Open Access

Open Access

ARTICLE

Numerical Investigation of the Thermal Behavior of a System with a Partition Wall Incorporating a Phase Change Material

Faculty of Sciences Ain Chock, Laboratory of Mechanics, Hassan II University of Casablanca, Casablanca, Morocco

* Corresponding Author: Nisrine Hanchi. Email:

(This article belongs to the Special Issue: Materials and Energy an Updated Image for 2021)

Fluid Dynamics & Materials Processing 2023, 19(5), 1227-1236. https://doi.org/10.32604/fdmp.2023.022530

Received 14 March 2022; Accepted 01 September 2022; Issue published 30 November 2022

Abstract

The work deals with the thermal behavior of a conventional partition wall incorporating a phase change material (PCM). The wall separates two environments with different thermal properties. The first one is conditioned, while the adjacent space is characterized by a temperature that changes sinusoidally in time. The effect of the PCM is assessed through a comparative analysis of the cases with and without PCM. The performances are evaluated in terms of dimensionless energy stored within the wall, comfort temperature and variations of these quantities as a function of the amount of PCM and its emplacement.Keywords

Nomenclature

| c | Concrete |

| p | PCM |

| | Specific heat (J.kg−1K−1) |

| | Liquid fraction of PCM |

| | Convective heat transfer coefficient (W.m−2 K−1) |

| | Thermal conductivity (W/m K) |

| | Partition wall length (m) |

| | Latent heat in fusion state (J/kg) |

| | Dimensionless amount of latent heat charged in PCM |

| | Dimensionless amount of global heat charged into the composite partition wall |

| | Time (s) |

| | Melting temperature (°C) |

| | Indoor temperature (°C) |

| | Maximum outdoor temperature (°C) |

| | Position within layer (m) |

| | Thermal diffusivity (m²/s) |

| | Density (kg.m−3) |

| | Pulsation (Rad/s) |

| | Melting range factor |

High energy consumption leads to the necessity of reducing the energy demand of the building. This could be realized by using efficient insulators [1,2] and new construction materials [3]. The use of passive storage such as PCM is recommended not only in buildings [4–6], but also in other contexts, such as transportation [7], industrial applications [8], electronics and electric systems [9,10], storage devices for solar heating or cooling [10,11]. Thus, thermal energy storage can be accomplished either using sensible heat storage and/or using latent heat storage. In building thermal applications, the partition wall is considered an essential element for thermal comfort to reduce the employment of air-conditioners. The outdoor thermal conditions and the activity in the neighboring room through the partition wall influence the thermal comfort inside buildings. So, PCM embedding inside the partition wall improves the characteristics involved and reduces the energy transmitted to the building premises. The PCM insertion effect plays out according to thermal melting temperature [12], latent heat of melting [13], phase change material emplacement and thickness [14]. The criteria of these studies are the flux density transmitted to the room or the daily and the annual energy per unit area consumed. In this current study, the principal aim is to study the impact of PCM emplacement regarding melting thermal level, and melting range temperature on the dimensionless amount of the energy charged in the composite wall comparatively to that involved for the basic wall. This study is carried out for the same thermal conditions in a periodically established regime.

2 Equations and Mathematical Expressions

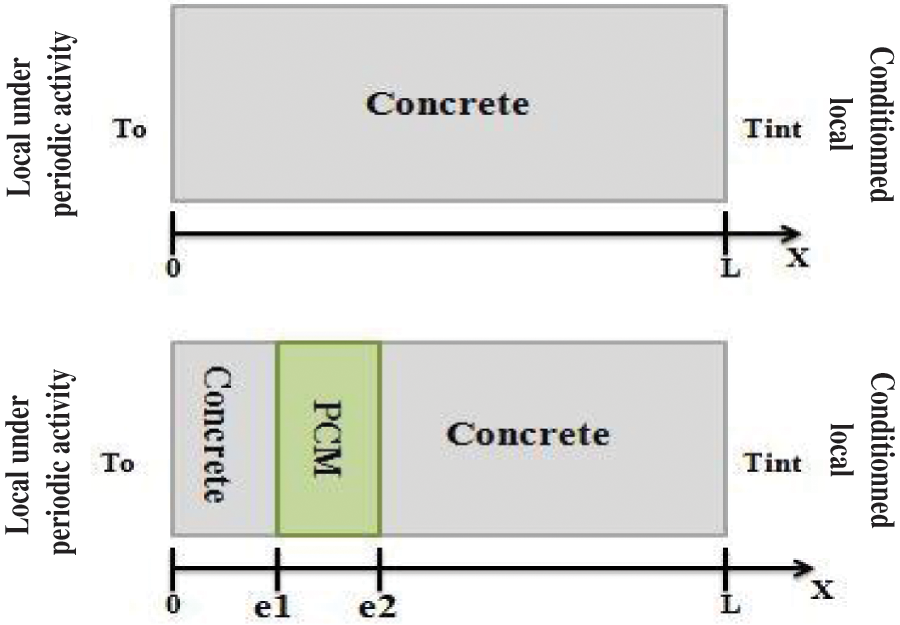

The study concerns the comparison of a referential partition wall with that integrating PCM (Fig. 1), without changing the basic structure

Figure 1: Scheme of the referential partition wall and that with PCM

In this work, we are interested in studying the effect of location, melting temperature

The energy equation for the multilayer partition wall system is as follows [15]:

The above equation is associated to:

-Interfaces conditions:

-Boundary conditions:

With:

The numerical code has been successfully validated [16] by comparison with analytical results corresponding to the Newman problem [17].

The study concerns comparing the amount of thermal energy charged into the composite partition wall (with PCM) to the referential wall (without PCM). The energy in the wall taken as a reference; is purely in sensible form. However, for the composite partition wall, it is either in a sensible form, or in sensible and latent form depending on the PCM’s fusion temperature, its melting range, its location, and also reposing on the thermal level of the neighboring local. Thus, we have calculated the dimensionless latent heat charged in PCM

These parameters are defined as:

With:

As the PCM takes place over a range temperature, the melting factor

Three PCMs are selected for this study, with melting temperatures equal to

The physical properties for the concrete and the PCMs are indicated in Table 1:

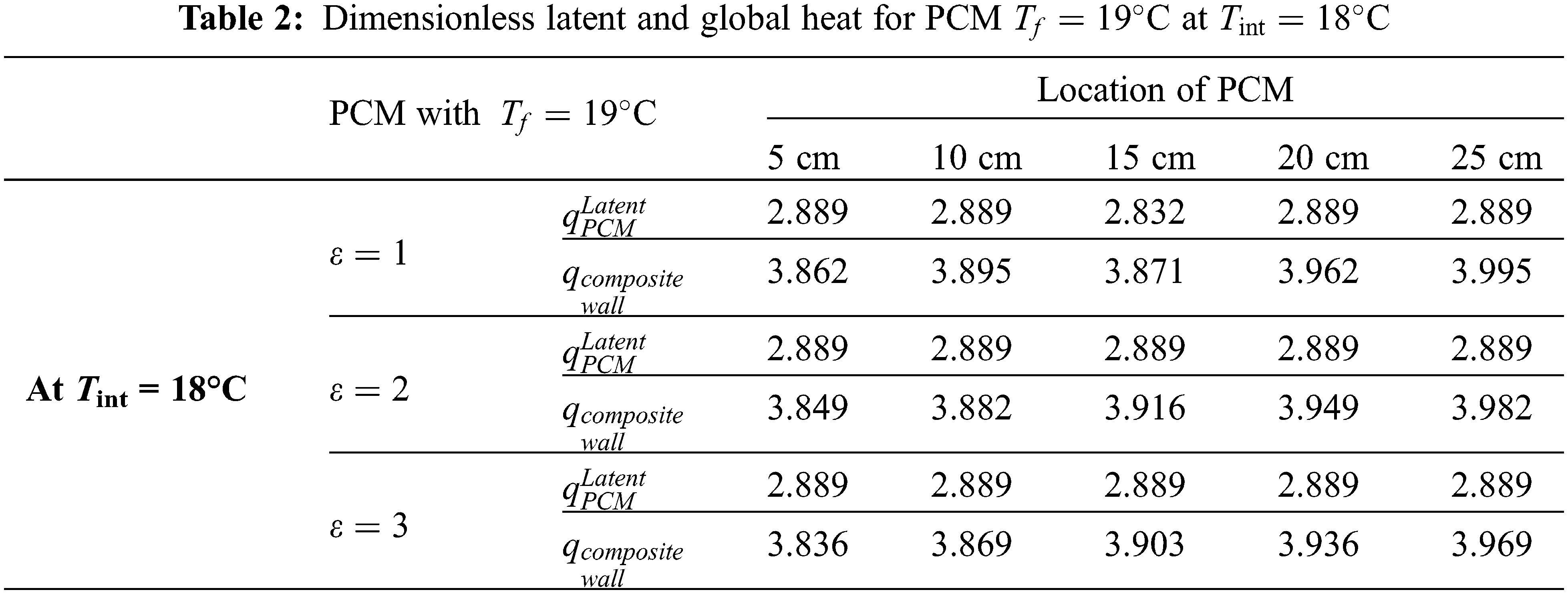

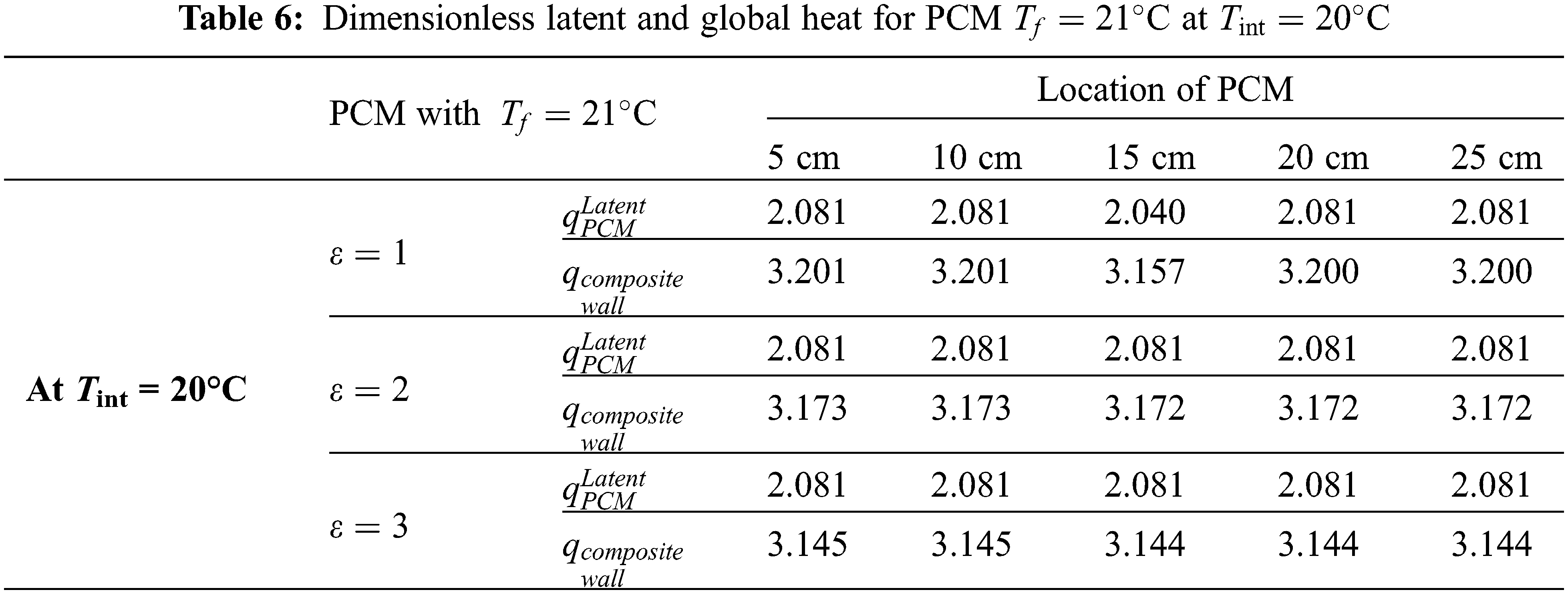

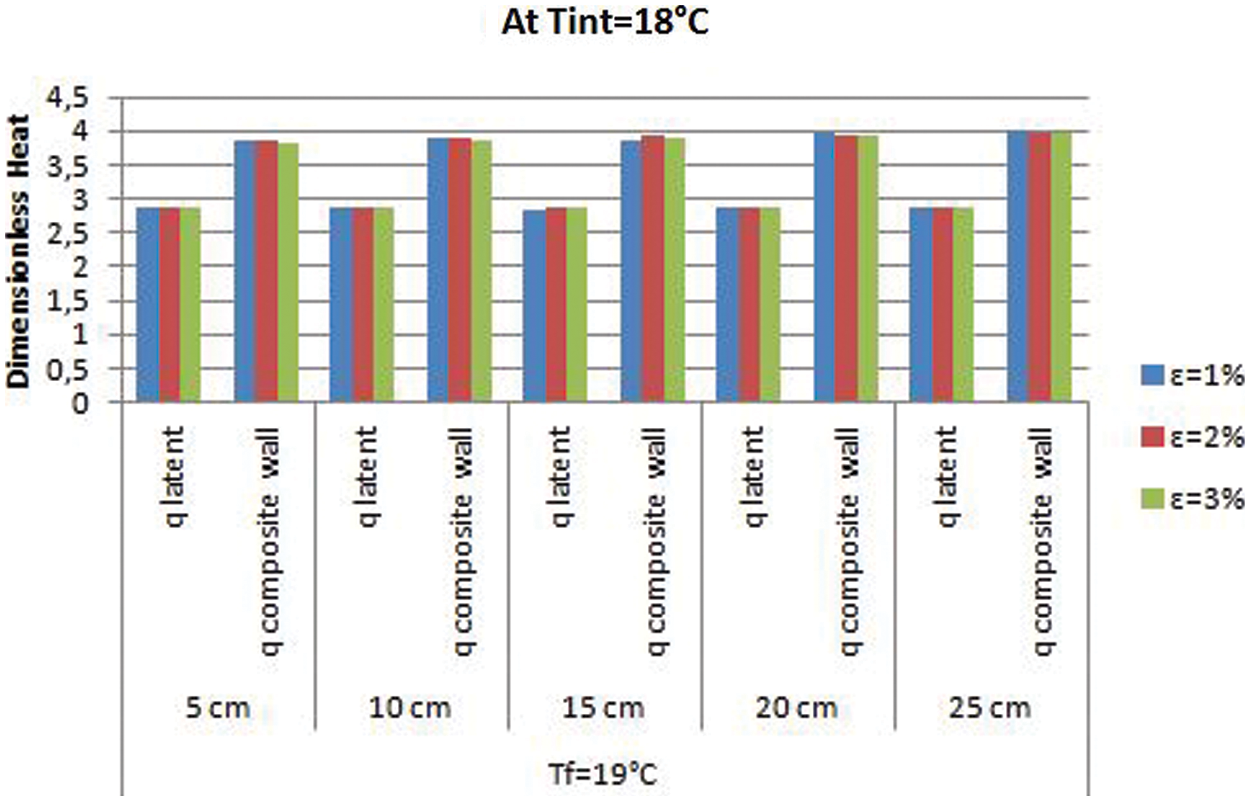

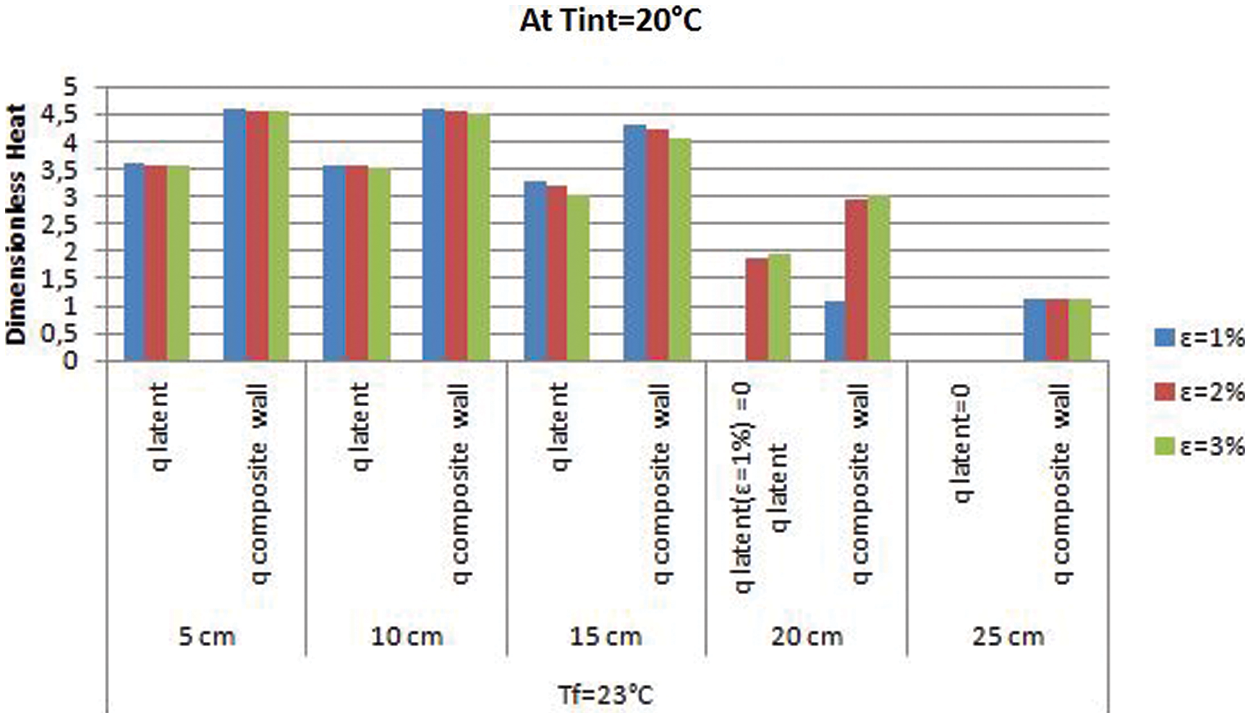

The results of the study are summarized in the Tables 2–7 associated to the Figs. 2–7. They show the effect of the melting factor

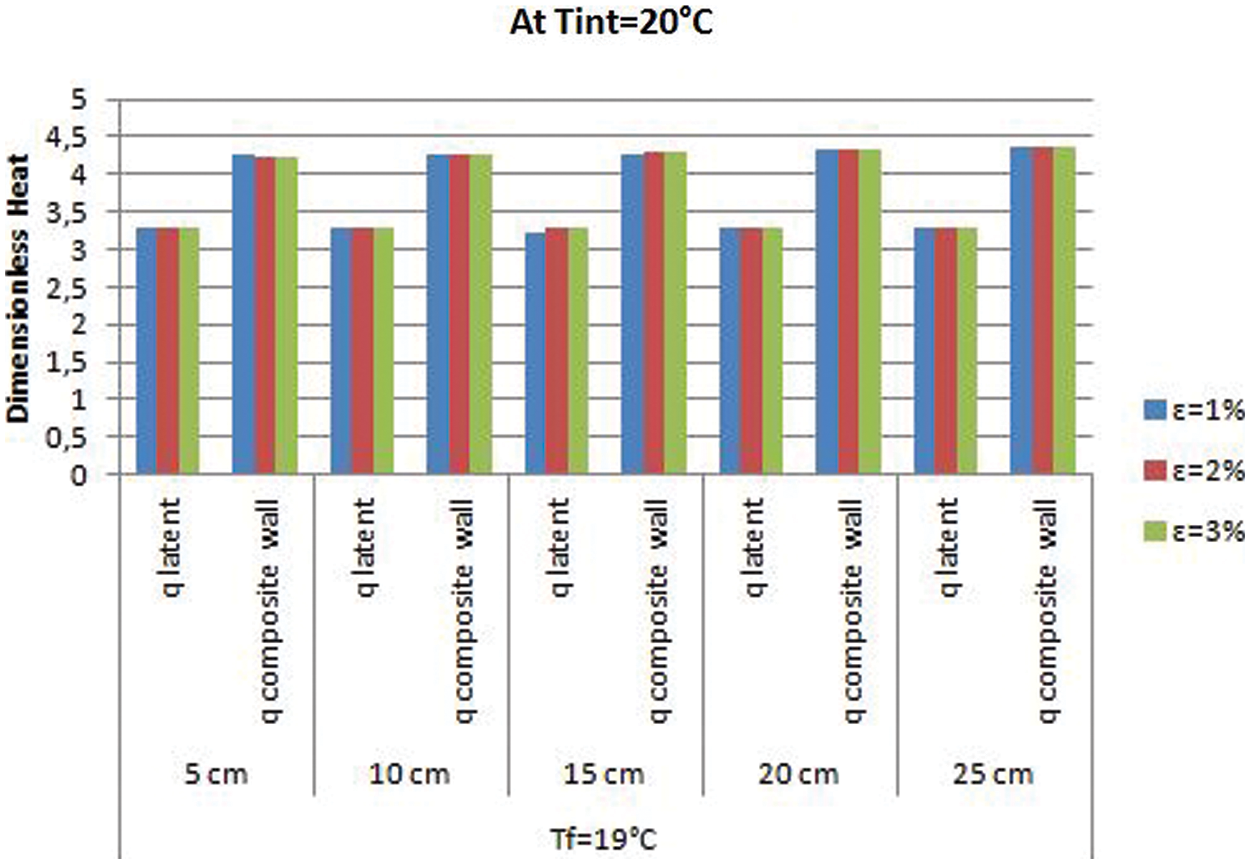

Figure 2: Dimensionless latent and global heat histograms at

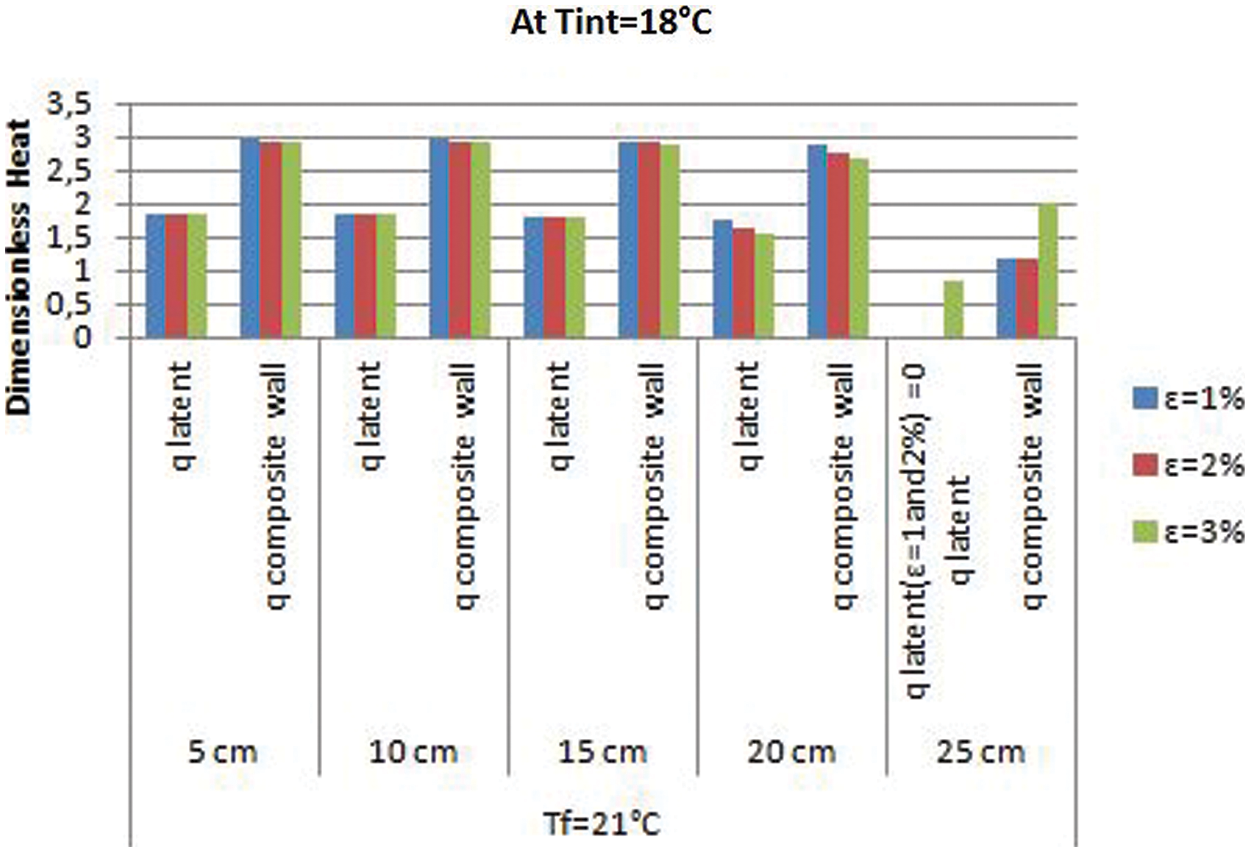

Figure 3: Dimensionless latent and global heat histograms at

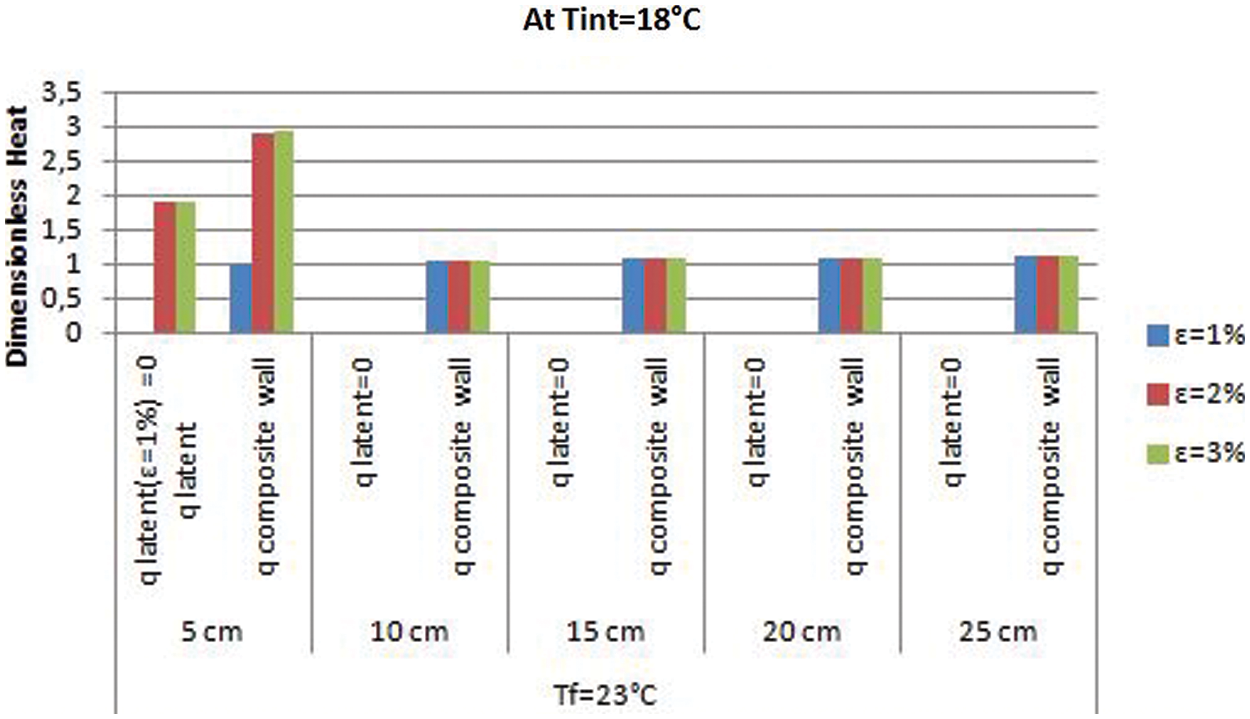

Figure 4: Dimensionless latent and global heat histograms at

Figure 5: Dimensionless latent and global heat histogram at

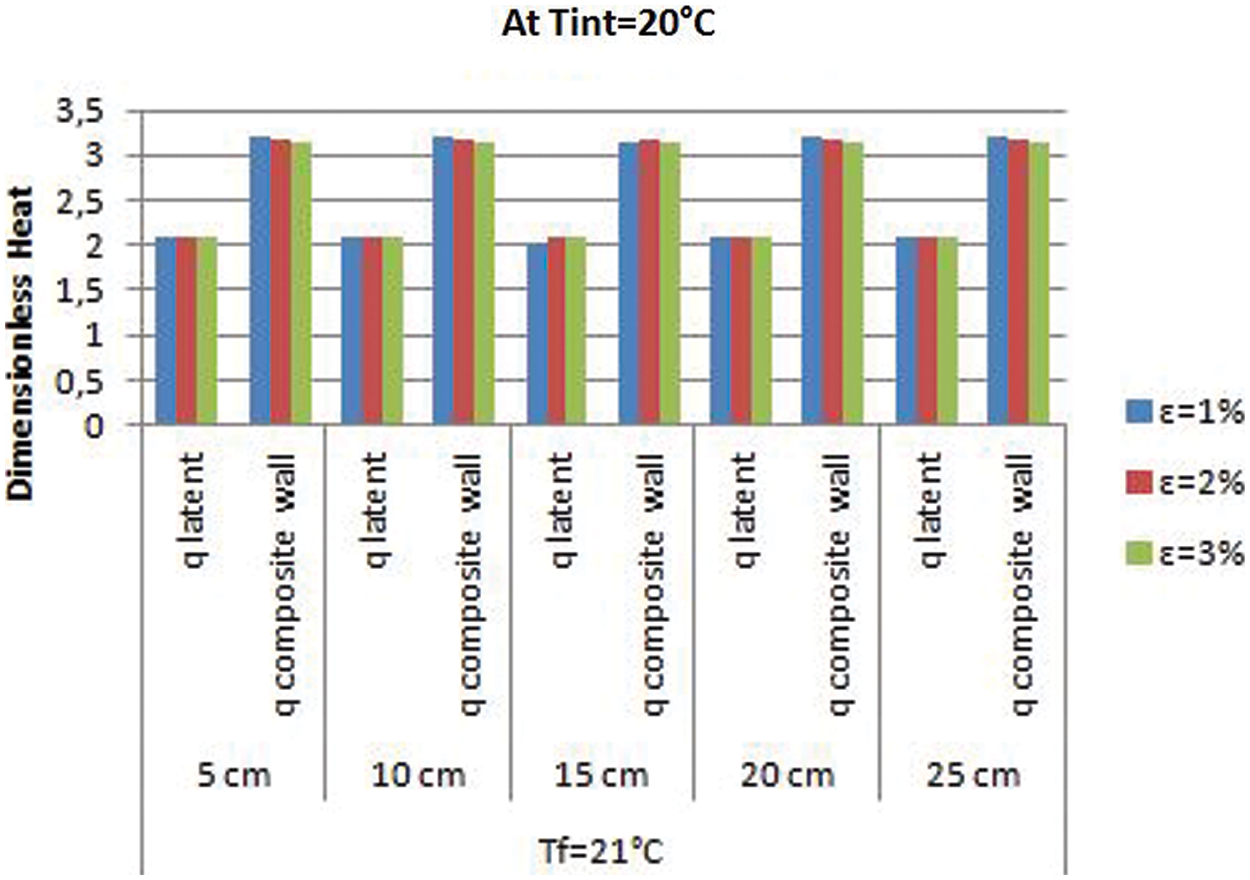

Figure 6: Dimensionless latent and global heat histograms at

Figure 7: Dimensionless latent and global heat histograms at

We noted that the PCM with the melting temperature (19°C) is associated with a thermal state characterized by a continuous melting in which all the amounts of

However, for the melting temperatures 21°C and 23°C, there is melting or an absence of melting depending on the melting interval, the thermal level, the comfort temperature of the conditioned room and the PCM location within the wall. For the PCM of melting temperature (21°C), the best results are shown at

Results of the study show that the PCM embedding is beneficial in terms of charged energy, for all the cases when

In this paper, we have studied the effect of the location, the melting temperature, and the melting range factor

Funding Statement: The authors received no specific funding for this study.

Conflicts of Interest: The authors declare that they have no conflicts of interest to report regarding the present study.

References

1. Jain, M., Pathak, K. K. (2018). Thermal modelling of insulator for energy saving in existing residential building. Journal of Building Engineering, 19(4), 62–68. DOI 10.1016/j.jobe.2018.04.012. [Google Scholar] [CrossRef]

2. Barrios, G., Huels, G., Rojas, J. (2012). Thermal performance of envelope wall/roofs of intermittent air conditioned rooms. Applied Thermal Engineering, 40, 1–7. DOI 10.1016/j.applthermaleng.2012.01.051. [Google Scholar] [CrossRef]

3. Kanchidurai, S., Krishanan, P. A., Baskar, K., Mohan, K. S. R. (2019). Strength characteristic of novel mesh embedment technique for new brick construction with least expensive material. Engineering Structures, 178(2), 484–492. DOI 10.1016/j.engstruct.2018.10.062. [Google Scholar] [CrossRef]

4. Stritih, U., Tyagi, V. V., Stropnik, R., Paksoy, H., Haghighat, F. et al. (2018). Integration of passive PCM technologies for net-zero energy buildings. Sustainable Cities and Society, 41(6), 286–295. DOI 10.1016/j.scs.2018.04.036. [Google Scholar] [CrossRef]

5. Tatsidjodoung, P., Le Pierrès, N., Luo, L. (2013). A review of potential materials for thermal energy storage in building applications. Renewable and Sustainable Energy Reviews, 18, 327–349. DOI 10.1016/j.rser.2012.10.025. [Google Scholar] [CrossRef]

6. Saffari, M., Gracia, A., Fernández, C., Cabeza, L. F. (2017). Simulation-based optimization of PCM melting temperature to improve the energy performance in buildings. Applied Energy, 202, 420–434. DOI 10.1016/j.apenergy.2017.05.107. [Google Scholar] [CrossRef]

7. Liu, M., Saman, W., Bruno, F. (2012). Development of a novel refrigeration system for refrigerated trucks incorporating phase change material. Applied Energy, 92, 336–342. DOI 10.1016/j.apenergy.2011.10.015. [Google Scholar] [CrossRef]

8. Nomura, T., Okinaka, N., Akiyama, T. (2010). Waste heat transportation system, using phase change material (PCM) from steelworks to chemical plant. Resources, Conservation and Recycling, 54(11), 1000–1006. DOI 10.1016/j.resconrec.2010.02.007. [Google Scholar] [CrossRef]

9. Wen, S., Fleming, E., Shi, L., da Silva, A. K. (2014). Numerical optimization and power output control of a hot thermal battery with phase change material. Numerical Heat Transfer, Part A: Applications, 65(9), 825–843. DOI 10.1080/10407782.2013.846621. [Google Scholar] [CrossRef]

10. Hammou, Z. A., Lacroix, M. (2005). A new PCM storage system for managing simultaneously solar and electric Power. Energy and Building, 38(3), 258–265. [Google Scholar]

11. Koś.ny, J., Biswas, K., Miller, W., Kriner, S. (2012). Field thermal performance of naturally ventilated solar roof with PCM heat sink. Solar Energy, 86(9), 2504–2514. [Google Scholar]

12. Zhou, G., Yang, Y., Wang, X., Cheng, J. (2010). Thermal characteristics of shape-stabilized phase change material wallboard with periodical outside temperature waves. Applied Energy, 87(8), 2666–2672. DOI 10.1016/j.apenergy.2010.02.001. [Google Scholar] [CrossRef]

13. Li, D., Zheng, Y., Liu, C., Wu, G. (2015). Numerical analysis on thermal performance of roof contained PCM of a single residential building. Energy Conversion and Management, 100(1), 147–156. DOI 10.1016/j.enconman.2015.05.014. [Google Scholar] [CrossRef]

14. Hamza, H., Hanchi, N., Abouelkhayrat, B., Lahjomri, J., Oubarra, A. (2016). Location and thickness effect of two phase change materials between layers of roof on energy consumption for air-conditioned room. Journal of Thermal Science and Engineering Applications, 8(2), 1–7. DOI 10.1115/1.4031924. [Google Scholar] [CrossRef]

15. Hanchi, N., Hamza, H., Zniber, K., Lahjomri, J., Oubarra, A. (2021). Effect of phase change material insertion on thermal energy stored inside a partition wall separating a conditioned room and a room of periodic temperature. Computational Thermal Sciences, 13(4), 77–92. DOI 10.1615/ComputThermalScien.v13.i4.50. [Google Scholar] [CrossRef]

16. Hanchi, N., Hamza, H., Idmoussa, R., Lahjomri, J., Oubarra, A. (2020). Influence of thermal insulation’s and phase change material’s insertion within a partition wall on the energy consumption of a conditioned room under adjacent local periodical temperature effect. MATEC Web of Conferences, 307, 01024. DOI 10.1051/matecconf/202030701024. [Google Scholar] [CrossRef]

17. Alexiades, V., Solomon, A. D. (1993). Mathematical modeling of melting and freezing processes. Washington DC: Hemisphere Publishing Corporation. [Google Scholar]

18. Socaciu, L., Pleşa, A., Ungureşan, P., Giurgiu, O. (2014). Review on phase change materials for building applications. Leonardo Electronic Journal of Practices and Technologies, 25, 179–194. [Google Scholar]

Cite This Article

Copyright © 2023 The Author(s). Published by Tech Science Press.

Copyright © 2023 The Author(s). Published by Tech Science Press.This work is licensed under a Creative Commons Attribution 4.0 International License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Submit a Paper

Submit a Paper Propose a Special lssue

Propose a Special lssue View Full Text

View Full Text Download PDF

Download PDF Downloads

Downloads

Citation Tools

Citation Tools