulation scenarios were meticulously designed to explore various aspects of water-polymer co-injection interference Based on the development history of J reservoir:

Scheme 1: Injection wells I1 and I2 are utilized for water injection at a rate of 300 m3/d for the purpose of water flooding until the overall water cut in the reservoir reaches 95%. This scenario serves as a benchmark against which the performance of water flooding alone can be compared, providing valuable insights into the reservoir’s response to water injection.

Scheme 2: Initially, injection wells I1 and I2 are employed for water flooding until an overall water cut of 80% is achieved. Subsequently, well I1 is converted to polymer injection with a total injected volume equivalent to 0.4 pore volumes (PV), followed by additional water flooding until reaching a final overall water cut of 95%. This scenario investigates the impact of polymer injection on reservoir performance when introduced after initial water flooding, examining its potential to enhance oil recovery in conjunction with existing water.

Scheme 3: Similar to Scheme 2, injection wells I1 and I2 undergo initial water flooding until an overall water cut of 80% is attained; thereafter, both wells are simultaneously converted to polymer injection with equal injected volumes of 0.2 PV each (ensuring that the total polymer volume matches that used in Scenario 2). Following this phase, further water flooding occurs until achieving a final overall water cut of 95%. This scenario explores the synergistic effects of simultaneous polymer and water injections, assessing whether their combined application can improve reservoir performance relative to either method applied independently.

Each scenario employs production wells operating under constant bottomhole pressure mode at 16 MPa, ensuring that the results are directly comparable across the different scenarios. The study provides valuable insights into the complex interactions between water and polymer flooding, paving the way for more effective reservoir management strategies in the future.

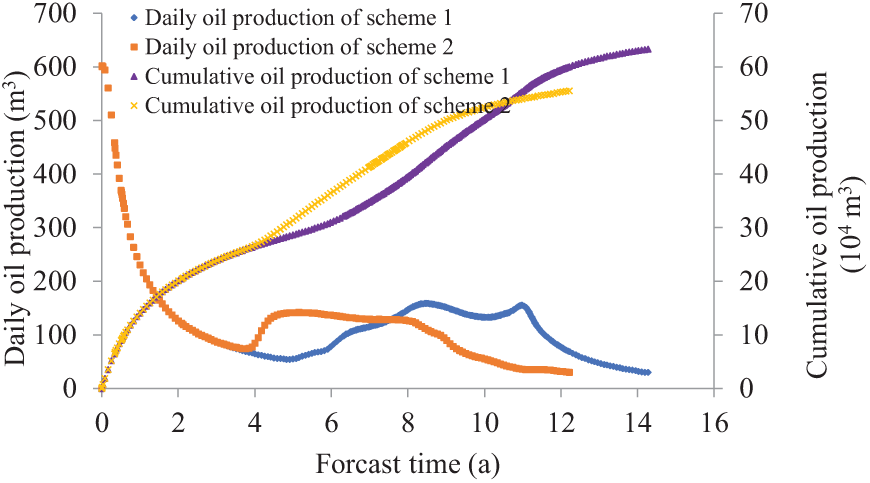

Through reservoir numerical simulation, dynamic indicators for different schemes can be obtained, providing valuable insights into the performance of various oil recovery strategies. Specifically, when the comprehensive water cut in the reservoir block reaches 95%, the cumulative oil production of Scheme 2 and Scheme 3 polymer flooding schemes demonstrates a notable improvement over the waterflooding approach in Scheme 1. This is attributed to the enhanced oil displacement capabilities of polymer flooding, which significantly improves the ultimate recovery factor.

Under equivalent polymer injection volumes, the cumulative oil production from simultaneous waterflooding and polymer flooding is marginally lower than that from dual-well polymer injection. This is attributed to the combined effects of waterflooding and polymer flooding, which result in a more complex flow pattern and increased resistance to oil displacement. However, the ultimate recovery factors for both approaches are nearly identical, indicating that the overall effectiveness of the two strategies is similar.

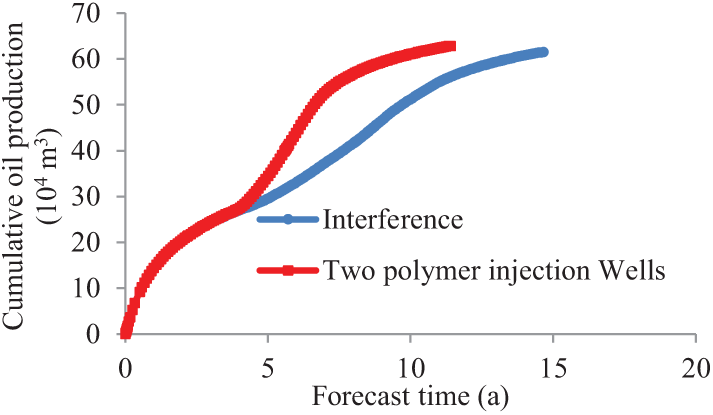

A more detailed analysis of daily oil production from the reservoir block reveals that the initial oil production rates from dual-well polymer injection are significantly higher than those from simultaneous waterflooding and polymer flooding. This is attributed to the more efficient displacement of oil by polymer injection in a single well, as compared to the combined effects of waterflooding and polymer flooding. However, after approximately five years of injection, the daily oil productions from both approaches become more comparable, as the reservoir begins to deplete and the oil displacement capabilities of both strategies become more similar.

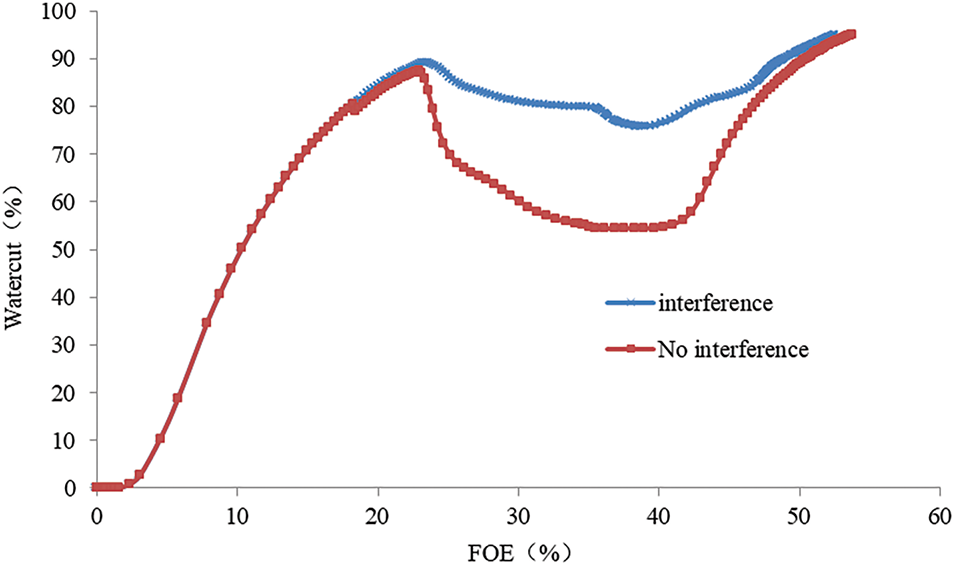

Interestingly, after about five years of injection, the speed of oil production from simultaneous waterflooding and polymer flooding surpasses that from dual-well polymer injection. This can be attributed to the complementary effects of waterflooding and polymer flooding, which enhance the overall oil displacement efficiency in the reservoir. Additionally, an examination of comprehensive water cuts within the reservoir block indicates a more significant decrease when employing dual-well polymer injections as opposed to simultaneous waterflooding and polymer flooding (Fig. 5). This suggests that the combined use of waterflooding and polymer flooding results in a more gradual and controlled decline in reservoir water cuts, potentially leading to improved oil recovery in the long run.

Figure 5: Comprehensive curves of extraction degree and water cut of scheme 2 and scheme 3

Furthermore, total injected and produced water volumes for the combined unit during waterflooding and polymer flooding exceed those for dual-well simultaneous injections by 133.93 × 104 m3 and 259.37 × 104 m3, respectively. This difference in water volumes has significant implications for the overall economic viability of the two strategies, and necessitates further evaluation regarding the balance between investment costs, oil production rates, and recovery factors. In conclusion, the results of this study highlight the importance of carefully considering various oil recovery strategies and their potential impacts on reservoir performance and economic viability.

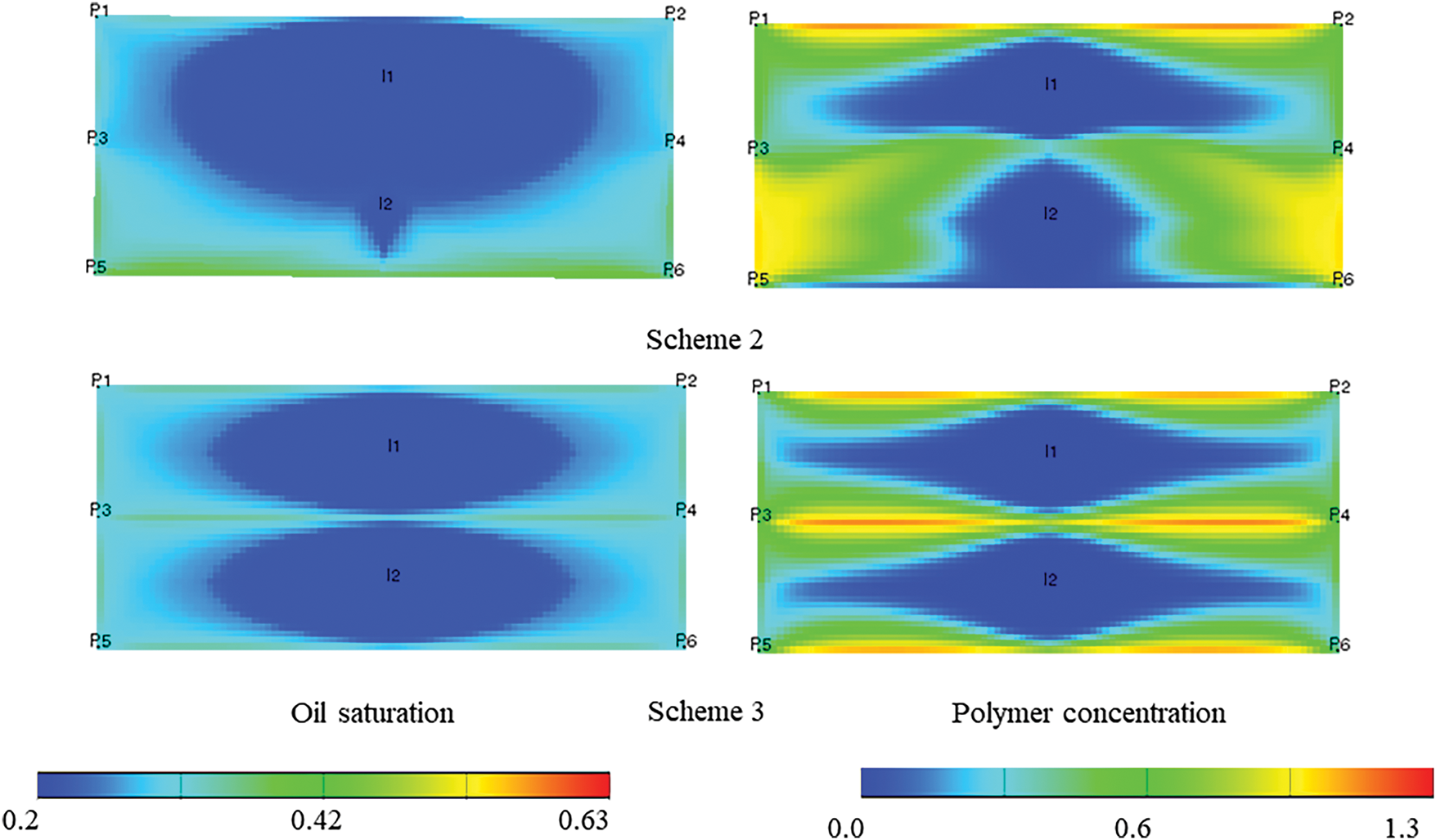

Furthermore, the reservoir numerical simulation can provide insights into the spatial distribution of oil saturation and polymer concentration within the reservoir (Fig. 6). It is evident that under both waterflooding and polymer flooding, there are distinct differences in the shapes of the distributions of oil saturation and polymer concentration. The leading edge of polymer flooding exhibits instability, with the upper injection unit achieving a high oil recovery rate and covering a large swept area, resulting in high oil recovery efficiency. Conversely, the lower injection unit demonstrates a low oil recovery rate and covers a smaller swept area, leading to reduced oil recovery efficiency. Simultaneous polymer injection into two wells results in identical distributions of oil saturation and polymer concentration across both units, yielding higher oil recovery efficiency compared to simultaneous waterflooding and polymer injection while significantly improving the equilibrium of oil displacement.

Figure 6: Distribution of oil saturation and polymer concentration of schemes 2 and 3

Upon conducting a thorough analysis of the dynamic indicators (Fig. 7), it becomes increasingly evident that simultaneous water injection and polymer injection result in a significant interference problem in the initial daily oil production and water cut reduction rate. However, as production time extends, the interference effect progressively diminishes. When not considering time value, the difference in cumulative oil production between simultaneous water injection and polymer injection vs. two-well polymer injection with the same polymer injected into the reservoir unit amounts to 1.32 × 104 m3. If the reservoir unit’s water cut rate is increased to 98%, this cumulative oil production difference further reduces to 0.97 × 104 m3, indicating a weakening of interference as reservoir water cut rate increases. In onshore polymer injection oilfields, where development time is virtually unlimited and injection systems are relatively easy to control, the interference problem between water injection and polymer injection is comparatively less pronounced. Conversely, for offshore oilfields with limited platform lifespans and significantly higher operating costs, there exists a more prominent issue of interference related to waterflooding and polymer flooding within a shorter development period. The longer development time required for setting up a 95% waterflooding scheme in the reservoir unit exacerbates this interference problem, particularly in the early stages of development. A comparative analysis of the cumulative oil production differences at different times reveals an increasing gap during the early-stage development, which reaches its maximum at a production time of 7a before beginning to decrease. This comprehensive analysis highlights that offshore oilfields, due to their distinct restrictive conditions, face more prominent interference problems than onshore fields, especially during the initial stages of development. Consequently, it is crucial to consider these factors when formulating development strategies and optimizing production processes in offshore oilfields.

Figure 7: Cumulative oil production of schemes 2 and 3

4 Analysis of Influencing Factors on Reservoir Development Efficiency Due to Interference between Water Injection and Polymer Injection

4.1 Ratio of Well Spacing to Row Spacing

The ratio of well spacing to line spacing in the injection-production well pattern has a significant impact on the development effectiveness of polymer flooding, mainly reflected in sweep efficiency, the uniformity of the displacement front, the utilization rate of polymer solution, and economic benefits. If the well spacing is too large, the flow path of the polymer solution in the reservoir is extended, making it more susceptible to fingering phenomena, which in turn reduces sweep efficiency. Excessive line spacing may lead to non-uniform vertical sweep, especially in heterogeneous reservoirs, where low-permeability layers may not be effectively displaced. Conversely, if the well spacing is too small, the polymer solution may breakthrough prematurely, resulting in a limited swept volume. Similarly, overly narrow line spacing may increase vertical sweep efficiency but could lead to insufficient planar sweep.

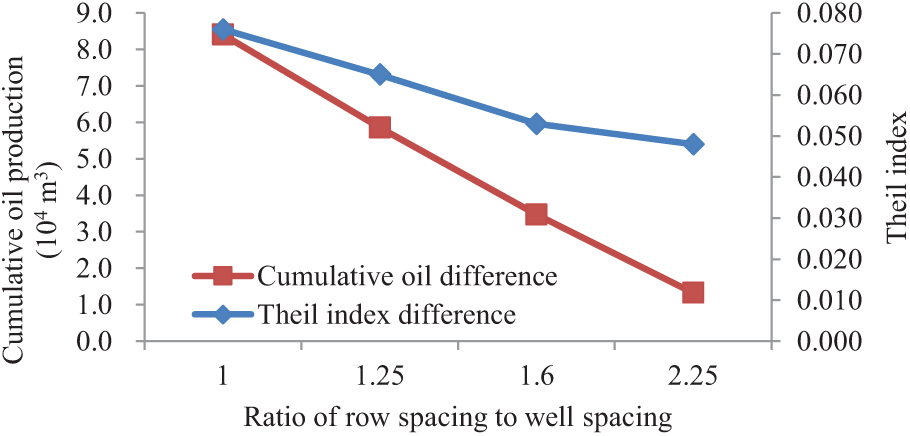

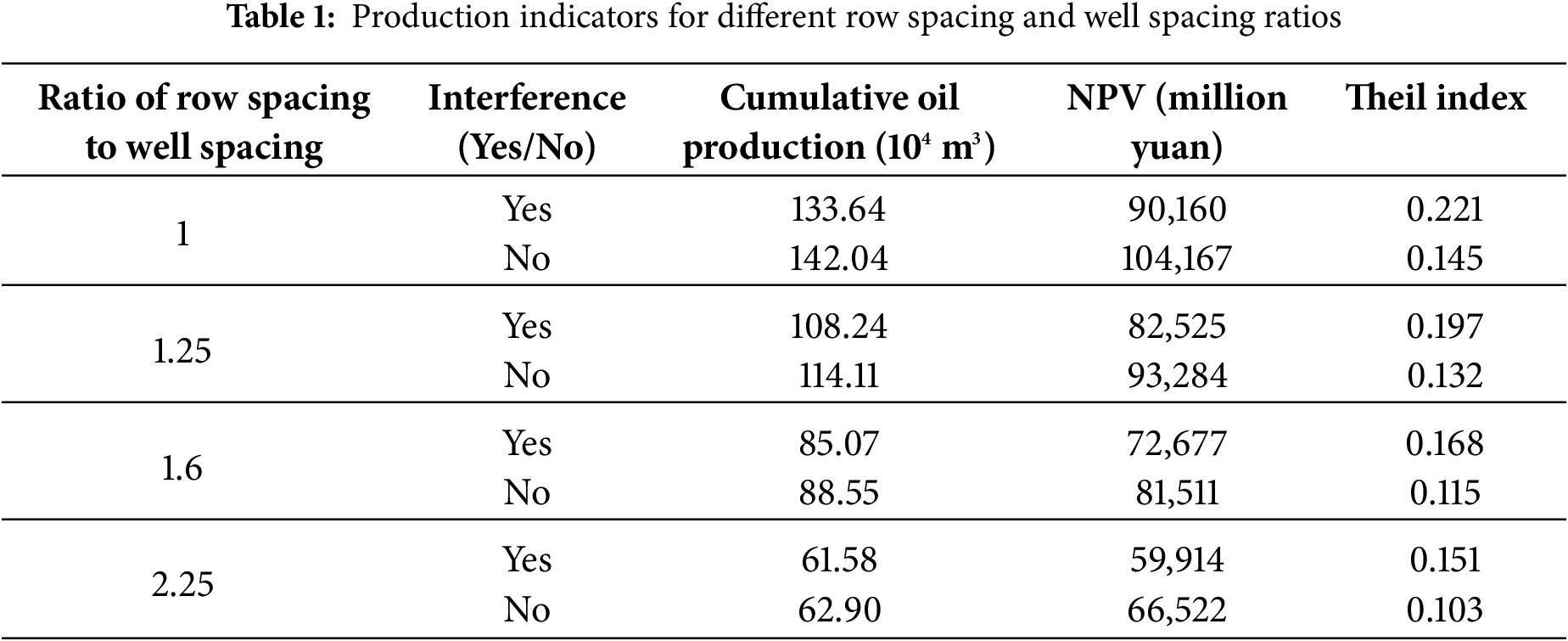

Based on the waterflooding and polymer flooding injection-production well pattern established above, the influence of the ratio of the spacing between injection wells and production wells on waterflooding interference can be studied by changing the ratio of L1 (spacing between injection wells) and L2 (spacing between production wells). Four schemes were designed with the ratio of L1 and L2 being 2.25, 1.6, 1.25, and 1, respectively. During the modeling process, the X-direction grid spacing was kept constant, and the Y-direction grid spacing was adjusted to change the size of the well spacing, thus establishing four different well spacing-to-injection spacing ratios of reservoir geological models. Based on the same geological model, two contrasting schemes were designed, one with one well injecting water and the other injecting polymer interfering with each other, and the other with two wells injecting polymer without interfering with each other. The simulation scheme development process was the same as the previous section. At the same time, the Tailor index was proposed to represent the degree of chemical flooding equilibrium, and the expression of the chemical flooding equilibrium Tailor index was as follows:

Through numerical simulation of oil reservoirs, annual oil production and cumulative oil production indicators for each scheme were obtained (Fig. 8 and Table 1). Comparison of cumulative oil production data from contrasting waterflooding and polymer flooding schemes within the same geological unit revealed minimal differences in order to objectively evaluate these variances considering investment costs such as those associated with polymer flooding expenses; thus necessitating further analysis using net present value indices. Simulation results indicated that when injection well-to-production well spacings are equal due to existing water gathering interference, there is some degree of influence on final cumulative oil production, net present value, and Thiel index values. This interference led to reduced cumulative oil production alongside significantly lower annual oil production during the initial six years post-injection compared to scenarios involving two wells injecting polymers; coupled with an extended four-year production period resulting in increased injection water volume leading to higher operational costs thereby yielding lower net present values than those observed in scenarios involving two-well injections.

Figure 8: Cumulative oil production and Theil index difference at different row spacing to well spacing ratios

As the ratio between injection wells’ spacings relative to that of production wells increases—indicating weakened levels of water gathering interference—differences in both cumulative oil productions as well as Thiel indices decrease.

4.2 Plane Permeability Differential

Plane heterogeneity leads to significant differences in permeability in different directions within the reservoir. In high-permeability zones, the injected polymer solution tends to flow preferentially, resulting in fingering phenomena, which reduces sweep efficiency and makes it difficult to effectively displace crude oil in low-permeability zones. The rapid breakthrough of high-permeability channels may cause the polymer solution to reach the production wells prematurely, shortening the effective displacement time and thereby reducing the effectiveness of polymer flooding.

When analyzing the impact of plane permeability differential on waterflooding and polymer flooding interference in terms of reservoir development, the optimization of deployment positions for injection and production wells on a plane is crucial. Based on the proposed typical injection and production well pattern for waterflooding and polymer flooding interference, a 3D heterogeneous model with a plane permeability gradient of 4 was established. The upper half of the reservoir was set to have a permeability of 400 mD, while the lower half was set at 1600 mD. Two simulation comparison schemes were designed: Scheme 1 involved deploying injection wells in low-permeability reservoirs and production wells in high-permeability reservoirs; Scheme 2 involved deploying injection wells in high-permeability reservoirs and production wells in low-permeability reservoirs. The production control conditions for both schemes were kept consistent.

Numerical simulation calculations (Fig. 9) revealed that initial daily oil production from injection wells deployed in high-permeable reservoirs exceeded that from those deployed in low-permeable ones. However, when considering cumulative oil production, it became evident that deployment of injection wells in low-permeable reservoirs resulted in higher cumulative oil output compared to those deployed in high-permeable ones. From an efficiency perspective, deployment of injection wells in low-permeable reservoirs outperformed their placement within high-permeable ones.

Figure 9: Cumulative daily oil production and cumulative oil production of the two schemes

To further analyze the merits and demerits of these two schemes requires consideration of their economic evaluation results. Taking into account factors such as production costs and cumulative oil output, with an assumed oil price of $60 per barrel used to calculate net present value, it was found that deployment of injection wells within high permeable reservoirs yielded a higher net present value than their placement within low permeable ones due to significantly higher initial daily oil output during early stages after conversion to polymer flooding.

Considering offshore field development characteristics where platform lifespan is limited, it can be concluded that deploying injection wells within high permeable reservoirs represents an optimal well placement strategy.

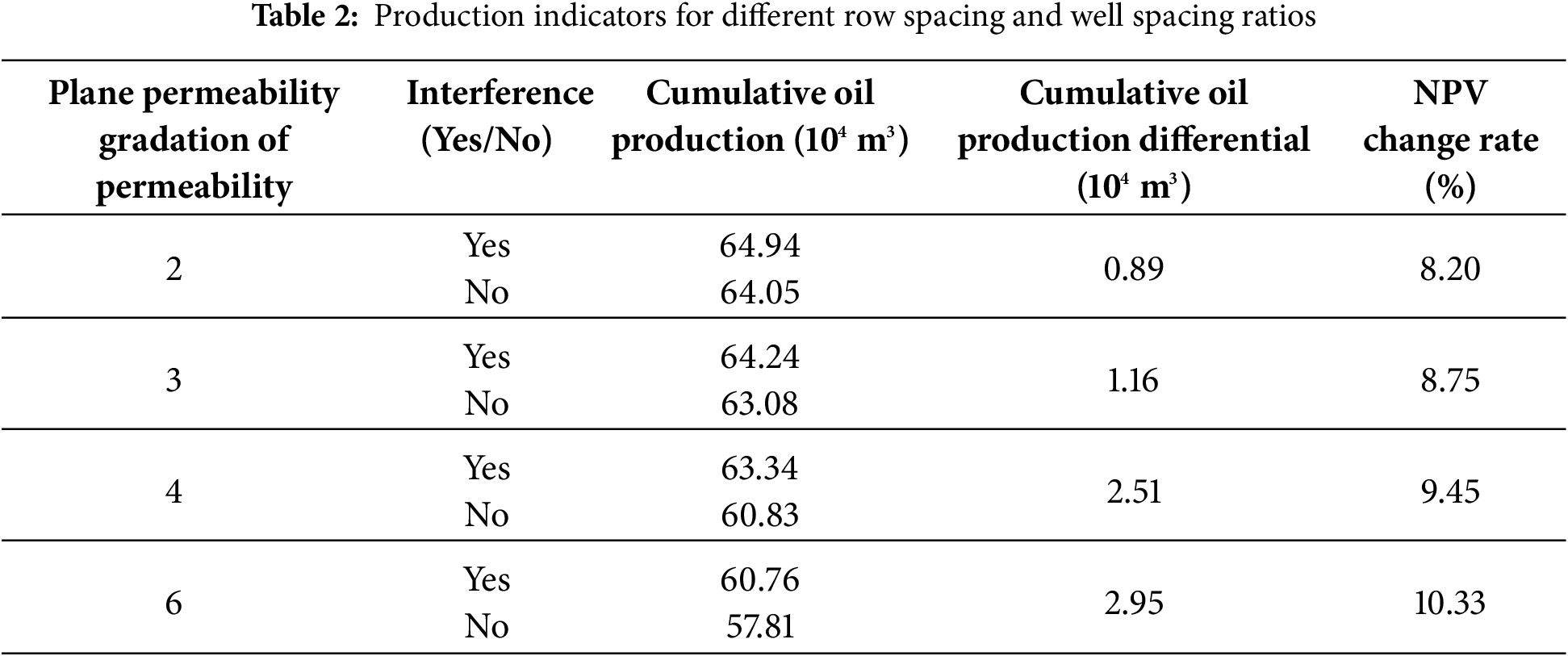

On the basis of the above study, a total of four scenarios were designed, with planar permeability grade difference of 2 (665, 1335 mD), 3 (500, 1500 mD), 4 (400, 1600 mD), and 6 (285, 1715 mD), and the simulation results of the three scenarios were compared with scenario ① under the above scenario with grade difference of 4 (Table 2). From the results, it can be seen that: (1) when the plane permeability grade difference is 2, the cumulative oil production difference is 0.89 × 104 m3, and when the permeability grade difference is 6, the cumulative oil production difference is 2.95 × 104 m3, so as the plane permeability grade difference is bigger, the cumulative oil production difference is bigger; (2) the change rule of the degree of difference of the NPV is in line with the cumulative oil production difference; (3) the bigger the plane permeability grade difference is, the reservoir; (4) the larger the water drive development effect of the unit is affected by the water gathering interference, and when the plane permeability grade difference is larger than 3, the influence degree becomes significantly larger.

4.3 Interlayer Permeability Differential

The impact of interlayer heterogeneity on polymer flooding development effectiveness is mainly reflected in intensified interlayer contradictions, differences in displacement efficiency, uneven distribution of polymer solution, and unbalanced recovery rates. Interlayer heterogeneity causes high-permeability layers to have strong liquid absorption capabilities, leading the polymer solution to preferentially enter these layers and form “interlayer breakthrough” phenomena. In contrast, low-permeability layers are difficult to effectively displace, resulting in a significant reduction in vertical sweep efficiency. The polymer solution flows rapidly through the high-permeability layers, with a large number of polymer molecules being adsorbed or retained in the pores of these layers. This leads to insufficient polymer injection into the low-permeability layers, resulting in poor displacement effects. The ineffective consumption of a large amount of polymer in the high-permeability layers, combined with the poor displacement effect in the low-permeability layers, leads to a decrease in the incremental oil production per unit of polymer and a reduction in economic efficiency.

According to the well network form of the typical water-polymeric isotropic injection and extraction unit in the actual reservoir, for the study of the factors influencing the interlayer permeability grade difference, establish the non-homogeneous model of the two interlayer layers, each small layer is homogeneous in plane, and there are differences in the permeability between the layers, and a total of four scenarios were designed, with the grade differences as follows: 2 (665, 1335 mD), 4 (400, 600 mD), 6 (285, 1715 mD), and 8 (222, 1778 mD). A total of eight numerical simulation models were established under four permeability gradient conditions, and the replacement process, working regime and polymer solution dosage of each group of schemes were exactly the same.

The reservoir numerical simulation calculations show that: (1) when the replacement mode is the same, with the increase of the interlayer grade difference, the cumulative oil production and net present value gradually decrease, and the Tyrrell’s index gradually increases. (2) When the interlayer grade difference is the same, the cumulative oil production of the two driving modes is basically equal, but the NPV of water-polymer co-driving is much smaller than that of the corresponding NPV of the two wells when injecting polymer. (3) As can be seen from Figs. 2–4, due to the existence of water-polymer interference, which leads to the decrease of cumulative oil production, in the 3 years when the polymer injection has just begun, its annual oil production is substantially lower than that in the case of polymer injection of 2 wells, coupled with the fact that its production life has been extended by 3 years compared with that in the case of polymer injection of 2 wells, which leads to a substantial increase in the amount of water injected into and the amount of cumulative water production, thus increasing the additional expenditure, so its NPV is smaller than that in the case of polymer injection of 2 wells. (4) By analyzing the difference in NPV, the larger the grade difference, the greater the degree of impact; when the grade difference is greater than 4, the impact is more significant.

4.4 Injecting Polymer Concentration

The concentration of injected polymer is a key parameter in polymer flooding development, directly affecting the viscosity of the displacing fluid, mobility control capability, and economic viability. An increase in polymer concentration significantly enhances the viscosity of the solution, thereby improving the mobility ratio between the displacing phase and the displaced phase (crude oil). This helps to suppress viscous fingering and expand the swept volume. However, if the concentration is too high, the solution viscosity may become excessively large, causing a sharp increase in injection pressure that could even exceed the formation fracturing pressure, resulting in formation damage. Conversely, if the concentration is too low, the solution viscosity will be insufficient to adequately improve the mobility ratio, leading to low sweep efficiency and a higher likelihood of channeling or fingering phenomena, which in turn affect the improvement of oil recovery.

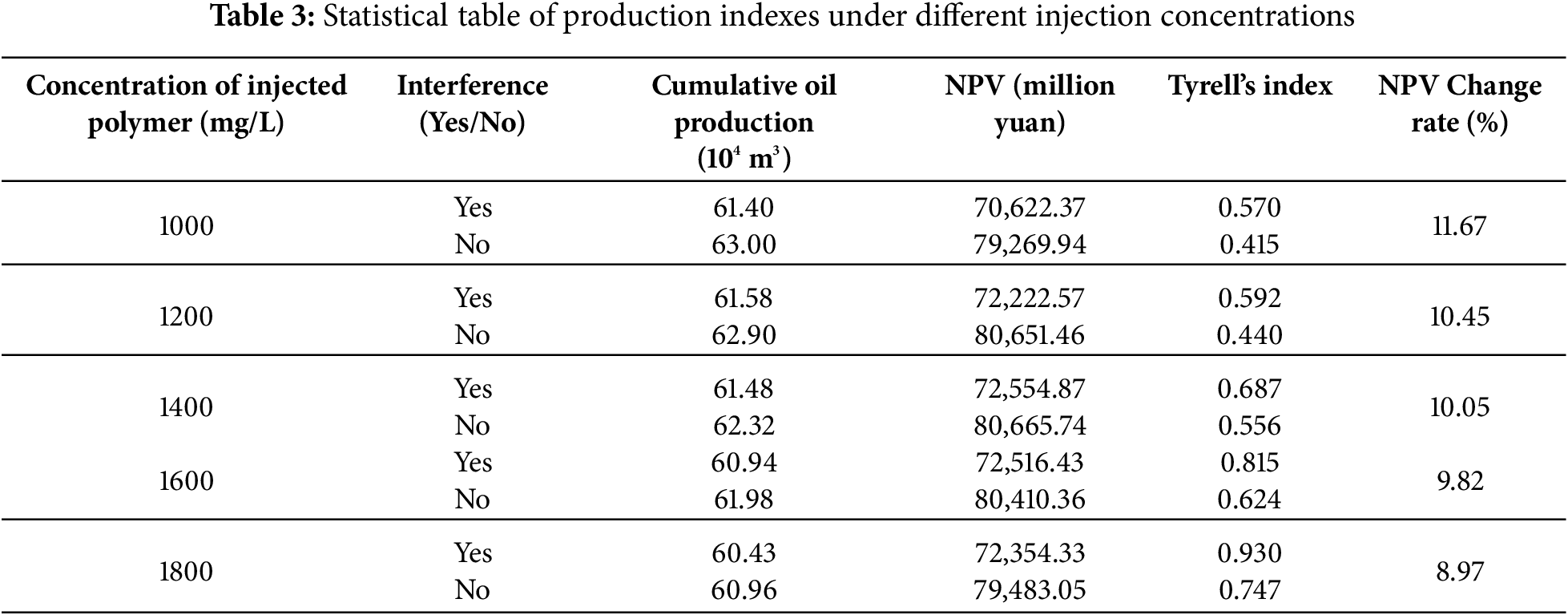

Based on the longitudinal inhomogeneous geological model with interlayer permeability gradient difference of 3, the ratio of row spacing to well spacing of the injection unit is 2.25, and the effect of polymer injection concentration on the interference of water-polymer is investigated by changing the size of polymer injection concentration, and five schemes are designed, with the polymer injection concentration of 1000, 1200, 1400, 1600, and 1800 mg/L, respectively. According to the results of reservoir numerical simulation (Table 3), it can be seen that: (1) when the driving mode is the same, with the increase of polymer injection concentration, the NPV first increases and then decreases, and the Tel index gradually increases; the NPV reaches the maximum value when the concentration reaches 1400 mg/L. The NPV is the same as that of the reservoir numerical simulation, and the NPV is the same as that of the reservoir numerical simulation. (2) The combined NPV rate of change and Terrell’s index as a judgment index, when the polymer injection concentration of 1200–1400 mg/L, the degree of influence of water-polymer interference is small.

4.5 Degree of Influence of Factors

The gray correlation method is used to evaluate the above five factors affecting water-polymer interference, and to determine the magnitude of the influence of each factor on the development effect when water drive and polymer drive coexist. Step 1: Determine the reference sequence, take the NPV of each scenario as the reference sequence denoted as X0 (t), denote the first as X0 (1), the second as X0 (2), ..., and the nth is X0 (n). So, the reference sequence can be expressed as X0 (t) = {X0 (1), X0 (2), ..., X0 (n)}. Then each influencing factor is taken as a comparison sequence, which is denoted as X1 (t), X2 (t), ..., Xi (t), similar to the representation of the reference sequence X0 (t), and there are X1 (t) = {X1 (1), X1 (2), ..., X1 (n)}, ..., Xi (t) = {Xi (1), Xi (2), ..., Xi (n)}, i = 1, 2, ..., m.

Step 2: Calculate the gray correlation coefficient

According to Eq. (1), combined with the homogenized dimensionless data, the absolute difference of each data can be calculated. where

Seek the correlation:

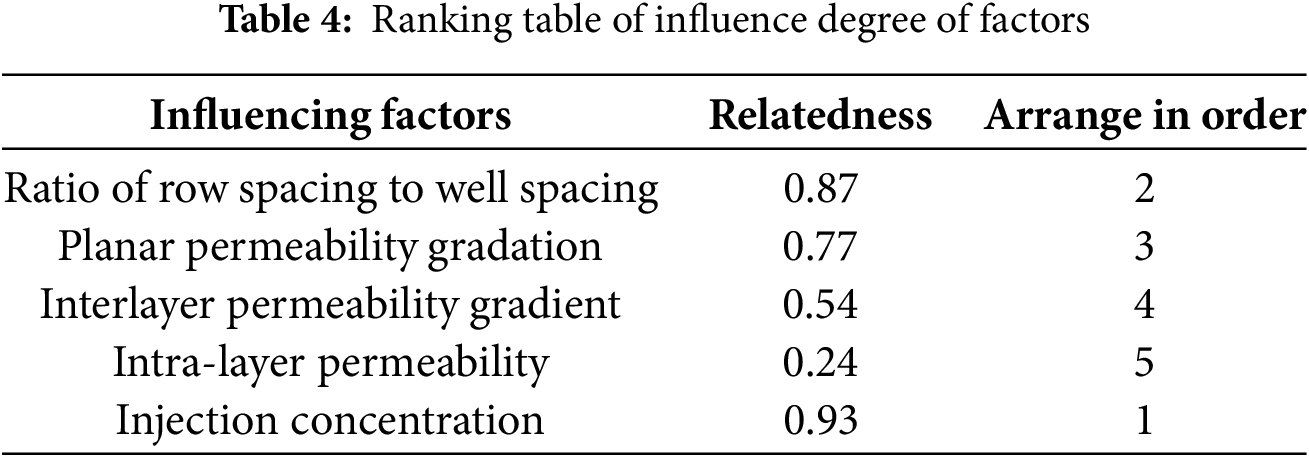

According to Eq. (2) the correlation of the parameters can be obtained (Table 4).

From Table 4, it can be seen that the order of magnitude of the influence of water-polymer interference is as follows: injection polymer concentration, ratio of row spacing to well spacing, planar permeability gradient, interlayer permeability gradient, and intralayer permeability gradient. In the case of water gathering interference, the polymer drive front penetrates and breaks through faster, resulting in lower sweep efficiency and affecting development effectiveness. Therefore, the polymer concentration and well pattern unit parameters have a relatively significant impact.

1. Numerical reservoir simulation approach was implemented to construct a corresponding mathematical model, elucidating the synergistic effects of water-polymer co-injection on reservoir performance. This investigation employed comparative analyses of key production indicators including daily oil output, cumulative oil production, oil saturation profiles, and polymer concentration distribution patterns to systematically evaluate development efficiency.

2. Based on the established theoretical simulation model, a comprehensive analysis was conducted to assess how various factors influence development outcomes under water-polymer co-injection conditions. These factors included the ratio of row spacing to well spacing in injection and extraction units, planar permeability gradient within the reservoir, interlayer permeability gradient, intralayer permeability gradient, and polymer injection concentration. To better visualize the impact of each factor, graphical representations were generated. These illustrations showed the influence of each factor on water-polymer interference across different scenarios, providing a clear and intuitive understanding of their relative importance.

3. The gray correlation method was utilized to rank the degree of mutual interference caused by water-polymer co-injection. The findings indicated a clear hierarchy of influencing factors. The polymer injection concentration had the most significant impact, followed by the ratio of row spacing to well spacing, planar permeability gradient, interlayer permeability gradient, and intralayer permeability gradient. This ranking provides valuable insights into the key factors that need to be considered and optimized to enhance reservoir development effectiveness. Overall, this research offers valuable directions for further improving reservoir development strategies through the optimization of water-polymer co-injection processes.

Acknowledgement: This study was supported by the CNOOC (China) Co., Ltd.’s major project “Key Technologies for Significantly Enhanced Oil Recovery in Offshore Oilfields”.

Funding Statement: This research was financially supported by National Science and Technology Major Project of China (2016ZX05025-001) and the Major Science and Technology Project of CNOOC (KJGG2021-0501).

Author Contributions: The authors confirm contribution to the paper as follows: study conception and design: Wensheng Zhou, Yaguang Qu; data collection: Chen Liu, Bin Wang; analysis and interpretation of results: Wensheng Zhou, Yaguang Qu, Chen Liu, Deqiang Wang; draft manuscript preparation: Wensheng Zhou, Yaguang Qu. All authors reviewed the results and approved the final version of the manuscript.

Availability of Data and Materials: Data available within the article.

Ethics Approval: Not applicable.

Conflicts of Interest: The authors declare no conflicts of interest to report regarding the present study.

Nomenclature

| Tel index | |

| The number of dividing units in the reservoir | |

| Arbitrary division of units | |

| Degree of extraction of the | |

| Mean value of the degree of extraction of all dividing units (%) | |

| ξ0i (t) | The correlation coefficient |

| ρ | The discrimination coefficient |

| PV | Pore Volume |

References

1. Babadagli T. Development of mature oil fields—a review. J Petrol Sci Eng. 2007;57(3–4):221–46. doi:10.1016/j.petrol.2006.10.006. [Google Scholar] [CrossRef]

2. Esene C, Rezaei N, Aborig A, Zendehboudi S. Comprehensive review of carbonated water injection for enhanced oil recovery. Fuel. 2019;237:1086–107. doi:10.1016/j.fuel.2018.08.106. [Google Scholar] [CrossRef]

3. Palsson B, Davies DR, Todd AC, Somerville JM. A holistic review of the water injection process. In: SPE European Formation Damage Conference; 2003 May 13–14; The Hague, The Netherlands. doi:10.2118/82224-ms. [Google Scholar] [CrossRef]

4. Sun X, Zhang Y, Wu J, Xie M, Hu H. Optimized cyclic water injection strategy for oil recovery in low-permeability reservoirs. J Energy Resour Technol. 2019;141(1):012905. doi:10.1115/1.4040751. [Google Scholar] [CrossRef]

5. Needham R, Doe P. Polymer flooding review. J Petrol Technol. 1987;39(12):1503–7. doi:10.2118/17140-PA. [Google Scholar] [CrossRef]

6. Chang HL. Polymer flooding technology yesterday, today, and tomorrow. J Petrol Technol. 1978;30(8):1113–28. doi:10.2118/7043-PA. [Google Scholar] [CrossRef]

7. Sidiq H, Abdulsalam V, Nabaz Z. Reservoir simulation study of enhanced oil recovery by sequential polymer flooding method. Adv Geo-Energy Res. 2019;3(2):115–21. doi:10.26804/ager.2019.02.01. [Google Scholar] [CrossRef]

8. Zerkalov G. Polymer flooding for enhanced oil recovery. Standford, CA, USA: Standford University; 2015. [Google Scholar]

9. Lu X, Cao B, Xie K, Cao W, Liu Y, Zhang Y, et al. Enhanced oil recovery mechanisms of polymer flooding in a heterogeneous oil reservoir. Petrol Explor Dev. 2021;48(1):169–78. doi:10.1016/S1876-3804(21)60013-7. [Google Scholar] [CrossRef]

10. Zhao Y, Yin S, Seright RS, Ning S, Zhang Y, Bai B. Enhancing heavy-oil-recovery efficiency by combining low-salinity-water and polymer flooding. SPE J. 2021;26(3):1535–51. doi:10.2118/204220-PA. [Google Scholar] [CrossRef]

11. Sarmah S, Gogoi SB, Jagatheesan K, Hazarika K. Formulation of a combined low saline water and polymer flooding for enhanced oil recovery. Int J Am Energy. 2022;43(1):1089–97. doi:10.1080/01430750.2019.1683068. [Google Scholar] [CrossRef]

12. Pan G, Zhang L, Huang J, Li H, Qu J. Twelve years field applications of offshore heavy oil polymer flooding from continuous injection to alternate injection of polymer-water. In: Offshore Technology Conference Asia; 2020 May 4–7; Kuala Lumpur, Malaysia. doi:10.4043/30277-ms. [Google Scholar] [CrossRef]

13. Tavakkoli O, Kamyab H, Shariati M, Mustafa Mohamed A, Junin R. Effect of nanoparticles on the performance of polymer/surfactant flooding for enhanced oil recovery: a review. Fuel. 2022;312:122867. doi:10.1016/j.fuel.2021.122867. [Google Scholar] [CrossRef]

14. Han M, Ayirala S, Al-Yousef A. Review of offshore chemical flooding field applications and lessons learned. In: SPE Improved Oil Recovery Conference; 2022 Apr 25–29; Virtual. doi:10.2118/209473-ms. [Google Scholar] [CrossRef]

15. Khanifar A, Deo Tewari R, Mousavimirkalaei SM, Bin Abd Raub MR. Best practices for assessing chemical EOR project risks for a major Malaysian offshore oilfield. In: SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition; 2019 Oct 29–31; Bali, Indonesia. doi:10.2118/196293-ms. [Google Scholar] [CrossRef]

16. Wang F, Yang H, Jiang H, Kang X, Hou X, Wang T, et al. Formation mechanism and location distribution of blockage during polymer flooding. J Petrol Sci Eng. 2020;194:107503. doi:10.1016/j.petrol.2020.107503. [Google Scholar] [CrossRef]

17. Druetta P, Picchioni F. Surfactant-polymer interactions in a combined enhanced oil recovery flooding. Energies. 2020;13(24):6520. doi:10.3390/en13246520. [Google Scholar] [CrossRef]

18. Chen S, Han M, AlSofi AM. Synergistic effects between different types of surfactants and an associating polymer on surfactant-polymer flooding under high-temperature and high-salinity conditions. Energy Fuels. 2021;35(18):14484–98. doi:10.1021/acs.energyfuels.1c01034. [Google Scholar] [CrossRef]

19. Song K, Tao J, Lyu X, Xu Y, Liu S, Wang Z, et al. Recent advances in polymer flooding in China. Molecules. 2022;27(20):6978. doi:10.3390/molecules27206978. [Google Scholar] [PubMed] [CrossRef]

20. Yoo H, Kim H, Sung W, Lee J. An experimental study on retention characteristics under two-phase flow considering oil saturation in polymer flooding. J Ind Eng Chem. 2020;87:120–9. doi:10.1016/j.jiec.2020.03.022. [Google Scholar] [CrossRef]

21. Zhang W, Hou J, Liu Y, Du Q, Cao W, Zhou K. Study on the effect of polymer viscosity and Darcy velocity on relative permeability curves in polymer flooding. J Petrol Sci Eng. 2021;200:108393. doi:10.1016/j.petrol.2021.108393. [Google Scholar] [CrossRef]

22. Kakati A, Kumar G, Sangwai JS. Low salinity polymer flooding: effect on polymer rheology, injectivity, retention, and oil recovery efficiency. Energy Fuels. 2020;34(5):5715–32. doi:10.1021/acs.energyfuels.0c00393. [Google Scholar] [CrossRef]

23. Wei J, Zhou X, Shi X, Gong P, Chen Y, Wang Y, et al. Remaining oil distribution and recovery performances with waterflooding and surfactant-polymer flooding: an experimental investigation. Int J Hydrog Energy. 2023;48(23):8430–9. doi:10.1016/j.ijhydene.2022.11.255. [Google Scholar] [CrossRef]

24. Song W, Hatzignatiou DG. On the reduction of the residual oil saturation through the injection of polymer and nanoparticle solutions. J Petrol Sci Eng. 2022;208:109430. doi:10.1016/j.petrol.2021.109430. [Google Scholar] [CrossRef]

Cite This Article

Copyright © 2025 The Author(s). Published by Tech Science Press.

Copyright © 2025 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools